JEEP CHEROKEE 1994 Service Repair Manual

Manufacturer: JEEP, Model Year: 1994, Model line: CHEROKEE, Model: JEEP CHEROKEE 1994Pages: 1784, PDF Size: 77.09 MB

Page 1271 of 1784

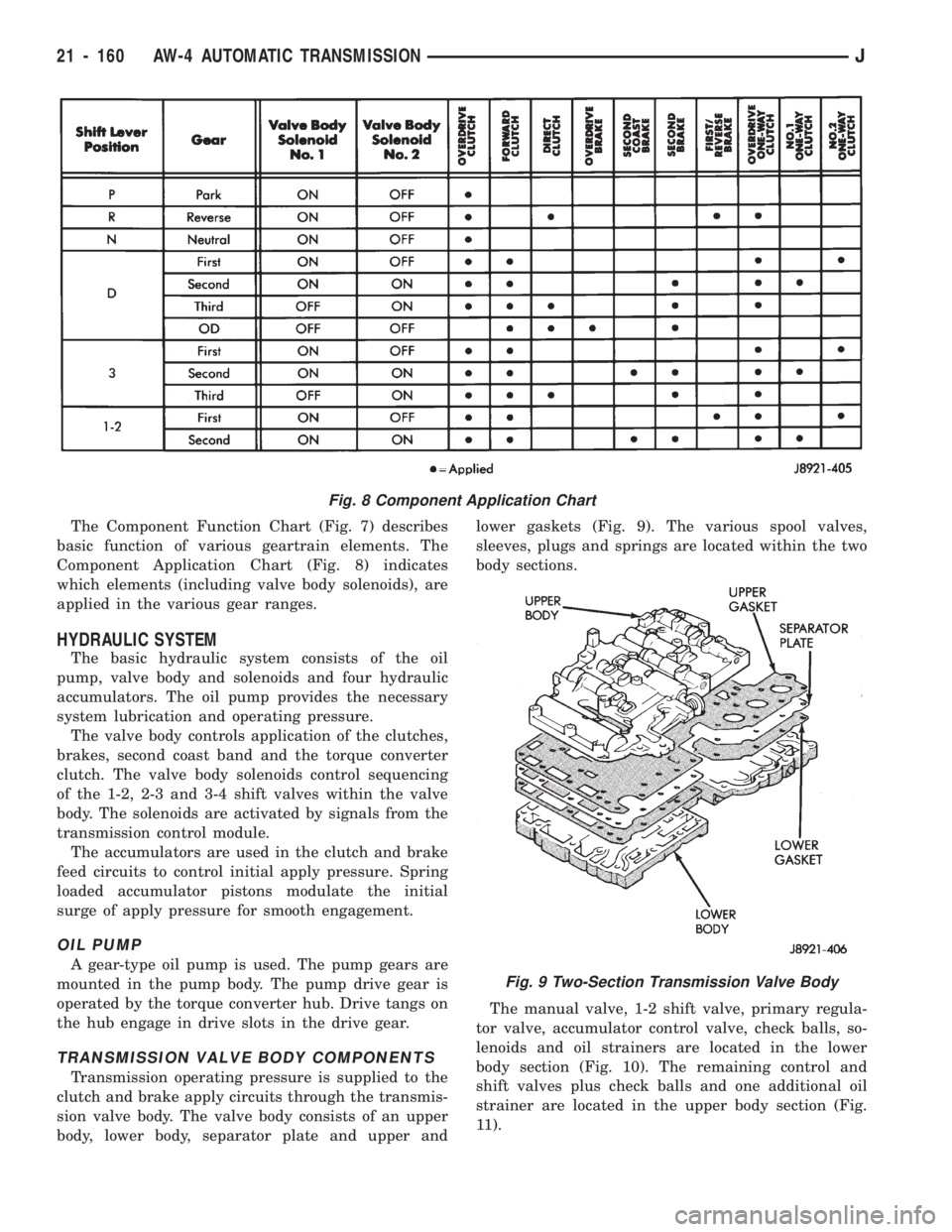

The Component Function Chart (Fig. 7) describes

basic function of various geartrain elements. The

Component Application Chart (Fig. 8) indicates

which elements (including valve body solenoids), are

applied in the various gear ranges.

HYDRAULIC SYSTEM

The basic hydraulic system consists of the oil

pump, valve body and solenoids and four hydraulic

accumulators. The oil pump provides the necessary

system lubrication and operating pressure.

The valve body controls application of the clutches,

brakes, second coast band and the torque converter

clutch. The valve body solenoids control sequencing

of the 1-2, 2-3 and 3-4 shift valves within the valve

body. The solenoids are activated by signals from the

transmission control module.

The accumulators are used in the clutch and brake

feed circuits to control initial apply pressure. Spring

loaded accumulator pistons modulate the initial

surge of apply pressure for smooth engagement.

OIL PUMP

A gear-type oil pump is used. The pump gears are

mounted in the pump body. The pump drive gear is

operated by the torque converter hub. Drive tangs on

the hub engage in drive slots in the drive gear.

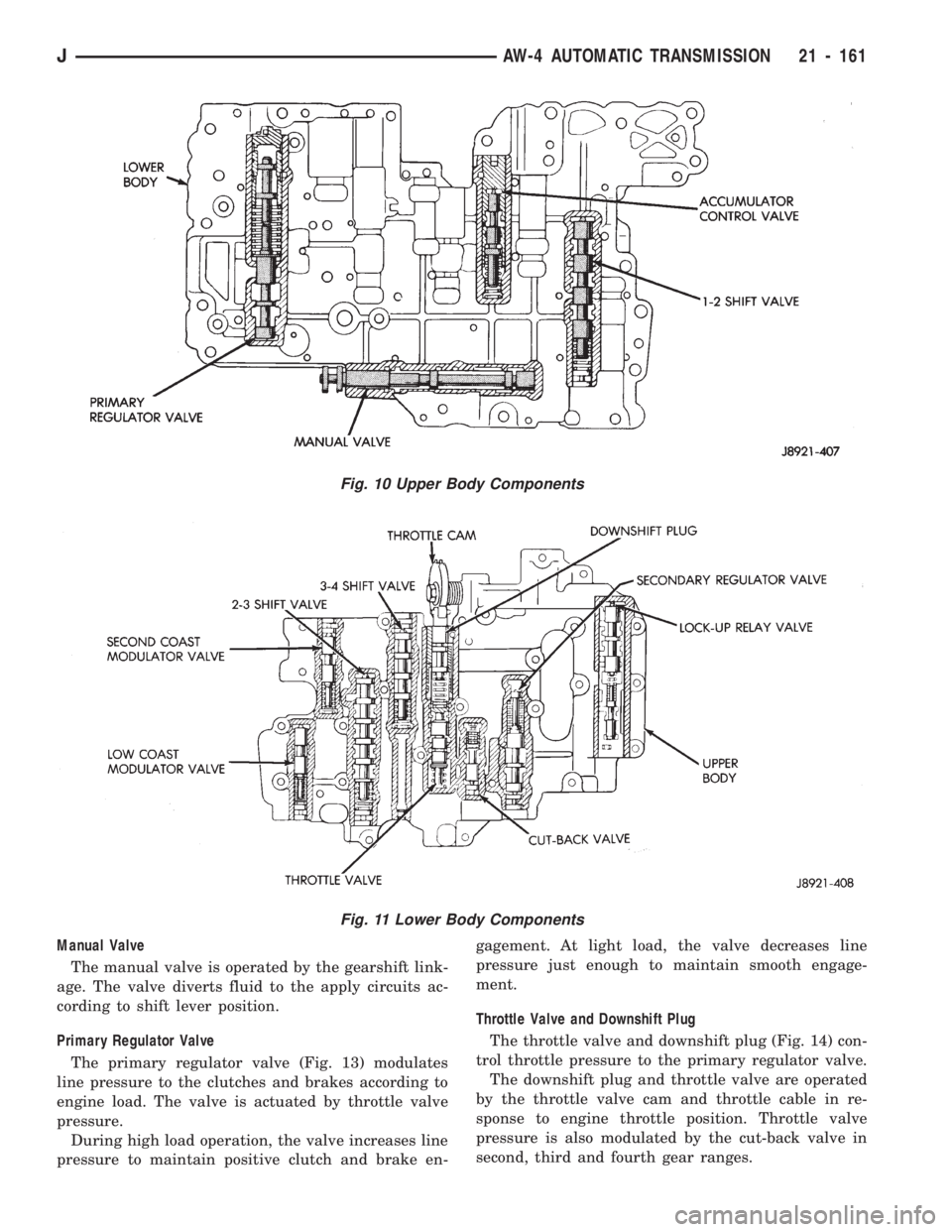

TRANSMISSION VALVE BODY COMPONENTS

Transmission operating pressure is supplied to the

clutch and brake apply circuits through the transmis-

sion valve body. The valve body consists of an upper

body, lower body, separator plate and upper andlower gaskets (Fig. 9). The various spool valves,

sleeves, plugs and springs are located within the two

body sections.

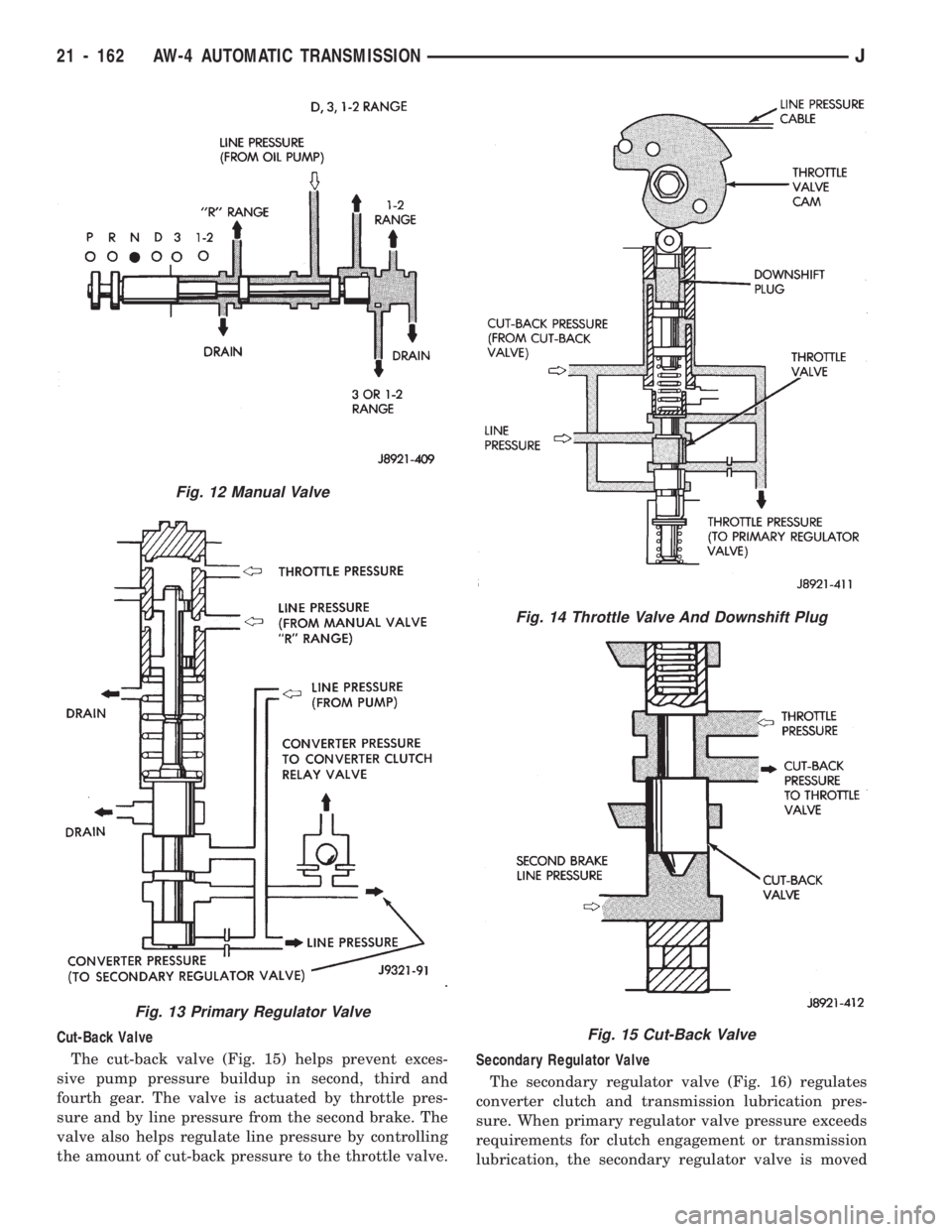

The manual valve, 1-2 shift valve, primary regula-

tor valve, accumulator control valve, check balls, so-

lenoids and oil strainers are located in the lower

body section (Fig. 10). The remaining control and

shift valves plus check balls and one additional oil

strainer are located in the upper body section (Fig.

11).

Fig. 8 Component Application Chart

Fig. 9 Two-Section Transmission Valve Body

21 - 160 AW-4 AUTOMATIC TRANSMISSIONJ

Page 1272 of 1784

Manual Valve

The manual valve is operated by the gearshift link-

age. The valve diverts fluid to the apply circuits ac-

cording to shift lever position.

Primary Regulator Valve

The primary regulator valve (Fig. 13) modulates

line pressure to the clutches and brakes according to

engine load. The valve is actuated by throttle valve

pressure.

During high load operation, the valve increases line

pressure to maintain positive clutch and brake en-gagement. At light load, the valve decreases line

pressure just enough to maintain smooth engage-

ment.

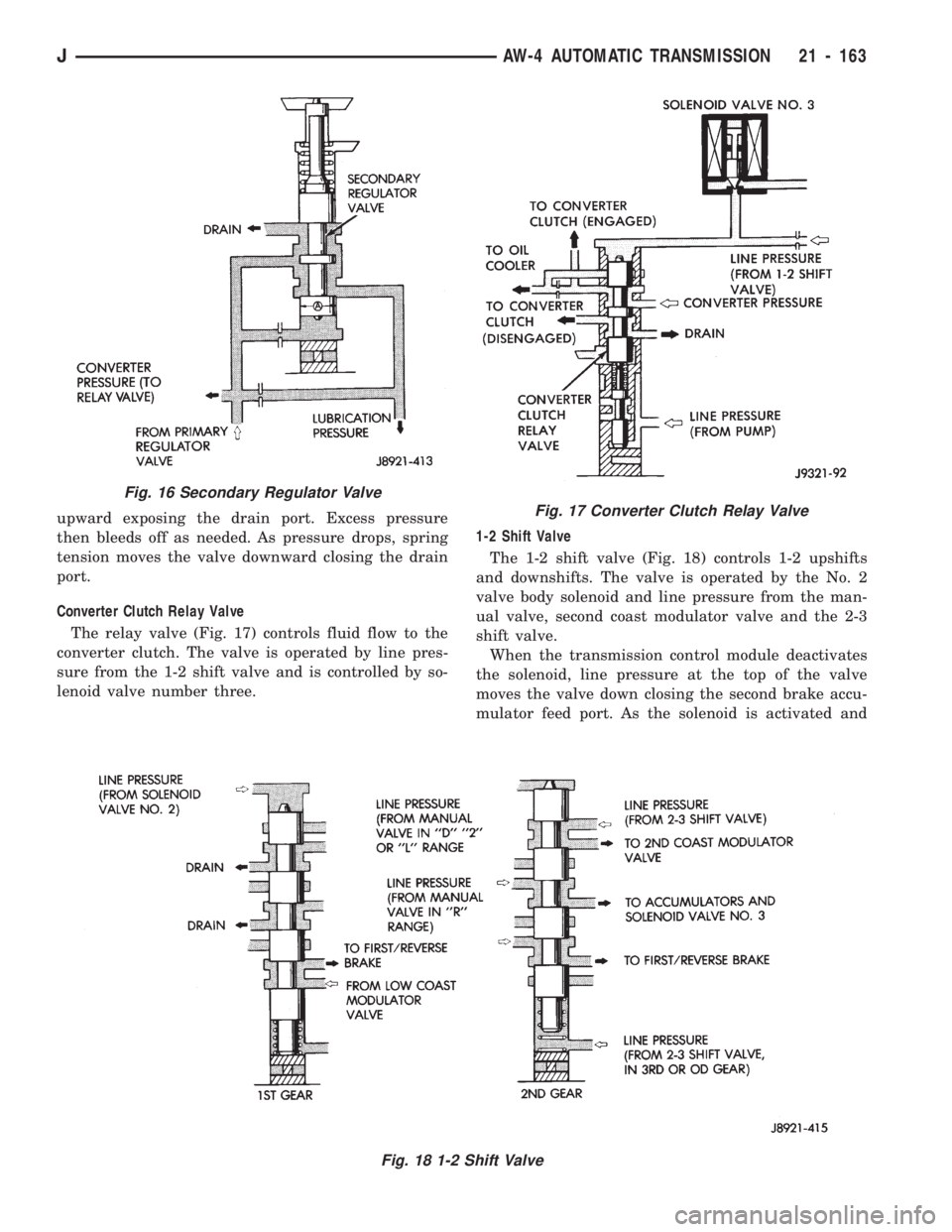

Throttle Valve and Downshift Plug

The throttle valve and downshift plug (Fig. 14) con-

trol throttle pressure to the primary regulator valve.

The downshift plug and throttle valve are operated

by the throttle valve cam and throttle cable in re-

sponse to engine throttle position. Throttle valve

pressure is also modulated by the cut-back valve in

second, third and fourth gear ranges.

Fig. 11 Lower Body Components

Fig. 10 Upper Body Components

JAW-4 AUTOMATIC TRANSMISSION 21 - 161

Page 1273 of 1784

Cut-Back Valve

The cut-back valve (Fig. 15) helps prevent exces-

sive pump pressure buildup in second, third and

fourth gear. The valve is actuated by throttle pres-

sure and by line pressure from the second brake. The

valve also helps regulate line pressure by controlling

the amount of cut-back pressure to the throttle valve.Secondary Regulator Valve

The secondary regulator valve (Fig. 16) regulates

converter clutch and transmission lubrication pres-

sure. When primary regulator valve pressure exceeds

requirements for clutch engagement or transmission

lubrication, the secondary regulator valve is moved

Fig. 12 Manual Valve

Fig. 13 Primary Regulator Valve

Fig. 14 Throttle Valve And Downshift Plug

Fig. 15 Cut-Back Valve

21 - 162 AW-4 AUTOMATIC TRANSMISSIONJ

Page 1274 of 1784

upward exposing the drain port. Excess pressure

then bleeds off as needed. As pressure drops, spring

tension moves the valve downward closing the drain

port.

Converter Clutch Relay Valve

The relay valve (Fig. 17) controls fluid flow to the

converter clutch. The valve is operated by line pres-

sure from the 1-2 shift valve and is controlled by so-

lenoid valve number three.1-2 Shift Valve

The 1-2 shift valve (Fig. 18) controls 1-2 upshifts

and downshifts. The valve is operated by the No. 2

valve body solenoid and line pressure from the man-

ual valve, second coast modulator valve and the 2-3

shift valve.

When the transmission control module deactivates

the solenoid, line pressure at the top of the valve

moves the valve down closing the second brake accu-

mulator feed port. As the solenoid is activated and

Fig. 16 Secondary Regulator Valve

Fig. 18 1-2 Shift Valve

Fig. 17 Converter Clutch Relay Valve

JAW-4 AUTOMATIC TRANSMISSION 21 - 163

Page 1275 of 1784

the drain port opens, spring force moves the valve up

exposing the second brake feed port for the shift to

second gear.

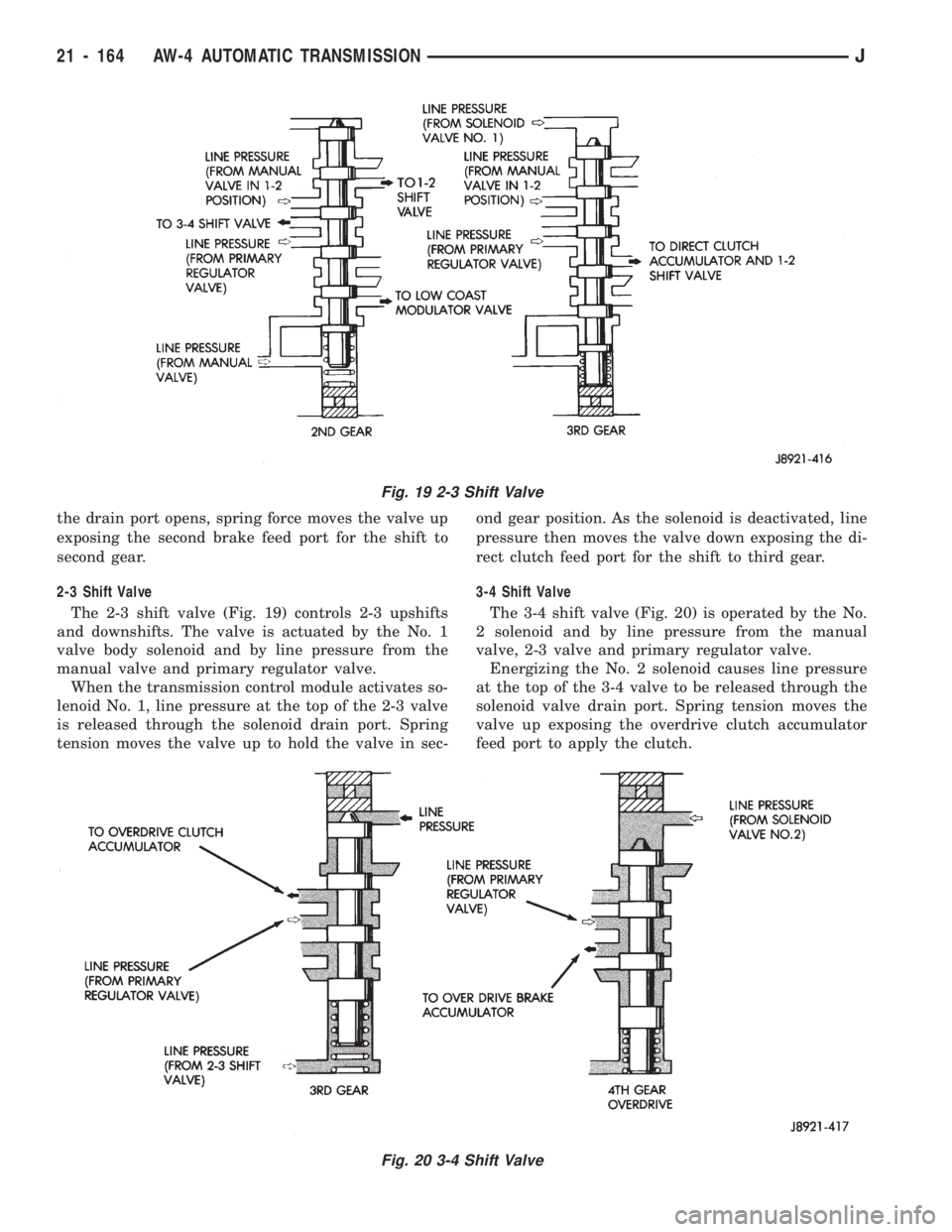

2-3 Shift Valve

The 2-3 shift valve (Fig. 19) controls 2-3 upshifts

and downshifts. The valve is actuated by the No. 1

valve body solenoid and by line pressure from the

manual valve and primary regulator valve.

When the transmission control module activates so-

lenoid No. 1, line pressure at the top of the 2-3 valve

is released through the solenoid drain port. Spring

tension moves the valve up to hold the valve in sec-ond gear position. As the solenoid is deactivated, line

pressure then moves the valve down exposing the di-

rect clutch feed port for the shift to third gear.

3-4 Shift Valve

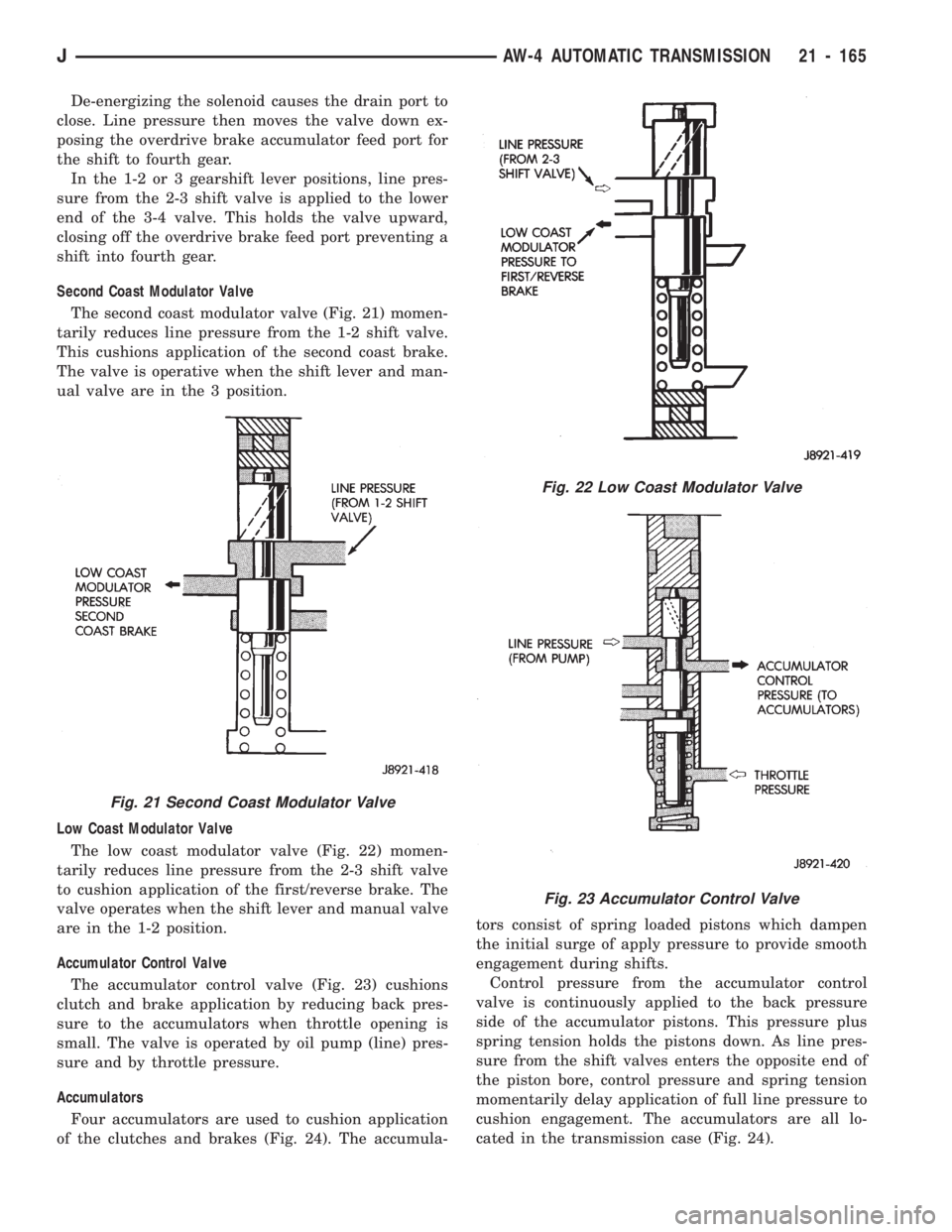

The 3-4 shift valve (Fig. 20) is operated by the No.

2 solenoid and by line pressure from the manual

valve, 2-3 valve and primary regulator valve.

Energizing the No. 2 solenoid causes line pressure

at the top of the 3-4 valve to be released through the

solenoid valve drain port. Spring tension moves the

valve up exposing the overdrive clutch accumulator

feed port to apply the clutch.

Fig. 19 2-3 Shift Valve

Fig. 20 3-4 Shift Valve

21 - 164 AW-4 AUTOMATIC TRANSMISSIONJ

Page 1276 of 1784

De-energizing the solenoid causes the drain port to

close. Line pressure then moves the valve down ex-

posing the overdrive brake accumulator feed port for

the shift to fourth gear.

In the 1-2 or 3 gearshift lever positions, line pres-

sure from the 2-3 shift valve is applied to the lower

end of the 3-4 valve. This holds the valve upward,

closing off the overdrive brake feed port preventing a

shift into fourth gear.

Second Coast Modulator Valve

The second coast modulator valve (Fig. 21) momen-

tarily reduces line pressure from the 1-2 shift valve.

This cushions application of the second coast brake.

The valve is operative when the shift lever and man-

ual valve are in the 3 position.

Low Coast Modulator Valve

The low coast modulator valve (Fig. 22) momen-

tarily reduces line pressure from the 2-3 shift valve

to cushion application of the first/reverse brake. The

valve operates when the shift lever and manual valve

are in the 1-2 position.

Accumulator Control Valve

The accumulator control valve (Fig. 23) cushions

clutch and brake application by reducing back pres-

sure to the accumulators when throttle opening is

small. The valve is operated by oil pump (line) pres-

sure and by throttle pressure.

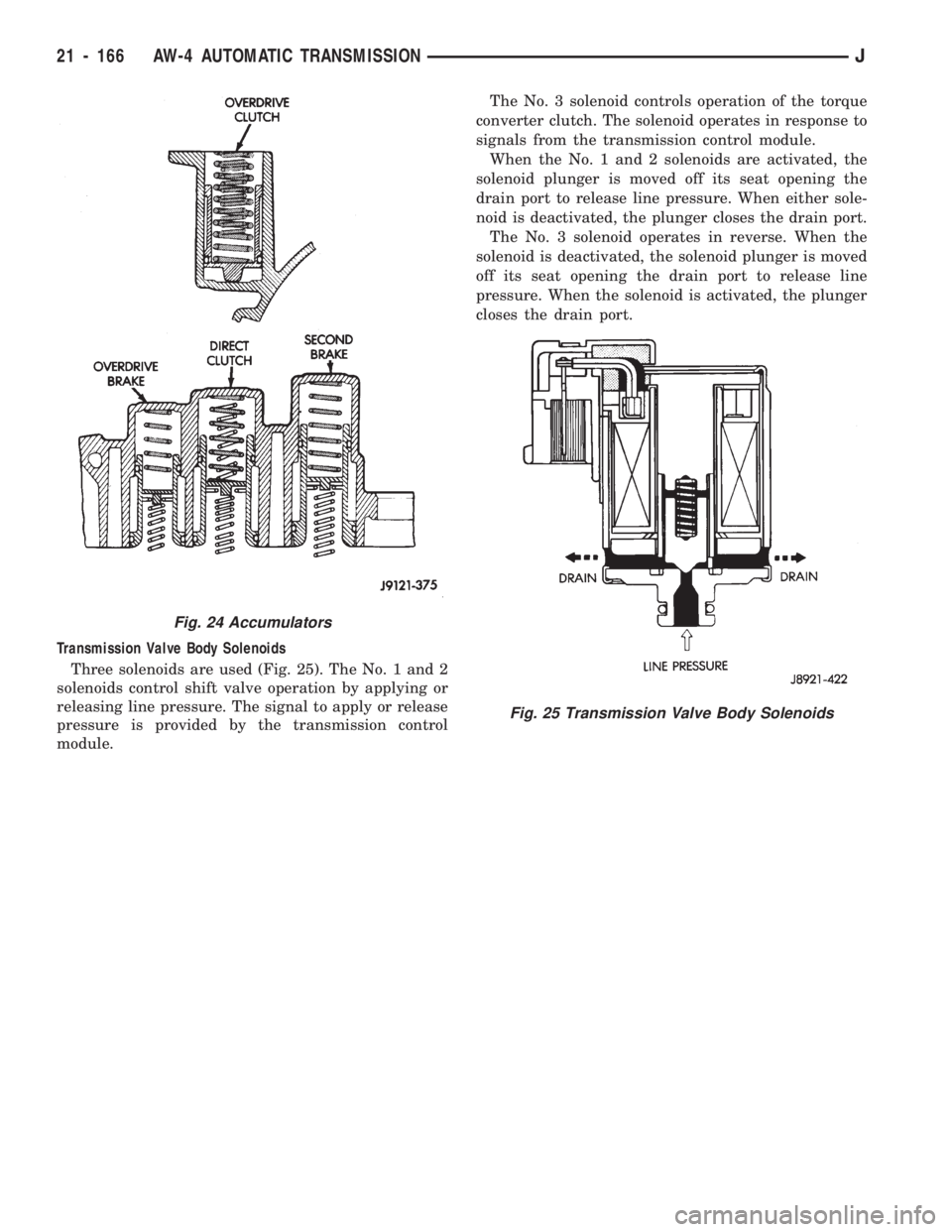

Accumulators

Four accumulators are used to cushion application

of the clutches and brakes (Fig. 24). The accumula-tors consist of spring loaded pistons which dampen

the initial surge of apply pressure to provide smooth

engagement during shifts.

Control pressure from the accumulator control

valve is continuously applied to the back pressure

side of the accumulator pistons. This pressure plus

spring tension holds the pistons down. As line pres-

sure from the shift valves enters the opposite end of

the piston bore, control pressure and spring tension

momentarily delay application of full line pressure to

cushion engagement. The accumulators are all lo-

cated in the transmission case (Fig. 24).

Fig. 21 Second Coast Modulator Valve

Fig. 22 Low Coast Modulator Valve

Fig. 23 Accumulator Control Valve

JAW-4 AUTOMATIC TRANSMISSION 21 - 165

Page 1277 of 1784

Transmission Valve Body Solenoids

Three solenoids are used (Fig. 25). The No. 1 and 2

solenoids control shift valve operation by applying or

releasing line pressure. The signal to apply or release

pressure is provided by the transmission control

module.The No. 3 solenoid controls operation of the torque

converter clutch. The solenoid operates in response to

signals from the transmission control module.

When the No. 1 and 2 solenoids are activated, the

solenoid plunger is moved off its seat opening the

drain port to release line pressure. When either sole-

noid is deactivated, the plunger closes the drain port.

The No. 3 solenoid operates in reverse. When the

solenoid is deactivated, the solenoid plunger is moved

off its seat opening the drain port to release line

pressure. When the solenoid is activated, the plunger

closes the drain port.

Fig. 24 Accumulators

Fig. 25 Transmission Valve Body Solenoids

21 - 166 AW-4 AUTOMATIC TRANSMISSIONJ

Page 1278 of 1784

AW-4 TRANSMISSION DIAGNOSIS

INDEX

page page

General Diagnosis Information.............. 167

Hydraulic Pressure Test................... 168

Manual Shifting Test..................... 168Preliminary Inspection and Adjustment........ 167

Time Lag Test .......................... 169

Torque Converter Stall Test................ 169

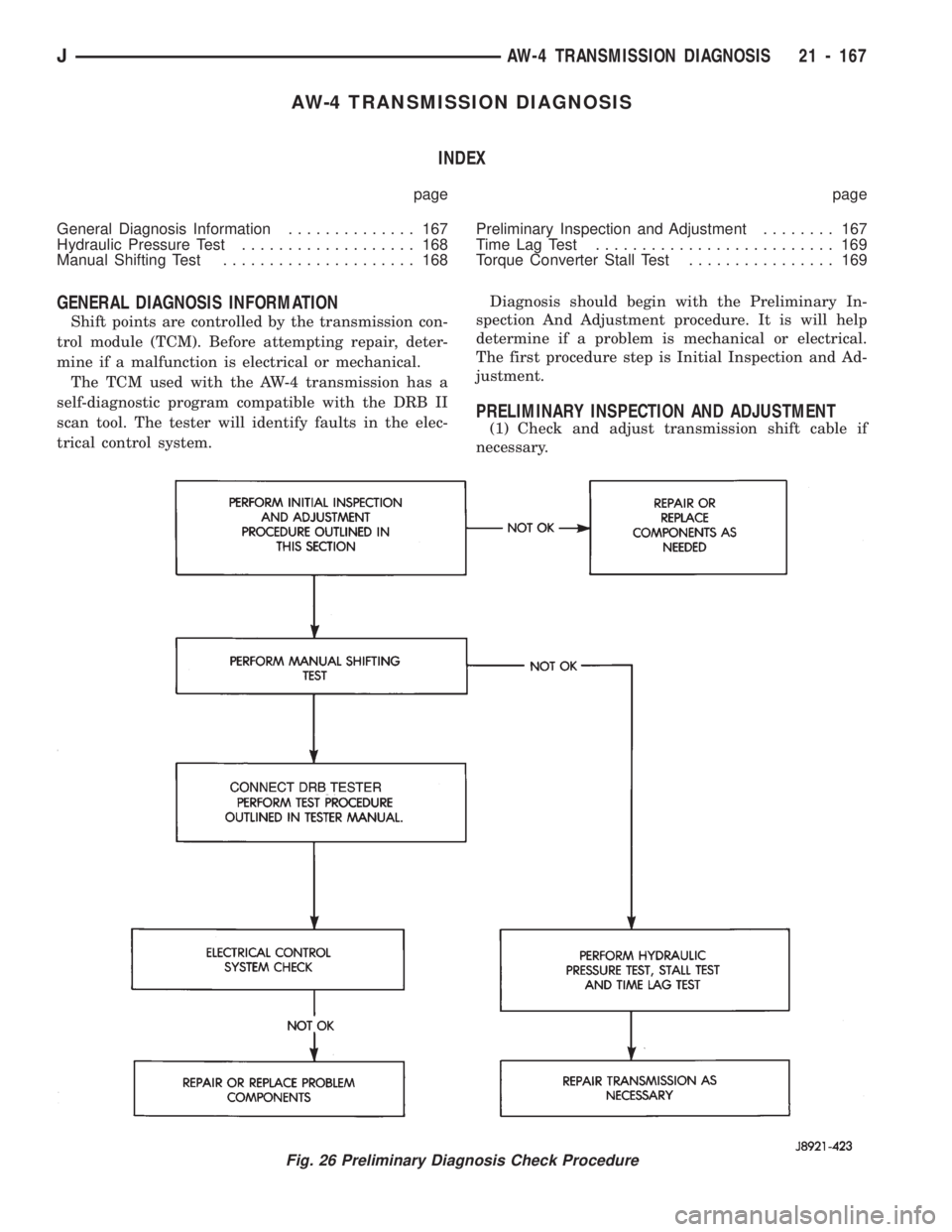

GENERAL DIAGNOSIS INFORMATION

Shift points are controlled by the transmission con-

trol module (TCM). Before attempting repair, deter-

mine if a malfunction is electrical or mechanical.

The TCM used with the AW-4 transmission has a

self-diagnostic program compatible with the DRB II

scan tool. The tester will identify faults in the elec-

trical control system.Diagnosis should begin with the Preliminary In-

spection And Adjustment procedure. It is will help

determine if a problem is mechanical or electrical.

The first procedure step is Initial Inspection and Ad-

justment.

PRELIMINARY INSPECTION AND ADJUSTMENT

(1) Check and adjust transmission shift cable if

necessary.

Fig. 26 Preliminary Diagnosis Check Procedure

JAW-4 TRANSMISSION DIAGNOSIS 21 - 167

Page 1279 of 1784

(2) Verify transmission throttle cable operation.

Repair or replace cable if necessary.

(3) Check engine throttle operation. Operate accel-

erator pedal and observe injector throttle plate move-

ment. Adjust linkage if throttle plate does not reach

wide open position.

(4) Check transmission fluid level when fluid is at

normal operating temperature. Start engine. Shift

transmission through all gear ranges then back to

Neutral. Correct level is to Full or Add mark on dip-

stick with engine at curb idle speed.

(5) Check and adjust park/neutral position switch

if necessary.

(6) Check throttle position sensor adjustment and

operation. Adjust the sensor if necessary.

MANUAL SHIFTING TEST

(1) This test determines if problem is related to

mechanical or electrical component.

(2) Stop engine and disconnect transmission con-

trol module or module fuse.

(3) Road test vehicle. Shift transmission into each

gear range. Transmission should operate as follows:

²lock in Park

²back up in Reverse

²not move in Neutral

²provide first gear only with shift lever in 1-2 posi-

tion

²operate in third gear only with shift lever in 3 po-

sition

²operate in overdrive fourth gear in D position

(4) If transmission operates as described, proceed

to next step. However, if forward gear ranges were

difficult to distinguish (all feel the same), or vehicle

would not back up, refer to diagnosis charts. Do not

perform stall or time lag tests.

CAUTION: Do not overspeed the engine during the

next test step. Ease off the throttle and allow the

vehicle to slow before downshifting.

(5) Continue road test. Manually downshift trans-

mission from D to 3, and from 3 to 1-2 position. Then

manually upshift transmission through forward

ranges again.

(6) If transmission operation is OK, perform stall,

time lag and pressure tests. If transmission shifting

problem is encountered, refer to diagnosis charts.

(7) If a problem still exists, continue testing with

DRB II scan tool.

HYDRAULIC PRESSURE TEST

PRESSURE TEST PROCEDURE

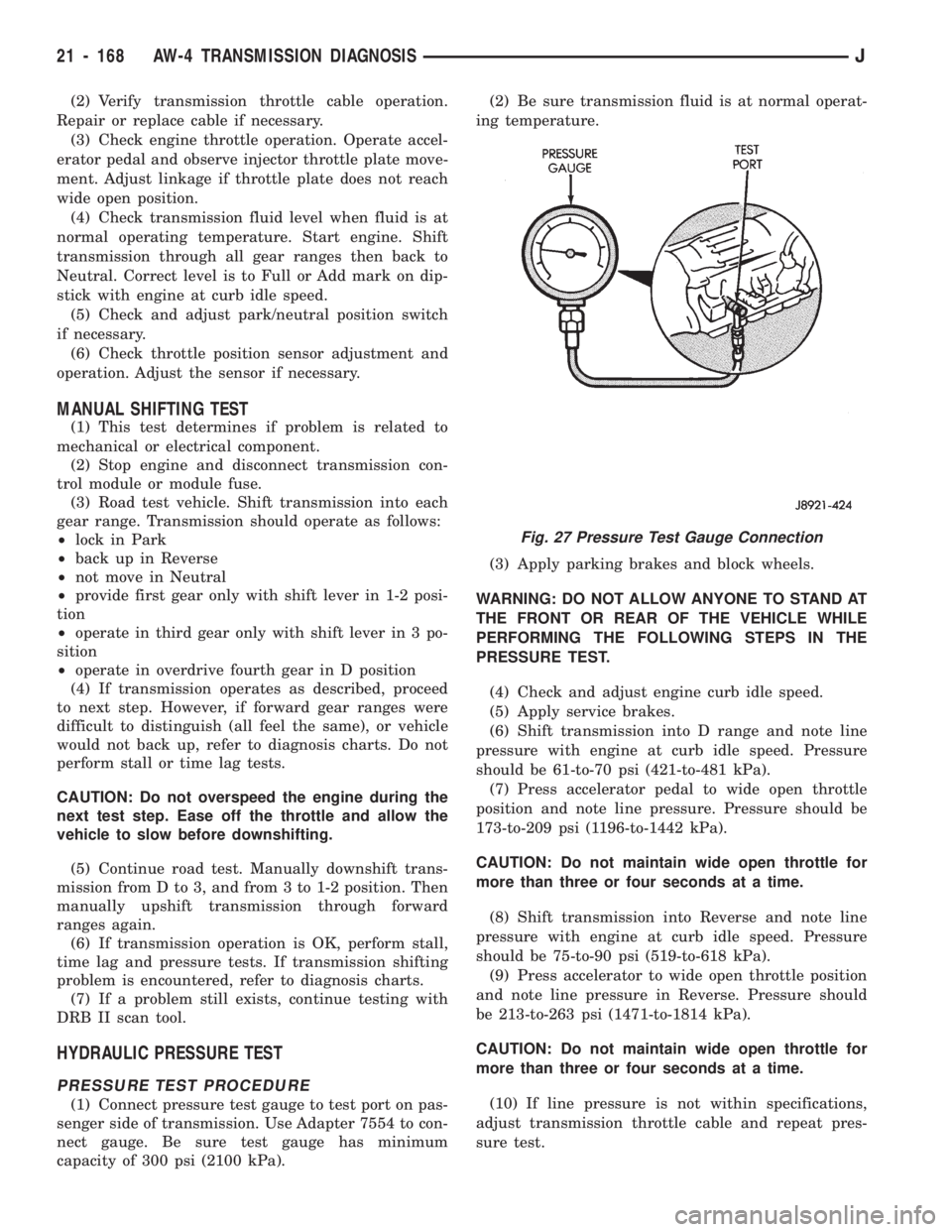

(1) Connect pressure test gauge to test port on pas-

senger side of transmission. Use Adapter 7554 to con-

nect gauge. Be sure test gauge has minimum

capacity of 300 psi (2100 kPa).(2) Be sure transmission fluid is at normal operat-

ing temperature.

(3) Apply parking brakes and block wheels.

WARNING: DO NOT ALLOW ANYONE TO STAND AT

THE FRONT OR REAR OF THE VEHICLE WHILE

PERFORMING THE FOLLOWING STEPS IN THE

PRESSURE TEST.

(4) Check and adjust engine curb idle speed.

(5) Apply service brakes.

(6) Shift transmission into D range and note line

pressure with engine at curb idle speed. Pressure

should be 61-to-70 psi (421-to-481 kPa).

(7) Press accelerator pedal to wide open throttle

position and note line pressure. Pressure should be

173-to-209 psi (1196-to-1442 kPa).

CAUTION: Do not maintain wide open throttle for

more than three or four seconds at a time.

(8) Shift transmission into Reverse and note line

pressure with engine at curb idle speed. Pressure

should be 75-to-90 psi (519-to-618 kPa).

(9) Press accelerator to wide open throttle position

and note line pressure in Reverse. Pressure should

be 213-to-263 psi (1471-to-1814 kPa).

CAUTION: Do not maintain wide open throttle for

more than three or four seconds at a time.

(10) If line pressure is not within specifications,

adjust transmission throttle cable and repeat pres-

sure test.

Fig. 27 Pressure Test Gauge Connection

21 - 168 AW-4 TRANSMISSION DIAGNOSISJ

Page 1280 of 1784

PRESSURE TEST ANALYSIS

If pressures in D and Reverse are higher than

specified, check for the following:

²throttle cable loose, worn, binding or out of adjust-

ment

²throttle valve, downshift plug, throttle cam, or pri-

mary regulator valve are sticking, worn or damaged

If pressures in D and Reverse are lower than spec-

ified, check for following:

²throttle cable loose, worn, binding or out of adjust-

ment

²throttle valve, downshift plug, throttle cam stick-

ing, worn or damaged

²primary regulator valve sticking, worn, or dam-

aged

²oil pump gears or housing worn or damaged

²overdrive clutch worn or damaged

If pressures are low in D range only, check for fol-

lowing:

²forward clutch worn or damaged

²fluid leakage in D range circuit (component seal

and O-rings)

If pressures are low in Reverse only, check for fol-

lowing:

²shift cable and manual valve out of adjustment

²fluid leakage in reverse circuit (component seal

and O-rings)

²direct clutch worn or damaged

²first/reverse brake worn or damaged

TORQUE CONVERTER STALL TEST

Stall testing checks the holding ability of the trans-

mission clutches and brakes and of the torque con-

verter stator overrunning clutch.

(1) Be sure transmission fluid is at normal operat-

ing temperature.

(2) Connect tachometer to engine. Position tachom-

eter so it can be viewed from drivers seat.

(3) Apply parking brakes and block wheels.

(4) Apply and hold service brakes.

(5) Shift transfer case into 2H position. On models

with NP249 transfer case, leave transfer case in 4H

position.

(6) Start engine.

WARNING: DO NOT ALLOW ANYONE TO STAND AT

THE FRONT OR REAR OF THE VEHICLE DURING

THE TEST.

(7) Shift transmission into D range.

(8) Press accelerator pedal to wide open throttle

position and note maximum engine rpm. Stall speed

should be 2100 to 2400 rpm in D range.

CAUTION: Do not maintain wide open throttle for

more than 3-4 seconds at a time.(9) Release throttle and shift transmission into

Neutral. Allow transmission fluid to cool for 15-20

seconds.

(10) Shift transmission into Reverse.

(11) Press accelerator down to wide open throttle

position and note maximum engine rpm. Stall speed

should be 2100-to-2400 rpm in Reverse.

STALL SPEED TEST ANALYSIS

If engine rpm is lower than specified in D and Re-

verse, check for the following:

²engine output/performance insufficient

²stator overrunning clutch in torque converter not

holding if engine speed was 1500 rpm or less.

If stall speed in D range is higher than specified,

check for the following:

²line pressure low

²forward clutch slipping

²No. 2 one-way clutch not holding

²overdrive one-way clutch not holding

If stall speed in Reverse was higher than specified,

check for the following:

²line pressure low

²direct clutch slipping

²first/ reverse brake slipping

²overdrive one-way clutch not holding

If stall speeds were higher than specified in both D

and Reverse, check for the following:

²low fluid level

²line pressure low

²overdrive one-way clutch not holding

TIME LAG TEST

This test checks general condition of the overdrive

clutch, forward clutch, rear clutch and first/reverse

brake. Condition is indicated by the amount of time

required for clutch/brake engagement with the en-

gine at curb idle speed. Engagement time is mea-

sured for D and Reverse positions. A stop watch is

recommended for test accuracy.

TEST PROCEDURE

(1) Check and adjust transmission fluid level if

necessary.

(2) Bring transmission to normal operating tem-

perature.

(3) Apply parking brakes and turn off air condi-

tioning unit.

(4) Shift transfer case into 2H range. On models

with NP249 transfer case, leave transfer case in 4H

range.

(5) Start engine and check curb idle speed. Adjust

speed if necessary. Curb idle must be correct to en-

sure accurate test results.

(6) Shift transmission into Neutral and set stop

watch.

(7) During following test steps, start stop watch as

soon as shift lever reaches D and Reverse ranges.

JAW-4 TRANSMISSION DIAGNOSIS 21 - 169