bolt pattern JEEP CHEROKEE 1994 Service Repair Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 1994, Model line: CHEROKEE, Model: JEEP CHEROKEE 1994Pages: 1784, PDF Size: 77.09 MB

Page 57 of 1784

MODEL 30 AXLE AND TUBE AXLE (2WD)

INDEX

page page

Axle Bushing Replacement................. 32

Axle Shaft Ð Cardan U-Joint................ 25

Axle Specifications....................... 46

Backlash and Contact Pattern Analysis........ 44

Cleaning/Inspection....................... 35

Differential and Pinion Measurement.......... 38

Differential Assembly...................... 36

Differential Disassembly.................... 34

Differential Installation..................... 43

Differential Removal...................... 32

Differential Shim Pack Measurement and Adjustment.42

Drive Axle Assembly ReplacementÐXJ Vehicles . 21

Drive Axle Assembly ReplacementÐYJ Vehicles . 21Final Assembly.......................... 44

Hub Bearing and Axle Shaft................ 24

Information............................. 20

Inner Axle Shaft Oil Seal Replacement........ 33

Lubricant Change........................ 22

Lubricant Specifications.................... 20

Pinion Gear Assembly/Installation............ 40

Pinion Gear Depth Information.............. 37

Pinion Removal/Disassembly................ 34

Pinion Seal Replacement.................. 23

Steering Knuckle and Ball Studs............. 30

Vacuum Disconnect Axle Ð YJ Vehicles....... 26

INFORMATION

The housing for Model 30 front axles consists of an

iron center casting (differential housing) with axle

shaft tubes extending from either side. The tubes are

pressed into and welded to the differential housing to

form a one-piece axle housing.

The integral type housing, hypoid gear design has

the centerline of the pinion set above the centerline

of the ring gear.

The axle has a fitting for a vent hose used to re-

lieve internal pressure caused by lubricant vaporiza-

tion and internal expansion.

The axles are equipped with semi-floating axle

shafts, meaning that loads are supported by the hub

bearings. The axle shafts are retained by nuts at the

hub bearings. The hub bearings are bolted to the

steering knuckle at the outboard end of the axle tube

yoke. The hub bearings are serviced as an assembly.

The axles are equipped with ABS brake sensors.

The sensors are attached to the knuckle assemblies

and tone rings are pressed on the axle shaft.Use

care when removing axle shafts as NOT to dam-

age the tone wheel or the sensor.

The stamped steel cover provides a means for in-

spection and servicing the differential.

The Model 30 axle has the assembly part number

and gear ratio listed on a tag. The tag is attached to

the housing cover. Build date identification codes are

stamped on the axle shaft tube cover side.

The differential case is a one-piece design. The dif-

ferential pinion mate shaft is retained with a roll

pin. Differential bearing preload and ring gear back-

lash is adjusted by the use of shims (select thick-

ness). The shims are located between the differential

bearing cones and case. Pinion bearing preload is set

and maintained by the use of collapsible spacer.

PINION GEAR DEPTH MEASUREMENT WITH

PINION GAUGE SET 6774, Pinion Block 6733 and

Dial Indicator C-3339 is performed when;²Axle/differential housing is being replaced

²Original pinion depth shim pack is lost or mis-

placed

²Replacing the differential case

²Original differential bearing shim pack is lost or

misplaced

COMMAND-TRACÐYJ VEHICLES

The Command-Trac system is a vacuum disconnect

axle. The system has a two-piece axle shaft coupled

together by a shift collar. For two-wheel drive oper-

ation, the vacuum motor and shift fork disengages

the axle shaft splines. For four-wheel drive opera-

tion, the vacuum motor and shift fork engages the

splines.

SELEC-TRACÐXJ VEHICLES

The Selec-Trac system is a non-disconnect axle.

Shifting from two-wheel to four-wheel drive is at the

transfer case.

For XJ vehicles equipped withSelec-Tracand

ABS brake system, refer to Group 5ÐBrakes for ad-

ditional service information.

LUBRICANT SPECIFICATIONS

Multi-purpose, hypoid gear lubricant should be

used for Model 30 axles. The lubricant should have

MIL-L-2105C and API GL 5 quality specifications.

MOPARtHypoid Gear Lubricant conforms to both of

these specifications.

²The factory fill for the Model 30 axle is SAE 75W

gear lubricant.Do not use heavier weight lubri-

cant, this will cause axle engagement difficulties.

²The factory installed lubricant quantity for the

NON-DISCONNECT TYPE AXLE is 5061 fluid oz..

²The factory installed lubricant quantity for the

VACUUM-DISCONNECT TYPE AXLE is 5661 fluid

oz..

2 - 20 FRONT SUSPENSION AND AXLEJ

Page 60 of 1784

(7) Install the cover and any identification tag.

Tighten the cover bolts in a criss-cross pattern to 41

Nzm (30 ft. lbs.) torque.

(8) Refill the differential with MOPARtHypoid

Gear Lubricant within 13 mm (1/2 in.) below the fill

plug hole.

(9) Install the fill hole plug and lower the vehicle.

PINION SEAL REPLACEMENT

CAUTION: The following procedures must be used

so the correct pinion bearing preload torque is re-

tained. If this procedure is not followed, the result

can be premature failure of the rear axle.

REMOVAL

(1) Raise and support the vehicle.

(2) Remove wheel and tire assemblies.

(3) Mark the propeller shaft yoke and pinion yoke

for installation alignment reference.

(4) Remove the propeller shaft from the yoke.

(5) Rotate the pinion gear three or four times.

Make sure brakes are not dragging during this

procedure.

(6) Measure the amount of torque (in Newton-

meters or inch-pounds) necessary to rotate the pinion

gear with a torque wrench. Note the torque for in-

stallation reference.It must be known to properly

adjust the pinion gear bearing preload torque

after seal installation.

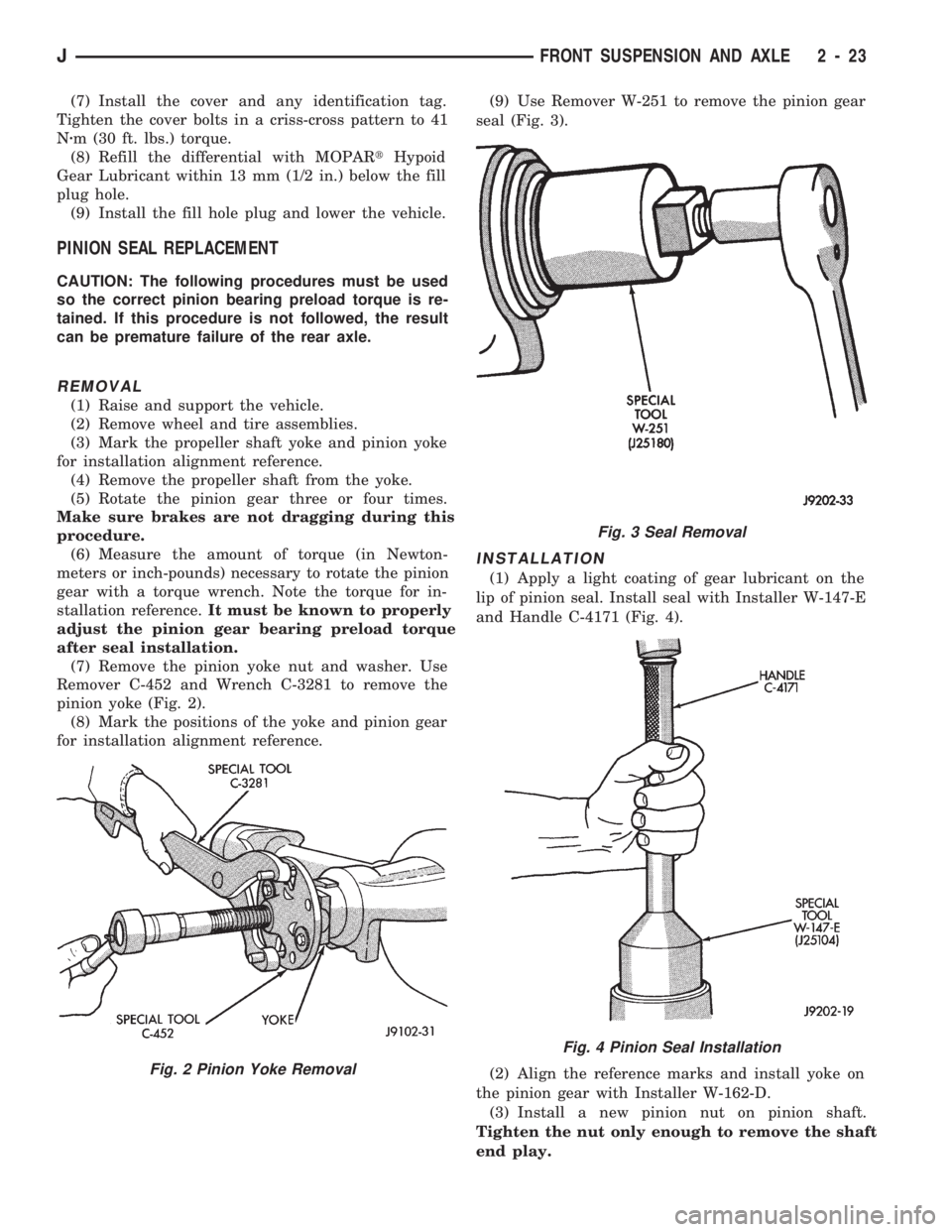

(7) Remove the pinion yoke nut and washer. Use

Remover C-452 and Wrench C-3281 to remove the

pinion yoke (Fig. 2).

(8) Mark the positions of the yoke and pinion gear

for installation alignment reference.(9) Use Remover W-251 to remove the pinion gear

seal (Fig. 3).

INSTALLATION

(1) Apply a light coating of gear lubricant on the

lip of pinion seal. Install seal with Installer W-147-E

and Handle C-4171 (Fig. 4).

(2) Align the reference marks and install yoke on

the pinion gear with Installer W-162-D.

(3) Install a new pinion nut on pinion shaft.

Tighten the nut only enough to remove the shaft

end play.

Fig. 2 Pinion Yoke Removal

Fig. 3 Seal Removal

Fig. 4 Pinion Seal Installation

JFRONT SUSPENSION AND AXLE 2 - 23

Page 74 of 1784

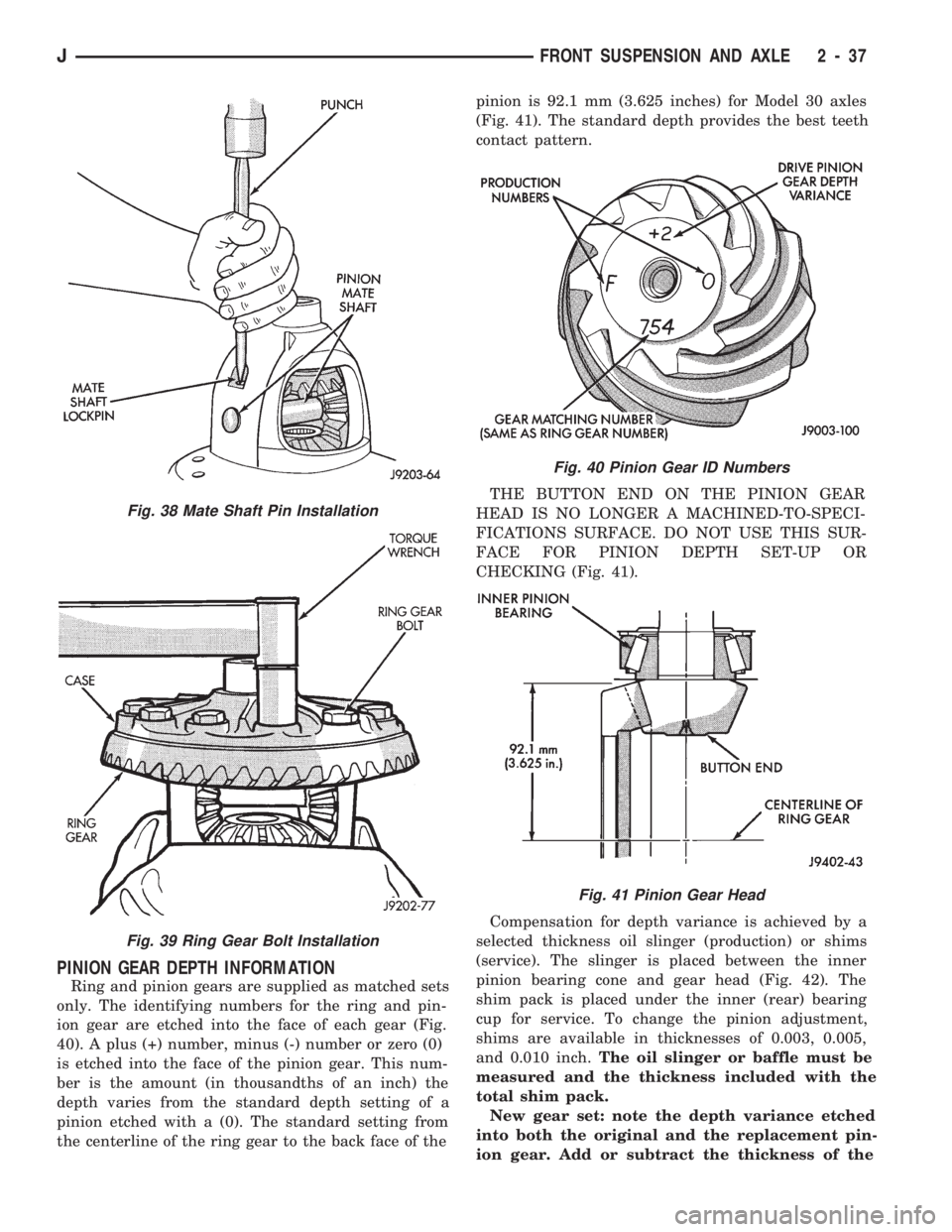

PINION GEAR DEPTH INFORMATION

Ring and pinion gears are supplied as matched sets

only. The identifying numbers for the ring and pin-

ion gear are etched into the face of each gear (Fig.

40). A plus (+) number, minus (-) number or zero (0)

is etched into the face of the pinion gear. This num-

ber is the amount (in thousandths of an inch) the

depth varies from the standard depth setting of a

pinion etched with a (0). The standard setting from

the centerline of the ring gear to the back face of thepinion is 92.1 mm (3.625 inches) for Model 30 axles

(Fig. 41). The standard depth provides the best teeth

contact pattern.

THE BUTTON END ON THE PINION GEAR

HEAD IS NO LONGER A MACHINED-TO-SPECI-

FICATIONS SURFACE. DO NOT USE THIS SUR-

FACE FOR PINION DEPTH SET-UP OR

CHECKING (Fig. 41).

Compensation for depth variance is achieved by a

selected thickness oil slinger (production) or shims

(service). The slinger is placed between the inner

pinion bearing cone and gear head (Fig. 42). The

shim pack is placed under the inner (rear) bearing

cup for service. To change the pinion adjustment,

shims are available in thicknesses of 0.003, 0.005,

and 0.010 inch.The oil slinger or baffle must be

measured and the thickness included with the

total shim pack.

New gear set: note the depth variance etched

into both the original and the replacement pin-

ion gear. Add or subtract the thickness of the

Fig. 38 Mate Shaft Pin Installation

Fig. 39 Ring Gear Bolt Installation

Fig. 40 Pinion Gear ID Numbers

Fig. 41 Pinion Gear Head

JFRONT SUSPENSION AND AXLE 2 - 37

Page 81 of 1784

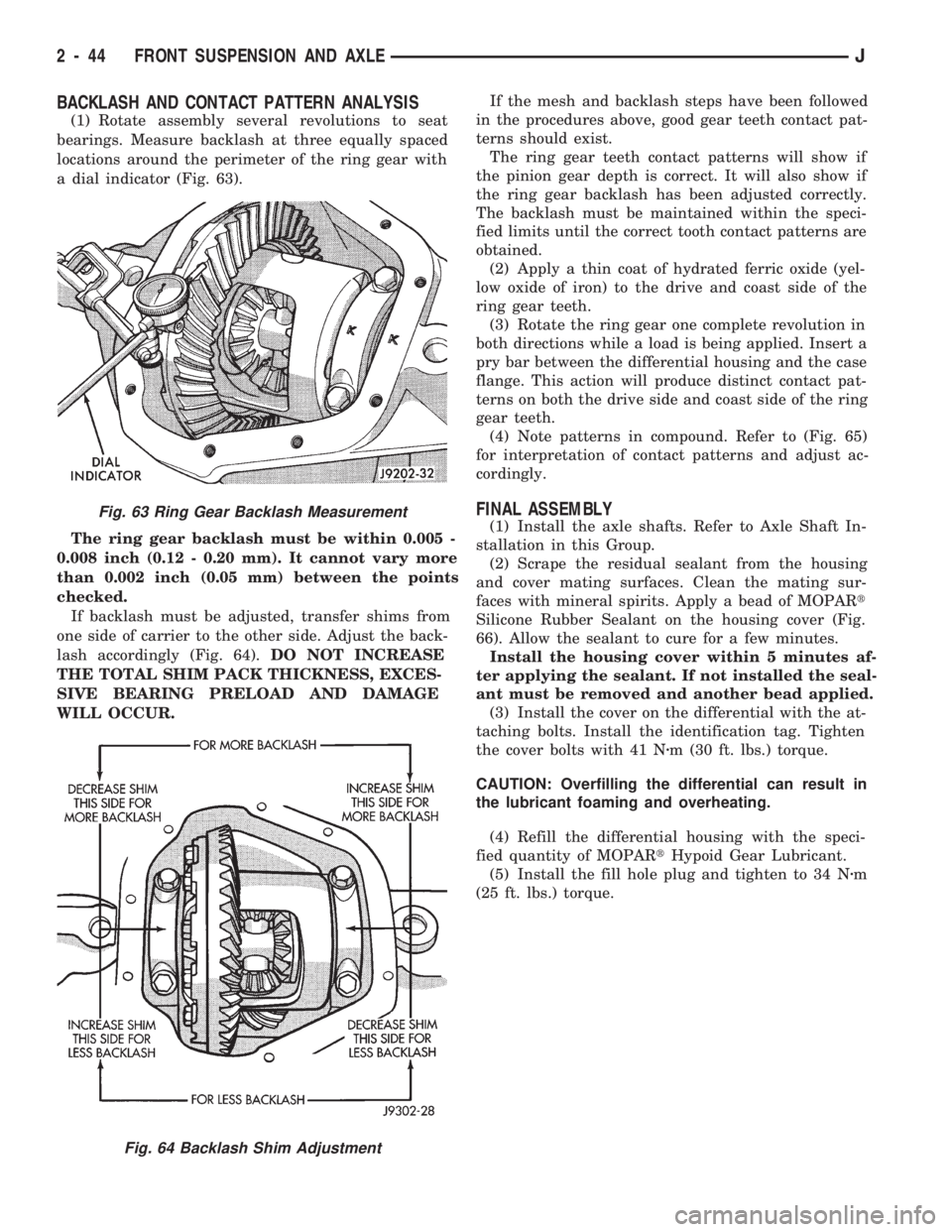

BACKLASH AND CONTACT PATTERN ANALYSIS

(1) Rotate assembly several revolutions to seat

bearings. Measure backlash at three equally spaced

locations around the perimeter of the ring gear with

a dial indicator (Fig. 63).

The ring gear backlash must be within 0.005 -

0.008 inch (0.12 - 0.20 mm). It cannot vary more

than 0.002 inch (0.05 mm) between the points

checked.

If backlash must be adjusted, transfer shims from

one side of carrier to the other side. Adjust the back-

lash accordingly (Fig. 64).DO NOT INCREASE

THE TOTAL SHIM PACK THICKNESS, EXCES-

SIVE BEARING PRELOAD AND DAMAGE

WILL OCCUR.If the mesh and backlash steps have been followed

in the procedures above, good gear teeth contact pat-

terns should exist.

The ring gear teeth contact patterns will show if

the pinion gear depth is correct. It will also show if

the ring gear backlash has been adjusted correctly.

The backlash must be maintained within the speci-

fied limits until the correct tooth contact patterns are

obtained.

(2) Apply a thin coat of hydrated ferric oxide (yel-

low oxide of iron) to the drive and coast side of the

ring gear teeth.

(3) Rotate the ring gear one complete revolution in

both directions while a load is being applied. Insert a

pry bar between the differential housing and the case

flange. This action will produce distinct contact pat-

terns on both the drive side and coast side of the ring

gear teeth.

(4) Note patterns in compound. Refer to (Fig. 65)

for interpretation of contact patterns and adjust ac-

cordingly.

FINAL ASSEMBLY

(1) Install the axle shafts. Refer to Axle Shaft In-

stallation in this Group.

(2) Scrape the residual sealant from the housing

and cover mating surfaces. Clean the mating sur-

faces with mineral spirits. Apply a bead of MOPARt

Silicone Rubber Sealant on the housing cover (Fig.

66). Allow the sealant to cure for a few minutes.

Install the housing cover within 5 minutes af-

ter applying the sealant. If not installed the seal-

ant must be removed and another bead applied.

(3) Install the cover on the differential with the at-

taching bolts. Install the identification tag. Tighten

the cover bolts with 41 Nzm (30 ft. lbs.) torque.

CAUTION: Overfilling the differential can result in

the lubricant foaming and overheating.

(4) Refill the differential housing with the speci-

fied quantity of MOPARtHypoid Gear Lubricant.

(5) Install the fill hole plug and tighten to 34 Nzm

(25 ft. lbs.) torque.Fig. 63 Ring Gear Backlash Measurement

Fig. 64 Backlash Shim Adjustment

2 - 44 FRONT SUSPENSION AND AXLEJ

Page 219 of 1784

when handling the cover and disc. Impact can distort

the cover, diaphragm spring, release fingers and the

hub of the clutch disc.

Use an alignment tool when positioning the disc on

the flywheel. The tool prevents accidental misalign-

ment which could result in cover distortion and disc

damage.

A frequent cause of clutch cover distortion (and

consequent misalignment) is improper bolt tighten-

ing. To avoid warping the cover, the bolts must tight-

ened alternately (diagonal pattern) and evenly (2-3

threads at a time) to specified torque.

Clutch Housing Misalignment

Clutch housing alignment is important to proper

clutch operation. The housing maintains alignment

between the crankshaft and transmission input shaft.

Misalignment can cause clutch noise, hard shifting,

incomplete release and chatter. It can also result in

premature wear of the pilot bearing, cover release

fingers and clutch disc. In severe cases, misalign-

ment can also cause premature wear of the transmis-

sion input shaft and shaft bearing.

Housing misalignment is generally caused by in-

correct seating on the engine or transmission, loose

housing bolts, missing alignment dowels or housing

damage. Infrequently, misalignment may also be

caused by housing mounting surfaces that are not

completely parallel. Misalignment can be corrected

with shims.INSTALLATION METHODS AND PARTS

USAGE

Distortion of clutch components during installation

and the use of non-standard components are addi-

tional causes of clutch malfunction.

Improper clutch cover bolt tightening can distort

the cover. The usual result is clutch grab, chatter

and rapid wear. Tighten the cover bolts as described

in Clutch Service section.

An improperly seated flywheel and/or clutch hous-

ing are additional causes of clutch failure. Improper

seating will produce misalignment and additional

clutch problems.

The use of non-standard or low quality parts will

also lead to problems and wear. Use recommended

factory quality parts to avoid comebacks.

INSPECTION AND DIAGNOSIS CHARTS

The clutch inspection chart (Fig. 1) outlines items

to be checked before and during clutch installation.

Use the chart as a check list to help avoid overlook-

ing potential problem sources during service opera-

tions.

The diagnosis charts describe common clutch prob-

lems, causes and correction. Fault conditions are

listed at the top of each chart. Conditions, causes and

corrective action are outlined in the indicated col-

umns.

The charts are provided as a convenient reference

when diagnosing faulty clutch operation.

6 - 4 CLUTCH DIAGNOSISJ

Page 844 of 1784

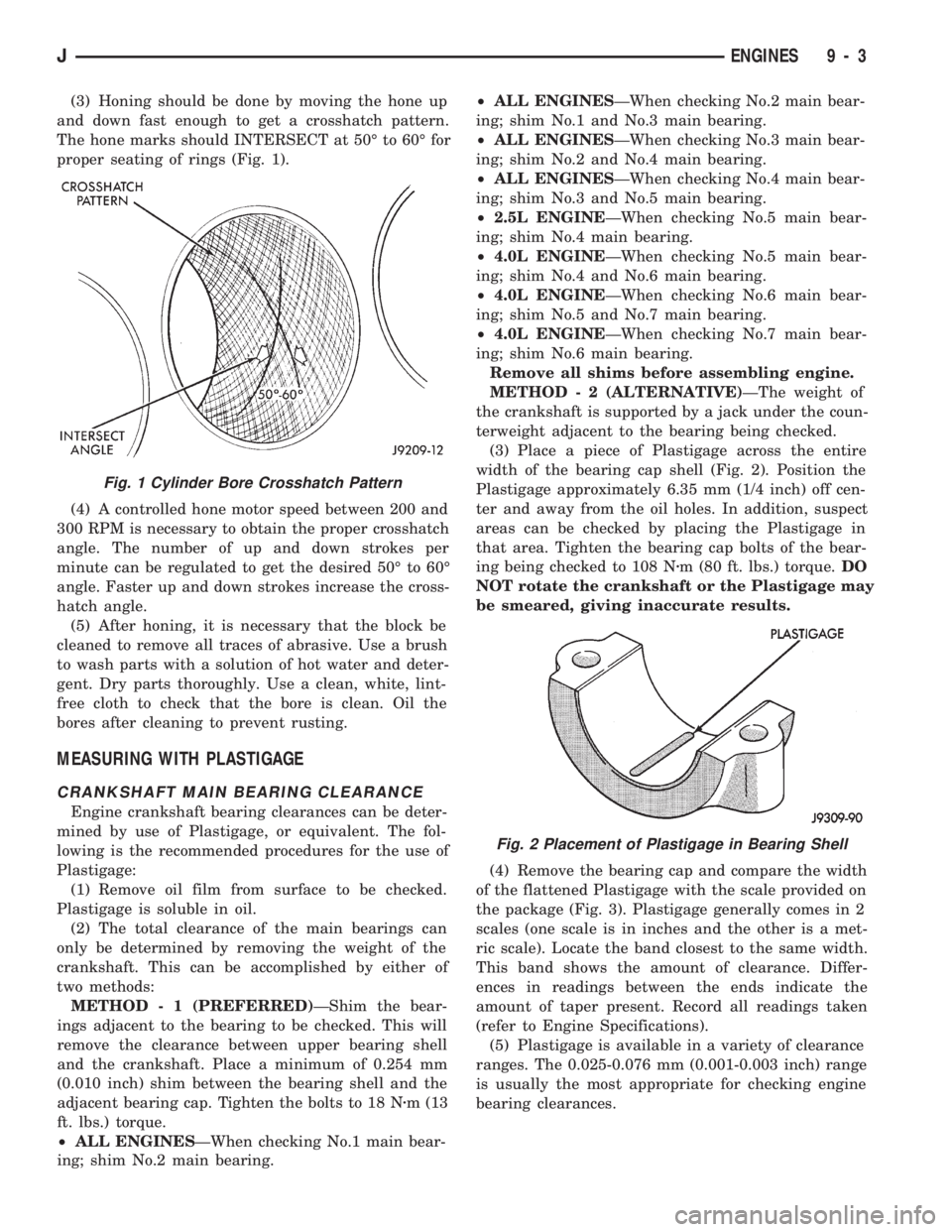

(3) Honing should be done by moving the hone up

and down fast enough to get a crosshatch pattern.

The hone marks should INTERSECT at 50É to 60É for

proper seating of rings (Fig. 1).

(4) A controlled hone motor speed between 200 and

300 RPM is necessary to obtain the proper crosshatch

angle. The number of up and down strokes per

minute can be regulated to get the desired 50É to 60É

angle. Faster up and down strokes increase the cross-

hatch angle.

(5) After honing, it is necessary that the block be

cleaned to remove all traces of abrasive. Use a brush

to wash parts with a solution of hot water and deter-

gent. Dry parts thoroughly. Use a clean, white, lint-

free cloth to check that the bore is clean. Oil the

bores after cleaning to prevent rusting.

MEASURING WITH PLASTIGAGE

CRANKSHAFT MAIN BEARING CLEARANCE

Engine crankshaft bearing clearances can be deter-

mined by use of Plastigage, or equivalent. The fol-

lowing is the recommended procedures for the use of

Plastigage:

(1) Remove oil film from surface to be checked.

Plastigage is soluble in oil.

(2) The total clearance of the main bearings can

only be determined by removing the weight of the

crankshaft. This can be accomplished by either of

two methods:

METHOD - 1 (PREFERRED)ÐShim the bear-

ings adjacent to the bearing to be checked. This will

remove the clearance between upper bearing shell

and the crankshaft. Place a minimum of 0.254 mm

(0.010 inch) shim between the bearing shell and the

adjacent bearing cap. Tighten the bolts to 18 Nzm (13

ft. lbs.) torque.

²ALL ENGINESÐWhen checking No.1 main bear-

ing; shim No.2 main bearing.²ALL ENGINESÐWhen checking No.2 main bear-

ing; shim No.1 and No.3 main bearing.

²ALL ENGINESÐWhen checking No.3 main bear-

ing; shim No.2 and No.4 main bearing.

²ALL ENGINESÐWhen checking No.4 main bear-

ing; shim No.3 and No.5 main bearing.

²2.5L ENGINEÐWhen checking No.5 main bear-

ing; shim No.4 main bearing.

²4.0L ENGINEÐWhen checking No.5 main bear-

ing; shim No.4 and No.6 main bearing.

²4.0L ENGINEÐWhen checking No.6 main bear-

ing; shim No.5 and No.7 main bearing.

²4.0L ENGINEÐWhen checking No.7 main bear-

ing; shim No.6 main bearing.

Remove all shims before assembling engine.

METHOD - 2 (ALTERNATIVE)ÐThe weight of

the crankshaft is supported by a jack under the coun-

terweight adjacent to the bearing being checked.

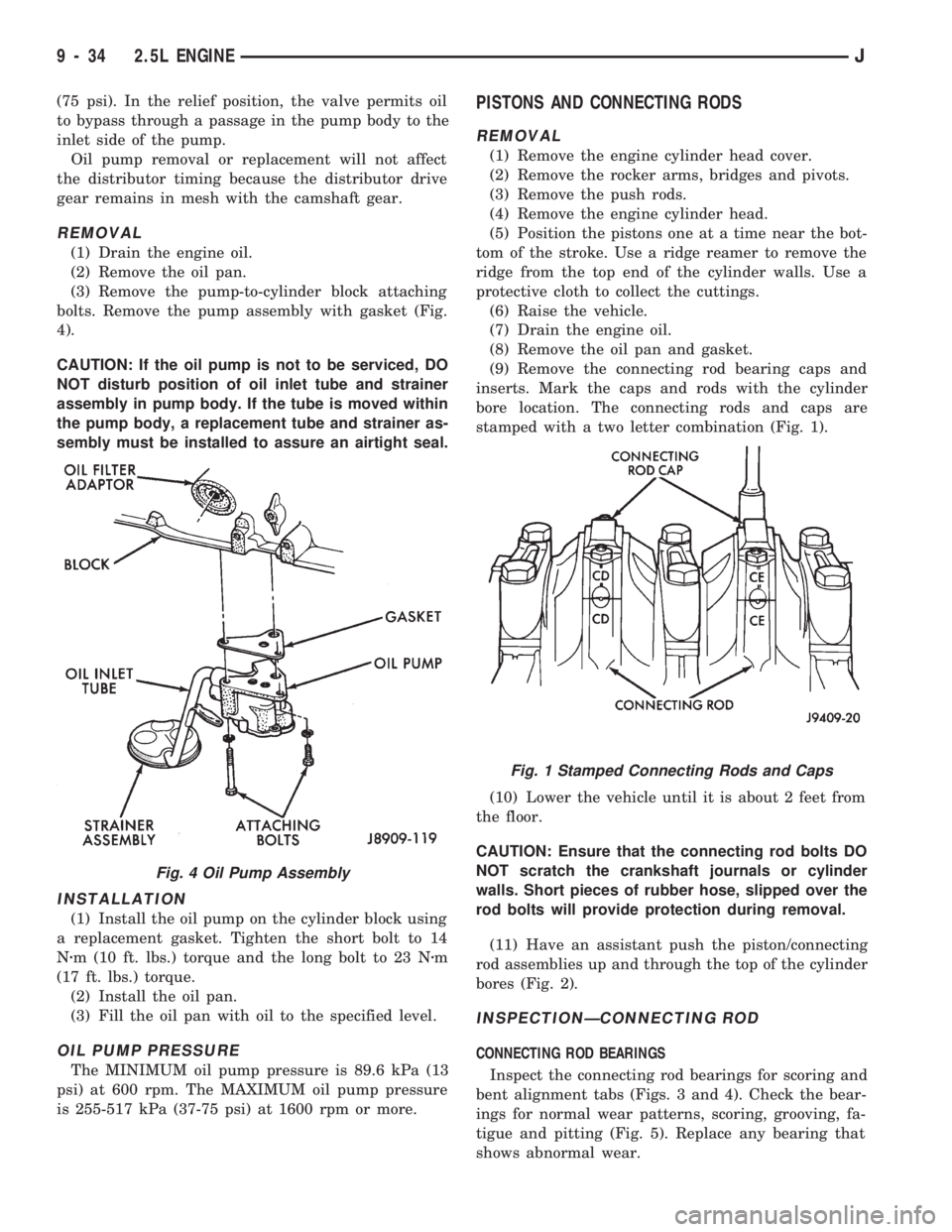

(3) Place a piece of Plastigage across the entire

width of the bearing cap shell (Fig. 2). Position the

Plastigage approximately 6.35 mm (1/4 inch) off cen-

ter and away from the oil holes. In addition, suspect

areas can be checked by placing the Plastigage in

that area. Tighten the bearing cap bolts of the bear-

ing being checked to 108 Nzm (80 ft. lbs.) torque.DO

NOT rotate the crankshaft or the Plastigage may

be smeared, giving inaccurate results.

(4) Remove the bearing cap and compare the width

of the flattened Plastigage with the scale provided on

the package (Fig. 3). Plastigage generally comes in 2

scales (one scale is in inches and the other is a met-

ric scale). Locate the band closest to the same width.

This band shows the amount of clearance. Differ-

ences in readings between the ends indicate the

amount of taper present. Record all readings taken

(refer to Engine Specifications).

(5) Plastigage is available in a variety of clearance

ranges. The 0.025-0.076 mm (0.001-0.003 inch) range

is usually the most appropriate for checking engine

bearing clearances.

Fig. 1 Cylinder Bore Crosshatch Pattern

Fig. 2 Placement of Plastigage in Bearing Shell

JENGINES 9 - 3

Page 875 of 1784

(75 psi). In the relief position, the valve permits oil

to bypass through a passage in the pump body to the

inlet side of the pump.

Oil pump removal or replacement will not affect

the distributor timing because the distributor drive

gear remains in mesh with the camshaft gear.

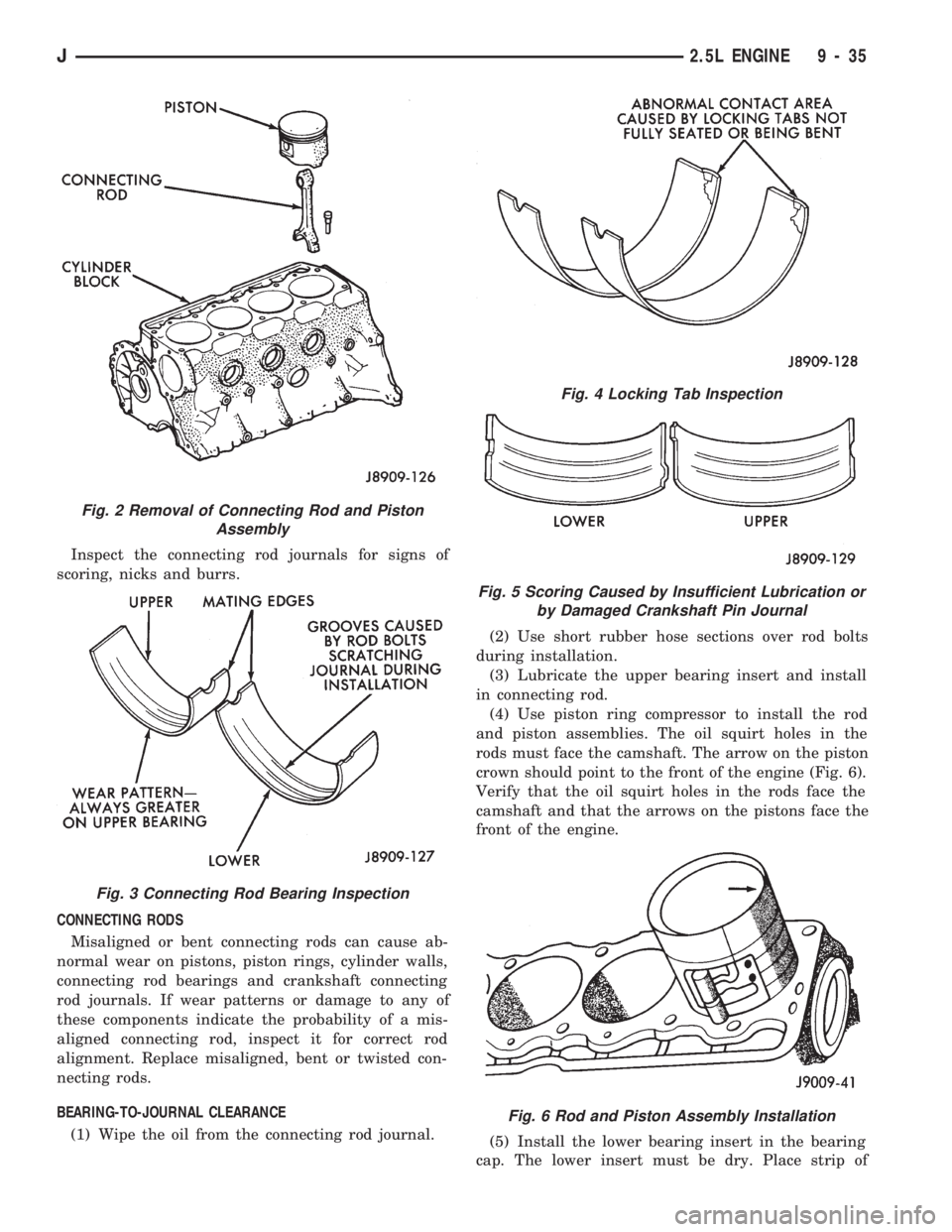

REMOVAL

(1) Drain the engine oil.

(2) Remove the oil pan.

(3) Remove the pump-to-cylinder block attaching

bolts. Remove the pump assembly with gasket (Fig.

4).

CAUTION: If the oil pump is not to be serviced, DO

NOT disturb position of oil inlet tube and strainer

assembly in pump body. If the tube is moved within

the pump body, a replacement tube and strainer as-

sembly must be installed to assure an airtight seal.

INSTALLATION

(1) Install the oil pump on the cylinder block using

a replacement gasket. Tighten the short bolt to 14

Nzm (10 ft. lbs.) torque and the long bolt to 23 Nzm

(17 ft. lbs.) torque.

(2) Install the oil pan.

(3) Fill the oil pan with oil to the specified level.

OIL PUMP PRESSURE

The MINIMUM oil pump pressure is 89.6 kPa (13

psi) at 600 rpm. The MAXIMUM oil pump pressure

is 255-517 kPa (37-75 psi) at 1600 rpm or more.

PISTONS AND CONNECTING RODS

REMOVAL

(1) Remove the engine cylinder head cover.

(2) Remove the rocker arms, bridges and pivots.

(3) Remove the push rods.

(4) Remove the engine cylinder head.

(5) Position the pistons one at a time near the bot-

tom of the stroke. Use a ridge reamer to remove the

ridge from the top end of the cylinder walls. Use a

protective cloth to collect the cuttings.

(6) Raise the vehicle.

(7) Drain the engine oil.

(8) Remove the oil pan and gasket.

(9) Remove the connecting rod bearing caps and

inserts. Mark the caps and rods with the cylinder

bore location. The connecting rods and caps are

stamped with a two letter combination (Fig. 1).

(10) Lower the vehicle until it is about 2 feet from

the floor.

CAUTION: Ensure that the connecting rod bolts DO

NOT scratch the crankshaft journals or cylinder

walls. Short pieces of rubber hose, slipped over the

rod bolts will provide protection during removal.

(11) Have an assistant push the piston/connecting

rod assemblies up and through the top of the cylinder

bores (Fig. 2).

INSPECTIONÐCONNECTING ROD

CONNECTING ROD BEARINGS

Inspect the connecting rod bearings for scoring and

bent alignment tabs (Figs. 3 and 4). Check the bear-

ings for normal wear patterns, scoring, grooving, fa-

tigue and pitting (Fig. 5). Replace any bearing that

shows abnormal wear.

Fig. 4 Oil Pump Assembly

Fig. 1 Stamped Connecting Rods and Caps

9 - 34 2.5L ENGINEJ

Page 876 of 1784

Inspect the connecting rod journals for signs of

scoring, nicks and burrs.

CONNECTING RODS

Misaligned or bent connecting rods can cause ab-

normal wear on pistons, piston rings, cylinder walls,

connecting rod bearings and crankshaft connecting

rod journals. If wear patterns or damage to any of

these components indicate the probability of a mis-

aligned connecting rod, inspect it for correct rod

alignment. Replace misaligned, bent or twisted con-

necting rods.

BEARING-TO-JOURNAL CLEARANCE

(1) Wipe the oil from the connecting rod journal.(2) Use short rubber hose sections over rod bolts

during installation.

(3) Lubricate the upper bearing insert and install

in connecting rod.

(4) Use piston ring compressor to install the rod

and piston assemblies. The oil squirt holes in the

rods must face the camshaft. The arrow on the piston

crown should point to the front of the engine (Fig. 6).

Verify that the oil squirt holes in the rods face the

camshaft and that the arrows on the pistons face the

front of the engine.

(5) Install the lower bearing insert in the bearing

cap. The lower insert must be dry. Place strip of

Fig. 2 Removal of Connecting Rod and Piston

Assembly

Fig. 3 Connecting Rod Bearing Inspection

Fig. 4 Locking Tab Inspection

Fig. 5 Scoring Caused by Insufficient Lubrication or

by Damaged Crankshaft Pin Journal

Fig. 6 Rod and Piston Assembly Installation

J2.5L ENGINE 9 - 35

Page 883 of 1784

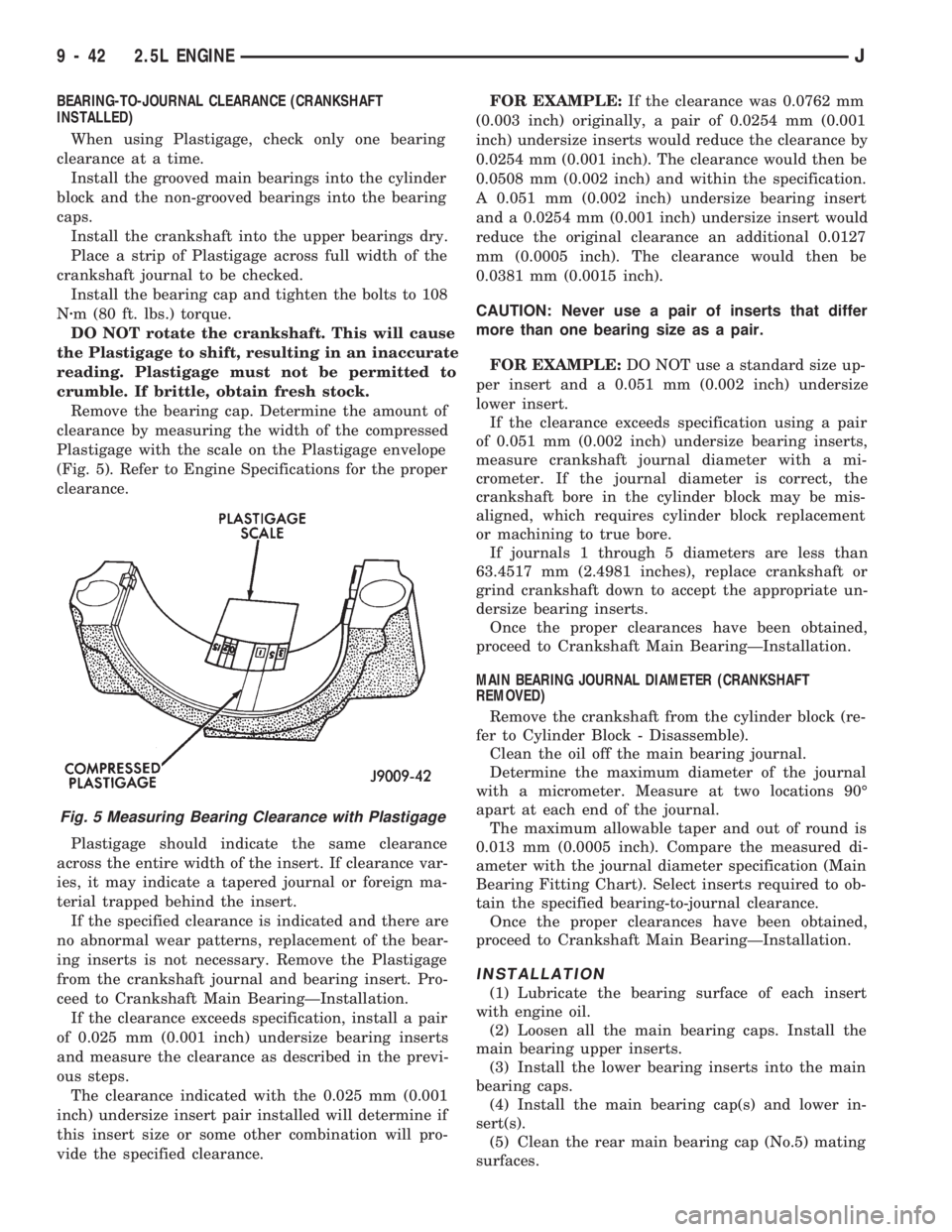

BEARING-TO-JOURNAL CLEARANCE (CRANKSHAFT

INSTALLED)

When using Plastigage, check only one bearing

clearance at a time.

Install the grooved main bearings into the cylinder

block and the non-grooved bearings into the bearing

caps.

Install the crankshaft into the upper bearings dry.

Place a strip of Plastigage across full width of the

crankshaft journal to be checked.

Install the bearing cap and tighten the bolts to 108

Nzm (80 ft. lbs.) torque.

DO NOT rotate the crankshaft. This will cause

the Plastigage to shift, resulting in an inaccurate

reading. Plastigage must not be permitted to

crumble. If brittle, obtain fresh stock.

Remove the bearing cap. Determine the amount of

clearance by measuring the width of the compressed

Plastigage with the scale on the Plastigage envelope

(Fig. 5). Refer to Engine Specifications for the proper

clearance.

Plastigage should indicate the same clearance

across the entire width of the insert. If clearance var-

ies, it may indicate a tapered journal or foreign ma-

terial trapped behind the insert.

If the specified clearance is indicated and there are

no abnormal wear patterns, replacement of the bear-

ing inserts is not necessary. Remove the Plastigage

from the crankshaft journal and bearing insert. Pro-

ceed to Crankshaft Main BearingÐInstallation.

If the clearance exceeds specification, install a pair

of 0.025 mm (0.001 inch) undersize bearing inserts

and measure the clearance as described in the previ-

ous steps.

The clearance indicated with the 0.025 mm (0.001

inch) undersize insert pair installed will determine if

this insert size or some other combination will pro-

vide the specified clearance.FOR EXAMPLE:If the clearance was 0.0762 mm

(0.003 inch) originally, a pair of 0.0254 mm (0.001

inch) undersize inserts would reduce the clearance by

0.0254 mm (0.001 inch). The clearance would then be

0.0508 mm (0.002 inch) and within the specification.

A 0.051 mm (0.002 inch) undersize bearing insert

and a 0.0254 mm (0.001 inch) undersize insert would

reduce the original clearance an additional 0.0127

mm (0.0005 inch). The clearance would then be

0.0381 mm (0.0015 inch).

CAUTION: Never use a pair of inserts that differ

more than one bearing size as a pair.

FOR EXAMPLE:DO NOT use a standard size up-

per insert and a 0.051 mm (0.002 inch) undersize

lower insert.

If the clearance exceeds specification using a pair

of 0.051 mm (0.002 inch) undersize bearing inserts,

measure crankshaft journal diameter with a mi-

crometer. If the journal diameter is correct, the

crankshaft bore in the cylinder block may be mis-

aligned, which requires cylinder block replacement

or machining to true bore.

If journals 1 through 5 diameters are less than

63.4517 mm (2.4981 inches), replace crankshaft or

grind crankshaft down to accept the appropriate un-

dersize bearing inserts.

Once the proper clearances have been obtained,

proceed to Crankshaft Main BearingÐInstallation.

MAIN BEARING JOURNAL DIAMETER (CRANKSHAFT

REMOVED)

Remove the crankshaft from the cylinder block (re-

fer to Cylinder Block - Disassemble).

Clean the oil off the main bearing journal.

Determine the maximum diameter of the journal

with a micrometer. Measure at two locations 90É

apart at each end of the journal.

The maximum allowable taper and out of round is

0.013 mm (0.0005 inch). Compare the measured di-

ameter with the journal diameter specification (Main

Bearing Fitting Chart). Select inserts required to ob-

tain the specified bearing-to-journal clearance.

Once the proper clearances have been obtained,

proceed to Crankshaft Main BearingÐInstallation.

INSTALLATION

(1) Lubricate the bearing surface of each insert

with engine oil.

(2) Loosen all the main bearing caps. Install the

main bearing upper inserts.

(3) Install the lower bearing inserts into the main

bearing caps.

(4) Install the main bearing cap(s) and lower in-

sert(s).

(5) Clean the rear main bearing cap (No.5) mating

surfaces.

Fig. 5 Measuring Bearing Clearance with Plastigage

9 - 42 2.5L ENGINEJ

Page 901 of 1784

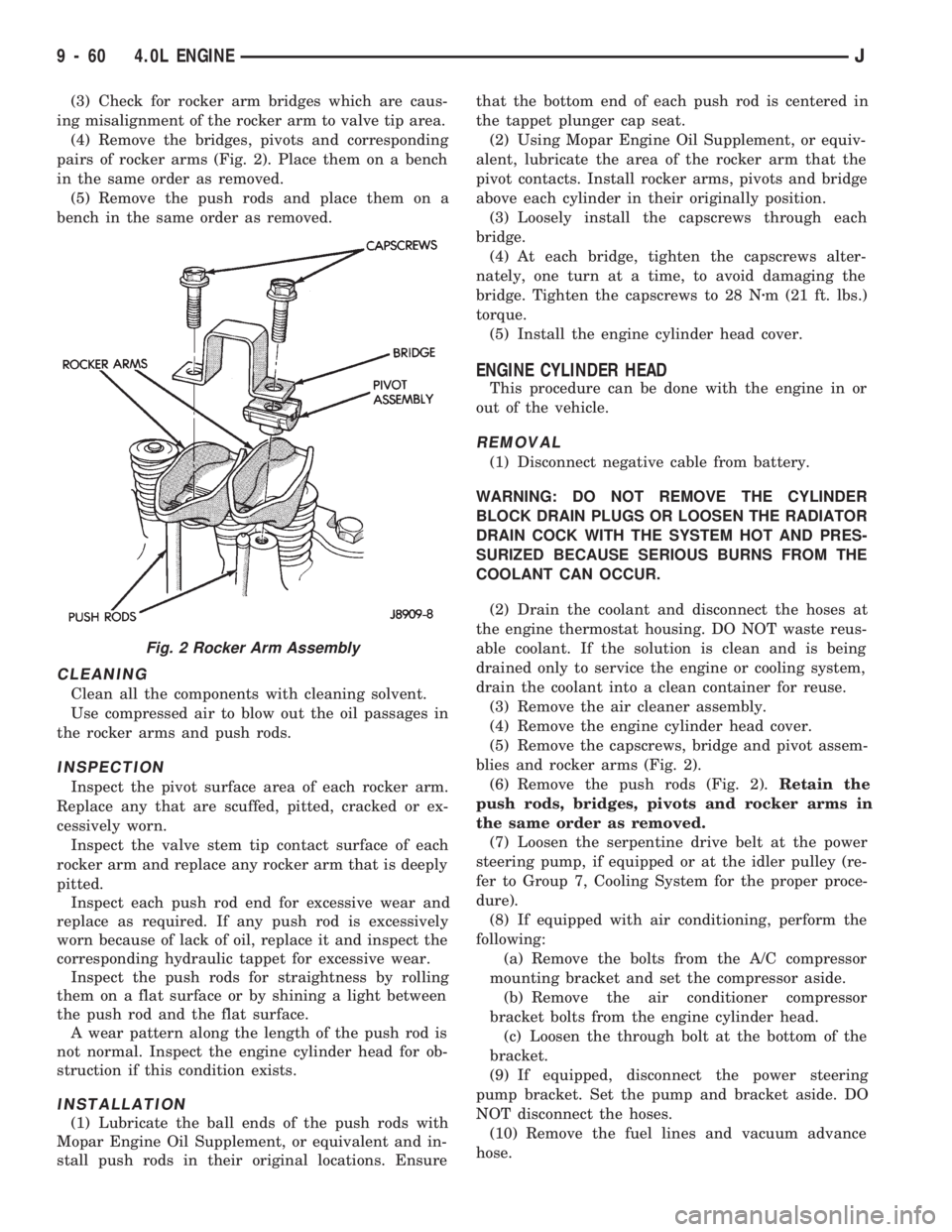

(3) Check for rocker arm bridges which are caus-

ing misalignment of the rocker arm to valve tip area.

(4) Remove the bridges, pivots and corresponding

pairs of rocker arms (Fig. 2). Place them on a bench

in the same order as removed.

(5) Remove the push rods and place them on a

bench in the same order as removed.

CLEANING

Clean all the components with cleaning solvent.

Use compressed air to blow out the oil passages in

the rocker arms and push rods.

INSPECTION

Inspect the pivot surface area of each rocker arm.

Replace any that are scuffed, pitted, cracked or ex-

cessively worn.

Inspect the valve stem tip contact surface of each

rocker arm and replace any rocker arm that is deeply

pitted.

Inspect each push rod end for excessive wear and

replace as required. If any push rod is excessively

worn because of lack of oil, replace it and inspect the

corresponding hydraulic tappet for excessive wear.

Inspect the push rods for straightness by rolling

them on a flat surface or by shining a light between

the push rod and the flat surface.

A wear pattern along the length of the push rod is

not normal. Inspect the engine cylinder head for ob-

struction if this condition exists.

INSTALLATION

(1) Lubricate the ball ends of the push rods with

Mopar Engine Oil Supplement, or equivalent and in-

stall push rods in their original locations. Ensurethat the bottom end of each push rod is centered in

the tappet plunger cap seat.

(2) Using Mopar Engine Oil Supplement, or equiv-

alent, lubricate the area of the rocker arm that the

pivot contacts. Install rocker arms, pivots and bridge

above each cylinder in their originally position.

(3) Loosely install the capscrews through each

bridge.

(4) At each bridge, tighten the capscrews alter-

nately, one turn at a time, to avoid damaging the

bridge. Tighten the capscrews to 28 Nzm (21 ft. lbs.)

torque.

(5) Install the engine cylinder head cover.

ENGINE CYLINDER HEAD

This procedure can be done with the engine in or

out of the vehicle.

REMOVAL

(1) Disconnect negative cable from battery.

WARNING: DO NOT REMOVE THE CYLINDER

BLOCK DRAIN PLUGS OR LOOSEN THE RADIATOR

DRAIN COCK WITH THE SYSTEM HOT AND PRES-

SURIZED BECAUSE SERIOUS BURNS FROM THE

COOLANT CAN OCCUR.

(2) Drain the coolant and disconnect the hoses at

the engine thermostat housing. DO NOT waste reus-

able coolant. If the solution is clean and is being

drained only to service the engine or cooling system,

drain the coolant into a clean container for reuse.

(3) Remove the air cleaner assembly.

(4) Remove the engine cylinder head cover.

(5) Remove the capscrews, bridge and pivot assem-

blies and rocker arms (Fig. 2).

(6) Remove the push rods (Fig. 2).Retain the

push rods, bridges, pivots and rocker arms in

the same order as removed.

(7) Loosen the serpentine drive belt at the power

steering pump, if equipped or at the idler pulley (re-

fer to Group 7, Cooling System for the proper proce-

dure).

(8) If equipped with air conditioning, perform the

following:

(a) Remove the bolts from the A/C compressor

mounting bracket and set the compressor aside.

(b) Remove the air conditioner compressor

bracket bolts from the engine cylinder head.

(c) Loosen the through bolt at the bottom of the

bracket.

(9) If equipped, disconnect the power steering

pump bracket. Set the pump and bracket aside. DO

NOT disconnect the hoses.

(10) Remove the fuel lines and vacuum advance

hose.

Fig. 2 Rocker Arm Assembly

9 - 60 4.0L ENGINEJ