sensor JEEP CHEROKEE 1994 Service Repair Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 1994, Model line: CHEROKEE, Model: JEEP CHEROKEE 1994Pages: 1784, PDF Size: 77.09 MB

Page 1219 of 1784

30RH/32RH TRANSMISSION REMOVAL AND INSTALLATION

INDEX

page page

ConverterÐPump SealÐDrive Plate Service . . . 109

Transmission and Converter Installation....... 109Transmission and Converter Removal........ 108

TRANSMISSION AND CONVERTER REMOVAL

(1) Remove fan shroud attaching bolts.

(2) Disconnect transmission fill tube at upper

bracket.

(3) Raise vehicle.

(4) Remove inspection cover from converter hous-

ing and remove skid plate for access, if necessary.

(5) Remove transmission fill tube and fill tube

O-ring.

(6) Remove starter motor.

(7) Mark propeller shafts and axle yokes for align-

ment reference.

(8) Disconnect propeller shafts at yokes. Secure

shafts to frame rails with wire.

(9) Disconnect exhaust pipes at exhaust manifolds,

if necessary.

(10) Drain transfer case lubricant.

(11) Disconnect vehicle speed sensor wires.

(12) Disconnect transfer case shift linkage.

(13) Disconnect gearshift linkage and throttle ca-

ble at transmission levers.

(14) Disconnect park/neutral position switch wires.

(15) Disconnect and remove crankshaft position

sensor. Retain sensor bolt for reinstallation.

CAUTION: The crankshaft position sensor can be

damaged during transmission removal (or installa-

tion) if the sensor is still bolted to the engine block.

To avoid damage, remove the sensor before remov-

ing the transmission.

(16) Remove converter housing access cover and

mark drive plate and converter for alignment refer-

ence.

(17) Remove bolts attaching converter to drive

plate.

(18) Support engine with support stand.

(19) Support transmission-transfer case assembly

with transmission jack. Secure transmission to jack

with safety chain.

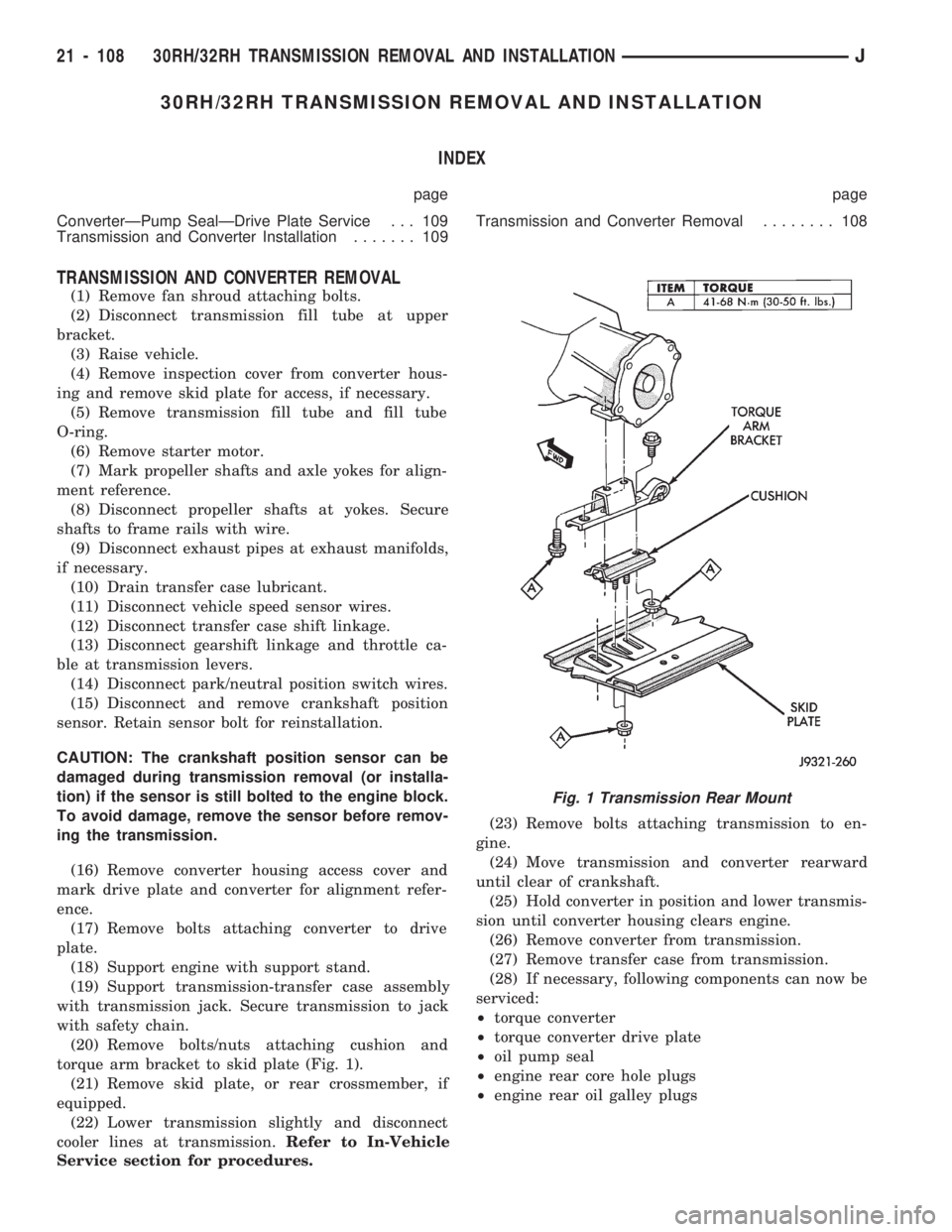

(20) Remove bolts/nuts attaching cushion and

torque arm bracket to skid plate (Fig. 1).

(21) Remove skid plate, or rear crossmember, if

equipped.

(22) Lower transmission slightly and disconnect

cooler lines at transmission.Refer to In-Vehicle

Service section for procedures.(23) Remove bolts attaching transmission to en-

gine.

(24) Move transmission and converter rearward

until clear of crankshaft.

(25) Hold converter in position and lower transmis-

sion until converter housing clears engine.

(26) Remove converter from transmission.

(27) Remove transfer case from transmission.

(28) If necessary, following components can now be

serviced:

²torque converter

²torque converter drive plate

²oil pump seal

²engine rear core hole plugs

²engine rear oil galley plugs

Fig. 1 Transmission Rear Mount

21 - 108 30RH/32RH TRANSMISSION REMOVAL AND INSTALLATIONJ

Page 1221 of 1784

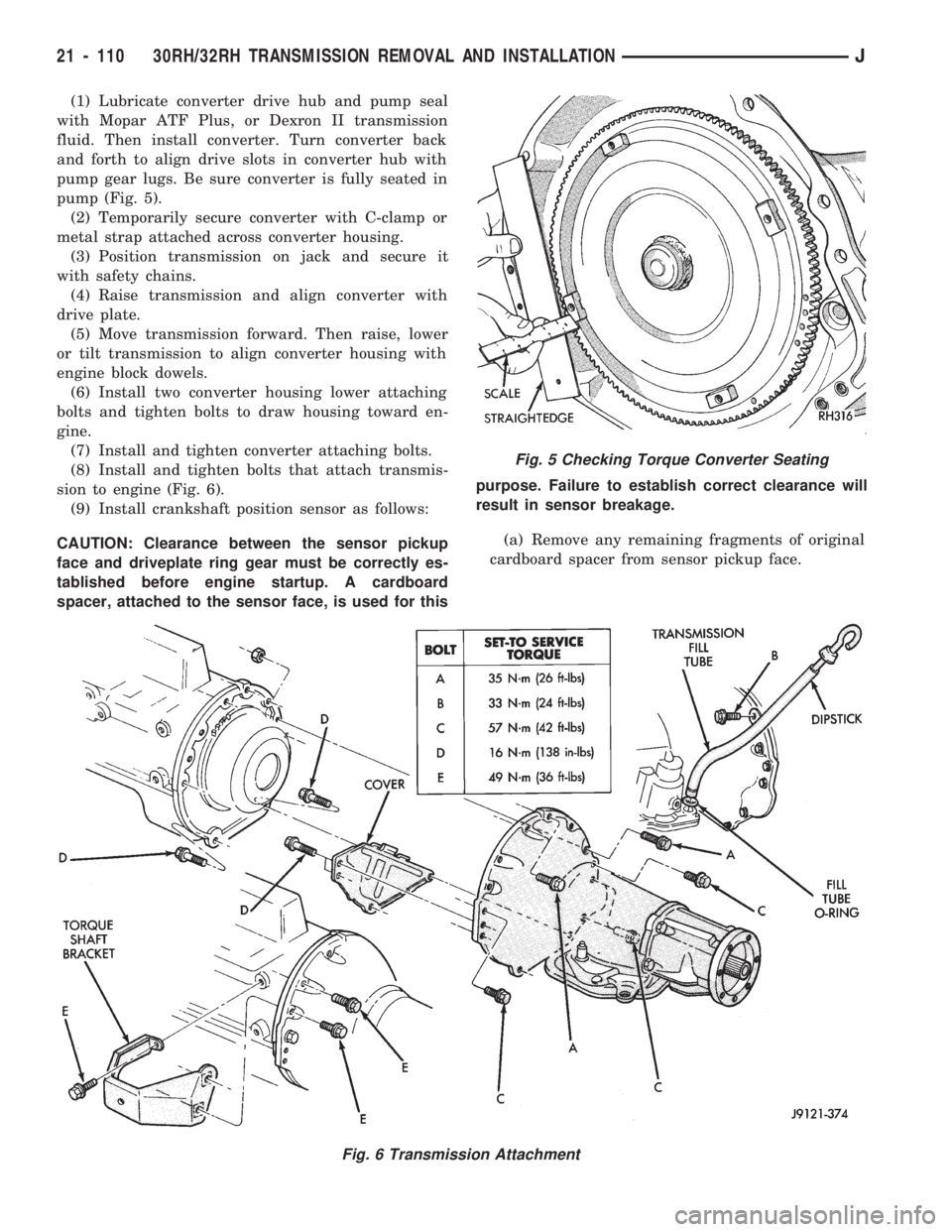

(1) Lubricate converter drive hub and pump seal

with Mopar ATF Plus, or Dexron II transmission

fluid. Then install converter. Turn converter back

and forth to align drive slots in converter hub with

pump gear lugs. Be sure converter is fully seated in

pump (Fig. 5).

(2) Temporarily secure converter with C-clamp or

metal strap attached across converter housing.

(3) Position transmission on jack and secure it

with safety chains.

(4) Raise transmission and align converter with

drive plate.

(5) Move transmission forward. Then raise, lower

or tilt transmission to align converter housing with

engine block dowels.

(6) Install two converter housing lower attaching

bolts and tighten bolts to draw housing toward en-

gine.

(7) Install and tighten converter attaching bolts.

(8) Install and tighten bolts that attach transmis-

sion to engine (Fig. 6).

(9) Install crankshaft position sensor as follows:

CAUTION: Clearance between the sensor pickup

face and driveplate ring gear must be correctly es-

tablished before engine startup. A cardboard

spacer, attached to the sensor face, is used for thispurpose. Failure to establish correct clearance will

result in sensor breakage.

(a) Remove any remaining fragments of original

cardboard spacer from sensor pickup face.

Fig. 5 Checking Torque Converter Seating

Fig. 6 Transmission Attachment

21 - 110 30RH/32RH TRANSMISSION REMOVAL AND INSTALLATIONJ

Page 1222 of 1784

(b) Align and install new spacer on sensor

pickup face. Spacer has adhesive backing so it will

adhere to sensor face.

(c) Insert sensor into housing until it just

touches ring gear teeth. Then install and tighten

sensor attaching bolt. Correct clearance is estab-

lished when spacer is peeled off by ring gear dur-

ing engine startup.

(10) Install transmission fill tube and O-ring (Fig.

6).

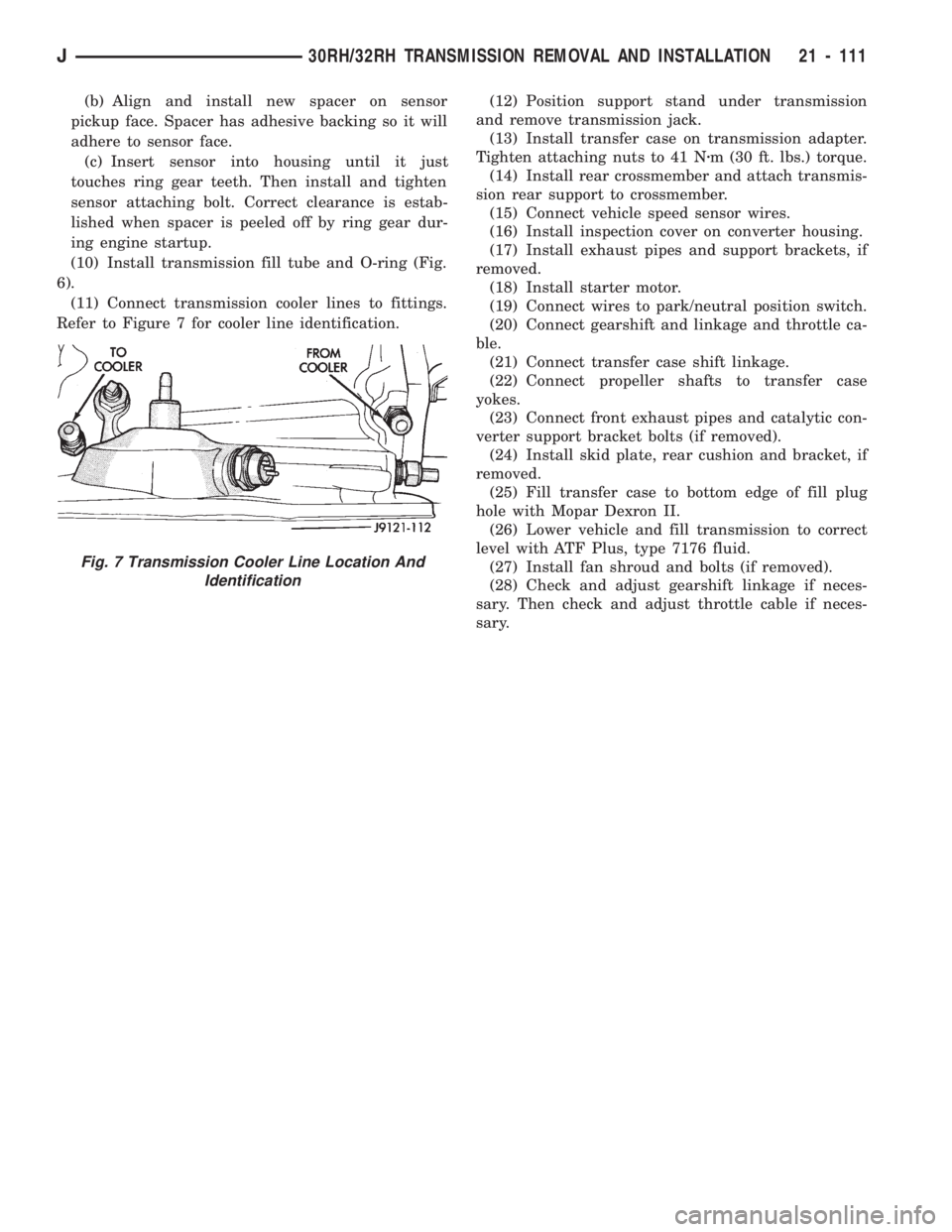

(11) Connect transmission cooler lines to fittings.

Refer to Figure 7 for cooler line identification.(12) Position support stand under transmission

and remove transmission jack.

(13) Install transfer case on transmission adapter.

Tighten attaching nuts to 41 Nzm (30 ft. lbs.) torque.

(14) Install rear crossmember and attach transmis-

sion rear support to crossmember.

(15) Connect vehicle speed sensor wires.

(16) Install inspection cover on converter housing.

(17) Install exhaust pipes and support brackets, if

removed.

(18) Install starter motor.

(19) Connect wires to park/neutral position switch.

(20) Connect gearshift and linkage and throttle ca-

ble.

(21) Connect transfer case shift linkage.

(22) Connect propeller shafts to transfer case

yokes.

(23) Connect front exhaust pipes and catalytic con-

verter support bracket bolts (if removed).

(24) Install skid plate, rear cushion and bracket, if

removed.

(25) Fill transfer case to bottom edge of fill plug

hole with Mopar Dexron II.

(26) Lower vehicle and fill transmission to correct

level with ATF Plus, type 7176 fluid.

(27) Install fan shroud and bolts (if removed).

(28) Check and adjust gearshift linkage if neces-

sary. Then check and adjust throttle cable if neces-

sary.

Fig. 7 Transmission Cooler Line Location And

Identification

J30RH/32RH TRANSMISSION REMOVAL AND INSTALLATION 21 - 111

Page 1268 of 1784

The valve body solenoids are controlled by signals

from the transmission control module (TCM). Signal

sequence is determined by vehicle speed and throttle

position.

Fourth gear is an 0.75:1 ratio overdrive range.

First, second, third and reverse gear are conventional

ranges. Third gear ratio is 1:1. A separate planetary

gear set provides overdrive operation in fourth gear.

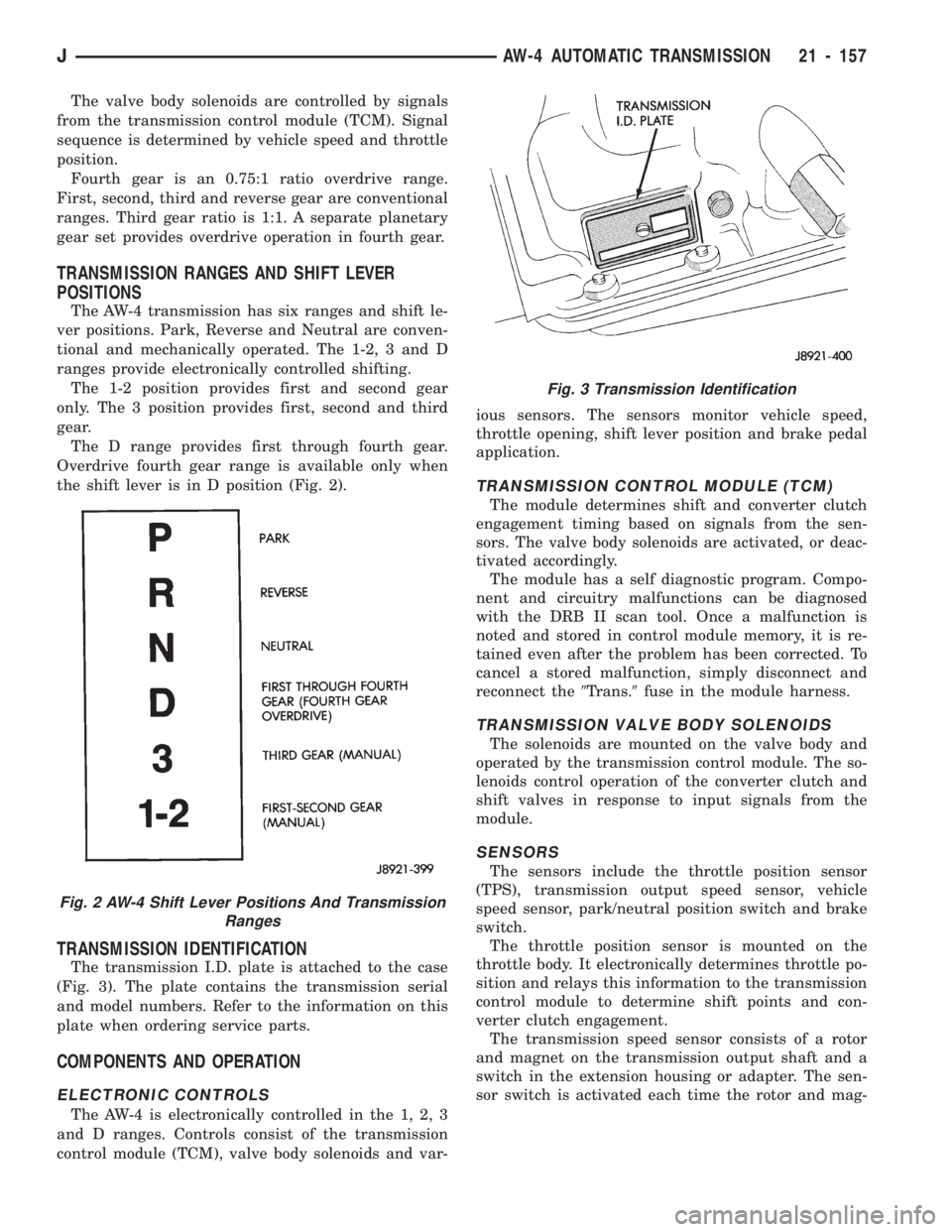

TRANSMISSION RANGES AND SHIFT LEVER

POSITIONS

The AW-4 transmission has six ranges and shift le-

ver positions. Park, Reverse and Neutral are conven-

tional and mechanically operated. The 1-2, 3 and D

ranges provide electronically controlled shifting.

The 1-2 position provides first and second gear

only. The 3 position provides first, second and third

gear.

The D range provides first through fourth gear.

Overdrive fourth gear range is available only when

the shift lever is in D position (Fig. 2).

TRANSMISSION IDENTIFICATION

The transmission I.D. plate is attached to the case

(Fig. 3). The plate contains the transmission serial

and model numbers. Refer to the information on this

plate when ordering service parts.

COMPONENTS AND OPERATION

ELECTRONIC CONTROLS

The AW-4 is electronically controlled in the 1, 2, 3

and D ranges. Controls consist of the transmission

control module (TCM), valve body solenoids and var-ious sensors. The sensors monitor vehicle speed,

throttle opening, shift lever position and brake pedal

application.

TRANSMISSION CONTROL MODULE (TCM)

The module determines shift and converter clutch

engagement timing based on signals from the sen-

sors. The valve body solenoids are activated, or deac-

tivated accordingly.

The module has a self diagnostic program. Compo-

nent and circuitry malfunctions can be diagnosed

with the DRB II scan tool. Once a malfunction is

noted and stored in control module memory, it is re-

tained even after the problem has been corrected. To

cancel a stored malfunction, simply disconnect and

reconnect the9Trans.9fuse in the module harness.

TRANSMISSION VALVE BODY SOLENOIDS

The solenoids are mounted on the valve body and

operated by the transmission control module. The so-

lenoids control operation of the converter clutch and

shift valves in response to input signals from the

module.

SENSORS

The sensors include the throttle position sensor

(TPS), transmission output speed sensor, vehicle

speed sensor, park/neutral position switch and brake

switch.

The throttle position sensor is mounted on the

throttle body. It electronically determines throttle po-

sition and relays this information to the transmission

control module to determine shift points and con-

verter clutch engagement.

The transmission speed sensor consists of a rotor

and magnet on the transmission output shaft and a

switch in the extension housing or adapter. The sen-

sor switch is activated each time the rotor and mag-

Fig. 2 AW-4 Shift Lever Positions And Transmission

Ranges

Fig. 3 Transmission Identification

JAW-4 AUTOMATIC TRANSMISSION 21 - 157

Page 1269 of 1784

net complete one revolution. Sensor signals are sent

to the transmission control module.

The park/neutral position switch is mounted on the

valve body manual shaft. The switch signals shift

linkage and manual valve position to the transmis-

sion control module through an interconnecting har-

ness. The switch prevents engine starting in all gears

other than Park or Neutral.

The brake switch is in circuit with the torque con-

verter clutch solenoid. The switch disengages the

converter clutch whenever the brakes are applied.

The switch is mounted on the brake pedal bracket

and signals the transmission control module when

the pedal is pressed or released.

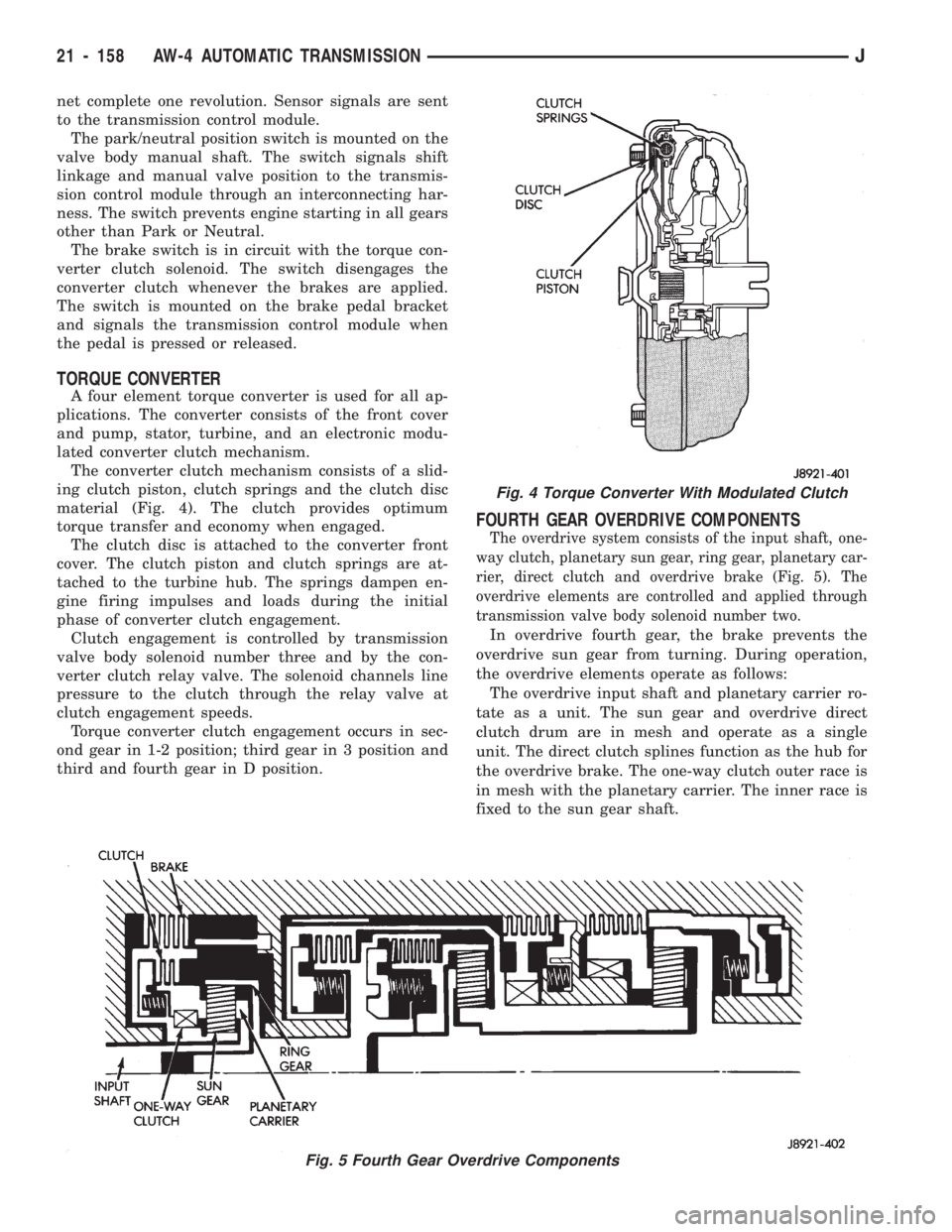

TORQUE CONVERTER

A four element torque converter is used for all ap-

plications. The converter consists of the front cover

and pump, stator, turbine, and an electronic modu-

lated converter clutch mechanism.

The converter clutch mechanism consists of a slid-

ing clutch piston, clutch springs and the clutch disc

material (Fig. 4). The clutch provides optimum

torque transfer and economy when engaged.

The clutch disc is attached to the converter front

cover. The clutch piston and clutch springs are at-

tached to the turbine hub. The springs dampen en-

gine firing impulses and loads during the initial

phase of converter clutch engagement.

Clutch engagement is controlled by transmission

valve body solenoid number three and by the con-

verter clutch relay valve. The solenoid channels line

pressure to the clutch through the relay valve at

clutch engagement speeds.

Torque converter clutch engagement occurs in sec-

ond gear in 1-2 position; third gear in 3 position and

third and fourth gear in D position.

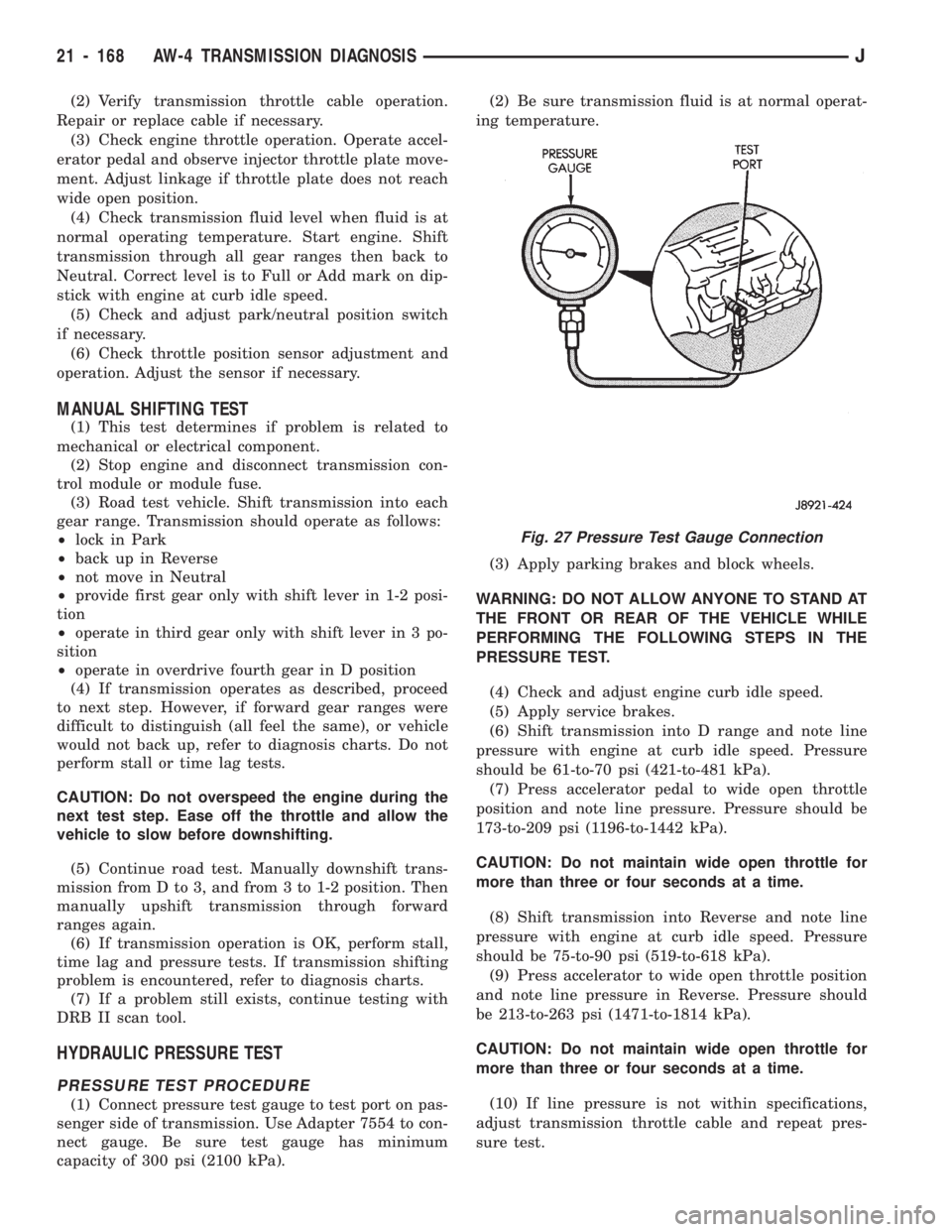

FOURTH GEAR OVERDRIVE COMPONENTS

The overdrive system consists of the input shaft, one-

way clutch, planetary sun gear, ring gear, planetary car-

rier, direct clutch and overdrive brake (Fig. 5). The

overdrive elements are controlled and applied through

transmission valve body solenoid number two.

In overdrive fourth gear, the brake prevents the

overdrive sun gear from turning. During operation,

the overdrive elements operate as follows:

The overdrive input shaft and planetary carrier ro-

tate as a unit. The sun gear and overdrive direct

clutch drum are in mesh and operate as a single

unit. The direct clutch splines function as the hub for

the overdrive brake. The one-way clutch outer race is

in mesh with the planetary carrier. The inner race is

fixed to the sun gear shaft.

Fig. 5 Fourth Gear Overdrive Components

Fig. 4 Torque Converter With Modulated Clutch

21 - 158 AW-4 AUTOMATIC TRANSMISSIONJ

Page 1279 of 1784

(2) Verify transmission throttle cable operation.

Repair or replace cable if necessary.

(3) Check engine throttle operation. Operate accel-

erator pedal and observe injector throttle plate move-

ment. Adjust linkage if throttle plate does not reach

wide open position.

(4) Check transmission fluid level when fluid is at

normal operating temperature. Start engine. Shift

transmission through all gear ranges then back to

Neutral. Correct level is to Full or Add mark on dip-

stick with engine at curb idle speed.

(5) Check and adjust park/neutral position switch

if necessary.

(6) Check throttle position sensor adjustment and

operation. Adjust the sensor if necessary.

MANUAL SHIFTING TEST

(1) This test determines if problem is related to

mechanical or electrical component.

(2) Stop engine and disconnect transmission con-

trol module or module fuse.

(3) Road test vehicle. Shift transmission into each

gear range. Transmission should operate as follows:

²lock in Park

²back up in Reverse

²not move in Neutral

²provide first gear only with shift lever in 1-2 posi-

tion

²operate in third gear only with shift lever in 3 po-

sition

²operate in overdrive fourth gear in D position

(4) If transmission operates as described, proceed

to next step. However, if forward gear ranges were

difficult to distinguish (all feel the same), or vehicle

would not back up, refer to diagnosis charts. Do not

perform stall or time lag tests.

CAUTION: Do not overspeed the engine during the

next test step. Ease off the throttle and allow the

vehicle to slow before downshifting.

(5) Continue road test. Manually downshift trans-

mission from D to 3, and from 3 to 1-2 position. Then

manually upshift transmission through forward

ranges again.

(6) If transmission operation is OK, perform stall,

time lag and pressure tests. If transmission shifting

problem is encountered, refer to diagnosis charts.

(7) If a problem still exists, continue testing with

DRB II scan tool.

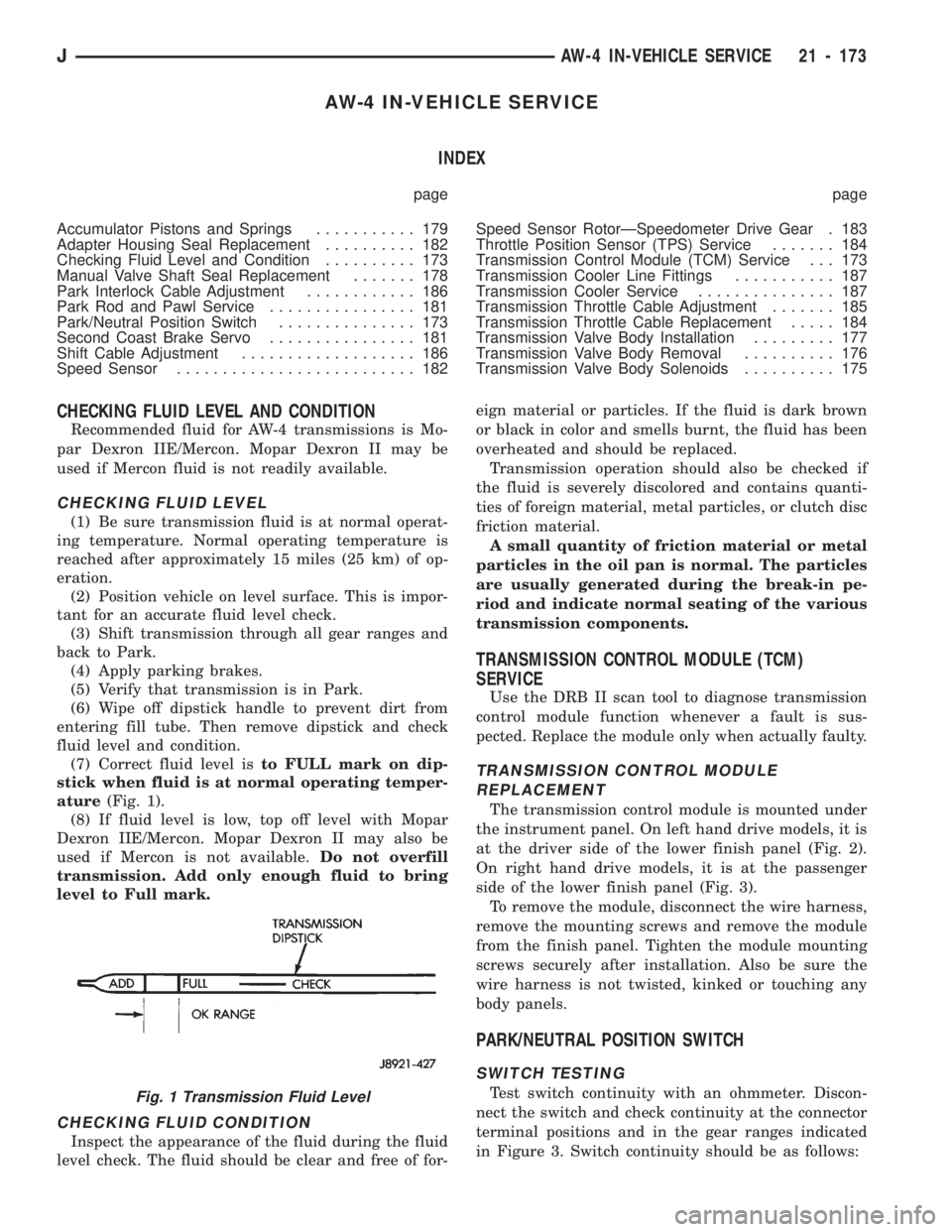

HYDRAULIC PRESSURE TEST

PRESSURE TEST PROCEDURE

(1) Connect pressure test gauge to test port on pas-

senger side of transmission. Use Adapter 7554 to con-

nect gauge. Be sure test gauge has minimum

capacity of 300 psi (2100 kPa).(2) Be sure transmission fluid is at normal operat-

ing temperature.

(3) Apply parking brakes and block wheels.

WARNING: DO NOT ALLOW ANYONE TO STAND AT

THE FRONT OR REAR OF THE VEHICLE WHILE

PERFORMING THE FOLLOWING STEPS IN THE

PRESSURE TEST.

(4) Check and adjust engine curb idle speed.

(5) Apply service brakes.

(6) Shift transmission into D range and note line

pressure with engine at curb idle speed. Pressure

should be 61-to-70 psi (421-to-481 kPa).

(7) Press accelerator pedal to wide open throttle

position and note line pressure. Pressure should be

173-to-209 psi (1196-to-1442 kPa).

CAUTION: Do not maintain wide open throttle for

more than three or four seconds at a time.

(8) Shift transmission into Reverse and note line

pressure with engine at curb idle speed. Pressure

should be 75-to-90 psi (519-to-618 kPa).

(9) Press accelerator to wide open throttle position

and note line pressure in Reverse. Pressure should

be 213-to-263 psi (1471-to-1814 kPa).

CAUTION: Do not maintain wide open throttle for

more than three or four seconds at a time.

(10) If line pressure is not within specifications,

adjust transmission throttle cable and repeat pres-

sure test.

Fig. 27 Pressure Test Gauge Connection

21 - 168 AW-4 TRANSMISSION DIAGNOSISJ

Page 1284 of 1784

AW-4 IN-VEHICLE SERVICE

INDEX

page page

Accumulator Pistons and Springs........... 179

Adapter Housing Seal Replacement.......... 182

Checking Fluid Level and Condition.......... 173

Manual Valve Shaft Seal Replacement....... 178

Park Interlock Cable Adjustment............ 186

Park Rod and Pawl Service................ 181

Park/Neutral Position Switch............... 173

Second Coast Brake Servo................ 181

Shift Cable Adjustment................... 186

Speed Sensor.......................... 182Speed Sensor RotorÐSpeedometer Drive Gear . 183

Throttle Position Sensor (TPS) Service....... 184

Transmission Control Module (TCM) Service . . . 173

Transmission Cooler Line Fittings........... 187

Transmission Cooler Service............... 187

Transmission Throttle Cable Adjustment....... 185

Transmission Throttle Cable Replacement..... 184

Transmission Valve Body Installation......... 177

Transmission Valve Body Removal.......... 176

Transmission Valve Body Solenoids.......... 175

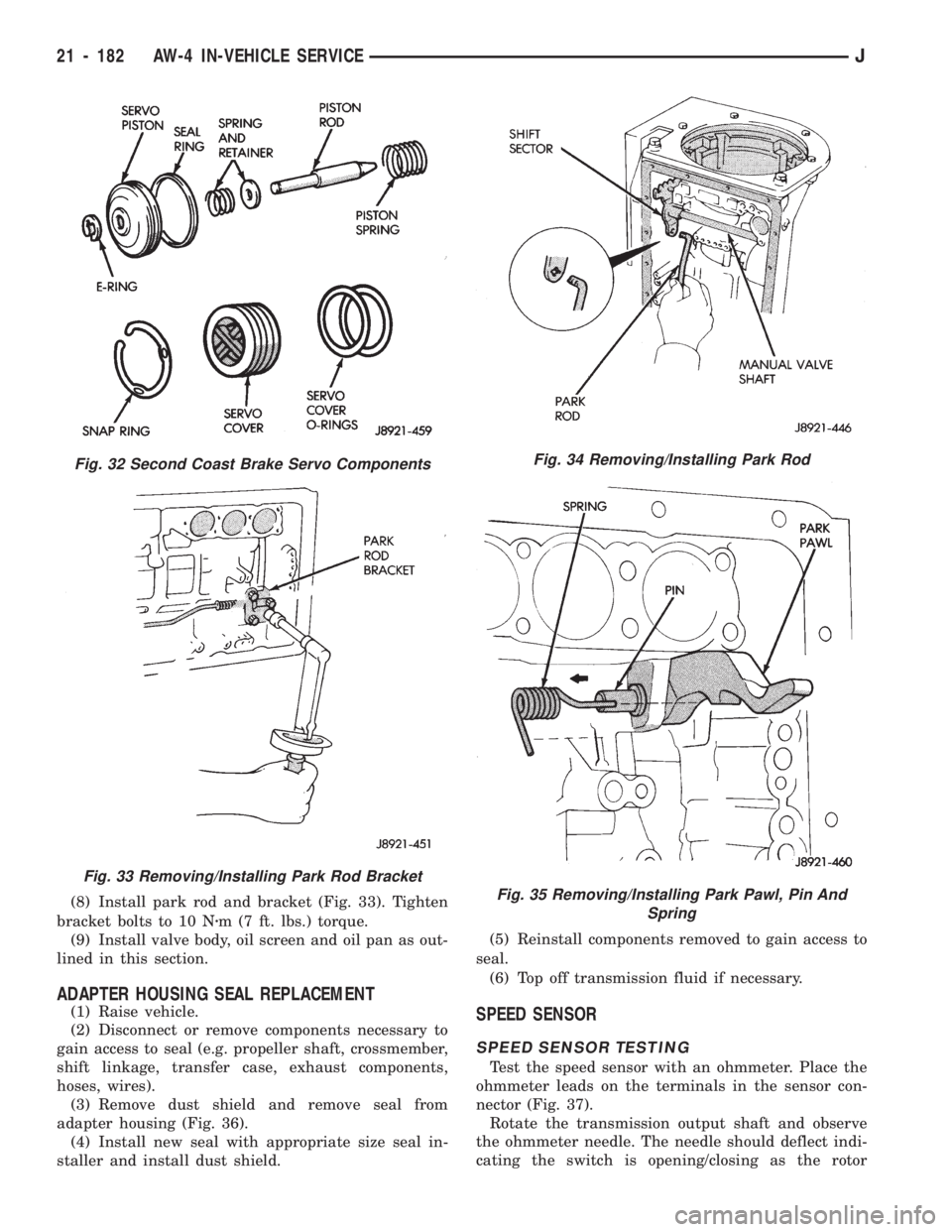

CHECKING FLUID LEVEL AND CONDITION

Recommended fluid for AW-4 transmissions is Mo-

par Dexron IIE/Mercon. Mopar Dexron II may be

used if Mercon fluid is not readily available.

CHECKING FLUID LEVEL

(1) Be sure transmission fluid is at normal operat-

ing temperature. Normal operating temperature is

reached after approximately 15 miles (25 km) of op-

eration.

(2) Position vehicle on level surface. This is impor-

tant for an accurate fluid level check.

(3) Shift transmission through all gear ranges and

back to Park.

(4) Apply parking brakes.

(5) Verify that transmission is in Park.

(6) Wipe off dipstick handle to prevent dirt from

entering fill tube. Then remove dipstick and check

fluid level and condition.

(7) Correct fluid level isto FULL mark on dip-

stick when fluid is at normal operating temper-

ature(Fig. 1).

(8) If fluid level is low, top off level with Mopar

Dexron IIE/Mercon. Mopar Dexron II may also be

used if Mercon is not available.Do not overfill

transmission. Add only enough fluid to bring

level to Full mark.

CHECKING FLUID CONDITION

Inspect the appearance of the fluid during the fluid

level check. The fluid should be clear and free of for-eign material or particles. If the fluid is dark brown

or black in color and smells burnt, the fluid has been

overheated and should be replaced.

Transmission operation should also be checked if

the fluid is severely discolored and contains quanti-

ties of foreign material, metal particles, or clutch disc

friction material.

A small quantity of friction material or metal

particles in the oil pan is normal. The particles

are usually generated during the break-in pe-

riod and indicate normal seating of the various

transmission components.

TRANSMISSION CONTROL MODULE (TCM)

SERVICE

Use the DRB II scan tool to diagnose transmission

control module function whenever a fault is sus-

pected. Replace the module only when actually faulty.

TRANSMISSION CONTROL MODULE

REPLACEMENT

The transmission control module is mounted under

the instrument panel. On left hand drive models, it is

at the driver side of the lower finish panel (Fig. 2).

On right hand drive models, it is at the passenger

side of the lower finish panel (Fig. 3).

To remove the module, disconnect the wire harness,

remove the mounting screws and remove the module

from the finish panel. Tighten the module mounting

screws securely after installation. Also be sure the

wire harness is not twisted, kinked or touching any

body panels.

PARK/NEUTRAL POSITION SWITCH

SWITCH TESTING

Test switch continuity with an ohmmeter. Discon-

nect the switch and check continuity at the connector

terminal positions and in the gear ranges indicated

in Figure 3. Switch continuity should be as follows:Fig. 1 Transmission Fluid Level

JAW-4 IN-VEHICLE SERVICE 21 - 173

Page 1293 of 1784

(8) Install park rod and bracket (Fig. 33). Tighten

bracket bolts to 10 Nzm (7 ft. lbs.) torque.

(9) Install valve body, oil screen and oil pan as out-

lined in this section.

ADAPTER HOUSING SEAL REPLACEMENT

(1) Raise vehicle.

(2) Disconnect or remove components necessary to

gain access to seal (e.g. propeller shaft, crossmember,

shift linkage, transfer case, exhaust components,

hoses, wires).

(3) Remove dust shield and remove seal from

adapter housing (Fig. 36).

(4) Install new seal with appropriate size seal in-

staller and install dust shield.(5) Reinstall components removed to gain access to

seal.

(6) Top off transmission fluid if necessary.SPEED SENSOR

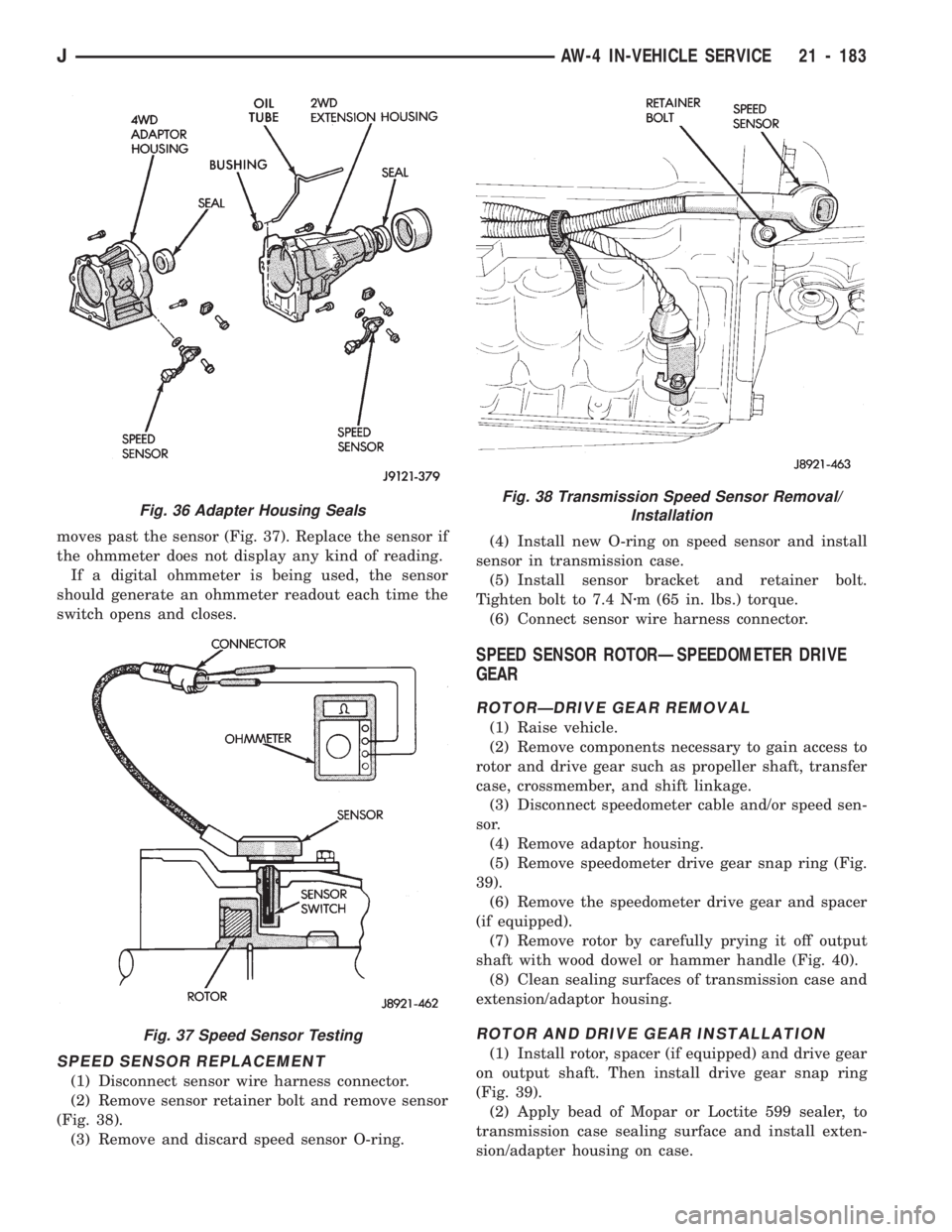

SPEED SENSOR TESTING

Test the speed sensor with an ohmmeter. Place the

ohmmeter leads on the terminals in the sensor con-

nector (Fig. 37).

Rotate the transmission output shaft and observe

the ohmmeter needle. The needle should deflect indi-

cating the switch is opening/closing as the rotor

Fig. 34 Removing/Installing Park Rod

Fig. 35 Removing/Installing Park Pawl, Pin And

Spring

Fig. 32 Second Coast Brake Servo Components

Fig. 33 Removing/Installing Park Rod Bracket

21 - 182 AW-4 IN-VEHICLE SERVICEJ

Page 1294 of 1784

moves past the sensor (Fig. 37). Replace the sensor if

the ohmmeter does not display any kind of reading.

If a digital ohmmeter is being used, the sensor

should generate an ohmmeter readout each time the

switch opens and closes.

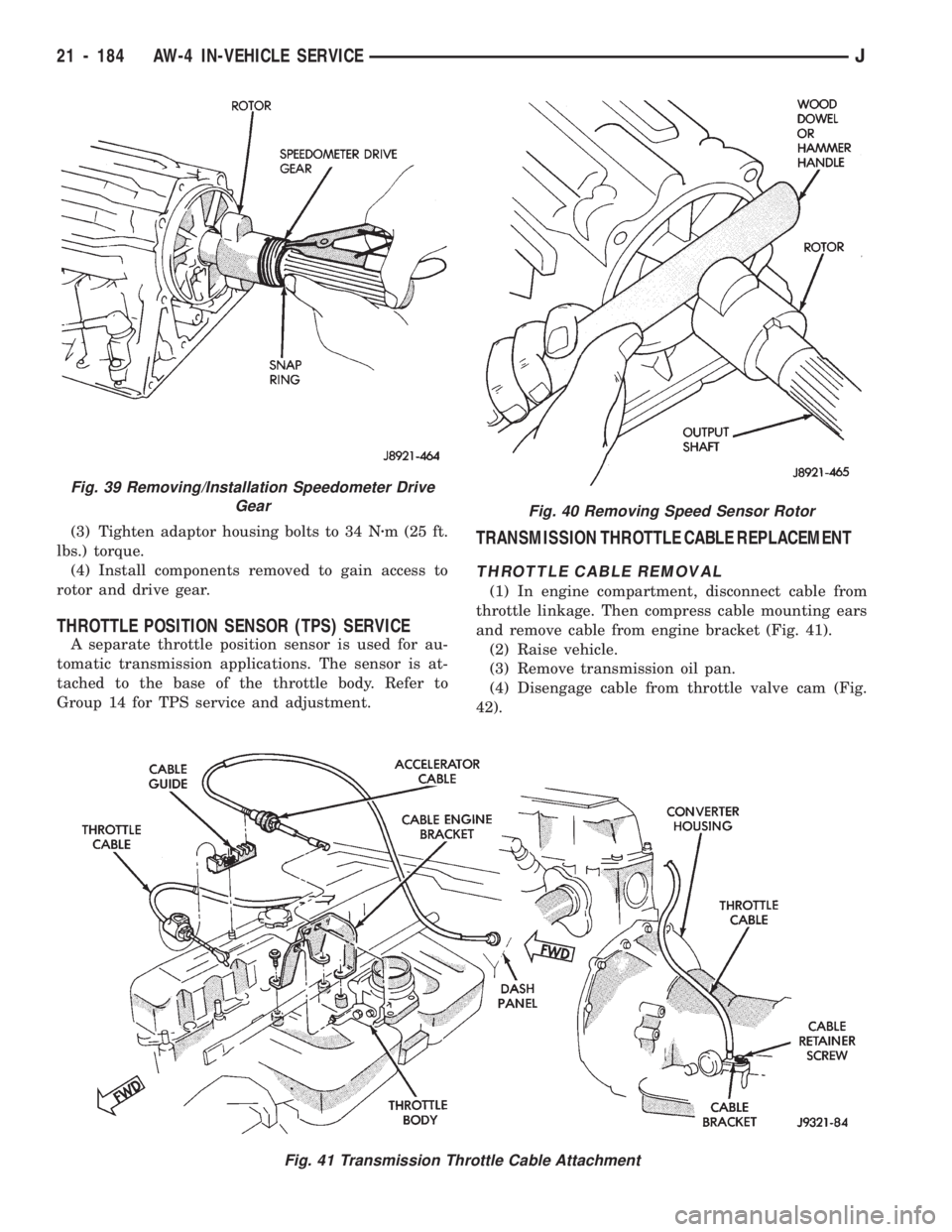

SPEED SENSOR REPLACEMENT

(1) Disconnect sensor wire harness connector.

(2) Remove sensor retainer bolt and remove sensor

(Fig. 38).

(3) Remove and discard speed sensor O-ring.(4) Install new O-ring on speed sensor and install

sensor in transmission case.

(5) Install sensor bracket and retainer bolt.

Tighten bolt to 7.4 Nzm (65 in. lbs.) torque.

(6) Connect sensor wire harness connector.

SPEED SENSOR ROTORÐSPEEDOMETER DRIVE

GEAR

ROTORÐDRIVE GEAR REMOVAL

(1) Raise vehicle.

(2) Remove components necessary to gain access to

rotor and drive gear such as propeller shaft, transfer

case, crossmember, and shift linkage.

(3) Disconnect speedometer cable and/or speed sen-

sor.

(4) Remove adaptor housing.

(5) Remove speedometer drive gear snap ring (Fig.

39).

(6) Remove the speedometer drive gear and spacer

(if equipped).

(7) Remove rotor by carefully prying it off output

shaft with wood dowel or hammer handle (Fig. 40).

(8) Clean sealing surfaces of transmission case and

extension/adaptor housing.

ROTOR AND DRIVE GEAR INSTALLATION

(1) Install rotor, spacer (if equipped) and drive gear

on output shaft. Then install drive gear snap ring

(Fig. 39).

(2) Apply bead of Mopar or Loctite 599 sealer, to

transmission case sealing surface and install exten-

sion/adapter housing on case.

Fig. 36 Adapter Housing Seals

Fig. 37 Speed Sensor Testing

Fig. 38 Transmission Speed Sensor Removal/

Installation

JAW-4 IN-VEHICLE SERVICE 21 - 183

Page 1295 of 1784

(3) Tighten adaptor housing bolts to 34 Nzm (25 ft.

lbs.) torque.

(4) Install components removed to gain access to

rotor and drive gear.

THROTTLE POSITION SENSOR (TPS) SERVICE

A separate throttle position sensor is used for au-

tomatic transmission applications. The sensor is at-

tached to the base of the throttle body. Refer to

Group 14 for TPS service and adjustment.

TRANSMISSION THROTTLE CABLE REPLACEMENT

THROTTLE CABLE REMOVAL

(1) In engine compartment, disconnect cable from

throttle linkage. Then compress cable mounting ears

and remove cable from engine bracket (Fig. 41).

(2) Raise vehicle.

(3) Remove transmission oil pan.

(4) Disengage cable from throttle valve cam (Fig.

42).

Fig. 41 Transmission Throttle Cable Attachment

Fig. 40 Removing Speed Sensor Rotor

Fig. 39 Removing/Installation Speedometer Drive

Gear

21 - 184 AW-4 IN-VEHICLE SERVICEJ