roof JEEP CHEROKEE 1994 Service User Guide

[x] Cancel search | Manufacturer: JEEP, Model Year: 1994, Model line: CHEROKEE, Model: JEEP CHEROKEE 1994Pages: 1784, PDF Size: 77.09 MB

Page 1485 of 1784

INSTALLATION

(1) Position the drip rail moulding with clips at

the roof flange and force the clips onto the roof

flange.

(2) Apply sealant to the inner side of the moulding

to seal the roof flange.

AIR EXHAUST GRILLEÐXJ VEHICLES

REMOVAL

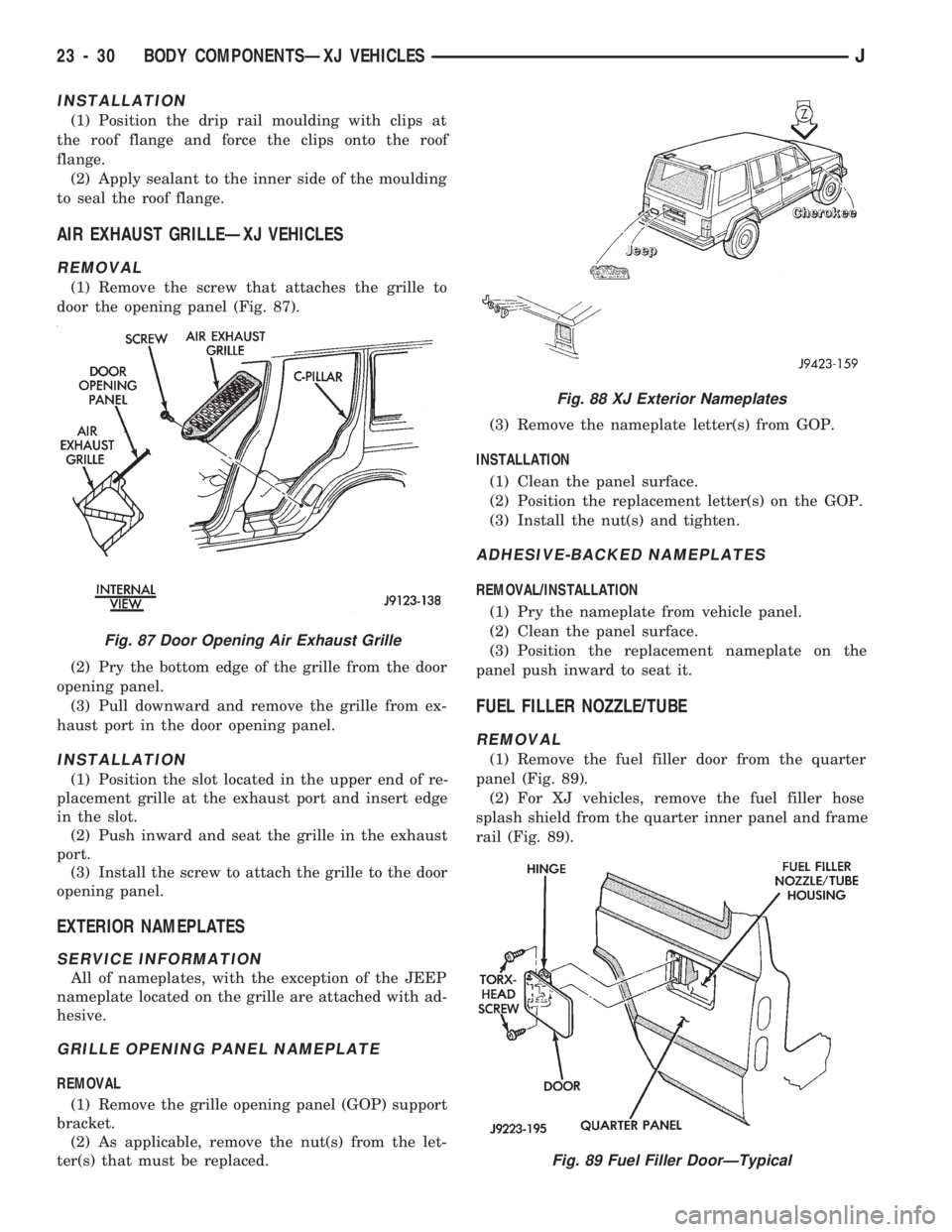

(1) Remove the screw that attaches the grille to

door the opening panel (Fig. 87).

(2) Pry the bottom edge of the grille from the door

opening panel.

(3) Pull downward and remove the grille from ex-

haust port in the door opening panel.

INSTALLATION

(1) Position the slot located in the upper end of re-

placement grille at the exhaust port and insert edge

in the slot.

(2) Push inward and seat the grille in the exhaust

port.

(3) Install the screw to attach the grille to the door

opening panel.

EXTERIOR NAMEPLATES

SERVICE INFORMATION

All of nameplates, with the exception of the JEEP

nameplate located on the grille are attached with ad-

hesive.

GRILLE OPENING PANEL NAMEPLATE

REMOVAL

(1) Remove the grille opening panel (GOP) support

bracket.

(2) As applicable, remove the nut(s) from the let-

ter(s) that must be replaced.(3) Remove the nameplate letter(s) from GOP.

INSTALLATION

(1) Clean the panel surface.

(2) Position the replacement letter(s) on the GOP.

(3) Install the nut(s) and tighten.

ADHESIVE-BACKED NAMEPLATES

REMOVAL/INSTALLATION

(1) Pry the nameplate from vehicle panel.

(2) Clean the panel surface.

(3) Position the replacement nameplate on the

panel push inward to seat it.

FUEL FILLER NOZZLE/TUBE

REMOVAL

(1) Remove the fuel filler door from the quarter

panel (Fig. 89).

(2) For XJ vehicles, remove the fuel filler hose

splash shield from the quarter inner panel and frame

rail (Fig. 89).

Fig. 89 Fuel Filler DoorÐTypical

Fig. 87 Door Opening Air Exhaust Grille

Fig. 88 XJ Exterior Nameplates

23 - 30 BODY COMPONENTSÐXJ VEHICLESJ

Page 1487 of 1784

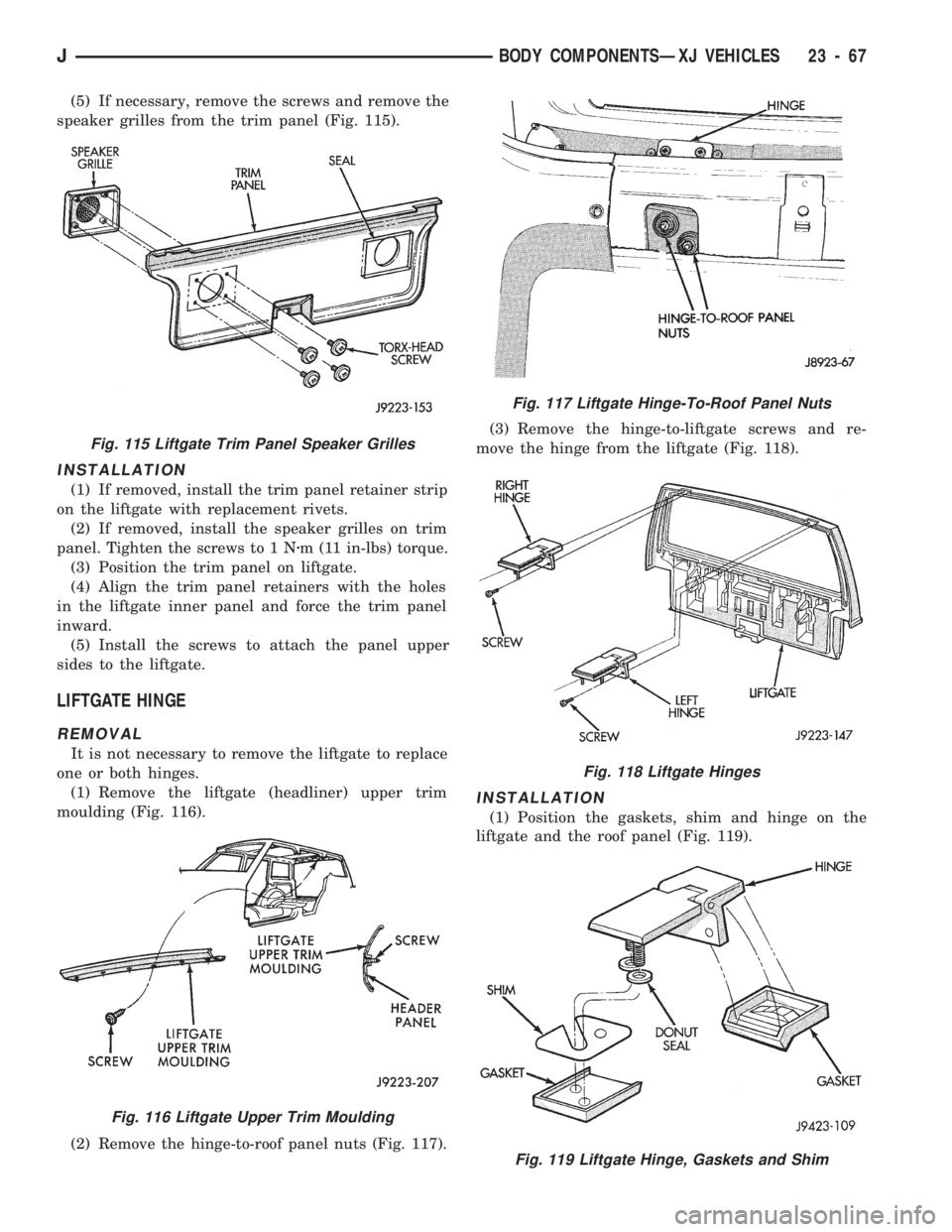

(3) For power/manual mirrors, remove the inside

trim cover.

(4) For remote control mirrors, loosen the toggle

control setscrew.

(5) For remote control mirrors, remove the inside

trim cover.

(6) Remove the mirror screws.

(7) Remove the mirror from the door. Refer to

Group 8ÐElectrical.

INSTALLATION

(1) Position the mirror adjacent to the vent win-

dow.

(2) Install the mirror screws. Tighten the screws

securely.

(3) For remote mirrors, position the inside trim

cover over the toggle control and tighten the set-

screw.

(4) Install the inside trim cover.

(5) Install the inside trim cover screw.

(6) Install the door trim panel.

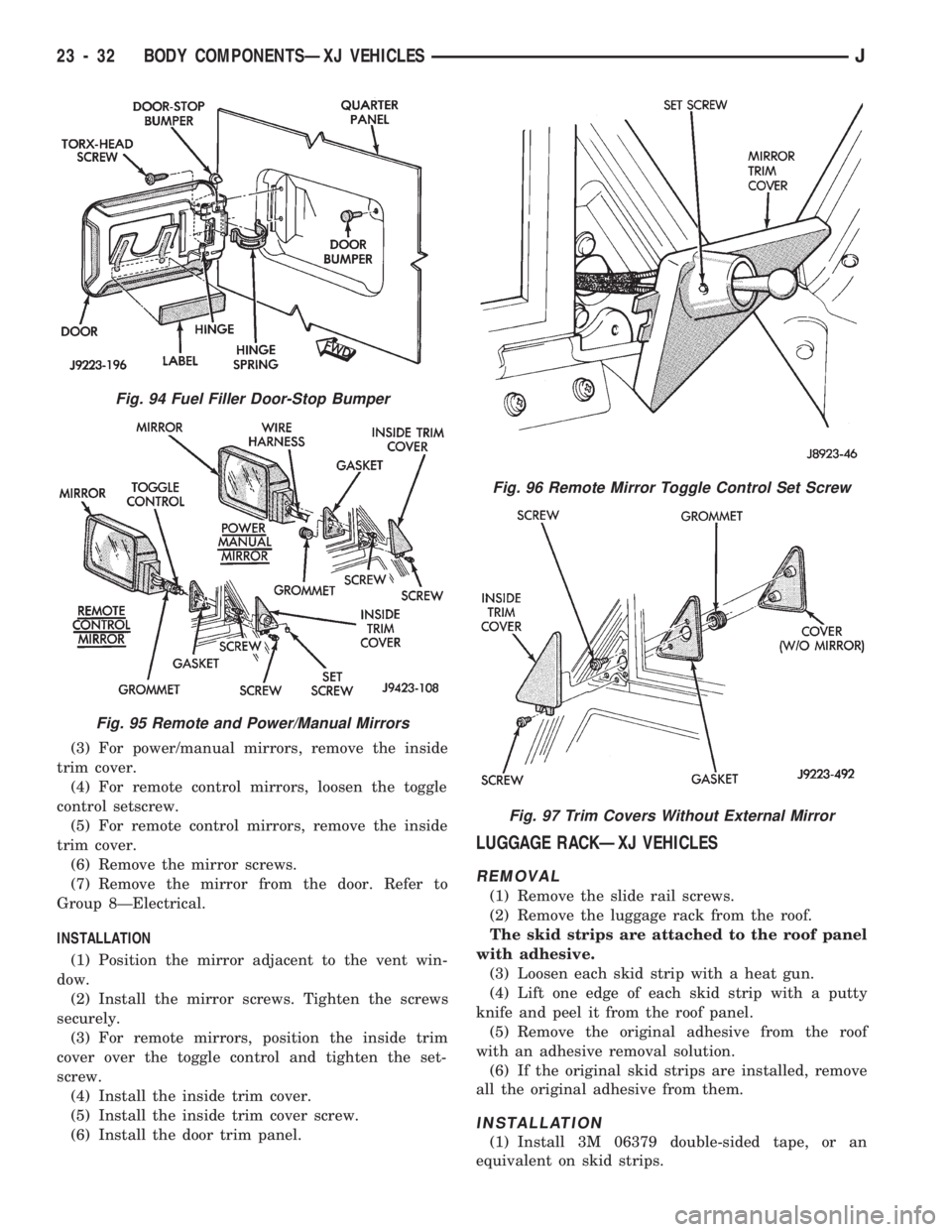

LUGGAGE RACKÐXJ VEHICLES

REMOVAL

(1) Remove the slide rail screws.

(2) Remove the luggage rack from the roof.

The skid strips are attached to the roof panel

with adhesive.

(3) Loosen each skid strip with a heat gun.

(4) Lift one edge of each skid strip with a putty

knife and peel it from the roof panel.

(5) Remove the original adhesive from the roof

with an adhesive removal solution.

(6) If the original skid strips are installed, remove

all the original adhesive from them.

INSTALLATION

(1) Install 3M 06379 double-sided tape, or an

equivalent on skid strips.

Fig. 94 Fuel Filler Door-Stop Bumper

Fig. 95 Remote and Power/Manual Mirrors

Fig. 96 Remote Mirror Toggle Control Set Screw

Fig. 97 Trim Covers Without External Mirror

23 - 32 BODY COMPONENTSÐXJ VEHICLESJ

Page 1488 of 1784

(2) Remove the backing from the double-sided

tape, align each skid strip on the roof, and position it

on the roof panel.

(3) Verify that each skid strip is properly aligned.

(4) Press each skid strip onto the roof panel with a

roller (or use hand pressure).To prevent water leaks, apply 3M Drip-Chek

Sealant, or equivalent.

(5) Position the luggage rack on the roof with the

screw holes aligned.

(6) Install and tighten the slide rail screws to 3

Nzm (28 in-lbs) torque.

Fig. 114 Luggage RackÐXJ VehiclesFig. 115 Skid Strip Installation

JBODY COMPONENTSÐXJ VEHICLES 23 - 33

Page 1522 of 1784

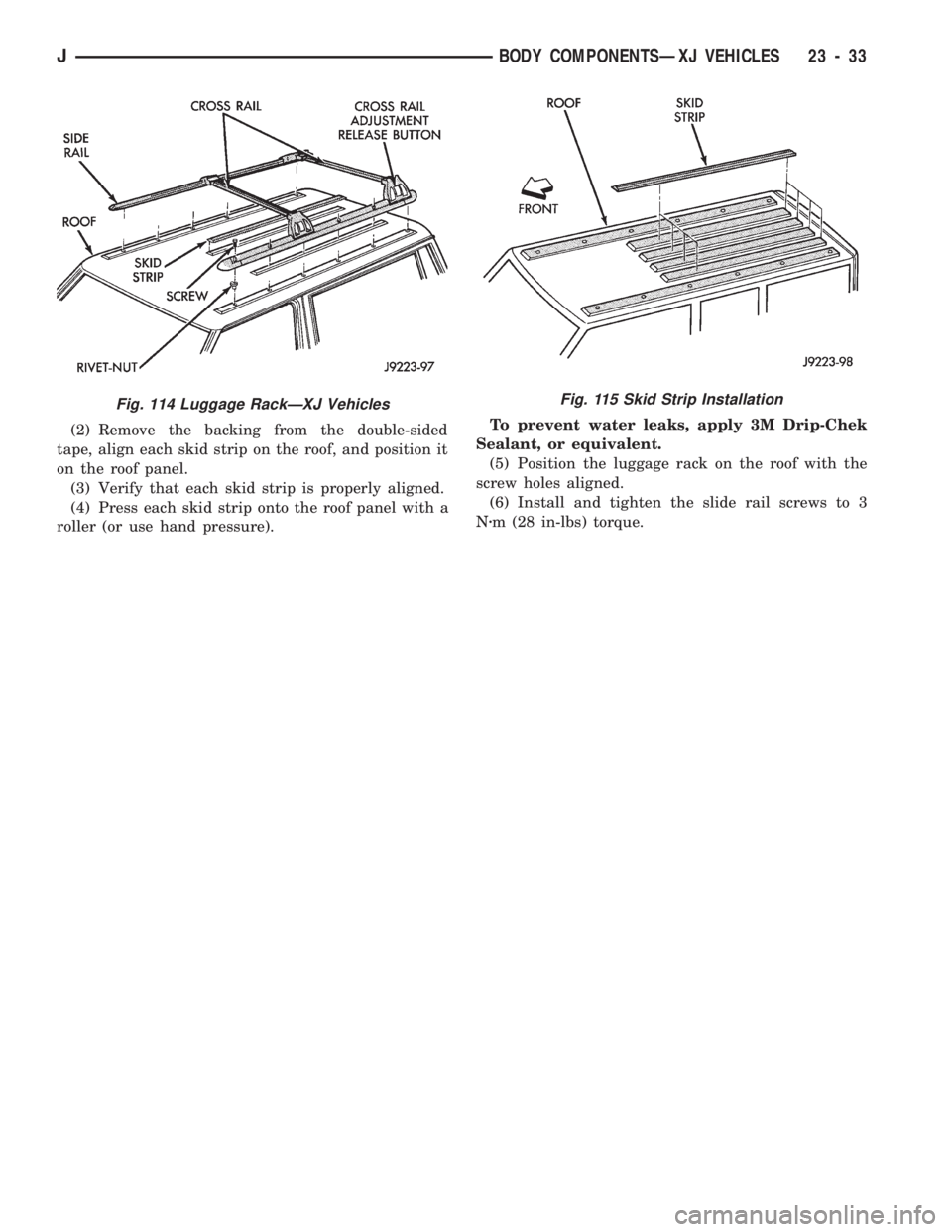

(5) If necessary, remove the screws and remove the

speaker grilles from the trim panel (Fig. 115).

INSTALLATION

(1) If removed, install the trim panel retainer strip

on the liftgate with replacement rivets.

(2) If removed, install the speaker grilles on trim

panel. Tighten the screws to 1 Nzm (11 in-lbs) torque.

(3) Position the trim panel on liftgate.

(4) Align the trim panel retainers with the holes

in the liftgate inner panel and force the trim panel

inward.

(5) Install the screws to attach the panel upper

sides to the liftgate.

LIFTGATE HINGE

REMOVAL

It is not necessary to remove the liftgate to replace

one or both hinges.

(1) Remove the liftgate (headliner) upper trim

moulding (Fig. 116).

(2) Remove the hinge-to-roof panel nuts (Fig. 117).(3) Remove the hinge-to-liftgate screws and re-

move the hinge from the liftgate (Fig. 118).

INSTALLATION

(1) Position the gaskets, shim and hinge on the

liftgate and the roof panel (Fig. 119).

Fig. 115 Liftgate Trim Panel Speaker Grilles

Fig. 116 Liftgate Upper Trim Moulding

Fig. 117 Liftgate Hinge-To-Roof Panel Nuts

Fig. 118 Liftgate Hinges

Fig. 119 Liftgate Hinge, Gaskets and Shim

JBODY COMPONENTSÐXJ VEHICLES 23 - 67

Page 1523 of 1784

(2) Install and tighten hinge-to-roof panel nuts to 9

Nzm (7 ft-lbs) torque.

(3) Install the liftgate-to-hinge screws. Tighten

screws to 9 Nzm (7 ft-lbs) torque.

(4) Install the liftgate (headliner) upper trim moul-

ding (Fig. 111).

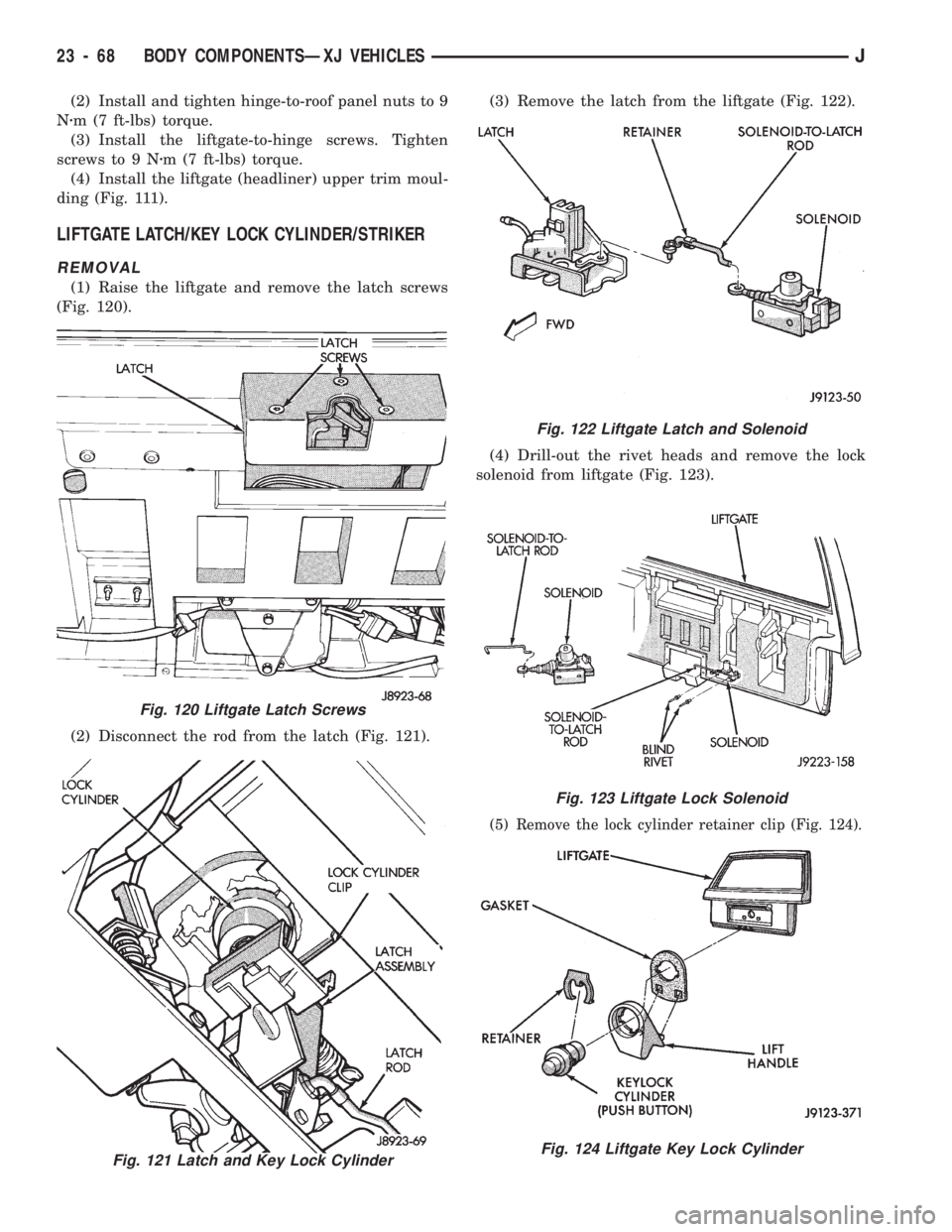

LIFTGATE LATCH/KEY LOCK CYLINDER/STRIKER

REMOVAL

(1) Raise the liftgate and remove the latch screws

(Fig. 120).

(2) Disconnect the rod from the latch (Fig. 121).(3) Remove the latch from the liftgate (Fig. 122).

(4) Drill-out the rivet heads and remove the lock

solenoid from liftgate (Fig. 123).

(5) Remove the lock cylinder retainer clip (Fig. 124).

Fig. 121 Latch and Key Lock Cylinder

Fig. 122 Liftgate Latch and Solenoid

Fig. 123 Liftgate Lock Solenoid

Fig. 124 Liftgate Key Lock Cylinder

Fig. 120 Liftgate Latch Screws

23 - 68 BODY COMPONENTSÐXJ VEHICLESJ

Page 1525 of 1784

INSTALLATION

(1) Connect the replacement support rod and cylin-

der to the ball studs.

(2) Secure the support rod and cylinder to the ball

studs with the retainer clips.

(3) Remove the support from the liftgate and test

the operation of the support rod.

LIFTGATE SUPPORT ROD CYLINDER DISPOSAL

WARNING: SAFETY GOGGLES MUST BE WORN

DURING THE DISPOSAL PROCEDURE. THE HIGH

PRESSURE GAS CHARGE IN THE SUPPORT ROD

CYLINDERS WILL BE RELEASED DURING THE

PROCEDURE.

(1) Remove the support rod cylinder(s) from the

liftgate.

(2) Position the support rod cylinder horizontally

in a vise and clamp the cylinder securely.

(3) Wrap the cylinder with 4-5 layers of shop tow-

els.

(4) Measure 1 and 1/2 inches inward from the end

of the cylinder. Mark this location on the towels with

chalk. The cylinder will be punctured at this location

to release the gas charge.

(5) Use a punch and hammer to puncture cylinder.

Force the punch through towels and into the cylinder

with a hammer. Continue striking the punch until

the gas begins to escapebut do not remove the

punch.

(6) Hold the towels and punch in position until all

the gas has escaped. Complete de-pressurization will

require about 4 to 10 seconds. After all the gas has

escaped, slowly remove the punch.

(7) Hold a towel over the hole in cylinder and press

the support rod piston all the way into the cylinder

to purge remaining oil.

(8) Remove the support rod cylinder from the vise

and discard it.

(9) If both support rod cylinders are being re-

placed, repeat this procedure for the remaining cylin-

der.

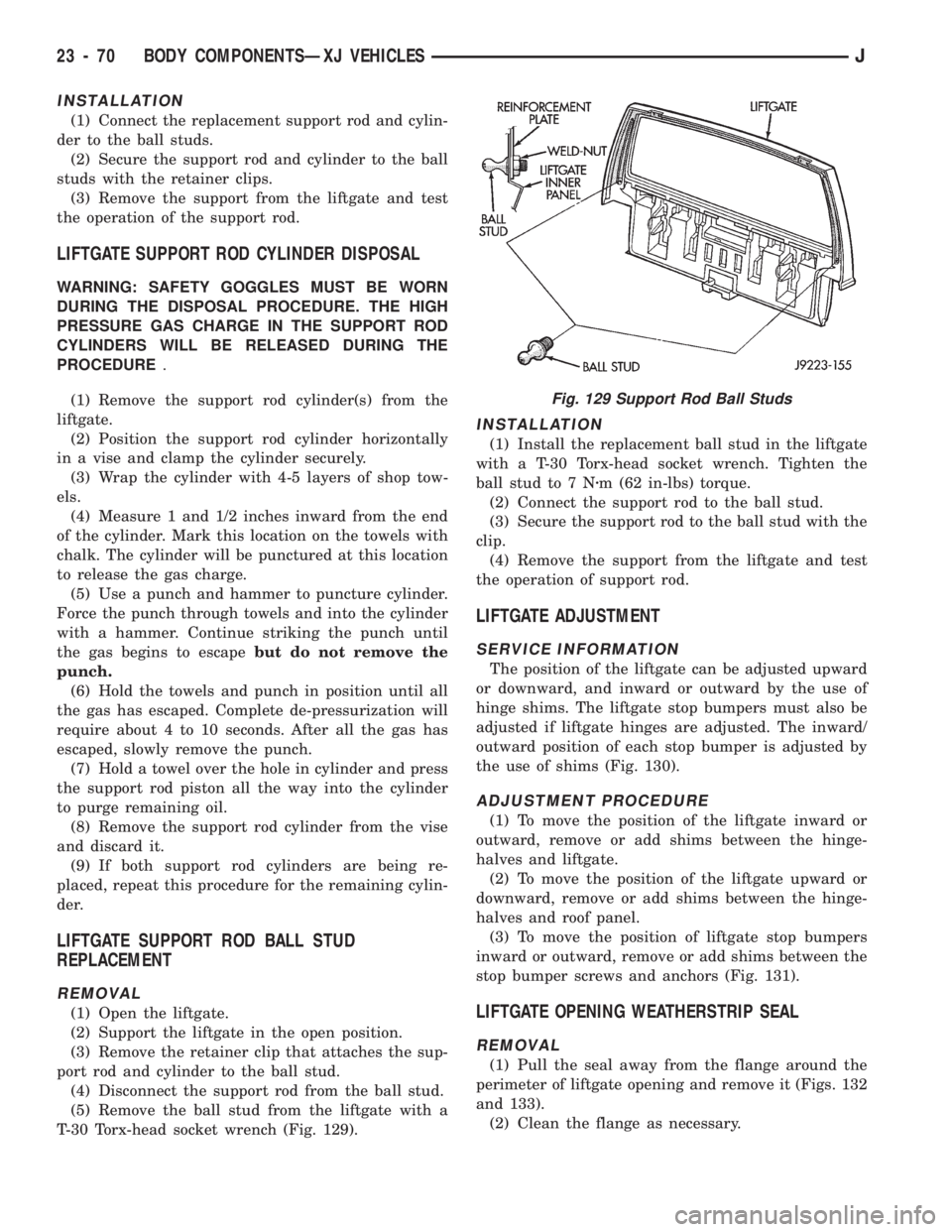

LIFTGATE SUPPORT ROD BALL STUD

REPLACEMENT

REMOVAL

(1) Open the liftgate.

(2) Support the liftgate in the open position.

(3) Remove the retainer clip that attaches the sup-

port rod and cylinder to the ball stud.

(4) Disconnect the support rod from the ball stud.

(5) Remove the ball stud from the liftgate with a

T-30 Torx-head socket wrench (Fig. 129).

INSTALLATION

(1) Install the replacement ball stud in the liftgate

with a T-30 Torx-head socket wrench. Tighten the

ball stud to 7 Nzm (62 in-lbs) torque.

(2) Connect the support rod to the ball stud.

(3) Secure the support rod to the ball stud with the

clip.

(4) Remove the support from the liftgate and test

the operation of support rod.

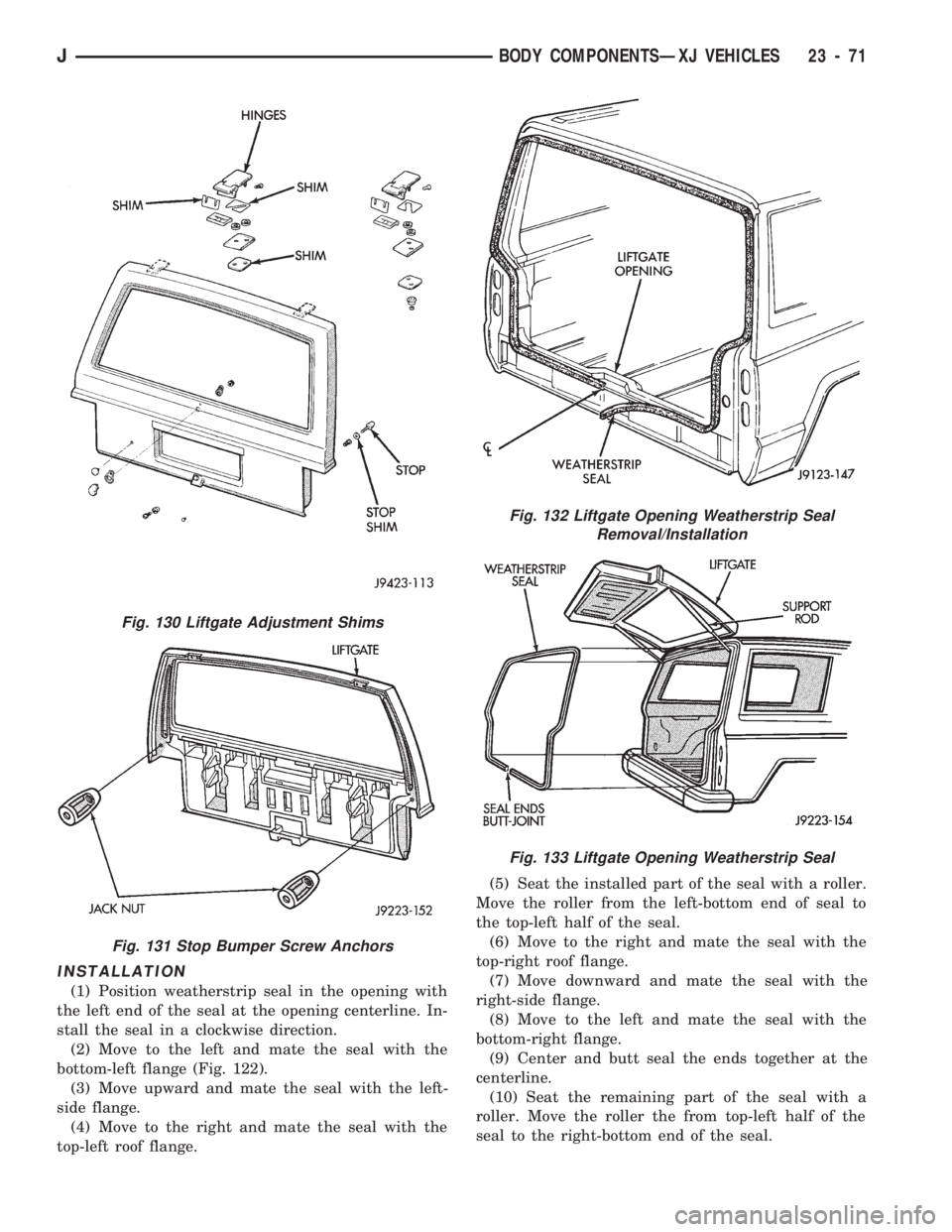

LIFTGATE ADJUSTMENT

SERVICE INFORMATION

The position of the liftgate can be adjusted upward

or downward, and inward or outward by the use of

hinge shims. The liftgate stop bumpers must also be

adjusted if liftgate hinges are adjusted. The inward/

outward position of each stop bumper is adjusted by

the use of shims (Fig. 130).

ADJUSTMENT PROCEDURE

(1) To move the position of the liftgate inward or

outward, remove or add shims between the hinge-

halves and liftgate.

(2) To move the position of the liftgate upward or

downward, remove or add shims between the hinge-

halves and roof panel.

(3) To move the position of liftgate stop bumpers

inward or outward, remove or add shims between the

stop bumper screws and anchors (Fig. 131).

LIFTGATE OPENING WEATHERSTRIP SEAL

REMOVAL

(1) Pull the seal away from the flange around the

perimeter of liftgate opening and remove it (Figs. 132

and 133).

(2) Clean the flange as necessary.

Fig. 129 Support Rod Ball Studs

23 - 70 BODY COMPONENTSÐXJ VEHICLESJ

Page 1526 of 1784

INSTALLATION

(1) Position weatherstrip seal in the opening with

the left end of the seal at the opening centerline. In-

stall the seal in a clockwise direction.

(2) Move to the left and mate the seal with the

bottom-left flange (Fig. 122).

(3) Move upward and mate the seal with the left-

side flange.

(4) Move to the right and mate the seal with the

top-left roof flange.(5) Seat the installed part of the seal with a roller.

Move the roller from the left-bottom end of seal to

the top-left half of the seal.

(6) Move to the right and mate the seal with the

top-right roof flange.

(7) Move downward and mate the seal with the

right-side flange.

(8) Move to the left and mate the seal with the

bottom-right flange.

(9) Center and butt seal the ends together at the

centerline.

(10) Seat the remaining part of the seal with a

roller. Move the roller the from top-left half of the

seal to the right-bottom end of the seal.

Fig. 130 Liftgate Adjustment Shims

Fig. 131 Stop Bumper Screw Anchors

Fig. 132 Liftgate Opening Weatherstrip Seal

Removal/Installation

Fig. 133 Liftgate Opening Weatherstrip Seal

JBODY COMPONENTSÐXJ VEHICLES 23 - 71

Page 1575 of 1784

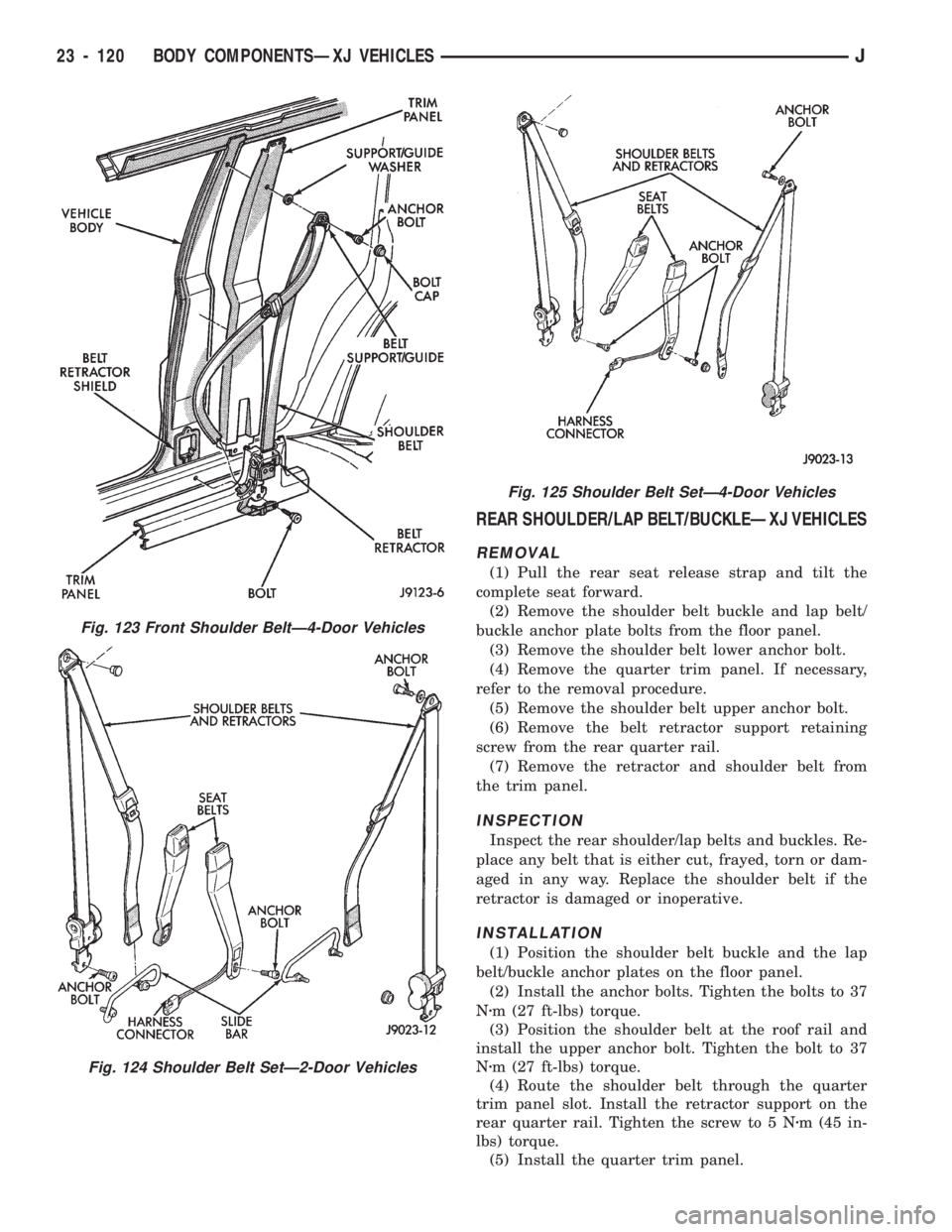

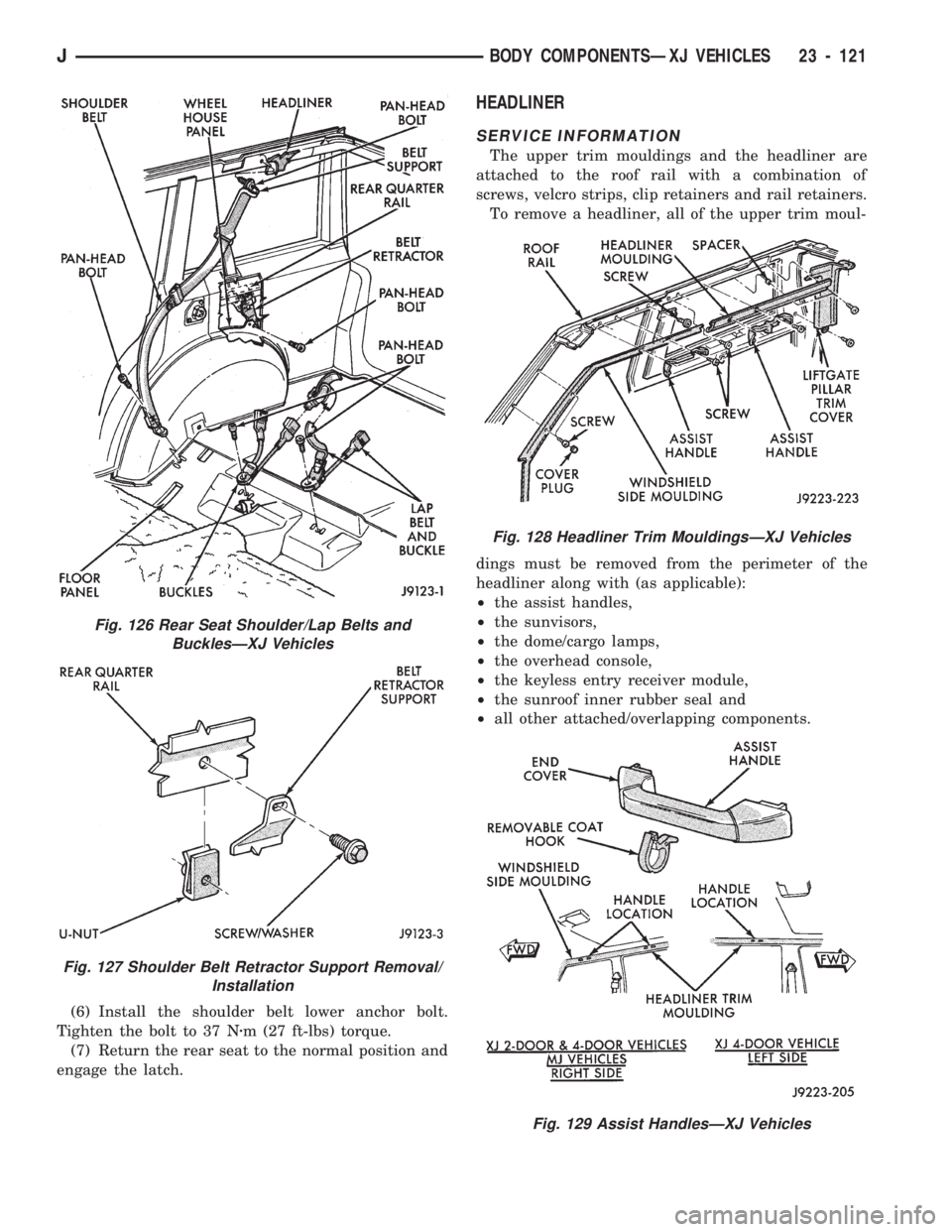

REAR SHOULDER/LAP BELT/BUCKLEÐXJ VEHICLES

REMOVAL

(1) Pull the rear seat release strap and tilt the

complete seat forward.

(2) Remove the shoulder belt buckle and lap belt/

buckle anchor plate bolts from the floor panel.

(3) Remove the shoulder belt lower anchor bolt.

(4) Remove the quarter trim panel. If necessary,

refer to the removal procedure.

(5) Remove the shoulder belt upper anchor bolt.

(6) Remove the belt retractor support retaining

screw from the rear quarter rail.

(7) Remove the retractor and shoulder belt from

the trim panel.

INSPECTION

Inspect the rear shoulder/lap belts and buckles. Re-

place any belt that is either cut, frayed, torn or dam-

aged in any way. Replace the shoulder belt if the

retractor is damaged or inoperative.

INSTALLATION

(1) Position the shoulder belt buckle and the lap

belt/buckle anchor plates on the floor panel.

(2) Install the anchor bolts. Tighten the bolts to 37

Nzm (27 ft-lbs) torque.

(3) Position the shoulder belt at the roof rail and

install the upper anchor bolt. Tighten the bolt to 37

Nzm (27 ft-lbs) torque.

(4) Route the shoulder belt through the quarter

trim panel slot. Install the retractor support on the

rear quarter rail. Tighten the screw to 5 Nzm (45 in-

lbs) torque.

(5) Install the quarter trim panel.

Fig. 123 Front Shoulder BeltÐ4-Door Vehicles

Fig. 124 Shoulder Belt SetÐ2-Door Vehicles

Fig. 125 Shoulder Belt SetÐ4-Door Vehicles

23 - 120 BODY COMPONENTSÐXJ VEHICLESJ

Page 1576 of 1784

(6) Install the shoulder belt lower anchor bolt.

Tighten the bolt to 37 Nzm (27 ft-lbs) torque.

(7) Return the rear seat to the normal position and

engage the latch.

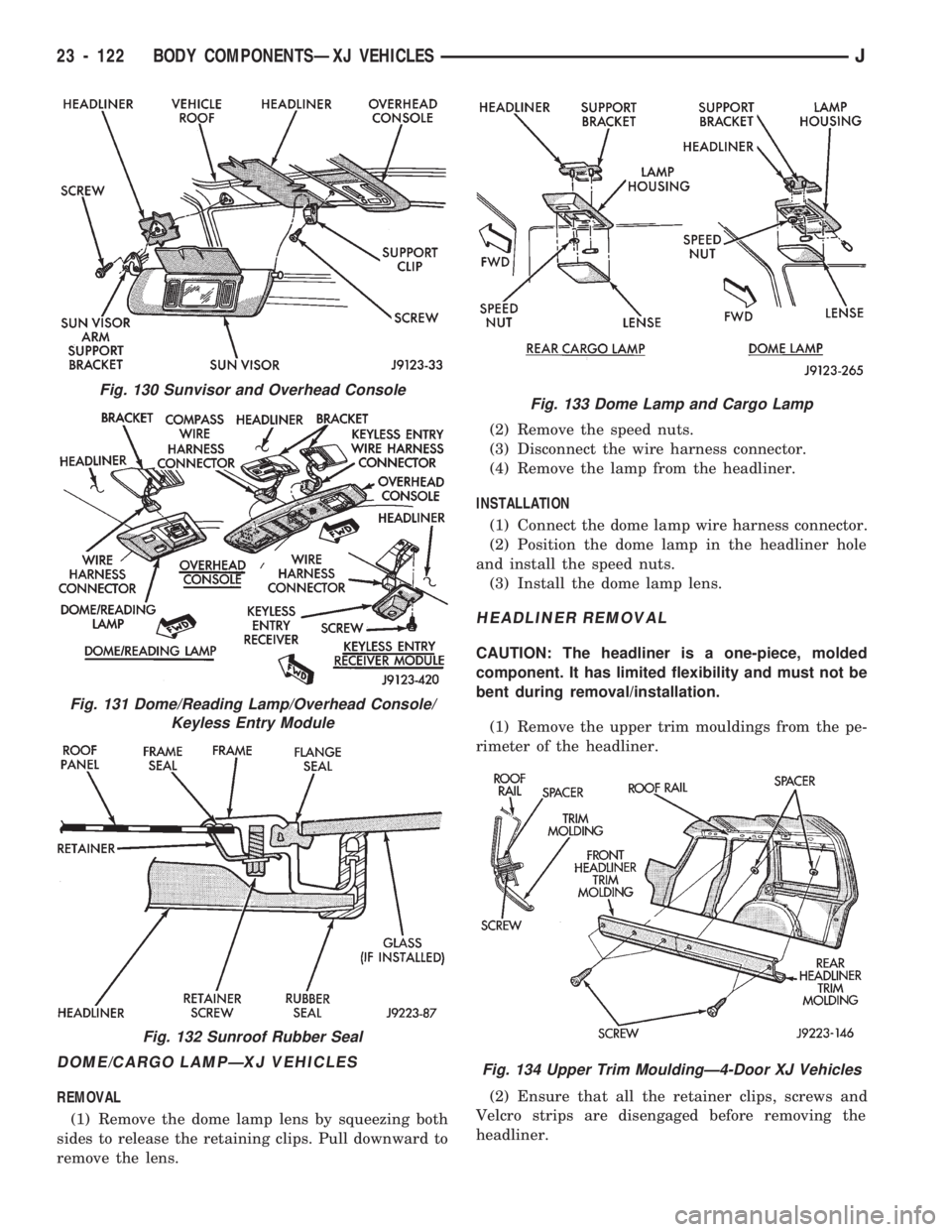

HEADLINER

SERVICE INFORMATION

The upper trim mouldings and the headliner are

attached to the roof rail with a combination of

screws, velcro strips, clip retainers and rail retainers.

To remove a headliner, all of the upper trim moul-

dings must be removed from the perimeter of the

headliner along with (as applicable):

²the assist handles,

²the sunvisors,

²the dome/cargo lamps,

²the overhead console,

²the keyless entry receiver module,

²the sunroof inner rubber seal and

²all other attached/overlapping components.

Fig. 128 Headliner Trim MouldingsÐXJ Vehicles

Fig. 129 Assist HandlesÐXJ Vehicles

Fig. 126 Rear Seat Shoulder/Lap Belts and

BucklesÐXJ Vehicles

Fig. 127 Shoulder Belt Retractor Support Removal/

Installation

JBODY COMPONENTSÐXJ VEHICLES 23 - 121

Page 1577 of 1784

DOME/CARGO LAMPÐXJ VEHICLES

REMOVAL

(1) Remove the dome lamp lens by squeezing both

sides to release the retaining clips. Pull downward to

remove the lens.(2) Remove the speed nuts.

(3) Disconnect the wire harness connector.

(4) Remove the lamp from the headliner.

INSTALLATION

(1) Connect the dome lamp wire harness connector.

(2) Position the dome lamp in the headliner hole

and install the speed nuts.

(3) Install the dome lamp lens.

HEADLINER REMOVAL

CAUTION: The headliner is a one-piece, molded

component. It has limited flexibility and must not be

bent during removal/installation.

(1) Remove the upper trim mouldings from the pe-

rimeter of the headliner.

(2) Ensure that all the retainer clips, screws and

Velcro strips are disengaged before removing the

headliner.

Fig. 130 Sunvisor and Overhead Console

Fig. 131 Dome/Reading Lamp/Overhead Console/

Keyless Entry Module

Fig. 132 Sunroof Rubber Seal

Fig. 133 Dome Lamp and Cargo Lamp

Fig. 134 Upper Trim MouldingÐ4-Door XJ Vehicles

23 - 122 BODY COMPONENTSÐXJ VEHICLESJ