warning light JEEP CHEROKEE 1994 Service User Guide

[x] Cancel search | Manufacturer: JEEP, Model Year: 1994, Model line: CHEROKEE, Model: JEEP CHEROKEE 1994Pages: 1784, PDF Size: 77.09 MB

Page 186 of 1784

ABS SYSTEM OPERATION

INDEX

page page

Acceleration Switch....................... 41

Combination Valve....................... 42

Electronic Control Unit (ECU)............... 41

General Information....................... 39

Hydraulic Control Unit (HCU)................ 39

Ignition Switch........................... 42Master Cylinder.......................... 40

Pedal Travel Sensor...................... 41

Power Brake Booster..................... 40

System Relays.......................... 42

System Warning Lights.................... 42

Wheel Speed Sensors..................... 41

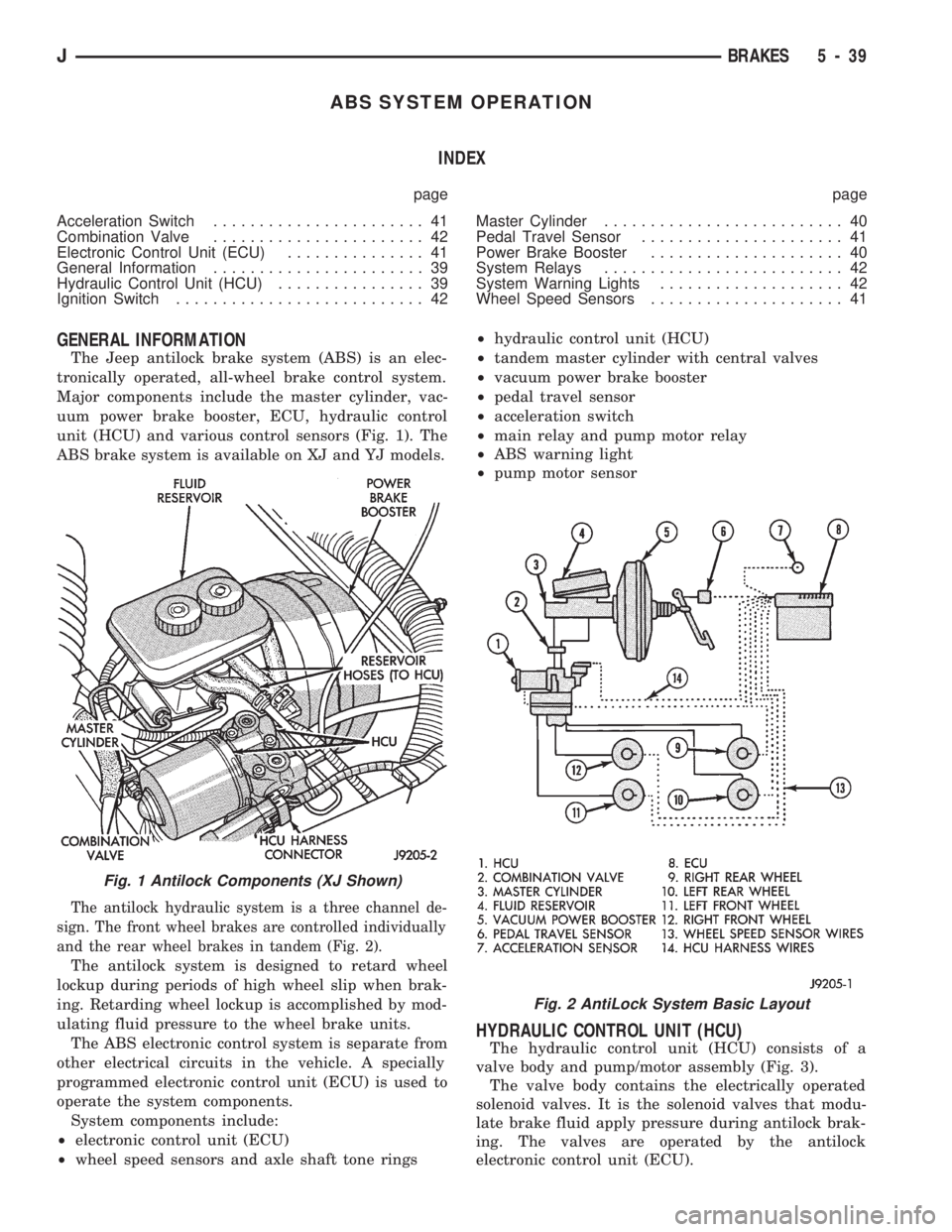

GENERAL INFORMATION

The Jeep antilock brake system (ABS) is an elec-

tronically operated, all-wheel brake control system.

Major components include the master cylinder, vac-

uum power brake booster, ECU, hydraulic control

unit (HCU) and various control sensors (Fig. 1). The

ABS brake system is available on XJ and YJ models.

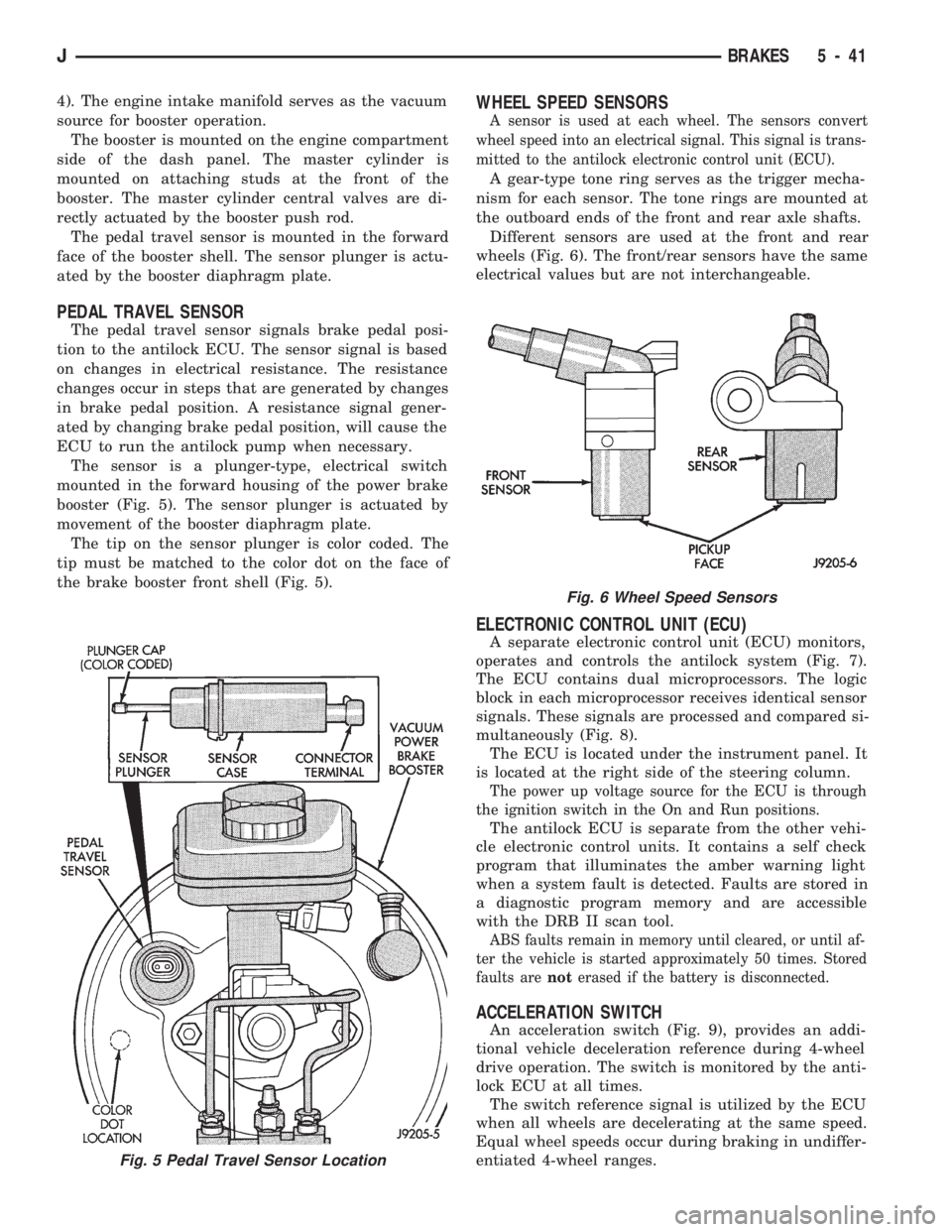

The antilock hydraulic system is a three channel de-

sign. The front wheel brakes are controlled individually

and the rear wheel brakes in tandem (Fig. 2).

The antilock system is designed to retard wheel

lockup during periods of high wheel slip when brak-

ing. Retarding wheel lockup is accomplished by mod-

ulating fluid pressure to the wheel brake units.

The ABS electronic control system is separate from

other electrical circuits in the vehicle. A specially

programmed electronic control unit (ECU) is used to

operate the system components.

System components include:

²electronic control unit (ECU)

²wheel speed sensors and axle shaft tone rings²hydraulic control unit (HCU)

²tandem master cylinder with central valves

²vacuum power brake booster

²pedal travel sensor

²acceleration switch

²main relay and pump motor relay

²ABS warning light

²pump motor sensor

HYDRAULIC CONTROL UNIT (HCU)

The hydraulic control unit (HCU) consists of a

valve body and pump/motor assembly (Fig. 3).

The valve body contains the electrically operated

solenoid valves. It is the solenoid valves that modu-

late brake fluid apply pressure during antilock brak-

ing. The valves are operated by the antilock

electronic control unit (ECU).

Fig. 1 Antilock Components (XJ Shown)

Fig. 2 AntiLock System Basic Layout

JBRAKES 5 - 39

Page 188 of 1784

4). The engine intake manifold serves as the vacuum

source for booster operation.

The booster is mounted on the engine compartment

side of the dash panel. The master cylinder is

mounted on attaching studs at the front of the

booster. The master cylinder central valves are di-

rectly actuated by the booster push rod.

The pedal travel sensor is mounted in the forward

face of the booster shell. The sensor plunger is actu-

ated by the booster diaphragm plate.

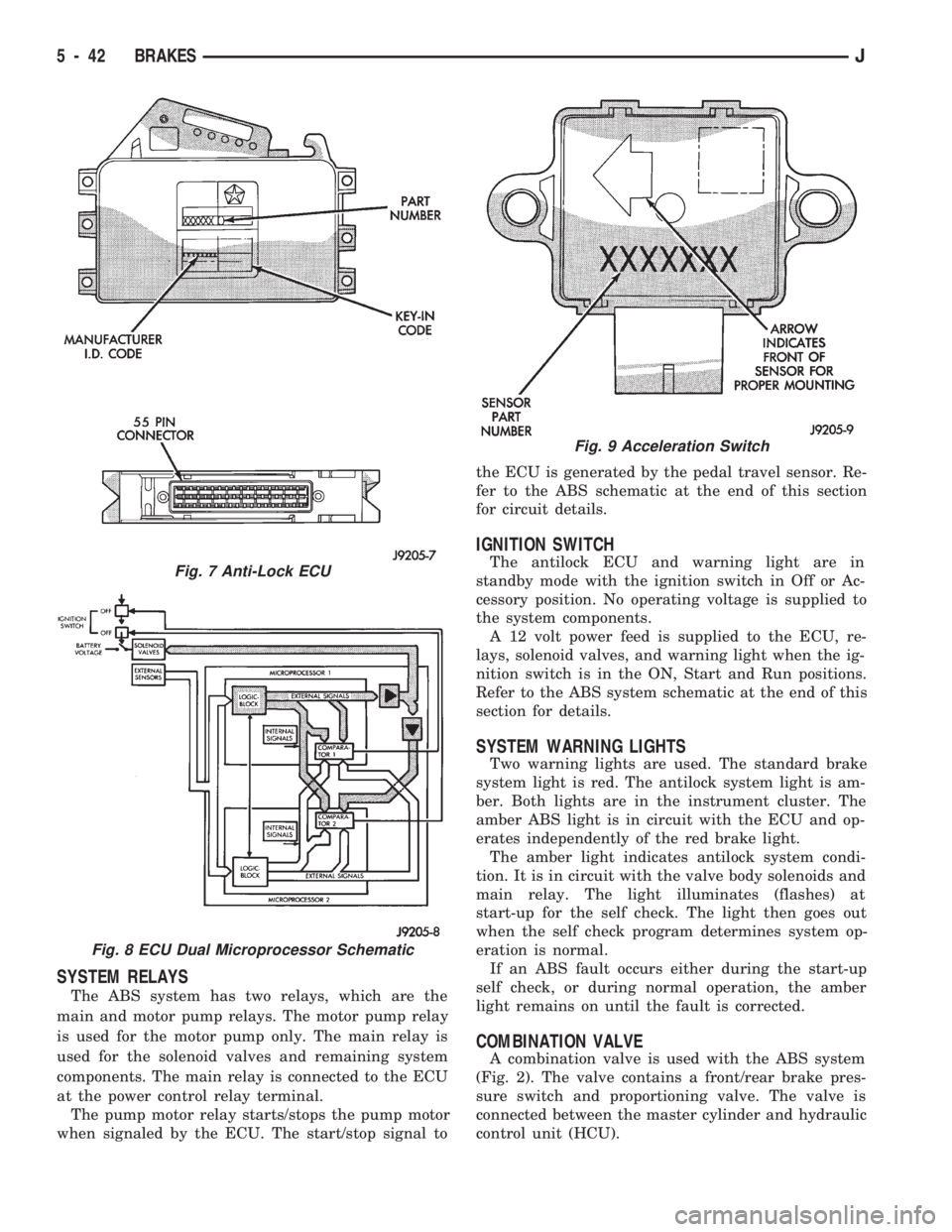

PEDAL TRAVEL SENSOR

The pedal travel sensor signals brake pedal posi-

tion to the antilock ECU. The sensor signal is based

on changes in electrical resistance. The resistance

changes occur in steps that are generated by changes

in brake pedal position. A resistance signal gener-

ated by changing brake pedal position, will cause the

ECU to run the antilock pump when necessary.

The sensor is a plunger-type, electrical switch

mounted in the forward housing of the power brake

booster (Fig. 5). The sensor plunger is actuated by

movement of the booster diaphragm plate.

The tip on the sensor plunger is color coded. The

tip must be matched to the color dot on the face of

the brake booster front shell (Fig. 5).

WHEEL SPEED SENSORS

A sensor is used at each wheel. The sensors convert

wheel speed into an electrical signal. This signal is trans-

mitted to the antilock electronic control unit (ECU).

A gear-type tone ring serves as the trigger mecha-

nism for each sensor. The tone rings are mounted at

the outboard ends of the front and rear axle shafts.

Different sensors are used at the front and rear

wheels (Fig. 6). The front/rear sensors have the same

electrical values but are not interchangeable.

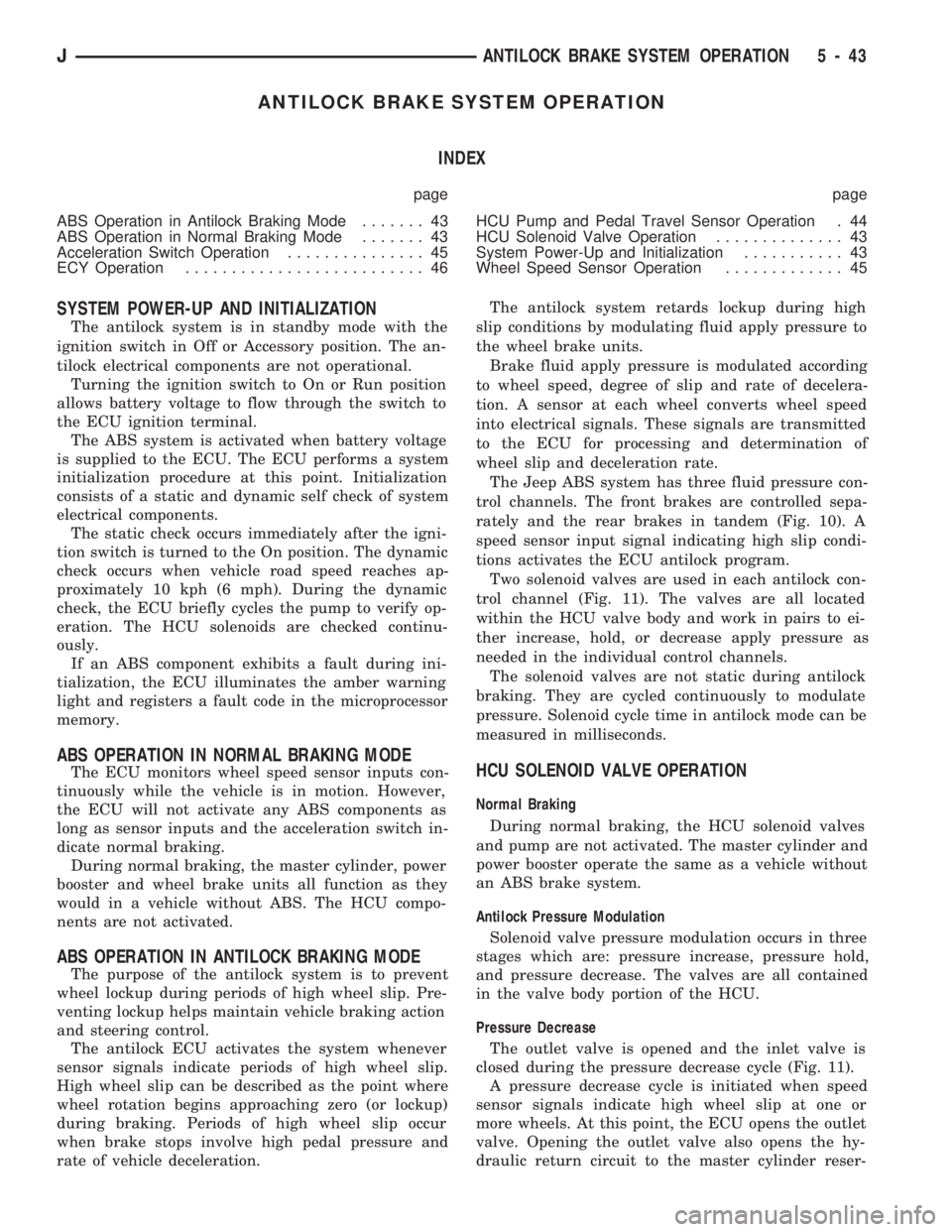

ELECTRONIC CONTROL UNIT (ECU)

A separate electronic control unit (ECU) monitors,

operates and controls the antilock system (Fig. 7).

The ECU contains dual microprocessors. The logic

block in each microprocessor receives identical sensor

signals. These signals are processed and compared si-

multaneously (Fig. 8).

The ECU is located under the instrument panel. It

is located at the right side of the steering column.

The power up voltage source for the ECU is through

the ignition switch in the On and Run positions.

The antilock ECU is separate from the other vehi-

cle electronic control units. It contains a self check

program that illuminates the amber warning light

when a system fault is detected. Faults are stored in

a diagnostic program memory and are accessible

with the DRB II scan tool.

ABS faults remain in memory until cleared, or until af-

ter the vehicle is started approximately 50 times. Stored

faults arenoterased if the battery is disconnected.

ACCELERATION SWITCH

An acceleration switch (Fig. 9), provides an addi-

tional vehicle deceleration reference during 4-wheel

drive operation. The switch is monitored by the anti-

lock ECU at all times.

The switch reference signal is utilized by the ECU

when all wheels are decelerating at the same speed.

Equal wheel speeds occur during braking in undiffer-

entiated 4-wheel ranges.

Fig. 5 Pedal Travel Sensor Location

Fig. 6 Wheel Speed Sensors

JBRAKES 5 - 41

Page 189 of 1784

SYSTEM RELAYS

The ABS system has two relays, which are the

main and motor pump relays. The motor pump relay

is used for the motor pump only. The main relay is

used for the solenoid valves and remaining system

components. The main relay is connected to the ECU

at the power control relay terminal.

The pump motor relay starts/stops the pump motor

when signaled by the ECU. The start/stop signal tothe ECU is generated by the pedal travel sensor. Re-

fer to the ABS schematic at the end of this section

for circuit details.

IGNITION SWITCH

The antilock ECU and warning light are in

standby mode with the ignition switch in Off or Ac-

cessory position. No operating voltage is supplied to

the system components.

A 12 volt power feed is supplied to the ECU, re-

lays, solenoid valves, and warning light when the ig-

nition switch is in the ON, Start and Run positions.

Refer to the ABS system schematic at the end of this

section for details.

SYSTEM WARNING LIGHTS

Two warning lights are used. The standard brake

system light is red. The antilock system light is am-

ber. Both lights are in the instrument cluster. The

amber ABS light is in circuit with the ECU and op-

erates independently of the red brake light.

The amber light indicates antilock system condi-

tion. It is in circuit with the valve body solenoids and

main relay. The light illuminates (flashes) at

start-up for the self check. The light then goes out

when the self check program determines system op-

eration is normal.

If an ABS fault occurs either during the start-up

self check, or during normal operation, the amber

light remains on until the fault is corrected.

COMBINATION VALVE

A combination valve is used with the ABS system

(Fig. 2). The valve contains a front/rear brake pres-

sure switch and proportioning valve. The valve is

connected between the master cylinder and hydraulic

control unit (HCU).

Fig. 7 Anti-Lock ECU

Fig. 8 ECU Dual Microprocessor Schematic

Fig. 9 Acceleration Switch

5 - 42 BRAKESJ

Page 190 of 1784

ANTILOCK BRAKE SYSTEM OPERATION

INDEX

page page

ABS Operation in Antilock Braking Mode....... 43

ABS Operation in Normal Braking Mode....... 43

Acceleration Switch Operation............... 45

ECY Operation.......................... 46HCU Pump and Pedal Travel Sensor Operation . 44

HCU Solenoid Valve Operation.............. 43

System Power-Up and Initialization........... 43

Wheel Speed Sensor Operation............. 45

SYSTEM POWER-UP AND INITIALIZATION

The antilock system is in standby mode with the

ignition switch in Off or Accessory position. The an-

tilock electrical components are not operational.

Turning the ignition switch to On or Run position

allows battery voltage to flow through the switch to

the ECU ignition terminal.

The ABS system is activated when battery voltage

is supplied to the ECU. The ECU performs a system

initialization procedure at this point. Initialization

consists of a static and dynamic self check of system

electrical components.

The static check occurs immediately after the igni-

tion switch is turned to the On position. The dynamic

check occurs when vehicle road speed reaches ap-

proximately 10 kph (6 mph). During the dynamic

check, the ECU briefly cycles the pump to verify op-

eration. The HCU solenoids are checked continu-

ously.

If an ABS component exhibits a fault during ini-

tialization, the ECU illuminates the amber warning

light and registers a fault code in the microprocessor

memory.

ABS OPERATION IN NORMAL BRAKING MODE

The ECU monitors wheel speed sensor inputs con-

tinuously while the vehicle is in motion. However,

the ECU will not activate any ABS components as

long as sensor inputs and the acceleration switch in-

dicate normal braking.

During normal braking, the master cylinder, power

booster and wheel brake units all function as they

would in a vehicle without ABS. The HCU compo-

nents are not activated.

ABS OPERATION IN ANTILOCK BRAKING MODE

The purpose of the antilock system is to prevent

wheel lockup during periods of high wheel slip. Pre-

venting lockup helps maintain vehicle braking action

and steering control.

The antilock ECU activates the system whenever

sensor signals indicate periods of high wheel slip.

High wheel slip can be described as the point where

wheel rotation begins approaching zero (or lockup)

during braking. Periods of high wheel slip occur

when brake stops involve high pedal pressure and

rate of vehicle deceleration.The antilock system retards lockup during high

slip conditions by modulating fluid apply pressure to

the wheel brake units.

Brake fluid apply pressure is modulated according

to wheel speed, degree of slip and rate of decelera-

tion. A sensor at each wheel converts wheel speed

into electrical signals. These signals are transmitted

to the ECU for processing and determination of

wheel slip and deceleration rate.

The Jeep ABS system has three fluid pressure con-

trol channels. The front brakes are controlled sepa-

rately and the rear brakes in tandem (Fig. 10). A

speed sensor input signal indicating high slip condi-

tions activates the ECU antilock program.

Two solenoid valves are used in each antilock con-

trol channel (Fig. 11). The valves are all located

within the HCU valve body and work in pairs to ei-

ther increase, hold, or decrease apply pressure as

needed in the individual control channels.

The solenoid valves are not static during antilock

braking. They are cycled continuously to modulate

pressure. Solenoid cycle time in antilock mode can be

measured in milliseconds.

HCU SOLENOID VALVE OPERATION

Normal Braking

During normal braking, the HCU solenoid valves

and pump are not activated. The master cylinder and

power booster operate the same as a vehicle without

an ABS brake system.

Antilock Pressure Modulation

Solenoid valve pressure modulation occurs in three

stages which are: pressure increase, pressure hold,

and pressure decrease. The valves are all contained

in the valve body portion of the HCU.

Pressure Decrease

The outlet valve is opened and the inlet valve is

closed during the pressure decrease cycle (Fig. 11).

A pressure decrease cycle is initiated when speed

sensor signals indicate high wheel slip at one or

more wheels. At this point, the ECU opens the outlet

valve. Opening the outlet valve also opens the hy-

draulic return circuit to the master cylinder reser-

JANTILOCK BRAKE SYSTEM OPERATION 5 - 43

Page 206 of 1784

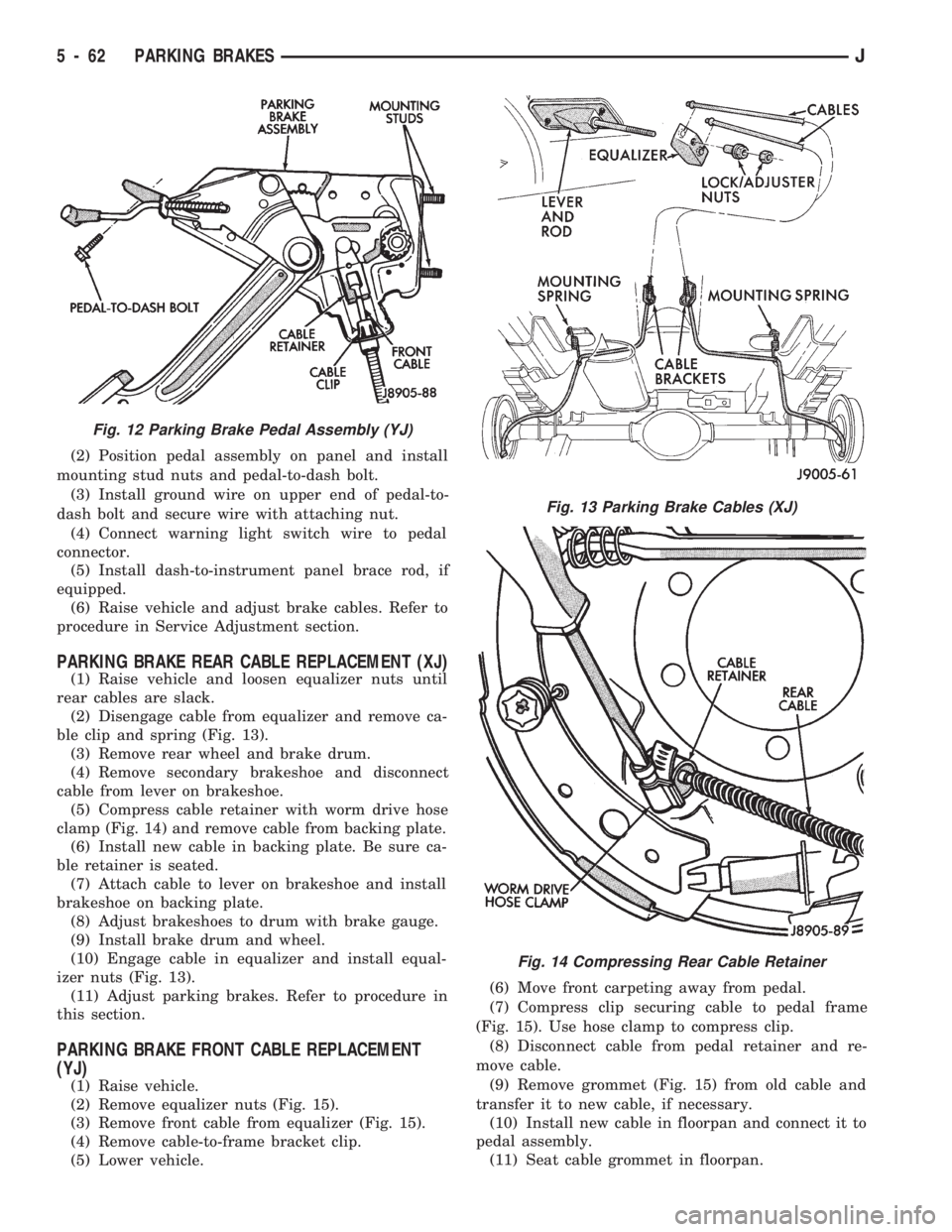

PARKING BRAKE LEVER REMOVAL (XJ WITH FULL

CONSOLE)

(1) Release parking brakes, if necessary.

(2) Raise vehicle.

(3) Remove adjusting nut from tensioner rod. Then

temporarily secure equalizer to nearby chassis com-

ponent with wire.

(4) Remove nuts attaching lever support plate to

underside of floorpan.

(5) Lower vehicle.

(6) On models with manual transmission, remove

shift knob, boot and bezel.

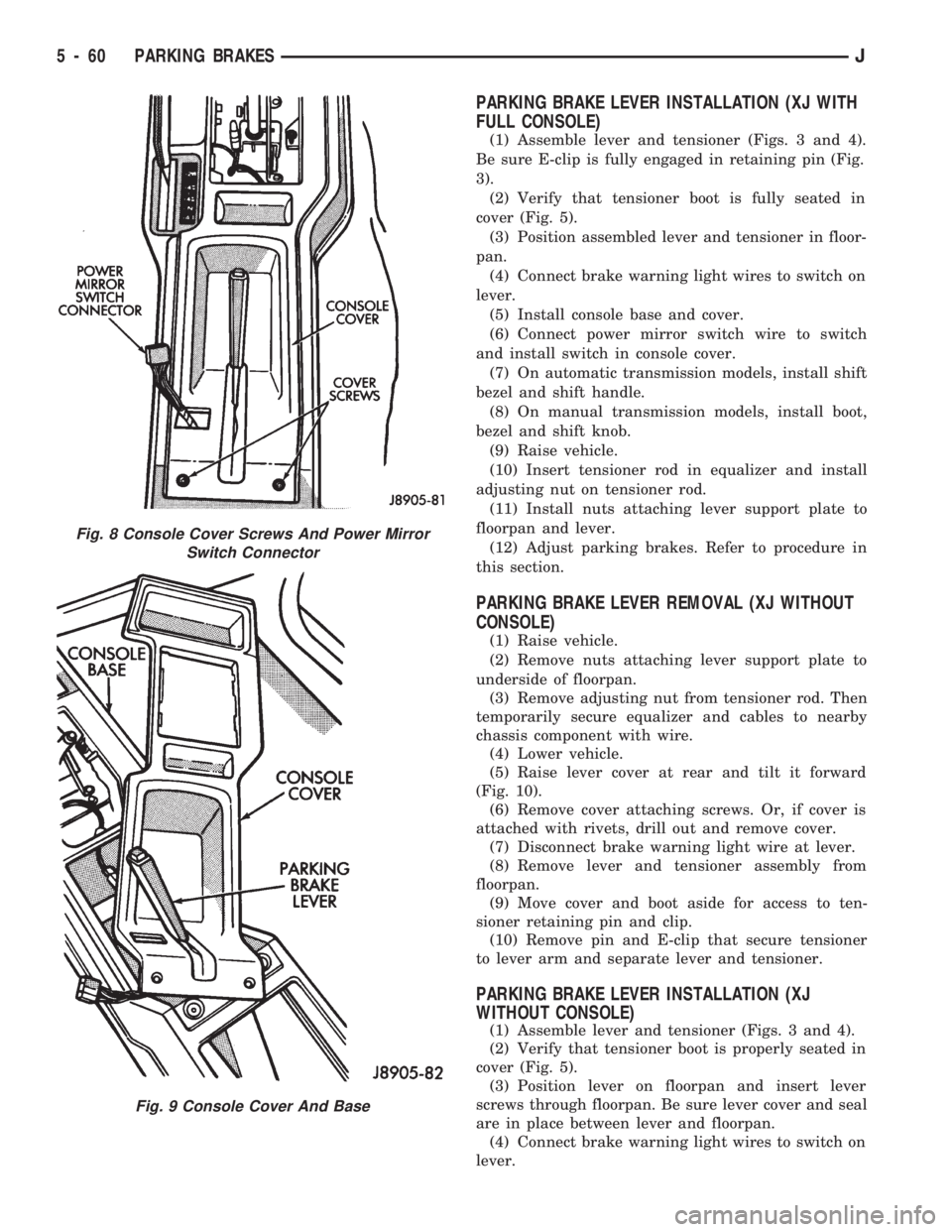

(7) On models with automatic transmission, re-

move shift handle cap and remove plunger, spring

and T-lock (Fig. 7).

(8) Remove shift handle and shift bezel (Fig. 7).

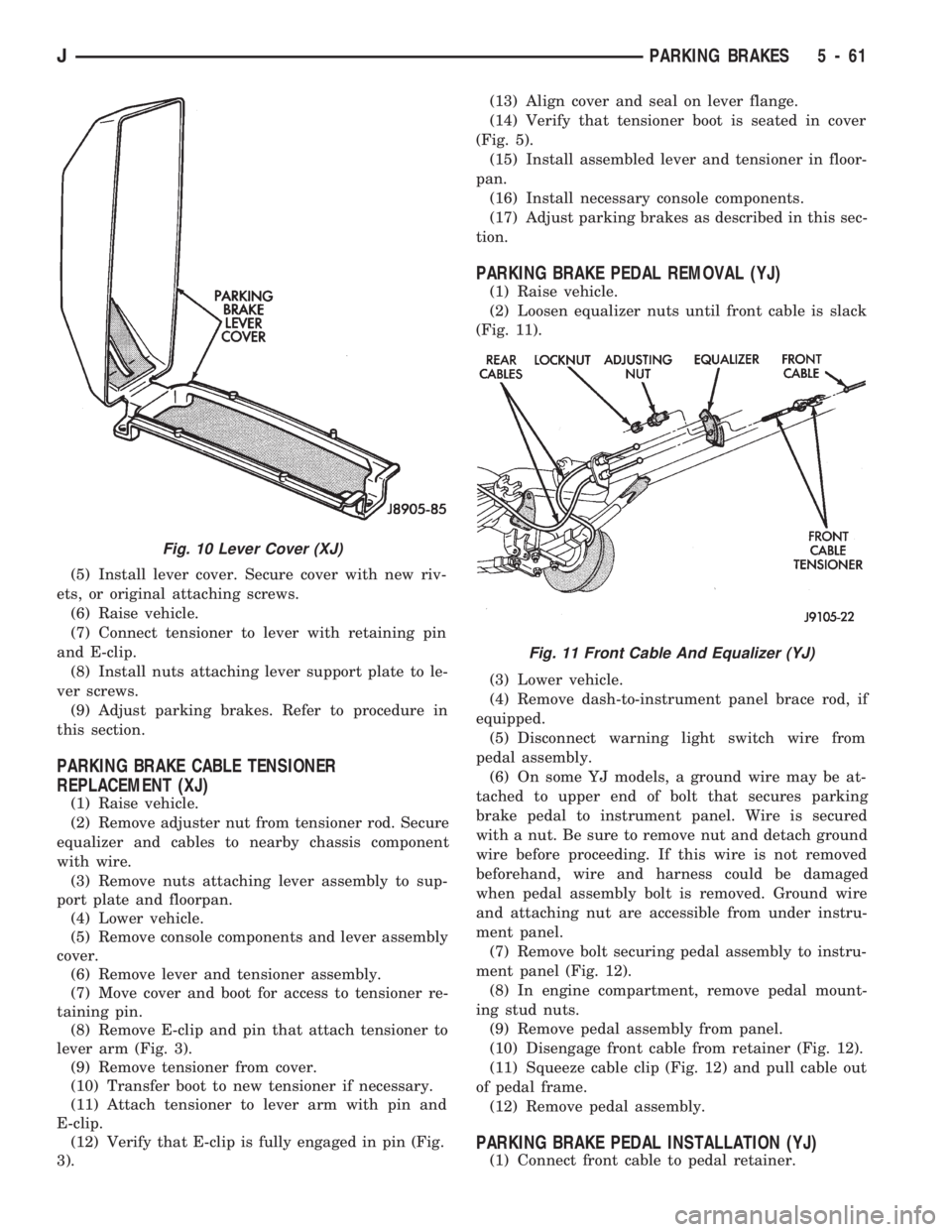

(9) Remove console cover screws (Fig. 8).(10) On models with power mirror switch, pry

switch out of console cover and disconnect switch

connector (Fig. 8).

(11) Remove console cover from base (Fig. 9).

(12) Remove console base.

(13) Disconnect brake warning light wire connec-

tor at lever.

(14) Remove lever and cable tensioner assembly

from floorpan.

(15) Move cover and boot aside for access to lever

arm (Fig. 3).

(16) Remove E-clip and pin that connect tensioner

to lever arm (Fig. 3).

Fig. 6 Hand Lever And Cable Tensioner Components (XJ)

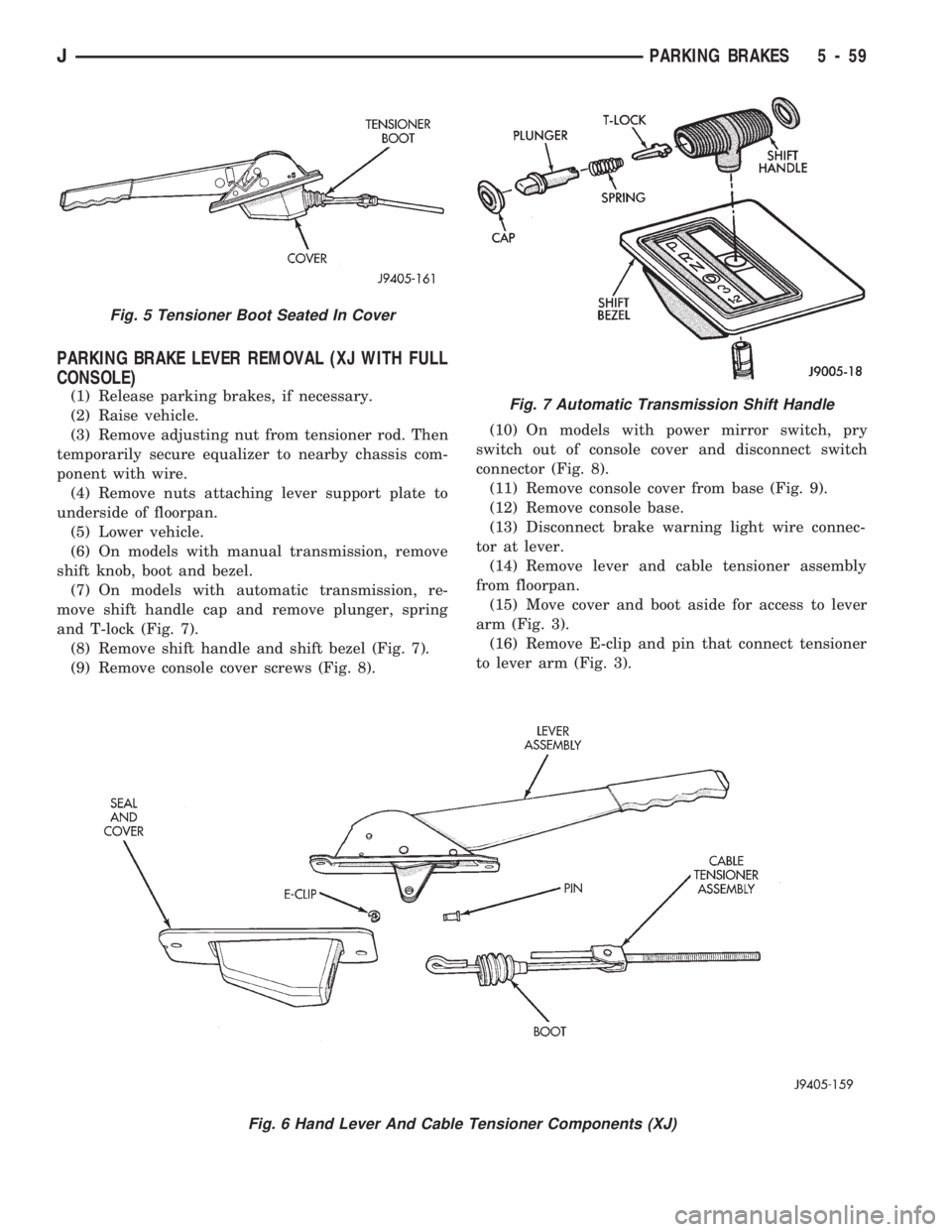

Fig. 5 Tensioner Boot Seated In Cover

Fig. 7 Automatic Transmission Shift Handle

JPARKING BRAKES 5 - 59

Page 207 of 1784

PARKING BRAKE LEVER INSTALLATION (XJ WITH

FULL CONSOLE)

(1) Assemble lever and tensioner (Figs. 3 and 4).

Be sure E-clip is fully engaged in retaining pin (Fig.

3).

(2) Verify that tensioner boot is fully seated in

cover (Fig. 5).

(3) Position assembled lever and tensioner in floor-

pan.

(4) Connect brake warning light wires to switch on

lever.

(5) Install console base and cover.

(6) Connect power mirror switch wire to switch

and install switch in console cover.

(7) On automatic transmission models, install shift

bezel and shift handle.

(8) On manual transmission models, install boot,

bezel and shift knob.

(9) Raise vehicle.

(10) Insert tensioner rod in equalizer and install

adjusting nut on tensioner rod.

(11) Install nuts attaching lever support plate to

floorpan and lever.

(12) Adjust parking brakes. Refer to procedure in

this section.

PARKING BRAKE LEVER REMOVAL (XJ WITHOUT

CONSOLE)

(1) Raise vehicle.

(2) Remove nuts attaching lever support plate to

underside of floorpan.

(3) Remove adjusting nut from tensioner rod. Then

temporarily secure equalizer and cables to nearby

chassis component with wire.

(4) Lower vehicle.

(5) Raise lever cover at rear and tilt it forward

(Fig. 10).

(6) Remove cover attaching screws. Or, if cover is

attached with rivets, drill out and remove cover.

(7) Disconnect brake warning light wire at lever.

(8) Remove lever and tensioner assembly from

floorpan.

(9) Move cover and boot aside for access to ten-

sioner retaining pin and clip.

(10) Remove pin and E-clip that secure tensioner

to lever arm and separate lever and tensioner.

PARKING BRAKE LEVER INSTALLATION (XJ

WITHOUT CONSOLE)

(1) Assemble lever and tensioner (Figs. 3 and 4).

(2) Verify that tensioner boot is properly seated in

cover (Fig. 5).

(3) Position lever on floorpan and insert lever

screws through floorpan. Be sure lever cover and seal

are in place between lever and floorpan.

(4) Connect brake warning light wires to switch on

lever.

Fig. 8 Console Cover Screws And Power Mirror

Switch Connector

Fig. 9 Console Cover And Base

5 - 60 PARKING BRAKESJ

Page 208 of 1784

(5) Install lever cover. Secure cover with new riv-

ets, or original attaching screws.

(6) Raise vehicle.

(7) Connect tensioner to lever with retaining pin

and E-clip.

(8) Install nuts attaching lever support plate to le-

ver screws.

(9) Adjust parking brakes. Refer to procedure in

this section.

PARKING BRAKE CABLE TENSIONER

REPLACEMENT (XJ)

(1) Raise vehicle.

(2) Remove adjuster nut from tensioner rod. Secure

equalizer and cables to nearby chassis component

with wire.

(3) Remove nuts attaching lever assembly to sup-

port plate and floorpan.

(4) Lower vehicle.

(5) Remove console components and lever assembly

cover.

(6) Remove lever and tensioner assembly.

(7) Move cover and boot for access to tensioner re-

taining pin.

(8) Remove E-clip and pin that attach tensioner to

lever arm (Fig. 3).

(9) Remove tensioner from cover.

(10) Transfer boot to new tensioner if necessary.

(11) Attach tensioner to lever arm with pin and

E-clip.

(12) Verify that E-clip is fully engaged in pin (Fig.

3).(13) Align cover and seal on lever flange.

(14) Verify that tensioner boot is seated in cover

(Fig. 5).

(15) Install assembled lever and tensioner in floor-

pan.

(16) Install necessary console components.

(17) Adjust parking brakes as described in this sec-

tion.

PARKING BRAKE PEDAL REMOVAL (YJ)

(1) Raise vehicle.

(2) Loosen equalizer nuts until front cable is slack

(Fig. 11).

(3) Lower vehicle.

(4) Remove dash-to-instrument panel brace rod, if

equipped.

(5) Disconnect warning light switch wire from

pedal assembly.

(6) On some YJ models, a ground wire may be at-

tached to upper end of bolt that secures parking

brake pedal to instrument panel. Wire is secured

with a nut. Be sure to remove nut and detach ground

wire before proceeding. If this wire is not removed

beforehand, wire and harness could be damaged

when pedal assembly bolt is removed. Ground wire

and attaching nut are accessible from under instru-

ment panel.

(7) Remove bolt securing pedal assembly to instru-

ment panel (Fig. 12).

(8) In engine compartment, remove pedal mount-

ing stud nuts.

(9) Remove pedal assembly from panel.

(10) Disengage front cable from retainer (Fig. 12).

(11) Squeeze cable clip (Fig. 12) and pull cable out

of pedal frame.

(12) Remove pedal assembly.

PARKING BRAKE PEDAL INSTALLATION (YJ)

(1) Connect front cable to pedal retainer.

Fig. 10 Lever Cover (XJ)

Fig. 11 Front Cable And Equalizer (YJ)

JPARKING BRAKES 5 - 61

Page 209 of 1784

(2) Position pedal assembly on panel and install

mounting stud nuts and pedal-to-dash bolt.

(3) Install ground wire on upper end of pedal-to-

dash bolt and secure wire with attaching nut.

(4) Connect warning light switch wire to pedal

connector.

(5) Install dash-to-instrument panel brace rod, if

equipped.

(6) Raise vehicle and adjust brake cables. Refer to

procedure in Service Adjustment section.

PARKING BRAKE REAR CABLE REPLACEMENT (XJ)

(1) Raise vehicle and loosen equalizer nuts until

rear cables are slack.

(2) Disengage cable from equalizer and remove ca-

ble clip and spring (Fig. 13).

(3) Remove rear wheel and brake drum.

(4) Remove secondary brakeshoe and disconnect

cable from lever on brakeshoe.

(5) Compress cable retainer with worm drive hose

clamp (Fig. 14) and remove cable from backing plate.

(6) Install new cable in backing plate. Be sure ca-

ble retainer is seated.

(7) Attach cable to lever on brakeshoe and install

brakeshoe on backing plate.

(8) Adjust brakeshoes to drum with brake gauge.

(9) Install brake drum and wheel.

(10) Engage cable in equalizer and install equal-

izer nuts (Fig. 13).

(11) Adjust parking brakes. Refer to procedure in

this section.

PARKING BRAKE FRONT CABLE REPLACEMENT

(YJ)

(1) Raise vehicle.

(2) Remove equalizer nuts (Fig. 15).

(3) Remove front cable from equalizer (Fig. 15).

(4) Remove cable-to-frame bracket clip.

(5) Lower vehicle.(6) Move front carpeting away from pedal.

(7) Compress clip securing cable to pedal frame

(Fig. 15). Use hose clamp to compress clip.

(8) Disconnect cable from pedal retainer and re-

move cable.

(9) Remove grommet (Fig. 15) from old cable and

transfer it to new cable, if necessary.

(10) Install new cable in floorpan and connect it to

pedal assembly.

(11) Seat cable grommet in floorpan.

Fig. 12 Parking Brake Pedal Assembly (YJ)

Fig. 13 Parking Brake Cables (XJ)

Fig. 14 Compressing Rear Cable Retainer

5 - 62 PARKING BRAKESJ

Page 225 of 1784

CLUTCH SERVICE

INDEX

page page

Clutch Cover and Disc Installation............ 10

Clutch Cover and Disc Removal............. 10

Clutch Fluid Level........................ 14

Clutch Housing Replacement................ 11

Clutch Hydraulic Linkage Installation.......... 12

Clutch Hydraulic Linkage Removal........... 11Clutch Pedal Installation................... 15

Clutch Pedal Removal..................... 15

Clutch Safety Precautions.................. 10

Flywheel Service......................... 15

Pilot Bearing Replacement................. 11

Release Bearing Replacement............... 11

CLUTCH SAFETY PRECAUTIONS

WARNING: EXERCISE CARE WHEN SERVICING

CLUTCH COMPONENTS. DUST AND DIRT ON

CLUTCH PARTS USE MAY CONTAIN ASBESTOS FI-

BERS. BREATHING EXCESSIVE CONCENTRATIONS

OF THESE FIBERS CAN CAUSE SERIOUS BODILY

HARM. WEAR A RESPIRATOR DURING SERVICE

AND NEVER CLEAN CLUTCH COMPONENTS WITH

COMPRESSED AIR OR WITH A DRY BRUSH. EI-

THER CLEAN THE COMPONENTS WITH A WATER

DAMPENED RAGS OR USE A VACUUM CLEANER

SPECIFICALLY DESIGNED FOR REMOVING ASBES-

TOS FIBERS AND DUST. DO NOT CREATE DUST

BY SANDING A CLUTCH DISC. REPLACE THE DISC

IF THE FRICTION MATERIAL IS DAMAGED OR

CONTAMINATED. DISPOSE OF ALL DUST AND

DIRT CONTAINING ASBESTOS FIBERS IN SEALED

BAGS OR CONTAINERS. THIS WILL HELP MINIMIZE

EXPOSURE TO YOURSELF AND TO OTHERS. FOL-

LOW ALL RECOMMENDED SAFETY PRACTICES

PRESCRIBED BY THE OCCUPATIONAL SAFETY

AND HEALTH ADMINISTRATION (OSHA) AND THE

ENVIRONMENTAL SAFETY AGENCY (EPA), FOR

THE HANDLING AND DISPOSAL OF PRODUCTS

CONTAINING ASBESTOS.

CLUTCH COVER AND DISC REMOVAL

(1) Remove transmission. Refer to procedures in

Group 21.

(2) If original clutch cover will be reinstalled,

mark position of cover on flywheel for assembly ref-

erence. Use paint or a scriber for this purpose.

(3) If clutch cover is to be replaced, cover bolts can

be removed in any sequence. However, if original

cover will be reinstalled, loosen cover bolts evenly

and in rotation to relieve spring tension equally.

This is necessary avoid warping cover.

(4) Remove cover bolts and remove cover and disc

(Fig. 2).

CLUTCH COVER AND DISC INSTALLATION

(1) Lightly scuff sand flywheel face with 180 grit

emery cloth. Then clean surface with a wax and

grease remover.

(2) Lubricate pilot bearing with Mopar high tem-

perature bearing grease.

(3) Check runout and free operation of new clutch

disc as follows:

(a) Slide disc onto transmission input shaft

splines. Disc should slide freely on splines.

(b) Leave disc on shaft and check face runout

with dial indicator. Check runout at disc hub and

about 6 mm (1/4 in.) from outer edge of facing.

(c) Face runout should not exceed 0.5 mm (0.020

in.). Obtain another clutch disc if runout exceeds

this limit.

(4) Position clutch disc on flywheel. Be sure side of

disc marked flywheel side is positioned against fly-

wheel (Fig. 2). If disc is not marked, be sure flat side

of disc hub is toward flywheel.

(5) Insert clutch alignment tool in clutch disc (Fig.

3).

(6) Insert alignment tool in pilot bearing and posi-

tion disc on flywheel. Be sure disc hub is positioned

correctly. Side of hub marked Flywheel Side should

face flywheel (Fig. 2). If disc is not marked, place flat

side of disc against flywheel.

(7) Position clutch cover over disc and on flywheel

(Fig. 3).

(8) Install clutch cover bolts finger tight.

(9) Tighten cover bolts evenly and in rotation a

few threads at a time.Cover bolts must be tight-

ened evenly and to specified torque to avoid dis-

torting cover. Tightening torques are 31 Nzm (23

ft. lbs.) on 2.5L engines and 54 Nzm (40 ft. lbs.) on

4.0L engines.

(10) Apply light coat of Mopar high temperature

bearing grease to pilot bearing hub and splines of

transmission input shaft.Do not overlubricate

shaft splines. This will result in grease contami-

nation of disc.

(11) Install transmission (Fig. 4). Refer to proce-

dures in Group 21.

6 - 10 CLUTCH SERVICEJ

Page 249 of 1784

ADDING ADDITIONAL COOLANTÐROUTINE

Do not remove radiator cap to add coolant to

system.When adding coolant to maintain correct

level, do so at coolant reserve/overflow tank. Use a

50/50 mixture of ethylene-glycol antifreeze contain-

ing Alugard 340-2 Ÿ and low mineral content water.

Remove radiator cap only for testing or when refill-

ing system after service. Removing cap unnecessarily

can cause loss of coolant and allow air to enter sys-

tem, which produces corrosion.

COOLANT LEVEL CHECK-SERVICE

The cooling system is closed and designed to main-

tain coolant level to top of radiator.

WARNING: DO NOT OPEN RADIATOR DRAINCOCK

WITH ENGINE RUNNING OR WHILE ENGINE IS HOT

AND COOLING SYSTEM IS UNDER PRESSURE.

When vehicle servicing requires a coolant level

check in radiator, drain several ounces of coolant

from radiator drain cock. Do this while observing

coolant reserve/overflow system tank. The coolant

level in reserve/overflow tank should drop slightly. If

not, inspect for a leak between radiator and coolant

reserve/overflow system connection. Remove radiator

cap. The coolant level should be to top of radiator. If

not and if coolant level in reserve/overflow tank is at

ADD mark, check for:

²An air leak in coolant reserve/overflow tank or its

hose

²An air leak in radiator filler neck

²Leak in pressure cap seal to radiator filler neck

LOW COOLANT LEVEL-AERATION

If the coolant level in radiator drops below top of

radiator core tubes, air will enter cooling system.

Low coolant level can cause thermostat pellet to be

suspended in air instead of coolant. This will cause

thermostat to open later, which in turn causes higher

coolant temperature. Air trapped in cooling system

also reduces amount of coolant circulating in heater

core resulting in low heat output.

DEAERATION

As the engine operates, any air trapped in cooling

system gathers under the radiator cap. The next time

the engine is operated, thermal expansion of coolant

will push any trapped air past radiator cap into the

coolant reserve/overflow tank. Here it escapes to the

atmosphere into the tank. When the engine cools

down the coolant, it will be drawn from the reserve/

overflow tank into the radiator to replace any re-

moved air.

DRAINING COOLING SYSTEM

ALL MODELSÐEXCEPT XJ WITH 4.0L ENGINE

WARNING: DO NOT REMOVE THE CYLINDER

BLOCK DRAIN PLUGS OR LOOSEN THE RADIATOR

DRAINCOCK WITH SYSTEM HOT AND UNDER

PRESSURE. SERIOUS BURNS FROM COOLANT

CAN OCCUR.

DO NOT WASTE reusable coolant. If the solution

is clean, drain the coolant into a clean container for

reuse.

DO NOT remove the radiator cap when draining

the coolant from the reserve/overflow tank. Open the

radiator draincock and when the tank is empty, re-

move the radiator cap. The coolant does not have to

be removed from the tank unless the system is being

refilled with a fresh mixture.

(1) Drain the coolant from the radiator by loosen-

ing the draincock.

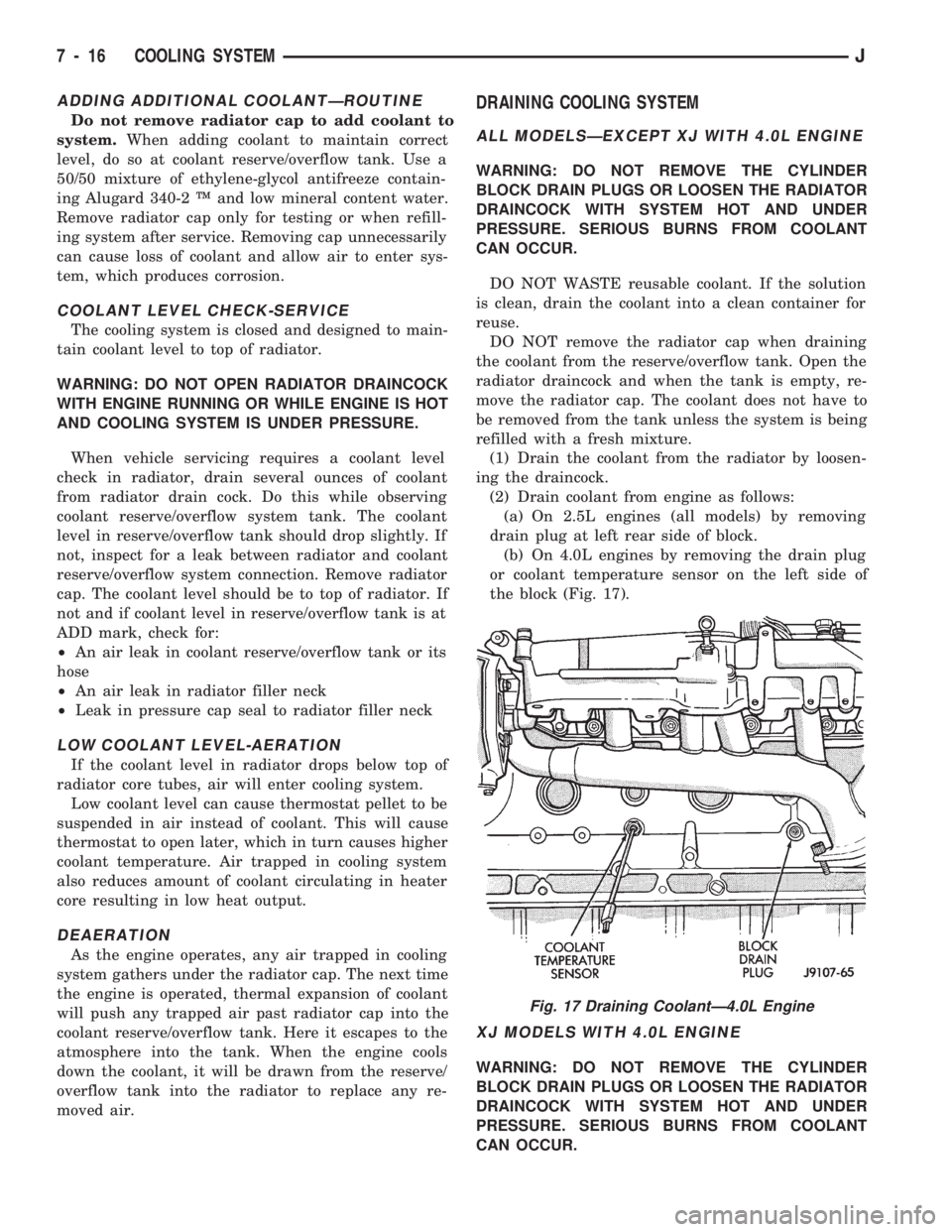

(2) Drain coolant from engine as follows:

(a) On 2.5L engines (all models) by removing

drain plug at left rear side of block.

(b) On 4.0L engines by removing the drain plug

or coolant temperature sensor on the left side of

the block (Fig. 17).

XJ MODELS WITH 4.0L ENGINE

WARNING: DO NOT REMOVE THE CYLINDER

BLOCK DRAIN PLUGS OR LOOSEN THE RADIATOR

DRAINCOCK WITH SYSTEM HOT AND UNDER

PRESSURE. SERIOUS BURNS FROM COOLANT

CAN OCCUR.

Fig. 17 Draining CoolantÐ4.0L Engine

7 - 16 COOLING SYSTEMJ