warning light JEEP CHEROKEE 1994 Service Owner's Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 1994, Model line: CHEROKEE, Model: JEEP CHEROKEE 1994Pages: 1784, PDF Size: 77.09 MB

Page 251 of 1784

REVERSE FLUSHING ENGINE

Drain the cooling system. Remove the thermostat

housing and thermostat. Install the thermostat hous-

ing. Disconnect the radiator upper hose from the ra-

diator and attach the flushing gun to the hose.

Disconnect the radiator lower hose from the water

pump. Attach a lead away hose to the water pump

inlet fitting.

CAUTION: On XJ models, be sure that the heater

control valve is closed (heat off). This is done to

prevent coolant flow with scale and other deposits

from entering the heater core.

Connect the water supply hose and air supply hose

to the flushing gun. Allow the engine to fill with wa-

ter. When the engine is filled, apply air in short

blasts, allowing the system to fill between air blasts.

Continue until clean water flows through the lead

away hose. For more information, refer to operating

instructions supplied with flushing equipment.

Remove the lead away hose, flushing gun, water

supply hose and air supply hose. Remove the thermo-

stat housing and install thermostat. Install the ther-

mostat housing with a replacement gasket. Refer to

Thermostat Replacement. Connect the radiator hoses.

Refill the cooling system with the correct antifreeze/

water mixture.

CHEMICAL CLEANING

In some instances, use a radiator cleaner (Mopar

Radiator Kleen or equivalent) before flushing. This

will soften scale and other deposits and aid the flush-

ing operation.

CAUTION: Be sure instructions on the container are

followed.

TESTING COOLING SYSTEM FOR LEAKS

ULTRAVIOLET LIGHT METHOD

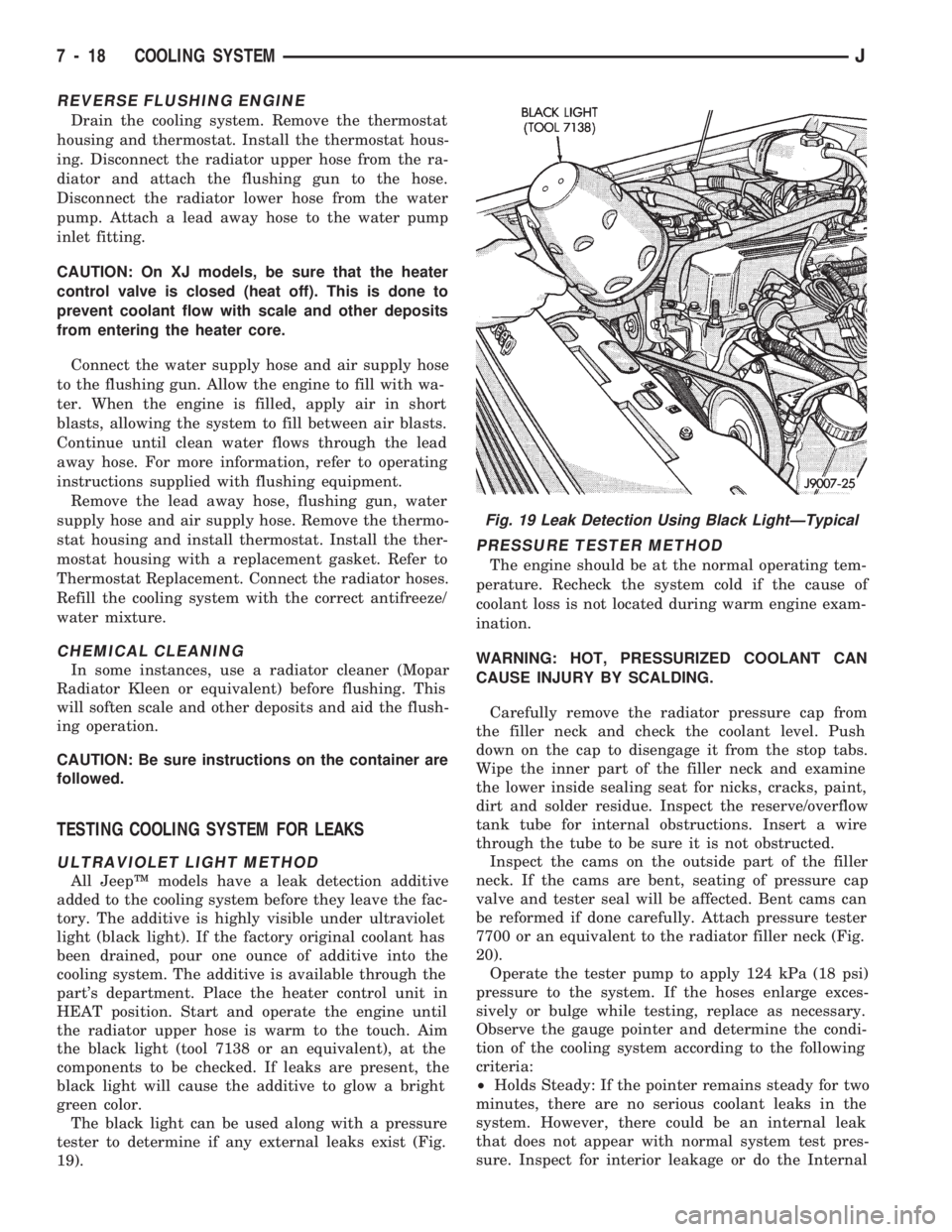

All JeepŸ models have a leak detection additive

added to the cooling system before they leave the fac-

tory. The additive is highly visible under ultraviolet

light (black light). If the factory original coolant has

been drained, pour one ounce of additive into the

cooling system. The additive is available through the

part's department. Place the heater control unit in

HEAT position. Start and operate the engine until

the radiator upper hose is warm to the touch. Aim

the black light (tool 7138 or an equivalent), at the

components to be checked. If leaks are present, the

black light will cause the additive to glow a bright

green color.

The black light can be used along with a pressure

tester to determine if any external leaks exist (Fig.

19).

PRESSURE TESTER METHOD

The engine should be at the normal operating tem-

perature. Recheck the system cold if the cause of

coolant loss is not located during warm engine exam-

ination.

WARNING: HOT, PRESSURIZED COOLANT CAN

CAUSE INJURY BY SCALDING.

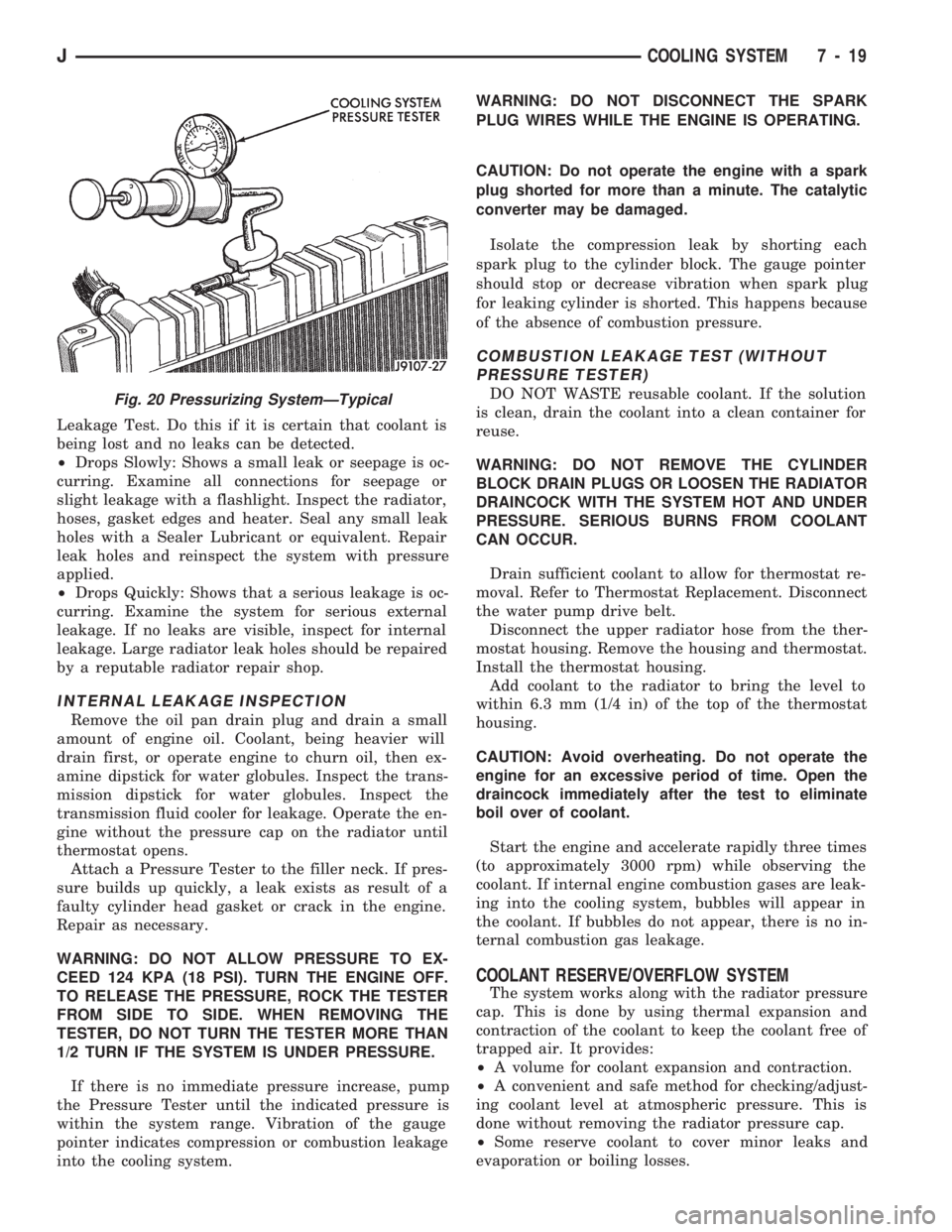

Carefully remove the radiator pressure cap from

the filler neck and check the coolant level. Push

down on the cap to disengage it from the stop tabs.

Wipe the inner part of the filler neck and examine

the lower inside sealing seat for nicks, cracks, paint,

dirt and solder residue. Inspect the reserve/overflow

tank tube for internal obstructions. Insert a wire

through the tube to be sure it is not obstructed.

Inspect the cams on the outside part of the filler

neck. If the cams are bent, seating of pressure cap

valve and tester seal will be affected. Bent cams can

be reformed if done carefully. Attach pressure tester

7700 or an equivalent to the radiator filler neck (Fig.

20).

Operate the tester pump to apply 124 kPa (18 psi)

pressure to the system. If the hoses enlarge exces-

sively or bulge while testing, replace as necessary.

Observe the gauge pointer and determine the condi-

tion of the cooling system according to the following

criteria:

²Holds Steady: If the pointer remains steady for two

minutes, there are no serious coolant leaks in the

system. However, there could be an internal leak

that does not appear with normal system test pres-

sure. Inspect for interior leakage or do the Internal

Fig. 19 Leak Detection Using Black LightÐTypical

7 - 18 COOLING SYSTEMJ

Page 252 of 1784

Leakage Test. Do this if it is certain that coolant is

being lost and no leaks can be detected.

²Drops Slowly: Shows a small leak or seepage is oc-

curring. Examine all connections for seepage or

slight leakage with a flashlight. Inspect the radiator,

hoses, gasket edges and heater. Seal any small leak

holes with a Sealer Lubricant or equivalent. Repair

leak holes and reinspect the system with pressure

applied.

²Drops Quickly: Shows that a serious leakage is oc-

curring. Examine the system for serious external

leakage. If no leaks are visible, inspect for internal

leakage. Large radiator leak holes should be repaired

by a reputable radiator repair shop.

INTERNAL LEAKAGE INSPECTION

Remove the oil pan drain plug and drain a small

amount of engine oil. Coolant, being heavier will

drain first, or operate engine to churn oil, then ex-

amine dipstick for water globules. Inspect the trans-

mission dipstick for water globules. Inspect the

transmission fluid cooler for leakage. Operate the en-

gine without the pressure cap on the radiator until

thermostat opens.

Attach a Pressure Tester to the filler neck. If pres-

sure builds up quickly, a leak exists as result of a

faulty cylinder head gasket or crack in the engine.

Repair as necessary.

WARNING: DO NOT ALLOW PRESSURE TO EX-

CEED 124 KPA (18 PSI). TURN THE ENGINE OFF.

TO RELEASE THE PRESSURE, ROCK THE TESTER

FROM SIDE TO SIDE. WHEN REMOVING THE

TESTER, DO NOT TURN THE TESTER MORE THAN

1/2 TURN IF THE SYSTEM IS UNDER PRESSURE.

If there is no immediate pressure increase, pump

the Pressure Tester until the indicated pressure is

within the system range. Vibration of the gauge

pointer indicates compression or combustion leakage

into the cooling system.WARNING: DO NOT DISCONNECT THE SPARK

PLUG WIRES WHILE THE ENGINE IS OPERATING.

CAUTION: Do not operate the engine with a spark

plug shorted for more than a minute. The catalytic

converter may be damaged.

Isolate the compression leak by shorting each

spark plug to the cylinder block. The gauge pointer

should stop or decrease vibration when spark plug

for leaking cylinder is shorted. This happens because

of the absence of combustion pressure.

COMBUSTION LEAKAGE TEST (WITHOUT

PRESSURE TESTER)

DO NOT WASTE reusable coolant. If the solution

is clean, drain the coolant into a clean container for

reuse.

WARNING: DO NOT REMOVE THE CYLINDER

BLOCK DRAIN PLUGS OR LOOSEN THE RADIATOR

DRAINCOCK WITH THE SYSTEM HOT AND UNDER

PRESSURE. SERIOUS BURNS FROM COOLANT

CAN OCCUR.

Drain sufficient coolant to allow for thermostat re-

moval. Refer to Thermostat Replacement. Disconnect

the water pump drive belt.

Disconnect the upper radiator hose from the ther-

mostat housing. Remove the housing and thermostat.

Install the thermostat housing.

Add coolant to the radiator to bring the level to

within 6.3 mm (1/4 in) of the top of the thermostat

housing.

CAUTION: Avoid overheating. Do not operate the

engine for an excessive period of time. Open the

draincock immediately after the test to eliminate

boil over of coolant.

Start the engine and accelerate rapidly three times

(to approximately 3000 rpm) while observing the

coolant. If internal engine combustion gases are leak-

ing into the cooling system, bubbles will appear in

the coolant. If bubbles do not appear, there is no in-

ternal combustion gas leakage.

COOLANT RESERVE/OVERFLOW SYSTEM

The system works along with the radiator pressure

cap. This is done by using thermal expansion and

contraction of the coolant to keep the coolant free of

trapped air. It provides:

²A volume for coolant expansion and contraction.

²A convenient and safe method for checking/adjust-

ing coolant level at atmospheric pressure. This is

done without removing the radiator pressure cap.

²Some reserve coolant to cover minor leaks and

evaporation or boiling losses.

Fig. 20 Pressurizing SystemÐTypical

JCOOLING SYSTEM 7 - 19

Page 254 of 1784

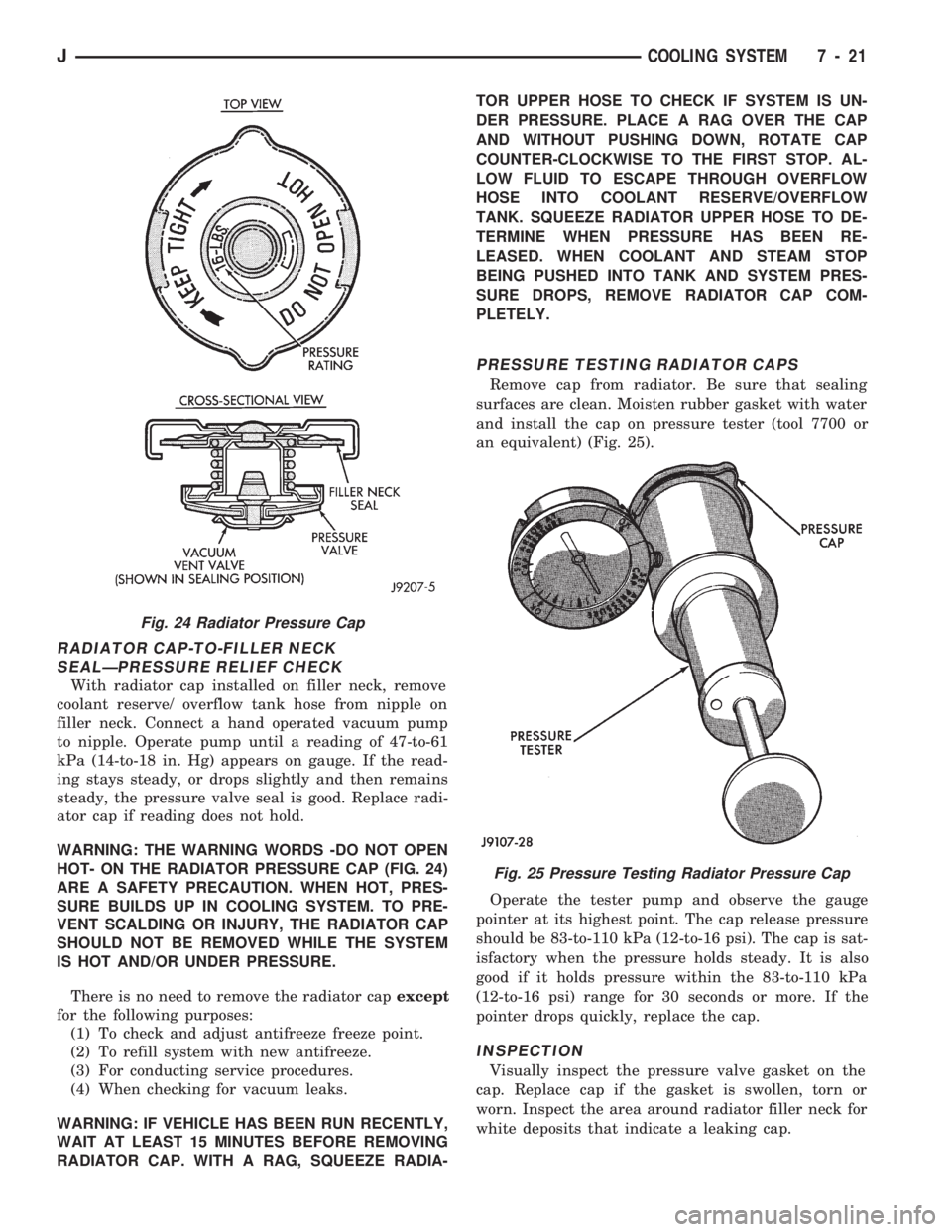

RADIATOR CAP-TO-FILLER NECK

SEALÐPRESSURE RELIEF CHECK

With radiator cap installed on filler neck, remove

coolant reserve/ overflow tank hose from nipple on

filler neck. Connect a hand operated vacuum pump

to nipple. Operate pump until a reading of 47-to-61

kPa (14-to-18 in. Hg) appears on gauge. If the read-

ing stays steady, or drops slightly and then remains

steady, the pressure valve seal is good. Replace radi-

ator cap if reading does not hold.

WARNING: THE WARNING WORDS -DO NOT OPEN

HOT- ON THE RADIATOR PRESSURE CAP (FIG. 24)

ARE A SAFETY PRECAUTION. WHEN HOT, PRES-

SURE BUILDS UP IN COOLING SYSTEM. TO PRE-

VENT SCALDING OR INJURY, THE RADIATOR CAP

SHOULD NOT BE REMOVED WHILE THE SYSTEM

IS HOT AND/OR UNDER PRESSURE.

There is no need to remove the radiator capexcept

for the following purposes:

(1) To check and adjust antifreeze freeze point.

(2) To refill system with new antifreeze.

(3) For conducting service procedures.

(4) When checking for vacuum leaks.

WARNING: IF VEHICLE HAS BEEN RUN RECENTLY,

WAIT AT LEAST 15 MINUTES BEFORE REMOVING

RADIATOR CAP. WITH A RAG, SQUEEZE RADIA-TOR UPPER HOSE TO CHECK IF SYSTEM IS UN-

DER PRESSURE. PLACE A RAG OVER THE CAP

AND WITHOUT PUSHING DOWN, ROTATE CAP

COUNTER-CLOCKWISE TO THE FIRST STOP. AL-

LOW FLUID TO ESCAPE THROUGH OVERFLOW

HOSE INTO COOLANT RESERVE/OVERFLOW

TANK. SQUEEZE RADIATOR UPPER HOSE TO DE-

TERMINE WHEN PRESSURE HAS BEEN RE-

LEASED. WHEN COOLANT AND STEAM STOP

BEING PUSHED INTO TANK AND SYSTEM PRES-

SURE DROPS, REMOVE RADIATOR CAP COM-

PLETELY.

PRESSURE TESTING RADIATOR CAPS

Remove cap from radiator. Be sure that sealing

surfaces are clean. Moisten rubber gasket with water

and install the cap on pressure tester (tool 7700 or

an equivalent) (Fig. 25).

Operate the tester pump and observe the gauge

pointer at its highest point. The cap release pressure

should be 83-to-110 kPa (12-to-16 psi). The cap is sat-

isfactory when the pressure holds steady. It is also

good if it holds pressure within the 83-to-110 kPa

(12-to-16 psi) range for 30 seconds or more. If the

pointer drops quickly, replace the cap.

INSPECTION

Visually inspect the pressure valve gasket on the

cap. Replace cap if the gasket is swollen, torn or

worn. Inspect the area around radiator filler neck for

white deposits that indicate a leaking cap.

Fig. 24 Radiator Pressure Cap

Fig. 25 Pressure Testing Radiator Pressure Cap

JCOOLING SYSTEM 7 - 21

Page 260 of 1784

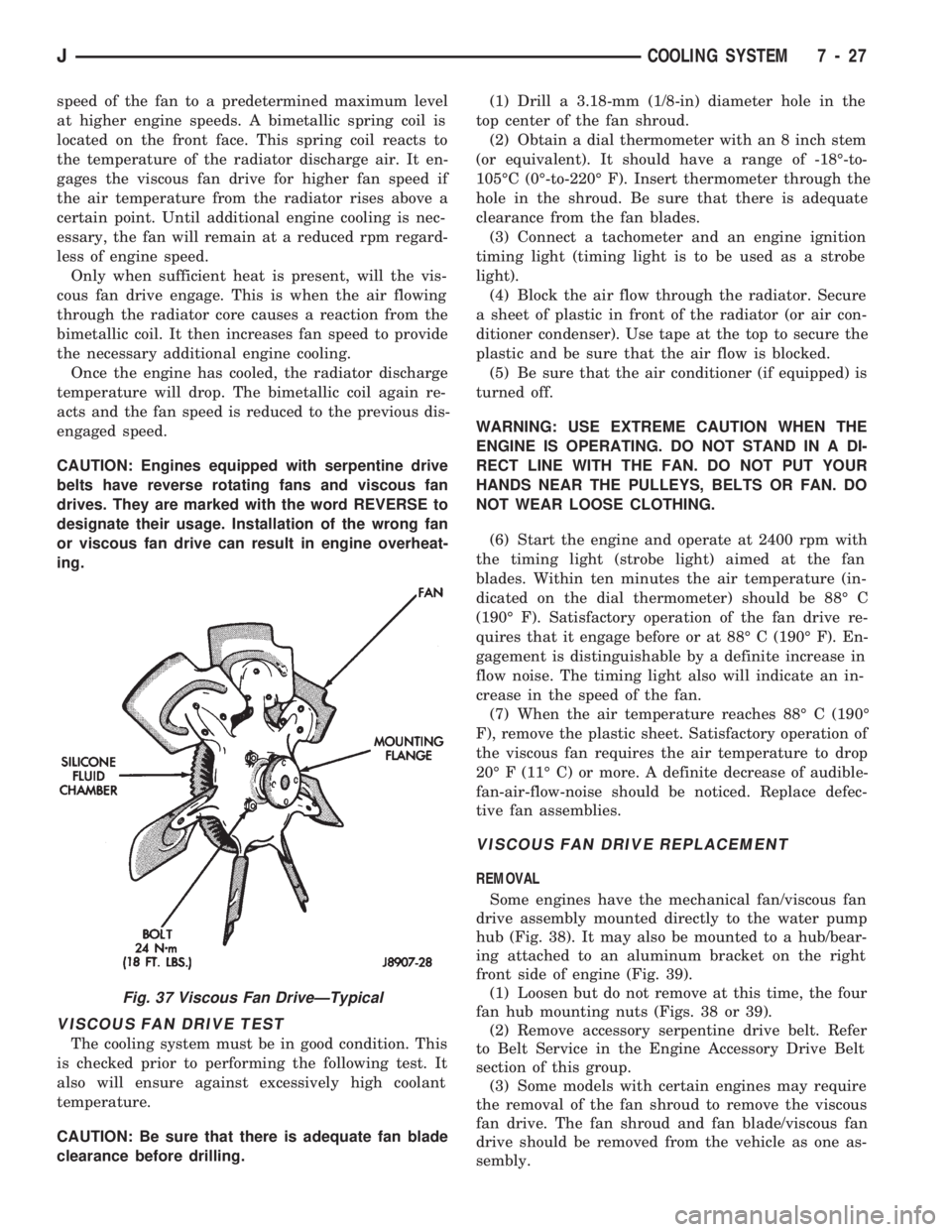

speed of the fan to a predetermined maximum level

at higher engine speeds. A bimetallic spring coil is

located on the front face. This spring coil reacts to

the temperature of the radiator discharge air. It en-

gages the viscous fan drive for higher fan speed if

the air temperature from the radiator rises above a

certain point. Until additional engine cooling is nec-

essary, the fan will remain at a reduced rpm regard-

less of engine speed.

Only when sufficient heat is present, will the vis-

cous fan drive engage. This is when the air flowing

through the radiator core causes a reaction from the

bimetallic coil. It then increases fan speed to provide

the necessary additional engine cooling.

Once the engine has cooled, the radiator discharge

temperature will drop. The bimetallic coil again re-

acts and the fan speed is reduced to the previous dis-

engaged speed.

CAUTION: Engines equipped with serpentine drive

belts have reverse rotating fans and viscous fan

drives. They are marked with the word REVERSE to

designate their usage. Installation of the wrong fan

or viscous fan drive can result in engine overheat-

ing.

VISCOUS FAN DRIVE TEST

The cooling system must be in good condition. This

is checked prior to performing the following test. It

also will ensure against excessively high coolant

temperature.

CAUTION: Be sure that there is adequate fan blade

clearance before drilling.(1) Drill a 3.18-mm (1/8-in) diameter hole in the

top center of the fan shroud.

(2) Obtain a dial thermometer with an 8 inch stem

(or equivalent). It should have a range of -18É-to-

105ÉC (0É-to-220É F). Insert thermometer through the

hole in the shroud. Be sure that there is adequate

clearance from the fan blades.

(3) Connect a tachometer and an engine ignition

timing light (timing light is to be used as a strobe

light).

(4) Block the air flow through the radiator. Secure

a sheet of plastic in front of the radiator (or air con-

ditioner condenser). Use tape at the top to secure the

plastic and be sure that the air flow is blocked.

(5) Be sure that the air conditioner (if equipped) is

turned off.

WARNING: USE EXTREME CAUTION WHEN THE

ENGINE IS OPERATING. DO NOT STAND IN A DI-

RECT LINE WITH THE FAN. DO NOT PUT YOUR

HANDS NEAR THE PULLEYS, BELTS OR FAN. DO

NOT WEAR LOOSE CLOTHING.

(6) Start the engine and operate at 2400 rpm with

the timing light (strobe light) aimed at the fan

blades. Within ten minutes the air temperature (in-

dicated on the dial thermometer) should be 88É C

(190É F). Satisfactory operation of the fan drive re-

quires that it engage before or at 88É C (190É F). En-

gagement is distinguishable by a definite increase in

flow noise. The timing light also will indicate an in-

crease in the speed of the fan.

(7) When the air temperature reaches 88É C (190É

F), remove the plastic sheet. Satisfactory operation of

the viscous fan requires the air temperature to drop

20É F (11É C) or more. A definite decrease of audible-

fan-air-flow-noise should be noticed. Replace defec-

tive fan assemblies.

VISCOUS FAN DRIVE REPLACEMENT

REMOVAL

Some engines have the mechanical fan/viscous fan

drive assembly mounted directly to the water pump

hub (Fig. 38). It may also be mounted to a hub/bear-

ing attached to an aluminum bracket on the right

front side of engine (Fig. 39).

(1) Loosen but do not remove at this time, the four

fan hub mounting nuts (Figs. 38 or 39).

(2) Remove accessory serpentine drive belt. Refer

to Belt Service in the Engine Accessory Drive Belt

section of this group.

(3) Some models with certain engines may require

the removal of the fan shroud to remove the viscous

fan drive. The fan shroud and fan blade/viscous fan

drive should be removed from the vehicle as one as-

sembly.

Fig. 37 Viscous Fan DriveÐTypical

JCOOLING SYSTEM 7 - 27

Page 325 of 1784

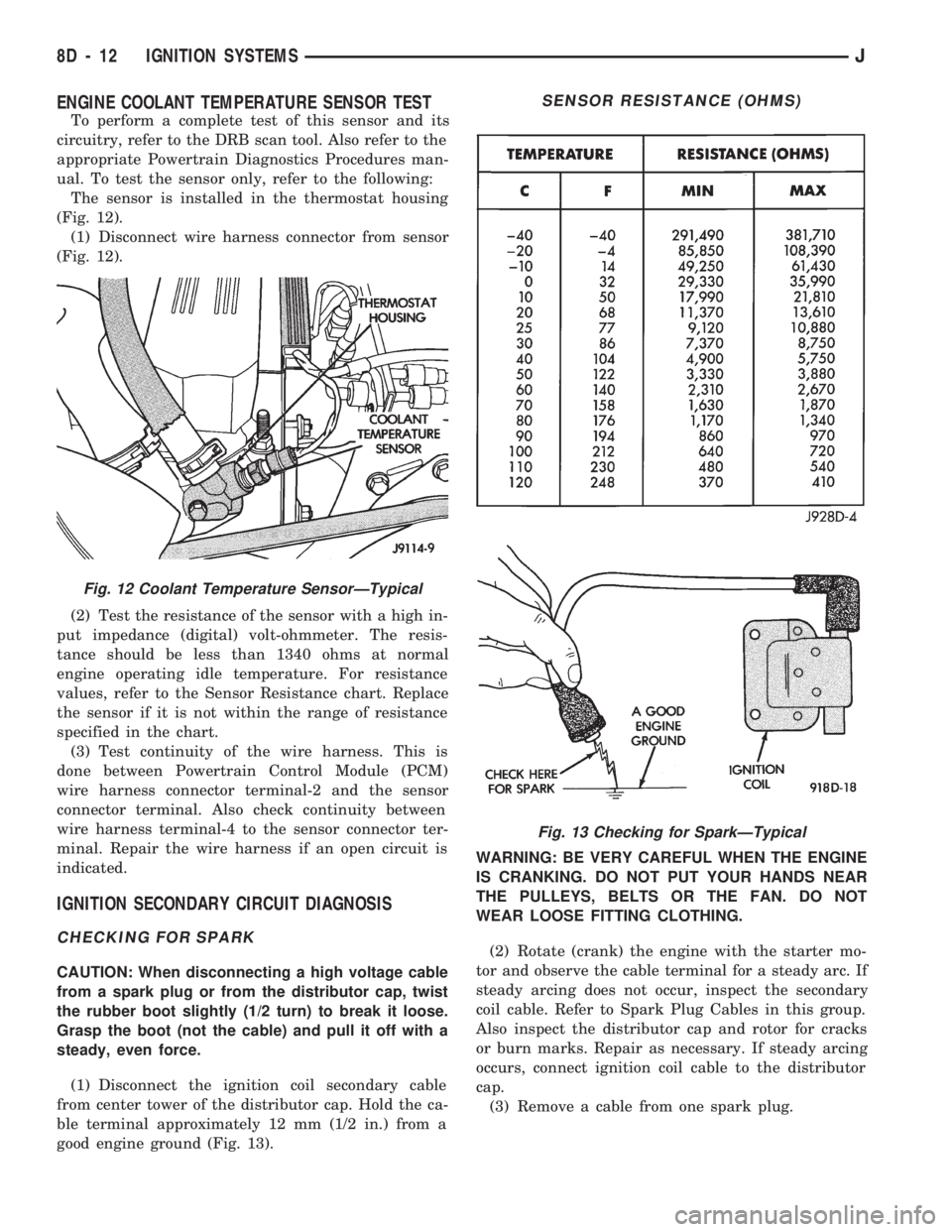

ENGINE COOLANT TEMPERATURE SENSOR TEST

To perform a complete test of this sensor and its

circuitry, refer to the DRB scan tool. Also refer to the

appropriate Powertrain Diagnostics Procedures man-

ual. To test the sensor only, refer to the following:

The sensor is installed in the thermostat housing

(Fig. 12).

(1) Disconnect wire harness connector from sensor

(Fig. 12).

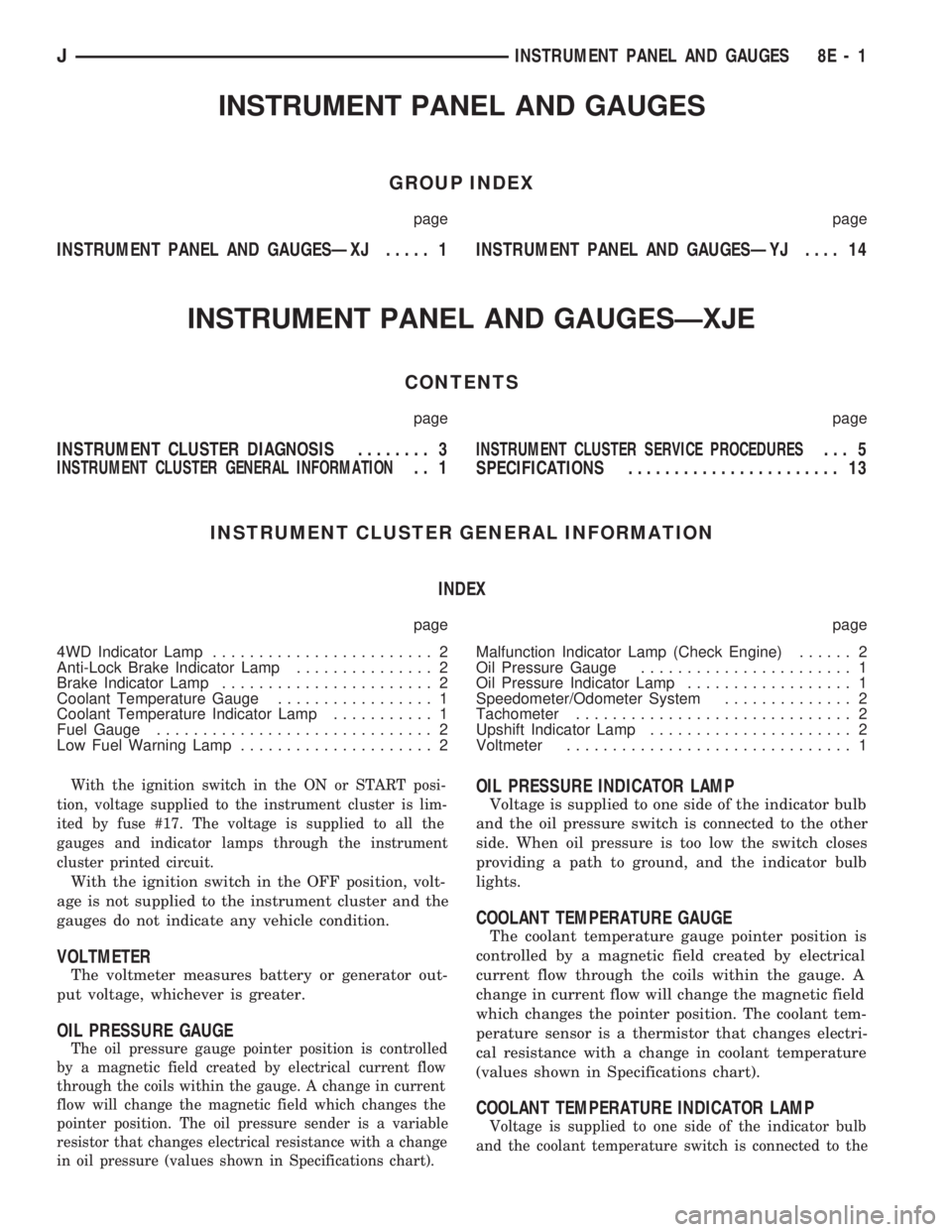

(2) Test the resistance of the sensor with a high in-

put impedance (digital) volt-ohmmeter. The resis-

tance should be less than 1340 ohms at normal

engine operating idle temperature. For resistance

values, refer to the Sensor Resistance chart. Replace

the sensor if it is not within the range of resistance

specified in the chart.

(3) Test continuity of the wire harness. This is

done between Powertrain Control Module (PCM)

wire harness connector terminal-2 and the sensor

connector terminal. Also check continuity between

wire harness terminal-4 to the sensor connector ter-

minal. Repair the wire harness if an open circuit is

indicated.

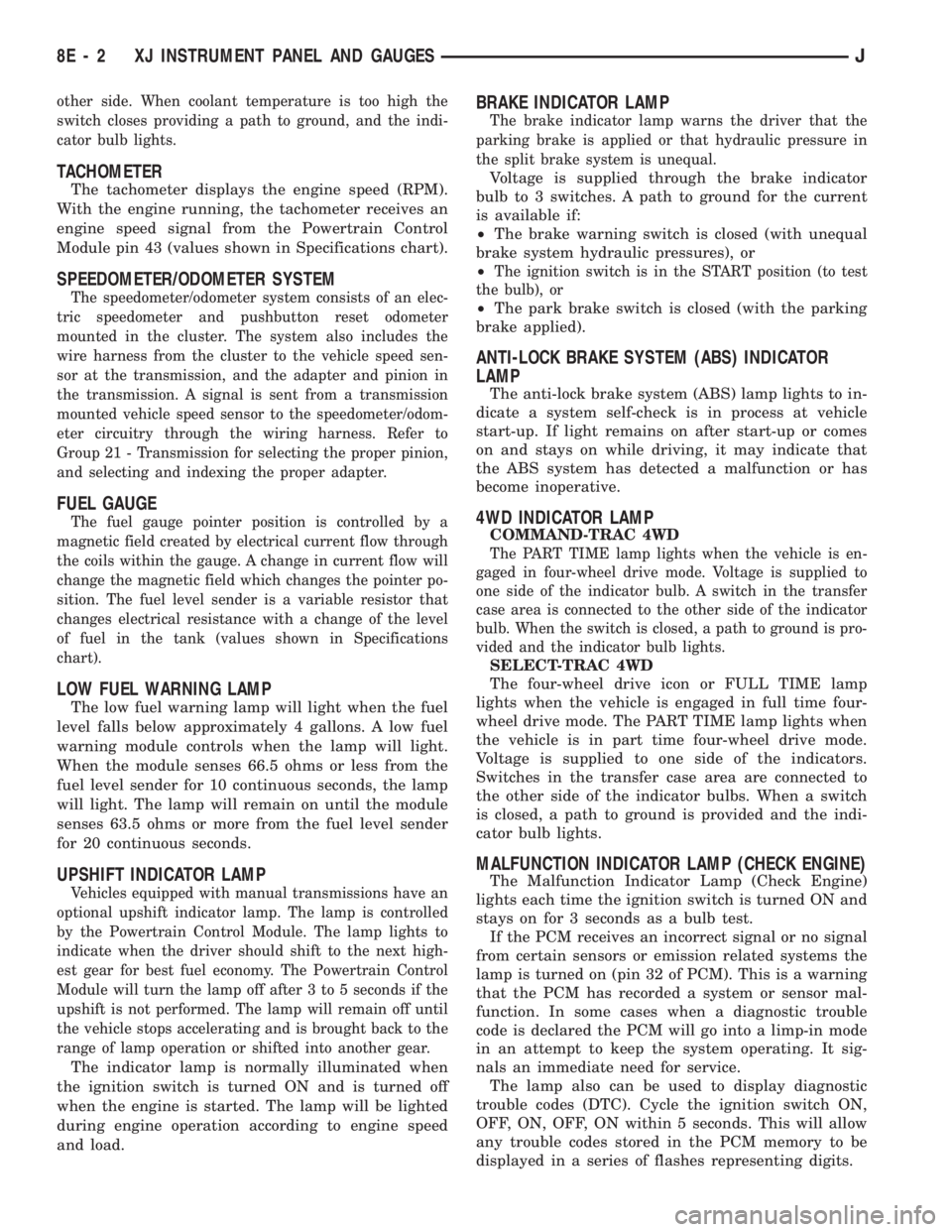

IGNITION SECONDARY CIRCUIT DIAGNOSIS

CHECKING FOR SPARK

CAUTION: When disconnecting a high voltage cable

from a spark plug or from the distributor cap, twist

the rubber boot slightly (1/2 turn) to break it loose.

Grasp the boot (not the cable) and pull it off with a

steady, even force.

(1) Disconnect the ignition coil secondary cable

from center tower of the distributor cap. Hold the ca-

ble terminal approximately 12 mm (1/2 in.) from a

good engine ground (Fig. 13).WARNING: BE VERY CAREFUL WHEN THE ENGINE

IS CRANKING. DO NOT PUT YOUR HANDS NEAR

THE PULLEYS, BELTS OR THE FAN. DO NOT

WEAR LOOSE FITTING CLOTHING.

(2) Rotate (crank) the engine with the starter mo-

tor and observe the cable terminal for a steady arc. If

steady arcing does not occur, inspect the secondary

coil cable. Refer to Spark Plug Cables in this group.

Also inspect the distributor cap and rotor for cracks

or burn marks. Repair as necessary. If steady arcing

occurs, connect ignition coil cable to the distributor

cap.

(3) Remove a cable from one spark plug.

Fig. 12 Coolant Temperature SensorÐTypical

SENSOR RESISTANCE (OHMS)

Fig. 13 Checking for SparkÐTypical

8D - 12 IGNITION SYSTEMSJ

Page 348 of 1784

INSTRUMENT PANEL AND GAUGES

GROUP INDEX

page page

INSTRUMENT PANEL AND GAUGESÐXJ..... 1INSTRUMENT PANEL AND GAUGESÐYJ.... 14

INSTRUMENT PANEL AND GAUGESÐXJE

CONTENTS

page page

INSTRUMENT CLUSTER DIAGNOSIS........ 3

INSTRUMENT CLUSTER GENERAL INFORMATION.. 1

INSTRUMENT CLUSTER SERVICE PROCEDURES... 5

SPECIFICATIONS....................... 13

INSTRUMENT CLUSTER GENERAL INFORMATION

INDEX

page page

4WD Indicator Lamp........................ 2

Anti-Lock Brake Indicator Lamp............... 2

Brake Indicator Lamp....................... 2

Coolant Temperature Gauge................. 1

Coolant Temperature Indicator Lamp........... 1

Fuel Gauge.............................. 2

Low Fuel Warning Lamp..................... 2Malfunction Indicator Lamp (Check Engine)...... 2

Oil Pressure Gauge....................... 1

Oil Pressure Indicator Lamp.................. 1

Speedometer/Odometer System.............. 2

Tachometer.............................. 2

Upshift Indicator Lamp...................... 2

Voltmeter............................... 1

With the ignition switch in the ON or START posi-

tion, voltage supplied to the instrument cluster is lim-

ited by fuse #17. The voltage is supplied to all the

gauges and indicator lamps through the instrument

cluster printed circuit.

With the ignition switch in the OFF position, volt-

age is not supplied to the instrument cluster and the

gauges do not indicate any vehicle condition.

VOLTMETER

The voltmeter measures battery or generator out-

put voltage, whichever is greater.

OIL PRESSURE GAUGE

The oil pressure gauge pointer position is controlled

by a magnetic field created by electrical current flow

through the coils within the gauge. A change in current

flow will change the magnetic field which changes the

pointer position. The oil pressure sender is a variable

resistor that changes electrical resistance with a change

in oil pressure (values shown in Specifications chart).

OIL PRESSURE INDICATOR LAMP

Voltage is supplied to one side of the indicator bulb

and the oil pressure switch is connected to the other

side. When oil pressure is too low the switch closes

providing a path to ground, and the indicator bulb

lights.

COOLANT TEMPERATURE GAUGE

The coolant temperature gauge pointer position is

controlled by a magnetic field created by electrical

current flow through the coils within the gauge. A

change in current flow will change the magnetic field

which changes the pointer position. The coolant tem-

perature sensor is a thermistor that changes electri-

cal resistance with a change in coolant temperature

(values shown in Specifications chart).

COOLANT TEMPERATURE INDICATOR LAMP

Voltage is supplied to one side of the indicator bulb

and the coolant temperature switch is connected to the

JINSTRUMENT PANEL AND GAUGES 8E - 1

Page 349 of 1784

other side. When coolant temperature is too high the

switch closes providing a path to ground, and the indi-

cator bulb lights.

TACHOMETER

The tachometer displays the engine speed (RPM).

With the engine running, the tachometer receives an

engine speed signal from the Powertrain Control

Module pin 43 (values shown in Specifications chart).

SPEEDOMETER/ODOMETER SYSTEM

The speedometer/odometer system consists of an elec-

tric speedometer and pushbutton reset odometer

mounted in the cluster. The system also includes the

wire harness from the cluster to the vehicle speed sen-

sor at the transmission, and the adapter and pinion in

the transmission. A signal is sent from a transmission

mounted vehicle speed sensor to the speedometer/odom-

eter circuitry through the wiring harness. Refer to

Group 21 - Transmission for selecting the proper pinion,

and selecting and indexing the proper adapter.

FUEL GAUGE

The fuel gauge pointer position is controlled by a

magnetic field created by electrical current flow through

the coils within the gauge. A change in current flow will

change the magnetic field which changes the pointer po-

sition. The fuel level sender is a variable resistor that

changes electrical resistance with a change of the level

of fuel in the tank (values shown in Specifications

chart).

LOW FUEL WARNING LAMP

The low fuel warning lamp will light when the fuel

level falls below approximately 4 gallons. A low fuel

warning module controls when the lamp will light.

When the module senses 66.5 ohms or less from the

fuel level sender for 10 continuous seconds, the lamp

will light. The lamp will remain on until the module

senses 63.5 ohms or more from the fuel level sender

for 20 continuous seconds.

UPSHIFT INDICATOR LAMP

Vehicles equipped with manual transmissions have an

optional upshift indicator lamp. The lamp is controlled

by the Powertrain Control Module. The lamp lights to

indicate when the driver should shift to the next high-

est gear for best fuel economy. The Powertrain Control

Module will turn the lamp off after 3 to 5 seconds if the

upshift is not performed. The lamp will remain off until

the vehicle stops accelerating and is brought back to the

range of lamp operation or shifted into another gear.

The indicator lamp is normally illuminated when

the ignition switch is turned ON and is turned off

when the engine is started. The lamp will be lighted

during engine operation according to engine speed

and load.

BRAKE INDICATOR LAMP

The brake indicator lamp warns the driver that the

parking brake is applied or that hydraulic pressure in

the split brake system is unequal.

Voltage is supplied through the brake indicator

bulb to 3 switches. A path to ground for the current

is available if:

²The brake warning switch is closed (with unequal

brake system hydraulic pressures), or

²

The ignition switch is in the START position (to test

the bulb), or

²The park brake switch is closed (with the parking

brake applied).

ANTI-LOCK BRAKE SYSTEM (ABS) INDICATOR

LAMP

The anti-lock brake system (ABS) lamp lights to in-

dicate a system self-check is in process at vehicle

start-up. If light remains on after start-up or comes

on and stays on while driving, it may indicate that

the ABS system has detected a malfunction or has

become inoperative.

4WD INDICATOR LAMP

COMMAND-TRAC 4WD

The PART TIME lamp lights when the vehicle is en-

gaged in four-wheel drive mode. Voltage is supplied to

one side of the indicator bulb. A switch in the transfer

case area is connected to the other side of the indicator

bulb. When the switch is closed, a path to ground is pro-

vided and the indicator bulb lights.

SELECT-TRAC 4WD

The four-wheel drive icon or FULL TIME lamp

lights when the vehicle is engaged in full time four-

wheel drive mode. The PART TIME lamp lights when

the vehicle is in part time four-wheel drive mode.

Voltage is supplied to one side of the indicators.

Switches in the transfer case area are connected to

the other side of the indicator bulbs. When a switch

is closed, a path to ground is provided and the indi-

cator bulb lights.

MALFUNCTION INDICATOR LAMP (CHECK ENGINE)

The Malfunction Indicator Lamp (Check Engine)

lights each time the ignition switch is turned ON and

stays on for 3 seconds as a bulb test.

If the PCM receives an incorrect signal or no signal

from certain sensors or emission related systems the

lamp is turned on (pin 32 of PCM). This is a warning

that the PCM has recorded a system or sensor mal-

function. In some cases when a diagnostic trouble

code is declared the PCM will go into a limp-in mode

in an attempt to keep the system operating. It sig-

nals an immediate need for service.

The lamp also can be used to display diagnostic

trouble codes (DTC). Cycle the ignition switch ON,

OFF, ON, OFF, ON within 5 seconds. This will allow

any trouble codes stored in the PCM memory to be

displayed in a series of flashes representing digits.

8E - 2 XJ INSTRUMENT PANEL AND GAUGESJ

Page 350 of 1784

INSTRUMENT CLUSTER DIAGNOSIS

INDEX

page page

4WD Indicator Inoperative................... 4

Anti-Lock Indicator......................... 4

Brake Indicator Inoperative.................. 4

Coolant Temperature Gauge Inoperative........ 3

Coolant Temperature Indicator Inoperative....... 3

Fuel Gauge Inoperative..................... 3

Gauges and Indicators Inoperative............ 3

Instrument Panel Lamps.................... 4

Low Fuel Warning Inoperative................ 4

Low Washer Indicator Inoperative............. 4Malfunction Indicator Lamp (Check Engine)...... 4

Oil Pressure Gauge Inoperative............... 3

Oil Pressure Indicator Inoperative............. 3

Radio/Clock Illumination.................... 4

Seat Belt Indicator........................ 4

Speedomete/Odometer Inoperative............. 3

Tachometer Inoperative..................... 3

Upshift Indicator Inoperative................. 4

Voltmeter Inoperative....................... 3

SPEEDOMETER/ODOMETER INOPERATIVE

(1) Check for continuity in the wire between the

vehicle speed sensor and cluster connector pin A5.

(2) With the ignition switch in the ON position,

check for battery voltage across pin A8 (B+) and pin

B2 (ground).

(3) Perform vehicle speed sensor test. Refer to the

appropriate vehicle Diagnostic Test Procedures man-

ual.

(4) If all the previous tests prove good, replace

speedometer/odometer.

GAUGES AND INDICATORS INOPERATIVE

(1) Remove and inspect fuse #17. Replace as re-

quired.

(2) Measure resistance at instrument cluster con-

nector terminal A3. Meter should read zero ohms. If

not, repair open to ground.

VOLTMETER INOPERATIVE

(1) Turn ignition switch to ON. Voltmeter should

read battery voltage. If not, go to step 2.

(2) Measure voltage at instrument cluster connec-

tor terminal A8. Meter should read battery voltage.

If OK, replace meter. If not, repair open to fuse #17.

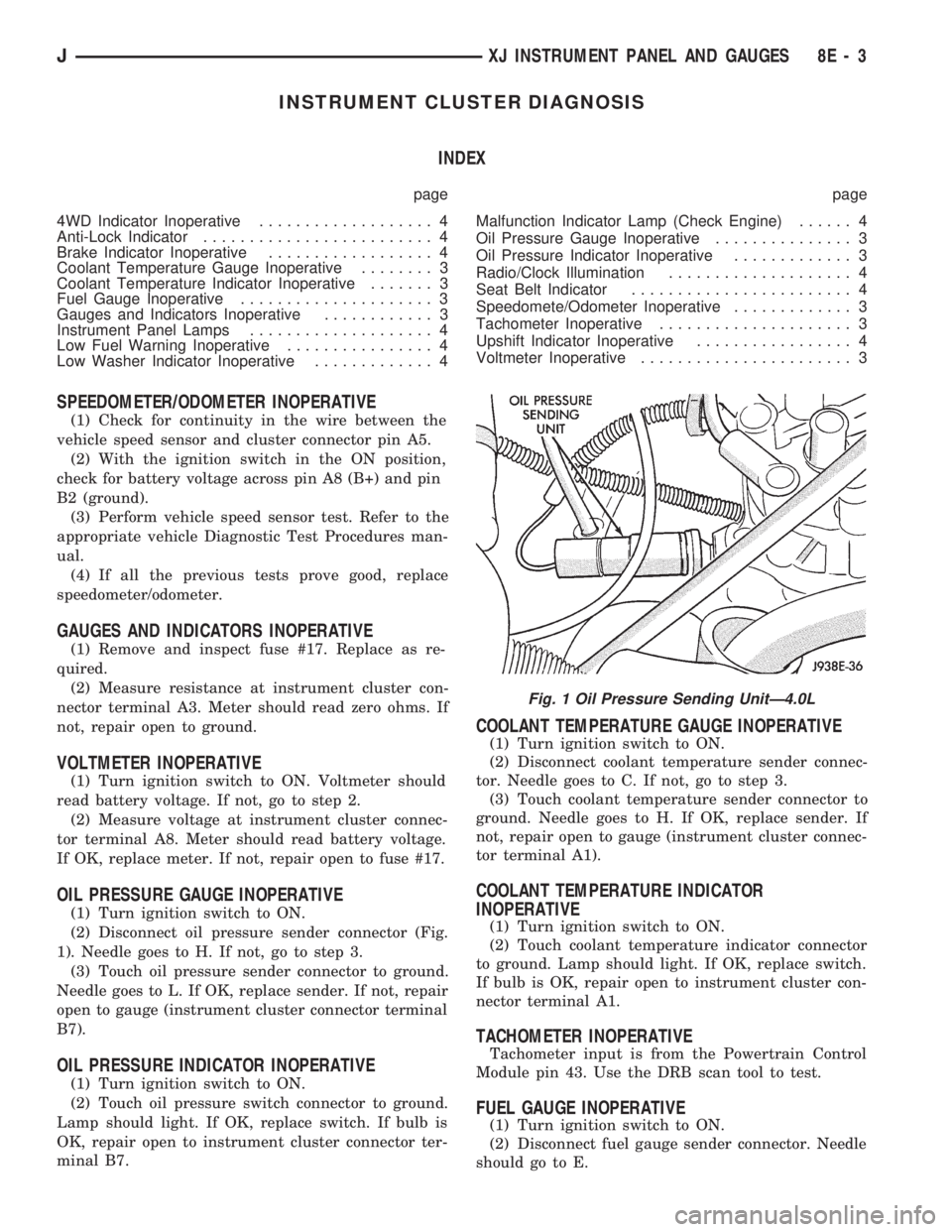

OIL PRESSURE GAUGE INOPERATIVE

(1) Turn ignition switch to ON.

(2) Disconnect oil pressure sender connector (Fig.

1). Needle goes to H. If not, go to step 3.

(3) Touch oil pressure sender connector to ground.

Needle goes to L. If OK, replace sender. If not, repair

open to gauge (instrument cluster connector terminal

B7).

OIL PRESSURE INDICATOR INOPERATIVE

(1) Turn ignition switch to ON.

(2) Touch oil pressure switch connector to ground.

Lamp should light. If OK, replace switch. If bulb is

OK, repair open to instrument cluster connector ter-

minal B7.

COOLANT TEMPERATURE GAUGE INOPERATIVE

(1) Turn ignition switch to ON.

(2) Disconnect coolant temperature sender connec-

tor. Needle goes to C. If not, go to step 3.

(3) Touch coolant temperature sender connector to

ground. Needle goes to H. If OK, replace sender. If

not, repair open to gauge (instrument cluster connec-

tor terminal A1).

COOLANT TEMPERATURE INDICATOR

INOPERATIVE

(1) Turn ignition switch to ON.

(2) Touch coolant temperature indicator connector

to ground. Lamp should light. If OK, replace switch.

If bulb is OK, repair open to instrument cluster con-

nector terminal A1.

TACHOMETER INOPERATIVE

Tachometer input is from the Powertrain Control

Module pin 43. Use the DRB scan tool to test.

FUEL GAUGE INOPERATIVE

(1) Turn ignition switch to ON.

(2) Disconnect fuel gauge sender connector. Needle

should go to E.

Fig. 1 Oil Pressure Sending UnitÐ4.0L

JXJ INSTRUMENT PANEL AND GAUGES 8E - 3

Page 351 of 1784

(3) Connect a jumper between terminal A and B on

the body half of the fuel gauge sender connector. The

gauge should move to F. If gauge is OK, replace

sender. If not, go to step 4.

(4) Measure resistance of sender. Meter should

read 105 to 5 ohms. If OK, go to step 5. If not, re-

place sender.

(5) Check for an open between sender connector

and gauge. If OK, replace gauge. If not, repair open

to gauge.

LOW FUEL WARNING INOPERATIVE

(1) Turn ignition switch to ON.

(2) Disconnect terminal B1 of the instrument clus-

ter connector. Wait at least 10 seconds. Lamp (LED)

should light. If OK, replace sender. If not, replace

low fuel warning module.

UPSHIFT INDICATOR INOPERATIVE

(1) Turn ignition switch to ON.

(2) Ground pin 7 of connector B. Lamp should

light. If not, replace bulb. If OK, continue with

step 3.

(3) Turn ignition switch to OFF. Check for conti-

nuity between connector B pin 2 and pin 54 of the

Powertrain Control Module. If OK, replace PCM. If

not, repair open.

BRAKE INDICATOR INOPERATIVE

(1) Turn ignition switch to ON. Apply parking

brake, brake warning switch connector unplugged.

(2) Jumper brake warning switch connector termi-

nal B to ground. Lamp should light. If bulb is OK,

repair open to indicator.

(3) Turn ignition switch to OFF. Measure resis-

tance between brake warning switch connector ter-

minal A and ground. Meter should read zero ohms. If

OK, check switch and/or brake system. If not, repair

open to park brake switch ground.

4WD INDICATOR INOPERATIVE

(1) Apply parking brake, start engine, vehicle in

4WD Lock or 4WD.

(2) Unplug switch and touch harness side of wire

to ground. Lamp should light. If OK, check switch

operation, replace if bad. If bulb is OK, repair open

to indicator.

LOW WASHER INDICATOR INOPERATIVE

(1) Turn ignition switch to ON.

(2) Jumper 12 volts to fluid level switch connector

terminal B. Lamp should light. If not, go to step 3.

(3) Measure resistance between terminal B and

ground. Meter should read zero ohms. If not, repair

open to bulb. If OK, go to step 4.

(4) Measure voltage at fluid level switch connector

terminal A. Meter should read battery voltage. If

OK, replace switch. If not, repair open to fuse.

MALFUNCTION INDICATOR LAMP (CHECK ENGINE)

(1) Turn ignition switch to ON.

(2) Jumper Powertrain Control Module terminal 2

to ground. Lamp should light. If bulb is OK, check

for open to instrument cluster connector terminal 2.

ANTI-LOCK INDICATOR

(1) Turn ignition switch to ON.

(2) Jumper instrument cluster connector terminal

6 to ground. Lamp should light. If bulb is OK, check

wiring for an open to module. Refer to Group 5 -

Brakes.

SEAT BELT INDICATOR

Jumper instrument cluster connector terminal 15

to 12 volts. Lamp should light. If not, replace bulb. If

OK, check wiring for an open to buzzer module. Re-

fer to Group 8U - Chime/Buzzer Warning Systems.

RADIO/CLOCK ILLUMINATION

With the ignition switch in ACCESSORY or ON,

power comes from the radio fuse. It then goes

through the normally closed contacts of the radio il-

lumination relay to the radio at connector terminal

11.

Pulling the headlamp switch to ON energizes the

radio illumination relay. This closes the normally

open contacts of the relay, and the brightness for the

radio display is controlled by the headlamp switch

rheostat. The back-lighting for the radio is also con-

trolled by the headlamp rheostat through radio con-

nector terminal 10.

Refer to Group 8F - Audio Systems, for radio illu-

mination relay diagnosis.

INSTRUMENT PANEL LAMPS

Voltage is supplied at all times from the 40 amp

Maxi fuse (located in the Power Distribution Center)

through the park lamps fuse to the headlamp switch.

The circuit continues through the instrument lamps

fuse to the individual instrument panel lamps to

ground. Lamp brightness is controlled by turning the

headlamp switch knob.

DIAGNOSIS

(1) Turn parking lamps ON.

(2) Check park lamps fuse. Replace as required.

(3) Check instrument lamps fuse. Replace as re-

quired.

(4) Measure voltage at battery side of instrument

lamps fuse with rheostat turned counterclockwise to

clockwise (LO to HI). Meter should read zero volts to

battery voltage. If not, replace headlamp switch.

(5) Measure resistance at ground side of instru-

ment lamps fuse with parking lamps OFF. Meter

should read almost zero ohms (except bulb filament).

If not, repair open to ground. If zero ohms, 12 volt

supply wire from fuse is shorted to ground, repair short.

8E - 4 XJ INSTRUMENT PANEL AND GAUGESJ

Page 353 of 1784

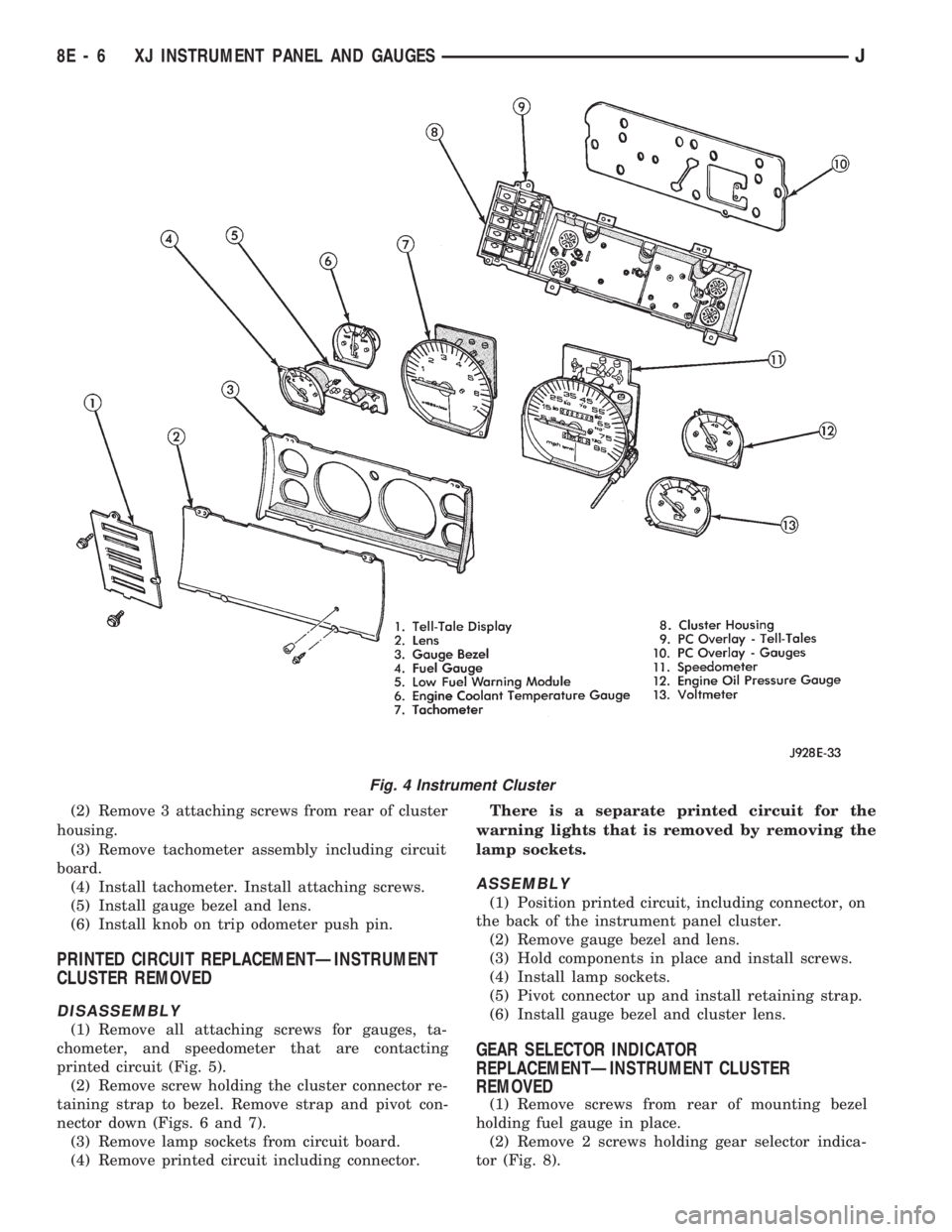

(2) Remove 3 attaching screws from rear of cluster

housing.

(3) Remove tachometer assembly including circuit

board.

(4) Install tachometer. Install attaching screws.

(5) Install gauge bezel and lens.

(6) Install knob on trip odometer push pin.

PRINTED CIRCUIT REPLACEMENTÐINSTRUMENT

CLUSTER REMOVED

DISASSEMBLY

(1) Remove all attaching screws for gauges, ta-

chometer, and speedometer that are contacting

printed circuit (Fig. 5).

(2) Remove screw holding the cluster connector re-

taining strap to bezel. Remove strap and pivot con-

nector down (Figs. 6 and 7).

(3) Remove lamp sockets from circuit board.

(4) Remove printed circuit including connector.There is a separate printed circuit for the

warning lights that is removed by removing the

lamp sockets.

ASSEMBLY

(1) Position printed circuit, including connector, on

the back of the instrument panel cluster.

(2) Remove gauge bezel and lens.

(3) Hold components in place and install screws.

(4) Install lamp sockets.

(5) Pivot connector up and install retaining strap.

(6) Install gauge bezel and cluster lens.

GEAR SELECTOR INDICATOR

REPLACEMENTÐINSTRUMENT CLUSTER

REMOVED

(1) Remove screws from rear of mounting bezel

holding fuel gauge in place.

(2) Remove 2 screws holding gear selector indica-

tor (Fig. 8).

Fig. 4 Instrument Cluster

8E - 6 XJ INSTRUMENT PANEL AND GAUGESJ