front JEEP CHEROKEE 1994 Service Repair Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 1994, Model line: CHEROKEE, Model: JEEP CHEROKEE 1994Pages: 1784, PDF Size: 77.09 MB

Page 1054 of 1784

STEERING LINKAGEÐYJ

INDEX

page page

Drag Link.............................. 17

Pitman Arm............................. 18

Service Information....................... 17Steering Dampener....................... 18

Tie Rod ................................ 17

SERVICE INFORMATION

The steering linkage consists of a pitman arm, drag

link, tie rod, and steering dampener. Adjustment

sleeves are used on the tie rod and drag link for toe

and steering wheel alignment.

Refer to Group 2, Front Suspension and Axle for

additional information.

The tie-rod end ball stud seals should be inspected

during all oil changes.

A damaged ball stud seal requires removal of the

seal. Inspect the tie-rod end ball stud at the throat

opening. Check for lubricant loss, contamination, ball

stud wear or corrosion. If these conditions exist, re-

place the tie-rod. A replacement seal can be installed

if lubricant is in good condition. Otherwise, a com-

plete replacement ball stud end should be installed.

Lubricate the tie-rod end with MOPARtMulti-Mile-

age Lubricant, or equivalent product.

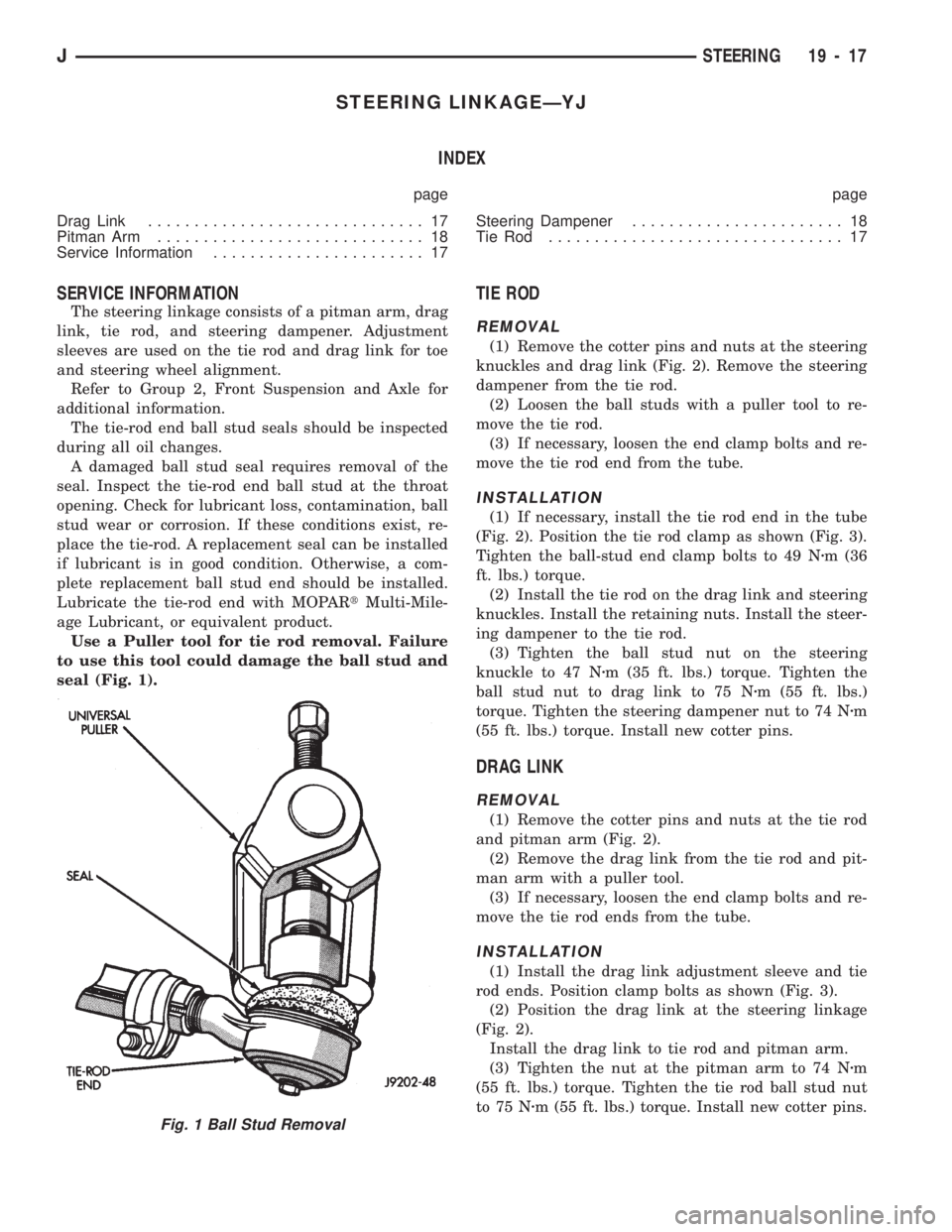

Use a Puller tool for tie rod removal. Failure

to use this tool could damage the ball stud and

seal (Fig. 1).

TIE ROD

REMOVAL

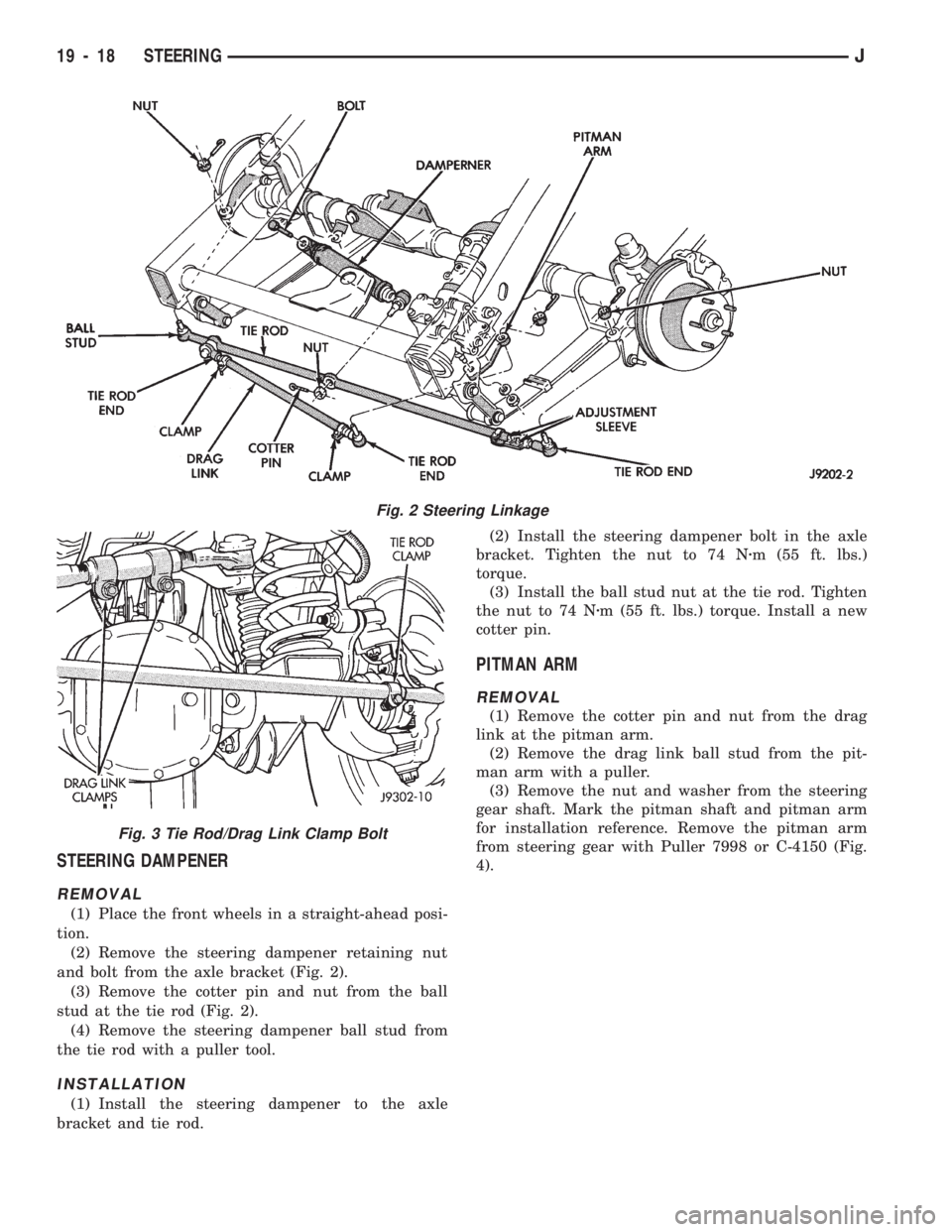

(1) Remove the cotter pins and nuts at the steering

knuckles and drag link (Fig. 2). Remove the steering

dampener from the tie rod.

(2) Loosen the ball studs with a puller tool to re-

move the tie rod.

(3) If necessary, loosen the end clamp bolts and re-

move the tie rod end from the tube.

INSTALLATION

(1) If necessary, install the tie rod end in the tube

(Fig. 2). Position the tie rod clamp as shown (Fig. 3).

Tighten the ball-stud end clamp bolts to 49 Nzm (36

ft. lbs.) torque.

(2) Install the tie rod on the drag link and steering

knuckles. Install the retaining nuts. Install the steer-

ing dampener to the tie rod.

(3) Tighten the ball stud nut on the steering

knuckle to 47 Nzm (35 ft. lbs.) torque. Tighten the

ball stud nut to drag link to 75 Nzm (55 ft. lbs.)

torque. Tighten the steering dampener nut to 74 Nzm

(55 ft. lbs.) torque. Install new cotter pins.

DRAG LINK

REMOVAL

(1) Remove the cotter pins and nuts at the tie rod

and pitman arm (Fig. 2).

(2) Remove the drag link from the tie rod and pit-

man arm with a puller tool.

(3) If necessary, loosen the end clamp bolts and re-

move the tie rod ends from the tube.

INSTALLATION

(1) Install the drag link adjustment sleeve and tie

rod ends. Position clamp bolts as shown (Fig. 3).

(2) Position the drag link at the steering linkage

(Fig. 2).

Install the drag link to tie rod and pitman arm.

(3) Tighten the nut at the pitman arm to 74 Nzm

(55 ft. lbs.) torque. Tighten the tie rod ball stud nut

to 75 Nzm (55 ft. lbs.) torque. Install new cotter pins.

Fig. 1 Ball Stud Removal

JSTEERING 19 - 17

Page 1055 of 1784

STEERING DAMPENER

REMOVAL

(1) Place the front wheels in a straight-ahead posi-

tion.

(2) Remove the steering dampener retaining nut

and bolt from the axle bracket (Fig. 2).

(3) Remove the cotter pin and nut from the ball

stud at the tie rod (Fig. 2).

(4) Remove the steering dampener ball stud from

the tie rod with a puller tool.

INSTALLATION

(1) Install the steering dampener to the axle

bracket and tie rod.(2) Install the steering dampener bolt in the axle

bracket. Tighten the nut to 74 Nzm (55 ft. lbs.)

torque.

(3) Install the ball stud nut at the tie rod. Tighten

the nut to 74 Nzm (55 ft. lbs.) torque. Install a new

cotter pin.

PITMAN ARM

REMOVAL

(1) Remove the cotter pin and nut from the drag

link at the pitman arm.

(2) Remove the drag link ball stud from the pit-

man arm with a puller.

(3) Remove the nut and washer from the steering

gear shaft. Mark the pitman shaft and pitman arm

for installation reference. Remove the pitman arm

from steering gear with Puller 7998 or C-4150 (Fig.

4).

Fig. 2 Steering Linkage

Fig. 3 Tie Rod/Drag Link Clamp Bolt

19 - 18 STEERINGJ

Page 1058 of 1784

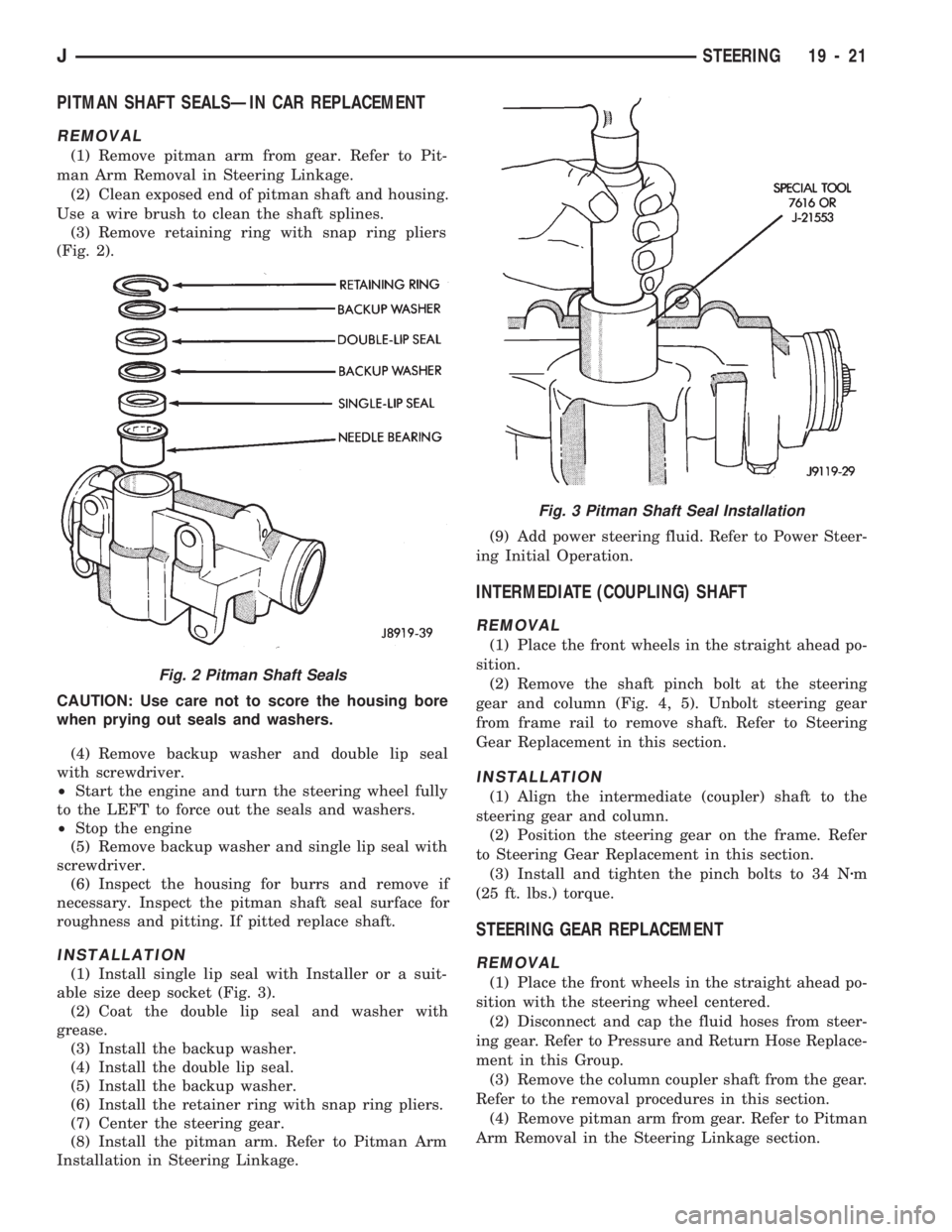

PITMAN SHAFT SEALSÐIN CAR REPLACEMENT

REMOVAL

(1) Remove pitman arm from gear. Refer to Pit-

man Arm Removal in Steering Linkage.

(2) Clean exposed end of pitman shaft and housing.

Use a wire brush to clean the shaft splines.

(3) Remove retaining ring with snap ring pliers

(Fig. 2).

CAUTION: Use care not to score the housing bore

when prying out seals and washers.

(4) Remove backup washer and double lip seal

with screwdriver.

²Start the engine and turn the steering wheel fully

to the LEFT to force out the seals and washers.

²Stop the engine

(5) Remove backup washer and single lip seal with

screwdriver.

(6) Inspect the housing for burrs and remove if

necessary. Inspect the pitman shaft seal surface for

roughness and pitting. If pitted replace shaft.

INSTALLATION

(1) Install single lip seal with Installer or a suit-

able size deep socket (Fig. 3).

(2) Coat the double lip seal and washer with

grease.

(3) Install the backup washer.

(4) Install the double lip seal.

(5) Install the backup washer.

(6) Install the retainer ring with snap ring pliers.

(7) Center the steering gear.

(8) Install the pitman arm. Refer to Pitman Arm

Installation in Steering Linkage.(9) Add power steering fluid. Refer to Power Steer-

ing Initial Operation.

INTERMEDIATE (COUPLING) SHAFT

REMOVAL

(1) Place the front wheels in the straight ahead po-

sition.

(2) Remove the shaft pinch bolt at the steering

gear and column (Fig. 4, 5). Unbolt steering gear

from frame rail to remove shaft. Refer to Steering

Gear Replacement in this section.

INSTALLATION

(1) Align the intermediate (coupler) shaft to the

steering gear and column.

(2) Position the steering gear on the frame. Refer

to Steering Gear Replacement in this section.

(3) Install and tighten the pinch bolts to 34 Nzm

(25 ft. lbs.) torque.

STEERING GEAR REPLACEMENT

REMOVAL

(1) Place the front wheels in the straight ahead po-

sition with the steering wheel centered.

(2) Disconnect and cap the fluid hoses from steer-

ing gear. Refer to Pressure and Return Hose Replace-

ment in this Group.

(3) Remove the column coupler shaft from the gear.

Refer to the removal procedures in this section.

(4) Remove pitman arm from gear. Refer to Pitman

Arm Removal in the Steering Linkage section.

Fig. 2 Pitman Shaft Seals

Fig. 3 Pitman Shaft Seal Installation

JSTEERING 19 - 21

Page 1080 of 1784

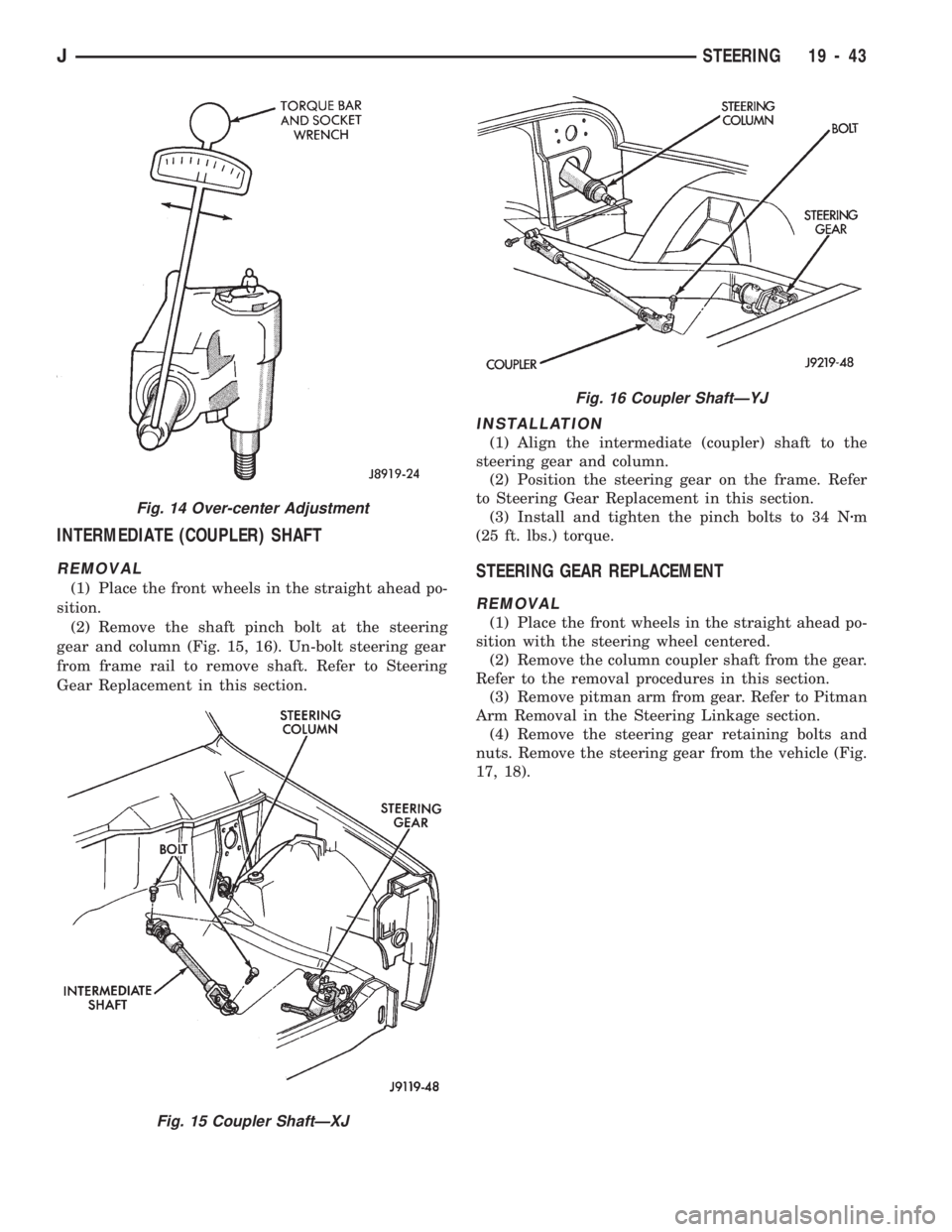

INTERMEDIATE (COUPLER) SHAFT

REMOVAL

(1) Place the front wheels in the straight ahead po-

sition.

(2) Remove the shaft pinch bolt at the steering

gear and column (Fig. 15, 16). Un-bolt steering gear

from frame rail to remove shaft. Refer to Steering

Gear Replacement in this section.

INSTALLATION

(1) Align the intermediate (coupler) shaft to the

steering gear and column.

(2) Position the steering gear on the frame. Refer

to Steering Gear Replacement in this section.

(3) Install and tighten the pinch bolts to 34 Nzm

(25 ft. lbs.) torque.

STEERING GEAR REPLACEMENT

REMOVAL

(1) Place the front wheels in the straight ahead po-

sition with the steering wheel centered.

(2) Remove the column coupler shaft from the gear.

Refer to the removal procedures in this section.

(3) Remove pitman arm from gear. Refer to Pitman

Arm Removal in the Steering Linkage section.

(4) Remove the steering gear retaining bolts and

nuts. Remove the steering gear from the vehicle (Fig.

17, 18).

Fig. 14 Over-center Adjustment

Fig. 15 Coupler ShaftÐXJ

Fig. 16 Coupler ShaftÐYJ

JSTEERING 19 - 43

Page 1082 of 1784

STEERING COLUMN GENERAL SERVICE

INDEX

page page

Column ReplacementÐXJ.................. 46

Column ReplacementÐYJ.................. 48

Park-Lock CableÐConsole Shift Automatic..... 45Service Information....................... 45

Steering Wheel.......................... 45

SERVICE INFORMATION

The column may be disassembled and reassembled.

Also most steering column components can be ser-

viced without removing the column from the vehicle.

For additional information, refer to Group 8H, Elec-

trical.

CAUTION: Bumping, jolting and hammering on the

steering column shaft and gear shift tube must be

avoided during all service procedures.

CAUTION: Disconnect negative (ground) cable from

the battery before servicing any component on the

column.

Safety goggles should be worn at all times

when involved with steering column service.

STEERING WHEEL

REMOVAL

(1) Make sure the front wheels are in thestraight

aheadposition.

(2) Disconnect the negative (ground) cable from the

battery.

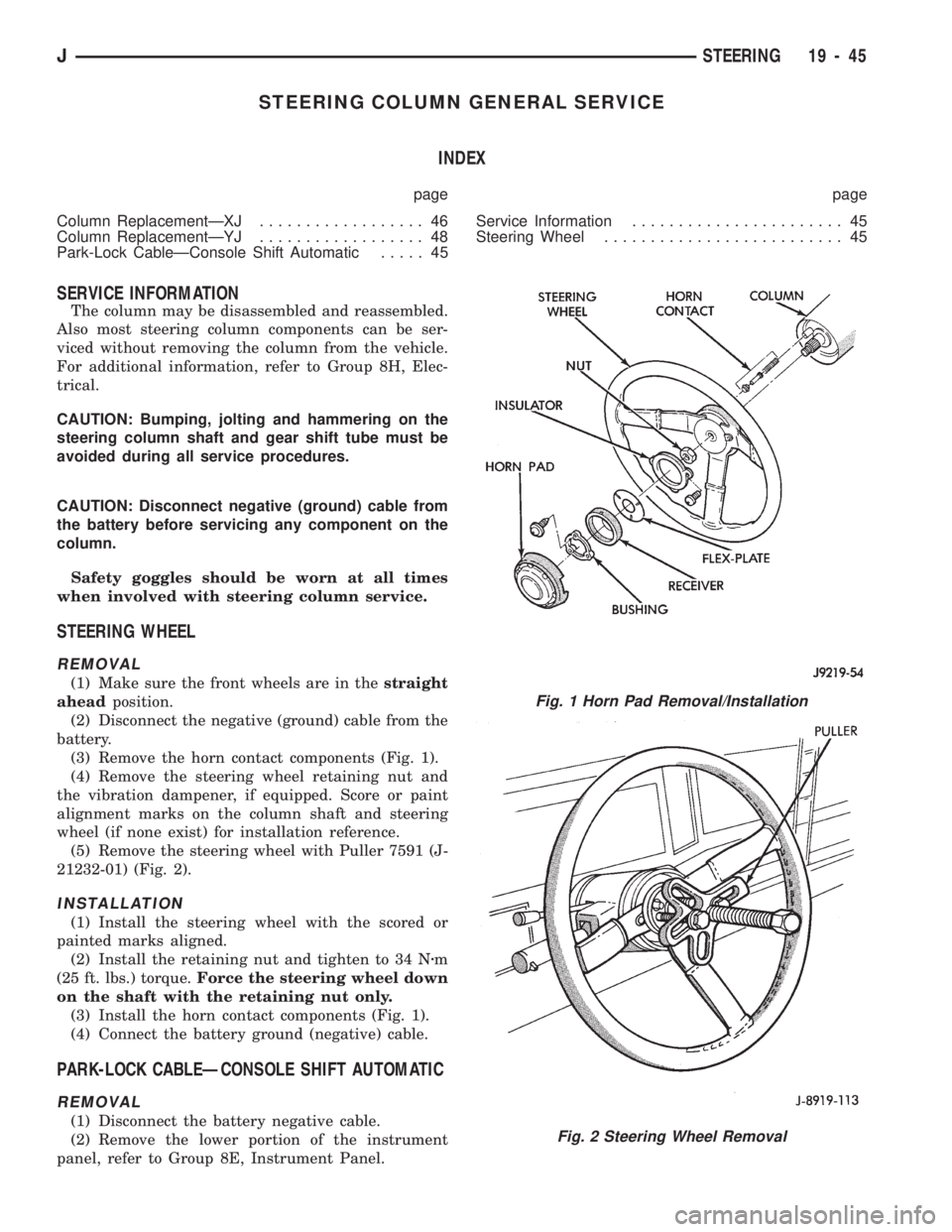

(3) Remove the horn contact components (Fig. 1).

(4) Remove the steering wheel retaining nut and

the vibration dampener, if equipped. Score or paint

alignment marks on the column shaft and steering

wheel (if none exist) for installation reference.

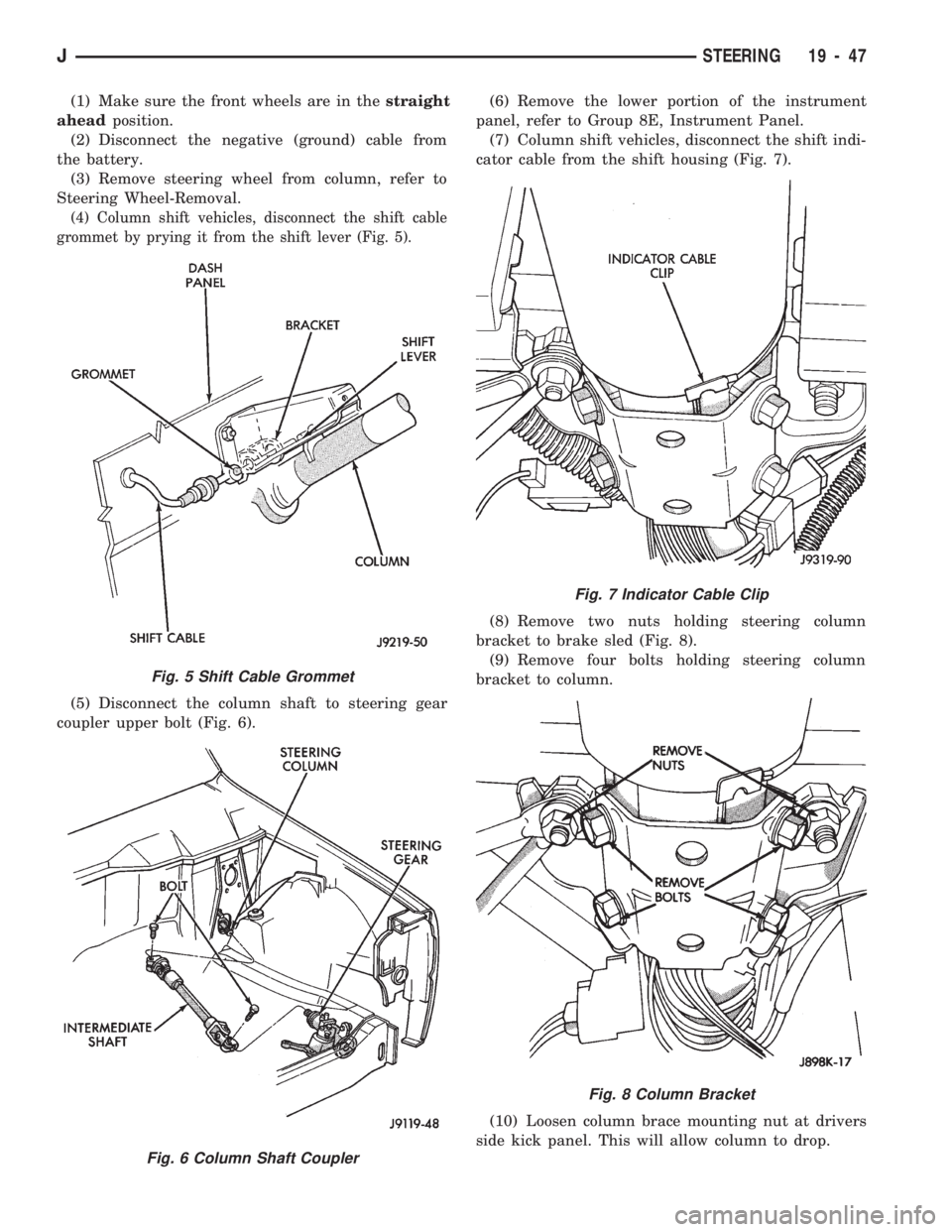

(5) Remove the steering wheel with Puller 7591 (J-

21232-01) (Fig. 2).

INSTALLATION

(1) Install the steering wheel with the scored or

painted marks aligned.

(2) Install the retaining nut and tighten to 34 Nzm

(25 ft. lbs.) torque.Force the steering wheel down

on the shaft with the retaining nut only.

(3) Install the horn contact components (Fig. 1).

(4) Connect the battery ground (negative) cable.

PARK-LOCK CABLEÐCONSOLE SHIFT AUTOMATIC

REMOVAL

(1) Disconnect the battery negative cable.

(2) Remove the lower portion of the instrument

panel, refer to Group 8E, Instrument Panel.

Fig. 1 Horn Pad Removal/Installation

Fig. 2 Steering Wheel Removal

JSTEERING 19 - 45

Page 1084 of 1784

(1) Make sure the front wheels are in thestraight

aheadposition.

(2) Disconnect the negative (ground) cable from

the battery.

(3) Remove steering wheel from column, refer to

Steering Wheel-Removal.

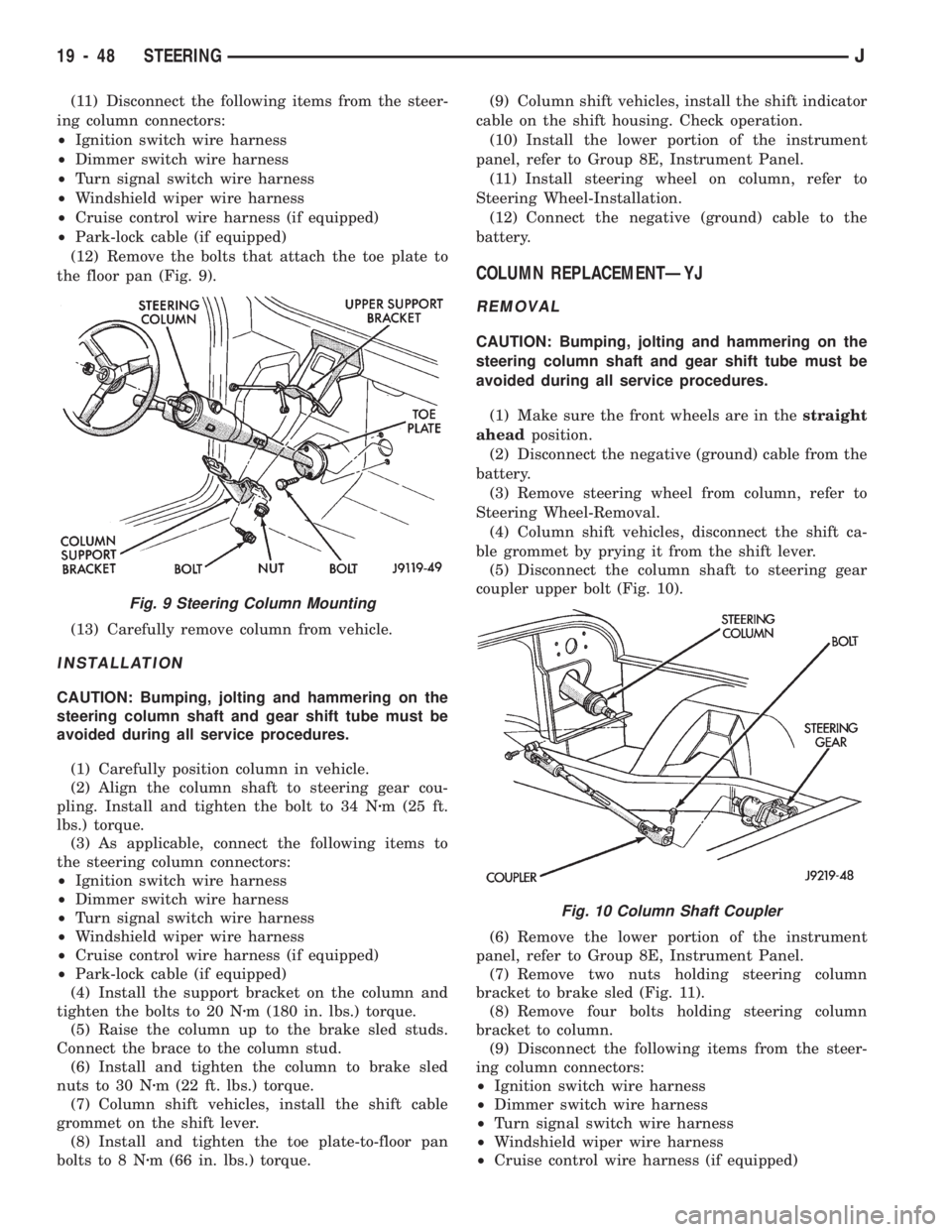

(4) Column shift vehicles, disconnect the shift cable

grommet by prying it from the shift lever (Fig. 5).

(5) Disconnect the column shaft to steering gear

coupler upper bolt (Fig. 6).(6) Remove the lower portion of the instrument

panel, refer to Group 8E, Instrument Panel.

(7) Column shift vehicles, disconnect the shift indi-

cator cable from the shift housing (Fig. 7).

(8) Remove two nuts holding steering column

bracket to brake sled (Fig. 8).

(9) Remove four bolts holding steering column

bracket to column.

(10) Loosen column brace mounting nut at drivers

side kick panel. This will allow column to drop.

Fig. 5 Shift Cable Grommet

Fig. 6 Column Shaft Coupler

Fig. 7 Indicator Cable Clip

Fig. 8 Column Bracket

JSTEERING 19 - 47

Page 1085 of 1784

(11) Disconnect the following items from the steer-

ing column connectors:

²Ignition switch wire harness

²Dimmer switch wire harness

²Turn signal switch wire harness

²Windshield wiper wire harness

²Cruise control wire harness (if equipped)

²Park-lock cable (if equipped)

(12) Remove the bolts that attach the toe plate to

the floor pan (Fig. 9).

(13) Carefully remove column from vehicle.

INSTALLATION

CAUTION: Bumping, jolting and hammering on the

steering column shaft and gear shift tube must be

avoided during all service procedures.

(1) Carefully position column in vehicle.

(2) Align the column shaft to steering gear cou-

pling. Install and tighten the bolt to 34 Nzm (25 ft.

lbs.) torque.

(3) As applicable, connect the following items to

the steering column connectors:

²Ignition switch wire harness

²Dimmer switch wire harness

²Turn signal switch wire harness

²Windshield wiper wire harness

²Cruise control wire harness (if equipped)

²Park-lock cable (if equipped)

(4) Install the support bracket on the column and

tighten the bolts to 20 Nzm (180 in. lbs.) torque.

(5) Raise the column up to the brake sled studs.

Connect the brace to the column stud.

(6) Install and tighten the column to brake sled

nuts to 30 Nzm (22 ft. lbs.) torque.

(7) Column shift vehicles, install the shift cable

grommet on the shift lever.

(8) Install and tighten the toe plate-to-floor pan

bolts to 8 Nzm (66 in. lbs.) torque.(9) Column shift vehicles, install the shift indicator

cable on the shift housing. Check operation.

(10) Install the lower portion of the instrument

panel, refer to Group 8E, Instrument Panel.

(11) Install steering wheel on column, refer to

Steering Wheel-Installation.

(12) Connect the negative (ground) cable to the

battery.

COLUMN REPLACEMENTÐYJ

REMOVAL

CAUTION: Bumping, jolting and hammering on the

steering column shaft and gear shift tube must be

avoided during all service procedures.

(1) Make sure the front wheels are in thestraight

aheadposition.

(2) Disconnect the negative (ground) cable from the

battery.

(3) Remove steering wheel from column, refer to

Steering Wheel-Removal.

(4) Column shift vehicles, disconnect the shift ca-

ble grommet by prying it from the shift lever.

(5) Disconnect the column shaft to steering gear

coupler upper bolt (Fig. 10).

(6) Remove the lower portion of the instrument

panel, refer to Group 8E, Instrument Panel.

(7) Remove two nuts holding steering column

bracket to brake sled (Fig. 11).

(8) Remove four bolts holding steering column

bracket to column.

(9) Disconnect the following items from the steer-

ing column connectors:

²Ignition switch wire harness

²Dimmer switch wire harness

²Turn signal switch wire harness

²Windshield wiper wire harness

²Cruise control wire harness (if equipped)

Fig. 9 Steering Column Mounting

Fig. 10 Column Shaft Coupler

19 - 48 STEERINGJ

Page 1091 of 1784

(8) Use a blunt punch to exert force on the block

tooth to disengage and remove the lock sector (Fig.

16).

The steering column must be removed from

the vehicle to disassemble the remaining steer-

ing column components.

(9) Remove the steering shaft (if not previously re-

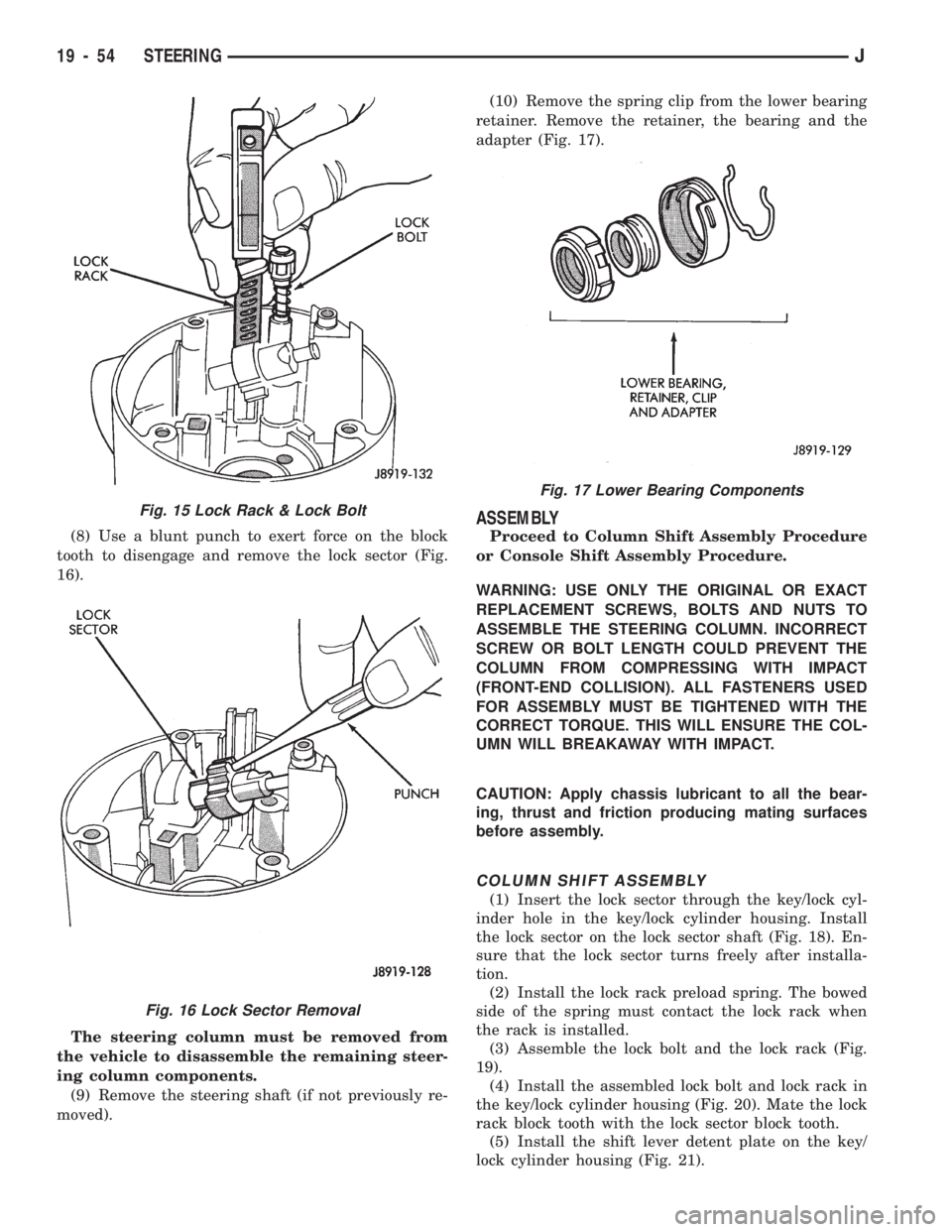

moved).(10) Remove the spring clip from the lower bearing

retainer. Remove the retainer, the bearing and the

adapter (Fig. 17).

ASSEMBLY

Proceed to Column Shift Assembly Procedure

or Console Shift Assembly Procedure.

WARNING: USE ONLY THE ORIGINAL OR EXACT

REPLACEMENT SCREWS, BOLTS AND NUTS TO

ASSEMBLE THE STEERING COLUMN. INCORRECT

SCREW OR BOLT LENGTH COULD PREVENT THE

COLUMN FROM COMPRESSING WITH IMPACT

(FRONT-END COLLISION). ALL FASTENERS USED

FOR ASSEMBLY MUST BE TIGHTENED WITH THE

CORRECT TORQUE. THIS WILL ENSURE THE COL-

UMN WILL BREAKAWAY WITH IMPACT.

CAUTION: Apply chassis lubricant to all the bear-

ing, thrust and friction producing mating surfaces

before assembly.

COLUMN SHIFT ASSEMBLY

(1) Insert the lock sector through the key/lock cyl-

inder hole in the key/lock cylinder housing. Install

the lock sector on the lock sector shaft (Fig. 18). En-

sure that the lock sector turns freely after installa-

tion.

(2) Install the lock rack preload spring. The bowed

side of the spring must contact the lock rack when

the rack is installed.

(3) Assemble the lock bolt and the lock rack (Fig.

19).

(4) Install the assembled lock bolt and lock rack in

the key/lock cylinder housing (Fig. 20). Mate the lock

rack block tooth with the lock sector block tooth.

(5) Install the shift lever detent plate on the key/

lock cylinder housing (Fig. 21).

Fig. 17 Lower Bearing Components

Fig. 15 Lock Rack & Lock Bolt

Fig. 16 Lock Sector Removal

19 - 54 STEERINGJ

Page 1096 of 1784

TILT STEERING COLUMN

DISASSEMBLY

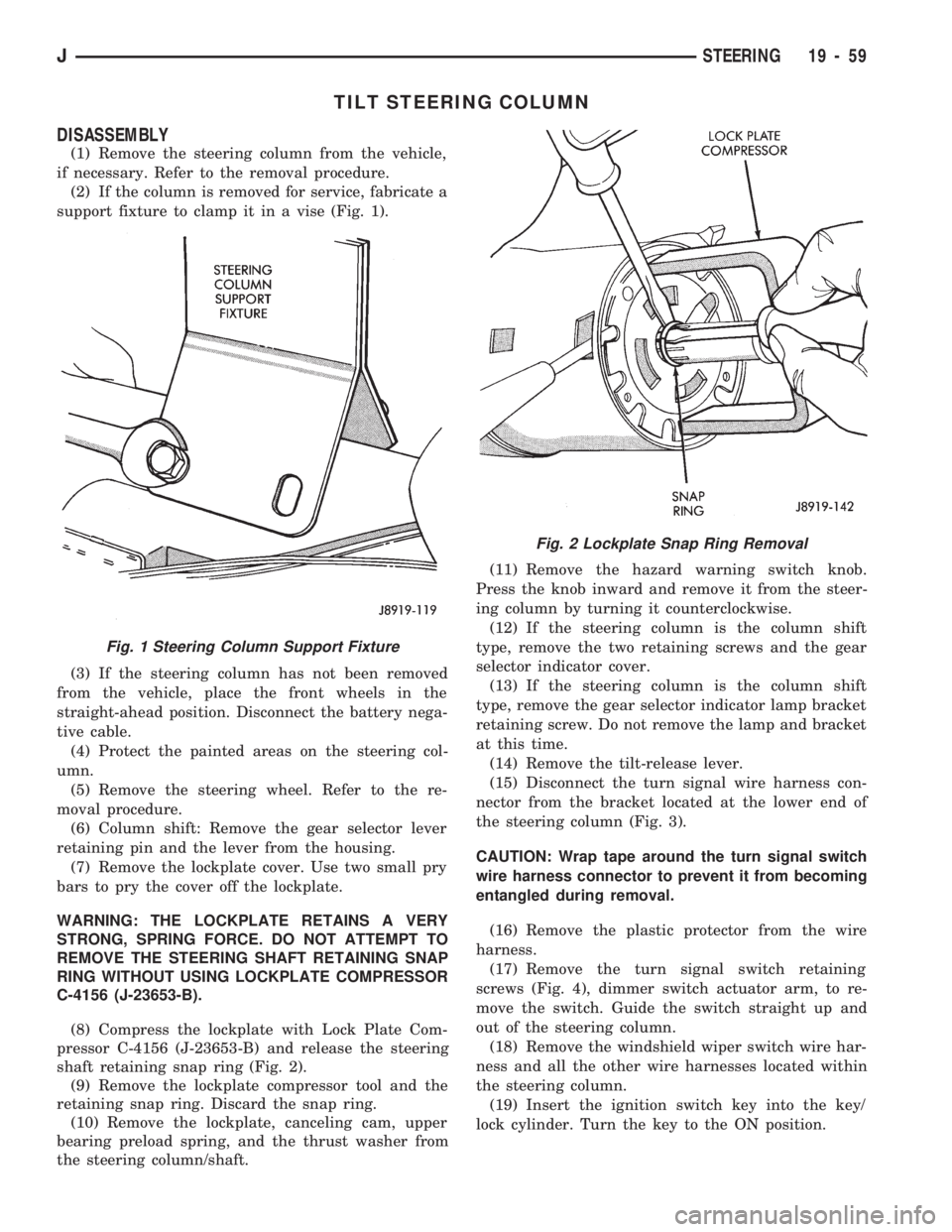

(1) Remove the steering column from the vehicle,

if necessary. Refer to the removal procedure.

(2) If the column is removed for service, fabricate a

support fixture to clamp it in a vise (Fig. 1).

(3) If the steering column has not been removed

from the vehicle, place the front wheels in the

straight-ahead position. Disconnect the battery nega-

tive cable.

(4) Protect the painted areas on the steering col-

umn.

(5) Remove the steering wheel. Refer to the re-

moval procedure.

(6) Column shift: Remove the gear selector lever

retaining pin and the lever from the housing.

(7) Remove the lockplate cover. Use two small pry

bars to pry the cover off the lockplate.

WARNING: THE LOCKPLATE RETAINS A VERY

STRONG, SPRING FORCE. DO NOT ATTEMPT TO

REMOVE THE STEERING SHAFT RETAINING SNAP

RING WITHOUT USING LOCKPLATE COMPRESSOR

C-4156 (J-23653-B).

(8) Compress the lockplate with Lock Plate Com-

pressor C-4156 (J-23653-B) and release the steering

shaft retaining snap ring (Fig. 2).

(9) Remove the lockplate compressor tool and the

retaining snap ring. Discard the snap ring.

(10) Remove the lockplate, canceling cam, upper

bearing preload spring, and the thrust washer from

the steering column/shaft.(11) Remove the hazard warning switch knob.

Press the knob inward and remove it from the steer-

ing column by turning it counterclockwise.

(12) If the steering column is the column shift

type, remove the two retaining screws and the gear

selector indicator cover.

(13) If the steering column is the column shift

type, remove the gear selector indicator lamp bracket

retaining screw. Do not remove the lamp and bracket

at this time.

(14) Remove the tilt-release lever.

(15) Disconnect the turn signal wire harness con-

nector from the bracket located at the lower end of

the steering column (Fig. 3).

CAUTION: Wrap tape around the turn signal switch

wire harness connector to prevent it from becoming

entangled during removal.

(16) Remove the plastic protector from the wire

harness.

(17) Remove the turn signal switch retaining

screws (Fig. 4), dimmer switch actuator arm, to re-

move the switch. Guide the switch straight up and

out of the steering column.

(18) Remove the windshield wiper switch wire har-

ness and all the other wire harnesses located within

the steering column.

(19) Insert the ignition switch key into the key/

lock cylinder. Turn the key to the ON position.

Fig. 1 Steering Column Support Fixture

Fig. 2 Lockplate Snap Ring Removal

JSTEERING 19 - 59

Page 1101 of 1784

ASSEMBLY

WARNING: USE ONLY THE ORIGINAL OR EXACT

REPLACEMENT SCREWS, BOLTS AND NUTS TO

ASSEMBLE THE STEERING COLUMN. INCORRECT

SCREW OR BOLT LENGTH COULD PREVENT THE

COLUMN FROM COMPRESSING WITH IMPACT

(FRONT-END COLLISION). ALL FASTENERS USED

FOR ASSEMBLY MUST BE TIGHTENED WITH THE

CORRECT TORQUE. THIS WILL ENSURE THE COL-

UMN WILL BREAKAWAY WITH IMPACT.CAUTION: Apply chassis lubricant to all the bear-

ing, thrust and friction producing mating surfaces

before assembly.

COLUMN SHIFT ASSEMBLY

(1) Install the shift bowl on the steering column

jacket.

(2) Install the shift tube spring, wave washer and

retainer plate in the shift bowl.

(3) Insert the shift tube through the lower end of

the steering column jacket. Align the tube key/spline

with the shift bowl keyway.

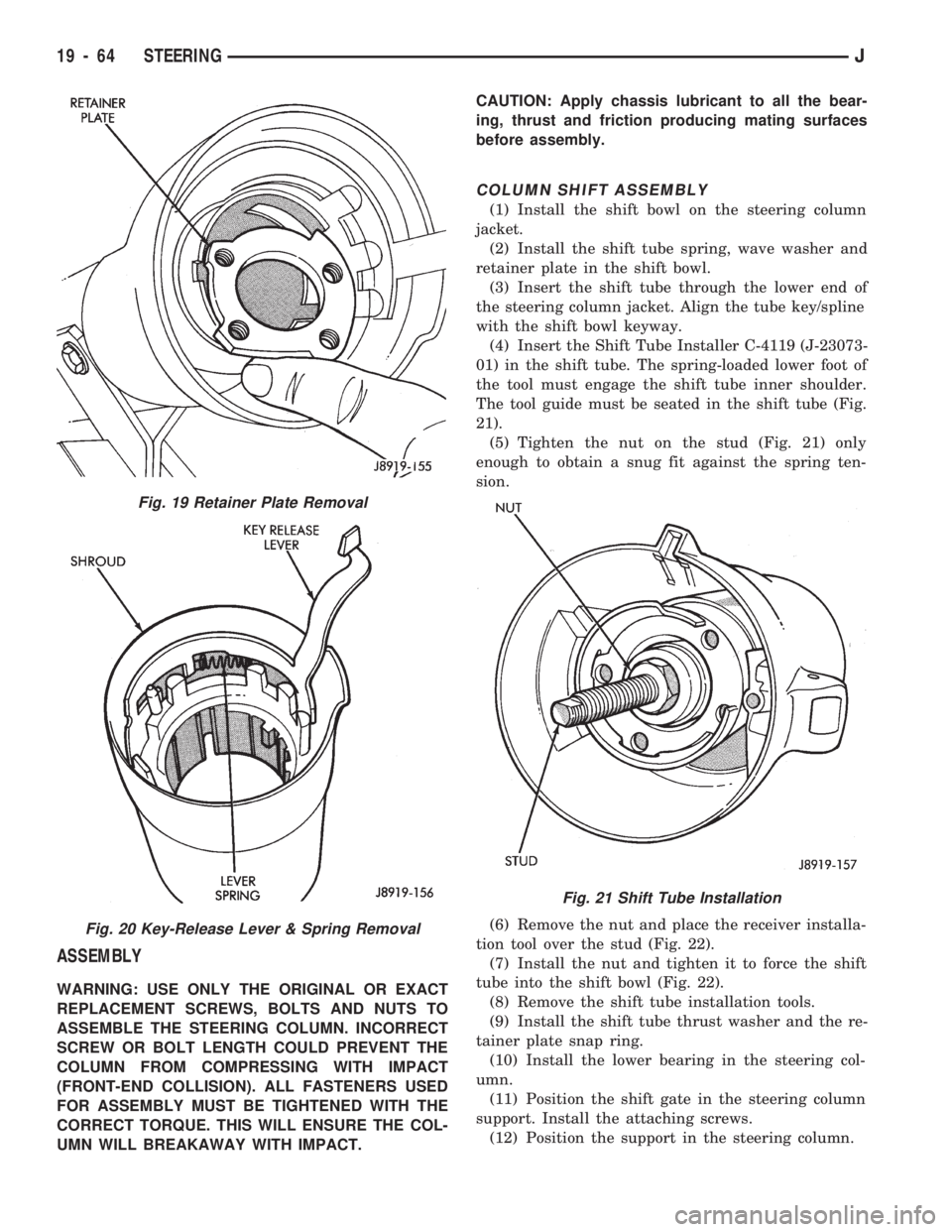

(4) Insert the Shift Tube Installer C-4119 (J-23073-

01) in the shift tube. The spring-loaded lower foot of

the tool must engage the shift tube inner shoulder.

The tool guide must be seated in the shift tube (Fig.

21).

(5) Tighten the nut on the stud (Fig. 21) only

enough to obtain a snug fit against the spring ten-

sion.

(6) Remove the nut and place the receiver installa-

tion tool over the stud (Fig. 22).

(7) Install the nut and tighten it to force the shift

tube into the shift bowl (Fig. 22).

(8) Remove the shift tube installation tools.

(9) Install the shift tube thrust washer and the re-

tainer plate snap ring.

(10) Install the lower bearing in the steering col-

umn.

(11) Position the shift gate in the steering column

support. Install the attaching screws.

(12) Position the support in the steering column.

Fig. 19 Retainer Plate Removal

Fig. 20 Key-Release Lever & Spring Removal

Fig. 21 Shift Tube Installation

19 - 64 STEERINGJ