front JEEP CHEROKEE 1994 Service Repair Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 1994, Model line: CHEROKEE, Model: JEEP CHEROKEE 1994Pages: 1784, PDF Size: 77.09 MB

Page 1108 of 1784

PUMP REPLACEMENT

REMOVAL

(1) Remove and cap pressure and return lines from

pump. Refer to Pressure and Return Line Replace-

ment in this section.

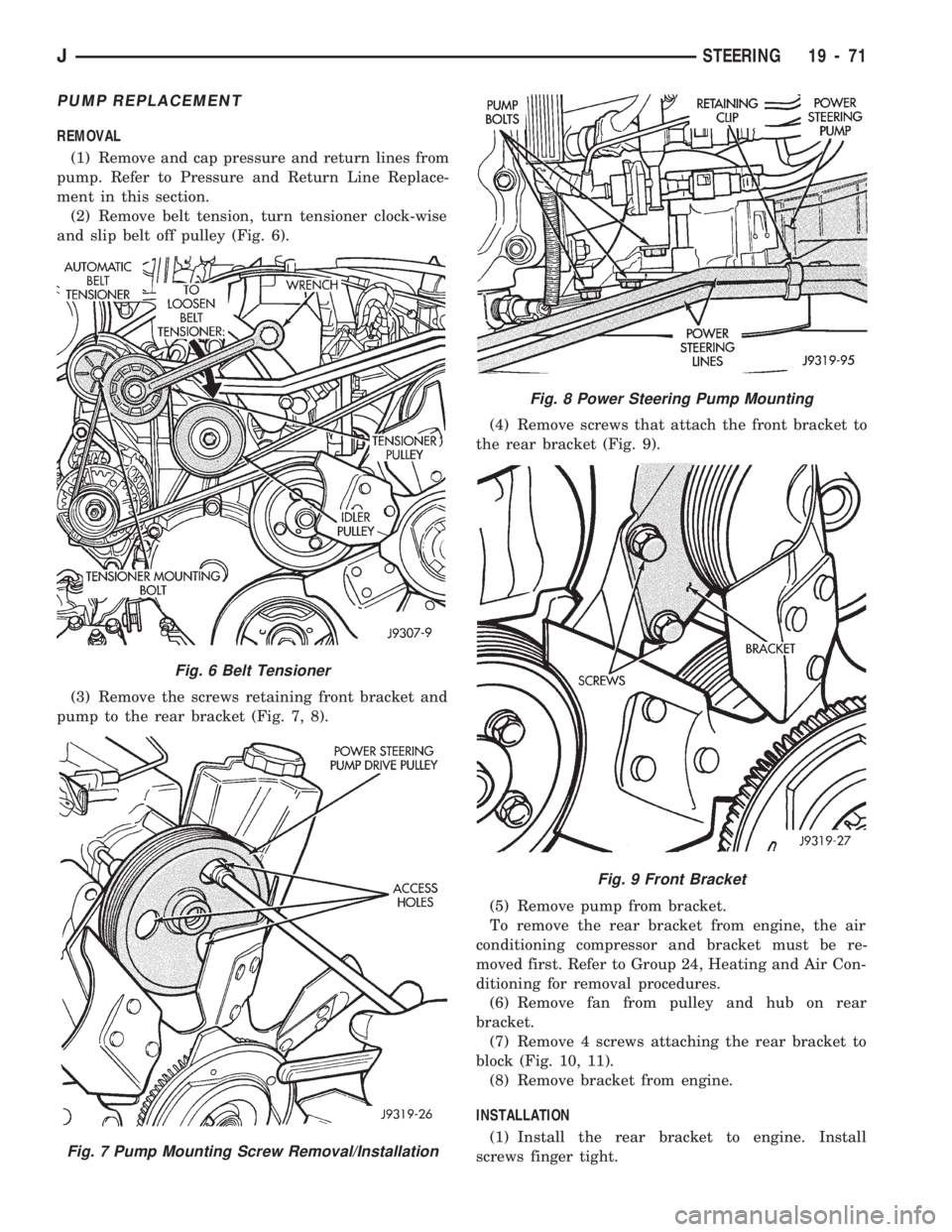

(2) Remove belt tension, turn tensioner clock-wise

and slip belt off pulley (Fig. 6).

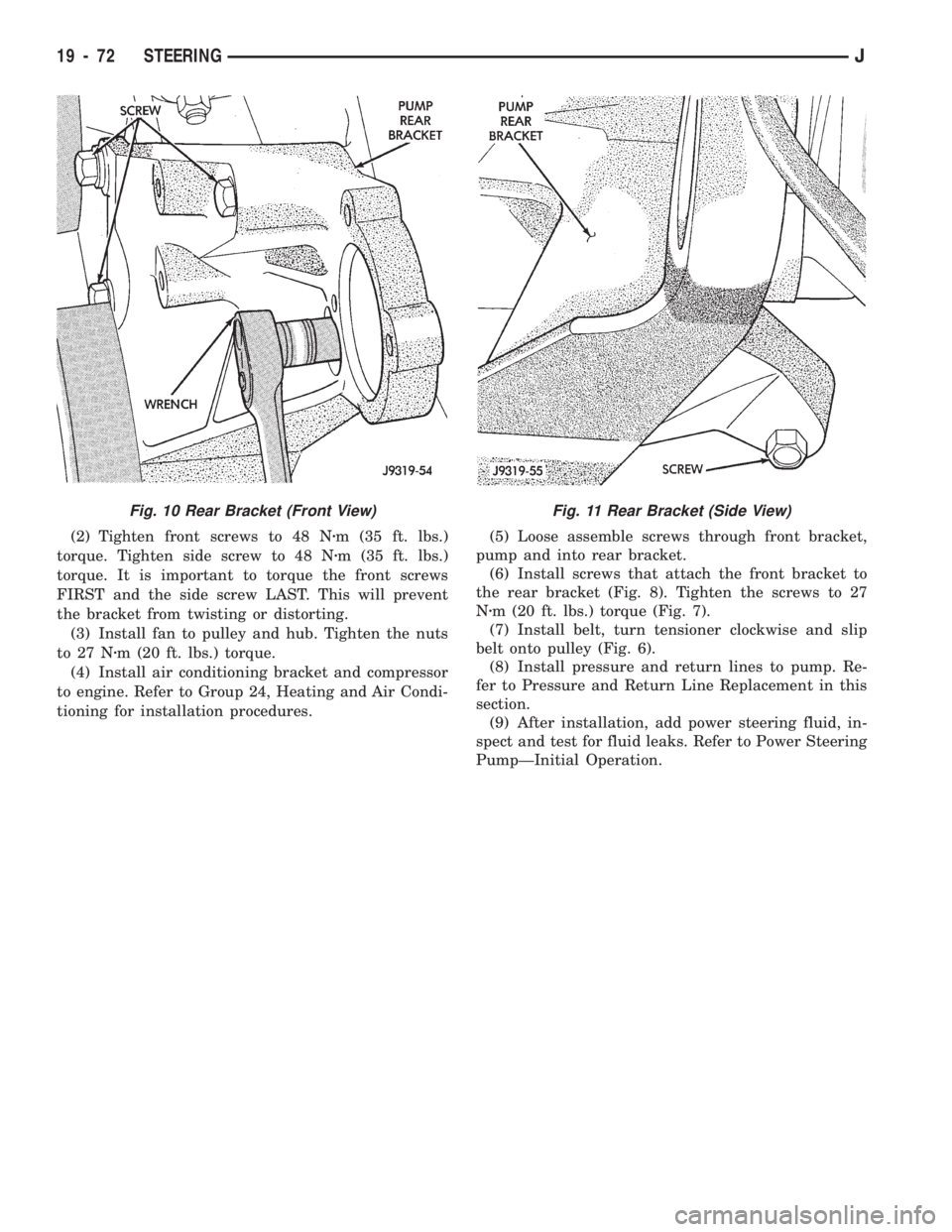

(3) Remove the screws retaining front bracket and

pump to the rear bracket (Fig. 7, 8).(4) Remove screws that attach the front bracket to

the rear bracket (Fig. 9).

(5) Remove pump from bracket.

To remove the rear bracket from engine, the air

conditioning compressor and bracket must be re-

moved first. Refer to Group 24, Heating and Air Con-

ditioning for removal procedures.

(6) Remove fan from pulley and hub on rear

bracket.

(7) Remove 4 screws attaching the rear bracket to

block (Fig. 10, 11).

(8) Remove bracket from engine.

INSTALLATION

(1) Install the rear bracket to engine. Install

screws finger tight.

Fig. 6 Belt Tensioner

Fig. 7 Pump Mounting Screw Removal/Installation

Fig. 8 Power Steering Pump Mounting

Fig. 9 Front Bracket

JSTEERING 19 - 71

Page 1109 of 1784

(2) Tighten front screws to 48 Nzm (35 ft. lbs.)

torque. Tighten side screw to 48 Nzm (35 ft. lbs.)

torque. It is important to torque the front screws

FIRST and the side screw LAST. This will prevent

the bracket from twisting or distorting.

(3) Install fan to pulley and hub. Tighten the nuts

to 27 Nzm (20 ft. lbs.) torque.

(4) Install air conditioning bracket and compressor

to engine. Refer to Group 24, Heating and Air Condi-

tioning for installation procedures.(5) Loose assemble screws through front bracket,

pump and into rear bracket.

(6) Install screws that attach the front bracket to

the rear bracket (Fig. 8). Tighten the screws to 27

Nzm (20 ft. lbs.) torque (Fig. 7).

(7) Install belt, turn tensioner clockwise and slip

belt onto pulley (Fig. 6).

(8) Install pressure and return lines to pump. Re-

fer to Pressure and Return Line Replacement in this

section.

(9) After installation, add power steering fluid, in-

spect and test for fluid leaks. Refer to Power Steering

PumpÐInitial Operation.

Fig. 11 Rear Bracket (Side View)Fig. 10 Rear Bracket (Front View)

19 - 72 STEERINGJ

Page 1113 of 1784

(Fig. 2). The first number is year of manufacture.

The second and third numbers indicate month of

manufacture. The next series of numbers is the

transmission serial number.

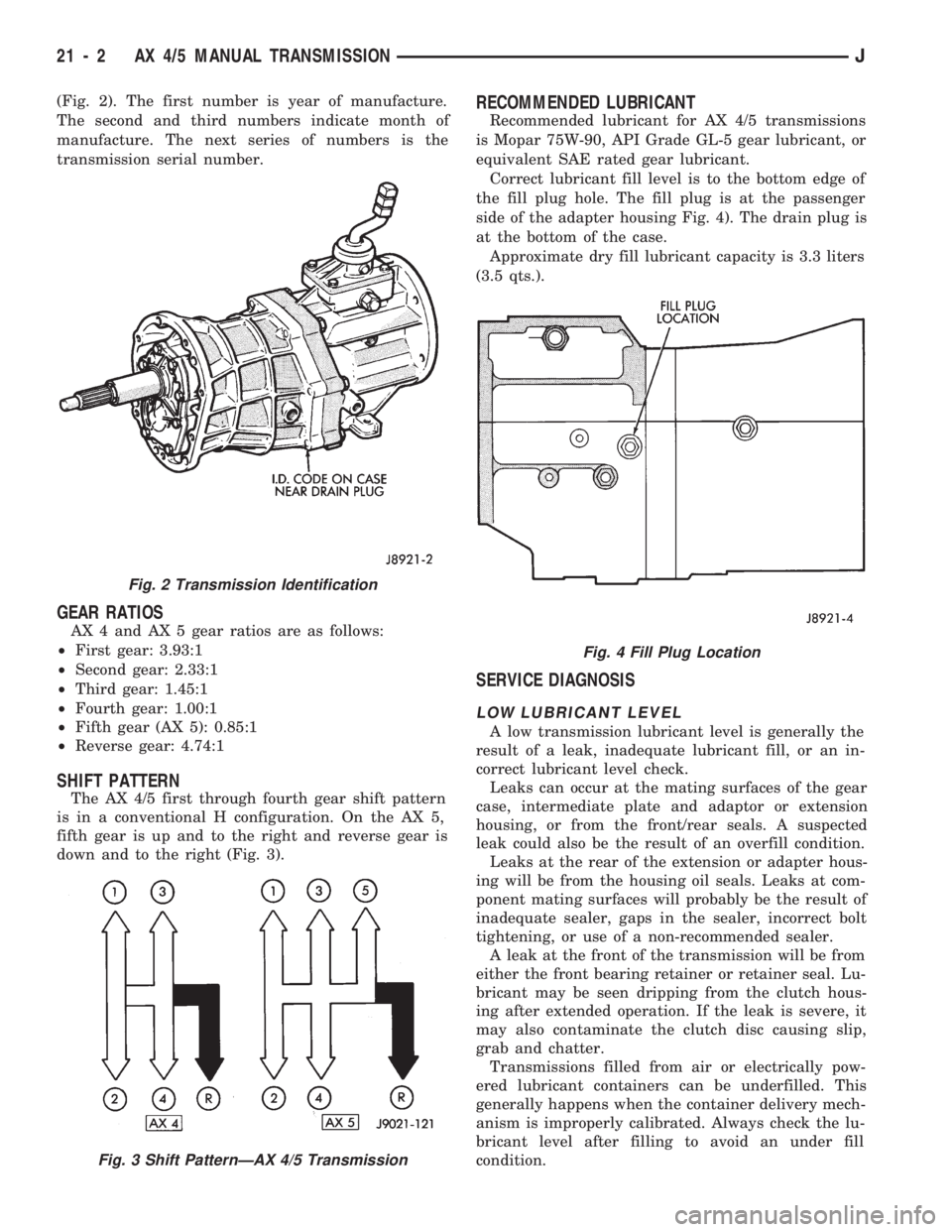

GEAR RATIOS

AX 4 and AX 5 gear ratios are as follows:

²First gear: 3.93:1

²Second gear: 2.33:1

²Third gear: 1.45:1

²Fourth gear: 1.00:1

²Fifth gear (AX 5): 0.85:1

²Reverse gear: 4.74:1

SHIFT PATTERN

The AX 4/5 first through fourth gear shift pattern

is in a conventional H configuration. On the AX 5,

fifth gear is up and to the right and reverse gear is

down and to the right (Fig. 3).

RECOMMENDED LUBRICANT

Recommended lubricant for AX 4/5 transmissions

is Mopar 75W-90, API Grade GL-5 gear lubricant, or

equivalent SAE rated gear lubricant.

Correct lubricant fill level is to the bottom edge of

the fill plug hole. The fill plug is at the passenger

side of the adapter housing Fig. 4). The drain plug is

at the bottom of the case.

Approximate dry fill lubricant capacity is 3.3 liters

(3.5 qts.).

SERVICE DIAGNOSIS

LOW LUBRICANT LEVEL

A low transmission lubricant level is generally the

result of a leak, inadequate lubricant fill, or an in-

correct lubricant level check.

Leaks can occur at the mating surfaces of the gear

case, intermediate plate and adaptor or extension

housing, or from the front/rear seals. A suspected

leak could also be the result of an overfill condition.

Leaks at the rear of the extension or adapter hous-

ing will be from the housing oil seals. Leaks at com-

ponent mating surfaces will probably be the result of

inadequate sealer, gaps in the sealer, incorrect bolt

tightening, or use of a non-recommended sealer.

A leak at the front of the transmission will be from

either the front bearing retainer or retainer seal. Lu-

bricant may be seen dripping from the clutch hous-

ing after extended operation. If the leak is severe, it

may also contaminate the clutch disc causing slip,

grab and chatter.

Transmissions filled from air or electrically pow-

ered lubricant containers can be underfilled. This

generally happens when the container delivery mech-

anism is improperly calibrated. Always check the lu-

bricant level after filling to avoid an under fill

condition.

Fig. 2 Transmission Identification

Fig. 3 Shift PatternÐAX 4/5 Transmission

Fig. 4 Fill Plug Location

21 - 2 AX 4/5 MANUAL TRANSMISSIONJ

Page 1115 of 1784

(6) Remove slave cylinder from clutch housing.

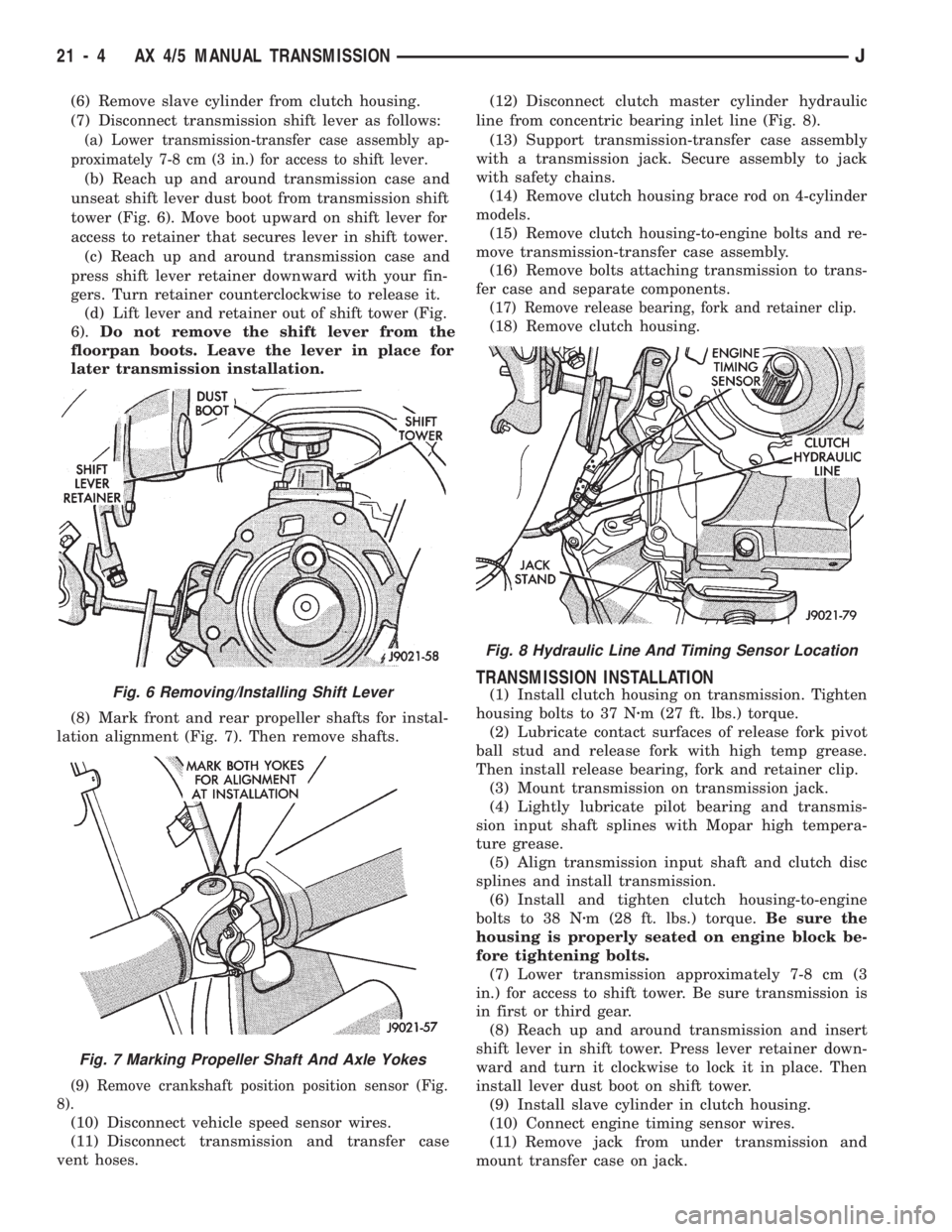

(7) Disconnect transmission shift lever as follows:

(a) Lower transmission-transfer case assembly ap-

proximately 7-8 cm (3 in.) for access to shift lever.

(b) Reach up and around transmission case and

unseat shift lever dust boot from transmission shift

tower (Fig. 6). Move boot upward on shift lever for

access to retainer that secures lever in shift tower.

(c) Reach up and around transmission case and

press shift lever retainer downward with your fin-

gers. Turn retainer counterclockwise to release it.

(d) Lift lever and retainer out of shift tower (Fig.

6).Do not remove the shift lever from the

floorpan boots. Leave the lever in place for

later transmission installation.

(8) Mark front and rear propeller shafts for instal-

lation alignment (Fig. 7). Then remove shafts.

(9) Remove crankshaft position position sensor (Fig.

8).

(10) Disconnect vehicle speed sensor wires.

(11) Disconnect transmission and transfer case

vent hoses.(12) Disconnect clutch master cylinder hydraulic

line from concentric bearing inlet line (Fig. 8).

(13) Support transmission-transfer case assembly

with a transmission jack. Secure assembly to jack

with safety chains.

(14) Remove clutch housing brace rod on 4-cylinder

models.

(15) Remove clutch housing-to-engine bolts and re-

move transmission-transfer case assembly.

(16) Remove bolts attaching transmission to trans-

fer case and separate components.

(17) Remove release bearing, fork and retainer clip.

(18) Remove clutch housing.

TRANSMISSION INSTALLATION

(1) Install clutch housing on transmission. Tighten

housing bolts to 37 Nzm (27 ft. lbs.) torque.

(2) Lubricate contact surfaces of release fork pivot

ball stud and release fork with high temp grease.

Then install release bearing, fork and retainer clip.

(3) Mount transmission on transmission jack.

(4) Lightly lubricate pilot bearing and transmis-

sion input shaft splines with Mopar high tempera-

ture grease.

(5) Align transmission input shaft and clutch disc

splines and install transmission.

(6) Install and tighten clutch housing-to-engine

bolts to 38 Nzm (28 ft. lbs.) torque.Be sure the

housing is properly seated on engine block be-

fore tightening bolts.

(7) Lower transmission approximately 7-8 cm (3

in.) for access to shift tower. Be sure transmission is

in first or third gear.

(8) Reach up and around transmission and insert

shift lever in shift tower. Press lever retainer down-

ward and turn it clockwise to lock it in place. Then

install lever dust boot on shift tower.

(9) Install slave cylinder in clutch housing.

(10) Connect engine timing sensor wires.

(11) Remove jack from under transmission and

mount transfer case on jack.Fig. 6 Removing/Installing Shift Lever

Fig. 7 Marking Propeller Shaft And Axle Yokes

Fig. 8 Hydraulic Line And Timing Sensor Location

21 - 4 AX 4/5 MANUAL TRANSMISSIONJ

Page 1116 of 1784

(12) Align transfer case and transmission shafts

and install transfer case. Tighten transfer case-to-

transmission nuts/bolts to 35 Nzm (26 ft. lbs.) torque.

(13) Remove jack stand from under engine and re-

position jack under transmission. Then remove trans-

mission jack.

(14) Connect transfer case vent hose and shift link-

age. Check and adjust linkage if necessary.

(15) Connect transmission and transfer case vent

hoses.

(16) Connect backup light switch wires.

(17) Connect vehicle speed sensor wires.

(18) Install and connect crankshaft position sensor

if equipped.

(19) Install rear crossmember, or skid plate (Fig. 5).

On XJ, tighten crossmember-to-frame bolts to 41 Nzm

(31 ft. lbs.) torque. Then tighten transmission-to-rear

support bolts/nuts to 45 Nzm (33 ft. lbs.) torque. On YJ,

tighten bolts/nuts to indicated torque (Fig. 5).

(20) Align and install front/rear propeller shafts.

Tighten shaft U-joint clamp bolts to 19 Nzm (170 in.

lbs.) torque.

(21) On XJ, install skid plate, if removed. Tighten

bolts to 42 Nzm (31 ft. lbs.) torque. Tighten stud nuts

to 17 Nzm (150 in. lbs.) torque.

(22) Top off transmission and transfer case lubri-

cant levels.

(23) Lower vehicle.

TRANSMISSION DISASSEMBLY AND OVERHAUL

ADAPTER HOUSING AND FRONT BEARING

RETAINER REMOVAL

(1) Drain transmission lubricant.

(2) Remove concentric bearing.

(3) Remove clutch housing bolts and remove housing.

(4) On 2-wheel drive models, remove vehicle speed

sensor, speedometer adapter and speedometer driven

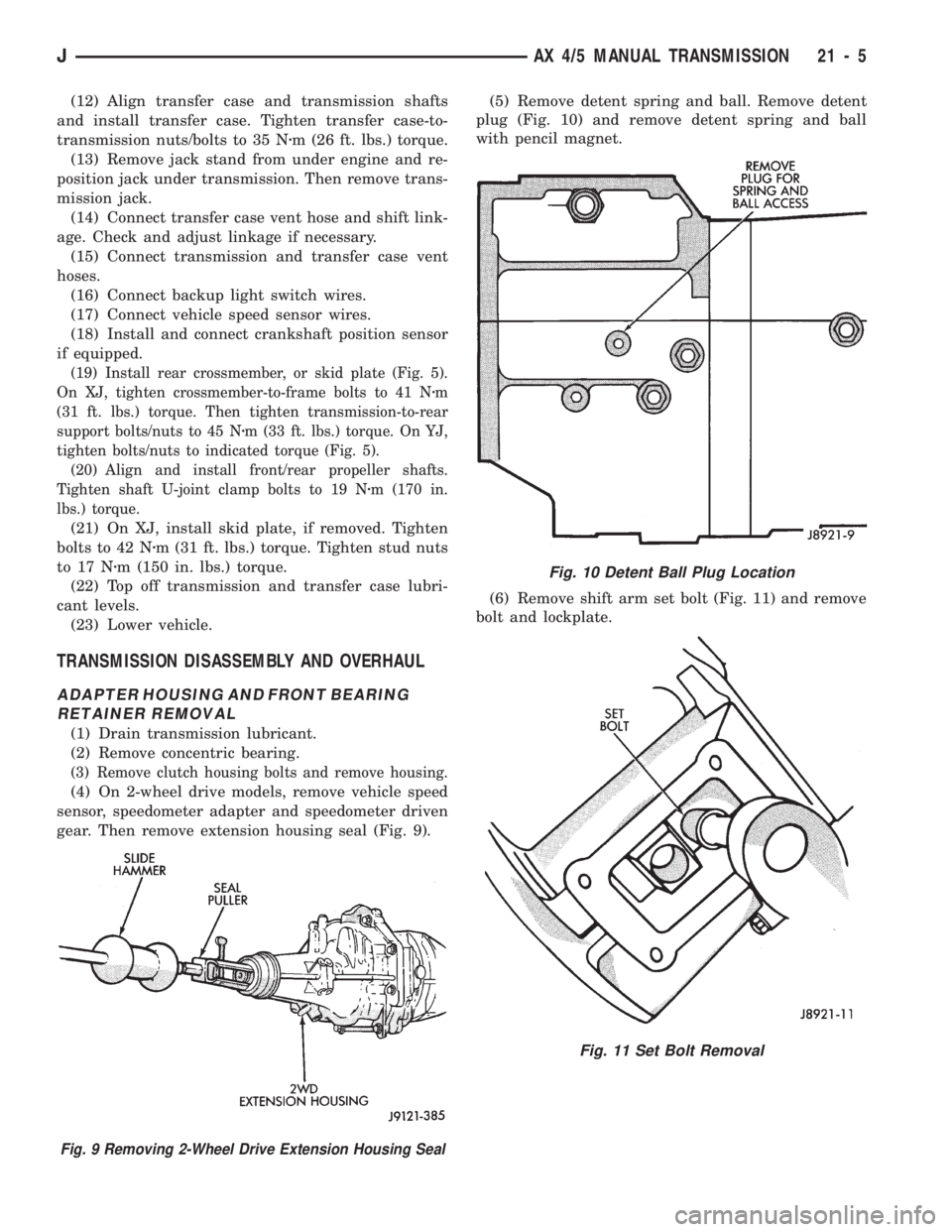

gear. Then remove extension housing seal (Fig. 9).(5) Remove detent spring and ball. Remove detent

plug (Fig. 10) and remove detent spring and ball

with pencil magnet.

(6) Remove shift arm set bolt (Fig. 11) and remove

bolt and lockplate.

Fig. 10 Detent Ball Plug Location

Fig. 11 Set Bolt Removal

Fig. 9 Removing 2-Wheel Drive Extension Housing Seal

JAX 4/5 MANUAL TRANSMISSION 21 - 5

Page 1117 of 1784

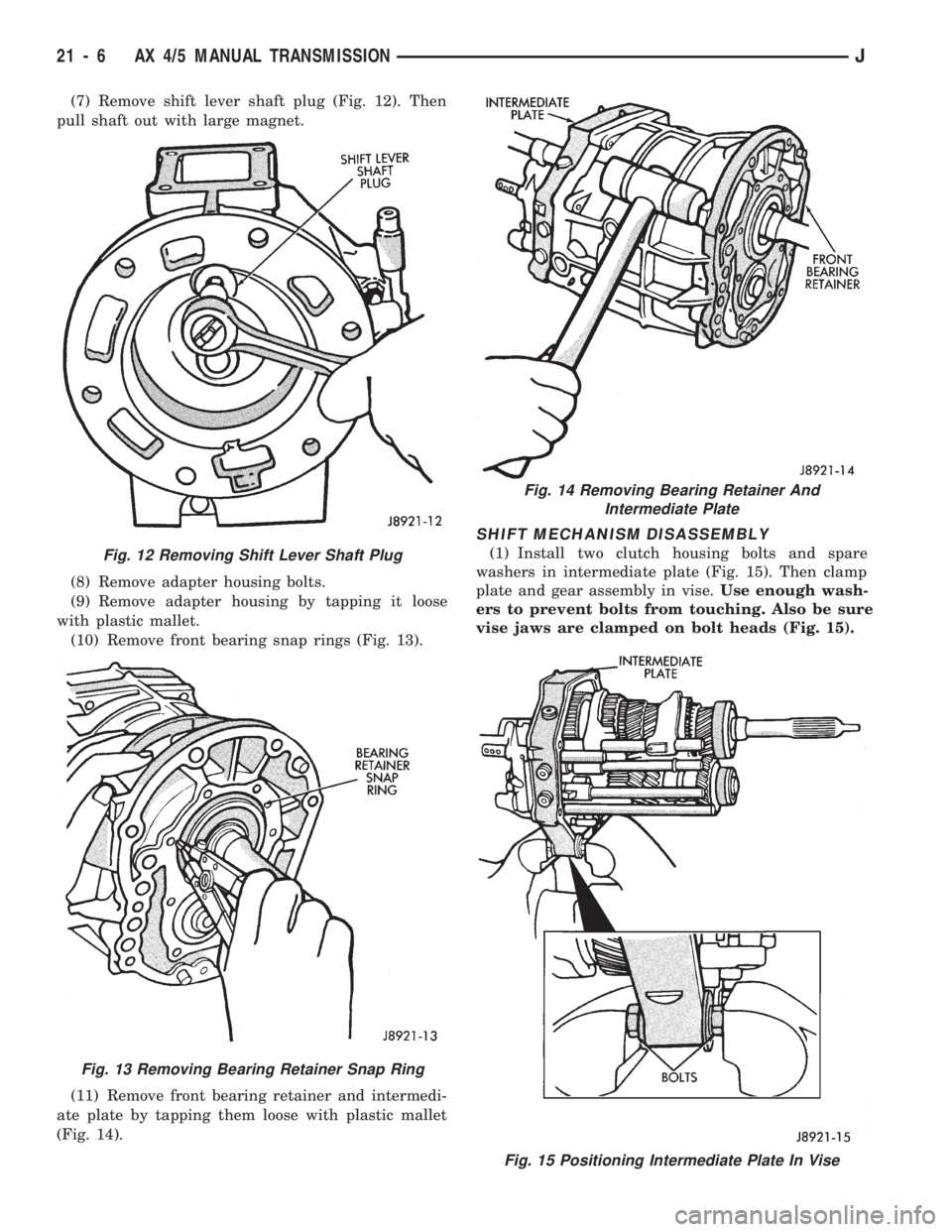

(7) Remove shift lever shaft plug (Fig. 12). Then

pull shaft out with large magnet.

(8) Remove adapter housing bolts.

(9) Remove adapter housing by tapping it loose

with plastic mallet.

(10) Remove front bearing snap rings (Fig. 13).

(11) Remove front bearing retainer and intermedi-

ate plate by tapping them loose with plastic mallet

(Fig. 14).

SHIFT MECHANISM DISASSEMBLY

(1) Install two clutch housing bolts and spare

washers in intermediate plate (Fig. 15). Then clamp

plate and gear assembly in vise.Use enough wash-

ers to prevent bolts from touching. Also be sure

vise jaws are clamped on bolt heads (Fig. 15).

Fig. 15 Positioning Intermediate Plate In Vise

Fig. 12 Removing Shift Lever Shaft Plug

Fig. 13 Removing Bearing Retainer Snap Ring

Fig. 14 Removing Bearing Retainer And

Intermediate Plate

21 - 6 AX 4/5 MANUAL TRANSMISSIONJ

Page 1126 of 1784

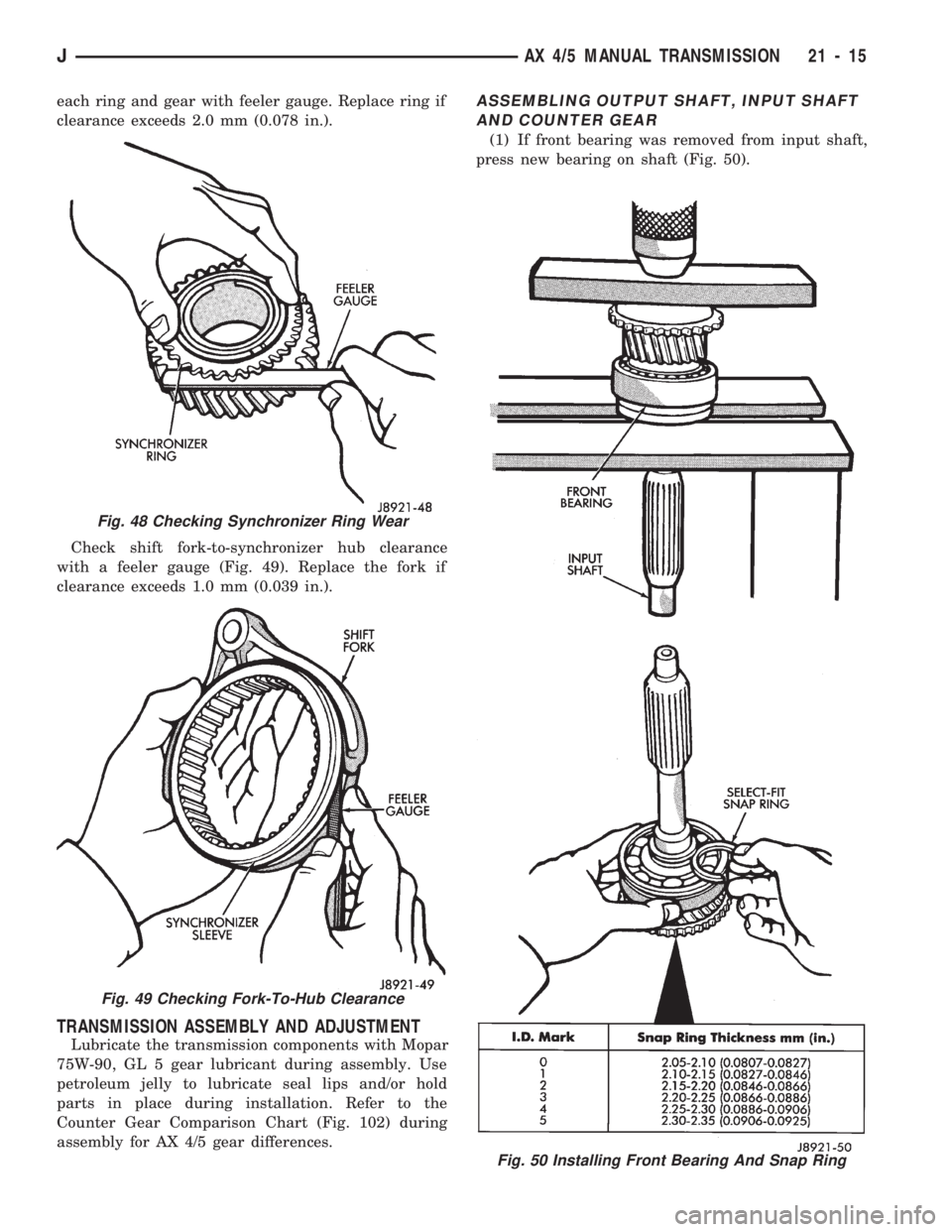

each ring and gear with feeler gauge. Replace ring if

clearance exceeds 2.0 mm (0.078 in.).

Check shift fork-to-synchronizer hub clearance

with a feeler gauge (Fig. 49). Replace the fork if

clearance exceeds 1.0 mm (0.039 in.).

TRANSMISSION ASSEMBLY AND ADJUSTMENT

Lubricate the transmission components with Mopar

75W-90, GL 5 gear lubricant during assembly. Use

petroleum jelly to lubricate seal lips and/or hold

parts in place during installation. Refer to the

Counter Gear Comparison Chart (Fig. 102) during

assembly for AX 4/5 gear differences.

ASSEMBLING OUTPUT SHAFT, INPUT SHAFT

AND COUNTER GEAR

(1) If front bearing was removed from input shaft,

press new bearing on shaft (Fig. 50).

Fig. 50 Installing Front Bearing And Snap Ring

Fig. 48 Checking Synchronizer Ring Wear

Fig. 49 Checking Fork-To-Hub Clearance

JAX 4/5 MANUAL TRANSMISSION 21 - 15

Page 1127 of 1784

(2) Secure front bearing with thickest snap ring

that will fit in groove (Fig. 50).

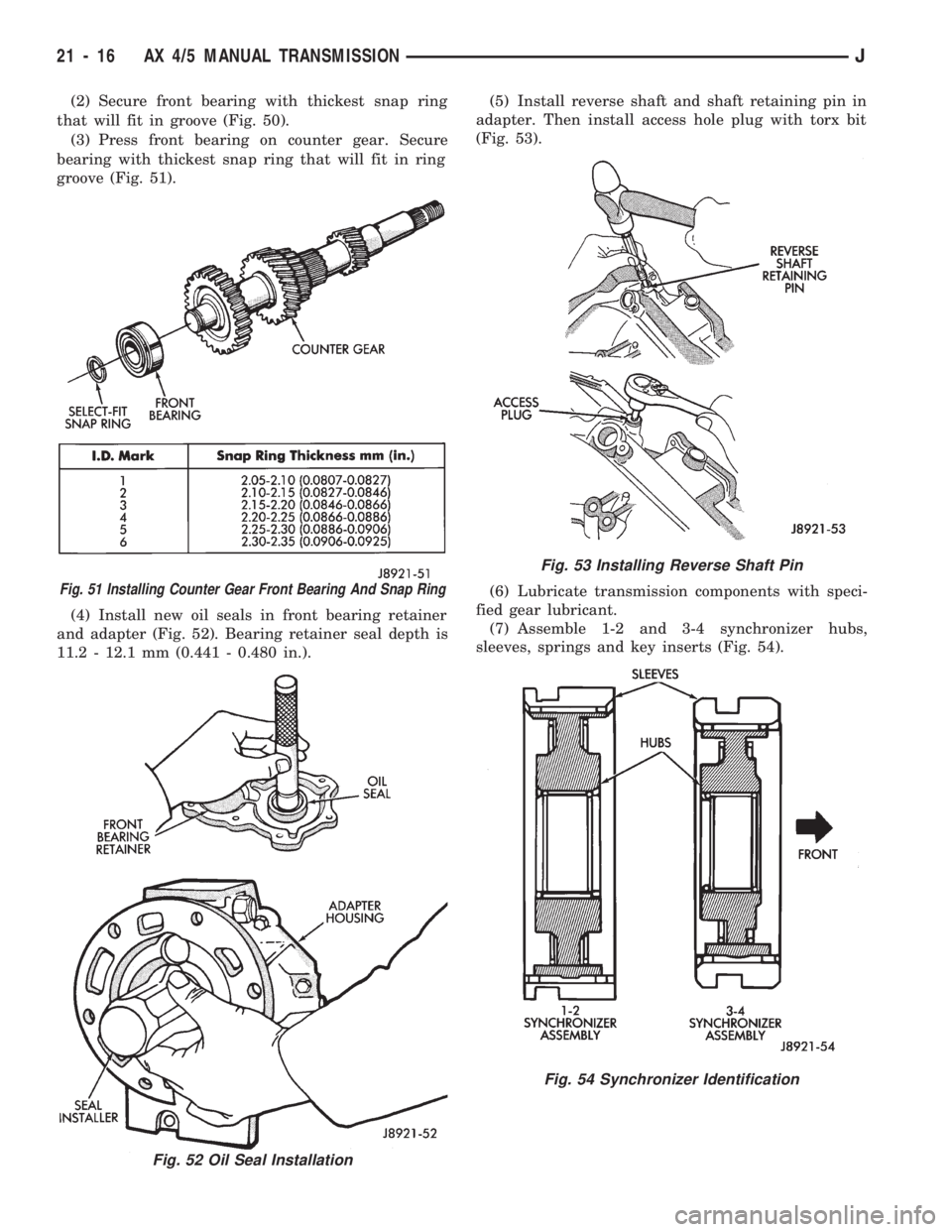

(3) Press front bearing on counter gear. Secure

bearing with thickest snap ring that will fit in ring

groove (Fig. 51).

(4) Install new oil seals in front bearing retainer

and adapter (Fig. 52). Bearing retainer seal depth is

11.2 - 12.1 mm (0.441 - 0.480 in.).(5) Install reverse shaft and shaft retaining pin in

adapter. Then install access hole plug with torx bit

(Fig. 53).

(6) Lubricate transmission components with speci-

fied gear lubricant.

(7) Assemble 1-2 and 3-4 synchronizer hubs,

sleeves, springs and key inserts (Fig. 54).

Fig. 51 Installing Counter Gear Front Bearing And Snap Ring

Fig. 52 Oil Seal Installation

Fig. 53 Installing Reverse Shaft Pin

Fig. 54 Synchronizer Identification

21 - 16 AX 4/5 MANUAL TRANSMISSIONJ

Page 1139 of 1784

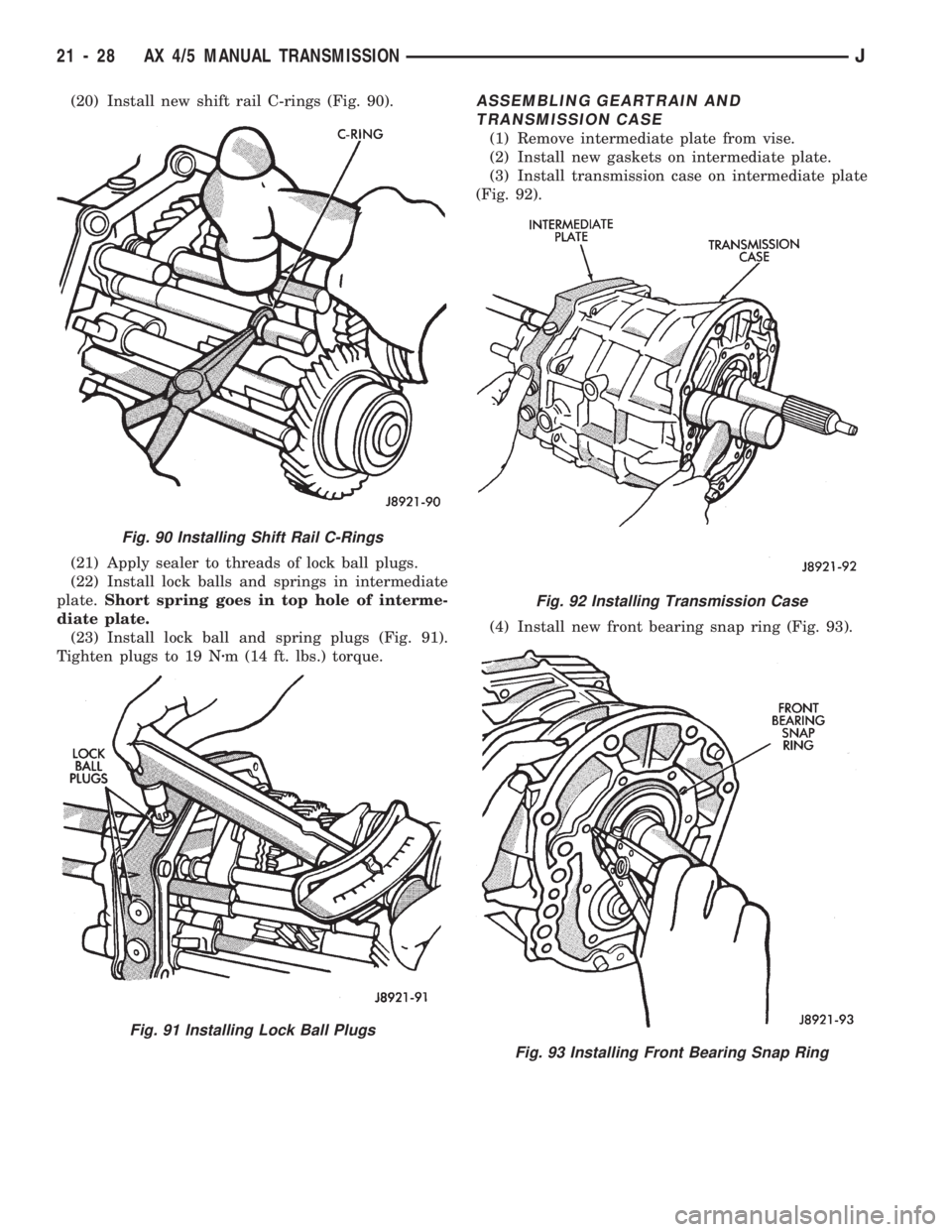

(20) Install new shift rail C-rings (Fig. 90).

(21) Apply sealer to threads of lock ball plugs.

(22) Install lock balls and springs in intermediate

plate.Short spring goes in top hole of interme-

diate plate.

(23) Install lock ball and spring plugs (Fig. 91).

Tighten plugs to 19 Nzm (14 ft. lbs.) torque.ASSEMBLING GEARTRAIN AND

TRANSMISSION CASE

(1) Remove intermediate plate from vise.

(2) Install new gaskets on intermediate plate.

(3) Install transmission case on intermediate plate

(Fig. 92).

(4) Install new front bearing snap ring (Fig. 93).

Fig. 92 Installing Transmission Case

Fig. 93 Installing Front Bearing Snap Ring

Fig. 90 Installing Shift Rail C-Rings

Fig. 91 Installing Lock Ball Plugs

21 - 28 AX 4/5 MANUAL TRANSMISSIONJ

Page 1140 of 1784

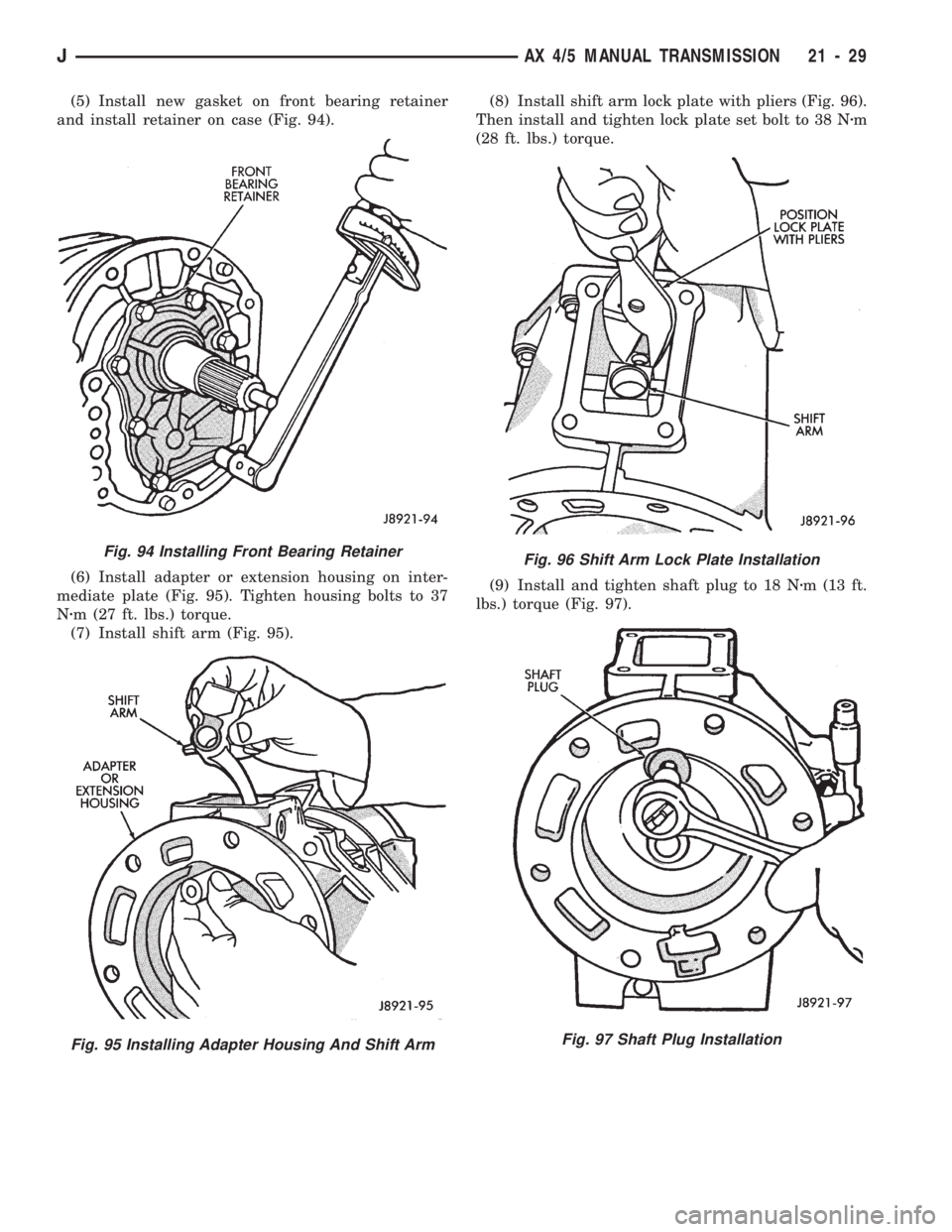

(5) Install new gasket on front bearing retainer

and install retainer on case (Fig. 94).

(6) Install adapter or extension housing on inter-

mediate plate (Fig. 95). Tighten housing bolts to 37

Nzm (27 ft. lbs.) torque.

(7) Install shift arm (Fig. 95).(8) Install shift arm lock plate with pliers (Fig. 96).

Then install and tighten lock plate set bolt to 38 Nzm

(28 ft. lbs.) torque.

(9) Install and tighten shaft plug to 18 Nzm (13 ft.

lbs.) torque (Fig. 97).

Fig. 94 Installing Front Bearing Retainer

Fig. 95 Installing Adapter Housing And Shift Arm

Fig. 96 Shift Arm Lock Plate Installation

Fig. 97 Shaft Plug Installation

JAX 4/5 MANUAL TRANSMISSION 21 - 29