lock JEEP CHEROKEE 1994 Service Repair Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 1994, Model line: CHEROKEE, Model: JEEP CHEROKEE 1994Pages: 1784, PDF Size: 77.09 MB

Page 1069 of 1784

turning the stub shaft COUNTERCLOCKWISE.

²The rack piston will be forced onto the tool and

hold the rack piston balls in place.

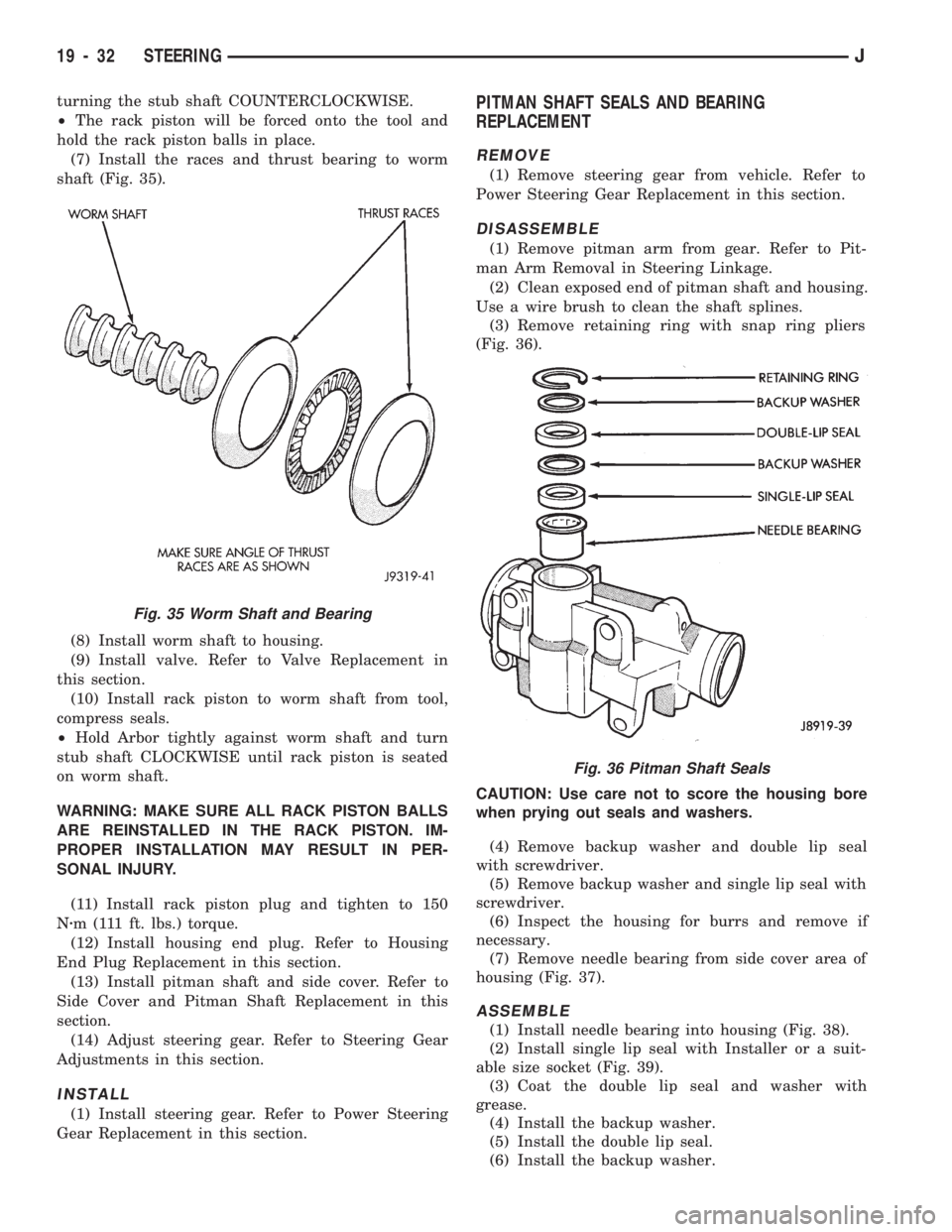

(7) Install the races and thrust bearing to worm

shaft (Fig. 35).

(8) Install worm shaft to housing.

(9) Install valve. Refer to Valve Replacement in

this section.

(10) Install rack piston to worm shaft from tool,

compress seals.

²Hold Arbor tightly against worm shaft and turn

stub shaft CLOCKWISE until rack piston is seated

on worm shaft.

WARNING: MAKE SURE ALL RACK PISTON BALLS

ARE REINSTALLED IN THE RACK PISTON. IM-

PROPER INSTALLATION MAY RESULT IN PER-

SONAL INJURY.

(11) Install rack piston plug and tighten to 150

Nzm (111 ft. lbs.) torque.

(12) Install housing end plug. Refer to Housing

End Plug Replacement in this section.

(13) Install pitman shaft and side cover. Refer to

Side Cover and Pitman Shaft Replacement in this

section.

(14) Adjust steering gear. Refer to Steering Gear

Adjustments in this section.

INSTALL

(1) Install steering gear. Refer to Power Steering

Gear Replacement in this section.

PITMAN SHAFT SEALS AND BEARING

REPLACEMENT

REMOVE

(1) Remove steering gear from vehicle. Refer to

Power Steering Gear Replacement in this section.

DISASSEMBLE

(1) Remove pitman arm from gear. Refer to Pit-

man Arm Removal in Steering Linkage.

(2) Clean exposed end of pitman shaft and housing.

Use a wire brush to clean the shaft splines.

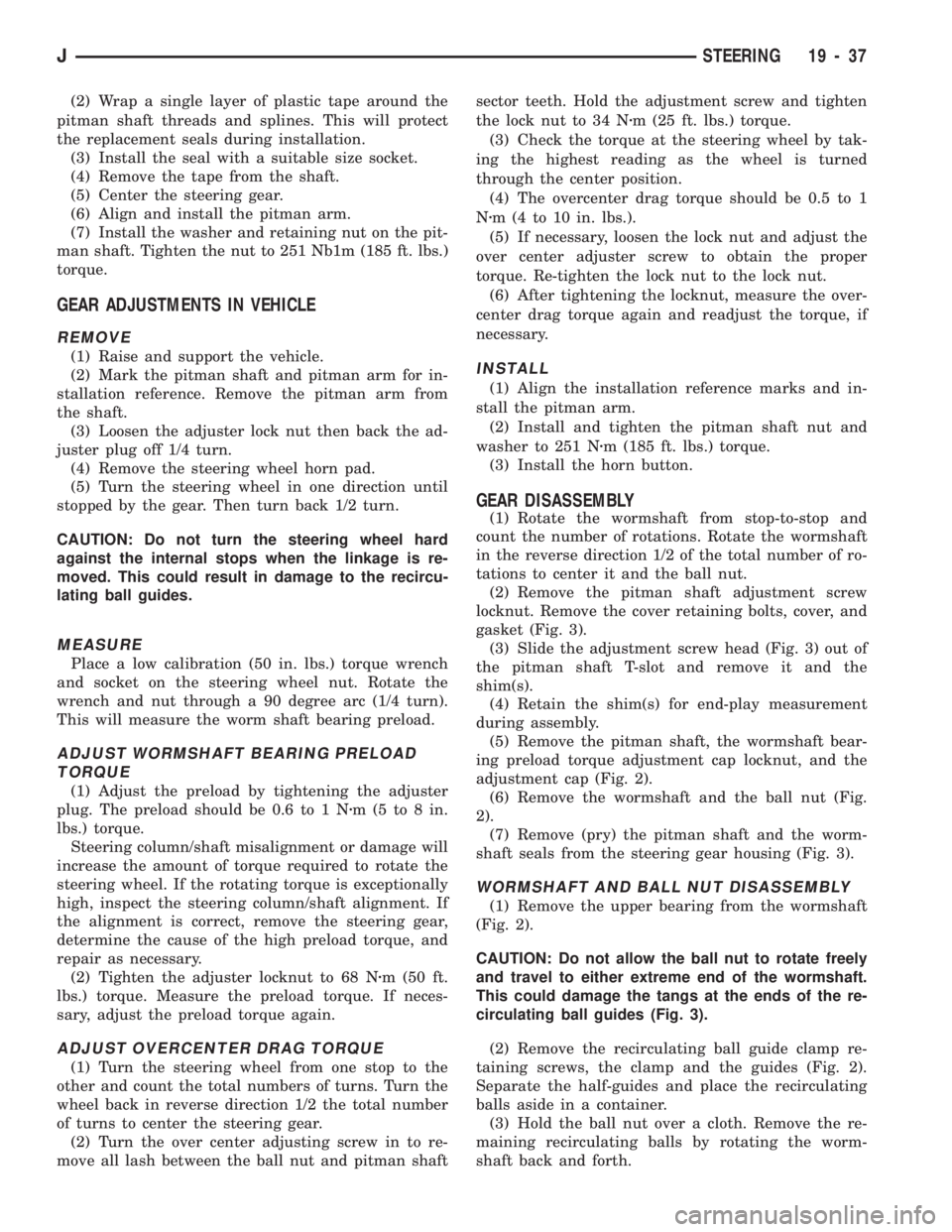

(3) Remove retaining ring with snap ring pliers

(Fig. 36).

CAUTION: Use care not to score the housing bore

when prying out seals and washers.

(4) Remove backup washer and double lip seal

with screwdriver.

(5) Remove backup washer and single lip seal with

screwdriver.

(6) Inspect the housing for burrs and remove if

necessary.

(7) Remove needle bearing from side cover area of

housing (Fig. 37).

ASSEMBLE

(1) Install needle bearing into housing (Fig. 38).

(2) Install single lip seal with Installer or a suit-

able size socket (Fig. 39).

(3) Coat the double lip seal and washer with

grease.

(4) Install the backup washer.

(5) Install the double lip seal.

(6) Install the backup washer.

Fig. 36 Pitman Shaft Seals

Fig. 35 Worm Shaft and Bearing

19 - 32 STEERINGJ

Page 1074 of 1784

(2) Wrap a single layer of plastic tape around the

pitman shaft threads and splines. This will protect

the replacement seals during installation.

(3) Install the seal with a suitable size socket.

(4) Remove the tape from the shaft.

(5) Center the steering gear.

(6) Align and install the pitman arm.

(7) Install the washer and retaining nut on the pit-

man shaft. Tighten the nut to 251 Nb1m (185 ft. lbs.)

torque.

GEAR ADJUSTMENTS IN VEHICLE

REMOVE

(1) Raise and support the vehicle.

(2) Mark the pitman shaft and pitman arm for in-

stallation reference. Remove the pitman arm from

the shaft.

(3) Loosen the adjuster lock nut then back the ad-

juster plug off 1/4 turn.

(4) Remove the steering wheel horn pad.

(5) Turn the steering wheel in one direction until

stopped by the gear. Then turn back 1/2 turn.

CAUTION: Do not turn the steering wheel hard

against the internal stops when the linkage is re-

moved. This could result in damage to the recircu-

lating ball guides.

MEASURE

Place a low calibration (50 in. lbs.) torque wrench

and socket on the steering wheel nut. Rotate the

wrench and nut through a 90 degree arc (1/4 turn).

This will measure the worm shaft bearing preload.

ADJUST WORMSHAFT BEARING PRELOAD

TORQUE

(1) Adjust the preload by tightening the adjuster

plug. The preload should be 0.6 to 1 Nzm(5to8in.

lbs.) torque.

Steering column/shaft misalignment or damage will

increase the amount of torque required to rotate the

steering wheel. If the rotating torque is exceptionally

high, inspect the steering column/shaft alignment. If

the alignment is correct, remove the steering gear,

determine the cause of the high preload torque, and

repair as necessary.

(2) Tighten the adjuster locknut to 68 Nzm (50 ft.

lbs.) torque. Measure the preload torque. If neces-

sary, adjust the preload torque again.

ADJUST OVERCENTER DRAG TORQUE

(1) Turn the steering wheel from one stop to the

other and count the total numbers of turns. Turn the

wheel back in reverse direction 1/2 the total number

of turns to center the steering gear.

(2) Turn the over center adjusting screw in to re-

move all lash between the ball nut and pitman shaftsector teeth. Hold the adjustment screw and tighten

the lock nut to 34 Nzm (25 ft. lbs.) torque.

(3) Check the torque at the steering wheel by tak-

ing the highest reading as the wheel is turned

through the center position.

(4) The overcenter drag torque should be 0.5 to 1

Nzm (4 to 10 in. lbs.).

(5) If necessary, loosen the lock nut and adjust the

over center adjuster screw to obtain the proper

torque. Re-tighten the lock nut to the lock nut.

(6) After tightening the locknut, measure the over-

center drag torque again and readjust the torque, if

necessary.

INSTALL

(1) Align the installation reference marks and in-

stall the pitman arm.

(2) Install and tighten the pitman shaft nut and

washer to 251 Nzm (185 ft. lbs.) torque.

(3) Install the horn button.

GEAR DISASSEMBLY

(1) Rotate the wormshaft from stop-to-stop and

count the number of rotations. Rotate the wormshaft

in the reverse direction 1/2 of the total number of ro-

tations to center it and the ball nut.

(2) Remove the pitman shaft adjustment screw

locknut. Remove the cover retaining bolts, cover, and

gasket (Fig. 3).

(3) Slide the adjustment screw head (Fig. 3) out of

the pitman shaft T-slot and remove it and the

shim(s).

(4) Retain the shim(s) for end-play measurement

during assembly.

(5) Remove the pitman shaft, the wormshaft bear-

ing preload torque adjustment cap locknut, and the

adjustment cap (Fig. 2).

(6) Remove the wormshaft and the ball nut (Fig.

2).

(7) Remove (pry) the pitman shaft and the worm-

shaft seals from the steering gear housing (Fig. 3).

WORMSHAFT AND BALL NUT DISASSEMBLY

(1) Remove the upper bearing from the wormshaft

(Fig. 2).

CAUTION: Do not allow the ball nut to rotate freely

and travel to either extreme end of the wormshaft.

This could damage the tangs at the ends of the re-

circulating ball guides (Fig. 3).

(2) Remove the recirculating ball guide clamp re-

taining screws, the clamp and the guides (Fig. 2).

Separate the half-guides and place the recirculating

balls aside in a container.

(3) Hold the ball nut over a cloth. Remove the re-

maining recirculating balls by rotating the worm-

shaft back and forth.

JSTEERING 19 - 37

Page 1079 of 1784

(7) Install the locknut on the wormshaft bearing

adjustment cap but do not tighten it at this time.

(8) Pack the steering gear housing with as much

chassis lubricant as possible.

Rotate the wormshaft in one direction until

the ball nut ceases. Pack the end of the housing

full of lubricant, rotate the shaft in the opposite

direction and repeat the packing procedure.

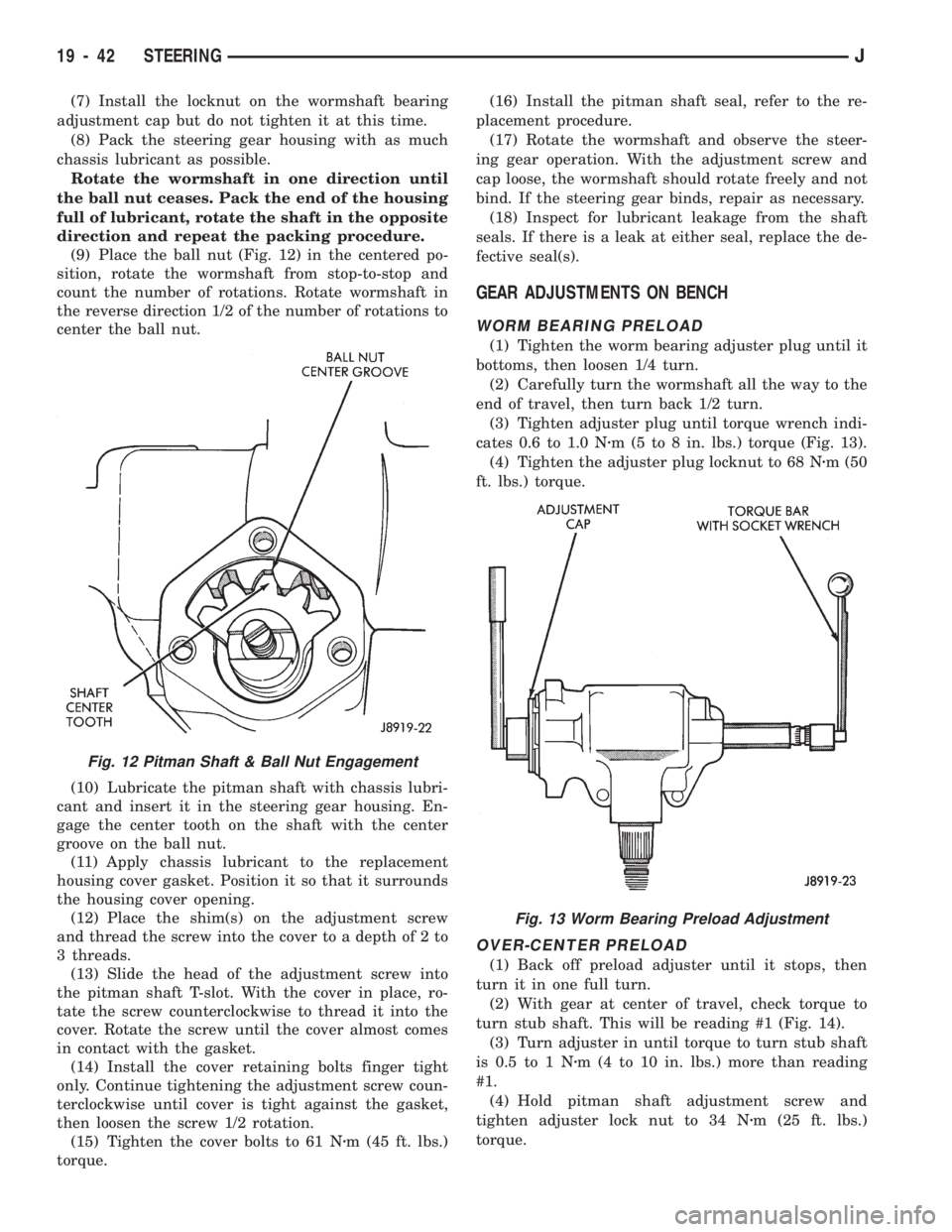

(9) Place the ball nut (Fig. 12) in the centered po-

sition, rotate the wormshaft from stop-to-stop and

count the number of rotations. Rotate wormshaft in

the reverse direction 1/2 of the number of rotations to

center the ball nut.

(10) Lubricate the pitman shaft with chassis lubri-

cant and insert it in the steering gear housing. En-

gage the center tooth on the shaft with the center

groove on the ball nut.

(11) Apply chassis lubricant to the replacement

housing cover gasket. Position it so that it surrounds

the housing cover opening.

(12) Place the shim(s) on the adjustment screw

and thread the screw into the cover to a depth of 2 to

3 threads.

(13) Slide the head of the adjustment screw into

the pitman shaft T-slot. With the cover in place, ro-

tate the screw counterclockwise to thread it into the

cover. Rotate the screw until the cover almost comes

in contact with the gasket.

(14) Install the cover retaining bolts finger tight

only. Continue tightening the adjustment screw coun-

terclockwise until cover is tight against the gasket,

then loosen the screw 1/2 rotation.

(15) Tighten the cover bolts to 61 Nzm (45 ft. lbs.)

torque.(16) Install the pitman shaft seal, refer to the re-

placement procedure.

(17) Rotate the wormshaft and observe the steer-

ing gear operation. With the adjustment screw and

cap loose, the wormshaft should rotate freely and not

bind. If the steering gear binds, repair as necessary.

(18) Inspect for lubricant leakage from the shaft

seals. If there is a leak at either seal, replace the de-

fective seal(s).

GEAR ADJUSTMENTS ON BENCH

WORM BEARING PRELOAD

(1) Tighten the worm bearing adjuster plug until it

bottoms, then loosen 1/4 turn.

(2) Carefully turn the wormshaft all the way to the

end of travel, then turn back 1/2 turn.

(3) Tighten adjuster plug until torque wrench indi-

cates 0.6 to 1.0 Nzm (5 to 8 in. lbs.) torque (Fig. 13).

(4) Tighten the adjuster plug locknut to 68 Nzm (50

ft. lbs.) torque.

OVER-CENTER PRELOAD

(1) Back off preload adjuster until it stops, then

turn it in one full turn.

(2) With gear at center of travel, check torque to

turn stub shaft. This will be reading #1 (Fig. 14).

(3) Turn adjuster in until torque to turn stub shaft

is 0.5 to 1 Nzm (4 to 10 in. lbs.) more than reading

#1.

(4) Hold pitman shaft adjustment screw and

tighten adjuster lock nut to 34 Nzm (25 ft. lbs.)

torque.

Fig. 12 Pitman Shaft & Ball Nut Engagement

Fig. 13 Worm Bearing Preload Adjustment

19 - 42 STEERINGJ

Page 1082 of 1784

STEERING COLUMN GENERAL SERVICE

INDEX

page page

Column ReplacementÐXJ.................. 46

Column ReplacementÐYJ.................. 48

Park-Lock CableÐConsole Shift Automatic..... 45Service Information....................... 45

Steering Wheel.......................... 45

SERVICE INFORMATION

The column may be disassembled and reassembled.

Also most steering column components can be ser-

viced without removing the column from the vehicle.

For additional information, refer to Group 8H, Elec-

trical.

CAUTION: Bumping, jolting and hammering on the

steering column shaft and gear shift tube must be

avoided during all service procedures.

CAUTION: Disconnect negative (ground) cable from

the battery before servicing any component on the

column.

Safety goggles should be worn at all times

when involved with steering column service.

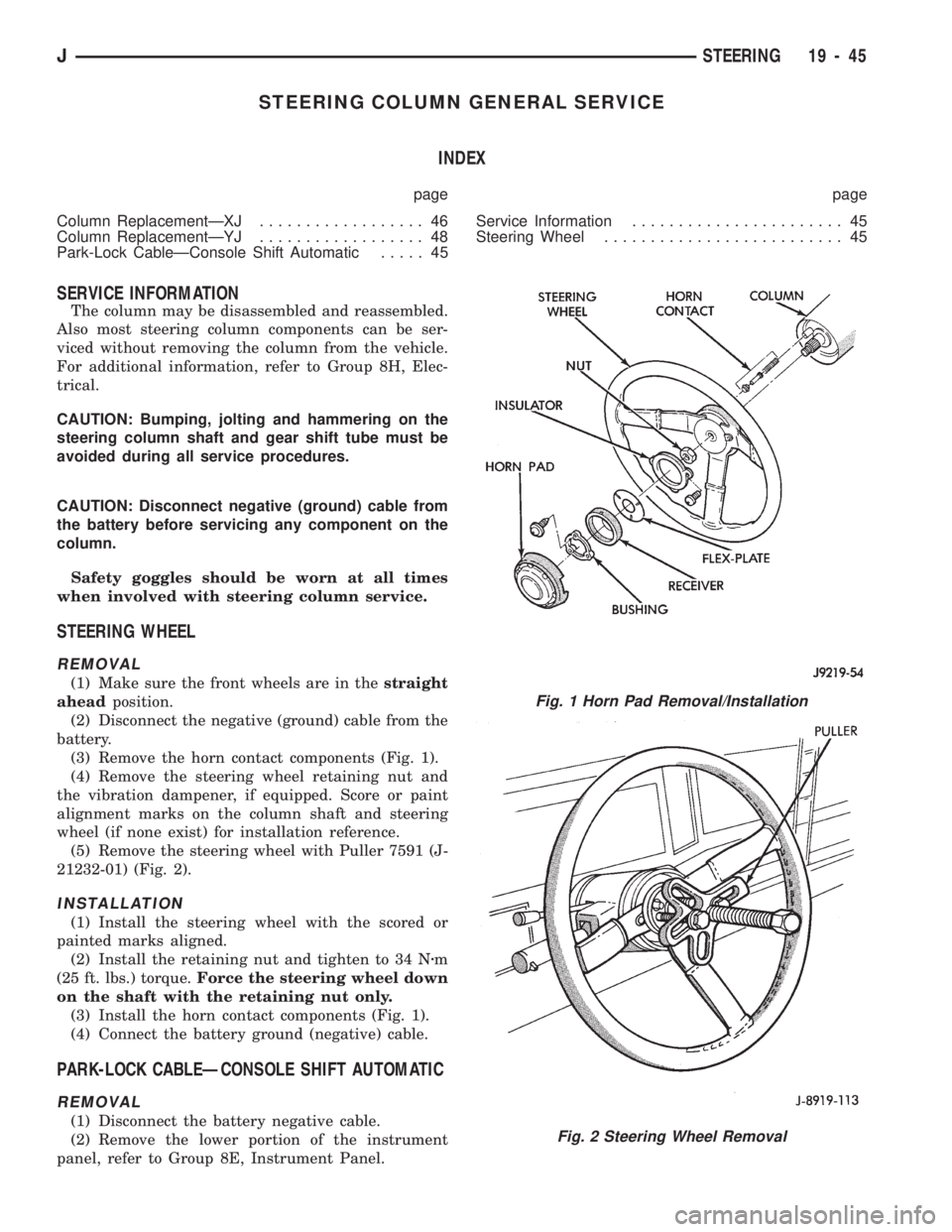

STEERING WHEEL

REMOVAL

(1) Make sure the front wheels are in thestraight

aheadposition.

(2) Disconnect the negative (ground) cable from the

battery.

(3) Remove the horn contact components (Fig. 1).

(4) Remove the steering wheel retaining nut and

the vibration dampener, if equipped. Score or paint

alignment marks on the column shaft and steering

wheel (if none exist) for installation reference.

(5) Remove the steering wheel with Puller 7591 (J-

21232-01) (Fig. 2).

INSTALLATION

(1) Install the steering wheel with the scored or

painted marks aligned.

(2) Install the retaining nut and tighten to 34 Nzm

(25 ft. lbs.) torque.Force the steering wheel down

on the shaft with the retaining nut only.

(3) Install the horn contact components (Fig. 1).

(4) Connect the battery ground (negative) cable.

PARK-LOCK CABLEÐCONSOLE SHIFT AUTOMATIC

REMOVAL

(1) Disconnect the battery negative cable.

(2) Remove the lower portion of the instrument

panel, refer to Group 8E, Instrument Panel.

Fig. 1 Horn Pad Removal/Installation

Fig. 2 Steering Wheel Removal

JSTEERING 19 - 45

Page 1083 of 1784

(3) Remove the steering column mounting bracket

to instrument panel nuts. Lower the steering column.

Refer to Steering Column Removal .

(4) Disconnect the park-lock cable from the steer-

ing column and bracket.

(5) Remove the center console and related trim.

(6) Pull the carpet backward to expose the cable at

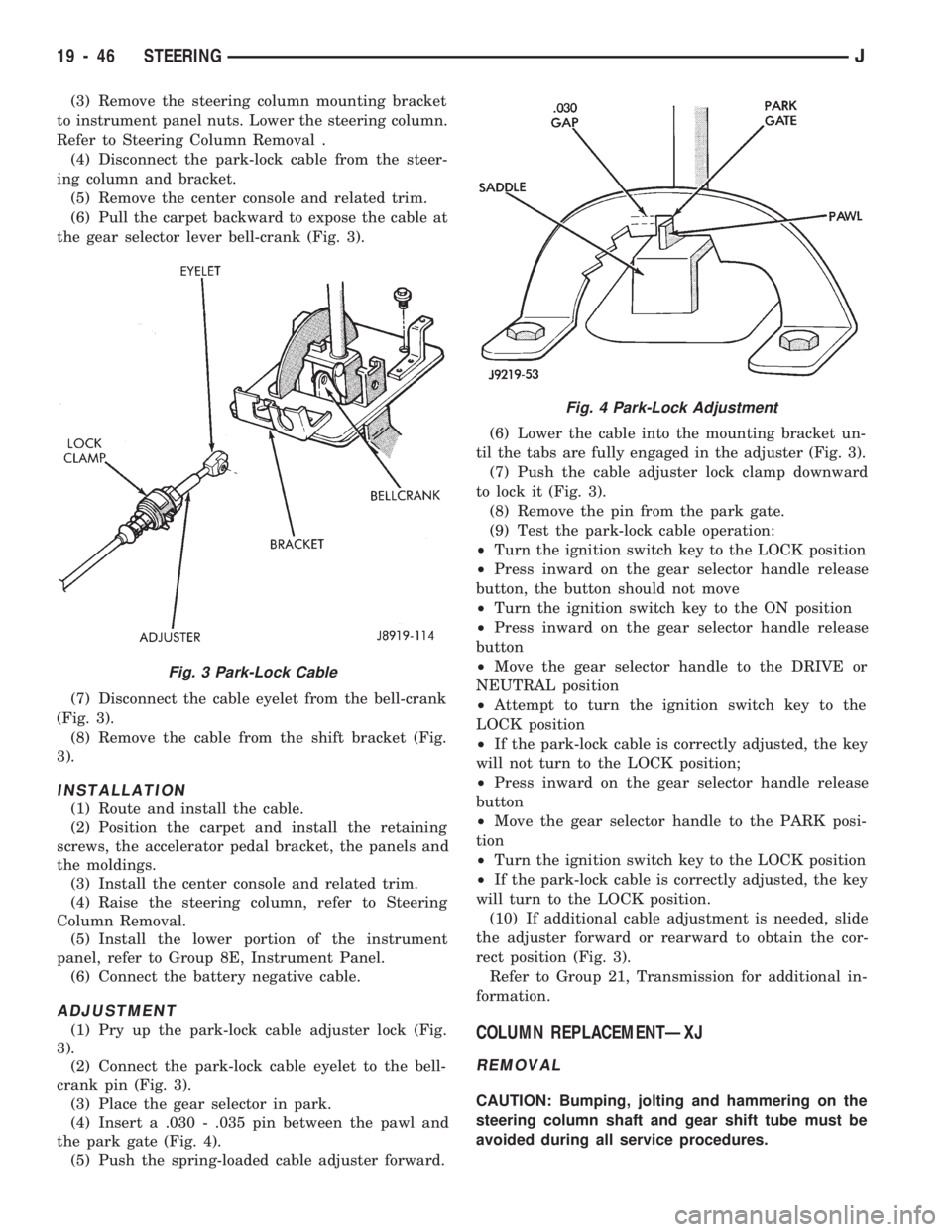

the gear selector lever bell-crank (Fig. 3).

(7) Disconnect the cable eyelet from the bell-crank

(Fig. 3).

(8) Remove the cable from the shift bracket (Fig.

3).

INSTALLATION

(1) Route and install the cable.

(2) Position the carpet and install the retaining

screws, the accelerator pedal bracket, the panels and

the moldings.

(3) Install the center console and related trim.

(4) Raise the steering column, refer to Steering

Column Removal.

(5) Install the lower portion of the instrument

panel, refer to Group 8E, Instrument Panel.

(6) Connect the battery negative cable.

ADJUSTMENT

(1) Pry up the park-lock cable adjuster lock (Fig.

3).

(2) Connect the park-lock cable eyelet to the bell-

crank pin (Fig. 3).

(3) Place the gear selector in park.

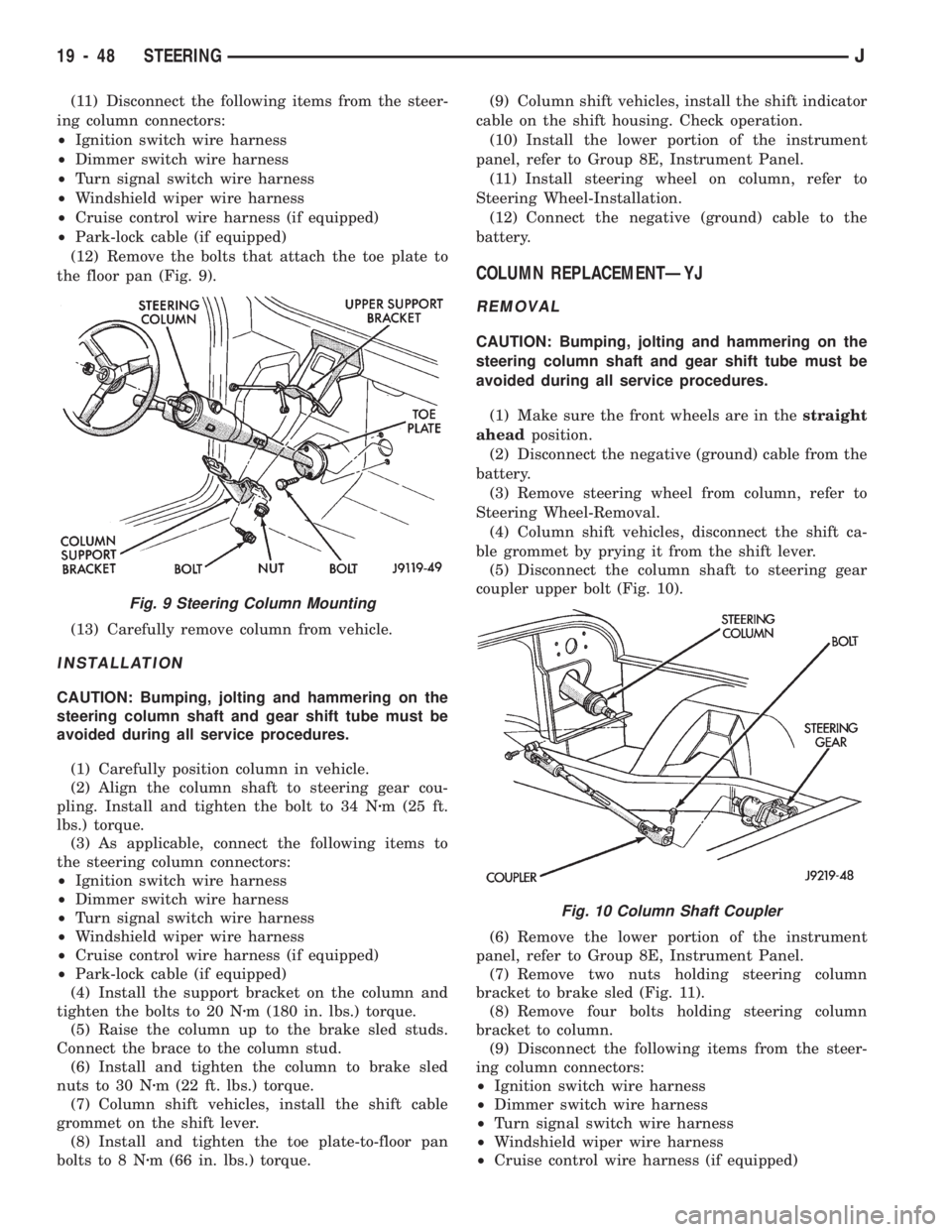

(4) Insert a .030 - .035 pin between the pawl and

the park gate (Fig. 4).

(5) Push the spring-loaded cable adjuster forward.(6) Lower the cable into the mounting bracket un-

til the tabs are fully engaged in the adjuster (Fig. 3).

(7) Push the cable adjuster lock clamp downward

to lock it (Fig. 3).

(8) Remove the pin from the park gate.

(9) Test the park-lock cable operation:

²Turn the ignition switch key to the LOCK position

²Press inward on the gear selector handle release

button, the button should not move

²Turn the ignition switch key to the ON position

²Press inward on the gear selector handle release

button

²Move the gear selector handle to the DRIVE or

NEUTRAL position

²Attempt to turn the ignition switch key to the

LOCK position

²If the park-lock cable is correctly adjusted, the key

will not turn to the LOCK position;

²Press inward on the gear selector handle release

button

²Move the gear selector handle to the PARK posi-

tion

²Turn the ignition switch key to the LOCK position

²If the park-lock cable is correctly adjusted, the key

will turn to the LOCK position.

(10) If additional cable adjustment is needed, slide

the adjuster forward or rearward to obtain the cor-

rect position (Fig. 3).

Refer to Group 21, Transmission for additional in-

formation.COLUMN REPLACEMENTÐXJ

REMOVAL

CAUTION: Bumping, jolting and hammering on the

steering column shaft and gear shift tube must be

avoided during all service procedures.

Fig. 3 Park-Lock Cable

Fig. 4 Park-Lock Adjustment

19 - 46 STEERINGJ

Page 1085 of 1784

(11) Disconnect the following items from the steer-

ing column connectors:

²Ignition switch wire harness

²Dimmer switch wire harness

²Turn signal switch wire harness

²Windshield wiper wire harness

²Cruise control wire harness (if equipped)

²Park-lock cable (if equipped)

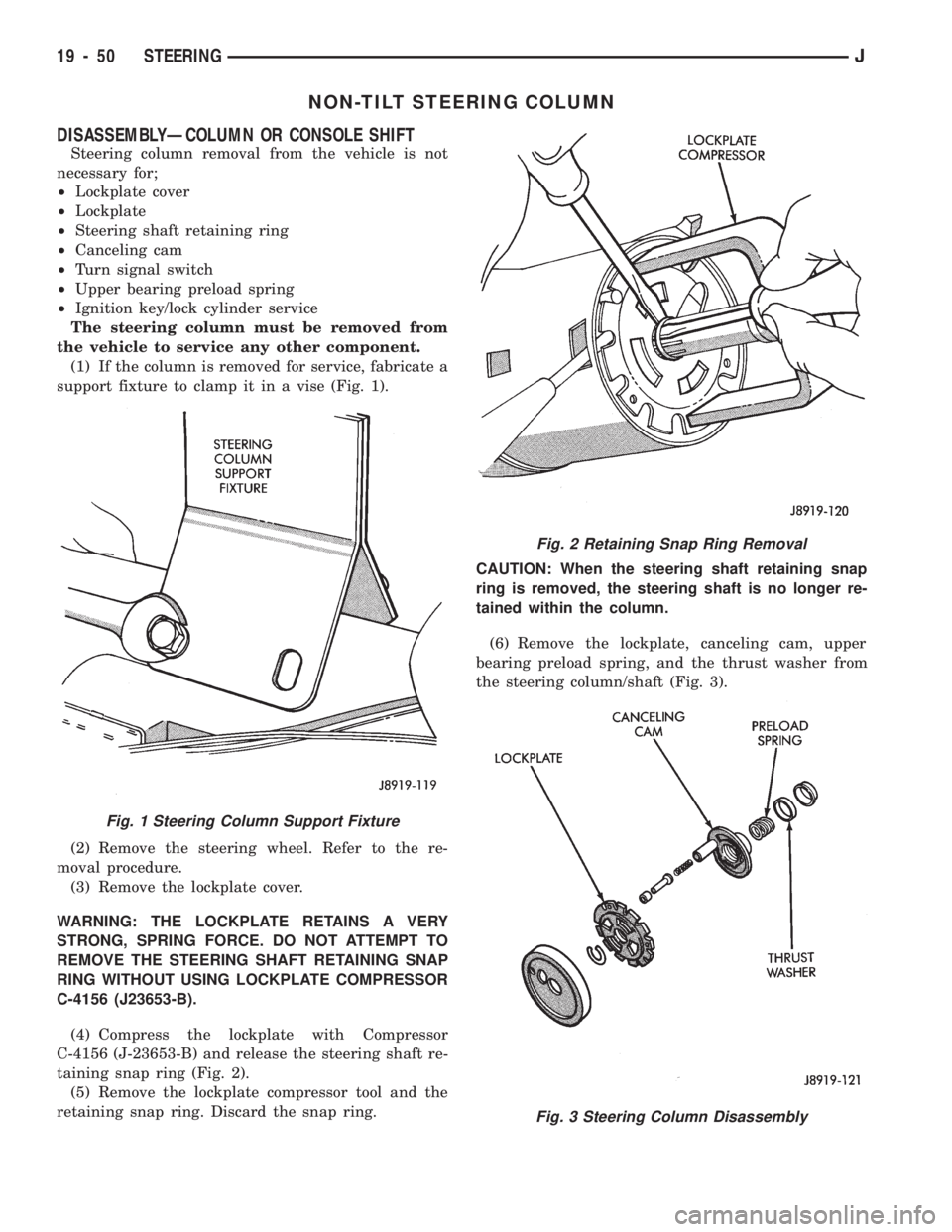

(12) Remove the bolts that attach the toe plate to

the floor pan (Fig. 9).

(13) Carefully remove column from vehicle.

INSTALLATION

CAUTION: Bumping, jolting and hammering on the

steering column shaft and gear shift tube must be

avoided during all service procedures.

(1) Carefully position column in vehicle.

(2) Align the column shaft to steering gear cou-

pling. Install and tighten the bolt to 34 Nzm (25 ft.

lbs.) torque.

(3) As applicable, connect the following items to

the steering column connectors:

²Ignition switch wire harness

²Dimmer switch wire harness

²Turn signal switch wire harness

²Windshield wiper wire harness

²Cruise control wire harness (if equipped)

²Park-lock cable (if equipped)

(4) Install the support bracket on the column and

tighten the bolts to 20 Nzm (180 in. lbs.) torque.

(5) Raise the column up to the brake sled studs.

Connect the brace to the column stud.

(6) Install and tighten the column to brake sled

nuts to 30 Nzm (22 ft. lbs.) torque.

(7) Column shift vehicles, install the shift cable

grommet on the shift lever.

(8) Install and tighten the toe plate-to-floor pan

bolts to 8 Nzm (66 in. lbs.) torque.(9) Column shift vehicles, install the shift indicator

cable on the shift housing. Check operation.

(10) Install the lower portion of the instrument

panel, refer to Group 8E, Instrument Panel.

(11) Install steering wheel on column, refer to

Steering Wheel-Installation.

(12) Connect the negative (ground) cable to the

battery.

COLUMN REPLACEMENTÐYJ

REMOVAL

CAUTION: Bumping, jolting and hammering on the

steering column shaft and gear shift tube must be

avoided during all service procedures.

(1) Make sure the front wheels are in thestraight

aheadposition.

(2) Disconnect the negative (ground) cable from the

battery.

(3) Remove steering wheel from column, refer to

Steering Wheel-Removal.

(4) Column shift vehicles, disconnect the shift ca-

ble grommet by prying it from the shift lever.

(5) Disconnect the column shaft to steering gear

coupler upper bolt (Fig. 10).

(6) Remove the lower portion of the instrument

panel, refer to Group 8E, Instrument Panel.

(7) Remove two nuts holding steering column

bracket to brake sled (Fig. 11).

(8) Remove four bolts holding steering column

bracket to column.

(9) Disconnect the following items from the steer-

ing column connectors:

²Ignition switch wire harness

²Dimmer switch wire harness

²Turn signal switch wire harness

²Windshield wiper wire harness

²Cruise control wire harness (if equipped)

Fig. 9 Steering Column Mounting

Fig. 10 Column Shaft Coupler

19 - 48 STEERINGJ

Page 1087 of 1784

NON-TILT STEERING COLUMN

DISASSEMBLYÐCOLUMN OR CONSOLE SHIFT

Steering column removal from the vehicle is not

necessary for;

²Lockplate cover

²Lockplate

²Steering shaft retaining ring

²Canceling cam

²Turn signal switch

²Upper bearing preload spring

²Ignition key/lock cylinder service

The steering column must be removed from

the vehicle to service any other component.

(1) If the column is removed for service, fabricate a

support fixture to clamp it in a vise (Fig. 1).

(2) Remove the steering wheel. Refer to the re-

moval procedure.

(3) Remove the lockplate cover.

WARNING: THE LOCKPLATE RETAINS A VERY

STRONG, SPRING FORCE. DO NOT ATTEMPT TO

REMOVE THE STEERING SHAFT RETAINING SNAP

RING WITHOUT USING LOCKPLATE COMPRESSOR

C-4156 (J23653-B).

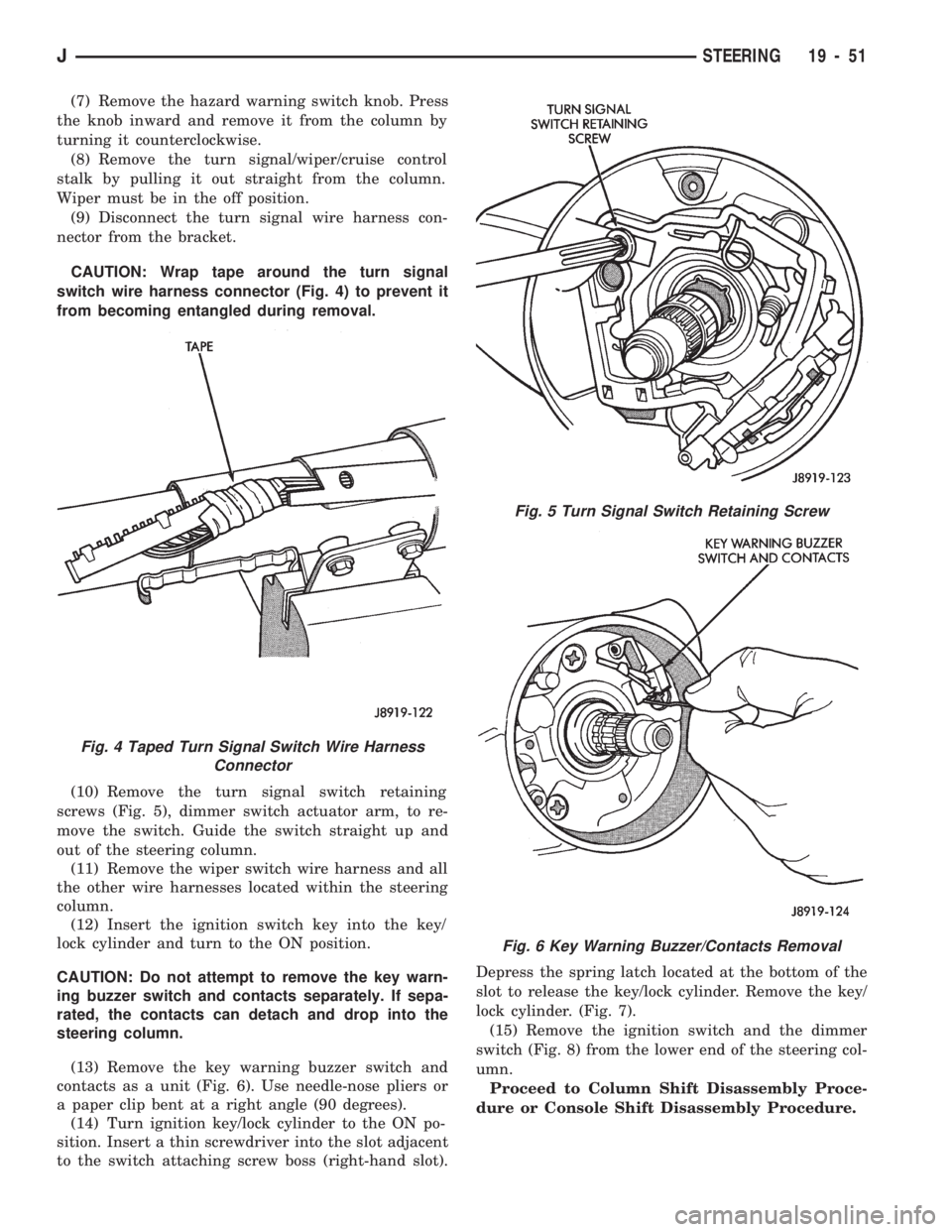

(4) Compress the lockplate with Compressor

C-4156 (J-23653-B) and release the steering shaft re-

taining snap ring (Fig. 2).

(5) Remove the lockplate compressor tool and the

retaining snap ring. Discard the snap ring.CAUTION: When the steering shaft retaining snap

ring is removed, the steering shaft is no longer re-

tained within the column.

(6) Remove the lockplate, canceling cam, upper

bearing preload spring, and the thrust washer from

the steering column/shaft (Fig. 3).

Fig. 2 Retaining Snap Ring Removal

Fig. 3 Steering Column Disassembly

Fig. 1 Steering Column Support Fixture

19 - 50 STEERINGJ

Page 1088 of 1784

(7) Remove the hazard warning switch knob. Press

the knob inward and remove it from the column by

turning it counterclockwise.

(8) Remove the turn signal/wiper/cruise control

stalk by pulling it out straight from the column.

Wiper must be in the off position.

(9) Disconnect the turn signal wire harness con-

nector from the bracket.

CAUTION: Wrap tape around the turn signal

switch wire harness connector (Fig. 4) to prevent it

from becoming entangled during removal.

(10) Remove the turn signal switch retaining

screws (Fig. 5), dimmer switch actuator arm, to re-

move the switch. Guide the switch straight up and

out of the steering column.

(11) Remove the wiper switch wire harness and all

the other wire harnesses located within the steering

column.

(12) Insert the ignition switch key into the key/

lock cylinder and turn to the ON position.

CAUTION: Do not attempt to remove the key warn-

ing buzzer switch and contacts separately. If sepa-

rated, the contacts can detach and drop into the

steering column.

(13) Remove the key warning buzzer switch and

contacts as a unit (Fig. 6). Use needle-nose pliers or

a paper clip bent at a right angle (90 degrees).

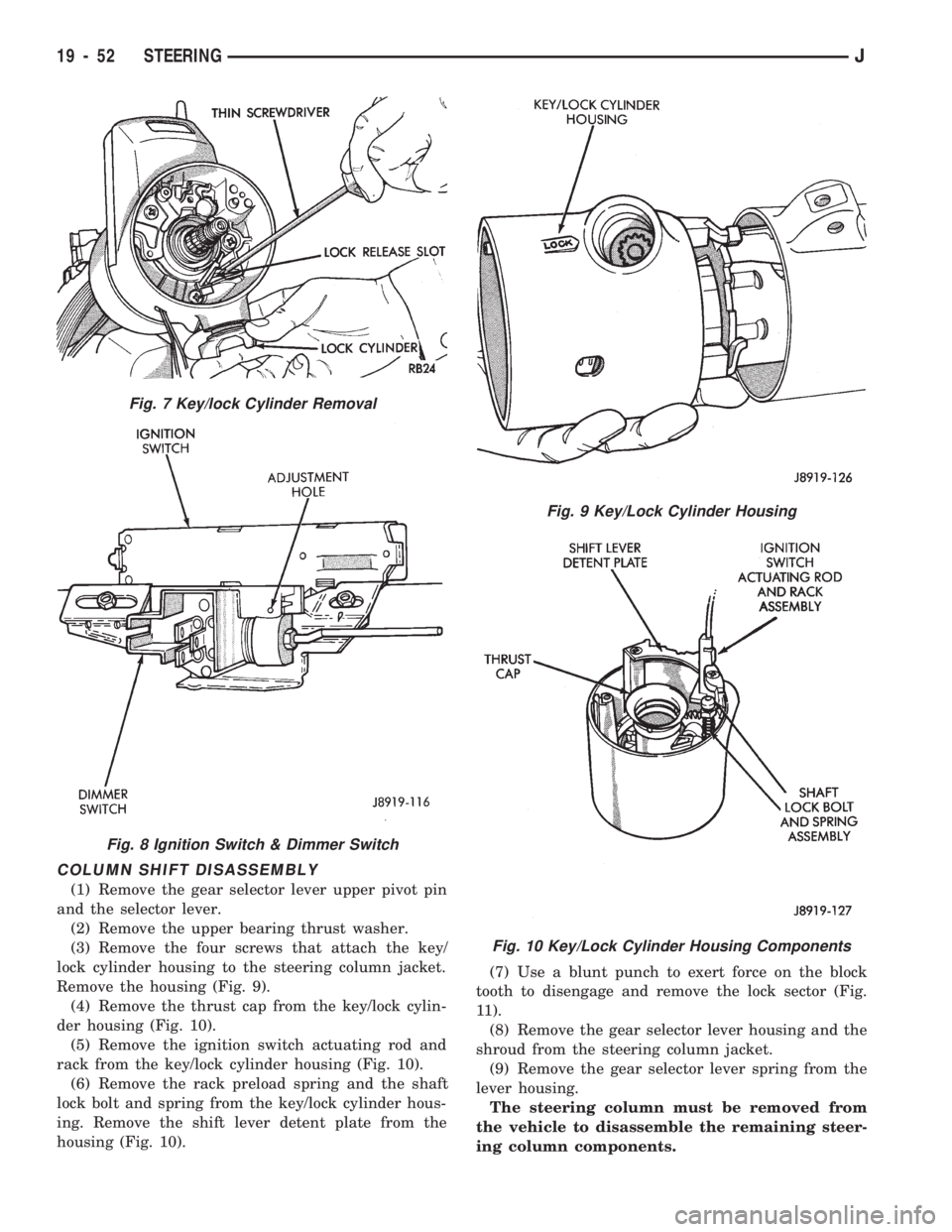

(14) Turn ignition key/lock cylinder to the ON po-

sition. Insert a thin screwdriver into the slot adjacent

to the switch attaching screw boss (right-hand slot).Depress the spring latch located at the bottom of the

slot to release the key/lock cylinder. Remove the key/

lock cylinder. (Fig. 7).

(15) Remove the ignition switch and the dimmer

switch (Fig. 8) from the lower end of the steering col-

umn.

Proceed to Column Shift Disassembly Proce-

dure or Console Shift Disassembly Procedure.

Fig. 4 Taped Turn Signal Switch Wire Harness

Connector

Fig. 5 Turn Signal Switch Retaining Screw

Fig. 6 Key Warning Buzzer/Contacts Removal

JSTEERING 19 - 51

Page 1089 of 1784

COLUMN SHIFT DISASSEMBLY

(1) Remove the gear selector lever upper pivot pin

and the selector lever.

(2) Remove the upper bearing thrust washer.

(3) Remove the four screws that attach the key/

lock cylinder housing to the steering column jacket.

Remove the housing (Fig. 9).

(4) Remove the thrust cap from the key/lock cylin-

der housing (Fig. 10).

(5) Remove the ignition switch actuating rod and

rack from the key/lock cylinder housing (Fig. 10).

(6) Remove the rack preload spring and the shaft

lock bolt and spring from the key/lock cylinder hous-

ing. Remove the shift lever detent plate from the

housing (Fig. 10).(7) Use a blunt punch to exert force on the block

tooth to disengage and remove the lock sector (Fig.

11).

(8) Remove the gear selector lever housing and the

shroud from the steering column jacket.

(9) Remove the gear selector lever spring from the

lever housing.

The steering column must be removed from

the vehicle to disassemble the remaining steer-

ing column components.

Fig. 7 Key/lock Cylinder Removal

Fig. 8 Ignition Switch & Dimmer Switch

Fig. 9 Key/Lock Cylinder Housing

Fig. 10 Key/Lock Cylinder Housing Components

19 - 52 STEERINGJ

Page 1090 of 1784

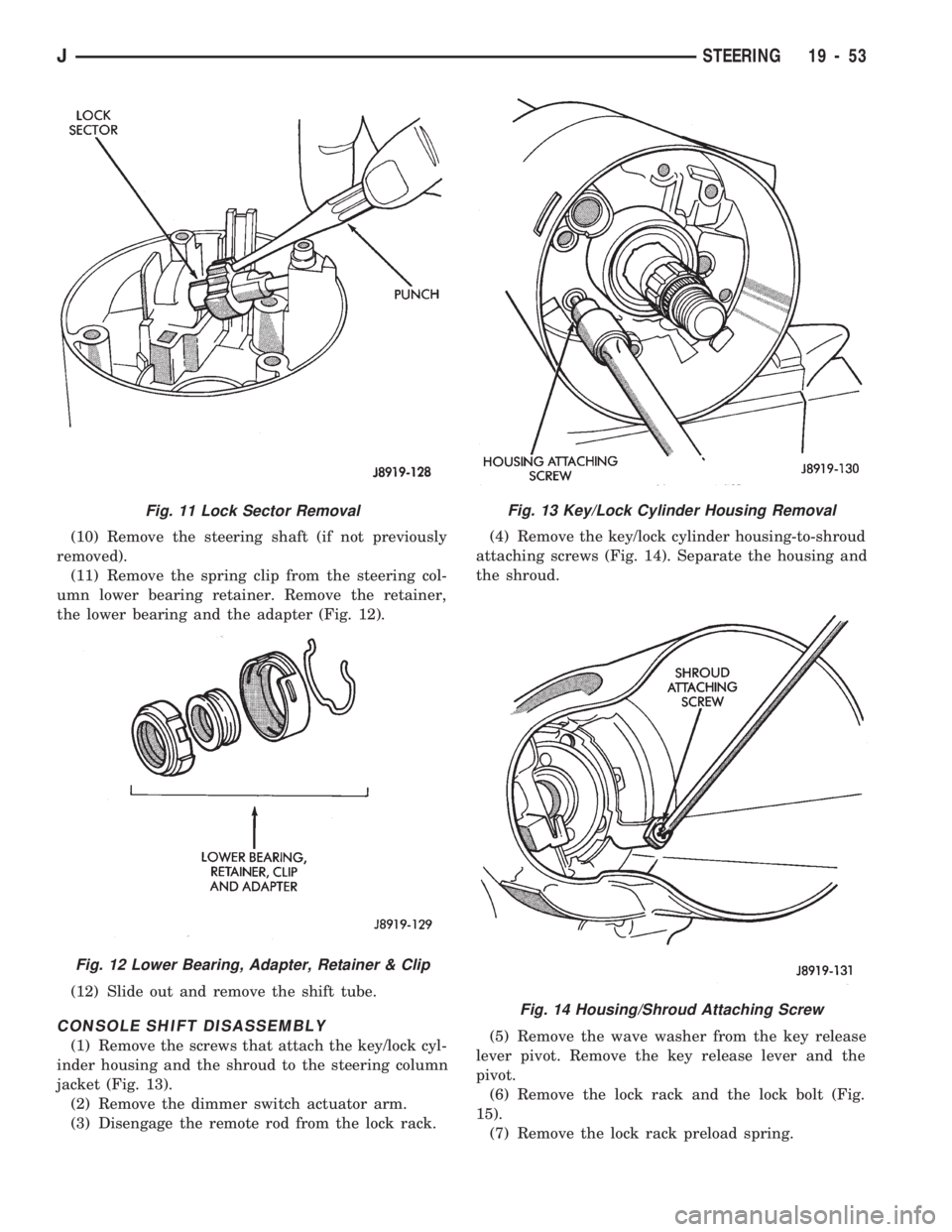

(10) Remove the steering shaft (if not previously

removed).

(11) Remove the spring clip from the steering col-

umn lower bearing retainer. Remove the retainer,

the lower bearing and the adapter (Fig. 12).

(12) Slide out and remove the shift tube.

CONSOLE SHIFT DISASSEMBLY

(1) Remove the screws that attach the key/lock cyl-

inder housing and the shroud to the steering column

jacket (Fig. 13).

(2) Remove the dimmer switch actuator arm.

(3) Disengage the remote rod from the lock rack.(4) Remove the key/lock cylinder housing-to-shroud

attaching screws (Fig. 14). Separate the housing and

the shroud.

(5) Remove the wave washer from the key release

lever pivot. Remove the key release lever and the

pivot.

(6) Remove the lock rack and the lock bolt (Fig.

15).

(7) Remove the lock rack preload spring.

Fig. 11 Lock Sector Removal

Fig. 12 Lower Bearing, Adapter, Retainer & Clip

Fig. 13 Key/Lock Cylinder Housing Removal

Fig. 14 Housing/Shroud Attaching Screw

JSTEERING 19 - 53