lock JEEP CHEROKEE 1994 Service Repair Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 1994, Model line: CHEROKEE, Model: JEEP CHEROKEE 1994Pages: 1784, PDF Size: 77.09 MB

Page 1119 of 1784

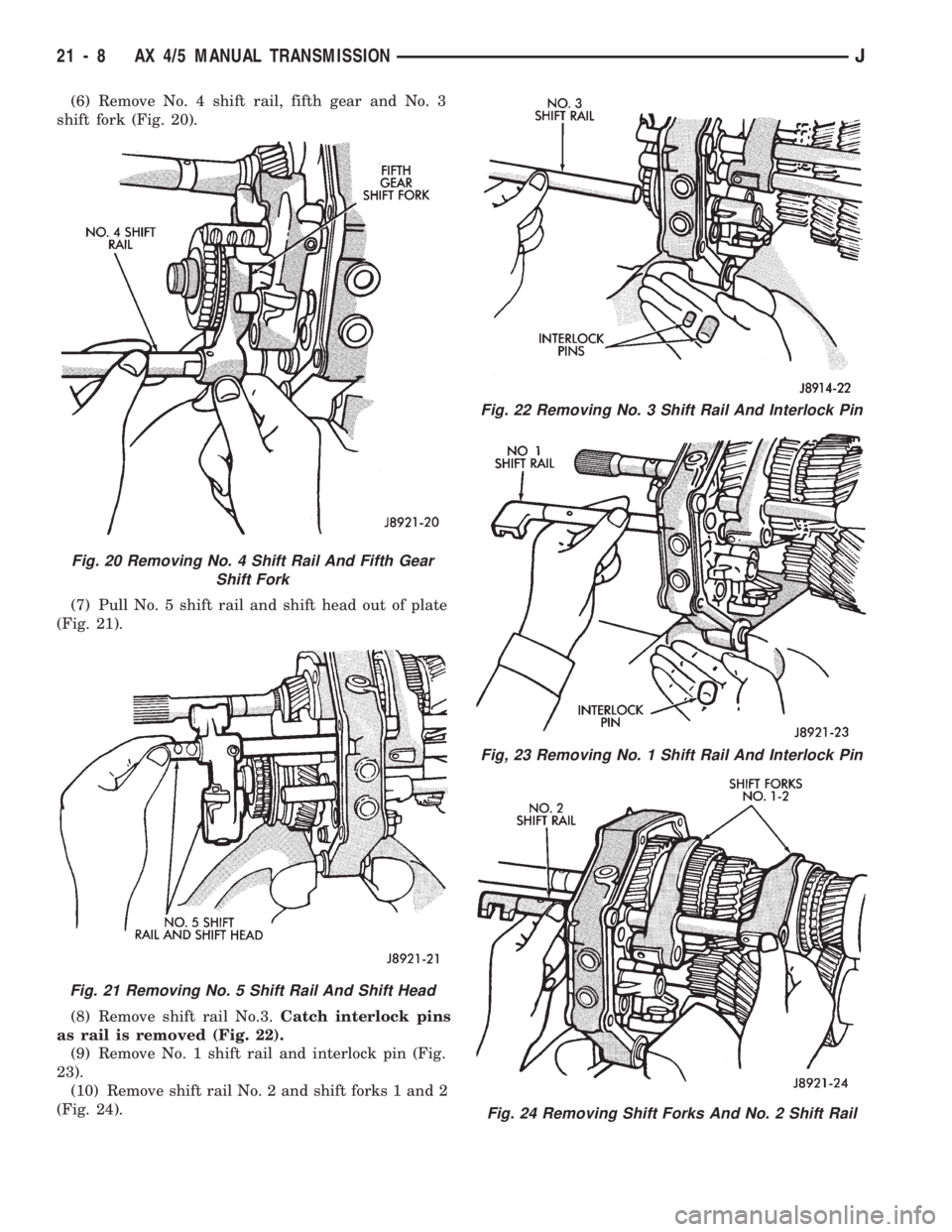

(6) Remove No. 4 shift rail, fifth gear and No. 3

shift fork (Fig. 20).

(7) Pull No. 5 shift rail and shift head out of plate

(Fig. 21).

(8) Remove shift rail No.3.Catch interlock pins

as rail is removed (Fig. 22).

(9) Remove No. 1 shift rail and interlock pin (Fig.

23).

(10) Remove shift rail No. 2 and shift forks 1 and 2

(Fig. 24).

Fig. 20 Removing No. 4 Shift Rail And Fifth Gear

Shift Fork

Fig. 21 Removing No. 5 Shift Rail And Shift Head

Fig. 22 Removing No. 3 Shift Rail And Interlock Pin

Fig, 23 Removing No. 1 Shift Rail And Interlock Pin

Fig. 24 Removing Shift Forks And No. 2 Shift Rail

21 - 8 AX 4/5 MANUAL TRANSMISSIONJ

Page 1120 of 1784

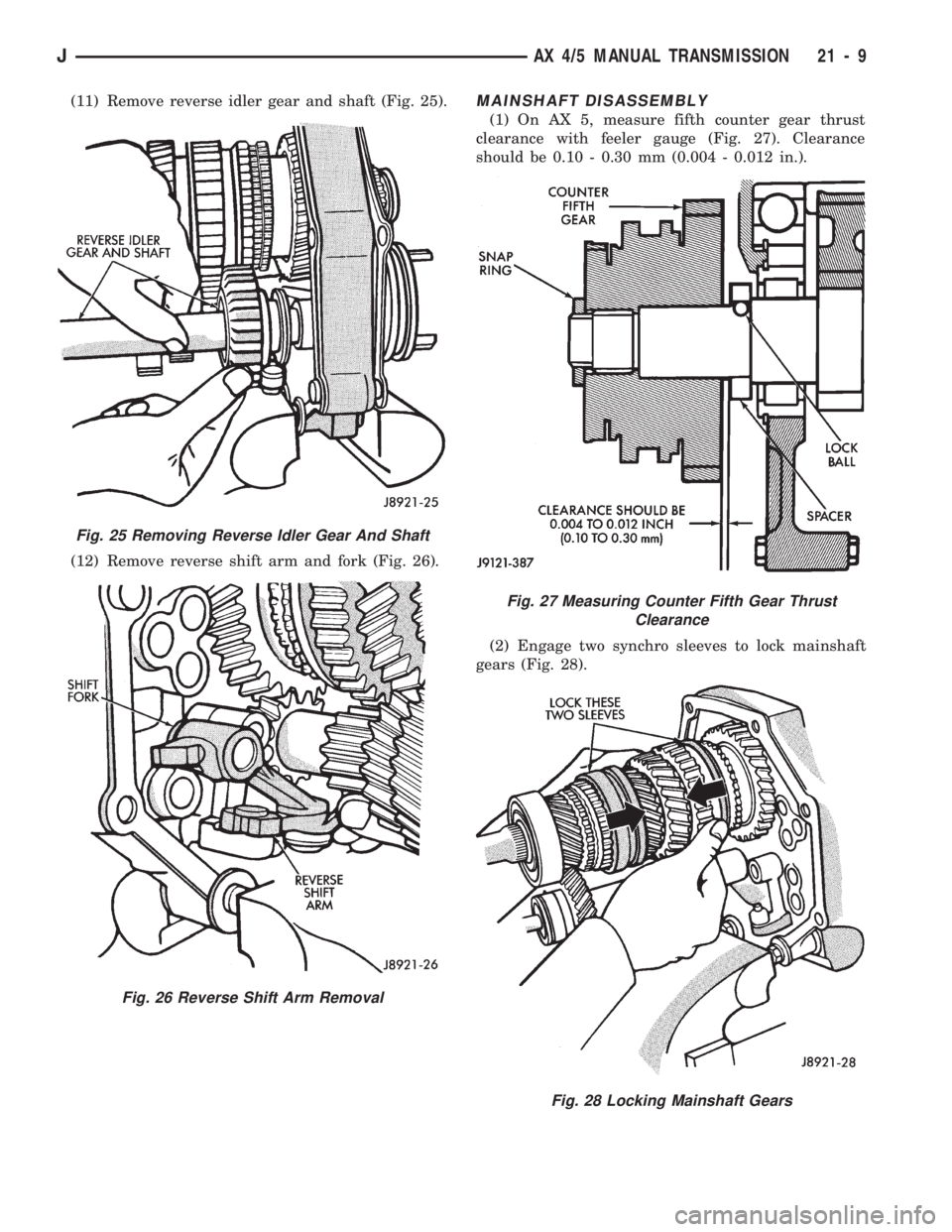

(11) Remove reverse idler gear and shaft (Fig. 25).

(12) Remove reverse shift arm and fork (Fig. 26).MAINSHAFT DISASSEMBLY

(1) On AX 5, measure fifth counter gear thrust

clearance with feeler gauge (Fig. 27). Clearance

should be 0.10 - 0.30 mm (0.004 - 0.012 in.).

(2) Engage two synchro sleeves to lock mainshaft

gears (Fig. 28).

Fig. 25 Removing Reverse Idler Gear And Shaft

Fig. 26 Reverse Shift Arm Removal

Fig. 27 Measuring Counter Fifth Gear Thrust

Clearance

Fig. 28 Locking Mainshaft Gears

JAX 4/5 MANUAL TRANSMISSION 21 - 9

Page 1121 of 1784

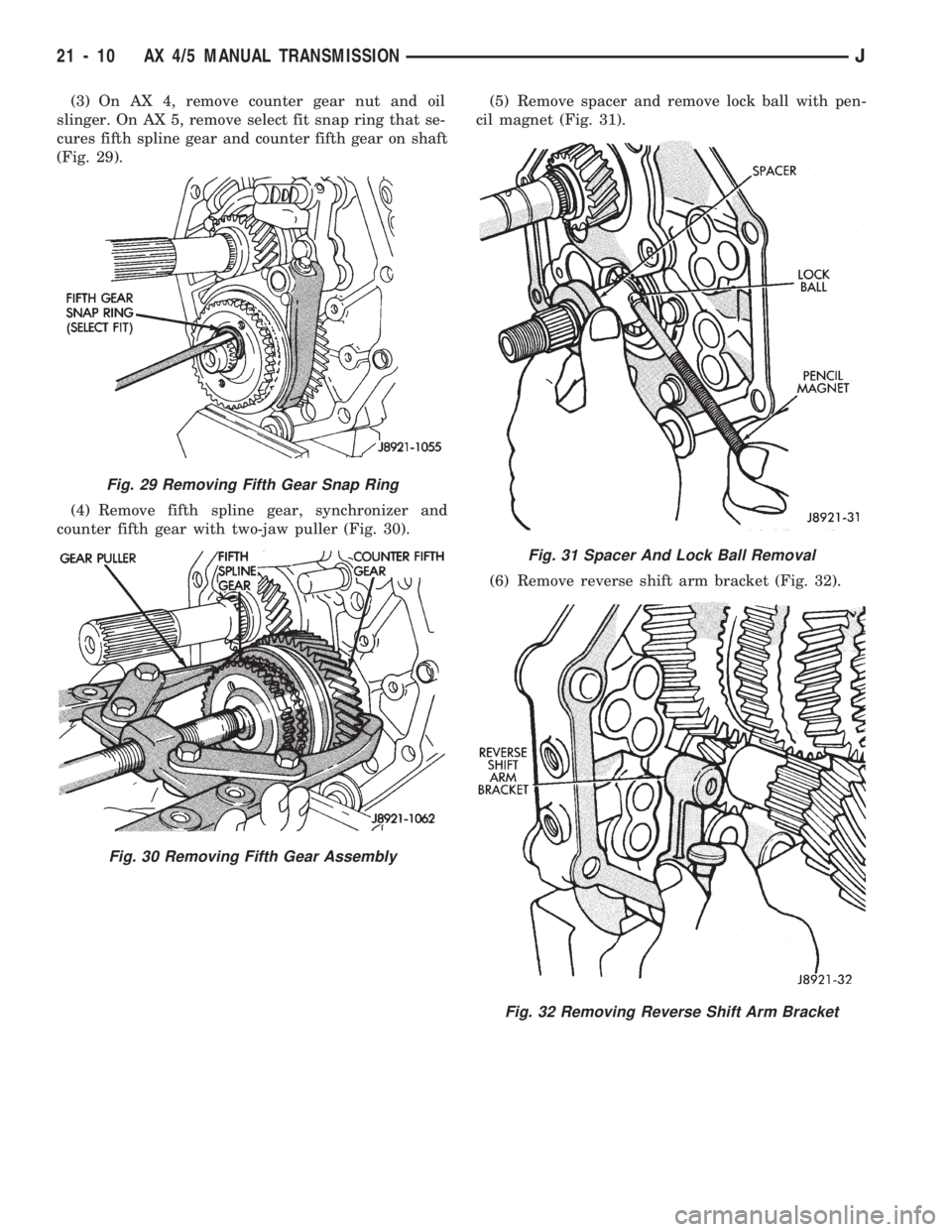

(3) On AX 4, remove counter gear nut and oil

slinger. On AX 5, remove select fit snap ring that se-

cures fifth spline gear and counter fifth gear on shaft

(Fig. 29).

(4) Remove fifth spline gear, synchronizer and

counter fifth gear with two-jaw puller (Fig. 30).(5) Remove spacer and remove lock ball with pen-

cil magnet (Fig. 31).

(6) Remove reverse shift arm bracket (Fig. 32).

Fig. 29 Removing Fifth Gear Snap Ring

Fig. 30 Removing Fifth Gear Assembly

Fig. 31 Spacer And Lock Ball Removal

Fig. 32 Removing Reverse Shift Arm Bracket

21 - 10 AX 4/5 MANUAL TRANSMISSIONJ

Page 1123 of 1784

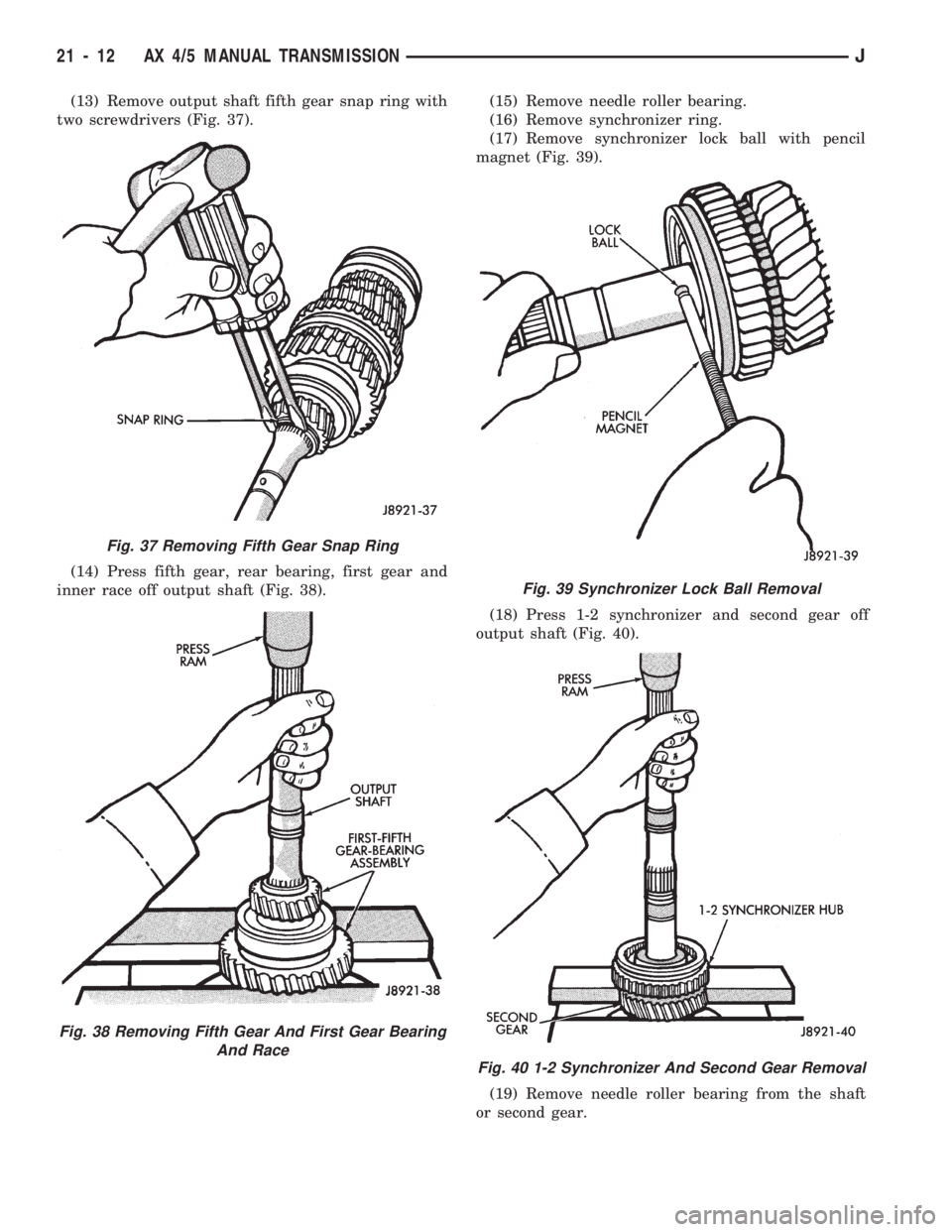

(13) Remove output shaft fifth gear snap ring with

two screwdrivers (Fig. 37).

(14) Press fifth gear, rear bearing, first gear and

inner race off output shaft (Fig. 38).(15) Remove needle roller bearing.

(16) Remove synchronizer ring.

(17) Remove synchronizer lock ball with pencil

magnet (Fig. 39).

(18) Press 1-2 synchronizer and second gear off

output shaft (Fig. 40).

(19) Remove needle roller bearing from the shaft

or second gear.

Fig. 37 Removing Fifth Gear Snap Ring

Fig. 38 Removing Fifth Gear And First Gear Bearing

And Race

Fig. 39 Synchronizer Lock Ball Removal

Fig. 40 1-2 Synchronizer And Second Gear Removal

21 - 12 AX 4/5 MANUAL TRANSMISSIONJ

Page 1128 of 1784

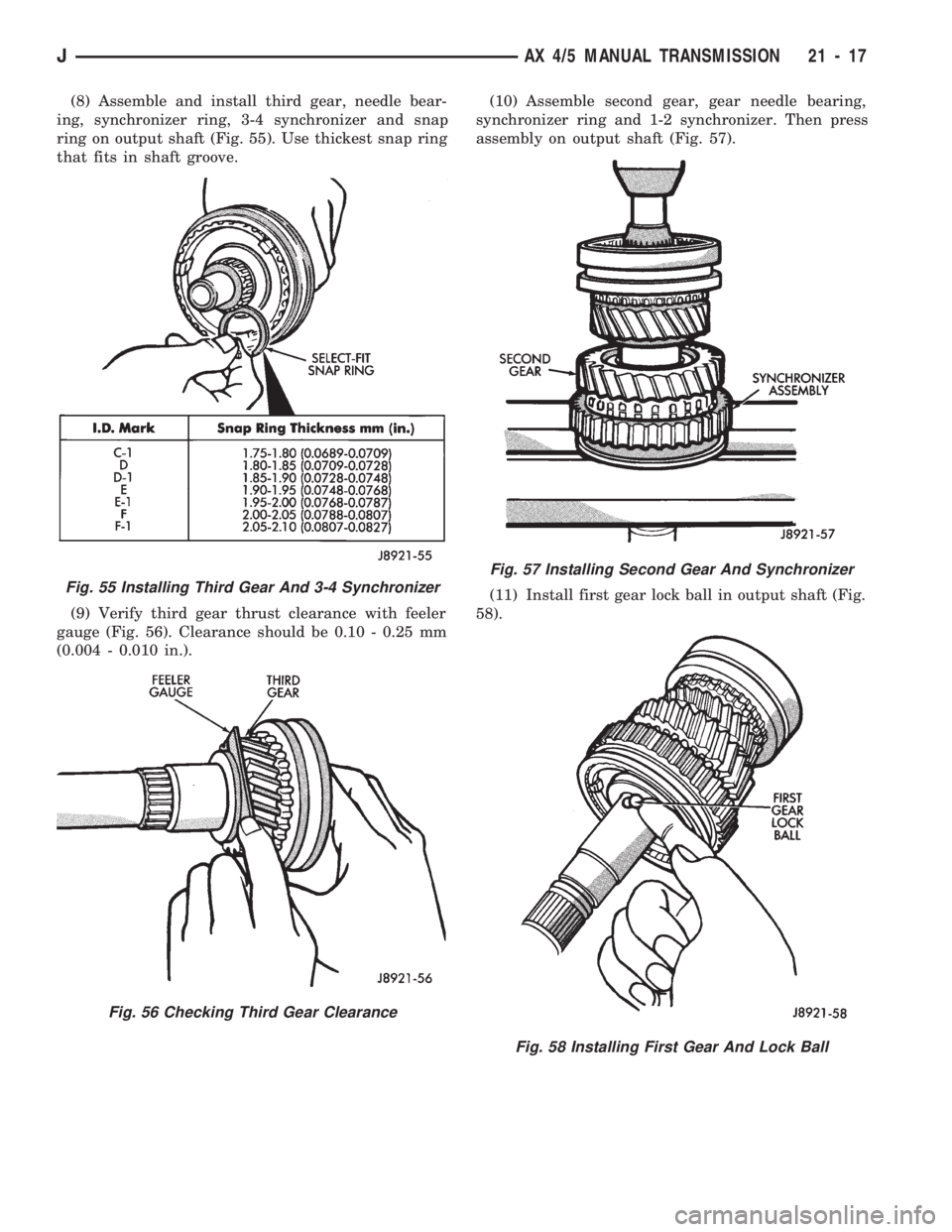

(8) Assemble and install third gear, needle bear-

ing, synchronizer ring, 3-4 synchronizer and snap

ring on output shaft (Fig. 55). Use thickest snap ring

that fits in shaft groove.

(9) Verify third gear thrust clearance with feeler

gauge (Fig. 56). Clearance should be 0.10 - 0.25 mm

(0.004 - 0.010 in.).(10) Assemble second gear, gear needle bearing,

synchronizer ring and 1-2 synchronizer. Then press

assembly on output shaft (Fig. 57).

(11) Install first gear lock ball in output shaft (Fig.

58).

Fig. 55 Installing Third Gear And 3-4 Synchronizer

Fig. 56 Checking Third Gear Clearance

Fig. 57 Installing Second Gear And Synchronizer

Fig. 58 Installing First Gear And Lock Ball

JAX 4/5 MANUAL TRANSMISSION 21 - 17

Page 1129 of 1784

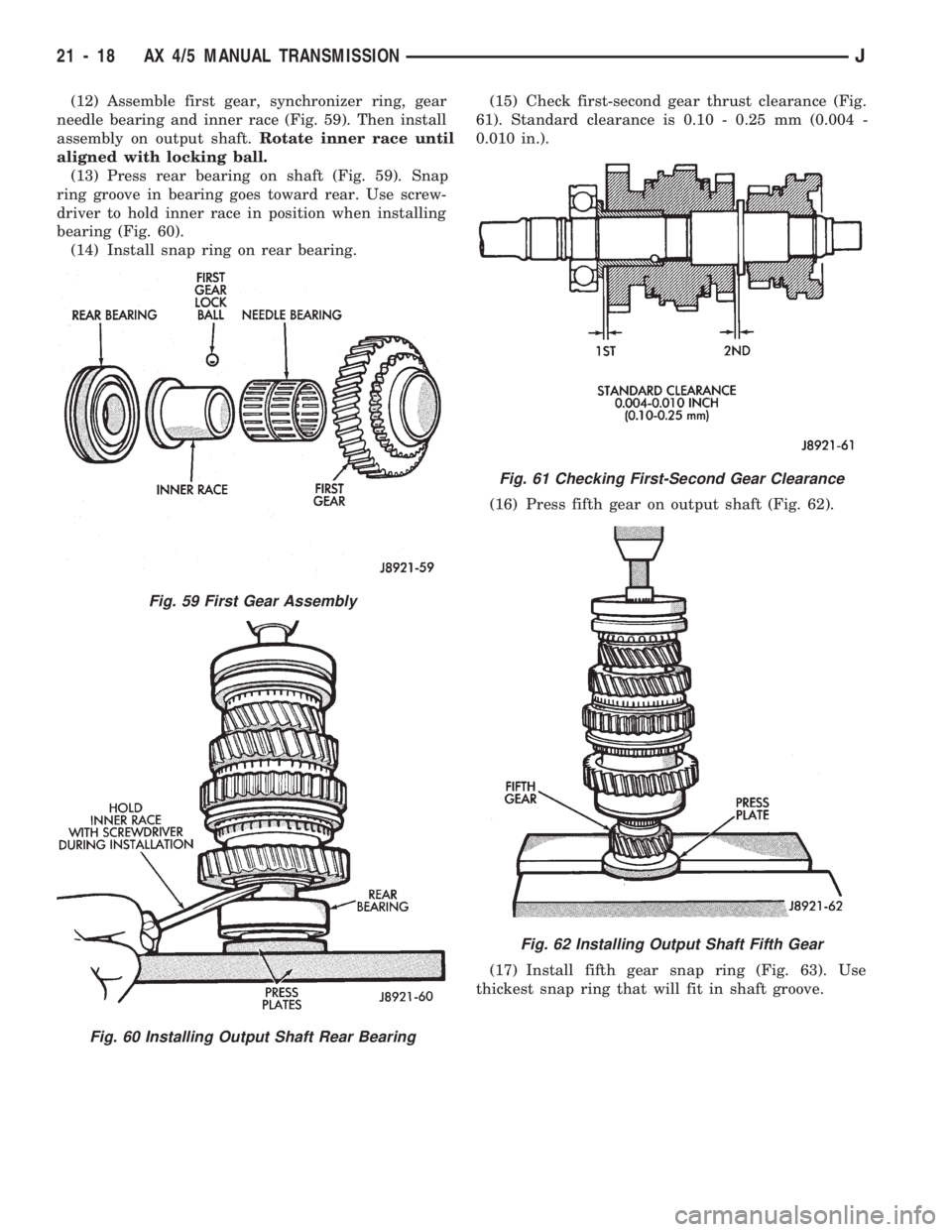

(12) Assemble first gear, synchronizer ring, gear

needle bearing and inner race (Fig. 59). Then install

assembly on output shaft.Rotate inner race until

aligned with locking ball.

(13) Press rear bearing on shaft (Fig. 59). Snap

ring groove in bearing goes toward rear. Use screw-

driver to hold inner race in position when installing

bearing (Fig. 60).

(14) Install snap ring on rear bearing.(15) Check first-second gear thrust clearance (Fig.

61). Standard clearance is 0.10 - 0.25 mm (0.004 -

0.010 in.).

(16) Press fifth gear on output shaft (Fig. 62).

(17) Install fifth gear snap ring (Fig. 63). Use

thickest snap ring that will fit in shaft groove.

Fig. 59 First Gear Assembly

Fig. 60 Installing Output Shaft Rear Bearing

Fig. 61 Checking First-Second Gear Clearance

Fig. 62 Installing Output Shaft Fifth Gear

21 - 18 AX 4/5 MANUAL TRANSMISSIONJ

Page 1131 of 1784

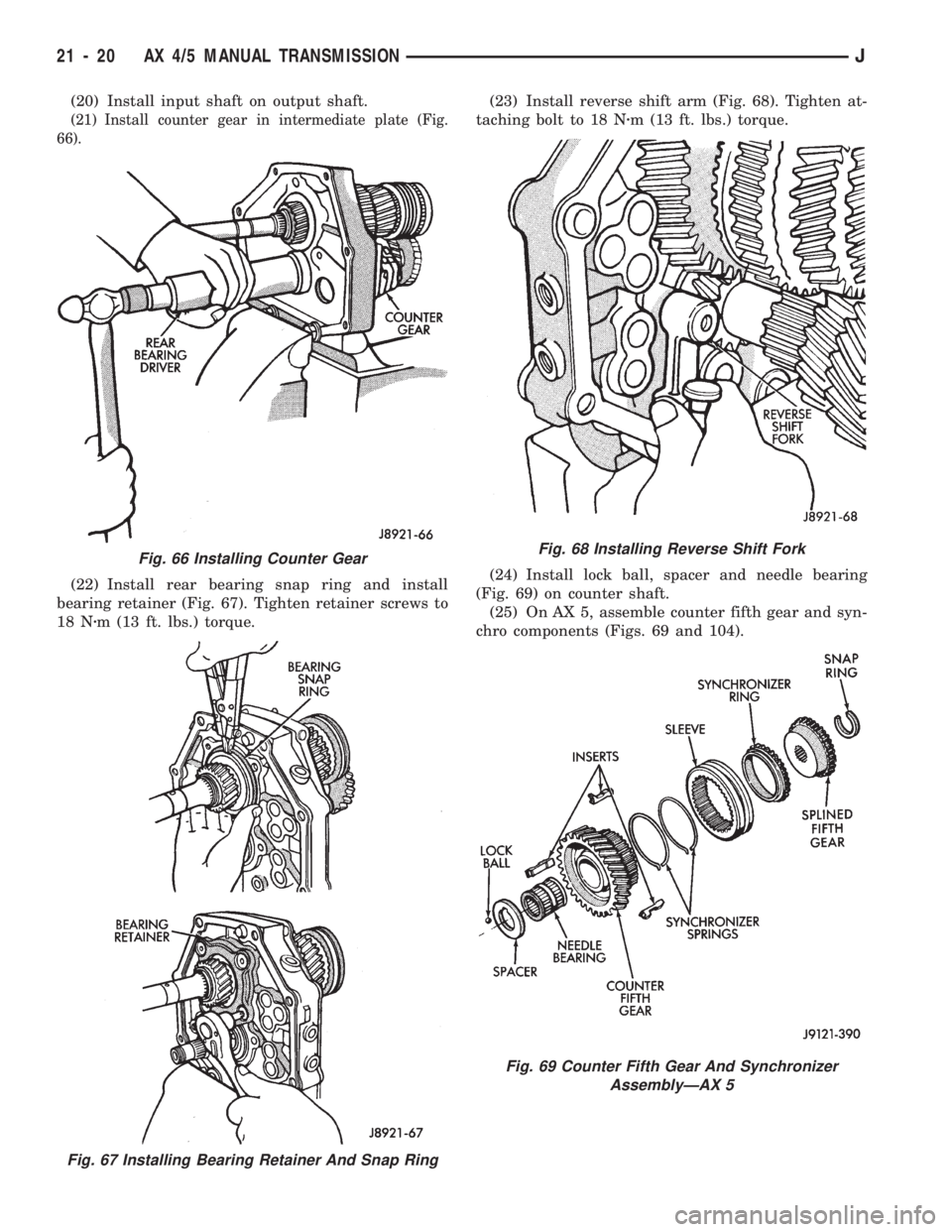

(20) Install input shaft on output shaft.

(21) Install counter gear in intermediate plate (Fig.

66).

(22) Install rear bearing snap ring and install

bearing retainer (Fig. 67). Tighten retainer screws to

18 Nzm (13 ft. lbs.) torque.(23) Install reverse shift arm (Fig. 68). Tighten at-

taching bolt to 18 Nzm (13 ft. lbs.) torque.

(24) Install lock ball, spacer and needle bearing

(Fig. 69) on counter shaft.

(25) On AX 5, assemble counter fifth gear and syn-

chro components (Figs. 69 and 104).

Fig. 66 Installing Counter Gear

Fig. 67 Installing Bearing Retainer And Snap Ring

Fig. 68 Installing Reverse Shift Fork

Fig. 69 Counter Fifth Gear And Synchronizer

AssemblyÐAX 5

21 - 20 AX 4/5 MANUAL TRANSMISSIONJ

Page 1132 of 1784

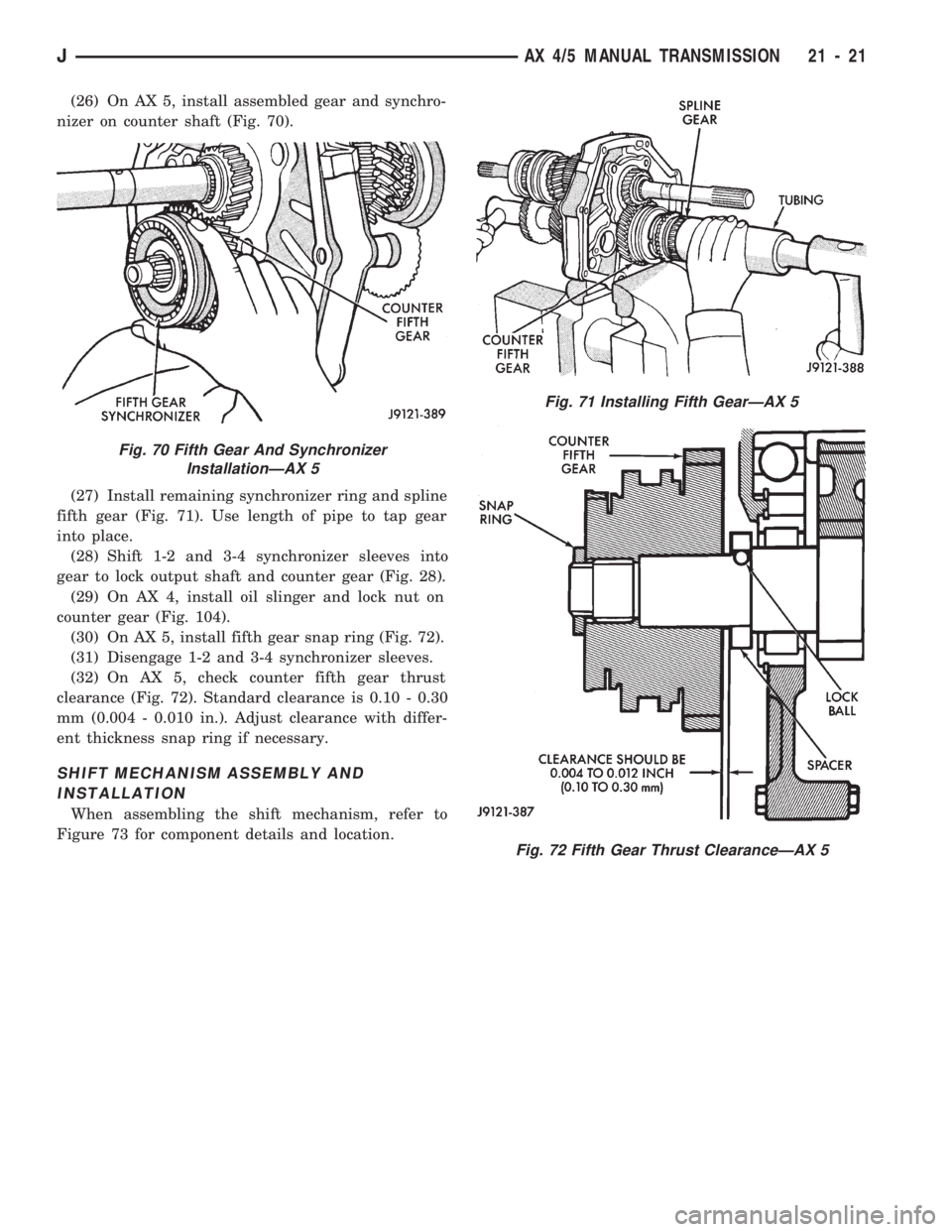

(26) On AX 5, install assembled gear and synchro-

nizer on counter shaft (Fig. 70).

(27) Install remaining synchronizer ring and spline

fifth gear (Fig. 71). Use length of pipe to tap gear

into place.

(28) Shift 1-2 and 3-4 synchronizer sleeves into

gear to lock output shaft and counter gear (Fig. 28).

(29) On AX 4, install oil slinger and lock nut on

counter gear (Fig. 104).

(30) On AX 5, install fifth gear snap ring (Fig. 72).

(31) Disengage 1-2 and 3-4 synchronizer sleeves.

(32) On AX 5, check counter fifth gear thrust

clearance (Fig. 72). Standard clearance is 0.10 - 0.30

mm (0.004 - 0.010 in.). Adjust clearance with differ-

ent thickness snap ring if necessary.

SHIFT MECHANISM ASSEMBLY AND

INSTALLATION

When assembling the shift mechanism, refer to

Figure 73 for component details and location.

Fig. 70 Fifth Gear And Synchronizer

InstallationÐAX 5

Fig. 71 Installing Fifth GearÐAX 5

Fig. 72 Fifth Gear Thrust ClearanceÐAX 5

JAX 4/5 MANUAL TRANSMISSION 21 - 21

Page 1134 of 1784

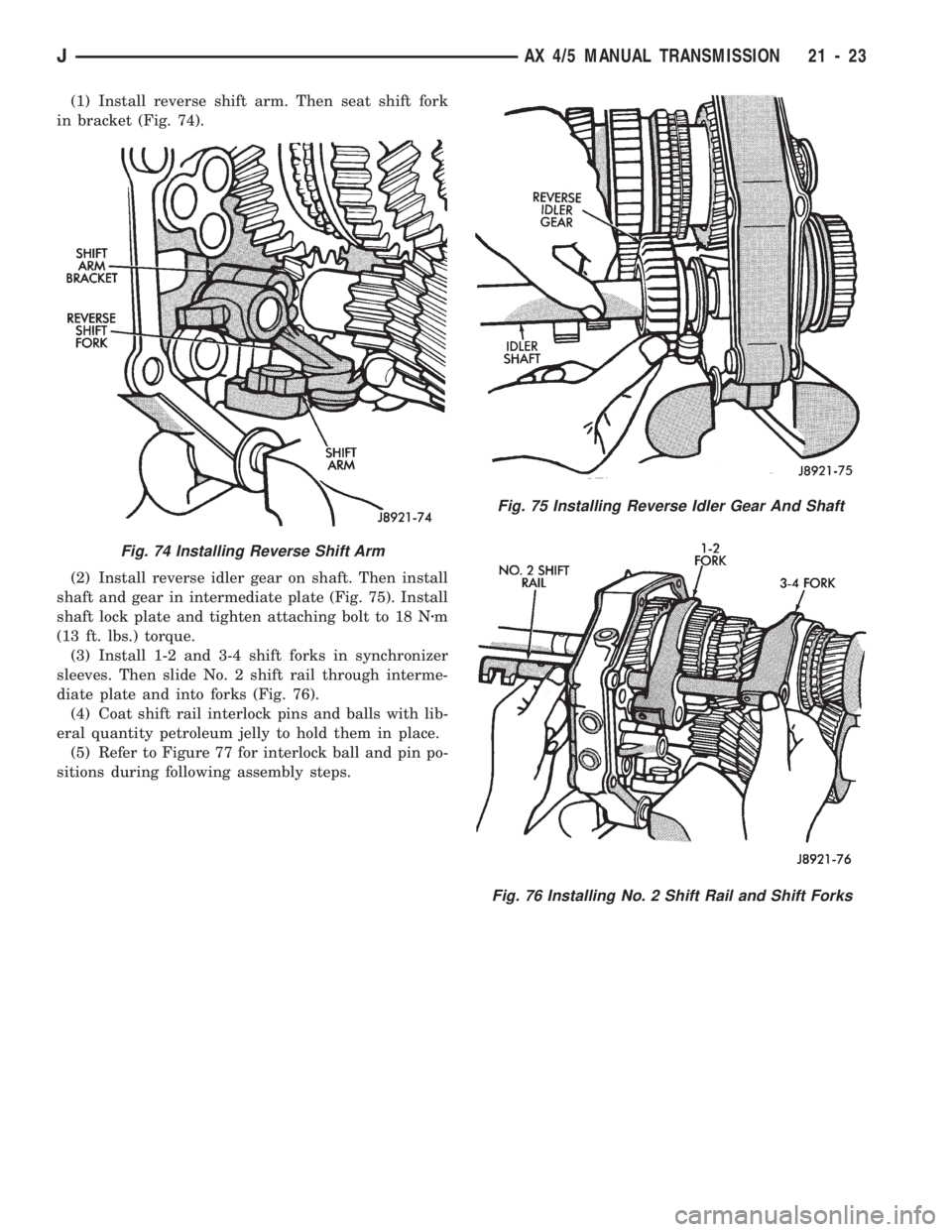

(1) Install reverse shift arm. Then seat shift fork

in bracket (Fig. 74).

(2) Install reverse idler gear on shaft. Then install

shaft and gear in intermediate plate (Fig. 75). Install

shaft lock plate and tighten attaching bolt to 18 Nzm

(13 ft. lbs.) torque.

(3) Install 1-2 and 3-4 shift forks in synchronizer

sleeves. Then slide No. 2 shift rail through interme-

diate plate and into forks (Fig. 76).

(4) Coat shift rail interlock pins and balls with lib-

eral quantity petroleum jelly to hold them in place.

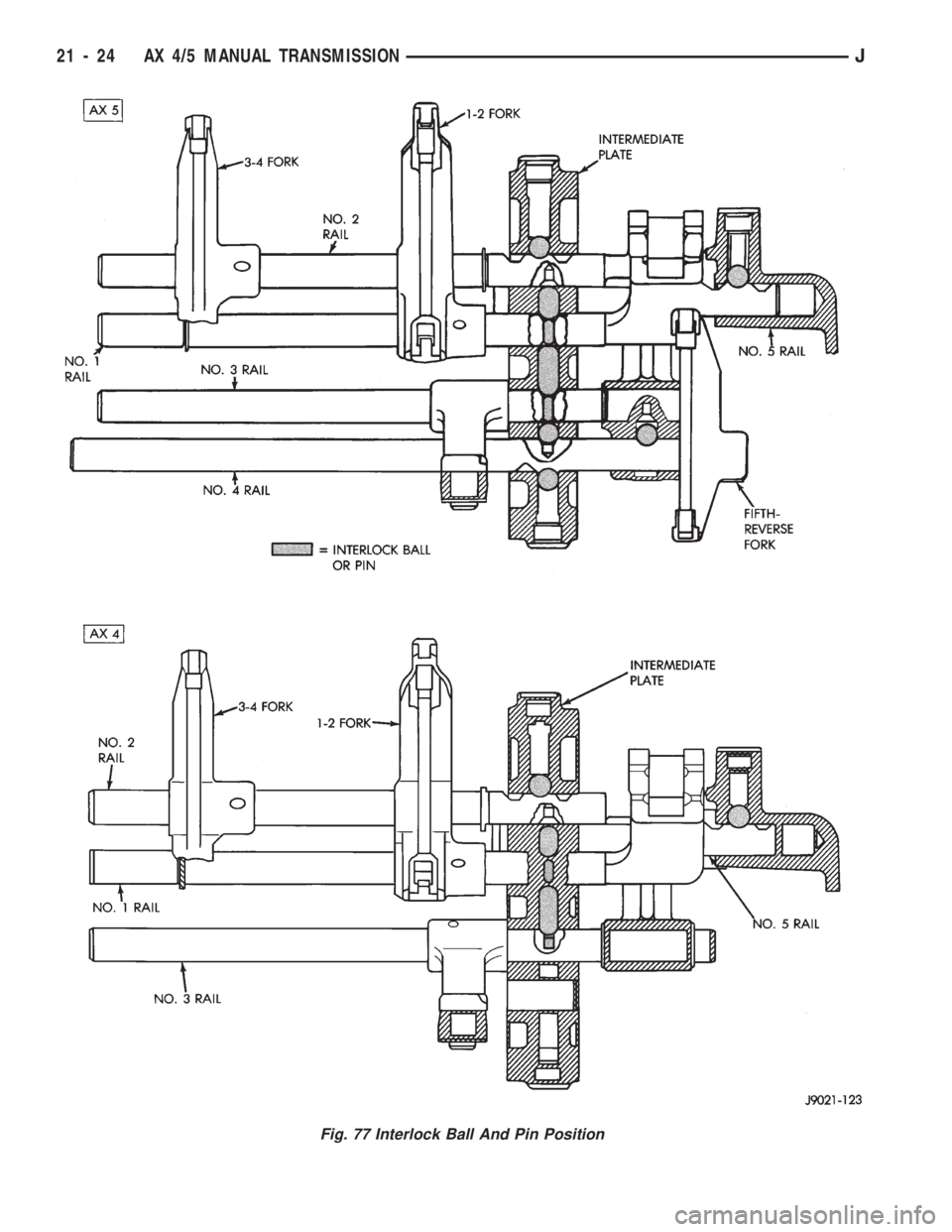

(5) Refer to Figure 77 for interlock ball and pin po-

sitions during following assembly steps.

Fig. 75 Installing Reverse Idler Gear And Shaft

Fig. 76 Installing No. 2 Shift Rail and Shift Forks

Fig. 74 Installing Reverse Shift Arm

JAX 4/5 MANUAL TRANSMISSION 21 - 23

Page 1135 of 1784

Fig. 77 Interlock Ball And Pin Position

21 - 24 AX 4/5 MANUAL TRANSMISSIONJ