engine JEEP CHEROKEE 1994 Service Repair Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 1994, Model line: CHEROKEE, Model: JEEP CHEROKEE 1994Pages: 1784, PDF Size: 77.09 MB

Page 886 of 1784

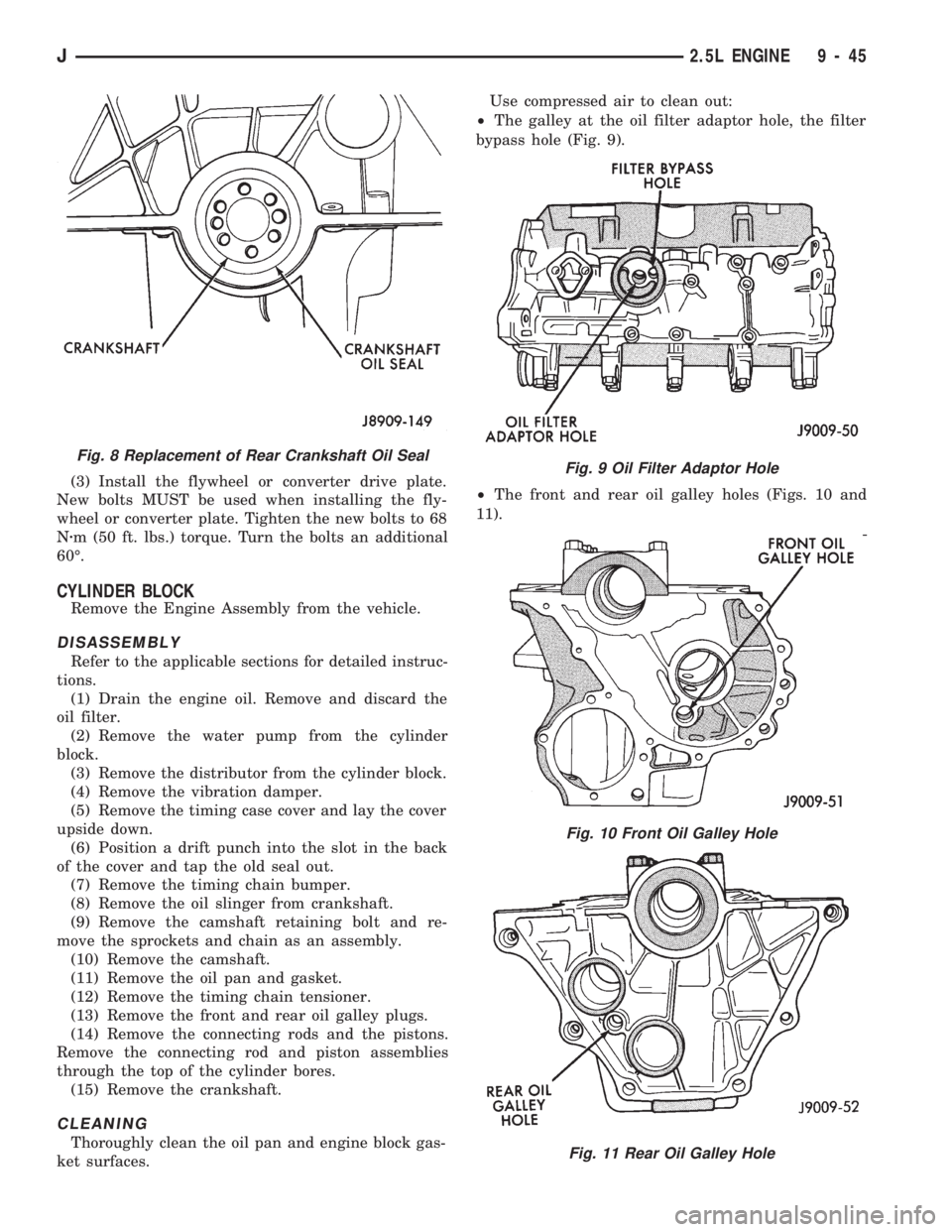

(3) Install the flywheel or converter drive plate.

New bolts MUST be used when installing the fly-

wheel or converter plate. Tighten the new bolts to 68

Nzm (50 ft. lbs.) torque. Turn the bolts an additional

60É.

CYLINDER BLOCK

Remove the Engine Assembly from the vehicle.

DISASSEMBLY

Refer to the applicable sections for detailed instruc-

tions.

(1) Drain the engine oil. Remove and discard the

oil filter.

(2) Remove the water pump from the cylinder

block.

(3) Remove the distributor from the cylinder block.

(4) Remove the vibration damper.

(5) Remove the timing case cover and lay the cover

upside down.

(6) Position a drift punch into the slot in the back

of the cover and tap the old seal out.

(7) Remove the timing chain bumper.

(8) Remove the oil slinger from crankshaft.

(9) Remove the camshaft retaining bolt and re-

move the sprockets and chain as an assembly.

(10) Remove the camshaft.

(11) Remove the oil pan and gasket.

(12) Remove the timing chain tensioner.

(13) Remove the front and rear oil galley plugs.

(14) Remove the connecting rods and the pistons.

Remove the connecting rod and piston assemblies

through the top of the cylinder bores.

(15) Remove the crankshaft.

CLEANING

Thoroughly clean the oil pan and engine block gas-

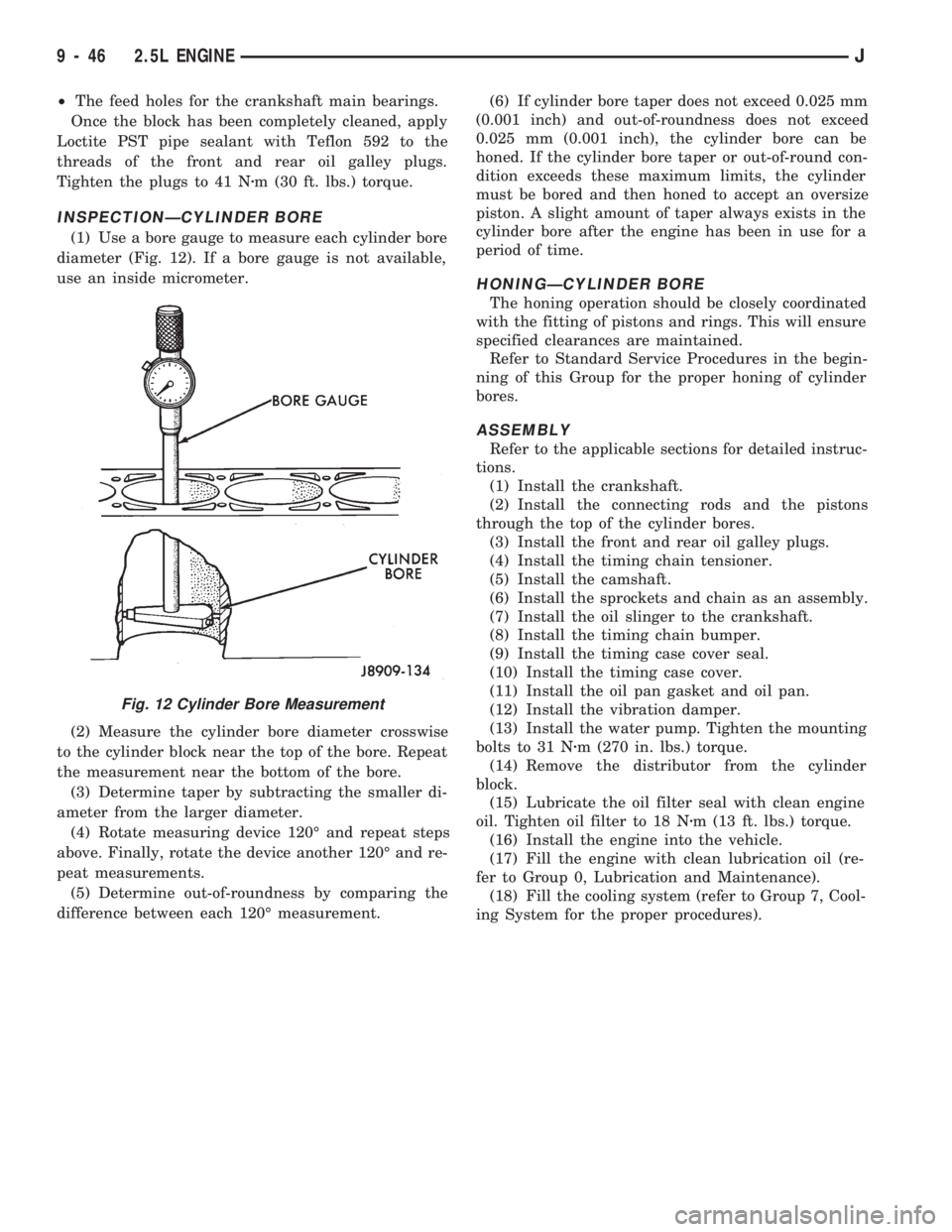

ket surfaces.Use compressed air to clean out:

²The galley at the oil filter adaptor hole, the filter

bypass hole (Fig. 9).

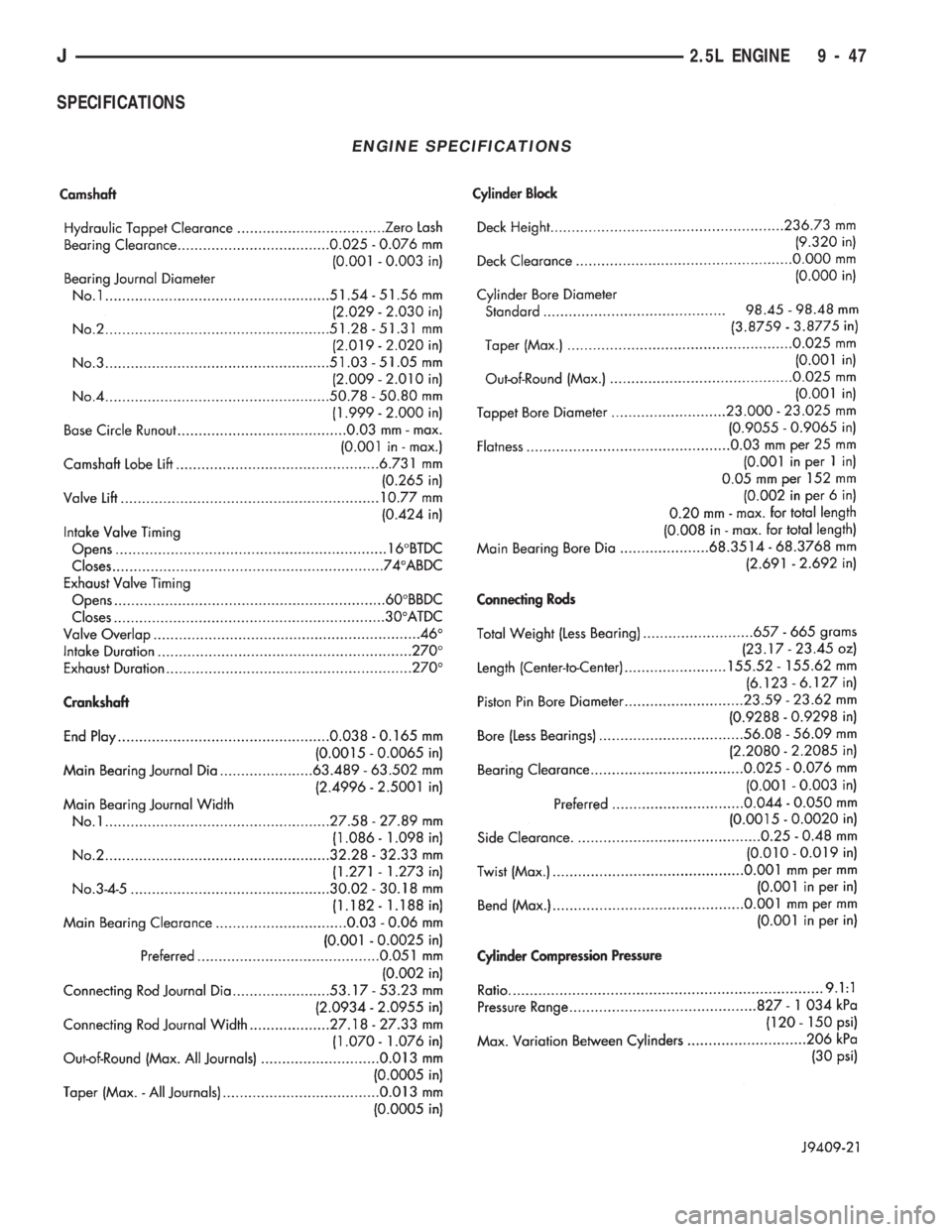

²The front and rear oil galley holes (Figs. 10 and

11).

Fig. 8 Replacement of Rear Crankshaft Oil SealFig. 9 Oil Filter Adaptor Hole

Fig. 10 Front Oil Galley Hole

Fig. 11 Rear Oil Galley Hole

J2.5L ENGINE 9 - 45

Page 887 of 1784

²The feed holes for the crankshaft main bearings.

Once the block has been completely cleaned, apply

Loctite PST pipe sealant with Teflon 592 to the

threads of the front and rear oil galley plugs.

Tighten the plugs to 41 Nzm (30 ft. lbs.) torque.

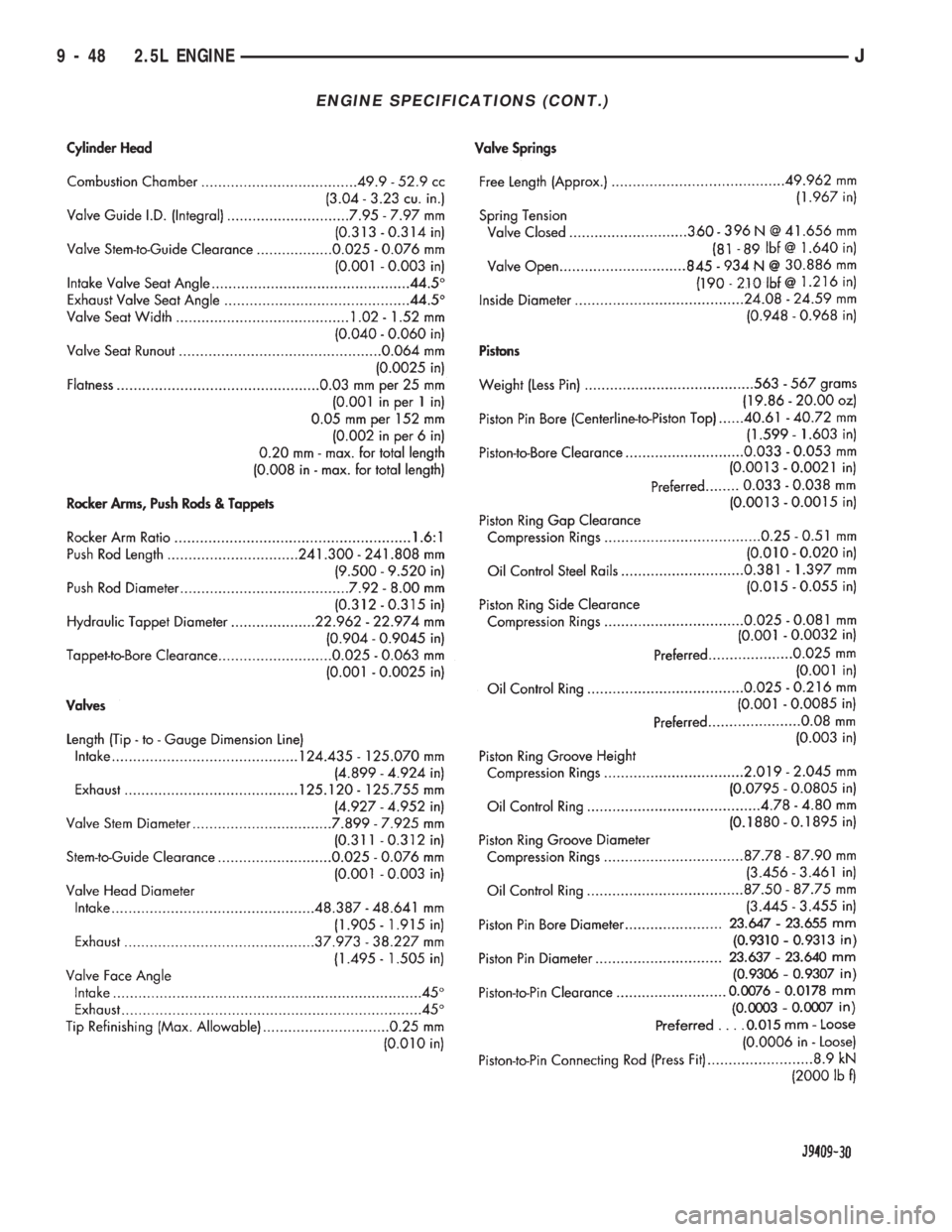

INSPECTIONÐCYLINDER BORE

(1) Use a bore gauge to measure each cylinder bore

diameter (Fig. 12). If a bore gauge is not available,

use an inside micrometer.

(2) Measure the cylinder bore diameter crosswise

to the cylinder block near the top of the bore. Repeat

the measurement near the bottom of the bore.

(3) Determine taper by subtracting the smaller di-

ameter from the larger diameter.

(4) Rotate measuring device 120É and repeat steps

above. Finally, rotate the device another 120É and re-

peat measurements.

(5) Determine out-of-roundness by comparing the

difference between each 120É measurement.(6) If cylinder bore taper does not exceed 0.025 mm

(0.001 inch) and out-of-roundness does not exceed

0.025 mm (0.001 inch), the cylinder bore can be

honed. If the cylinder bore taper or out-of-round con-

dition exceeds these maximum limits, the cylinder

must be bored and then honed to accept an oversize

piston. A slight amount of taper always exists in the

cylinder bore after the engine has been in use for a

period of time.

HONINGÐCYLINDER BORE

The honing operation should be closely coordinated

with the fitting of pistons and rings. This will ensure

specified clearances are maintained.

Refer to Standard Service Procedures in the begin-

ning of this Group for the proper honing of cylinder

bores.

ASSEMBLY

Refer to the applicable sections for detailed instruc-

tions.

(1) Install the crankshaft.

(2) Install the connecting rods and the pistons

through the top of the cylinder bores.

(3) Install the front and rear oil galley plugs.

(4) Install the timing chain tensioner.

(5) Install the camshaft.

(6) Install the sprockets and chain as an assembly.

(7) Install the oil slinger to the crankshaft.

(8) Install the timing chain bumper.

(9) Install the timing case cover seal.

(10) Install the timing case cover.

(11) Install the oil pan gasket and oil pan.

(12) Install the vibration damper.

(13) Install the water pump. Tighten the mounting

bolts to 31 Nzm (270 in. lbs.) torque.

(14) Remove the distributor from the cylinder

block.

(15) Lubricate the oil filter seal with clean engine

oil. Tighten oil filter to 18 Nzm (13 ft. lbs.) torque.

(16) Install the engine into the vehicle.

(17) Fill the engine with clean lubrication oil (re-

fer to Group 0, Lubrication and Maintenance).

(18) Fill the cooling system (refer to Group 7, Cool-

ing System for the proper procedures).

Fig. 12 Cylinder Bore Measurement

9 - 46 2.5L ENGINEJ

Page 888 of 1784

SPECIFICATIONS

ENGINE SPECIFICATIONS

J2.5L ENGINE 9 - 47

Page 889 of 1784

ENGINE SPECIFICATIONS (CONT.)

9 - 48 2.5L ENGINEJ

Page 890 of 1784

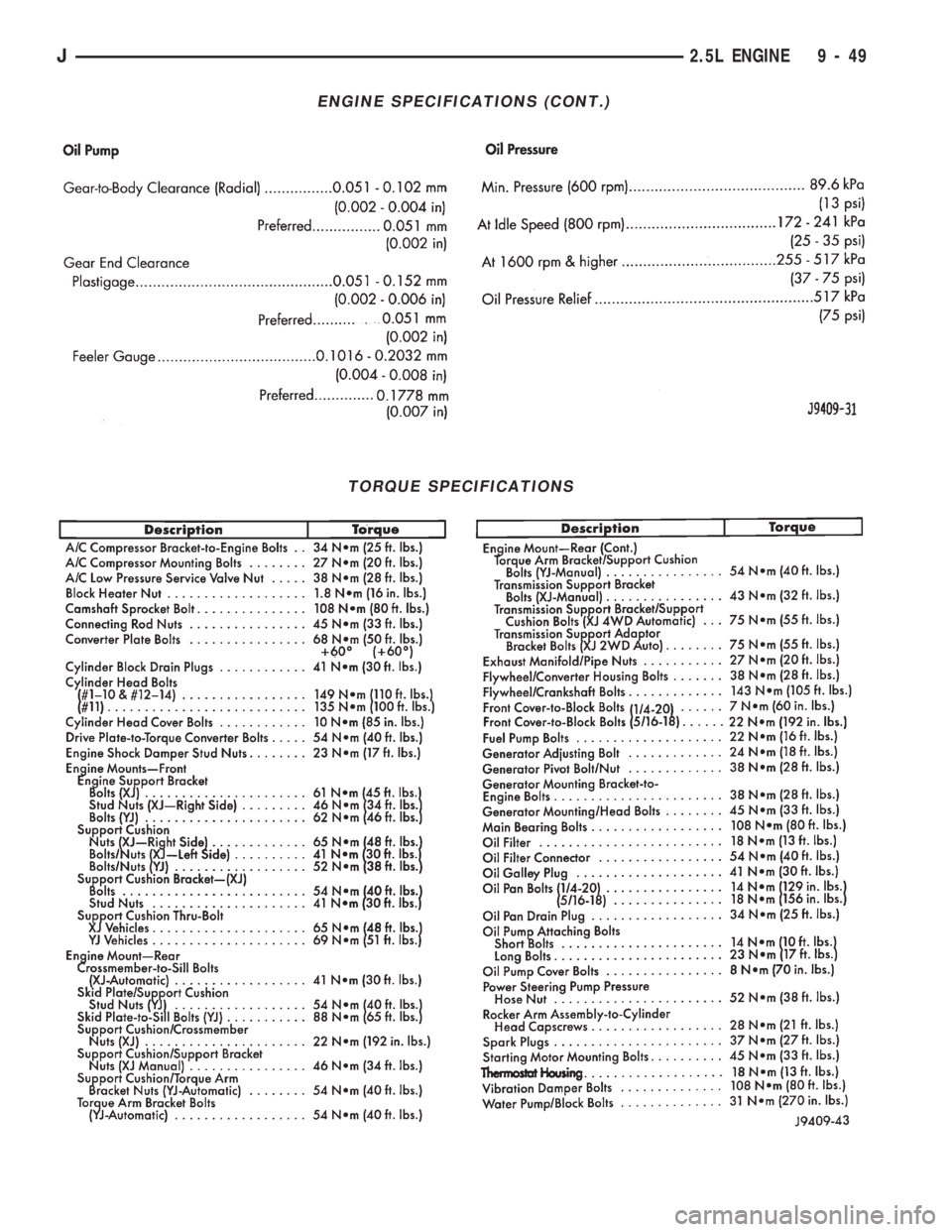

ENGINE SPECIFICATIONS (CONT.)

TORQUE SPECIFICATIONS

J2.5L ENGINE 9 - 49

Page 891 of 1784

4.0L ENGINE SERVICE PROCEDURES

INDEX

page page

Camshaft............................... 69

Camshaft Pin Replacement................. 71

Crankshaft Main Bearings.................. 80

Cylinder Block........................... 85

Engine AssemblyÐXJ Vehicles.............. 54

Engine AssemblyÐYJ Vehicles.............. 57

Engine Cylinder Head..................... 60

Engine Cylinder Head Cover................ 59

Engine MountÐRear...................... 52

Engine MountsÐFront..................... 51

General Information....................... 50

Hydraulic Tappets........................ 65

Oil Pan ................................ 72Oil Pump............................... 73

Pistons and Connecting Rods............... 74

Rear Main Oil Seals...................... 84

Rocker Arms............................ 59

Specifications........................... 87

Timing Case Cover....................... 67

Timing Case Cover Oil Seal Replacement...... 67

Timing Chain and Sprockets................ 68

Valve Springs and Oil Seals................ 62

Valve Timing............................ 66

Valves and Valve Springs.................. 63

Vibration Damper........................ 67

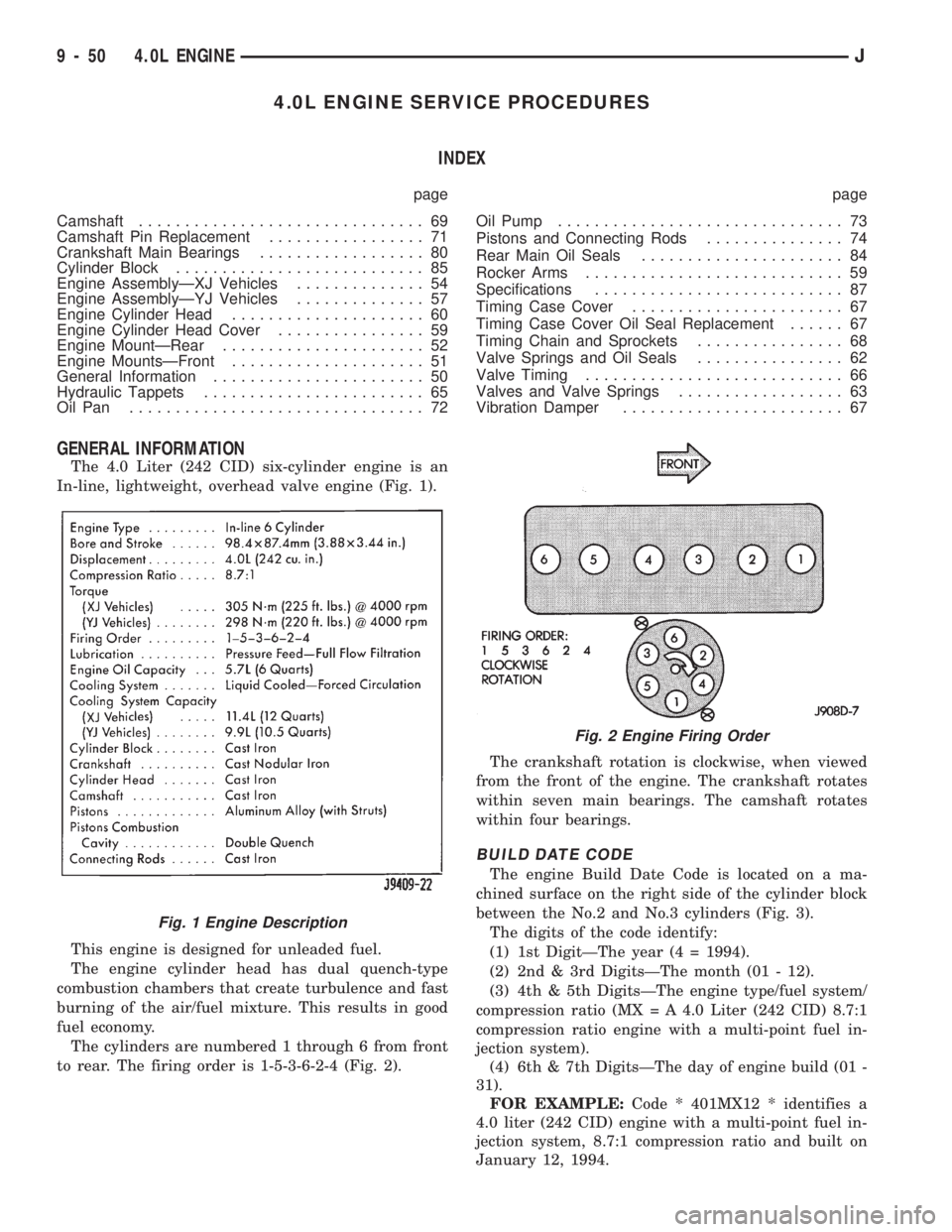

GENERAL INFORMATION

The 4.0 Liter (242 CID) six-cylinder engine is an

In-line, lightweight, overhead valve engine (Fig. 1).

This engine is designed for unleaded fuel.

The engine cylinder head has dual quench-type

combustion chambers that create turbulence and fast

burning of the air/fuel mixture. This results in good

fuel economy.

The cylinders are numbered 1 through 6 from front

to rear. The firing order is 1-5-3-6-2-4 (Fig. 2).The crankshaft rotation is clockwise, when viewed

from the front of the engine. The crankshaft rotates

within seven main bearings. The camshaft rotates

within four bearings.

BUILD DATE CODE

The engine Build Date Code is located on a ma-

chined surface on the right side of the cylinder block

between the No.2 and No.3 cylinders (Fig. 3).

The digits of the code identify:

(1) 1st DigitÐThe year (4 = 1994).

(2) 2nd & 3rd DigitsÐThe month (01 - 12).

(3) 4th & 5th DigitsÐThe engine type/fuel system/

compression ratio (MX = A 4.0 Liter (242 CID) 8.7:1

compression ratio engine with a multi-point fuel in-

jection system).

(4) 6th & 7th DigitsÐThe day of engine build (01 -

31).

FOR EXAMPLE:Code * 401MX12 * identifies a

4.0 liter (242 CID) engine with a multi-point fuel in-

jection system, 8.7:1 compression ratio and built on

January 12, 1994.

Fig. 2 Engine Firing Order

Fig. 1 Engine Description

9 - 50 4.0L ENGINEJ

Page 892 of 1784

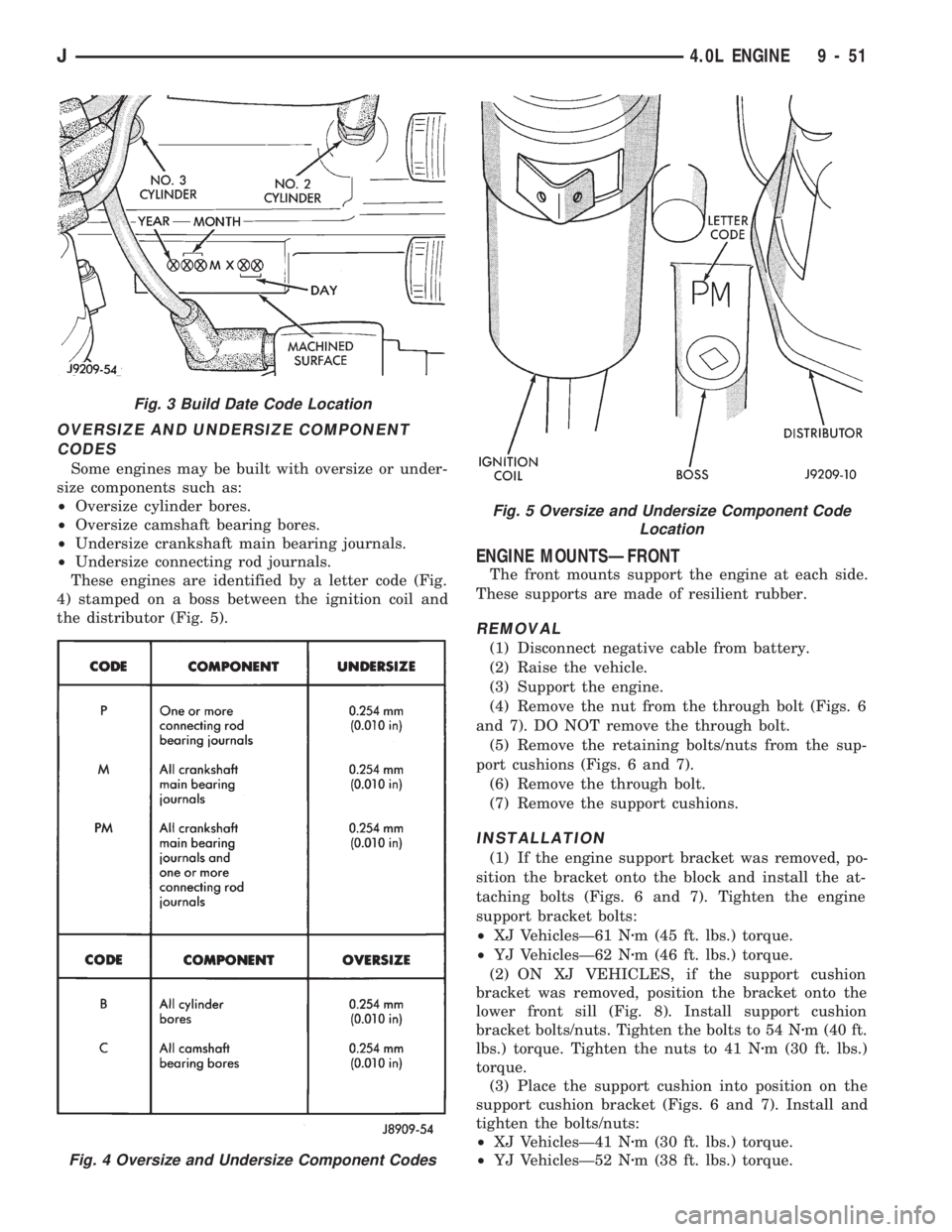

OVERSIZE AND UNDERSIZE COMPONENT

CODES

Some engines may be built with oversize or under-

size components such as:

²Oversize cylinder bores.

²Oversize camshaft bearing bores.

²Undersize crankshaft main bearing journals.

²Undersize connecting rod journals.

These engines are identified by a letter code (Fig.

4) stamped on a boss between the ignition coil and

the distributor (Fig. 5).

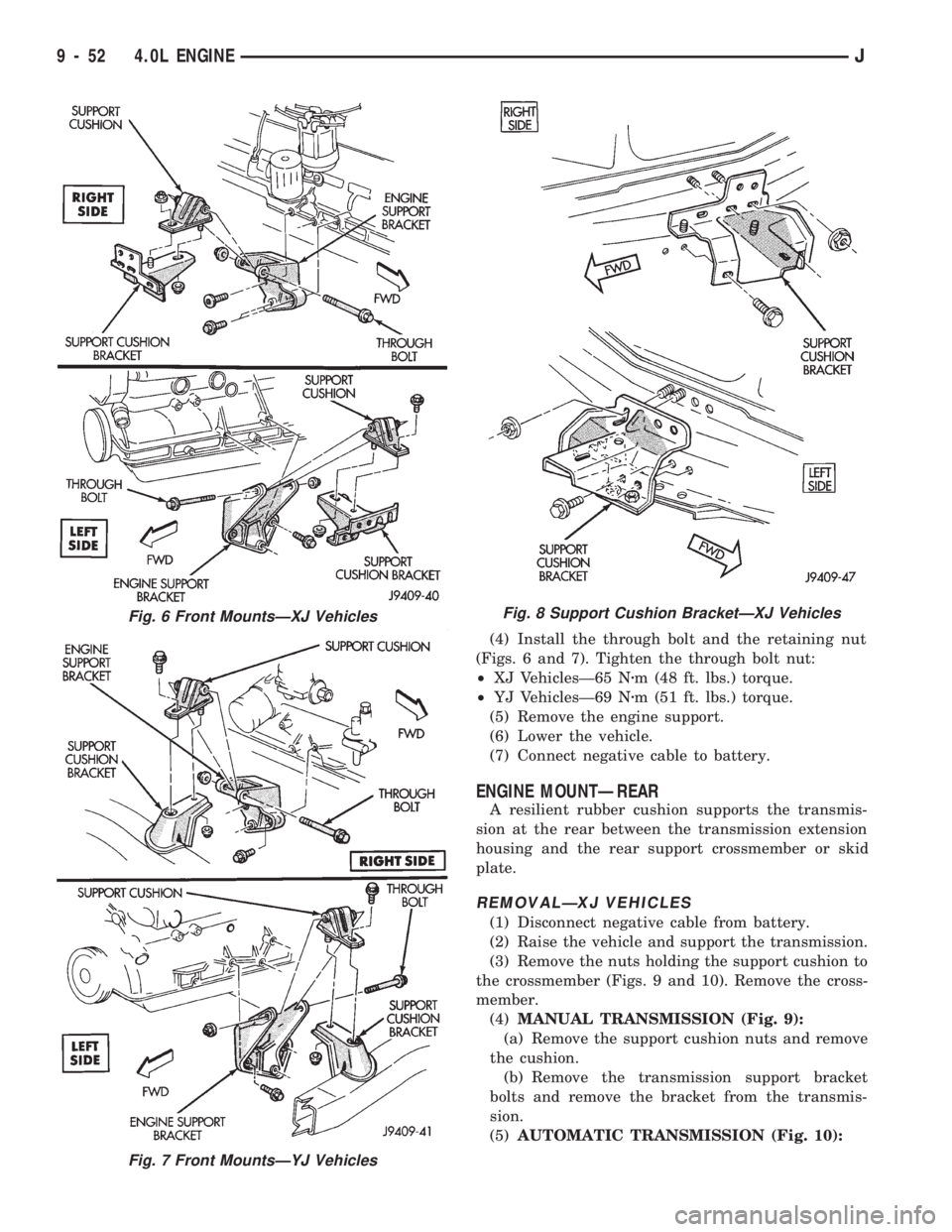

ENGINE MOUNTSÐFRONT

The front mounts support the engine at each side.

These supports are made of resilient rubber.

REMOVAL

(1) Disconnect negative cable from battery.

(2) Raise the vehicle.

(3) Support the engine.

(4) Remove the nut from the through bolt (Figs. 6

and 7). DO NOT remove the through bolt.

(5) Remove the retaining bolts/nuts from the sup-

port cushions (Figs. 6 and 7).

(6) Remove the through bolt.

(7) Remove the support cushions.

INSTALLATION

(1) If the engine support bracket was removed, po-

sition the bracket onto the block and install the at-

taching bolts (Figs. 6 and 7). Tighten the engine

support bracket bolts:

²XJ VehiclesÐ61 Nzm (45 ft. lbs.) torque.

²YJ VehiclesÐ62 Nzm (46 ft. lbs.) torque.

(2) ON XJ VEHICLES, if the support cushion

bracket was removed, position the bracket onto the

lower front sill (Fig. 8). Install support cushion

bracket bolts/nuts. Tighten the bolts to 54 Nzm (40 ft.

lbs.) torque. Tighten the nuts to 41 Nzm (30 ft. lbs.)

torque.

(3) Place the support cushion into position on the

support cushion bracket (Figs. 6 and 7). Install and

tighten the bolts/nuts:

²XJ VehiclesÐ41 Nzm (30 ft. lbs.) torque.

²YJ VehiclesÐ52 Nzm (38 ft. lbs.) torque.

Fig. 3 Build Date Code Location

Fig. 4 Oversize and Undersize Component Codes

Fig. 5 Oversize and Undersize Component Code

Location

J4.0L ENGINE 9 - 51

Page 893 of 1784

(4) Install the through bolt and the retaining nut

(Figs. 6 and 7). Tighten the through bolt nut:

²XJ VehiclesÐ65 Nzm (48 ft. lbs.) torque.

²YJ VehiclesÐ69 Nzm (51 ft. lbs.) torque.

(5) Remove the engine support.

(6) Lower the vehicle.

(7) Connect negative cable to battery.

ENGINE MOUNTÐREAR

A resilient rubber cushion supports the transmis-

sion at the rear between the transmission extension

housing and the rear support crossmember or skid

plate.

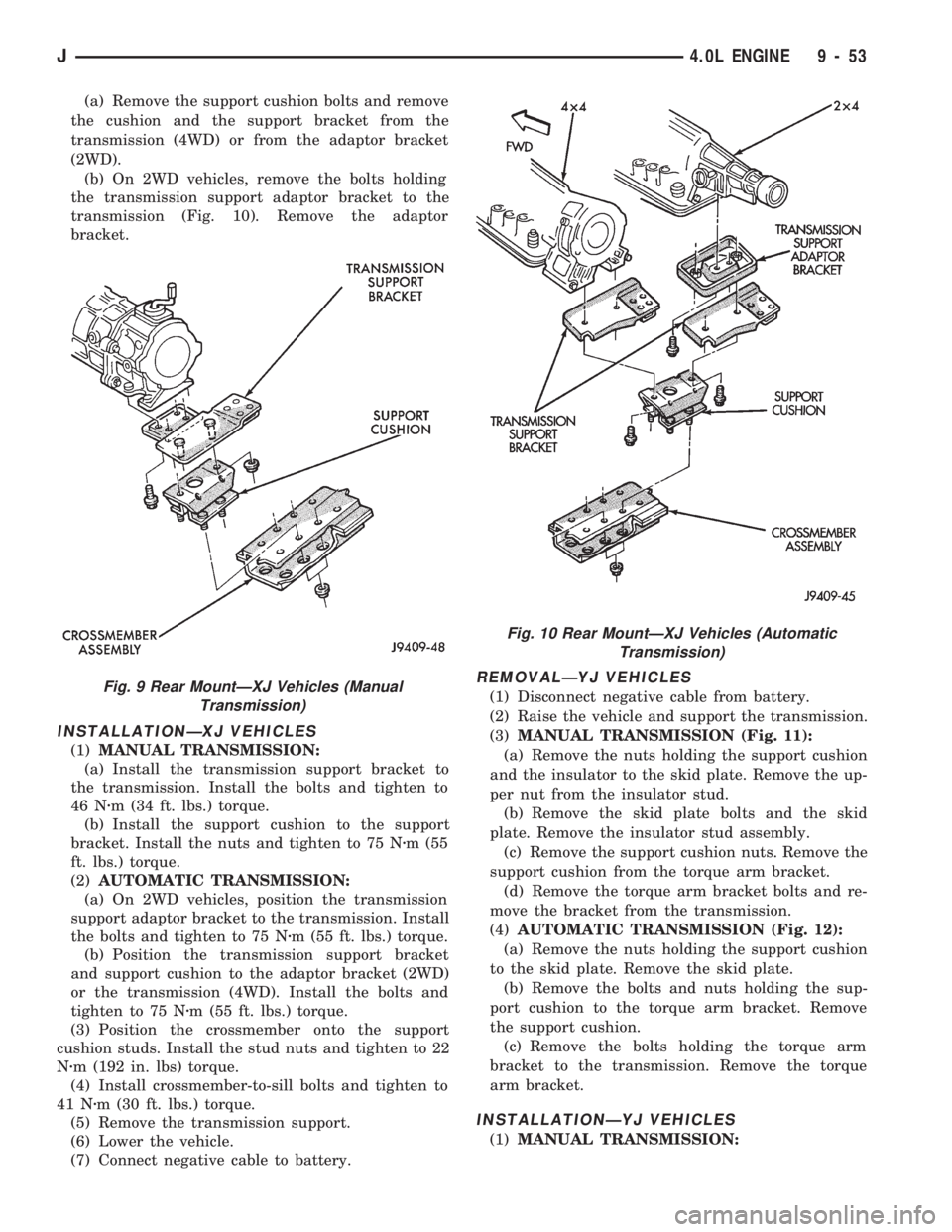

REMOVALÐXJ VEHICLES

(1) Disconnect negative cable from battery.

(2) Raise the vehicle and support the transmission.

(3) Remove the nuts holding the support cushion to

the crossmember (Figs. 9 and 10). Remove the cross-

member.

(4)MANUAL TRANSMISSION (Fig. 9):

(a) Remove the support cushion nuts and remove

the cushion.

(b) Remove the transmission support bracket

bolts and remove the bracket from the transmis-

sion.

(5)AUTOMATIC TRANSMISSION (Fig. 10):

Fig. 6 Front MountsÐXJ Vehicles

Fig. 7 Front MountsÐYJ Vehicles

Fig. 8 Support Cushion BracketÐXJ Vehicles

9 - 52 4.0L ENGINEJ

Page 894 of 1784

(a) Remove the support cushion bolts and remove

the cushion and the support bracket from the

transmission (4WD) or from the adaptor bracket

(2WD).

(b) On 2WD vehicles, remove the bolts holding

the transmission support adaptor bracket to the

transmission (Fig. 10). Remove the adaptor

bracket.

INSTALLATIONÐXJ VEHICLES

(1)MANUAL TRANSMISSION:

(a) Install the transmission support bracket to

the transmission. Install the bolts and tighten to

46 Nzm (34 ft. lbs.) torque.

(b) Install the support cushion to the support

bracket. Install the nuts and tighten to 75 Nzm (55

ft. lbs.) torque.

(2)AUTOMATIC TRANSMISSION:

(a) On 2WD vehicles, position the transmission

support adaptor bracket to the transmission. Install

the bolts and tighten to 75 Nzm (55 ft. lbs.) torque.

(b) Position the transmission support bracket

and support cushion to the adaptor bracket (2WD)

or the transmission (4WD). Install the bolts and

tighten to 75 Nzm (55 ft. lbs.) torque.

(3) Position the crossmember onto the support

cushion studs. Install the stud nuts and tighten to 22

Nzm (192 in. lbs) torque.

(4) Install crossmember-to-sill bolts and tighten to

41 Nzm (30 ft. lbs.) torque.

(5) Remove the transmission support.

(6) Lower the vehicle.

(7) Connect negative cable to battery.

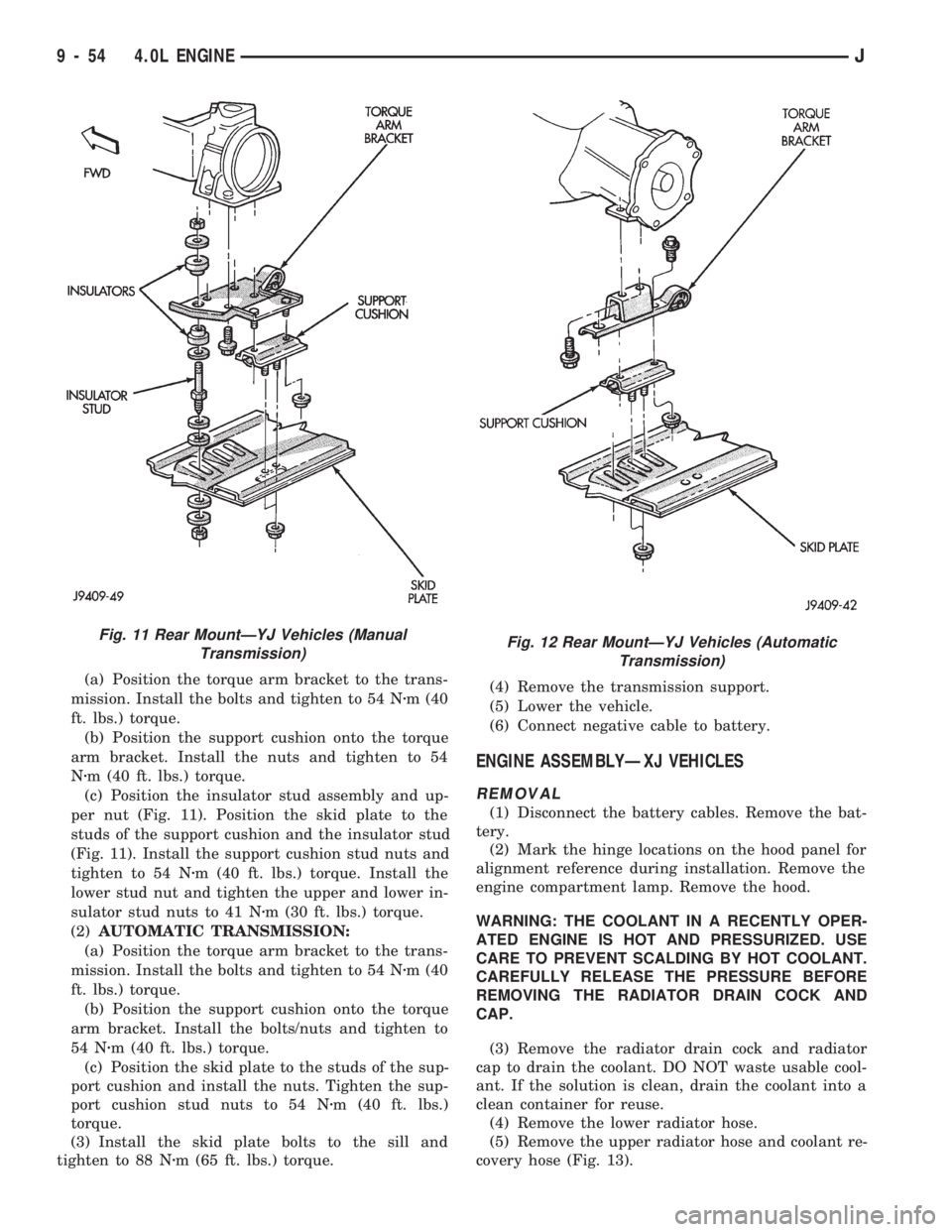

REMOVALÐYJ VEHICLES

(1) Disconnect negative cable from battery.

(2) Raise the vehicle and support the transmission.

(3)MANUAL TRANSMISSION (Fig. 11):

(a) Remove the nuts holding the support cushion

and the insulator to the skid plate. Remove the up-

per nut from the insulator stud.

(b) Remove the skid plate bolts and the skid

plate. Remove the insulator stud assembly.

(c) Remove the support cushion nuts. Remove the

support cushion from the torque arm bracket.

(d) Remove the torque arm bracket bolts and re-

move the bracket from the transmission.

(4)AUTOMATIC TRANSMISSION (Fig. 12):

(a) Remove the nuts holding the support cushion

to the skid plate. Remove the skid plate.

(b) Remove the bolts and nuts holding the sup-

port cushion to the torque arm bracket. Remove

the support cushion.

(c) Remove the bolts holding the torque arm

bracket to the transmission. Remove the torque

arm bracket.

INSTALLATIONÐYJ VEHICLES

(1)MANUAL TRANSMISSION:

Fig. 9 Rear MountÐXJ Vehicles (Manual

Transmission)

Fig. 10 Rear MountÐXJ Vehicles (Automatic

Transmission)

J4.0L ENGINE 9 - 53

Page 895 of 1784

(a) Position the torque arm bracket to the trans-

mission. Install the bolts and tighten to 54 Nzm (40

ft. lbs.) torque.

(b) Position the support cushion onto the torque

arm bracket. Install the nuts and tighten to 54

Nzm (40 ft. lbs.) torque.

(c) Position the insulator stud assembly and up-

per nut (Fig. 11). Position the skid plate to the

studs of the support cushion and the insulator stud

(Fig. 11). Install the support cushion stud nuts and

tighten to 54 Nzm (40 ft. lbs.) torque. Install the

lower stud nut and tighten the upper and lower in-

sulator stud nuts to 41 Nzm (30 ft. lbs.) torque.

(2)AUTOMATIC TRANSMISSION:

(a) Position the torque arm bracket to the trans-

mission. Install the bolts and tighten to 54 Nzm (40

ft. lbs.) torque.

(b) Position the support cushion onto the torque

arm bracket. Install the bolts/nuts and tighten to

54 Nzm (40 ft. lbs.) torque.

(c) Position the skid plate to the studs of the sup-

port cushion and install the nuts. Tighten the sup-

port cushion stud nuts to 54 Nzm (40 ft. lbs.)

torque.

(3) Install the skid plate bolts to the sill and

tighten to 88 Nzm (65 ft. lbs.) torque.(4) Remove the transmission support.

(5) Lower the vehicle.

(6) Connect negative cable to battery.

ENGINE ASSEMBLYÐXJ VEHICLES

REMOVAL

(1) Disconnect the battery cables. Remove the bat-

tery.

(2) Mark the hinge locations on the hood panel for

alignment reference during installation. Remove the

engine compartment lamp. Remove the hood.

WARNING: THE COOLANT IN A RECENTLY OPER-

ATED ENGINE IS HOT AND PRESSURIZED. USE

CARE TO PREVENT SCALDING BY HOT COOLANT.

CAREFULLY RELEASE THE PRESSURE BEFORE

REMOVING THE RADIATOR DRAIN COCK AND

CAP.

(3) Remove the radiator drain cock and radiator

cap to drain the coolant. DO NOT waste usable cool-

ant. If the solution is clean, drain the coolant into a

clean container for reuse.

(4) Remove the lower radiator hose.

(5) Remove the upper radiator hose and coolant re-

covery hose (Fig. 13).

Fig. 11 Rear MountÐYJ Vehicles (Manual

Transmission)Fig. 12 Rear MountÐYJ Vehicles (Automatic

Transmission)

9 - 54 4.0L ENGINEJ