index JEEP CHEROKEE 1994 Service Owner's Guide

[x] Cancel search | Manufacturer: JEEP, Model Year: 1994, Model line: CHEROKEE, Model: JEEP CHEROKEE 1994Pages: 1784, PDF Size: 77.09 MB

Page 225 of 1784

CLUTCH SERVICE

INDEX

page page

Clutch Cover and Disc Installation............ 10

Clutch Cover and Disc Removal............. 10

Clutch Fluid Level........................ 14

Clutch Housing Replacement................ 11

Clutch Hydraulic Linkage Installation.......... 12

Clutch Hydraulic Linkage Removal........... 11Clutch Pedal Installation................... 15

Clutch Pedal Removal..................... 15

Clutch Safety Precautions.................. 10

Flywheel Service......................... 15

Pilot Bearing Replacement................. 11

Release Bearing Replacement............... 11

CLUTCH SAFETY PRECAUTIONS

WARNING: EXERCISE CARE WHEN SERVICING

CLUTCH COMPONENTS. DUST AND DIRT ON

CLUTCH PARTS USE MAY CONTAIN ASBESTOS FI-

BERS. BREATHING EXCESSIVE CONCENTRATIONS

OF THESE FIBERS CAN CAUSE SERIOUS BODILY

HARM. WEAR A RESPIRATOR DURING SERVICE

AND NEVER CLEAN CLUTCH COMPONENTS WITH

COMPRESSED AIR OR WITH A DRY BRUSH. EI-

THER CLEAN THE COMPONENTS WITH A WATER

DAMPENED RAGS OR USE A VACUUM CLEANER

SPECIFICALLY DESIGNED FOR REMOVING ASBES-

TOS FIBERS AND DUST. DO NOT CREATE DUST

BY SANDING A CLUTCH DISC. REPLACE THE DISC

IF THE FRICTION MATERIAL IS DAMAGED OR

CONTAMINATED. DISPOSE OF ALL DUST AND

DIRT CONTAINING ASBESTOS FIBERS IN SEALED

BAGS OR CONTAINERS. THIS WILL HELP MINIMIZE

EXPOSURE TO YOURSELF AND TO OTHERS. FOL-

LOW ALL RECOMMENDED SAFETY PRACTICES

PRESCRIBED BY THE OCCUPATIONAL SAFETY

AND HEALTH ADMINISTRATION (OSHA) AND THE

ENVIRONMENTAL SAFETY AGENCY (EPA), FOR

THE HANDLING AND DISPOSAL OF PRODUCTS

CONTAINING ASBESTOS.

CLUTCH COVER AND DISC REMOVAL

(1) Remove transmission. Refer to procedures in

Group 21.

(2) If original clutch cover will be reinstalled,

mark position of cover on flywheel for assembly ref-

erence. Use paint or a scriber for this purpose.

(3) If clutch cover is to be replaced, cover bolts can

be removed in any sequence. However, if original

cover will be reinstalled, loosen cover bolts evenly

and in rotation to relieve spring tension equally.

This is necessary avoid warping cover.

(4) Remove cover bolts and remove cover and disc

(Fig. 2).

CLUTCH COVER AND DISC INSTALLATION

(1) Lightly scuff sand flywheel face with 180 grit

emery cloth. Then clean surface with a wax and

grease remover.

(2) Lubricate pilot bearing with Mopar high tem-

perature bearing grease.

(3) Check runout and free operation of new clutch

disc as follows:

(a) Slide disc onto transmission input shaft

splines. Disc should slide freely on splines.

(b) Leave disc on shaft and check face runout

with dial indicator. Check runout at disc hub and

about 6 mm (1/4 in.) from outer edge of facing.

(c) Face runout should not exceed 0.5 mm (0.020

in.). Obtain another clutch disc if runout exceeds

this limit.

(4) Position clutch disc on flywheel. Be sure side of

disc marked flywheel side is positioned against fly-

wheel (Fig. 2). If disc is not marked, be sure flat side

of disc hub is toward flywheel.

(5) Insert clutch alignment tool in clutch disc (Fig.

3).

(6) Insert alignment tool in pilot bearing and posi-

tion disc on flywheel. Be sure disc hub is positioned

correctly. Side of hub marked Flywheel Side should

face flywheel (Fig. 2). If disc is not marked, place flat

side of disc against flywheel.

(7) Position clutch cover over disc and on flywheel

(Fig. 3).

(8) Install clutch cover bolts finger tight.

(9) Tighten cover bolts evenly and in rotation a

few threads at a time.Cover bolts must be tight-

ened evenly and to specified torque to avoid dis-

torting cover. Tightening torques are 31 Nzm (23

ft. lbs.) on 2.5L engines and 54 Nzm (40 ft. lbs.) on

4.0L engines.

(10) Apply light coat of Mopar high temperature

bearing grease to pilot bearing hub and splines of

transmission input shaft.Do not overlubricate

shaft splines. This will result in grease contami-

nation of disc.

(11) Install transmission (Fig. 4). Refer to proce-

dures in Group 21.

6 - 10 CLUTCH SERVICEJ

Page 237 of 1784

DIAGNOSIS

INDEX

page page

DRB Scan Tool........................... 5

On-Board Diagnostics (OBD)................. 4Preliminary Checks........................ 5

ON-BOARD DIAGNOSTICS (OBD)

FOR COOLING SYSTEM COMPONENTS

The powertrain control module (PCM) has been

programmed to monitor the certain following cooling

system components:

²If the engine has remained cool for too long a pe-

riod, such as with a stuck open thermostat, a Diag-

nostic Trouble Code (DTC) number 17 can be

observed at the Check Engine Lamp.

²If an open or shorted condition has developed in

the relay circuit controlling the electric radiator fan,

a Diagnostic Trouble Code (DTC) number 35 can be

observed at the Check Engine Lamp.

If the problem is sensed in a monitored circuit of-

ten enough to indicate an actual problem, a DTC is

stored. The DTC will be stored in the PCM memory

for eventual display to the service technician. If the

problem is repaired or ceases to exist, the PCM can-

cels the DTC after 51 engine starts.

Certain criteria must be met for a DTC to be en-

tered into PCM memory. The criteria may be a spe-

cific range of engine rpm, engine temperature and/or

input voltage to the PCM.

A DTC indicates that the PCM has recognized an

abnormal signal in a circuit or the system. A DTC

may indicate the result of a failure, but never iden-

tify the failed component directly.

It is possible that a DTC for a monitored circuit

may not be entered into memory even though a mal-

function has occurred. Refer to On-Board Diagnostics

(OBD) in Group 14, Fuel Systems for additional in-

formation.

ACCESSING DIAGNOSTIC TROUBLE CODES

A stored Diagnostic Trouble Code (DTC) can be dis-

played by cycling the ignition key On-Off-On-Off-On

within three seconds and observing the Malfunction

Indicator Lamp. This lamp was formerly referred to

as the Check Engine Lamp. The lamp is located on

the instrument panel.

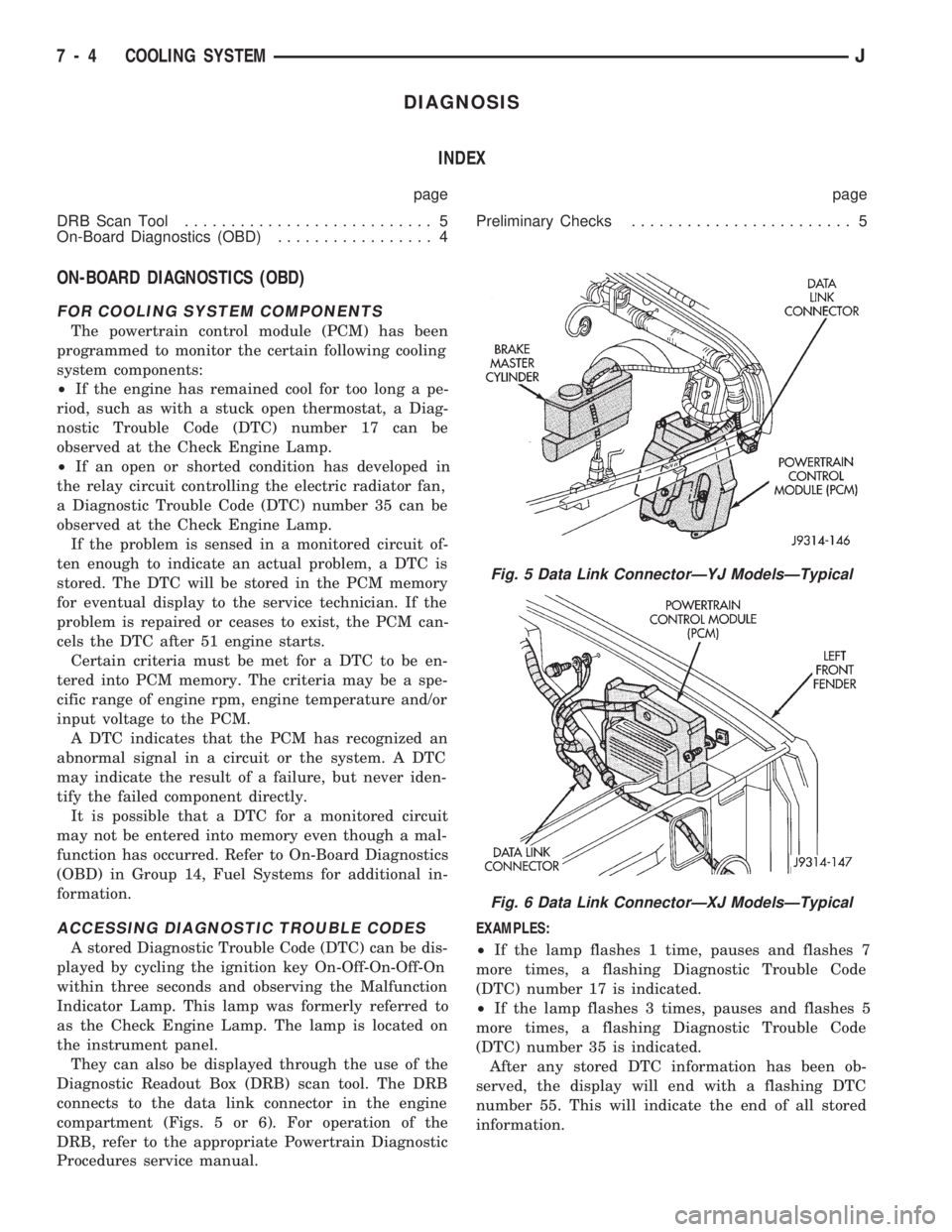

They can also be displayed through the use of the

Diagnostic Readout Box (DRB) scan tool. The DRB

connects to the data link connector in the engine

compartment (Figs. 5 or 6). For operation of the

DRB, refer to the appropriate Powertrain Diagnostic

Procedures service manual.EXAMPLES:

²If the lamp flashes 1 time, pauses and flashes 7

more times, a flashing Diagnostic Trouble Code

(DTC) number 17 is indicated.

²If the lamp flashes 3 times, pauses and flashes 5

more times, a flashing Diagnostic Trouble Code

(DTC) number 35 is indicated.

After any stored DTC information has been ob-

served, the display will end with a flashing DTC

number 55. This will indicate the end of all stored

information.

Fig. 5 Data Link ConnectorÐYJ ModelsÐTypical

Fig. 6 Data Link ConnectorÐXJ ModelsÐTypical

7 - 4 COOLING SYSTEMJ

Page 242 of 1784

SERVICE PROCEDURES

INDEX

page page

Coolant................................ 15

Coolant Reserve/Overflow System............ 19

Cooling System Cleaning/Reverse Flushing..... 17

Cooling System Fans..................... 26

Cooling System Hoses.................... 26

Draining Cooling System................... 16

Radiator Pressure Cap.................... 20

Radiators............................... 22Refilling Cooling System................... 17

Testing Cooling System for Leaks............ 18

Thermostat............................. 13

Transmission Oil Coolers................... 29

Water Pump Tests........................ 9

Water PumpsÐGeneral Information............ 9

Water PumpsÐRemoval/Installation........... 10

WATER PUMPSÐGENERAL INFORMATION

A centrifugal water pump circulates coolant

through the water jackets, passages, intake manifold,

radiator core, cooling system hoses and heater core.

The pump is driven from the engine crankshaft by a

drive belt on all engines.

The water pump impeller is pressed onto the rear

of a shaft that rotates in bearings pressed into the

housing. The housing has a small hole to allow seep-

age to escape. The water pump seals are lubricated

by the antifreeze in the coolant mixture. No addi-

tional lubrication is necessary.

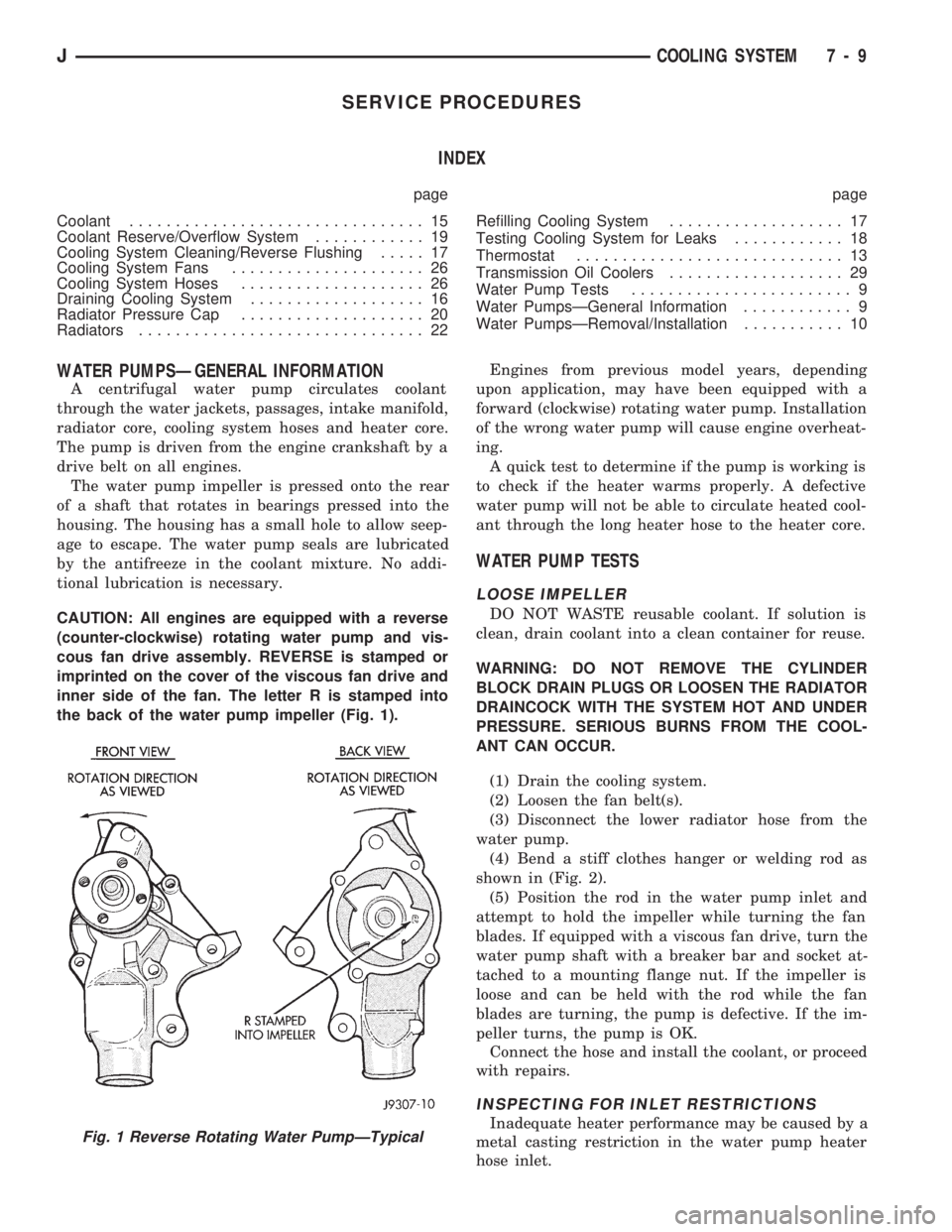

CAUTION: All engines are equipped with a reverse

(counter-clockwise) rotating water pump and vis-

cous fan drive assembly. REVERSE is stamped or

imprinted on the cover of the viscous fan drive and

inner side of the fan. The letter R is stamped into

the back of the water pump impeller (Fig. 1).Engines from previous model years, depending

upon application, may have been equipped with a

forward (clockwise) rotating water pump. Installation

of the wrong water pump will cause engine overheat-

ing.

A quick test to determine if the pump is working is

to check if the heater warms properly. A defective

water pump will not be able to circulate heated cool-

ant through the long heater hose to the heater core.

WATER PUMP TESTS

LOOSE IMPELLER

DO NOT WASTE reusable coolant. If solution is

clean, drain coolant into a clean container for reuse.

WARNING: DO NOT REMOVE THE CYLINDER

BLOCK DRAIN PLUGS OR LOOSEN THE RADIATOR

DRAINCOCK WITH THE SYSTEM HOT AND UNDER

PRESSURE. SERIOUS BURNS FROM THE COOL-

ANT CAN OCCUR.

(1) Drain the cooling system.

(2) Loosen the fan belt(s).

(3) Disconnect the lower radiator hose from the

water pump.

(4) Bend a stiff clothes hanger or welding rod as

shown in (Fig. 2).

(5) Position the rod in the water pump inlet and

attempt to hold the impeller while turning the fan

blades. If equipped with a viscous fan drive, turn the

water pump shaft with a breaker bar and socket at-

tached to a mounting flange nut. If the impeller is

loose and can be held with the rod while the fan

blades are turning, the pump is defective. If the im-

peller turns, the pump is OK.

Connect the hose and install the coolant, or proceed

with repairs.

INSPECTING FOR INLET RESTRICTIONS

Inadequate heater performance may be caused by a

metal casting restriction in the water pump heater

hose inlet.Fig. 1 Reverse Rotating Water PumpÐTypical

JCOOLING SYSTEM 7 - 9

Page 264 of 1784

ENGINE ACCESSORY DRIVE BELTS

INDEX

page page

Automatic Belt TensionerÐXJ Models......... 36

Belt Diagnosis........................... 31

Belt Schematics......................... 34

Belt ServiceÐExcept Right Hand Drive........ 34

Belt ServiceÐWith Right Hand Drive.......... 35Belt Tension Specifications................. 34

Belt TensionÐExcept Right Hand Drive (RHD) . . 33

Belt TensionÐRight Hand Drive (RHD)........ 34

General Information....................... 31

GENERAL INFORMATION

CAUTION: When installing a serpentine accessory

drive belt, the belt MUST be routed correctly. If not,

the engine may overheat due to water pump rotat-

ing in wrong direction. Refer to the appropriate en-

gine Belt Schematic in this group for the correct

belt routing. Or, refer to the Belt Routing Label lo-

cated in the engine compartment.

BELT DIAGNOSIS

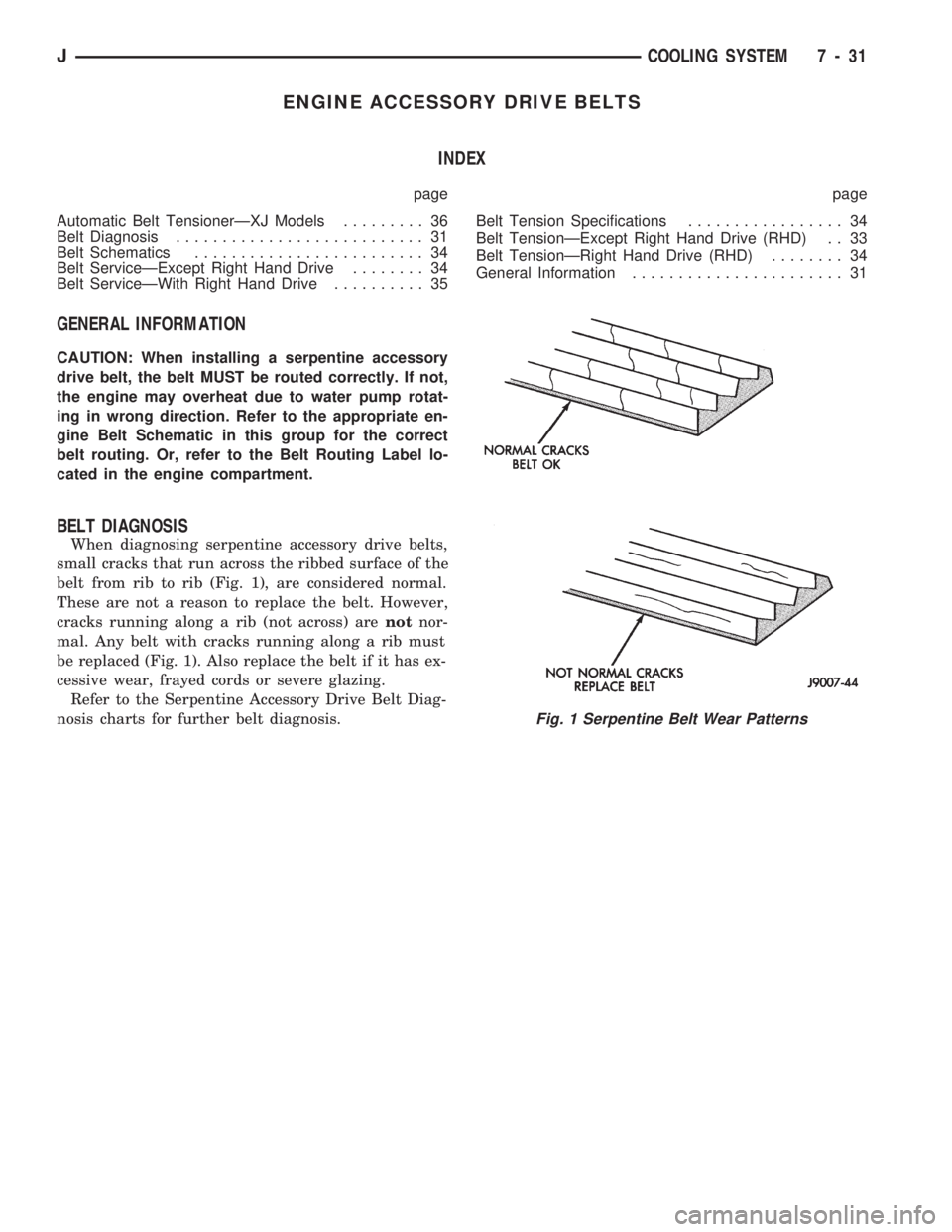

When diagnosing serpentine accessory drive belts,

small cracks that run across the ribbed surface of the

belt from rib to rib (Fig. 1), are considered normal.

These are not a reason to replace the belt. However,

cracks running along a rib (not across) arenotnor-

mal. Any belt with cracks running along a rib must

be replaced (Fig. 1). Also replace the belt if it has ex-

cessive wear, frayed cords or severe glazing.

Refer to the Serpentine Accessory Drive Belt Diag-

nosis charts for further belt diagnosis.

Fig. 1 Serpentine Belt Wear Patterns

JCOOLING SYSTEM 7 - 31

Page 274 of 1784

ELECTRICAL

GROUP INDEX

Group Group

AUDIO SYSTEMS....................... 8F

BATTERY/STARTER/GENERATOR SERVICE . . 8B

BATTERY/STARTING/CHARGING SYSTEMS

DIAGNOSTICS........................ 8A

CHIME/WARNING BUZZER SYSTEM....... 8U

HORNS............................... 8G

IGNITION SYSTEMS.................... 8D

INSTRUMENT PANEL AND GAUGES........ 8E

LAMPS............................... 8L

OVERHEAD CONSOLE................... 8CPOWER LOCKS........................ 8P

POWER MIRRORS...................... 8T

POWER SEAT.......................... 8R

POWER WINDOWS..................... 8S

REAR WINDOW DEFOGGER.............. 8N

TURN SIGNALS AND HAZARD WARNING

FLASHERS........................... 8J

VEHICLE SPEED CONTROL SYSTEM....... 8H

WINDSHIELD WIPERS AND WASHERS..... 8K

WIRING DIAGRAMS.................... 8W

BATTERY/STARTING/CHARGING SYSTEMS DIAGNOSTICS

CONTENTS

page page

BATTERY TEST PROCEDURES............. 2

ENGINE STARTER MOTOR TEST

PROCEDURES ON VEHICLE.............. 9GENERATOR TEST PROCEDURES ON

VEHICLE............................. 14

IGNITION OFF DRAW (IOD) DIAGNOSIS...... 8

USING ON-BOARD DIAGNOSTIC SYSTEM.... 19

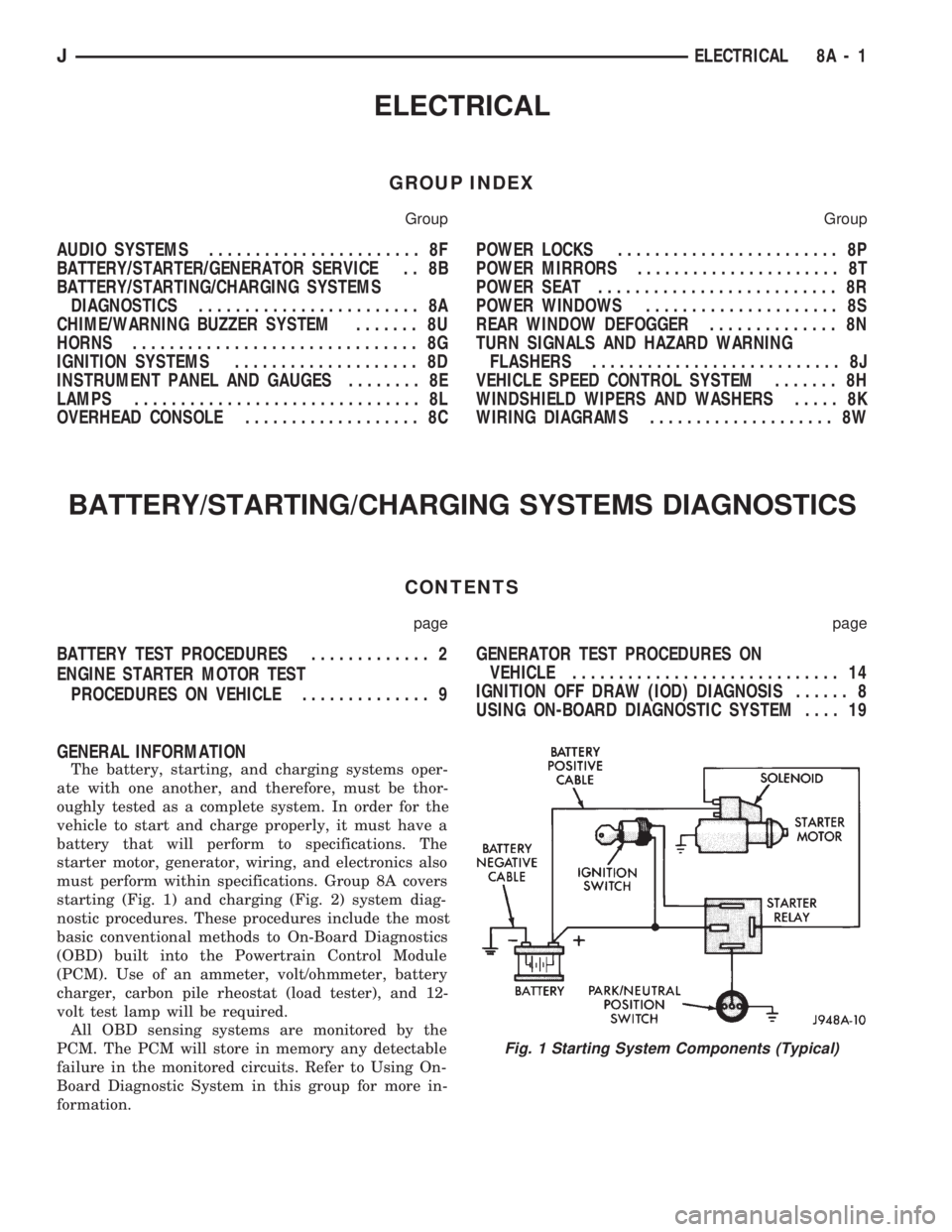

GENERAL INFORMATION

The battery, starting, and charging systems oper-

ate with one another, and therefore, must be thor-

oughly tested as a complete system. In order for the

vehicle to start and charge properly, it must have a

battery that will perform to specifications. The

starter motor, generator, wiring, and electronics also

must perform within specifications. Group 8A covers

starting (Fig. 1) and charging (Fig. 2) system diag-

nostic procedures. These procedures include the most

basic conventional methods to On-Board Diagnostics

(OBD) built into the Powertrain Control Module

(PCM). Use of an ammeter, volt/ohmmeter, battery

charger, carbon pile rheostat (load tester), and 12-

volt test lamp will be required.

All OBD sensing systems are monitored by the

PCM. The PCM will store in memory any detectable

failure in the monitored circuits. Refer to Using On-

Board Diagnostic System in this group for more in-

formation.

Fig. 1 Starting System Components (Typical)

JELECTRICAL 8A - 1

Page 275 of 1784

BATTERY TEST PROCEDURES

INDEX

page page

Battery Charging.......................... 5

Battery Diagnostics Chart................... 7

Battery Load Test......................... 4

Battery Open Circuit Voltage Test............. 3Battery Testing General Information........... 3

General Information........................ 2

Hydrometer Test.......................... 3

Specifications............................ 8

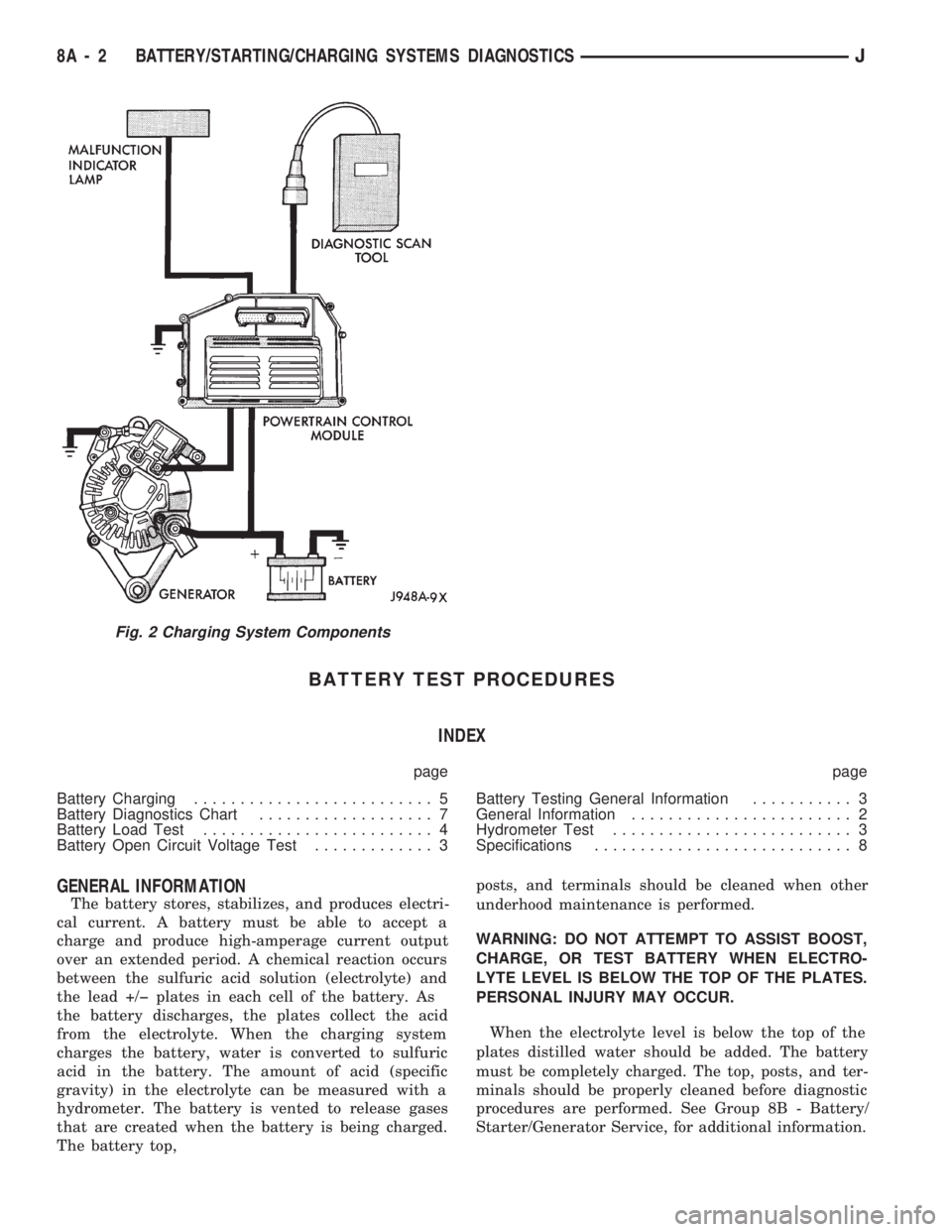

GENERAL INFORMATION

The battery stores, stabilizes, and produces electri-

cal current. A battery must be able to accept a

charge and produce high-amperage current output

over an extended period. A chemical reaction occurs

between the sulfuric acid solution (electrolyte) and

the lead +/þ plates in each cell of the battery. As

the battery discharges, the plates collect the acid

from the electrolyte. When the charging system

charges the battery, water is converted to sulfuric

acid in the battery. The amount of acid (specific

gravity) in the electrolyte can be measured with a

hydrometer. The battery is vented to release gases

that are created when the battery is being charged.

The battery top,posts, and terminals should be cleaned when other

underhood maintenance is performed.

WARNING: DO NOT ATTEMPT TO ASSIST BOOST,

CHARGE, OR TEST BATTERY WHEN ELECTRO-

LYTE LEVEL IS BELOW THE TOP OF THE PLATES.

PERSONAL INJURY MAY OCCUR.

When the electrolyte level is below the top of the

plates distilled water should be added. The battery

must be completely charged. The top, posts, and ter-

minals should be properly cleaned before diagnostic

procedures are performed. See Group 8B - Battery/

Starter/Generator Service, for additional information.

Fig. 2 Charging System Components

8A - 2 BATTERY/STARTING/CHARGING SYSTEMS DIAGNOSTICSJ

Page 282 of 1784

ENGINE STARTER MOTOR TEST PROCEDURES ON VEHICLE

INDEX

page page

2.5L Starter Motor Noise Diagnosis........... 13

General Information........................ 9

Starter Control Circuit Tests................ 11

Starter Feed Circuit Tests - (Voltage Drop Method).9

Starter System Diagnostic Inspections.......... 9

Starting System Cold Cranking Test........... 9

GENERAL INFORMATION

The starting system consists of an:

²ignition switch

²starter relay

²park/neutral position switch (automatic transmis-

sion)

²wiring harness

²battery

²starter motor with an integral solenoid.

These components form 2 separate circuits. A high

amperage circuit that feeds the starter motor up to

300+ amps, and a control circuit that operates on

less than 20 amps.

STARTER SYSTEM DIAGNOSTIC INSPECTIONS

Before removing any unit from the starter motor

system for repair, perform the following inspections:

BATTERY INSPECTION

To determine condition of the battery, perform the

testing procedure outlined in Battery Test Proce-

dures.

WIRING INSPECTION

Inspect wiring for damage. Inspect all connections

at the starter motor solenoid, park/neutral position

switch (if equipped), back-up lamp switch connector,

ignition switch, starter relay, and battery (including

all ground connections). Clean and tighten all con-

nections as required.

SOLENOID, RELAY AND IGNITION SWITCH

INSPECTION

Inspect the solenoid, relay and switch to determine

their condition. Also, if equipped with automatic

transmission, inspect condition of the park/neutral

position switch. Testing information can be found in

the following pages.

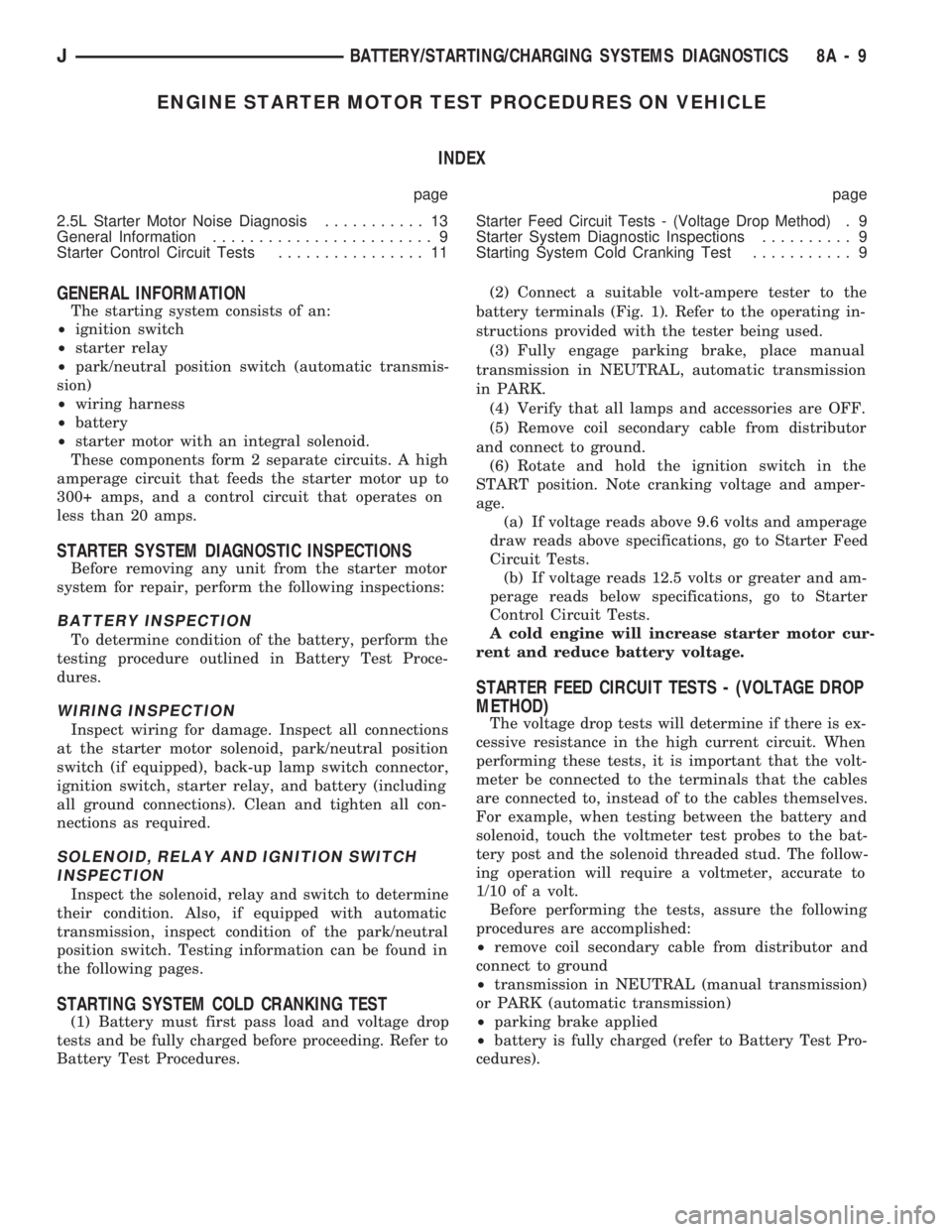

STARTING SYSTEM COLD CRANKING TEST

(1) Battery must first pass load and voltage drop

tests and be fully charged before proceeding. Refer to

Battery Test Procedures.(2) Connect a suitable volt-ampere tester to the

battery terminals (Fig. 1). Refer to the operating in-

structions provided with the tester being used.

(3) Fully engage parking brake, place manual

transmission in NEUTRAL, automatic transmission

in PARK.

(4) Verify that all lamps and accessories are OFF.

(5) Remove coil secondary cable from distributor

and connect to ground.

(6) Rotate and hold the ignition switch in the

START position. Note cranking voltage and amper-

age.

(a) If voltage reads above 9.6 volts and amperage

draw reads above specifications, go to Starter Feed

Circuit Tests.

(b) If voltage reads 12.5 volts or greater and am-

perage reads below specifications, go to Starter

Control Circuit Tests.

A cold engine will increase starter motor cur-

rent and reduce battery voltage.

STARTER FEED CIRCUIT TESTS - (VOLTAGE DROP

METHOD)

The voltage drop tests will determine if there is ex-

cessive resistance in the high current circuit. When

performing these tests, it is important that the volt-

meter be connected to the terminals that the cables

are connected to, instead of to the cables themselves.

For example, when testing between the battery and

solenoid, touch the voltmeter test probes to the bat-

tery post and the solenoid threaded stud. The follow-

ing operation will require a voltmeter, accurate to

1/10 of a volt.

Before performing the tests, assure the following

procedures are accomplished:

²remove coil secondary cable from distributor and

connect to ground

²transmission in NEUTRAL (manual transmission)

or PARK (automatic transmission)

²parking brake applied

²battery is fully charged (refer to Battery Test Pro-

cedures).

JBATTERY/STARTING/CHARGING SYSTEMS DIAGNOSTICS 8A - 9

Page 287 of 1784

GENERATOR TEST PROCEDURES ON VEHICLE

INDEX

page page

Diagnostic Procedures..................... 15

General Information....................... 14Operational Check with Battery Indicator

(Base Cluster Only)..................... 14

Operational Check with Voltmeter............ 15

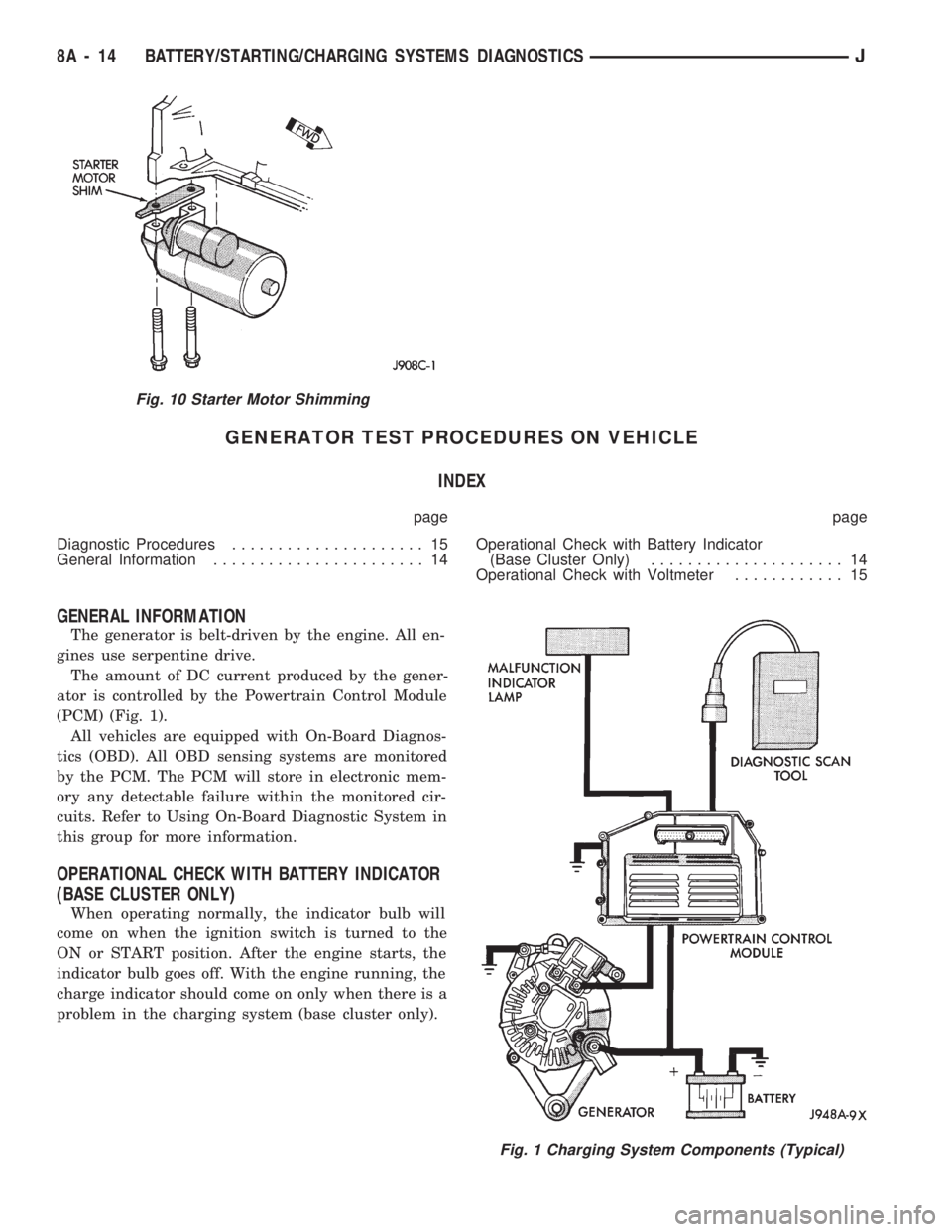

GENERAL INFORMATION

The generator is belt-driven by the engine. All en-

gines use serpentine drive.

The amount of DC current produced by the gener-

ator is controlled by the Powertrain Control Module

(PCM) (Fig. 1).

All vehicles are equipped with On-Board Diagnos-

tics (OBD). All OBD sensing systems are monitored

by the PCM. The PCM will store in electronic mem-

ory any detectable failure within the monitored cir-

cuits. Refer to Using On-Board Diagnostic System in

this group for more information.

OPERATIONAL CHECK WITH BATTERY INDICATOR

(BASE CLUSTER ONLY)

When operating normally, the indicator bulb will

come on when the ignition switch is turned to the

ON or START position. After the engine starts, the

indicator bulb goes off. With the engine running, the

charge indicator should come on only when there is a

problem in the charging system (base cluster only).

Fig. 10 Starter Motor Shimming

Fig. 1 Charging System Components (Typical)

8A - 14 BATTERY/STARTING/CHARGING SYSTEMS DIAGNOSTICSJ

Page 297 of 1784

ENGINE STARTER MOTOR SERVICE PROCEDURES

INDEX

page page

2.5L Starter General Information.............. 4

2.5L Starter Motor Removal/Installation......... 5

4.0L Starter General Information.............. 6

4.0L Starter Motor Removal/Installation......... 6General Information........................ 4

Park/Neutral Position Switch................. 6

Starter Relay Replacement.................. 4

GENERAL INFORMATION

This section will cover the starting system compo-

nent service procedures only. For diagnostic proce-

dures, refer to Group 8A - Battery/Starting/Charging

Systems Diagnostics.

Starting system components: battery, starter mo-

tor, starter relay, starter solenoid, ignition switch,

connecting wires and battery cables. A park/neutral

position switch is used with automatic transmissions.

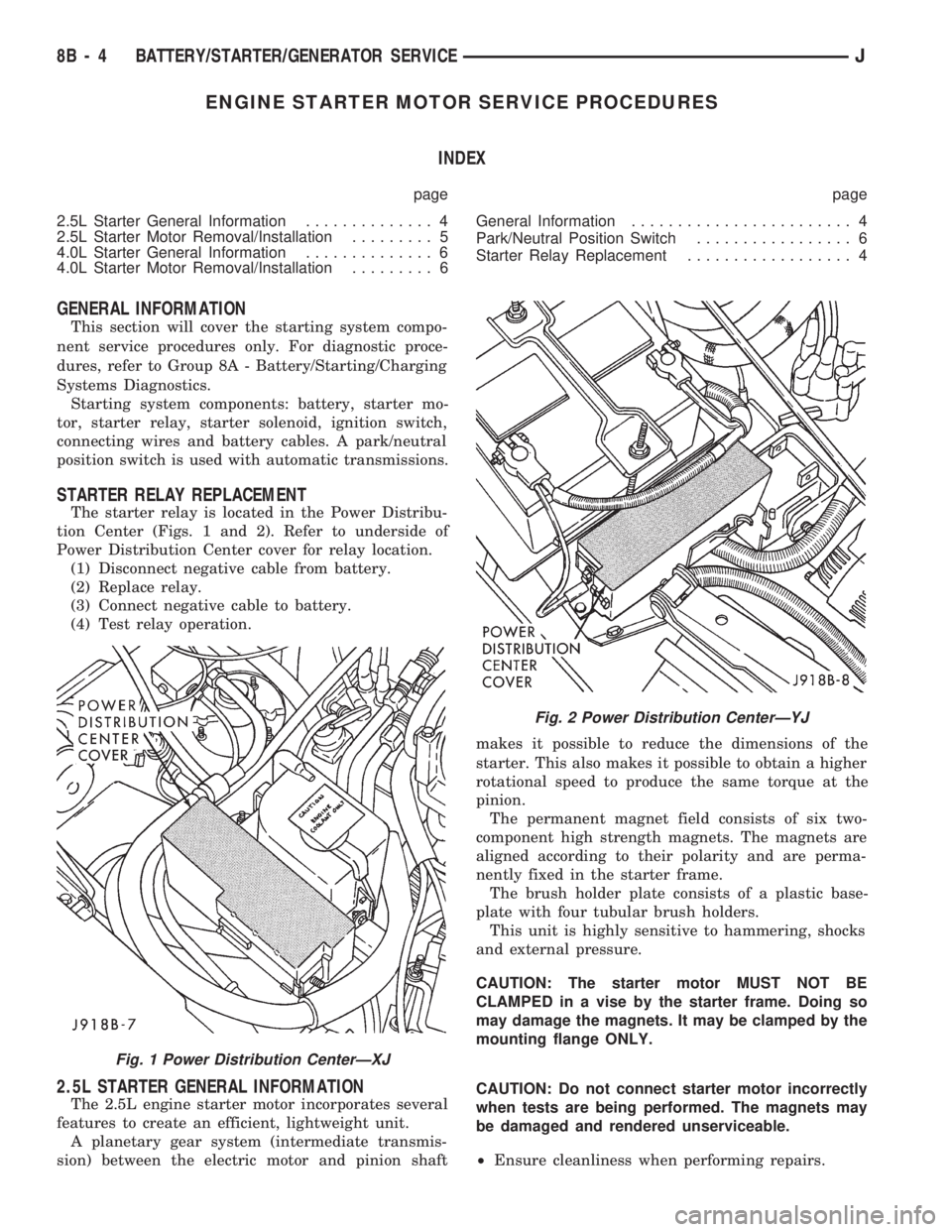

STARTER RELAY REPLACEMENT

The starter relay is located in the Power Distribu-

tion Center (Figs. 1 and 2). Refer to underside of

Power Distribution Center cover for relay location.

(1) Disconnect negative cable from battery.

(2) Replace relay.

(3) Connect negative cable to battery.

(4) Test relay operation.

2.5L STARTER GENERAL INFORMATION

The 2.5L engine starter motor incorporates several

features to create an efficient, lightweight unit.

A planetary gear system (intermediate transmis-

sion) between the electric motor and pinion shaftmakes it possible to reduce the dimensions of the

starter. This also makes it possible to obtain a higher

rotational speed to produce the same torque at the

pinion.

The permanent magnet field consists of six two-

component high strength magnets. The magnets are

aligned according to their polarity and are perma-

nently fixed in the starter frame.

The brush holder plate consists of a plastic base-

plate with four tubular brush holders.

This unit is highly sensitive to hammering, shocks

and external pressure.

CAUTION: The starter motor MUST NOT BE

CLAMPED in a vise by the starter frame. Doing so

may damage the magnets. It may be clamped by the

mounting flange ONLY.

CAUTION: Do not connect starter motor incorrectly

when tests are being performed. The magnets may

be damaged and rendered unserviceable.

²Ensure cleanliness when performing repairs.

Fig. 1 Power Distribution CenterÐXJ

Fig. 2 Power Distribution CenterÐYJ

8B - 4 BATTERY/STARTER/GENERATOR SERVICEJ

Page 314 of 1784

IGNITION SYSTEMS

CONTENTS

page page

COMPONENT IDENTIFICATION/SYSTEM

OPERATION.......................... 1

COMPONENT REMOVAL/INSTALLATION..... 20DIAGNOSTICS/SERVICE PROCEDURES....... 8

IGNITION SWITCH...................... 30

SPECIFICATIONS....................... 33

COMPONENT IDENTIFICATION/SYSTEM OPERATION

INDEX

page page

Automatic Shut Down (ASD) Relay............ 1

Camshaft Position Sensor................... 1

Crankshaft Position Sensor.................. 2

Distributors.............................. 3

Engine Coolant Temperature Sensor........... 4

General Information........................ 1Ignition Coil.............................. 4

Intake Manifold Air Temperature Sensor........ 5

Manifold Absolute Pressure (MAP) Sensor...... 5

Powertrain Control Module (PCM)............. 6

Throttle Position Sensor.................... 6

GENERAL INFORMATION

Throughout this group, references are made to par-

ticular vehicle models by alphabetical designation

(XJ or YJ) or by the particular vehicle nameplate. A

chart showing a breakdown of alphabetical designa-

tions is included in the Introduction group at the be-

ginning of this manual.

This section of the group, Component Identifica-

tion/System Operation, will discuss ignition system

operation and will identify ignition system compo-

nents.

For diagnostic procedures and adjustments, refer to

the Diagnostics/Service Procedures section of this

group.

For removal and installation of ignition system

components, refer to the Component Removal/Instal-

lation section of this group.

For other useful information, refer to On-Board Di-

agnostics in the General Diagnosis sections of Group

14, Fuel System in this manual.

For operation of the DRB Scan Tool, refer to the

appropriate Powertrain Diagnostic Procedures ser-

vice manual.

An Ignition specifications section is included at the

end of this group. A general Maintenance Schedule

(mileage intervals) for ignition related items can be

found in Group 0, Lubrication and Maintenance. This

schedule can also be found in the Owners Manual.

IGNITION SYSTEMS

A multi-port, fuel injected engine is used on all

models. The ignition system is controlled by the Pow-

ertrain Control Module (PCM) on all engines. The

PCM was formerly referred to as the SBEC or engine

controller.

The ignition system consists of:

²Spark Plugs

²Ignition Coil

²Secondary Ignition Cables

²Ignition distributor (contains rotor and camshaft

position sensor)

²Powertrain Control Module (PCM)

²Crankshaft Position Sensor

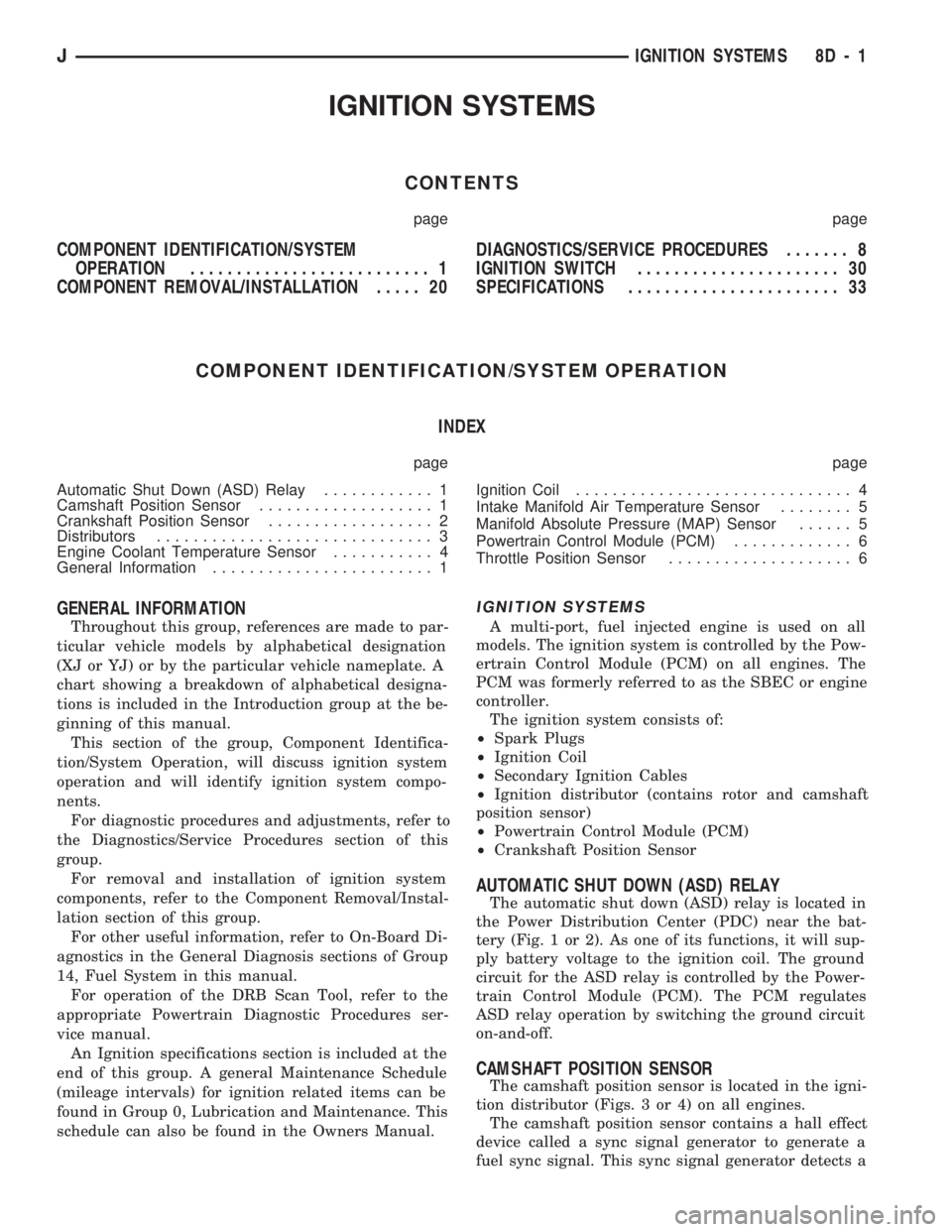

AUTOMATIC SHUT DOWN (ASD) RELAY

The automatic shut down (ASD) relay is located in

the Power Distribution Center (PDC) near the bat-

tery (Fig. 1 or 2). As one of its functions, it will sup-

ply battery voltage to the ignition coil. The ground

circuit for the ASD relay is controlled by the Power-

train Control Module (PCM). The PCM regulates

ASD relay operation by switching the ground circuit

on-and-off.

CAMSHAFT POSITION SENSOR

The camshaft position sensor is located in the igni-

tion distributor (Figs. 3 or 4) on all engines.

The camshaft position sensor contains a hall effect

device called a sync signal generator to generate a

fuel sync signal. This sync signal generator detects a

JIGNITION SYSTEMS 8D - 1