index JEEP CHEROKEE 1994 Service Workshop Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 1994, Model line: CHEROKEE, Model: JEEP CHEROKEE 1994Pages: 1784, PDF Size: 77.09 MB

Page 383 of 1784

RADIO ANTENNA

INDEX

page page

Antenna Tests............................ 9

General Information........................ 8Replacement............................. 8

GENERAL INFORMATION

AM/FM radio model antennas must have a good

ground to eliminate static. The antenna mast is con-

nected to the inner wire of the coaxial cable and is

not grounded to any part of the vehicle. The coaxial

shield (the wire mesh) surrounding the center con-

ductor wire of the antenna lead-in cable is grounded

to the radio and the antenna base.

REPLACEMENT

XJ

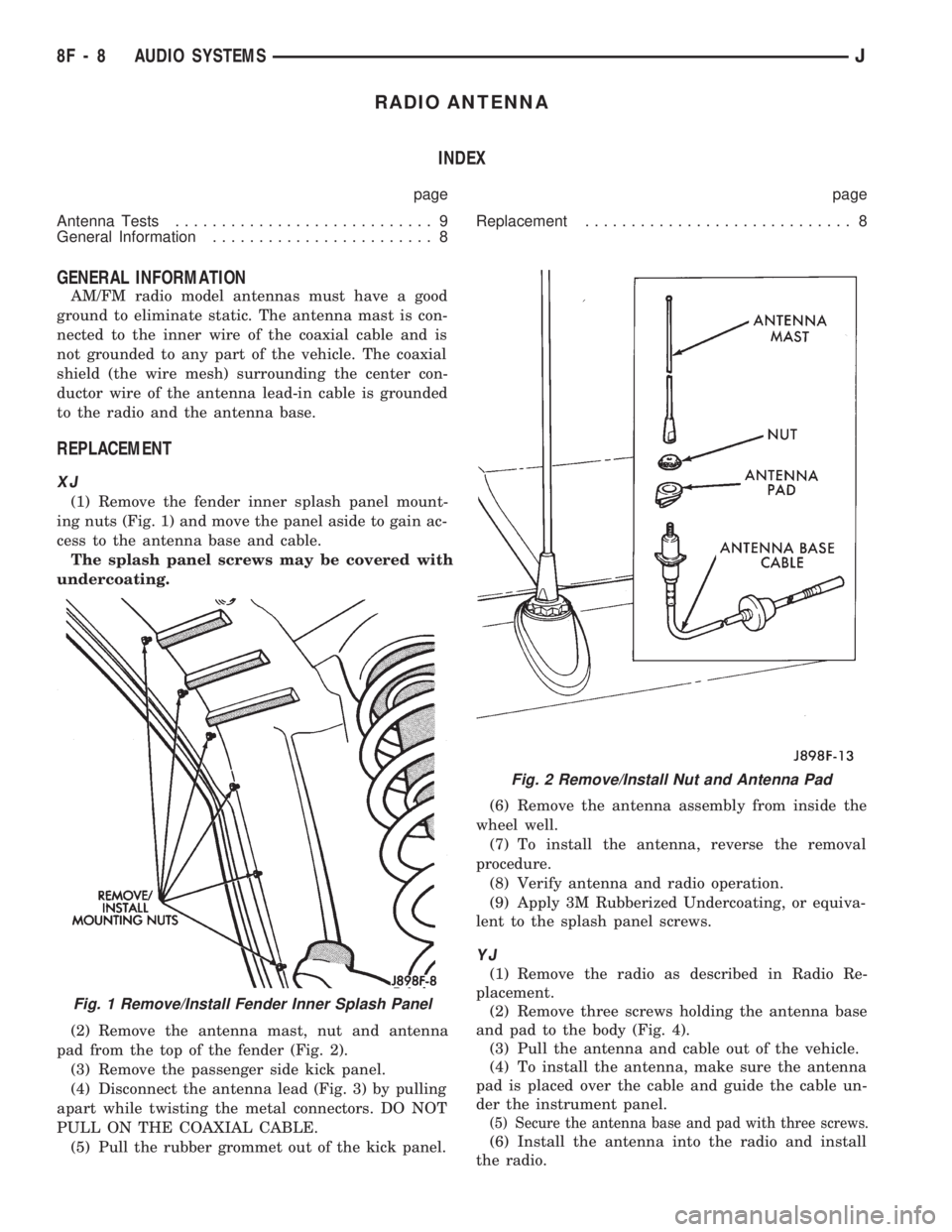

(1) Remove the fender inner splash panel mount-

ing nuts (Fig. 1) and move the panel aside to gain ac-

cess to the antenna base and cable.

The splash panel screws may be covered with

undercoating.

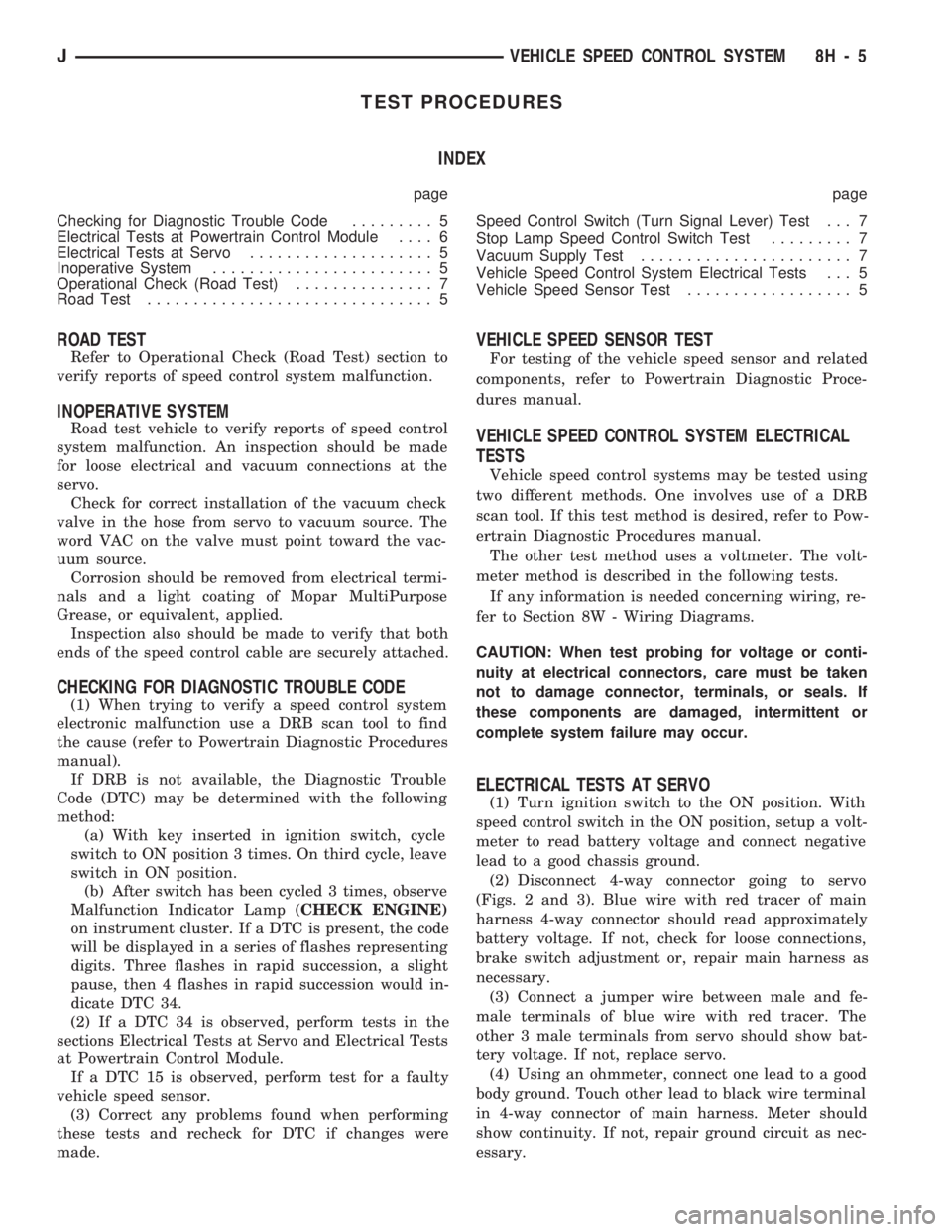

(2) Remove the antenna mast, nut and antenna

pad from the top of the fender (Fig. 2).

(3) Remove the passenger side kick panel.

(4) Disconnect the antenna lead (Fig. 3) by pulling

apart while twisting the metal connectors. DO NOT

PULL ON THE COAXIAL CABLE.

(5) Pull the rubber grommet out of the kick panel.(6) Remove the antenna assembly from inside the

wheel well.

(7) To install the antenna, reverse the removal

procedure.

(8) Verify antenna and radio operation.

(9) Apply 3M Rubberized Undercoating, or equiva-

lent to the splash panel screws.

YJ

(1) Remove the radio as described in Radio Re-

placement.

(2) Remove three screws holding the antenna base

and pad to the body (Fig. 4).

(3) Pull the antenna and cable out of the vehicle.

(4) To install the antenna, make sure the antenna

pad is placed over the cable and guide the cable un-

der the instrument panel.

(5) Secure the antenna base and pad with three screws.

(6) Install the antenna into the radio and install

the radio.

Fig. 1 Remove/Install Fender Inner Splash Panel

Fig. 2 Remove/Install Nut and Antenna Pad

8F - 8 AUDIO SYSTEMSJ

Page 394 of 1784

TEST PROCEDURES

INDEX

page page

Checking for Diagnostic Trouble Code......... 5

Electrical Tests at Powertrain Control Module.... 6

Electrical Tests at Servo.................... 5

Inoperative System........................ 5

Operational Check (Road Test)............... 7

Road Test............................... 5Speed Control Switch (Turn Signal Lever) Test . . . 7

Stop Lamp Speed Control Switch Test......... 7

Vacuum Supply Test....................... 7

Vehicle Speed Control System Electrical Tests . . . 5

Vehicle Speed Sensor Test.................. 5

ROAD TEST

Refer to Operational Check (Road Test) section to

verify reports of speed control system malfunction.

INOPERATIVE SYSTEM

Road test vehicle to verify reports of speed control

system malfunction. An inspection should be made

for loose electrical and vacuum connections at the

servo.

Check for correct installation of the vacuum check

valve in the hose from servo to vacuum source. The

word VAC on the valve must point toward the vac-

uum source.

Corrosion should be removed from electrical termi-

nals and a light coating of Mopar MultiPurpose

Grease, or equivalent, applied.

Inspection also should be made to verify that both

ends of the speed control cable are securely attached.

CHECKING FOR DIAGNOSTIC TROUBLE CODE

(1) When trying to verify a speed control system

electronic malfunction use a DRB scan tool to find

the cause (refer to Powertrain Diagnostic Procedures

manual).

If DRB is not available, the Diagnostic Trouble

Code (DTC) may be determined with the following

method:

(a) With key inserted in ignition switch, cycle

switch to ON position 3 times. On third cycle, leave

switch in ON position.

(b) After switch has been cycled 3 times, observe

Malfunction Indicator Lamp (CHECK ENGINE)

on instrument cluster. If a DTC is present, the code

will be displayed in a series of flashes representing

digits. Three flashes in rapid succession, a slight

pause, then 4 flashes in rapid succession would in-

dicate DTC 34.

(2) If a DTC 34 is observed, perform tests in the

sections Electrical Tests at Servo and Electrical Tests

at Powertrain Control Module.

If a DTC 15 is observed, perform test for a faulty

vehicle speed sensor.

(3) Correct any problems found when performing

these tests and recheck for DTC if changes were

made.

VEHICLE SPEED SENSOR TEST

For testing of the vehicle speed sensor and related

components, refer to Powertrain Diagnostic Proce-

dures manual.

VEHICLE SPEED CONTROL SYSTEM ELECTRICAL

TESTS

Vehicle speed control systems may be tested using

two different methods. One involves use of a DRB

scan tool. If this test method is desired, refer to Pow-

ertrain Diagnostic Procedures manual.

The other test method uses a voltmeter. The volt-

meter method is described in the following tests.

If any information is needed concerning wiring, re-

fer to Section 8W - Wiring Diagrams.

CAUTION: When test probing for voltage or conti-

nuity at electrical connectors, care must be taken

not to damage connector, terminals, or seals. If

these components are damaged, intermittent or

complete system failure may occur.

ELECTRICAL TESTS AT SERVO

(1) Turn ignition switch to the ON position. With

speed control switch in the ON position, setup a volt-

meter to read battery voltage and connect negative

lead to a good chassis ground.

(2) Disconnect 4-way connector going to servo

(Figs. 2 and 3). Blue wire with red tracer of main

harness 4-way connector should read approximately

battery voltage. If not, check for loose connections,

brake switch adjustment or, repair main harness as

necessary.

(3) Connect a jumper wire between male and fe-

male terminals of blue wire with red tracer. The

other 3 male terminals from servo should show bat-

tery voltage. If not, replace servo.

(4) Using an ohmmeter, connect one lead to a good

body ground. Touch other lead to black wire terminal

in 4-way connector of main harness. Meter should

show continuity. If not, repair ground circuit as nec-

essary.

JVEHICLE SPEED CONTROL SYSTEM 8H - 5

Page 398 of 1784

SERVICE PROCEDURES

INDEX

page page

Servo Cable Replacement................... 9

Speed Control Servo Replacement............ 9Speed Control Switch Replacement............ 9

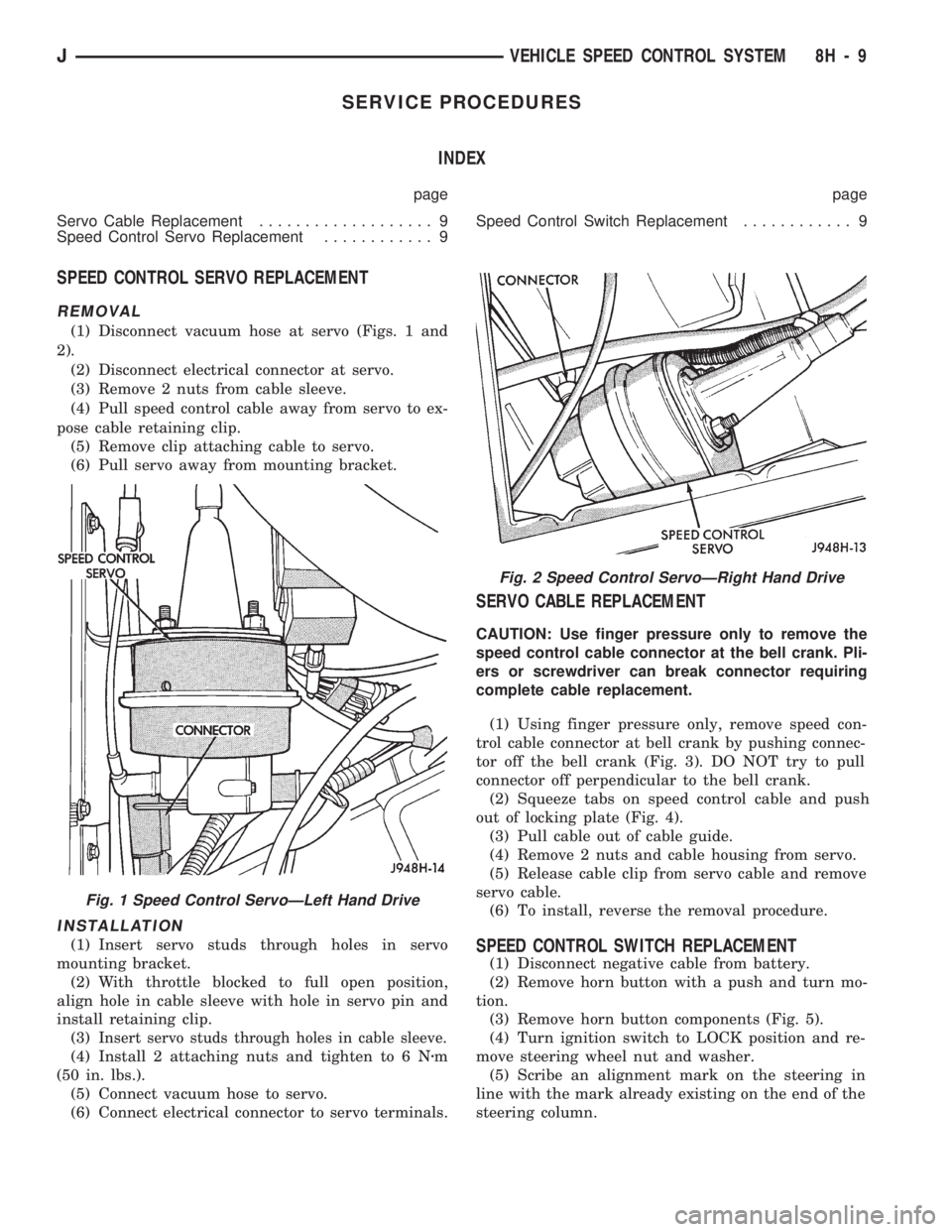

SPEED CONTROL SERVO REPLACEMENT

REMOVAL

(1) Disconnect vacuum hose at servo (Figs. 1 and

2).

(2) Disconnect electrical connector at servo.

(3) Remove 2 nuts from cable sleeve.

(4) Pull speed control cable away from servo to ex-

pose cable retaining clip.

(5) Remove clip attaching cable to servo.

(6) Pull servo away from mounting bracket.

INSTALLATION

(1) Insert servo studs through holes in servo

mounting bracket.

(2) With throttle blocked to full open position,

align hole in cable sleeve with hole in servo pin and

install retaining clip.

(3)

Insert servo studs through holes in cable sleeve.

(4) Install 2 attaching nuts and tighten to 6 Nzm

(50 in. lbs.).

(5) Connect vacuum hose to servo.

(6) Connect electrical connector to servo terminals.

SERVO CABLE REPLACEMENT

CAUTION: Use finger pressure only to remove the

speed control cable connector at the bell crank. Pli-

ers or screwdriver can break connector requiring

complete cable replacement.

(1) Using finger pressure only, remove speed con-

trol cable connector at bell crank by pushing connec-

tor off the bell crank (Fig. 3). DO NOT try to pull

connector off perpendicular to the bell crank.

(2) Squeeze tabs on speed control cable and push

out of locking plate (Fig. 4).

(3) Pull cable out of cable guide.

(4) Remove 2 nuts and cable housing from servo.

(5) Release cable clip from servo cable and remove

servo cable.

(6) To install, reverse the removal procedure.

SPEED CONTROL SWITCH REPLACEMENT

(1) Disconnect negative cable from battery.

(2) Remove horn button with a push and turn mo-

tion.

(3) Remove horn button components (Fig. 5).

(4) Turn ignition switch to LOCK position and re-

move steering wheel nut and washer.

(5) Scribe an alignment mark on the steering in

line with the mark already existing on the end of the

steering column.

Fig. 2 Speed Control ServoÐRight Hand Drive

Fig. 1 Speed Control ServoÐLeft Hand Drive

JVEHICLE SPEED CONTROL SYSTEM 8H - 9

Page 408 of 1784

WINDSHIELD WIPERS

CONTENTS

page page

WIPER CONTROL SWITCH REPLACEMENT . . 15

WIPER SWITCH TESTING................ 19XJ .................................... 1

YJ .................................... 8

XJ

INDEX

page page

Diagnosing Rear Wiper..................... 6

Diagnosing Rear Wiper Washer.............. 6

Diagnosing Windshield Washer (Intermittent)..... 5

Diagnosing Windshield Washer (Non-Intermittent) . 4

Diagnosing Windshield Wipers............... 11

Front Wipers/Washers...................... 1

Intermittent Wiper Module................... 5

Liftgate Wiper............................ 5Liftgate Wiper Switch Replacement............ 6

Rear Wiper/Washer Switch Testing............ 7

Torque Specifications XJ.................... 7

Washer Pump Replacement................. 6

Washer Pump ReplacementÐLeft Hand Drive.... 2

Washer Pump ReplacementÐRight Hand Drive . . 3

Windshield Wiper Motor.................... 2

FRONT WIPERS/WASHERS

GENERAL

Two-speed electric windshield wipers and electric

washers are standard equipment. An optional inter-

mittent wiper system provides a pause between wipe

cycles for use during conditions of very light precipi-

tation.

The windshield wipers can be operated with the

windshield wiper switch only when the ignition

switch is in the ON or ACCESSORY position. A cir-

cuit breaker located in the fuse block protects the cir-

cuitry of the wiper system.

WIPERS

The standard windshield wiper circuit contains

three components; wiper/washer switch, motor, and

front washer pump. Both standard and intermittent

circuits are the same, except that the intermittent

circuit requires a module and delay resistance in the

wiper switch. Both circuits receive battery feed from,

and are protected by a 5.5 amp circuit breaker.

In the standard wiper circuit, the switch connects

the motor directly to battery feed for low and high

speed operation. In the intermittent circuit, the

switch supplies battery feed to the intermittent wiper

module, which then supplies the motor. In the delay

position, the module is connected with the variable

resistor in the wiper switch. The value of the resis-tance is used by the module to charge a capacitor,

which triggers the amount of delay between wipes.

The wiper motor has an arrangement of brushes

providing the two wiper speeds. When the wipers are

turned off, the park switch maintains current to the

motor until the wipers reach the park position on the

windshield.

The park arm in the motor assembly is connected

to the park switch and is driven by the motor. When

the wiper switch is turned off, current flows through

the contact and the module to the motor until the

wipers reach the park position.

CAUTION: The wiper arms and blades must not be

moved manually from side to side or damage may

result.

WASHERS

With the washer switch ON, current flows through

the washer pump to ground. The front washer pump

runs as long as the driver holds the switch ON. On

standard wipers, the washer switch automatically

moves the wiper switch to LO when the washer is

turned on. On intermittent wipers, the wiper module

runs the wiper motor on LO. Turning the switch to

OFF stops the wipers.

If the washer knob is depressed while the wiper

switch is in the OFF position, the wiper control will

operate for approximately 3 wipes and automatically

turn OFF.

JWINDSHIELD WIPERS 8K - 1

Page 415 of 1784

YJ

INDEX

page page

Diagnosing Windshield Wipers............... 11

Diagnosing Intermittent Windshield Washer..... 12

Diagnosing Non-Intermittent Windshield Washer . 12

Diagnosing Rear Wiper/Washer.............. 14

Front Wiper Arm and Pivot Assembly Replacement . 9

Front Wiper Arm Replacement............... 8

Front Wiper Blade Replacement.............. 8

Front Wiper Motor........................ 10Front Wipers/Washers General Information...... 8

Rear Washer Pump Replacement............ 13

Rear Wiper Arm Replacement............... 12

Rear Wiper Motor Replacement.............. 13

Rear Wiper Switch Replacement............. 13

Rear Wiper/Washer Switch Testing........... 14

Washer Nozzle Replacement................ 13

Washer Pump Replacement................ 11

FRONT WIPERS/WASHERS GENERAL

INFORMATION

The non-intermittent windshield wiper circuit con-

tains three components; control switch, motor and

washer pump. The intermittent circuit contains the

same components and a wiper module that provides

the delay function. Both circuits receive battery feed

from and are protected by a 5.3 amp circuit breaker.

In the non-intermittent wiper circuit, the switch

connects the motor directly to ignition feed for low

and high speed operation. In the intermittent circuit,

the switch supplies ignition feed to the delay module,

which then supplies the motor. In the delay position,

the module is connected with the variable resistor in

the wiper switch. The value of the resistance is used

by the solid state module to charge a capacitor,

which triggers the amount of delay between wipes.

The wiper motor has an arrangement of brushes

providing the two wiper speeds. When the wipers are

turned off, the park switch maintains current to the

motor until the wipers reach the park position on the

windshield.

The washer pump receives ignition feed either di-

rectly from the wiper switch or from the intermittent

module. In either case the electric motor will drive

the washer pump.

The wiper motor is mounted on the lower left cor-

ner of the windshield.

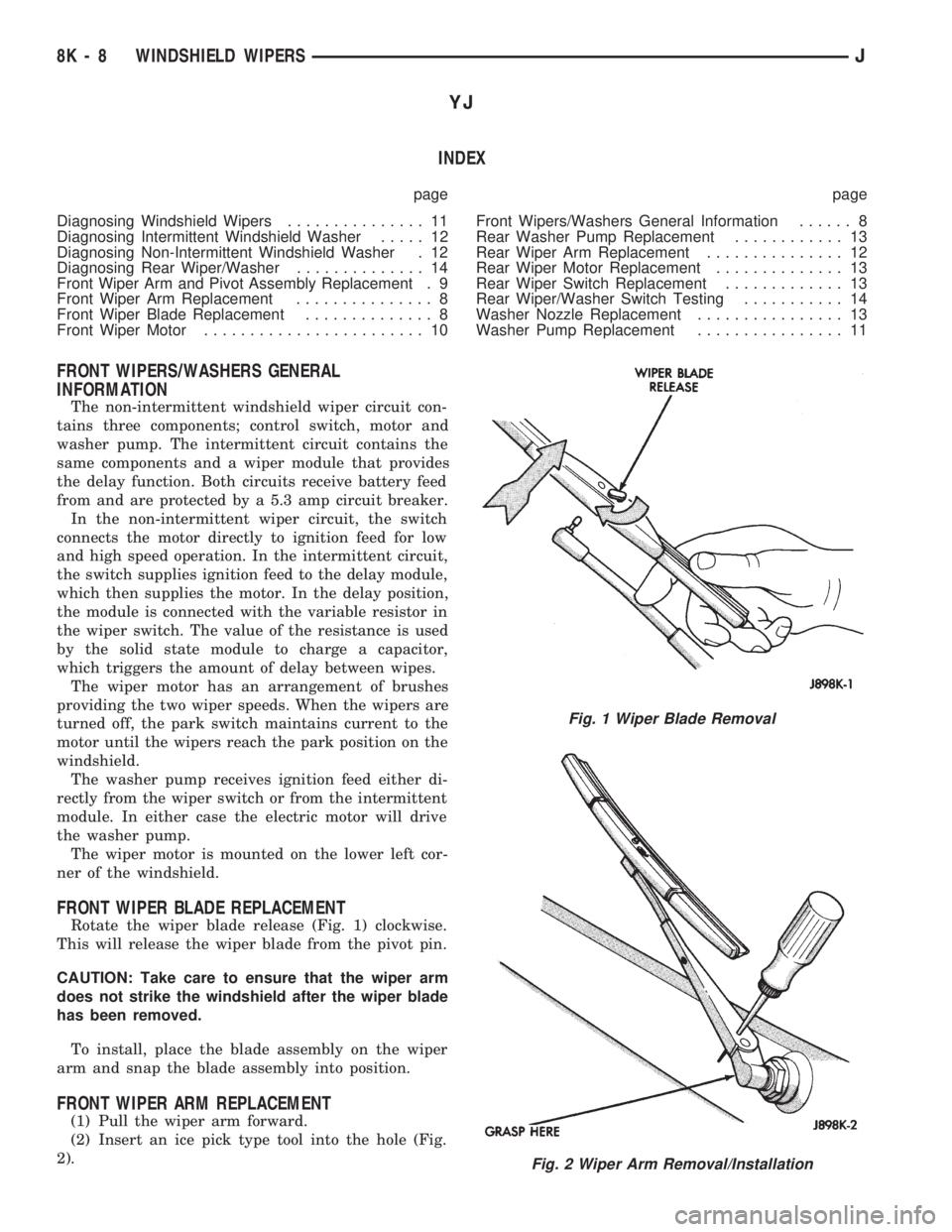

FRONT WIPER BLADE REPLACEMENT

Rotate the wiper blade release (Fig. 1) clockwise.

This will release the wiper blade from the pivot pin.

CAUTION: Take care to ensure that the wiper arm

does not strike the windshield after the wiper blade

has been removed.

To install, place the blade assembly on the wiper

arm and snap the blade assembly into position.

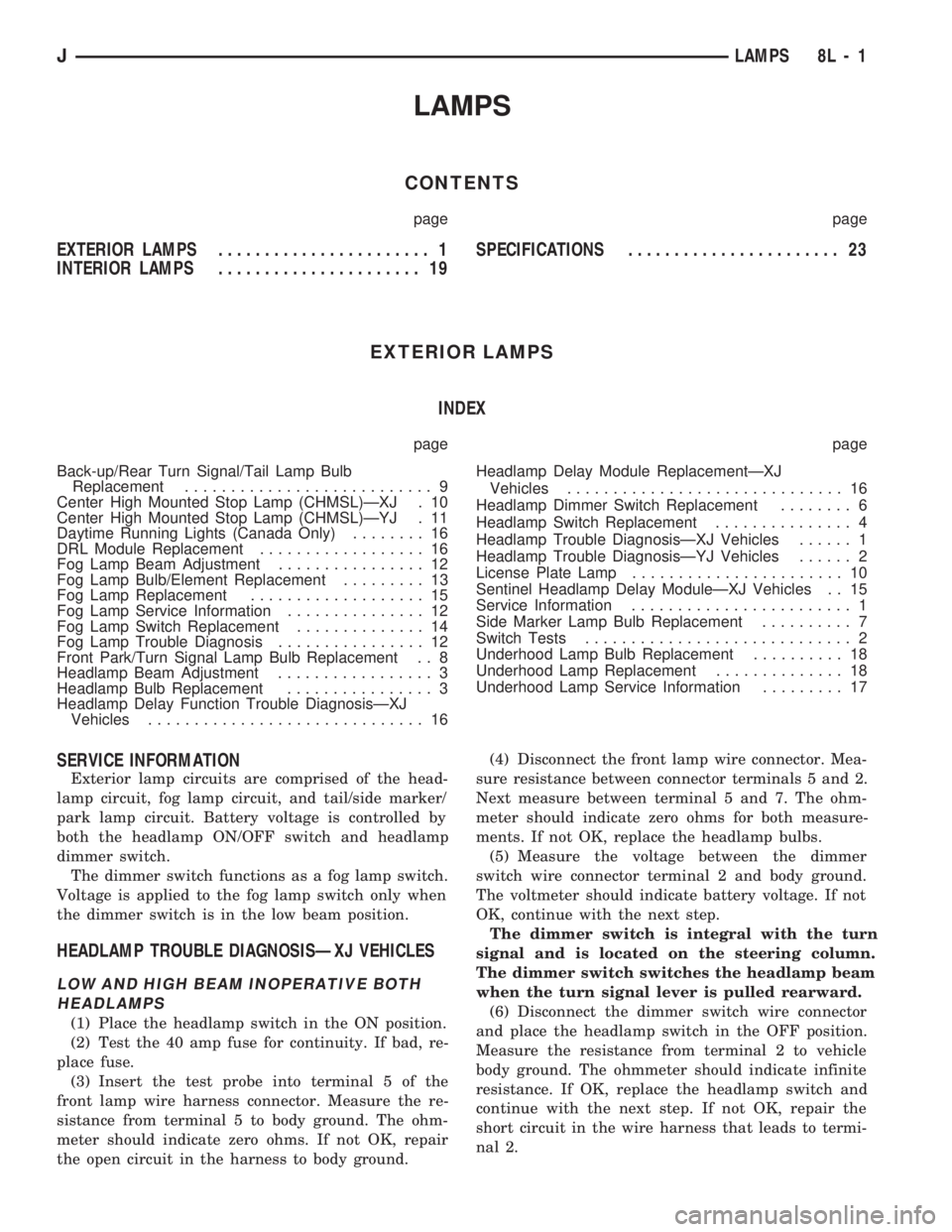

FRONT WIPER ARM REPLACEMENT

(1) Pull the wiper arm forward.

(2) Insert an ice pick type tool into the hole (Fig.

2).

Fig. 1 Wiper Blade Removal

Fig. 2 Wiper Arm Removal/Installation

8K - 8 WINDSHIELD WIPERSJ

Page 428 of 1784

LAMPS

CONTENTS

page page

EXTERIOR LAMPS....................... 1

INTERIOR LAMPS...................... 19SPECIFICATIONS....................... 23

EXTERIOR LAMPS

INDEX

page page

Back-up/Rear Turn Signal/Tail Lamp Bulb

Replacement........................... 9

Center High Mounted Stop Lamp (CHMSL)ÐXJ . 10

Center High Mounted Stop Lamp (CHMSL)ÐYJ . 11

Daytime Running Lights (Canada Only)........ 16

DRL Module Replacement.................. 16

Fog Lamp Beam Adjustment................ 12

Fog Lamp Bulb/Element Replacement......... 13

Fog Lamp Replacement................... 15

Fog Lamp Service Information............... 12

Fog Lamp Switch Replacement.............. 14

Fog Lamp Trouble Diagnosis................ 12

Front Park/Turn Signal Lamp Bulb Replacement . . 8

Headlamp Beam Adjustment................. 3

Headlamp Bulb Replacement................ 3

Headlamp Delay Function Trouble DiagnosisÐXJ

Vehicles.............................. 16Headlamp Delay Module ReplacementÐXJ

Vehicles.............................. 16

Headlamp Dimmer Switch Replacement........ 6

Headlamp Switch Replacement............... 4

Headlamp Trouble DiagnosisÐXJ Vehicles...... 1

Headlamp Trouble DiagnosisÐYJ Vehicles...... 2

License Plate Lamp....................... 10

Sentinel Headlamp Delay ModuleÐXJ Vehicles . . 15

Service Information........................ 1

Side Marker Lamp Bulb Replacement.......... 7

Switch Tests............................. 2

Underhood Lamp Bulb Replacement.......... 18

Underhood Lamp Replacement.............. 18

Underhood Lamp Service Information......... 17

SERVICE INFORMATION

Exterior lamp circuits are comprised of the head-

lamp circuit, fog lamp circuit, and tail/side marker/

park lamp circuit. Battery voltage is controlled by

both the headlamp ON/OFF switch and headlamp

dimmer switch.

The dimmer switch functions as a fog lamp switch.

Voltage is applied to the fog lamp switch only when

the dimmer switch is in the low beam position.

HEADLAMP TROUBLE DIAGNOSISÐXJ VEHICLES

LOW AND HIGH BEAM INOPERATIVE BOTH

HEADLAMPS

(1) Place the headlamp switch in the ON position.

(2) Test the 40 amp fuse for continuity. If bad, re-

place fuse.

(3) Insert the test probe into terminal 5 of the

front lamp wire harness connector. Measure the re-

sistance from terminal 5 to body ground. The ohm-

meter should indicate zero ohms. If not OK, repair

the open circuit in the harness to body ground.(4) Disconnect the front lamp wire connector. Mea-

sure resistance between connector terminals 5 and 2.

Next measure between terminal 5 and 7. The ohm-

meter should indicate zero ohms for both measure-

ments. If not OK, replace the headlamp bulbs.

(5) Measure the voltage between the dimmer

switch wire connector terminal 2 and body ground.

The voltmeter should indicate battery voltage. If not

OK, continue with the next step.

The dimmer switch is integral with the turn

signal and is located on the steering column.

The dimmer switch switches the headlamp beam

when the turn signal lever is pulled rearward.

(6) Disconnect the dimmer switch wire connector

and place the headlamp switch in the OFF position.

Measure the resistance from terminal 2 to vehicle

body ground. The ohmmeter should indicate infinite

resistance. If OK, replace the headlamp switch and

continue with the next step. If not OK, repair the

short circuit in the wire harness that leads to termi-

nal 2.

JLAMPS 8L - 1

Page 446 of 1784

INTERIOR LAMPS

INDEX

page page

Dome Lamp Replacement.................. 20

Dome/Courtesy Lamp Service Information...... 19

Dome/Courtesy Lamp Trouble Diagnosis....... 19

Hardtop Dome/Cargo Lamp Bulb ReplacementÐYJ

Vehicles.............................. 20Illuminated Entry System Service Information . . . 20

Illuminated Entry System Trouble Diagnosis.... 21

Lighted Vanity Mirror...................... 19

Lighted Vanity Mirror Trouble Diagnosis....... 19

Overhead ConsoleÐXJ Vehicles............. 20

DOME/COURTESY LAMP SERVICE INFORMATION

XJ VEHICLES

Voltage is applied at all times via the dome lamp

fuse to each of the interior lamp bulbs. The interior

lamp bulbs illuminate when they are connected to

body ground via the switch:

²headlamp switch,

²glove box switch,

²door pillar switch, and

²liftgate switch (if the cargo lamp is ON.)

If equipped with Security Alarm Module, refer to

Group 8QÐVehicle Theft Security System.

YJ VEHICLES

The dome/cargo and courtesy lamps are controlled

via ON/OFF switches. The ON/OFF switches are in

the lamp ground circuits. Voltage via the dome/cour-

tesy lamp fuse is applied directly to the lamp bulbs.

When either door is opened, the door pillar switch

contacts close and provide a direct path to vehicle

body ground.

The cargo/cargo and courtesy lamps can also be

turned on via the interior lamp illumination rheo-

stat.

DOME/COURTESY LAMP TROUBLE DIAGNOSIS

ALL LAMPS INOPERATIVE

(1) Rotate the headlamp switch rheostat clockwise.

The lamps should light. If not OK, remove, inspect

and test the dome lamp fuse. Replace if bad.

(2) If the fuse is OK, repair the open circuit in the

wire harness to vehicle body ground.

ONE LAMP INOPERATIVE

(1) Measure the resistance across the bulb holder

terminals. The ohmmeter should indicate zero ohms.

If not, replace the bulb.

(2) Measure the voltage between the voltage side

of the bulb holder and vehicle body ground. The volt-

meter should indicate battery voltage. If not, repair

the open circuit in the wire harness to the splice.

LAMPS INOPERATIVE WITH ONE OR MORE

DOORS OPENED

(1) Remove the inoperative switch from the door

pillar and connect the switch wire directly to ground.

The lamp should light.

(2) If not, check for an open circuit in black

(ground) wire. Repair as necessary. If lamps still do

not light, replace the switch.

LIGHTED VANITY MIRROR

SERVICE INFORMATIONÐXJ VEHICLES

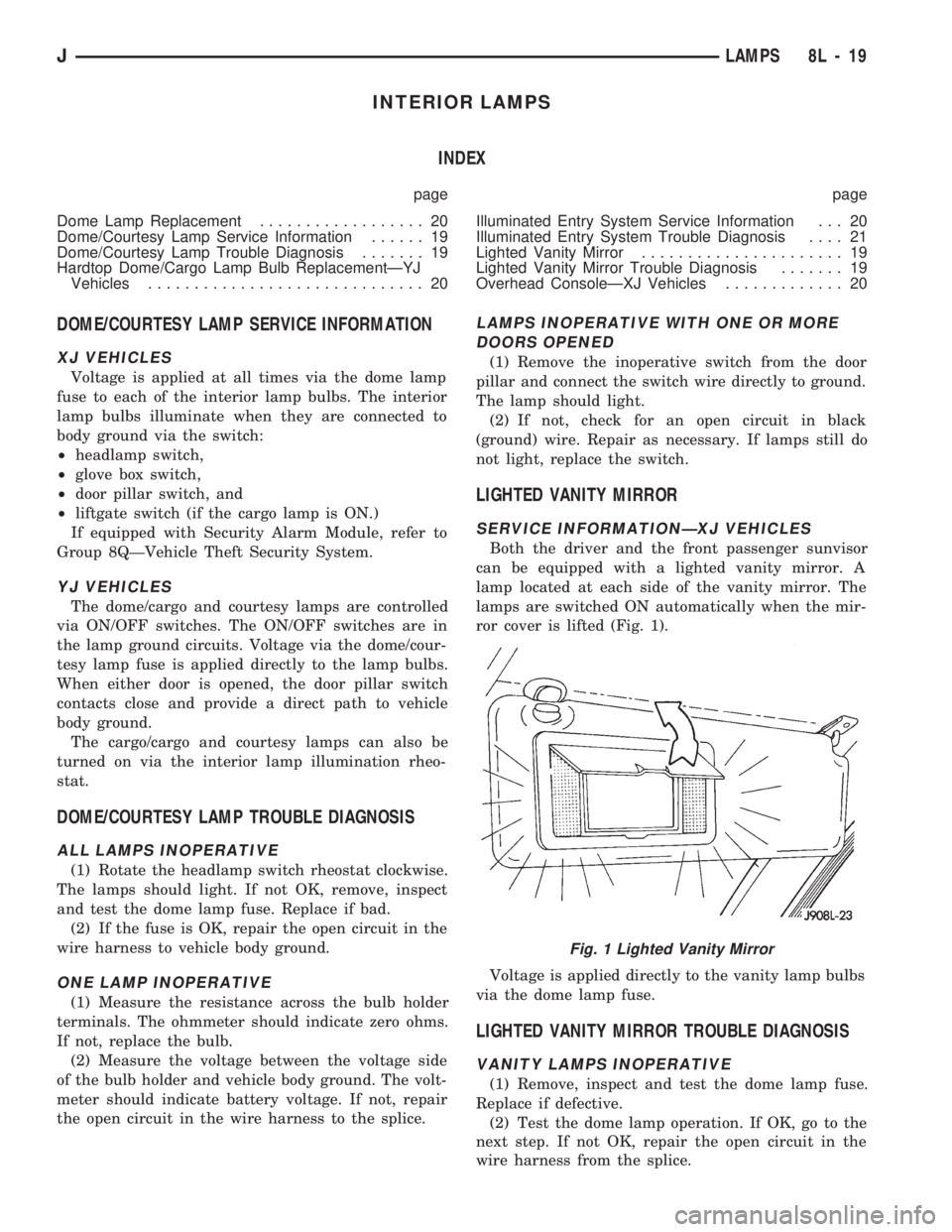

Both the driver and the front passenger sunvisor

can be equipped with a lighted vanity mirror. A

lamp located at each side of the vanity mirror. The

lamps are switched ON automatically when the mir-

ror cover is lifted (Fig. 1).

Voltage is applied directly to the vanity lamp bulbs

via the dome lamp fuse.

LIGHTED VANITY MIRROR TROUBLE DIAGNOSIS

VANITY LAMPS INOPERATIVE

(1) Remove, inspect and test the dome lamp fuse.

Replace if defective.

(2) Test the dome lamp operation. If OK, go to the

next step. If not OK, repair the open circuit in the

wire harness from the splice.

Fig. 1 Lighted Vanity Mirror

JLAMPS 8L - 19

Page 452 of 1784

REAR WINDOW DEFOGGER

CONTENTS

page page

GENERAL.............................. 1

XJ .................................... 4YJ .................................... 4

GENERAL

INDEX

page page

Diagnosis............................... 2

Rear Window Defogger Grid Repair........... 2Rear Window Defogger Grid Test............. 1

Switch Testing............................ 2

Using heating elements bonded to the rear window

glass, the rear defogger will clear condensation, frost

and light snow coverings from the rear window.

The horizontal grid lines and vertical bus bar lines,

printed and baked on inside surface of the rear win-

dow glass, comprise an electrical circuit. The electri-

cally conductive lines are composed of a silver-

ceramic material which when baked on glass

becomes bonded to the glass and is highly resistant

to abrasion.

The electrical current required to produce the heat

in the grid is supplied through a relay and driver op-

erated switch. When the switch is momentarily de-

pressed, the relay senses a voltage change. This

voltage change causes the relay to change state and

complete a circuit to energize the relay. Once the re-

lay energizes, the contacts close connecting the grid

to battery power.

On the XJ, the power circuit to the grid is pro-

tected by the 25 amp, #18 fuse in the fuse box.

Power for fuse #18 comes from the power distribu-

tion center, fuse #F10. Power for the relay is pro-

tected by the 20 amp, #8 fuse located in the fuse box.

On the YJ, the grid is protected by a 25 amp #6

fuse, located in the fuse box. Power for the relay is

protected by 15 amp #9 fuse, located in the fuse box.

To defog the rear window, momentarily depress the

rocker switch. A light on the rocker switch will illu-

minate indicating that the defogger is operating.

If the ignition switch is ON the first activation of

the defog/defrost feature will last for 10 minutes.

Succeeding activations will last for 5 minutes unless

the ignition switch is turned OFF; then it will recy-

cle back to 10 minutes for the first activation.To stop defogger operation, momentarily push the

switch a second time.

CAUTION: Use care when washing the inside of the

rear window to prevent damage to the defogger

heating elements. Use a soft cloth and a mild wash-

ing solution. Wiping motions should be parallel to

the heating elements. Also, keep all objects a safe

distance from the window to prevent damaging the

heating elements.

REAR WINDOW DEFOGGER GRID TEST

It is possible, that a break may exist or occur in an

individual grid line resulting in no current flow

through the line. When a grid has an open circuit,

the area of glass normally cleared by that grid re-

mains fogged or iced unless, and until it is cleared by

the adjacent grids.

With the engine running at idle, push the rear

window defogger switch to the ON position and re-

lease. The pilot lamp in the rocker switch should

light, indicating defogger operation.

Using a 12-volt DC voltmeter, contact the positive

lead to the feed side vertical bus element on the in-

side surface of the glass. Contact the negative lead to

the ground side bus element. Meter should read be-

tween 11 and 13 volts. Connect the negative lead of

the voltmeter to a good ground; the meter reading

should be constant.

Keep the negative lead connected to ground. Use

the positive lead and carefully contact each grid at

the approximate centerline of the window.

JREAR WINDOW DEFOGGER 8N - 1

Page 456 of 1784

POWER DOOR LOCKS

CONTENTS

page page

KEYLESS ENTRY........................ 8POWER LOCKS......................... 1

POWER LOCKS

INDEX

page page

Actuator Motor Stall Test.................... 6

Description.............................. 1

Diagnosing Power Door Locks............... 1

General................................. 1Liftgate Lock Cylinder Replacement............ 7

Solenoid and Latch Assembly Replacement..... 6

Switch Replacement....................... 6

GENERAL

The door lock actuators, including liftgate, are con-

trolled by two-way switches. To lock the doors, push

down on either switch. To unlock doors from inside

the vehicle push upward on either switch.

The power door locks do not lock or unlock the

doors from outside the vehicle. Insert the key into

the lock cylinder to lock or unlock each individual

door.

DESCRIPTION

The door locks are operated by reversible motors

that receive voltage from fuse #13 in the fuse panel.

Voltage is applied to the driver's side door lock

switch and the passenger's side door lock switch

through the #9 fuse. With the driver's side door lock

switch in LOCK, voltage is applied through the

switch to the door lock relay coil. The relay coil is

energized which closes the circuit from the circuit

breaker to the lock motor. The motor is grounded by

the unlock relay.

The passenger's side door lock window switch oper-

ates the same as the driver's door switch. The volt-

age and ground paths are reversed to unlock the

doors.

The power door lock operates with battery power

and, therefore, is independent of the ignition switch.

DIAGNOSING POWER DOOR LOCKS

If vehicle has Keyless Entry and the door locks op-

erate properly using door switches but do not work

with transmitter, refer to Keyless Entry in this

group.

NO DOOR LOCKS OPERATE USING DOOR

LOCK SWITCHES

(1) Inspect fuse #13. Replace if necessary. If OK,

measure voltage at battery side of fuse. There should

be 12 volts. If not, repair open from Power Distribu-

tion Center.

(2) Remove door switch and measure voltage at

terminal 1. Meter should read battery voltage. If not,

repair open to #9 fuse.

(3) The power window relays are in the relay cen-

ter. The relay center is located on the lower instru-

ment panel trim cover just right of the steering

column (Fig. 1). Remove both relays.

(4) Measure resistance between lock and unlock re-

lay terminal 4 (87A) and ground. Meter should read

zero ohms. If not, repair open to ground.

(5) Measure voltage at terminal 5 (87) of both the

lock and unlock relays. Meter should read battery

voltage. If OK, next step. If not, repair open to cir-

cuit breaker.

(6) Measure resistance at terminal 2 (85) of both

the lock and unlock relays. Meter should read zero

ohms. If not, repair open to ground.

(7) Hold driver's side switch in LOCK position.

Measure voltage at lock relay terminal 1 (86). Meter

should read battery voltage. If OK, next step. If not,

repair open to driver's side switch.

(8) Hold driver's side switch in UNLOCK position.

Measure voltage at unlock relay terminal 1 (86).

Meter should read battery voltage. If OK, next step.

If not, repair open to driver's side switch.

JPOWER DOOR LOCKS 8P - 1

Page 463 of 1784

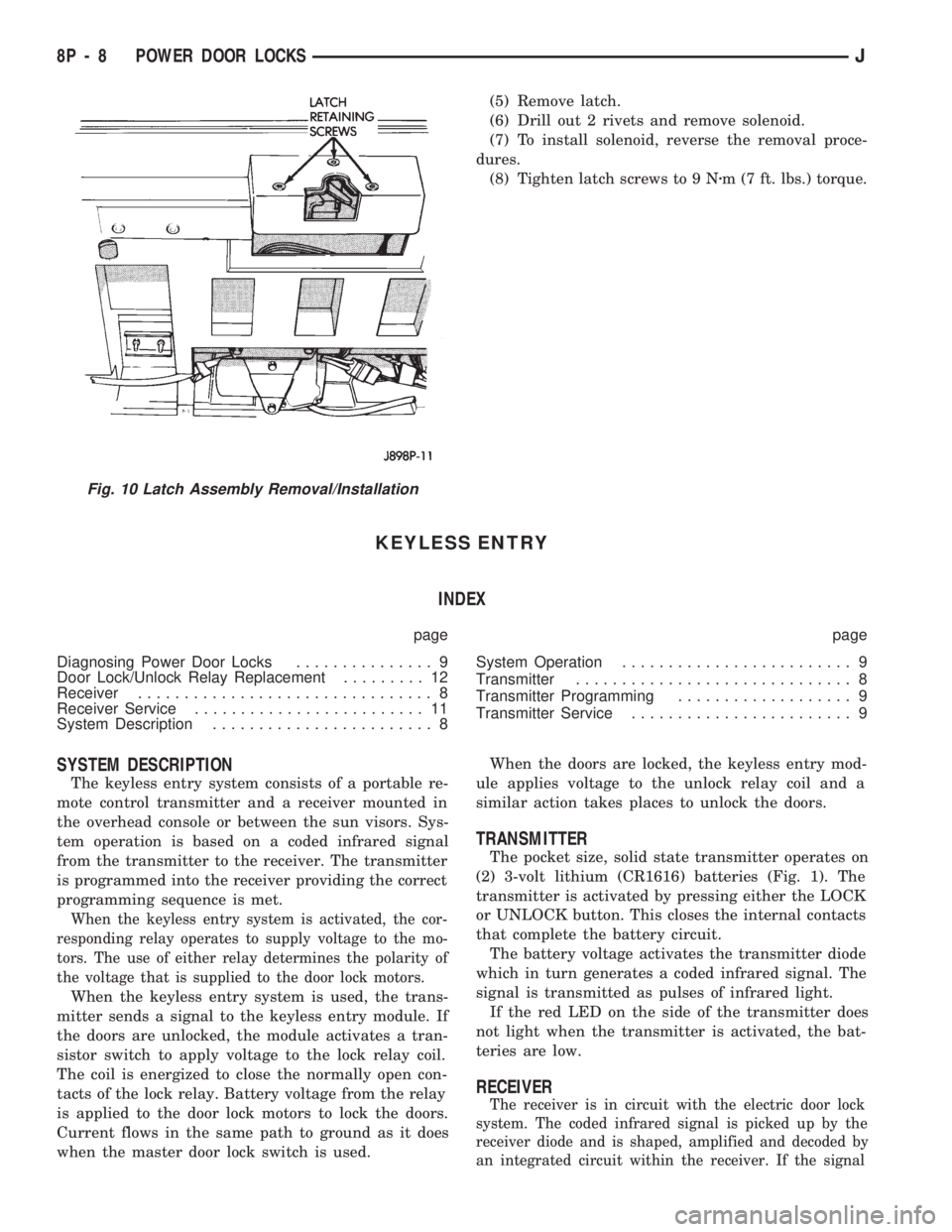

(5) Remove latch.

(6) Drill out 2 rivets and remove solenoid.

(7) To install solenoid, reverse the removal proce-

dures.

(8) Tighten latch screws to 9 Nzm (7 ft. lbs.) torque.

KEYLESS ENTRY

INDEX

page page

Diagnosing Power Door Locks............... 9

Door Lock/Unlock Relay Replacement......... 12

Receiver................................ 8

Receiver Service......................... 11

System Description........................ 8System Operation......................... 9

Transmitter.............................. 8

Transmitter Programming................... 9

Transmitter Service........................ 9

SYSTEM DESCRIPTION

The keyless entry system consists of a portable re-

mote control transmitter and a receiver mounted in

the overhead console or between the sun visors. Sys-

tem operation is based on a coded infrared signal

from the transmitter to the receiver. The transmitter

is programmed into the receiver providing the correct

programming sequence is met.

When the keyless entry system is activated, the cor-

responding relay operates to supply voltage to the mo-

tors. The use of either relay determines the polarity of

the voltage that is supplied to the door lock motors.

When the keyless entry system is used, the trans-

mitter sends a signal to the keyless entry module. If

the doors are unlocked, the module activates a tran-

sistor switch to apply voltage to the lock relay coil.

The coil is energized to close the normally open con-

tacts of the lock relay. Battery voltage from the relay

is applied to the door lock motors to lock the doors.

Current flows in the same path to ground as it does

when the master door lock switch is used.When the doors are locked, the keyless entry mod-

ule applies voltage to the unlock relay coil and a

similar action takes places to unlock the doors.

TRANSMITTER

The pocket size, solid state transmitter operates on

(2) 3-volt lithium (CR1616) batteries (Fig. 1). The

transmitter is activated by pressing either the LOCK

or UNLOCK button. This closes the internal contacts

that complete the battery circuit.

The battery voltage activates the transmitter diode

which in turn generates a coded infrared signal. The

signal is transmitted as pulses of infrared light.

If the red LED on the side of the transmitter does

not light when the transmitter is activated, the bat-

teries are low.

RECEIVER

The receiver is in circuit with the electric door lock

system. The coded infrared signal is picked up by the

receiver diode and is shaped, amplified and decoded by

an integrated circuit within the receiver. If the signal

Fig. 10 Latch Assembly Removal/Installation

8P - 8 POWER DOOR LOCKSJ