index JEEP CHEROKEE 1994 Service Owner's Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 1994, Model line: CHEROKEE, Model: JEEP CHEROKEE 1994Pages: 1784, PDF Size: 77.09 MB

Page 169 of 1784

POWER BRAKE BOOSTER

INDEX

page page

Power Brake Booster Installation............. 23

Power Brake Booster Operation............. 22Power Brake Booster Removal.............. 22

Service Information....................... 22

SERVICE INFORMATION

The power brake booster is not a serviceable com-

ponent. If a booster malfunction occurs, the booster

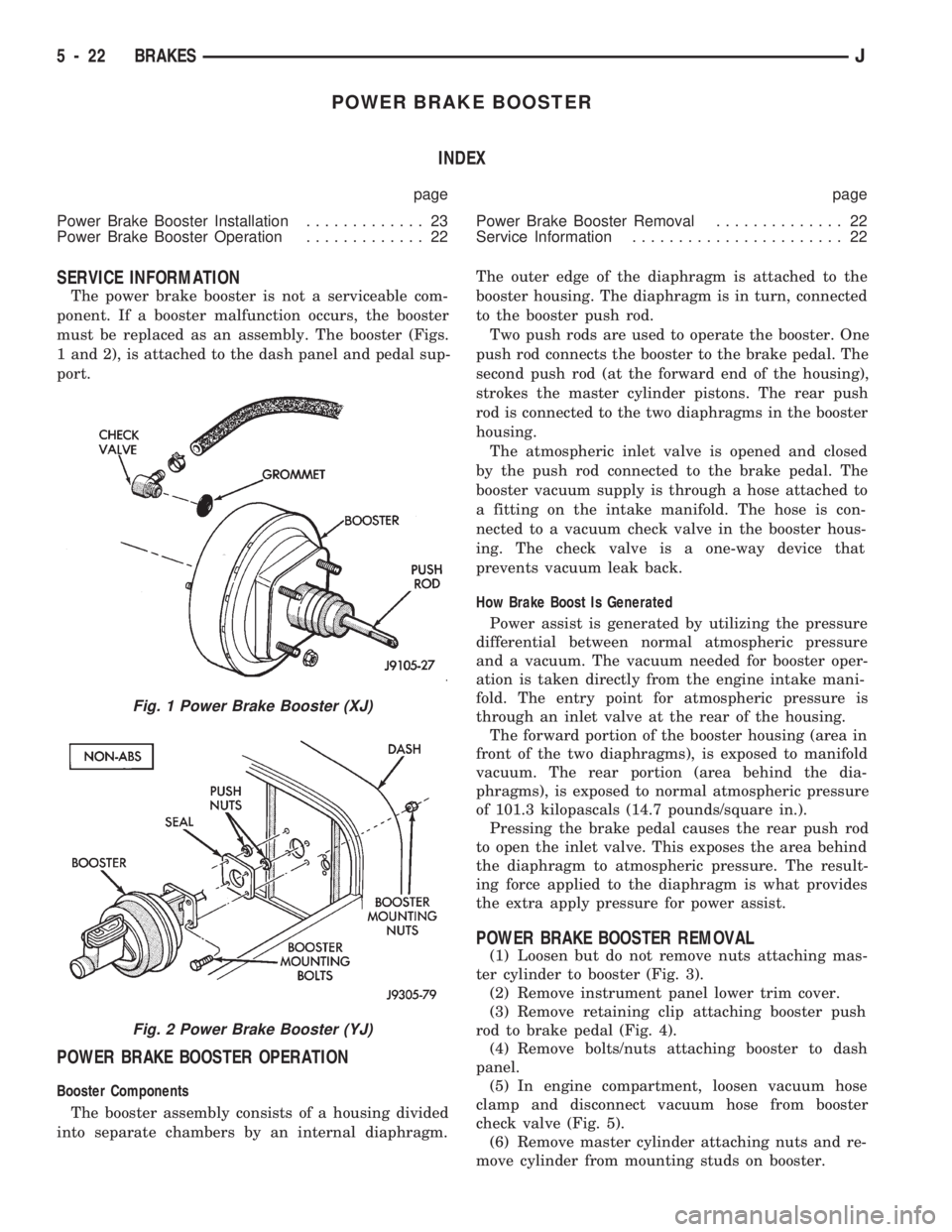

must be replaced as an assembly. The booster (Figs.

1 and 2), is attached to the dash panel and pedal sup-

port.

POWER BRAKE BOOSTER OPERATION

Booster Components

The booster assembly consists of a housing divided

into separate chambers by an internal diaphragm.The outer edge of the diaphragm is attached to the

booster housing. The diaphragm is in turn, connected

to the booster push rod.

Two push rods are used to operate the booster. One

push rod connects the booster to the brake pedal. The

second push rod (at the forward end of the housing),

strokes the master cylinder pistons. The rear push

rod is connected to the two diaphragms in the booster

housing.

The atmospheric inlet valve is opened and closed

by the push rod connected to the brake pedal. The

booster vacuum supply is through a hose attached to

a fitting on the intake manifold. The hose is con-

nected to a vacuum check valve in the booster hous-

ing. The check valve is a one-way device that

prevents vacuum leak back.

How Brake Boost Is Generated

Power assist is generated by utilizing the pressure

differential between normal atmospheric pressure

and a vacuum. The vacuum needed for booster oper-

ation is taken directly from the engine intake mani-

fold. The entry point for atmospheric pressure is

through an inlet valve at the rear of the housing.

The forward portion of the booster housing (area in

front of the two diaphragms), is exposed to manifold

vacuum. The rear portion (area behind the dia-

phragms), is exposed to normal atmospheric pressure

of 101.3 kilopascals (14.7 pounds/square in.).

Pressing the brake pedal causes the rear push rod

to open the inlet valve. This exposes the area behind

the diaphragm to atmospheric pressure. The result-

ing force applied to the diaphragm is what provides

the extra apply pressure for power assist.

POWER BRAKE BOOSTER REMOVAL

(1) Loosen but do not remove nuts attaching mas-

ter cylinder to booster (Fig. 3).

(2) Remove instrument panel lower trim cover.

(3) Remove retaining clip attaching booster push

rod to brake pedal (Fig. 4).

(4) Remove bolts/nuts attaching booster to dash

panel.

(5) In engine compartment, loosen vacuum hose

clamp and disconnect vacuum hose from booster

check valve (Fig. 5).

(6) Remove master cylinder attaching nuts and re-

move cylinder from mounting studs on booster.

Fig. 1 Power Brake Booster (XJ)

Fig. 2 Power Brake Booster (YJ)

5 - 22 BRAKESJ

Page 171 of 1784

DISC BRAKES

INDEX

page page

Caliper Assembly........................ 29

Caliper Cleaning and Inspection............. 28

Caliper Disassembly...................... 27

Caliper Installation........................ 30

Caliper Operation and Wear Compensation..... 24

Caliper Removal......................... 27

Disc Brake Rotor Refinishing................ 32

Disc Brake Rotor Runout................... 31Disc Brake Rotor Thickness................ 31

Disc Brake Rotor Thickness Variation......... 31

Disc Brakeshoe Installation................. 26

Disc Brakeshoe Removal.................. 25

General Information....................... 24

Rotor Installation......................... 30

Rotor Removal.......................... 30

Wheel Nut Tightening..................... 32

GENERAL INFORMATION

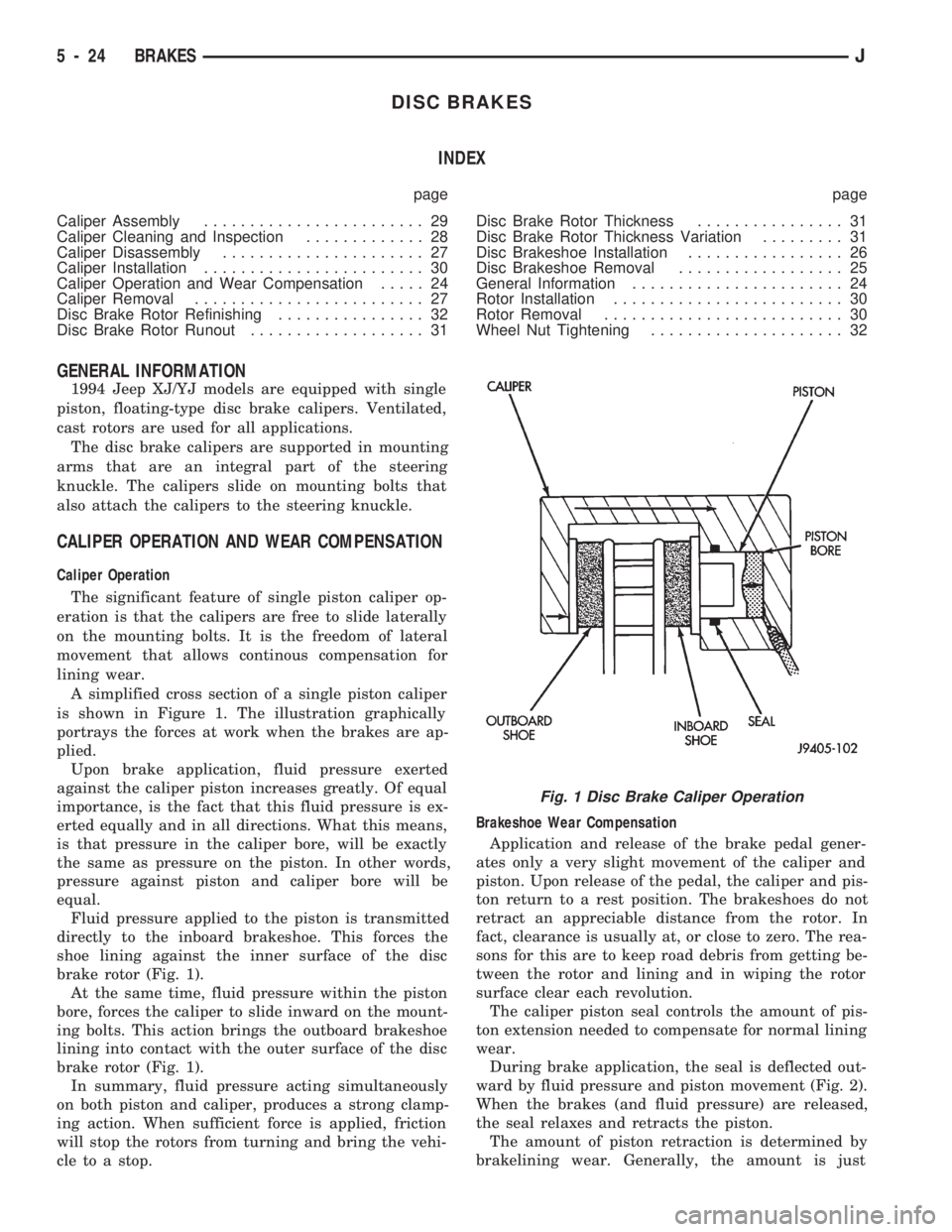

1994 Jeep XJ/YJ models are equipped with single

piston, floating-type disc brake calipers. Ventilated,

cast rotors are used for all applications.

The disc brake calipers are supported in mounting

arms that are an integral part of the steering

knuckle. The calipers slide on mounting bolts that

also attach the calipers to the steering knuckle.

CALIPER OPERATION AND WEAR COMPENSATION

Caliper Operation

The significant feature of single piston caliper op-

eration is that the calipers are free to slide laterally

on the mounting bolts. It is the freedom of lateral

movement that allows continous compensation for

lining wear.

A simplified cross section of a single piston caliper

is shown in Figure 1. The illustration graphically

portrays the forces at work when the brakes are ap-

plied.

Upon brake application, fluid pressure exerted

against the caliper piston increases greatly. Of equal

importance, is the fact that this fluid pressure is ex-

erted equally and in all directions. What this means,

is that pressure in the caliper bore, will be exactly

the same as pressure on the piston. In other words,

pressure against piston and caliper bore will be

equal.

Fluid pressure applied to the piston is transmitted

directly to the inboard brakeshoe. This forces the

shoe lining against the inner surface of the disc

brake rotor (Fig. 1).

At the same time, fluid pressure within the piston

bore, forces the caliper to slide inward on the mount-

ing bolts. This action brings the outboard brakeshoe

lining into contact with the outer surface of the disc

brake rotor (Fig. 1).

In summary, fluid pressure acting simultaneously

on both piston and caliper, produces a strong clamp-

ing action. When sufficient force is applied, friction

will stop the rotors from turning and bring the vehi-

cle to a stop.Brakeshoe Wear Compensation

Application and release of the brake pedal gener-

ates only a very slight movement of the caliper and

piston. Upon release of the pedal, the caliper and pis-

ton return to a rest position. The brakeshoes do not

retract an appreciable distance from the rotor. In

fact, clearance is usually at, or close to zero. The rea-

sons for this are to keep road debris from getting be-

tween the rotor and lining and in wiping the rotor

surface clear each revolution.

The caliper piston seal controls the amount of pis-

ton extension needed to compensate for normal lining

wear.

During brake application, the seal is deflected out-

ward by fluid pressure and piston movement (Fig. 2).

When the brakes (and fluid pressure) are released,

the seal relaxes and retracts the piston.

The amount of piston retraction is determined by

brakelining wear. Generally, the amount is just

Fig. 1 Disc Brake Caliper Operation

5 - 24 BRAKESJ

Page 181 of 1784

DRUM BRAKES

INDEX

page page

Brake Drum Refinishing.................... 37

Drum Brake Adjustment................... 35

Drum Brakeshoe Installation................ 34

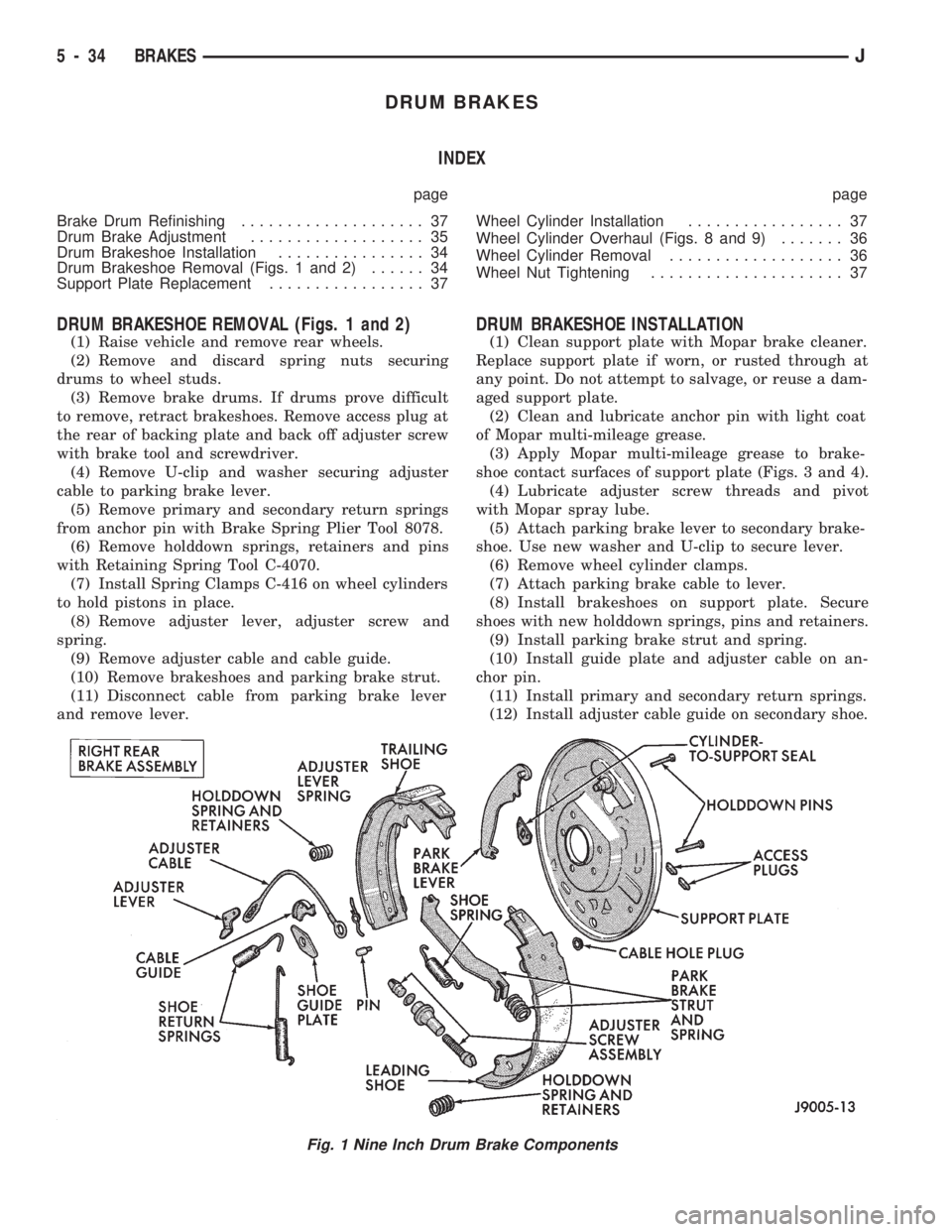

Drum Brakeshoe Removal (Figs. 1 and 2)...... 34

Support Plate Replacement................. 37Wheel Cylinder Installation................. 37

Wheel Cylinder Overhaul (Figs. 8 and 9)....... 36

Wheel Cylinder Removal................... 36

Wheel Nut Tightening..................... 37

DRUM BRAKESHOE REMOVAL (Figs. 1 and 2)

(1) Raise vehicle and remove rear wheels.

(2) Remove and discard spring nuts securing

drums to wheel studs.

(3) Remove brake drums. If drums prove difficult

to remove, retract brakeshoes. Remove access plug at

the rear of backing plate and back off adjuster screw

with brake tool and screwdriver.

(4) Remove U-clip and washer securing adjuster

cable to parking brake lever.

(5) Remove primary and secondary return springs

from anchor pin with Brake Spring Plier Tool 8078.

(6) Remove holddown springs, retainers and pins

with Retaining Spring Tool C-4070.

(7) Install Spring Clamps C-416 on wheel cylinders

to hold pistons in place.

(8) Remove adjuster lever, adjuster screw and

spring.

(9) Remove adjuster cable and cable guide.

(10) Remove brakeshoes and parking brake strut.

(11) Disconnect cable from parking brake lever

and remove lever.

DRUM BRAKESHOE INSTALLATION

(1) Clean support plate with Mopar brake cleaner.

Replace support plate if worn, or rusted through at

any point. Do not attempt to salvage, or reuse a dam-

aged support plate.

(2) Clean and lubricate anchor pin with light coat

of Mopar multi-mileage grease.

(3) Apply Mopar multi-mileage grease to brake-

shoe contact surfaces of support plate (Figs. 3 and 4).

(4) Lubricate adjuster screw threads and pivot

with Mopar spray lube.

(5) Attach parking brake lever to secondary brake-

shoe. Use new washer and U-clip to secure lever.

(6) Remove wheel cylinder clamps.

(7) Attach parking brake cable to lever.

(8) Install brakeshoes on support plate. Secure

shoes with new holddown springs, pins and retainers.

(9) Install parking brake strut and spring.

(10) Install guide plate and adjuster cable on an-

chor pin.

(11) Install primary and secondary return springs.

(12) Install adjuster cable guide on secondary shoe.

Fig. 1 Nine Inch Drum Brake Components

5 - 34 BRAKESJ

Page 186 of 1784

ABS SYSTEM OPERATION

INDEX

page page

Acceleration Switch....................... 41

Combination Valve....................... 42

Electronic Control Unit (ECU)............... 41

General Information....................... 39

Hydraulic Control Unit (HCU)................ 39

Ignition Switch........................... 42Master Cylinder.......................... 40

Pedal Travel Sensor...................... 41

Power Brake Booster..................... 40

System Relays.......................... 42

System Warning Lights.................... 42

Wheel Speed Sensors..................... 41

GENERAL INFORMATION

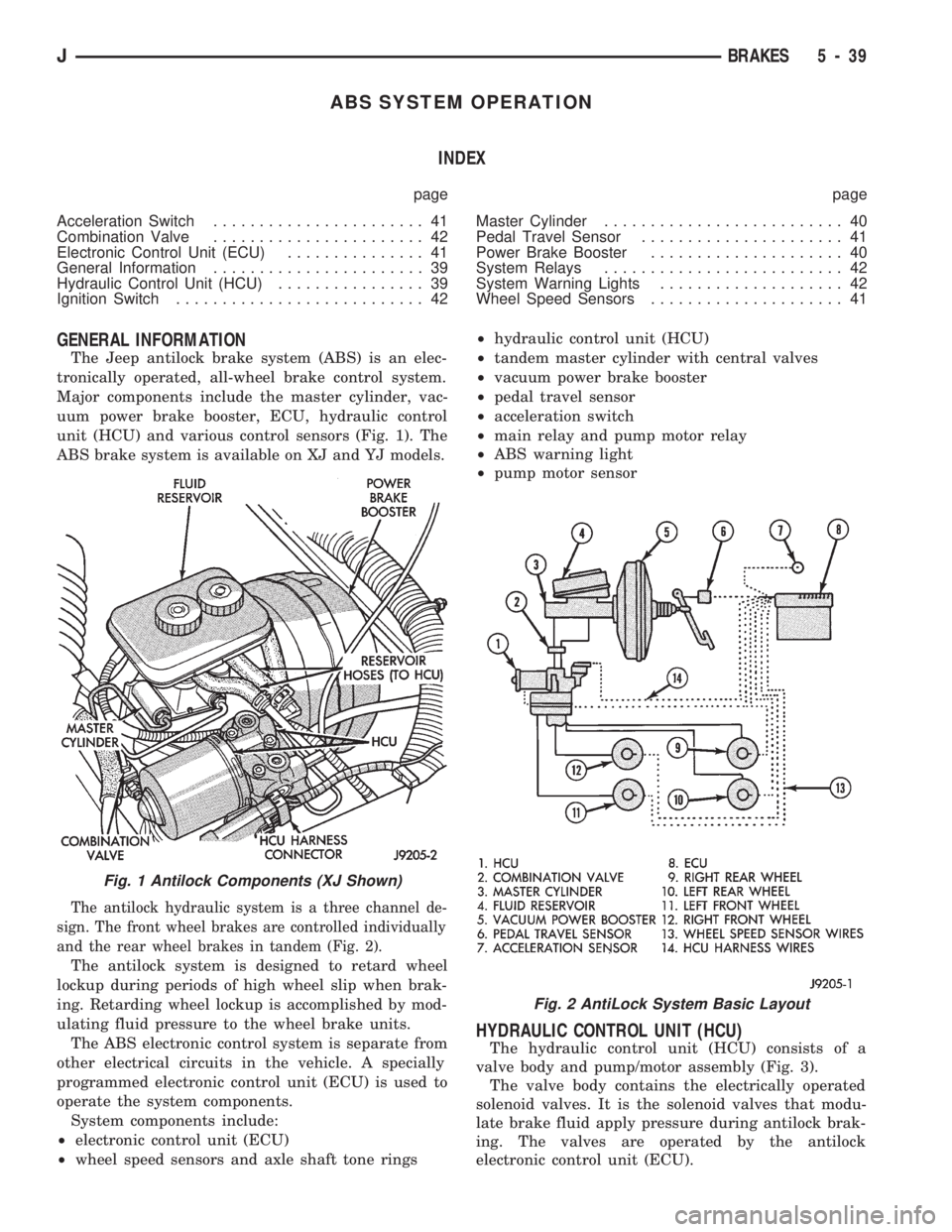

The Jeep antilock brake system (ABS) is an elec-

tronically operated, all-wheel brake control system.

Major components include the master cylinder, vac-

uum power brake booster, ECU, hydraulic control

unit (HCU) and various control sensors (Fig. 1). The

ABS brake system is available on XJ and YJ models.

The antilock hydraulic system is a three channel de-

sign. The front wheel brakes are controlled individually

and the rear wheel brakes in tandem (Fig. 2).

The antilock system is designed to retard wheel

lockup during periods of high wheel slip when brak-

ing. Retarding wheel lockup is accomplished by mod-

ulating fluid pressure to the wheel brake units.

The ABS electronic control system is separate from

other electrical circuits in the vehicle. A specially

programmed electronic control unit (ECU) is used to

operate the system components.

System components include:

²electronic control unit (ECU)

²wheel speed sensors and axle shaft tone rings²hydraulic control unit (HCU)

²tandem master cylinder with central valves

²vacuum power brake booster

²pedal travel sensor

²acceleration switch

²main relay and pump motor relay

²ABS warning light

²pump motor sensor

HYDRAULIC CONTROL UNIT (HCU)

The hydraulic control unit (HCU) consists of a

valve body and pump/motor assembly (Fig. 3).

The valve body contains the electrically operated

solenoid valves. It is the solenoid valves that modu-

late brake fluid apply pressure during antilock brak-

ing. The valves are operated by the antilock

electronic control unit (ECU).

Fig. 1 Antilock Components (XJ Shown)

Fig. 2 AntiLock System Basic Layout

JBRAKES 5 - 39

Page 190 of 1784

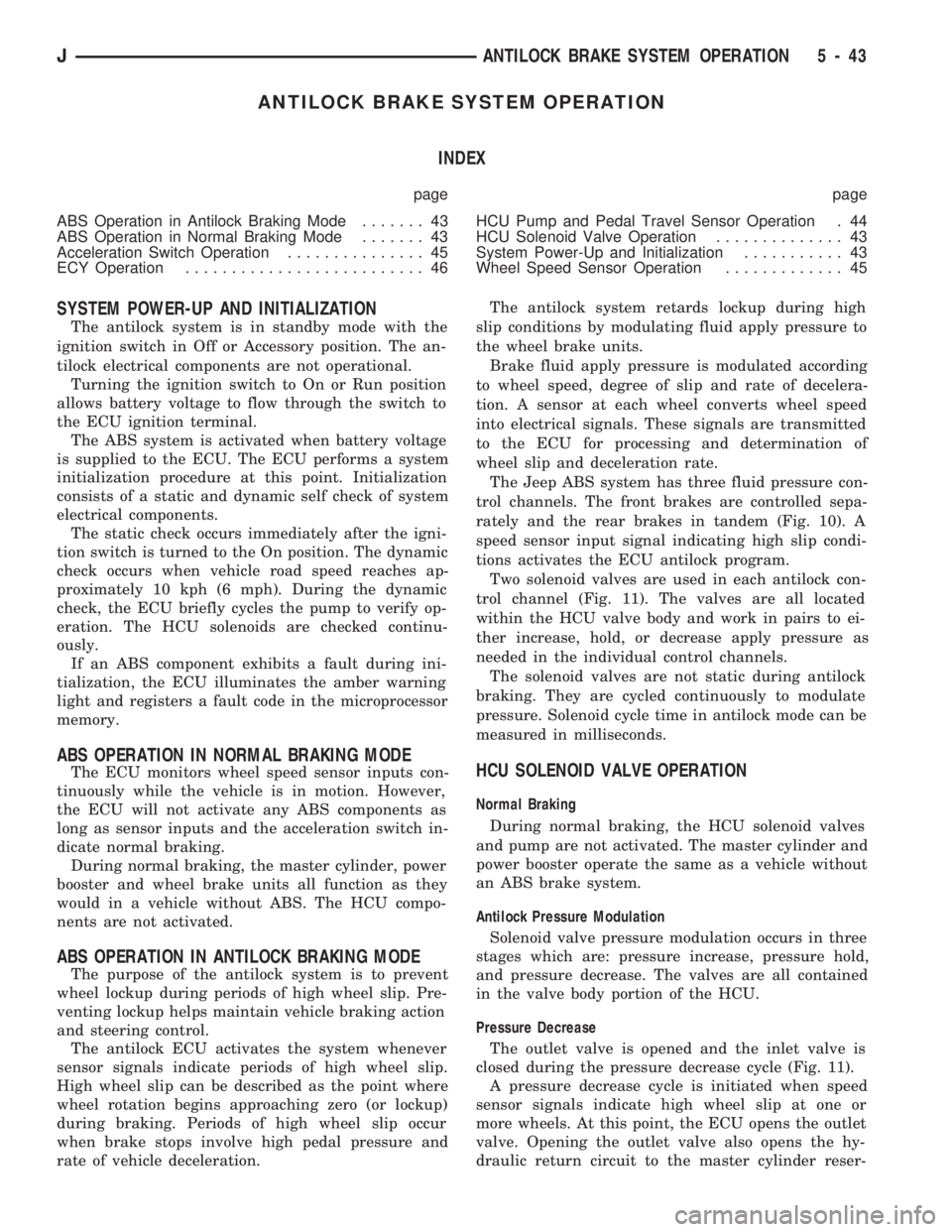

ANTILOCK BRAKE SYSTEM OPERATION

INDEX

page page

ABS Operation in Antilock Braking Mode....... 43

ABS Operation in Normal Braking Mode....... 43

Acceleration Switch Operation............... 45

ECY Operation.......................... 46HCU Pump and Pedal Travel Sensor Operation . 44

HCU Solenoid Valve Operation.............. 43

System Power-Up and Initialization........... 43

Wheel Speed Sensor Operation............. 45

SYSTEM POWER-UP AND INITIALIZATION

The antilock system is in standby mode with the

ignition switch in Off or Accessory position. The an-

tilock electrical components are not operational.

Turning the ignition switch to On or Run position

allows battery voltage to flow through the switch to

the ECU ignition terminal.

The ABS system is activated when battery voltage

is supplied to the ECU. The ECU performs a system

initialization procedure at this point. Initialization

consists of a static and dynamic self check of system

electrical components.

The static check occurs immediately after the igni-

tion switch is turned to the On position. The dynamic

check occurs when vehicle road speed reaches ap-

proximately 10 kph (6 mph). During the dynamic

check, the ECU briefly cycles the pump to verify op-

eration. The HCU solenoids are checked continu-

ously.

If an ABS component exhibits a fault during ini-

tialization, the ECU illuminates the amber warning

light and registers a fault code in the microprocessor

memory.

ABS OPERATION IN NORMAL BRAKING MODE

The ECU monitors wheel speed sensor inputs con-

tinuously while the vehicle is in motion. However,

the ECU will not activate any ABS components as

long as sensor inputs and the acceleration switch in-

dicate normal braking.

During normal braking, the master cylinder, power

booster and wheel brake units all function as they

would in a vehicle without ABS. The HCU compo-

nents are not activated.

ABS OPERATION IN ANTILOCK BRAKING MODE

The purpose of the antilock system is to prevent

wheel lockup during periods of high wheel slip. Pre-

venting lockup helps maintain vehicle braking action

and steering control.

The antilock ECU activates the system whenever

sensor signals indicate periods of high wheel slip.

High wheel slip can be described as the point where

wheel rotation begins approaching zero (or lockup)

during braking. Periods of high wheel slip occur

when brake stops involve high pedal pressure and

rate of vehicle deceleration.The antilock system retards lockup during high

slip conditions by modulating fluid apply pressure to

the wheel brake units.

Brake fluid apply pressure is modulated according

to wheel speed, degree of slip and rate of decelera-

tion. A sensor at each wheel converts wheel speed

into electrical signals. These signals are transmitted

to the ECU for processing and determination of

wheel slip and deceleration rate.

The Jeep ABS system has three fluid pressure con-

trol channels. The front brakes are controlled sepa-

rately and the rear brakes in tandem (Fig. 10). A

speed sensor input signal indicating high slip condi-

tions activates the ECU antilock program.

Two solenoid valves are used in each antilock con-

trol channel (Fig. 11). The valves are all located

within the HCU valve body and work in pairs to ei-

ther increase, hold, or decrease apply pressure as

needed in the individual control channels.

The solenoid valves are not static during antilock

braking. They are cycled continuously to modulate

pressure. Solenoid cycle time in antilock mode can be

measured in milliseconds.

HCU SOLENOID VALVE OPERATION

Normal Braking

During normal braking, the HCU solenoid valves

and pump are not activated. The master cylinder and

power booster operate the same as a vehicle without

an ABS brake system.

Antilock Pressure Modulation

Solenoid valve pressure modulation occurs in three

stages which are: pressure increase, pressure hold,

and pressure decrease. The valves are all contained

in the valve body portion of the HCU.

Pressure Decrease

The outlet valve is opened and the inlet valve is

closed during the pressure decrease cycle (Fig. 11).

A pressure decrease cycle is initiated when speed

sensor signals indicate high wheel slip at one or

more wheels. At this point, the ECU opens the outlet

valve. Opening the outlet valve also opens the hy-

draulic return circuit to the master cylinder reser-

JANTILOCK BRAKE SYSTEM OPERATION 5 - 43

Page 194 of 1784

ABS COMPONENT SERVICE

INDEX

page page

Acceleration Sensor Installation.............. 52

Acceleration Sensor Removal............... 52

Combination Valve ReplacementÐXJ......... 55

Combination Valve ReplacementÐYJ......... 55

Component Serviceability................... 47

Correct Fluid Level....................... 48

ECU ReplacementÐXJ.................... 53

ECU ReplacementÐYJ.................... 53

Front Wheel Sensor Installation.............. 49

Front Wheel Sensor Removal............... 49

HCU InstallationÐXJ...................... 54

HCU InstallationÐYJ...................... 54HCU RemovalÐXJ....................... 53

HCU RemovalÐYJ....................... 54

Importance of Clean Brake Fluid............. 48

Master Cylinder Installation................. 50

Master Cylinder Removal.................. 50

Pedal Travel Sensor Service................ 51

Power Brake Booster Installation............. 51

Power Brake Booster Removal.............. 51

Rear Wheel Sensor Installation.............. 50

Rear Wheel Sensor Removal............... 49

Recommended Brake Fluid................. 48

Wheel Sensor Air Gap Adjustment........... 49

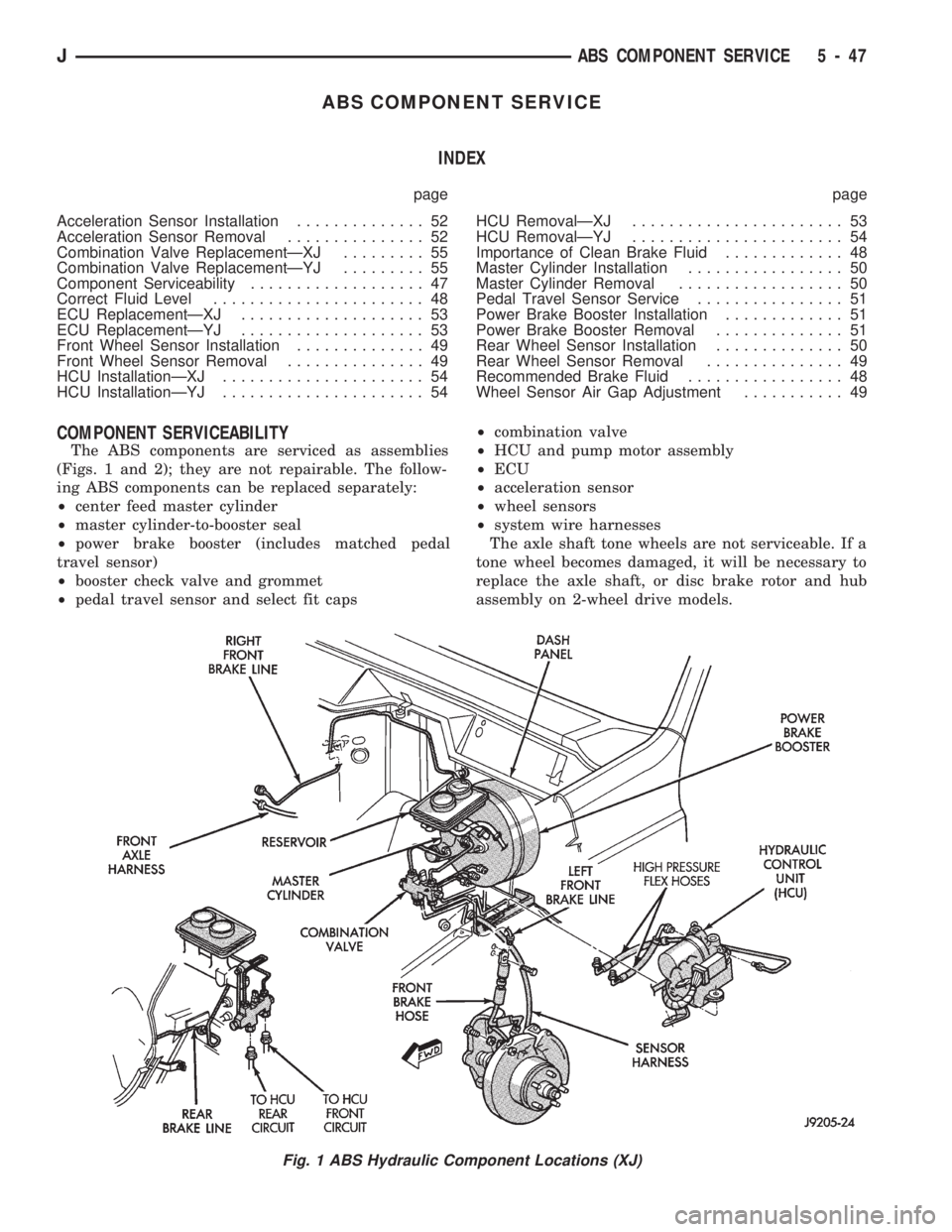

COMPONENT SERVICEABILITY

The ABS components are serviced as assemblies

(Figs. 1 and 2); they are not repairable. The follow-

ing ABS components can be replaced separately:

²center feed master cylinder

²master cylinder-to-booster seal

²power brake booster (includes matched pedal

travel sensor)

²booster check valve and grommet

²pedal travel sensor and select fit caps²combination valve

²HCU and pump motor assembly

²ECU

²acceleration sensor

²wheel sensors

²system wire harnesses

The axle shaft tone wheels are not serviceable. If a

tone wheel becomes damaged, it will be necessary to

replace the axle shaft, or disc brake rotor and hub

assembly on 2-wheel drive models.

Fig. 1 ABS Hydraulic Component Locations (XJ)

JABS COMPONENT SERVICE 5 - 47

Page 203 of 1784

PARKING BRAKES

INDEX

page page

General Service Information................ 56

Parking Brake Adjustment (XJ/YJ)............ 63

Parking Brake Cable Tensioner Replacement (XJ).61

Parking Brake Front Cable Replacement (YJ) . . . 62

Parking Brake Lever Installation

(XJ with Full Console)................... 60

Parking Brake Lever Installation

(XJ with Mini Console)................... 58

Parking Brake Lever Installation

(XJ Without Console).................... 60

Parking Brake Lever Removal

(XJ with Full Console).................... 59

Parking Brake Lever Removal

(XJ with Mini Console)................... 58

Parking Brake Lever Removal (XJ Without Console).60

Parking Brake Operation................... 56

Parking Brake Pedal Installation (YJ).......... 61

Parking Brake Pedal Removal (YJ)........... 61

Parking Brake Rear Cable Replacement (XJ) . . . 62

Parking Brake Rear Cable Replacement (YJ) . . . 63

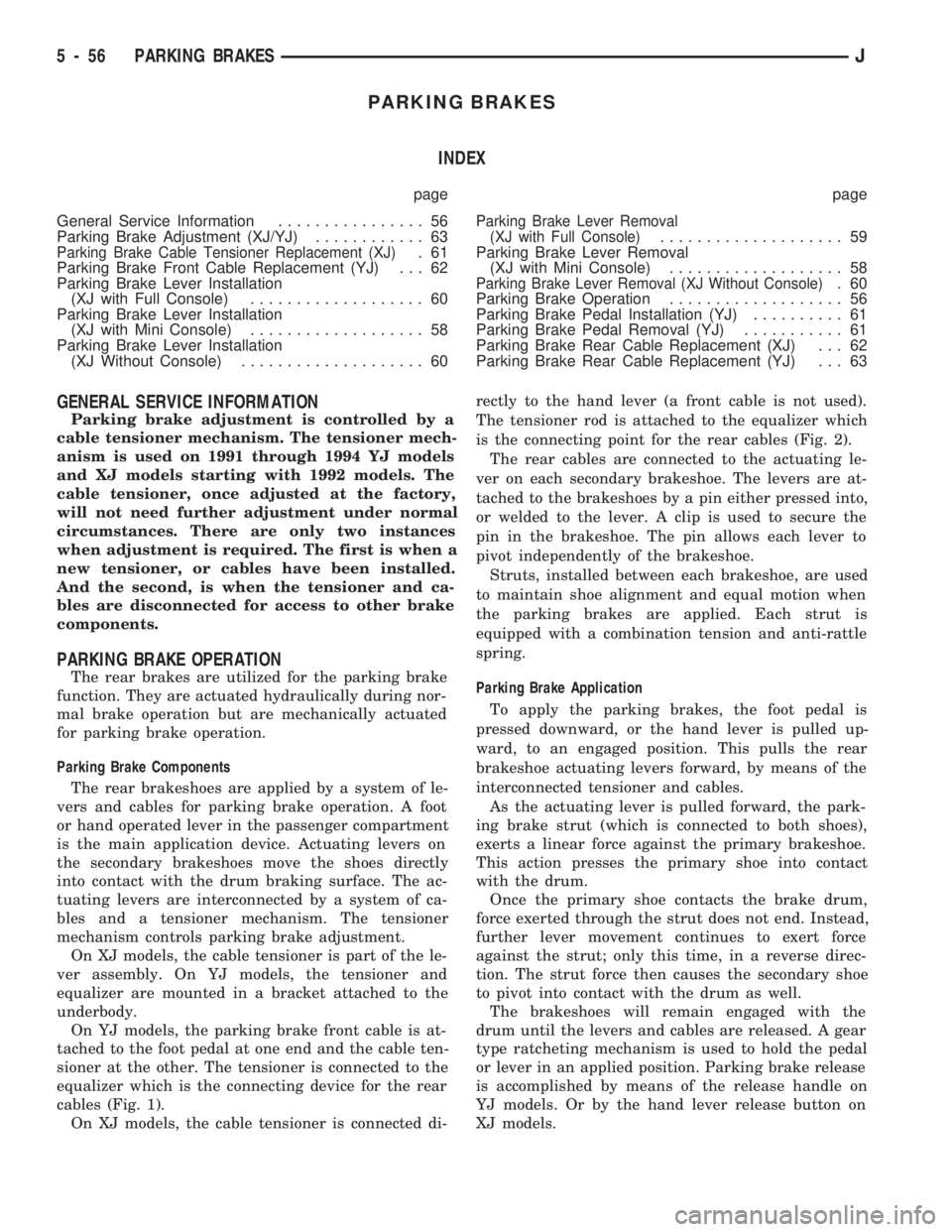

GENERAL SERVICE INFORMATION

Parking brake adjustment is controlled by a

cable tensioner mechanism. The tensioner mech-

anism is used on 1991 through 1994 YJ models

and XJ models starting with 1992 models. The

cable tensioner, once adjusted at the factory,

will not need further adjustment under normal

circumstances. There are only two instances

when adjustment is required. The first is when a

new tensioner, or cables have been installed.

And the second, is when the tensioner and ca-

bles are disconnected for access to other brake

components.

PARKING BRAKE OPERATION

The rear brakes are utilized for the parking brake

function. They are actuated hydraulically during nor-

mal brake operation but are mechanically actuated

for parking brake operation.

Parking Brake Components

The rear brakeshoes are applied by a system of le-

vers and cables for parking brake operation. A foot

or hand operated lever in the passenger compartment

is the main application device. Actuating levers on

the secondary brakeshoes move the shoes directly

into contact with the drum braking surface. The ac-

tuating levers are interconnected by a system of ca-

bles and a tensioner mechanism. The tensioner

mechanism controls parking brake adjustment.

On XJ models, the cable tensioner is part of the le-

ver assembly. On YJ models, the tensioner and

equalizer are mounted in a bracket attached to the

underbody.

On YJ models, the parking brake front cable is at-

tached to the foot pedal at one end and the cable ten-

sioner at the other. The tensioner is connected to the

equalizer which is the connecting device for the rear

cables (Fig. 1).

On XJ models, the cable tensioner is connected di-rectly to the hand lever (a front cable is not used).

The tensioner rod is attached to the equalizer which

is the connecting point for the rear cables (Fig. 2).

The rear cables are connected to the actuating le-

ver on each secondary brakeshoe. The levers are at-

tached to the brakeshoes by a pin either pressed into,

or welded to the lever. A clip is used to secure the

pin in the brakeshoe. The pin allows each lever to

pivot independently of the brakeshoe.

Struts, installed between each brakeshoe, are used

to maintain shoe alignment and equal motion when

the parking brakes are applied. Each strut is

equipped with a combination tension and anti-rattle

spring.

Parking Brake Application

To apply the parking brakes, the foot pedal is

pressed downward, or the hand lever is pulled up-

ward, to an engaged position. This pulls the rear

brakeshoe actuating levers forward, by means of the

interconnected tensioner and cables.

As the actuating lever is pulled forward, the park-

ing brake strut (which is connected to both shoes),

exerts a linear force against the primary brakeshoe.

This action presses the primary shoe into contact

with the drum.

Once the primary shoe contacts the brake drum,

force exerted through the strut does not end. Instead,

further lever movement continues to exert force

against the strut; only this time, in a reverse direc-

tion. The strut force then causes the secondary shoe

to pivot into contact with the drum as well.

The brakeshoes will remain engaged with the

drum until the levers and cables are released. A gear

type ratcheting mechanism is used to hold the pedal

or lever in an applied position. Parking brake release

is accomplished by means of the release handle on

YJ models. Or by the hand lever release button on

XJ models.

5 - 56 PARKING BRAKESJ

Page 212 of 1784

BRAKE PEDAL AND BRAKELIGHT SWITCH

INDEX

page page

Brake Pedal Installation.................... 66

Brake Pedal Removal..................... 65

Brake Pedal Service...................... 65

Brakelight Switch Adjustment................ 66Brakelight Switch Installation................ 66

Brakelight Switch Removal................. 66

General Information....................... 65

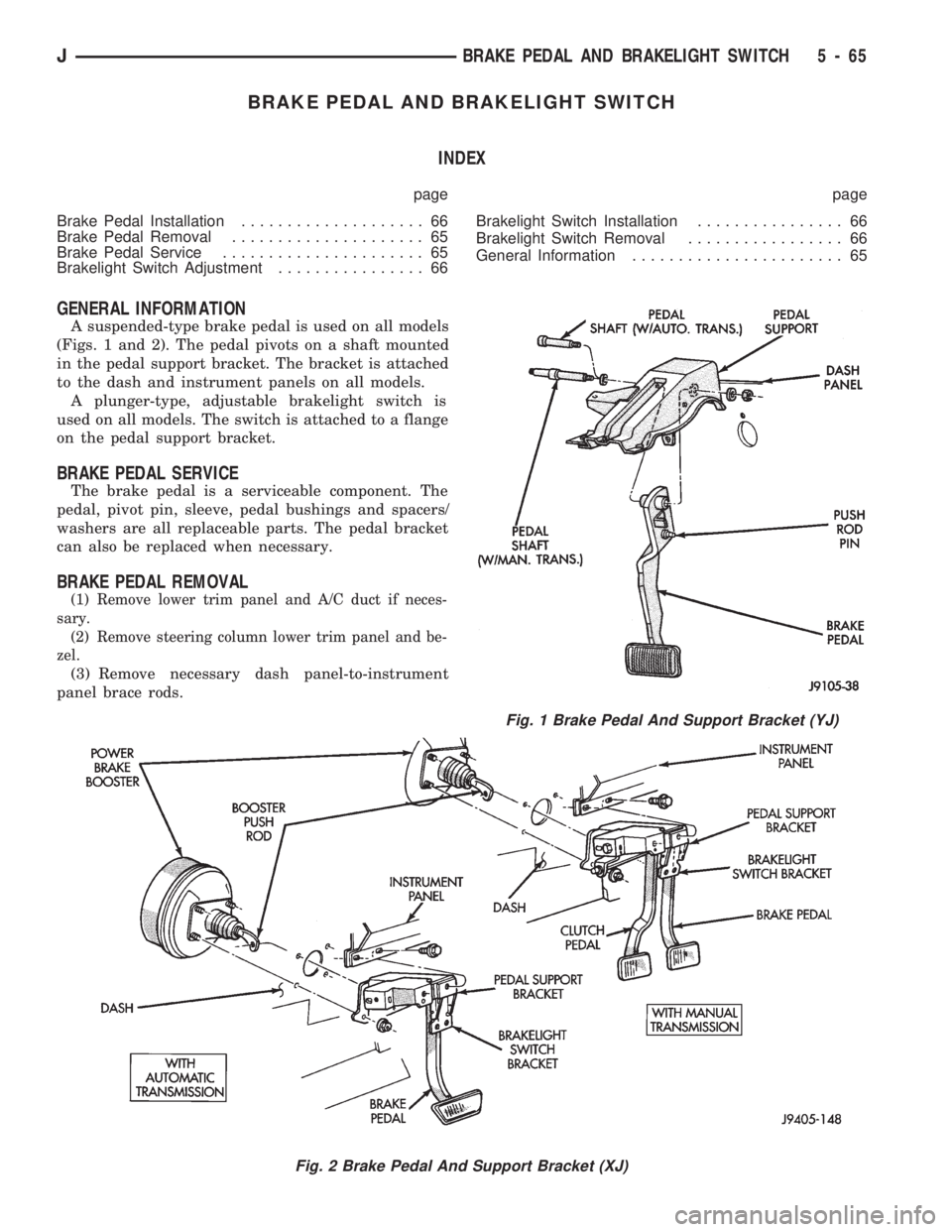

GENERAL INFORMATION

A suspended-type brake pedal is used on all models

(Figs. 1 and 2). The pedal pivots on a shaft mounted

in the pedal support bracket. The bracket is attached

to the dash and instrument panels on all models.

A plunger-type, adjustable brakelight switch is

used on all models. The switch is attached to a flange

on the pedal support bracket.

BRAKE PEDAL SERVICE

The brake pedal is a serviceable component. The

pedal, pivot pin, sleeve, pedal bushings and spacers/

washers are all replaceable parts. The pedal bracket

can also be replaced when necessary.

BRAKE PEDAL REMOVAL

(1) Remove lower trim panel and A/C duct if neces-

sary.

(2) Remove steering column lower trim panel and be-

zel.

(3) Remove necessary dash panel-to-instrument

panel brace rods.

Fig. 1 Brake Pedal And Support Bracket (YJ)

Fig. 2 Brake Pedal And Support Bracket (XJ)

JBRAKE PEDAL AND BRAKELIGHT SWITCH 5 - 65

Page 216 of 1784

CLUTCH

CONTENTS

page page

CLUTCH DIAGNOSIS..................... 3

CLUTCH SERVICE...................... 10GENERAL INFORMATION.................. 1

GENERAL INFORMATION

INDEX

page page

Clutch Component Lubrication................ 1

Clutch Components........................ 1Clutch Linkage Fluid....................... 1

Clutch Operation.......................... 2

CLUTCH COMPONENTS

MECHANICAL COMPONENTS

The clutch mechanism in XJ/YJ models with man-

ual transmission consists of a single, dry-type clutch

disc and a diaphragm style clutch cover. A hydraulic

linkage is used to operate the clutch disc and cover.

The transmission input shaft is supported in the

crankshaft by a bearing. A sleeve type release bear-

ing is used to engage and disengage the clutch cover

pressure plate.

The release bearing is operated by a release fork in

the clutch housing. The fork pivots on a ball stud

mounted inside the housing. The release fork is actu-

ated by a hydraulic slave cylinder mounted in the

housing. The slave cylinder is operated by a clutch

master cylinder mounted on the dash panel. The cyl-

inder push rod is connected to the clutch pedal.

The clutch disc has cushion springs in the disc hub.

The clutch disc facing is riveted to the hub. The fac-

ing is made from a non-asbestos material. The clutch

cover pressure plate is a diaphragm type with a one-

piece spring and multiple release fingers. The pres-

sure plate release fingers are preset during

manufacture and are not adjustable.

HYDRAULIC LINKAGE COMPONENTS

The hydraulic linkage consists of a clutch master

cylinder with integral reservoir, a clutch slave cylin-

der and an interconnecting fluid line.

The clutch master cylinder push rod is connected to

the clutch pedal. The slave cylinder push rod is con-

nected to the clutch release fork. The master cylinder

is mounted on the driver side of the dash panel ad-jacent to the brake master cylinder and booster as-

sembly. This positioning is similar for both left and

right hand drive models.

CLUTCH LINKAGE FLUID

The integral clutch master cylinder reservoir, slave

cylinder and fluid lines are prefilled with fluid prior

to assembly operations.

The hydraulic system should not require additional

fluid under normal circumstances. In fact,the reser-

voir fluid level will actually increase as normal

clutch wear occurs. For this reason, it is impor-

tant to avoid overfilling, or removing fluid from

the reservoir.

If inspection or diagnosis indicates additional fluid

may be needed, use Mopar brake fluid, or an equiv-

alent meeting standards SAE J1703 and DOT 3. Do

not use any other type of fluid.

CLUTCH COMPONENT LUBRICATION

Proper clutch component lubrication is important

to satisfactory operation. Using the correct lubricant

and not overlubricating are equally important. Apply

recommended lubricant sparingly to avoid disc and

pressure plate contamination.

Clutch and transmission components requiring lu-

brication are:

²pilot bearing

²release lever pivot ball stud

²release lever contact surfaces

²release bearing bore

²clutch disc hub splines

²clutch pedal pivot shaft bore

²clutch pedal bushings

²input shaft splines

JCLUTCH 6 - 1

Page 218 of 1784

CLUTCH DIAGNOSIS

INDEX

page page

Clutch Problem Causes..................... 3

General Diagnosis Information................ 3Inspection and Diagnosis Charts.............. 4

GENERAL DIAGNOSIS INFORMATION

Unless the cause of a clutch problem is obvious, ac-

curate problem diagnosis will usually require a road

test to confirm a problem. Component inspection will

then be required to determine the actual problem

cause.

During a road test, drive the vehicle at normal

speeds. Shift the transmission through all gear

ranges and observe clutch action. If chatter, grab,

slip, or improper release is experienced, remove and

inspect the clutch components. However, if the prob-

lem is noise or hard shifting, further diagnosis may

be needed as the transmission or another driveline

component may be at fault. Careful observation dur-

ing the test will help narrow the problem area.

CLUTCH PROBLEM CAUSES

CONTAMINATION

Fluid contamination is a frequent cause of clutch

malfunctions. Oil, water, or clutch fluid on the clutch

contact surfaces will cause faulty operation. The

usual result is chatter, slip and grab.

During inspection, note if any components are con-

taminated with oil, hydraulic fluid, or water/road

splash.

Oil contamination indicates a leak at either the

rear main seal or transmission input shaft. Oil leak-

age produces a residue of oil on the housing interior

and on the clutch cover and flywheel. Heat buildup

caused by slippage between the cover, disc and fly-

wheel, can sometimes bake the oil residue onto the

components. The glaze-like residue ranges in color

from amber to black.

Road splash contamination means dirt/water is en-

tering the clutch housing due to loose bolts, housing

cracks, or through hydraulic line openings. Driving

through deep water puddles can force water/road

splash into the housing through such openings.

Clutch fluid leaks are from loose or damaged slave

cylinder fluid lines and connecting fittings. However,

clutch fluid leaks will usually be noted and corrected

before severe contamination occurs.

CLUTCH MISALIGNMENT

Clutch components must be in proper alignment

with the crankshaft and transmission input shaft.Misalignment caused by excessive runout or warpage

of any clutch component will cause grab, chatter and

improper clutch release.

Flywheel Runout

Check flywheel runout whenever misalignment is

suspected. Flywheel runout should not exceed 0.08

mm (0.003 in.). Measure runout at the outer edge of

the flywheel face with a dial indicator. Mount the in-

dicator on a stud installed in place of one of the fly-

wheel bolts.

Common causes of runout are:

²heat warpage

²improper machining

²incorrect bolt tightening

²improper seating on crankshaft flange shoulder

²foreign material on crankshaft flange

Flywheel machining is not recommended. The fly-

wheel clutch surface is machined to a unique contour

and machining will negate this feature. However,

minor flywheel scoring can be cleaned up by hand

with 180 grit emery, or with surface grinding equip-

ment. Remove only enough material to reduce scor-

ing (approximately 0.001 - 0.003 in.). Heavy stock

removal isnot recommended.Replace the flywheel

if scoring is severe and deeper than 0.076 mm (0.003

in.). Excessive stock removal can result in flywheel

cracking or warpage after installation; it can also

weaken the flywheel and interfere with proper clutch

release.

Clean the crankshaft flange before mounting the

flywheel. Dirt and grease on the flange surface may

cock the flywheel causing excessive runout. Use new

bolts when remounting a flywheel and secure the

bolts with Mopar Lock And Seal. Tighten flywheel

bolts to specified torque only. Overtightening can dis-

tort the flywheel hub causing runout.

Clutch Cover And Disc Runout

Check the clutch disc before installation. Axial

(face) runout of anewdisc should not exceed 0.50

mm (0.020 in.). Measure runout about 6 mm (1/4 in.)

from the outer edge of the disc facing. Obtain an-

other disc if runout is excessive.

Check condition of the clutch before installation. A

warped cover or diaphragm spring will cause grab

and incomplete release or engagement. Be careful

JCLUTCH DIAGNOSIS 6 - 3