lock JEEP CHEROKEE 1994 Service Owner's Guide

[x] Cancel search | Manufacturer: JEEP, Model Year: 1994, Model line: CHEROKEE, Model: JEEP CHEROKEE 1994Pages: 1784, PDF Size: 77.09 MB

Page 155 of 1784

(2) If red warning light is illuminated, or if neither

warning light is illuminated, make several stops and

note pedal action and brake response.

(3) Check brake pedal response with transmission

in Neutral and engine running. Pedal should remain

firm under steady foot pressure. If pedal falls away,

problem is either in vacuum booster or master cylin-

der.

(4) During road test, make normal and firm brake

stops in 25-40 mph range. Note faulty brake opera-

tion such as pull, grab, drag, noise, fade, pedal pul-

sation, etc.

(5) Inspect suspect brake components and refer to

problem diagnosis information for causes of various

brake conditions.

COMPONENT INSPECTION

Fluid leak points and dragging brake units can

usually be located without removing any compo-

nents. The area around a leak point will be wet with

fluid. The components at a dragging brake unit

(wheel, tire, rotor) will be quite warm or hot to the

touch.

Other brake problem conditions will require compo-

nent removal for proper inspection. Raise the vehicle

and remove the necessary wheels for better visual ac-

cess.

During component inspection, pay particular atten-

tion to heavily rusted/corroded brake components

(e.g. rotors, caliper pistons, brake return/holddown

springs, support plates, etc.).

Heavy accumulations of rust may be covering se-

vere damage to a brake component. It is wise to re-

move surface rust in order to accurately determine

the depth of rust penetration and damage. Light sur-

face rust is fairly normal and not a major concern (as

long as it is removed). However, heavy rust buildup,

especially on high mileage vehicles may cover struc-

tural damage to such important components as

brakelines, rotors, support plates, and brake boosters.

Refer to the wheel brake service procedures in this

group for more information.

DIAGNOSING SERVICE BRAKE PROBLEMS

BRAKE WARNING LIGHT OPERATION

The red brake warning light will illuminate under

the following conditions:

²for 2-3 seconds at startup as part of normal bulb

check

²parking brakes applied

²low pedal caused by malfunction in front/rear

brake hydraulic circuit (differential switch valve ac-

tuated)

If the red light remains on after startup, first ver-

ify that the parking brakes are fully released. Then

check pedal action and fluid level. A red light indi-

cates that the valve in the differential pressureswitch has been actuated. If a problem is confirmed,

inspect the hydraulic system and wheel brake compo-

nents.

On models with ABS brakes, the amber warning

light only illuminates when an ABS component has

malfunctioned. The ABS light operates indepen-

dently of the red warning light. Refer to the antilock

brake section for more detailed diagnosis informa-

tion.

PEDAL FALLS AWAY

A brake pedal that falls away under steady foot

pressure is generally the result of a system leak. The

leak point could be at a brakeline, fitting, hose,

wheel cylinder, or caliper. Internal leakage in the

master cylinder caused by worn or damaged piston

cups, may also be the problem cause.

If leakage is severe, fluid will be evident at or

around the leaking component. However internal

leakage in the master cylinder will not be physically

evident. Refer to the cylinder test procedure in this

section.

LOW PEDAL

If a low pedal is experienced, pump the pedal sev-

eral times. If the pedal comes back up, worn lining

and worn rotors or drums are the most likely causes.

However, if the pedal remains low and/or the warn-

ing light illuminates, the problem is in the master

cylinder, wheel cylinders, or calipers.

A decrease in master cylinder fluid level may only

be the result of normal lining wear. Fluid level will

decrease as lining wear occurs. It is a result of the

outward movement of caliper and wheel cylinder pis-

tons to compensate for normal wear.

SPONGY PEDAL

A spongy pedal is most often caused by air in the

system. However, thin drums or substandard brake

lines and hoses will also cause a condition similar to

a spongy pedal. The proper course of action is to

bleed the system, or replace thin drums and suspect

quality brake lines and hoses.

HARD PEDAL OR HIGH PEDAL EFFORT

A hard pedal or high pedal effort may be due to

lining that is water soaked, contaminated, glazed, or

badly worn. The power booster or check valve could

also be faulty. Test the booster and valve as de-

scribed in this section.

BRAKE DRAG

Brake drag occurs when the lining is in constant

contact with the rotor or drum. Drag can occur at

one wheel, all wheels, fronts only, or rears only. It is

a product of incomplete brakeshoe release. Drag can

be minor or severe enough to overheat the linings,

rotors and drums.

5 - 8 BRAKESJ

Page 156 of 1784

Brake drag also has a direct effect on fuel economy.

If undetected, minor brake drag can be misdiagnosed

as an engine or transmission/torque converter prob-

lem.

Minor drag will usually cause slight surface char-

ring of the lining. It can also generate hard spots in

rotors and drums from the overheat/cool down pro-

cess. In most cases, the rotors, drums, wheels and

tires are quite warm to the touch after the vehicle is

stopped.

Severe drag can char the brake lining all the way

through. It can also distort and score rotors and

drums to the point of replacement. The wheels, tires

and brake components will be extremely hot. In se-

vere cases, the lining may generate smoke as it chars

from overheating.

An additional cause of drag involves the use of in-

correct length caliper mounting bolts. Bolts that are

too long can cause a partial apply condition. The cor-

rect caliper bolts have a shank length of 67 mm

(2.637 in.), plus or minus 0.6 mm (0.0236 in.). Refer

to the Disc Brake service section for more detail on

caliper bolt dimensions and identification.

Some common causes of brake drag are:

²loose or damaged wheel bearing

²seized or sticking caliper or wheel cylinder piston

²caliper binding on bushings or slide surfaces

²wrong length caliper mounting bolts (too long)

²loose caliper mounting bracket

²distorted brake drum or shoes

²rear brakeshoes binding on worn/damaged support

plates

²severely rusted/corroded components

²misassembled components.

If brake drag occurs at all wheels, the problem may

be related to a blocked master cylinder compensator

port or faulty power booster (binds-does not release).

The brakelight switch can also be a cause of drag.

An improperly mounted or adjusted brakelight

switch can prevent full brake pedal return. The re-

sult will be the same as if the master cylinder com-

pensator ports are blocked. The brakes would be

partially applied causing drag.

BRAKE FADE

Brake fade is a product of overheating caused by

brake drag. However, overheating and subsequent

fade can also be caused by riding the brake pedal,

making repeated high deceleration stops in a short

time span, or constant braking on steep roads. Refer

to the Brake Drag information in this section for

causes.

PEDAL PULSATION

Pedal pulsation is caused by components that are

loose, or beyond tolerance limits.

Disc brake rotors with excessive lateral runout or

thickness variation, or out of round brake drums arethe primary causes of pulsation. Other causes are

loose wheel bearings or calipers and worn, damaged

tires.

PULL

A front pull condition could be the result of:

²contaminated lining in one caliper

²seized caliper piston

²binding caliper

²wrong caliper mounting bolts (too long)

²loose caliper

²loose or corroded mounting bolts

²improper brakeshoes

²damaged rotor

²incorrect wheel bearing adjustment (at one wheel)

A worn, damaged wheel bearing or suspension

component are further causes of pull. A damaged

front tire (bruised, ply separation) can also cause

pull. Wrong caliper bolts (too long) will cause a par-

tial apply condition and pull if only one caliper is in-

volved.

A common and frequently misdiagnosed pull condi-

tion is where direction of pull changes after a few

stops. The cause is a combination of brake drag fol-

lowed by fade at the dragging brake unit.

As the dragging brake overheats, efficiency is so

reduced that fade occurs. If the opposite brake unit is

still functioning normally, its braking effect is mag-

nified. This causes pull to switch direction in favor of

the brake unit that is functioning normally.

When diagnosing a change in pull condition, re-

member that pull will return to the original direction

if the dragging brake unit is allowed to cool down

(and is not seriously damaged).

REAR BRAKE GRAB

Rear grab (or pull) is usually caused by contami-

nated lining, bent or binding shoes and support

plates, or improperly assembled components. This is

particularly true when only one rear wheel is in-

volved. However, when both rear wheels are affected,

the master cylinder or proportioning valve could be

at fault.

BRAKES DO NOT HOLD AFTER DRIVING

THROUGH DEEP WATER PUDDLES

This condition is generally caused by water soaked

lining. If the lining is only wet, it can be dried by

driving with the brakes lightly applied for a mile or

two. However, if the lining is both wet and dirty, dis-

assembly and cleaning will be necessary.

BRAKE FLUID CONTAMINATION

There are two basic causes of brake fluid contami-

nation. The first involves allowing dirt, debris, or

other liquid materials to enter the cylinder reservoirs

JBRAKES 5 - 9

Page 160 of 1784

BRAKE BLEEDINGÐBRAKE FLUID AND LEVELÐBRAKELINES AND HOSES

INDEX

page page

Brake BleedingÐXJ/YJ with ABS Brakes....... 14

Brake BleedingÐXJ/YJ with Standard Brakes . . . 13

Brake Fluid Contamination.................. 13

Brake Fluid Level........................ 13Brakeline Charts......................... 15

Brakelines and Hoses..................... 15

Combination Valve....................... 15

Recommended Brake Fluid................. 13

RECOMMENDED BRAKE FLUID

The only brake fluid recommended for Jeep vehi-

cles with standard or antilock brakes, is Mopar brake

fluid, or an equivalent fluid meeting SAE J1703 and

DOT 3 standards.

Use new brake fluid only to top off the master

cylinder or refill the system. Never use re-

claimed fluid, fluid not meeting the SAE/DOT

standards or fluid from an unsealed container.

Do not use fluid from any container that has

been left open for any length of time. Fluid in

open containers can absorb moisture.

BRAKE FLUID LEVEL

Always clean the master cylinder and cover before

checking fluid level. If not cleaned, dirt from the

cover could enter the fluid. Also check the cover seal

and replace it if torn or distorted.

Correct fluid level is to within 6 mm (1/4 in.) of the

reservoir rim, or to the fill mark on models with a

plastic reservoir. Refer to the Antilock Brake section

for fluid levels on models equipped with ABS brakes.

BRAKE FLUID CONTAMINATION

Oil in the fluid will cause brake system rubber

seals to soften and swell. The seals may also become

porous and begin to deteriorate.

If fluid contamination is suspected, drain off a sam-

ple from the master cylinder. A suction gun or simi-

lar device can be used for this purpose.

Empty the drained fluid into a glass container.

Contaminants in the fluid will cause the fluid to sep-

arate into distinct layers. If contamination has oc-

curred, the system rubber seals, hoses and cups must

be replaced and the system thoroughly flushed with

clean brake fluid.

BRAKE BLEEDINGÐXJ/YJ WITH STANDARD

BRAKES

Use Mopar DOT 3 brake fluid, or an equivalent

meeting SAE/DOT standards J1703-F and DOT 3, to

fill and bleed the system.

On standard brake models, bleeding can be per-

formed either manually or with pressure equipment.

However, if pressure equipment is used, it will be

necessary to hold the front brake metering valveopen in order to bleed the front brakes. The valve

can be held open with a tension clip tool or by hand.

It will also be necessary that a suitable size pressure

tank hose adapter be available for use on the master

cylinder.

MANUAL BLEEDING PROCEDURE

(1) If master cylinder has been overhauled or a

new cylinder will be installed, bleed cylinder on

bench before installation. This shortens time needed

to bleed system and ensures proper cylinder opera-

tion.

(2) Wipe master cylinder reservoir and cap clean

with shop towels.

(3) Remove cover and fill master cylinder reservoir

with Mopar, or equivalent DOT 3 brake fluid.

(4) Open all caliper and wheel cylinder bleed

screws.

(5) Close bleed screws after fluid begins flowing

from each bleed screw.

(6) Top off master cylinder reservoir again.

(7) Use following bleed sequence:

²master cylinder

²right rear

²left rear

²right front

²left front

(8) Observe following brake bleeding precautions:

²Do not pump brake pedal at any time while bleed-

ing. Air in system will be compressed into small bub-

bles that are distributed throughout hydraulic

system. This will make a second and third bleeding

operation necessary.

²Bleed only one wheel brake unit at a time and use

a bleed hose to bleed each wheel brake unit (Fig. 7).

²Attach one end of bleed hose to bleed screw and in-

sert opposite end in glass container partially filled

with brake fluid (Fig. 7). Glass container makes it

easier to see air bubbles as they exit the bleed hose.

²Be sure end of bleed hose is immersed in fluid. Im-

mersing hose end in fluid prevents air from being

drawn back into cylinder and brakeline.

(9) Bleed master cylinder first. Have helper oper-

ate brake pedal while bleeding each master cylinder

fluid outlet line.

JBRAKES 5 - 13

Page 167 of 1784

STANDARD MASTER CYLINDER

INDEX

page page

General Service Information................ 20

Master Cylinder Installation................. 20Master Cylinder Overhaul.................. 20

Master Cylinder Removal.................. 20

GENERAL SERVICE INFORMATION

The service information in this section covers the

standard (non-ABS) master cylinder only. The center

feed master cylinder used with the ABS system is

covered in the antilock brake component service sec-

tion.

MASTER CYLINDER REMOVAL

(1) Disconnect brake lines at master cylinder.

(2) Remove cylinder mounting nuts and remove

master cylinder.

(3) Remove cylinder cover and drain fluid.

MASTER CYLINDER INSTALLATION

(1) Bleed master cylinder on bench before installa-

tion. Refer to overhaul assembly procedure in this

section for bleeding method.

(2) Install cylinder on brake booster studs and in-

stall cylinder attaching nuts. Tighten nuts to 21 NIm

(15 ft. lbs.).

(3) Connect brakelines to cylinder.

(4) Fill and bleed brake system.

MASTER CYLINDER OVERHAUL

CYLINDER DISASSEMBLY

(1) Remove cylinder cover and drain fluid.

(2) Examine cylinder cover seal. Discard seal if

torn or distorted.

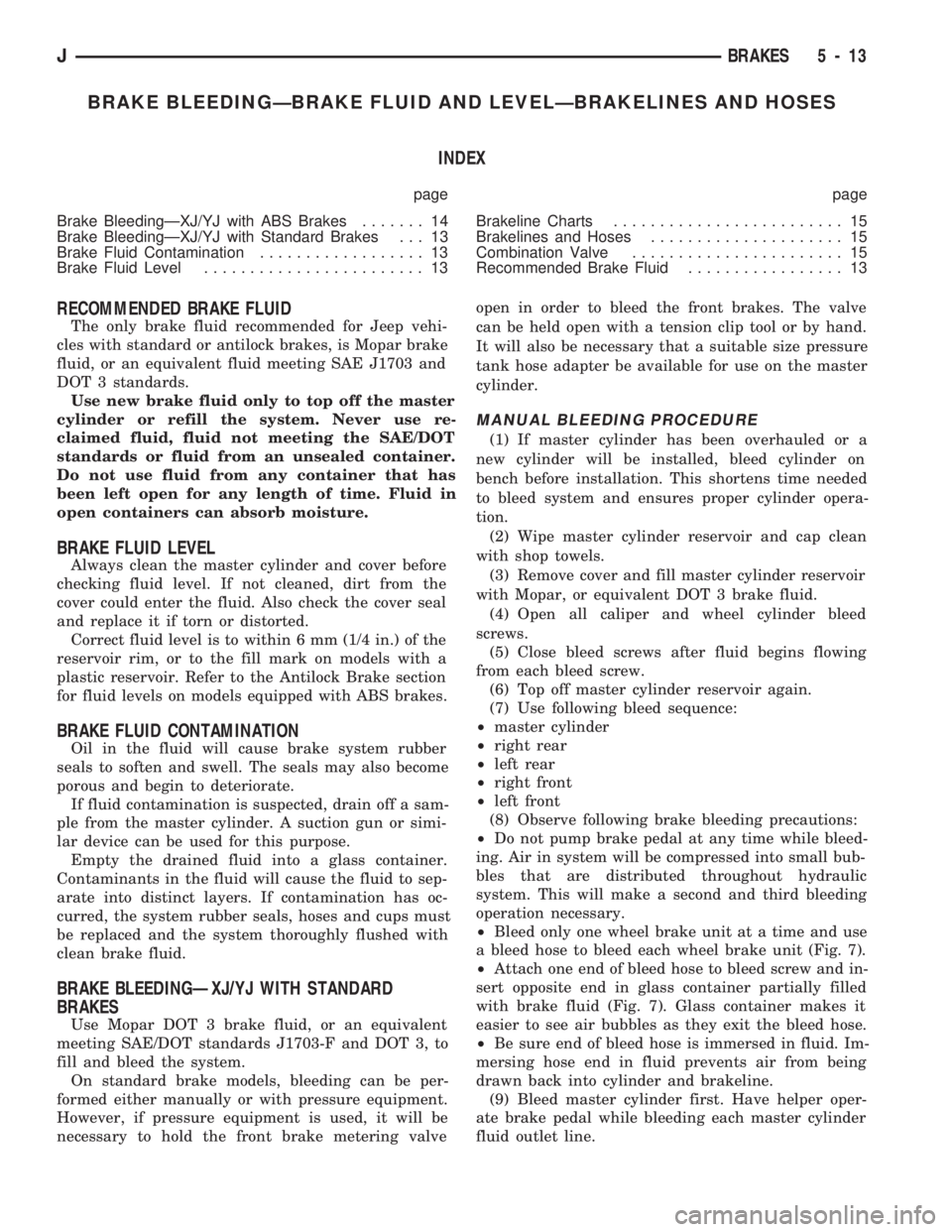

(3) Clamp cylinder in vise (Fig. 1).

(4) Press primary piston inward with wood dowel

or phillips screwdriver and remove snap ring (Fig. 2).

(5) Remove and discard primary piston (Fig. 3).

Piston is serviced only as an assembly.

(6) Remove secondary piston (Fig. 4). Apply air

pressure through rear outlet port to ease piston out

of bore. Cover small ports at bottom of rear reservoir

with towel to prevent air leakage.

(7) Discard secondary piston. Do not disassemble

piston as components are only serviced as assembly.

CLEANING AND INSPECTION

Clean the cylinder with Mopar brake cleaning sol-

vent or clean brake fluid. Remove cleaning residue

with compressed air.

Inspect the cylinder bore. A light discoloration of

the bore surface is normal and acceptable but only if

the surface is in good condition.Replace the cylinder if the bore is scored, corroded,

or pitted.Do not hone the cylinder bore in an at-

tempt to restore the surface. Replace the cylin-

der if the bore is corroded or if doubt exists

about cylinder bore condition.

Fig. 1 Cylinder Mounted In Vise

Fig. 2 Removing/Installing Piston Snap Ring

5 - 20 BRAKESJ

Page 170 of 1784

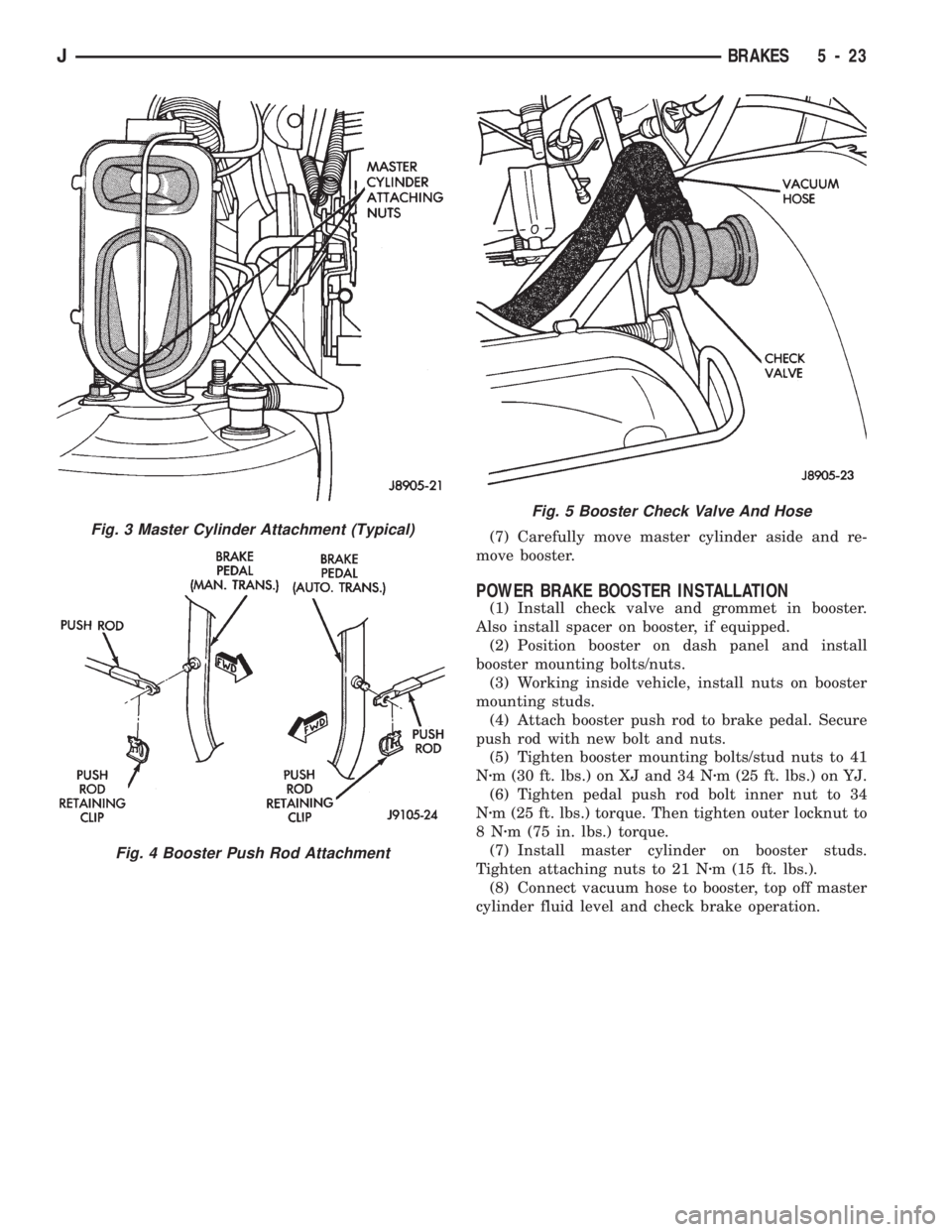

(7) Carefully move master cylinder aside and re-

move booster.

POWER BRAKE BOOSTER INSTALLATION

(1) Install check valve and grommet in booster.

Also install spacer on booster, if equipped.

(2) Position booster on dash panel and install

booster mounting bolts/nuts.

(3) Working inside vehicle, install nuts on booster

mounting studs.

(4) Attach booster push rod to brake pedal. Secure

push rod with new bolt and nuts.

(5) Tighten booster mounting bolts/stud nuts to 41

Nzm (30 ft. lbs.) on XJ and 34 Nzm (25 ft. lbs.) on YJ.

(6) Tighten pedal push rod bolt inner nut to 34

Nzm (25 ft. lbs.) torque. Then tighten outer locknut to

8Nzm (75 in. lbs.) torque.

(7) Install master cylinder on booster studs.

Tighten attaching nuts to 21 Nzm (15 ft. lbs.).

(8) Connect vacuum hose to booster, top off master

cylinder fluid level and check brake operation.

Fig. 3 Master Cylinder Attachment (Typical)

Fig. 4 Booster Push Rod Attachment

Fig. 5 Booster Check Valve And Hose

JBRAKES 5 - 23

Page 183 of 1784

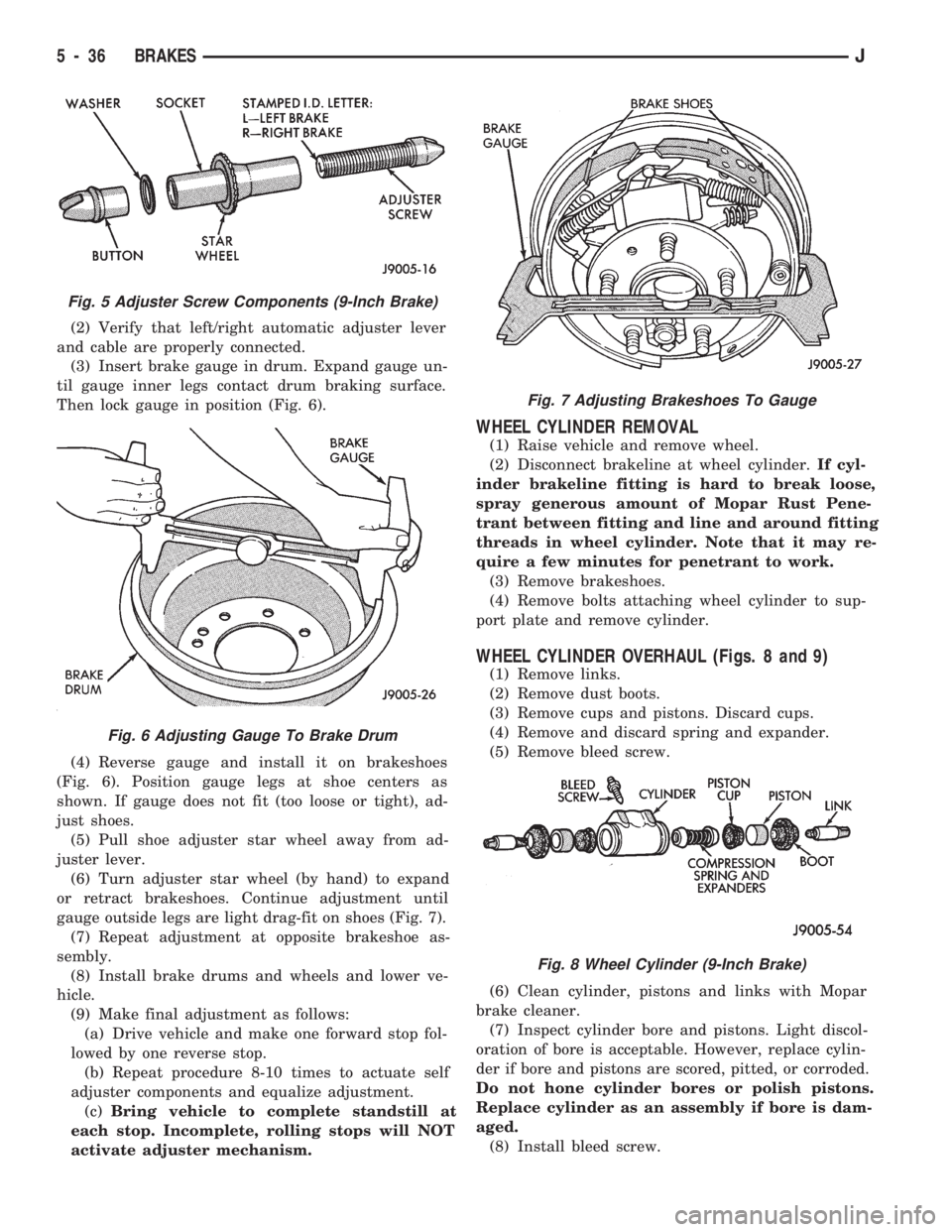

(2) Verify that left/right automatic adjuster lever

and cable are properly connected.

(3) Insert brake gauge in drum. Expand gauge un-

til gauge inner legs contact drum braking surface.

Then lock gauge in position (Fig. 6).

(4) Reverse gauge and install it on brakeshoes

(Fig. 6). Position gauge legs at shoe centers as

shown. If gauge does not fit (too loose or tight), ad-

just shoes.

(5) Pull shoe adjuster star wheel away from ad-

juster lever.

(6) Turn adjuster star wheel (by hand) to expand

or retract brakeshoes. Continue adjustment until

gauge outside legs are light drag-fit on shoes (Fig. 7).

(7) Repeat adjustment at opposite brakeshoe as-

sembly.

(8) Install brake drums and wheels and lower ve-

hicle.

(9) Make final adjustment as follows:

(a) Drive vehicle and make one forward stop fol-

lowed by one reverse stop.

(b) Repeat procedure 8-10 times to actuate self

adjuster components and equalize adjustment.

(c)Bring vehicle to complete standstill at

each stop. Incomplete, rolling stops will NOT

activate adjuster mechanism.

WHEEL CYLINDER REMOVAL

(1) Raise vehicle and remove wheel.

(2) Disconnect brakeline at wheel cylinder.If cyl-

inder brakeline fitting is hard to break loose,

spray generous amount of Mopar Rust Pene-

trant between fitting and line and around fitting

threads in wheel cylinder. Note that it may re-

quire a few minutes for penetrant to work.

(3) Remove brakeshoes.

(4) Remove bolts attaching wheel cylinder to sup-

port plate and remove cylinder.

WHEEL CYLINDER OVERHAUL (Figs. 8 and 9)

(1) Remove links.

(2) Remove dust boots.

(3) Remove cups and pistons. Discard cups.

(4) Remove and discard spring and expander.

(5) Remove bleed screw.

(6) Clean cylinder, pistons and links with Mopar

brake cleaner.

(7) Inspect cylinder bore and pistons. Light discol-

oration of bore is acceptable. However, replace cylin-

der if bore and pistons are scored, pitted, or corroded.

Do not hone cylinder bores or polish pistons.

Replace cylinder as an assembly if bore is dam-

aged.

(8) Install bleed screw.

Fig. 5 Adjuster Screw Components (9-Inch Brake)

Fig. 6 Adjusting Gauge To Brake Drum

Fig. 7 Adjusting Brakeshoes To Gauge

Fig. 8 Wheel Cylinder (9-Inch Brake)

5 - 36 BRAKESJ

Page 184 of 1784

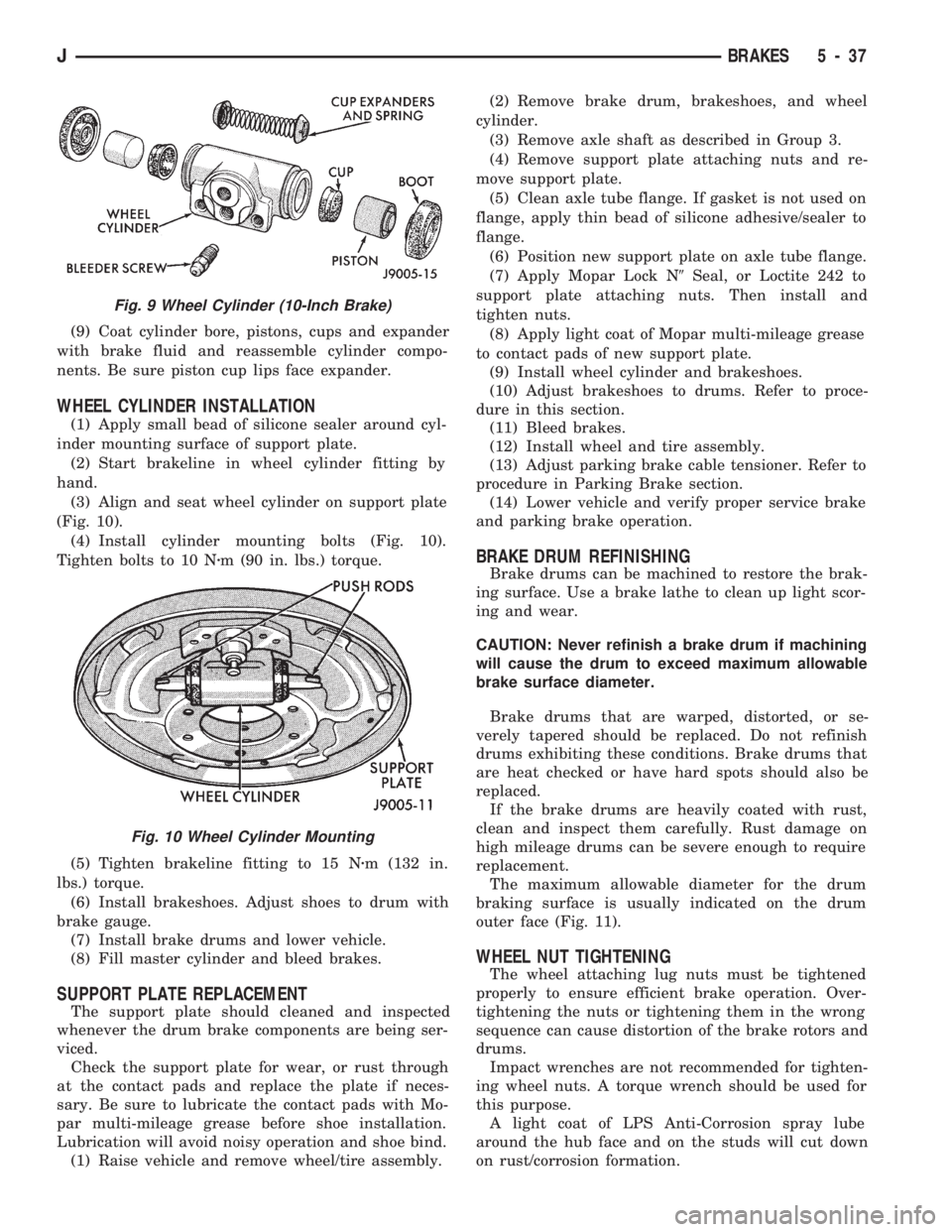

(9) Coat cylinder bore, pistons, cups and expander

with brake fluid and reassemble cylinder compo-

nents. Be sure piston cup lips face expander.

WHEEL CYLINDER INSTALLATION

(1) Apply small bead of silicone sealer around cyl-

inder mounting surface of support plate.

(2) Start brakeline in wheel cylinder fitting by

hand.

(3) Align and seat wheel cylinder on support plate

(Fig. 10).

(4) Install cylinder mounting bolts (Fig. 10).

Tighten bolts to 10 Nzm (90 in. lbs.) torque.

(5) Tighten brakeline fitting to 15 Nzm (132 in.

lbs.) torque.

(6) Install brakeshoes. Adjust shoes to drum with

brake gauge.

(7) Install brake drums and lower vehicle.

(8) Fill master cylinder and bleed brakes.

SUPPORT PLATE REPLACEMENT

The support plate should cleaned and inspected

whenever the drum brake components are being ser-

viced.

Check the support plate for wear, or rust through

at the contact pads and replace the plate if neces-

sary. Be sure to lubricate the contact pads with Mo-

par multi-mileage grease before shoe installation.

Lubrication will avoid noisy operation and shoe bind.

(1) Raise vehicle and remove wheel/tire assembly.(2) Remove brake drum, brakeshoes, and wheel

cylinder.

(3) Remove axle shaft as described in Group 3.

(4) Remove support plate attaching nuts and re-

move support plate.

(5) Clean axle tube flange. If gasket is not used on

flange, apply thin bead of silicone adhesive/sealer to

flange.

(6) Position new support plate on axle tube flange.

(7) Apply Mopar Lock N9Seal, or Loctite 242 to

support plate attaching nuts. Then install and

tighten nuts.

(8) Apply light coat of Mopar multi-mileage grease

to contact pads of new support plate.

(9) Install wheel cylinder and brakeshoes.

(10) Adjust brakeshoes to drums. Refer to proce-

dure in this section.

(11) Bleed brakes.

(12) Install wheel and tire assembly.

(13) Adjust parking brake cable tensioner. Refer to

procedure in Parking Brake section.

(14) Lower vehicle and verify proper service brake

and parking brake operation.

BRAKE DRUM REFINISHING

Brake drums can be machined to restore the brak-

ing surface. Use a brake lathe to clean up light scor-

ing and wear.

CAUTION: Never refinish a brake drum if machining

will cause the drum to exceed maximum allowable

brake surface diameter.

Brake drums that are warped, distorted, or se-

verely tapered should be replaced. Do not refinish

drums exhibiting these conditions. Brake drums that

are heat checked or have hard spots should also be

replaced.

If the brake drums are heavily coated with rust,

clean and inspect them carefully. Rust damage on

high mileage drums can be severe enough to require

replacement.

The maximum allowable diameter for the drum

braking surface is usually indicated on the drum

outer face (Fig. 11).

WHEEL NUT TIGHTENING

The wheel attaching lug nuts must be tightened

properly to ensure efficient brake operation. Over-

tightening the nuts or tightening them in the wrong

sequence can cause distortion of the brake rotors and

drums.

Impact wrenches are not recommended for tighten-

ing wheel nuts. A torque wrench should be used for

this purpose.

A light coat of LPS Anti-Corrosion spray lube

around the hub face and on the studs will cut down

on rust/corrosion formation.

Fig. 9 Wheel Cylinder (10-Inch Brake)

Fig. 10 Wheel Cylinder Mounting

JBRAKES 5 - 37

Page 186 of 1784

ABS SYSTEM OPERATION

INDEX

page page

Acceleration Switch....................... 41

Combination Valve....................... 42

Electronic Control Unit (ECU)............... 41

General Information....................... 39

Hydraulic Control Unit (HCU)................ 39

Ignition Switch........................... 42Master Cylinder.......................... 40

Pedal Travel Sensor...................... 41

Power Brake Booster..................... 40

System Relays.......................... 42

System Warning Lights.................... 42

Wheel Speed Sensors..................... 41

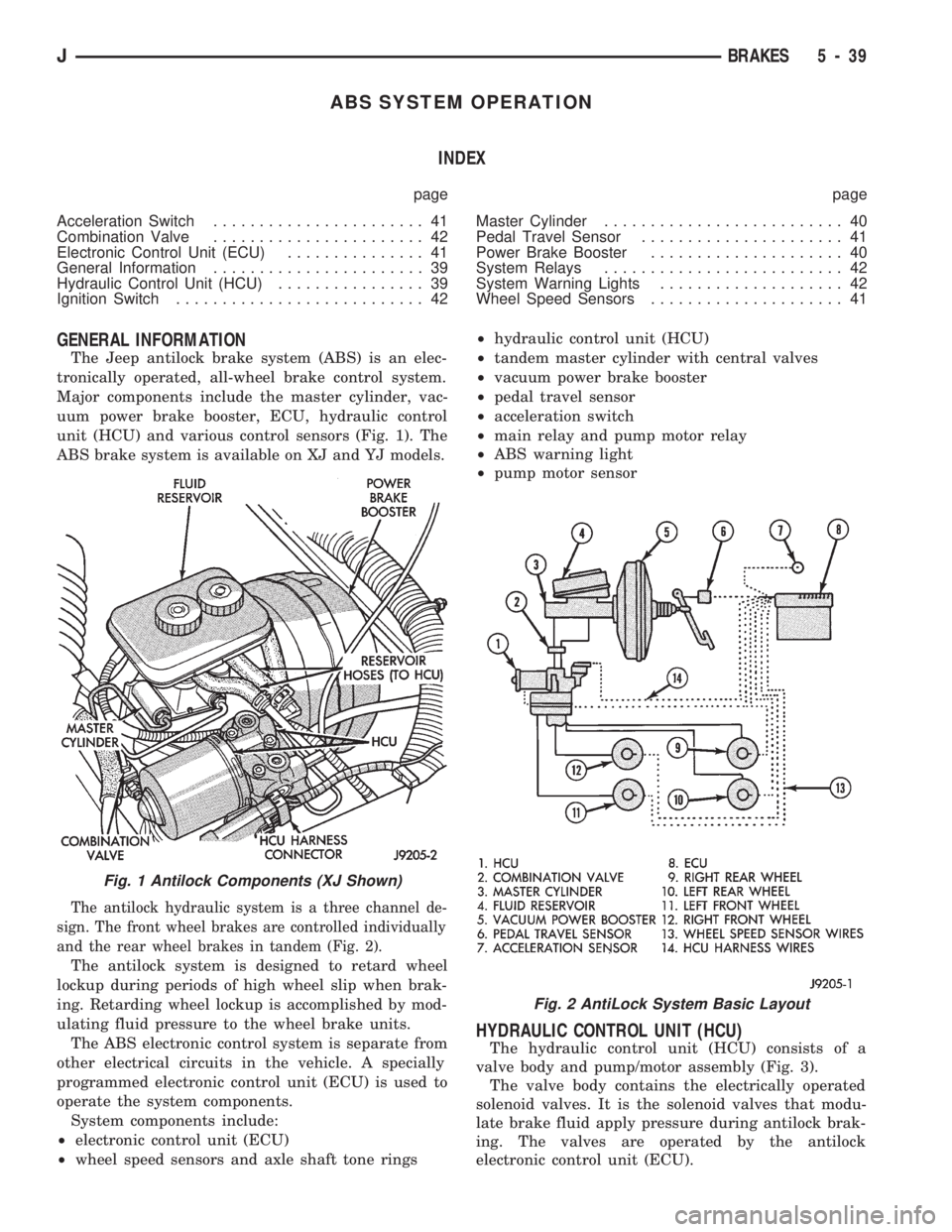

GENERAL INFORMATION

The Jeep antilock brake system (ABS) is an elec-

tronically operated, all-wheel brake control system.

Major components include the master cylinder, vac-

uum power brake booster, ECU, hydraulic control

unit (HCU) and various control sensors (Fig. 1). The

ABS brake system is available on XJ and YJ models.

The antilock hydraulic system is a three channel de-

sign. The front wheel brakes are controlled individually

and the rear wheel brakes in tandem (Fig. 2).

The antilock system is designed to retard wheel

lockup during periods of high wheel slip when brak-

ing. Retarding wheel lockup is accomplished by mod-

ulating fluid pressure to the wheel brake units.

The ABS electronic control system is separate from

other electrical circuits in the vehicle. A specially

programmed electronic control unit (ECU) is used to

operate the system components.

System components include:

²electronic control unit (ECU)

²wheel speed sensors and axle shaft tone rings²hydraulic control unit (HCU)

²tandem master cylinder with central valves

²vacuum power brake booster

²pedal travel sensor

²acceleration switch

²main relay and pump motor relay

²ABS warning light

²pump motor sensor

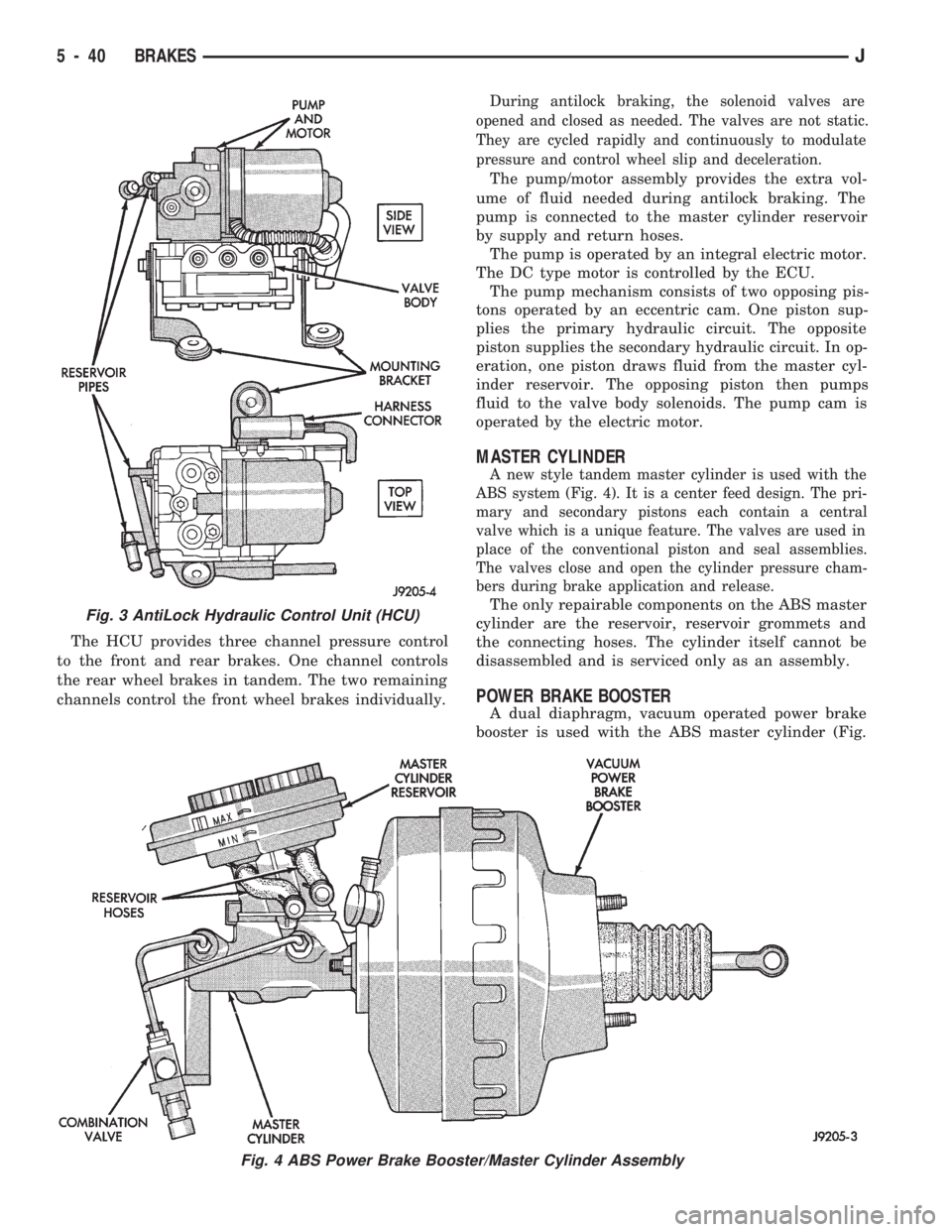

HYDRAULIC CONTROL UNIT (HCU)

The hydraulic control unit (HCU) consists of a

valve body and pump/motor assembly (Fig. 3).

The valve body contains the electrically operated

solenoid valves. It is the solenoid valves that modu-

late brake fluid apply pressure during antilock brak-

ing. The valves are operated by the antilock

electronic control unit (ECU).

Fig. 1 Antilock Components (XJ Shown)

Fig. 2 AntiLock System Basic Layout

JBRAKES 5 - 39

Page 187 of 1784

The HCU provides three channel pressure control

to the front and rear brakes. One channel controls

the rear wheel brakes in tandem. The two remaining

channels control the front wheel brakes individually.

During antilock braking, the solenoid valves are

opened and closed as needed. The valves are not static.

They are cycled rapidly and continuously to modulate

pressure and control wheel slip and deceleration.

The pump/motor assembly provides the extra vol-

ume of fluid needed during antilock braking. The

pump is connected to the master cylinder reservoir

by supply and return hoses.

The pump is operated by an integral electric motor.

The DC type motor is controlled by the ECU.

The pump mechanism consists of two opposing pis-

tons operated by an eccentric cam. One piston sup-

plies the primary hydraulic circuit. The opposite

piston supplies the secondary hydraulic circuit. In op-

eration, one piston draws fluid from the master cyl-

inder reservoir. The opposing piston then pumps

fluid to the valve body solenoids. The pump cam is

operated by the electric motor.

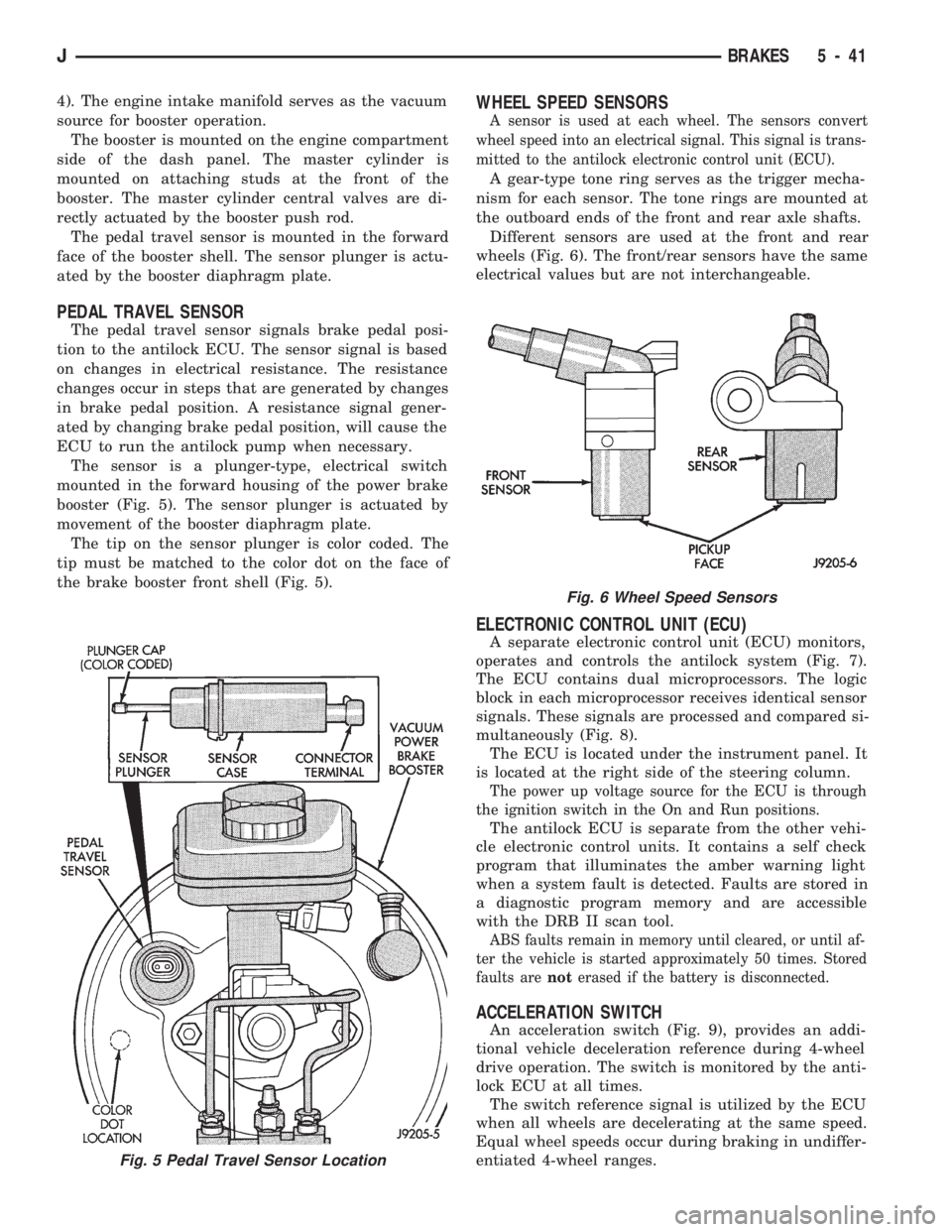

MASTER CYLINDER

A new style tandem master cylinder is used with the

ABS system (Fig. 4). It is a center feed design. The pri-

mary and secondary pistons each contain a central

valve which is a unique feature. The valves are used in

place of the conventional piston and seal assemblies.

The valves close and open the cylinder pressure cham-

bers during brake application and release.

The only repairable components on the ABS master

cylinder are the reservoir, reservoir grommets and

the connecting hoses. The cylinder itself cannot be

disassembled and is serviced only as an assembly.

POWER BRAKE BOOSTER

A dual diaphragm, vacuum operated power brake

booster is used with the ABS master cylinder (Fig.

Fig. 3 AntiLock Hydraulic Control Unit (HCU)

Fig. 4 ABS Power Brake Booster/Master Cylinder Assembly

5 - 40 BRAKESJ

Page 188 of 1784

4). The engine intake manifold serves as the vacuum

source for booster operation.

The booster is mounted on the engine compartment

side of the dash panel. The master cylinder is

mounted on attaching studs at the front of the

booster. The master cylinder central valves are di-

rectly actuated by the booster push rod.

The pedal travel sensor is mounted in the forward

face of the booster shell. The sensor plunger is actu-

ated by the booster diaphragm plate.

PEDAL TRAVEL SENSOR

The pedal travel sensor signals brake pedal posi-

tion to the antilock ECU. The sensor signal is based

on changes in electrical resistance. The resistance

changes occur in steps that are generated by changes

in brake pedal position. A resistance signal gener-

ated by changing brake pedal position, will cause the

ECU to run the antilock pump when necessary.

The sensor is a plunger-type, electrical switch

mounted in the forward housing of the power brake

booster (Fig. 5). The sensor plunger is actuated by

movement of the booster diaphragm plate.

The tip on the sensor plunger is color coded. The

tip must be matched to the color dot on the face of

the brake booster front shell (Fig. 5).

WHEEL SPEED SENSORS

A sensor is used at each wheel. The sensors convert

wheel speed into an electrical signal. This signal is trans-

mitted to the antilock electronic control unit (ECU).

A gear-type tone ring serves as the trigger mecha-

nism for each sensor. The tone rings are mounted at

the outboard ends of the front and rear axle shafts.

Different sensors are used at the front and rear

wheels (Fig. 6). The front/rear sensors have the same

electrical values but are not interchangeable.

ELECTRONIC CONTROL UNIT (ECU)

A separate electronic control unit (ECU) monitors,

operates and controls the antilock system (Fig. 7).

The ECU contains dual microprocessors. The logic

block in each microprocessor receives identical sensor

signals. These signals are processed and compared si-

multaneously (Fig. 8).

The ECU is located under the instrument panel. It

is located at the right side of the steering column.

The power up voltage source for the ECU is through

the ignition switch in the On and Run positions.

The antilock ECU is separate from the other vehi-

cle electronic control units. It contains a self check

program that illuminates the amber warning light

when a system fault is detected. Faults are stored in

a diagnostic program memory and are accessible

with the DRB II scan tool.

ABS faults remain in memory until cleared, or until af-

ter the vehicle is started approximately 50 times. Stored

faults arenoterased if the battery is disconnected.

ACCELERATION SWITCH

An acceleration switch (Fig. 9), provides an addi-

tional vehicle deceleration reference during 4-wheel

drive operation. The switch is monitored by the anti-

lock ECU at all times.

The switch reference signal is utilized by the ECU

when all wheels are decelerating at the same speed.

Equal wheel speeds occur during braking in undiffer-

entiated 4-wheel ranges.

Fig. 5 Pedal Travel Sensor Location

Fig. 6 Wheel Speed Sensors

JBRAKES 5 - 41