front JEEP CHEROKEE 1994 Service Repair Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 1994, Model line: CHEROKEE, Model: JEEP CHEROKEE 1994Pages: 1784, PDF Size: 77.09 MB

Page 1634 of 1784

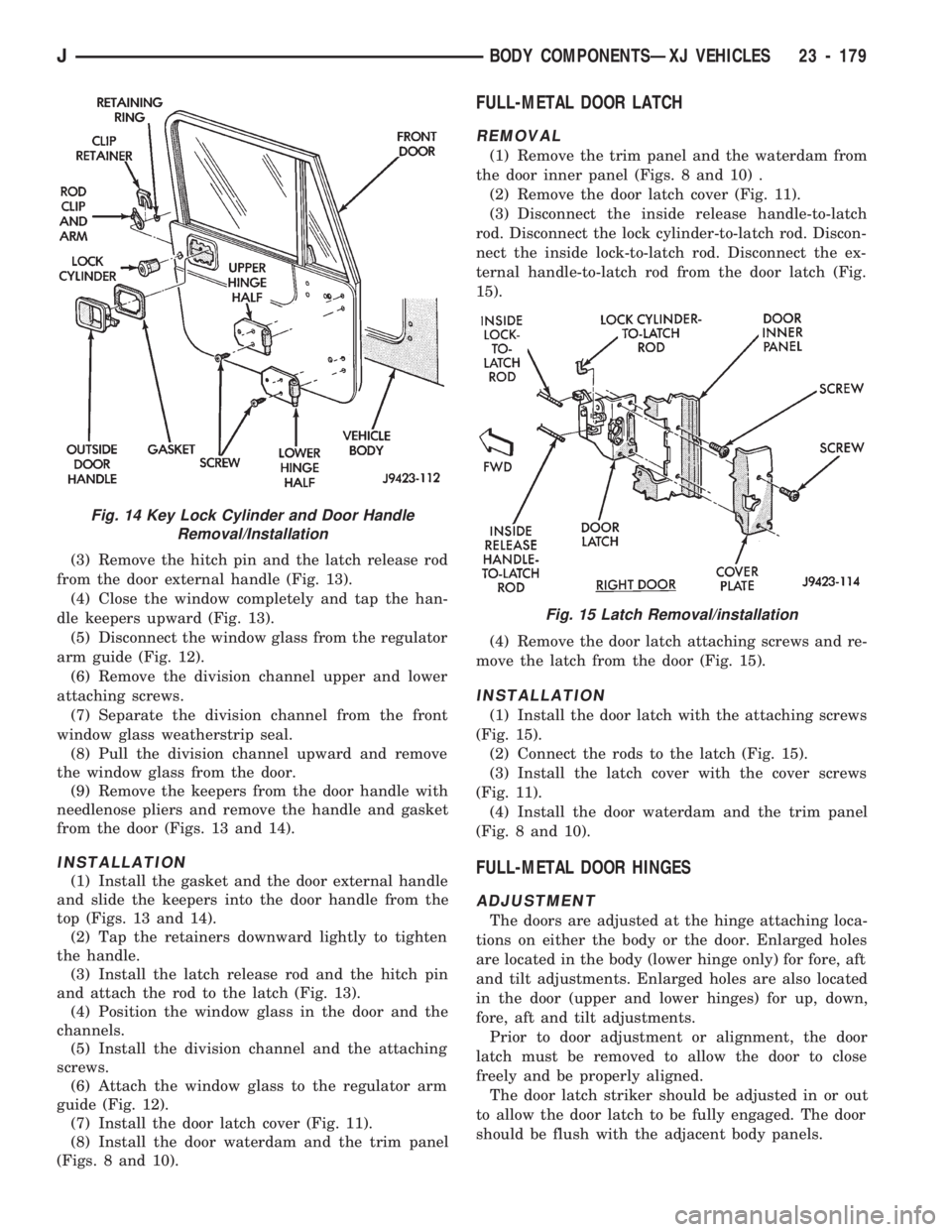

(3) Remove the hitch pin and the latch release rod

from the door external handle (Fig. 13).

(4) Close the window completely and tap the han-

dle keepers upward (Fig. 13).

(5) Disconnect the window glass from the regulator

arm guide (Fig. 12).

(6) Remove the division channel upper and lower

attaching screws.

(7) Separate the division channel from the front

window glass weatherstrip seal.

(8) Pull the division channel upward and remove

the window glass from the door.

(9) Remove the keepers from the door handle with

needlenose pliers and remove the handle and gasket

from the door (Figs. 13 and 14).

INSTALLATION

(1) Install the gasket and the door external handle

and slide the keepers into the door handle from the

top (Figs. 13 and 14).

(2) Tap the retainers downward lightly to tighten

the handle.

(3) Install the latch release rod and the hitch pin

and attach the rod to the latch (Fig. 13).

(4) Position the window glass in the door and the

channels.

(5) Install the division channel and the attaching

screws.

(6) Attach the window glass to the regulator arm

guide (Fig. 12).

(7) Install the door latch cover (Fig. 11).

(8) Install the door waterdam and the trim panel

(Figs. 8 and 10).

FULL-METAL DOOR LATCH

REMOVAL

(1) Remove the trim panel and the waterdam from

the door inner panel (Figs. 8 and 10) .

(2) Remove the door latch cover (Fig. 11).

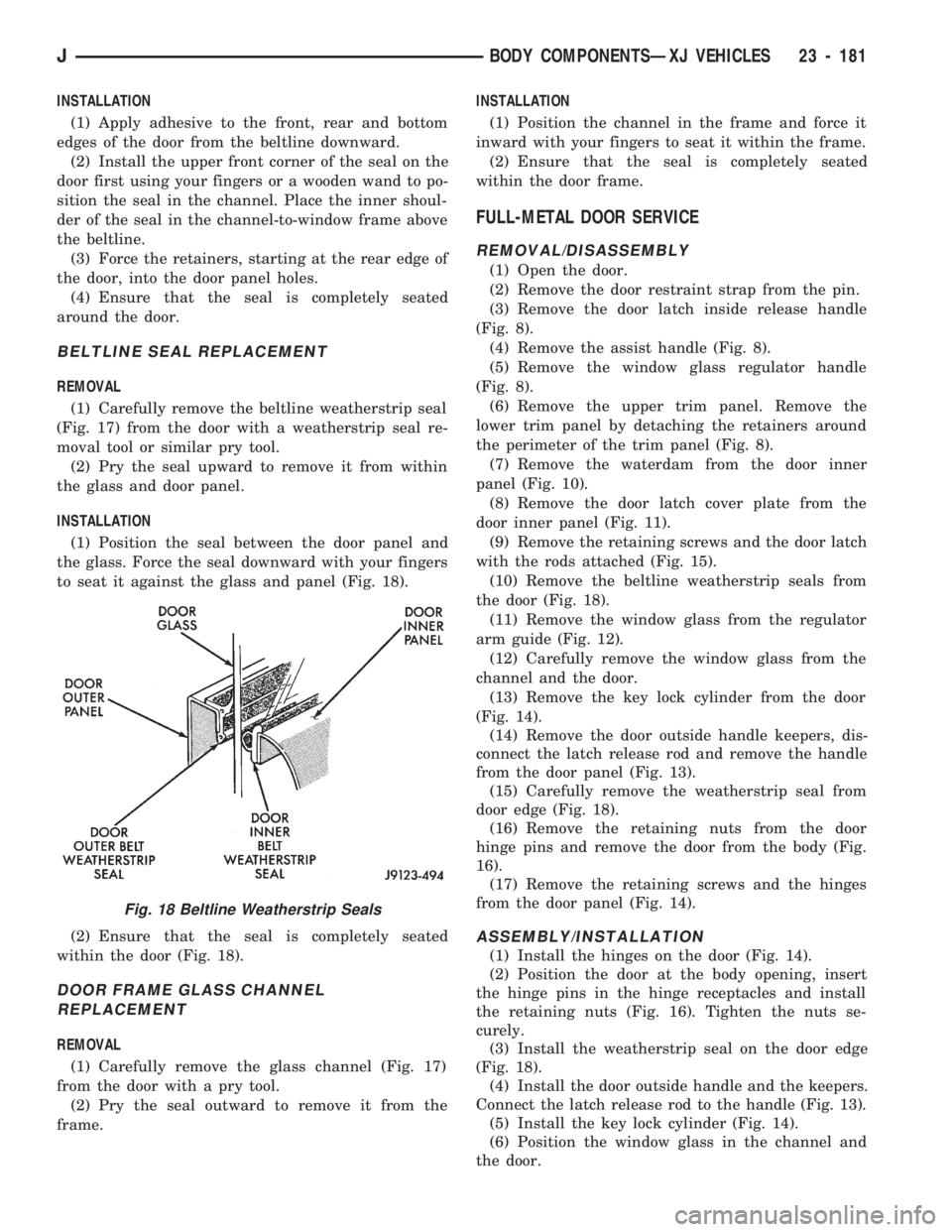

(3) Disconnect the inside release handle-to-latch

rod. Disconnect the lock cylinder-to-latch rod. Discon-

nect the inside lock-to-latch rod. Disconnect the ex-

ternal handle-to-latch rod from the door latch (Fig.

15).

(4) Remove the door latch attaching screws and re-

move the latch from the door (Fig. 15).

INSTALLATION

(1) Install the door latch with the attaching screws

(Fig. 15).

(2) Connect the rods to the latch (Fig. 15).

(3) Install the latch cover with the cover screws

(Fig. 11).

(4) Install the door waterdam and the trim panel

(Fig. 8 and 10).

FULL-METAL DOOR HINGES

ADJUSTMENT

The doors are adjusted at the hinge attaching loca-

tions on either the body or the door. Enlarged holes

are located in the body (lower hinge only) for fore, aft

and tilt adjustments. Enlarged holes are also located

in the door (upper and lower hinges) for up, down,

fore, aft and tilt adjustments.

Prior to door adjustment or alignment, the door

latch must be removed to allow the door to close

freely and be properly aligned.

The door latch striker should be adjusted in or out

to allow the door latch to be fully engaged. The door

should be flush with the adjacent body panels.

Fig. 15 Latch Removal/installation

Fig. 14 Key Lock Cylinder and Door Handle

Removal/Installation

JBODY COMPONENTSÐXJ VEHICLES 23 - 179

Page 1636 of 1784

INSTALLATION

(1) Apply adhesive to the front, rear and bottom

edges of the door from the beltline downward.

(2) Install the upper front corner of the seal on the

door first using your fingers or a wooden wand to po-

sition the seal in the channel. Place the inner shoul-

der of the seal in the channel-to-window frame above

the beltline.

(3) Force the retainers, starting at the rear edge of

the door, into the door panel holes.

(4) Ensure that the seal is completely seated

around the door.

BELTLINE SEAL REPLACEMENT

REMOVAL

(1) Carefully remove the beltline weatherstrip seal

(Fig. 17) from the door with a weatherstrip seal re-

moval tool or similar pry tool.

(2) Pry the seal upward to remove it from within

the glass and door panel.

INSTALLATION

(1) Position the seal between the door panel and

the glass. Force the seal downward with your fingers

to seat it against the glass and panel (Fig. 18).

(2) Ensure that the seal is completely seated

within the door (Fig. 18).

DOOR FRAME GLASS CHANNEL

REPLACEMENT

REMOVAL

(1) Carefully remove the glass channel (Fig. 17)

from the door with a pry tool.

(2) Pry the seal outward to remove it from the

frame.INSTALLATION

(1) Position the channel in the frame and force it

inward with your fingers to seat it within the frame.

(2) Ensure that the seal is completely seated

within the door frame.

FULL-METAL DOOR SERVICE

REMOVAL/DISASSEMBLY

(1) Open the door.

(2) Remove the door restraint strap from the pin.

(3) Remove the door latch inside release handle

(Fig. 8).

(4) Remove the assist handle (Fig. 8).

(5) Remove the window glass regulator handle

(Fig. 8).

(6) Remove the upper trim panel. Remove the

lower trim panel by detaching the retainers around

the perimeter of the trim panel (Fig. 8).

(7) Remove the waterdam from the door inner

panel (Fig. 10).

(8) Remove the door latch cover plate from the

door inner panel (Fig. 11).

(9) Remove the retaining screws and the door latch

with the rods attached (Fig. 15).

(10) Remove the beltline weatherstrip seals from

the door (Fig. 18).

(11) Remove the window glass from the regulator

arm guide (Fig. 12).

(12) Carefully remove the window glass from the

channel and the door.

(13) Remove the key lock cylinder from the door

(Fig. 14).

(14) Remove the door outside handle keepers, dis-

connect the latch release rod and remove the handle

from the door panel (Fig. 13).

(15) Carefully remove the weatherstrip seal from

door edge (Fig. 18).

(16) Remove the retaining nuts from the door

hinge pins and remove the door from the body (Fig.

16).

(17) Remove the retaining screws and the hinges

from the door panel (Fig. 14).

ASSEMBLY/INSTALLATION

(1) Install the hinges on the door (Fig. 14).

(2) Position the door at the body opening, insert

the hinge pins in the hinge receptacles and install

the retaining nuts (Fig. 16). Tighten the nuts se-

curely.

(3) Install the weatherstrip seal on the door edge

(Fig. 18).

(4) Install the door outside handle and the keepers.

Connect the latch release rod to the handle (Fig. 13).

(5) Install the key lock cylinder (Fig. 14).

(6) Position the window glass in the channel and

the door.

Fig. 18 Beltline Weatherstrip Seals

JBODY COMPONENTSÐXJ VEHICLES 23 - 181

Page 1645 of 1784

INTERIOR COMPONENTS

INDEX

page page

Carpet/Floor Mats....................... 198

Floor Consoles......................... 197

Front Shoulder Belts..................... 196

Glove Box............................. 194

Instrument Cluster and Gauge Housings...... 190

Instrument Cluster Bezel.................. 191Instrument Panel........................ 190

Instrument Panel Components.............. 191

Instrument Panel Service.................. 192

Rear Shoulder Belts..................... 196

Seats................................ 195

Sunvisors............................. 196

INSTRUMENT PANEL

SERVICE INFORMATION

The instrument panel is constructed of sheet metal

and is attached to cowl panel with screws. The in-

strument panel and defroster grille pad is attached

to the instrument panel with screws.

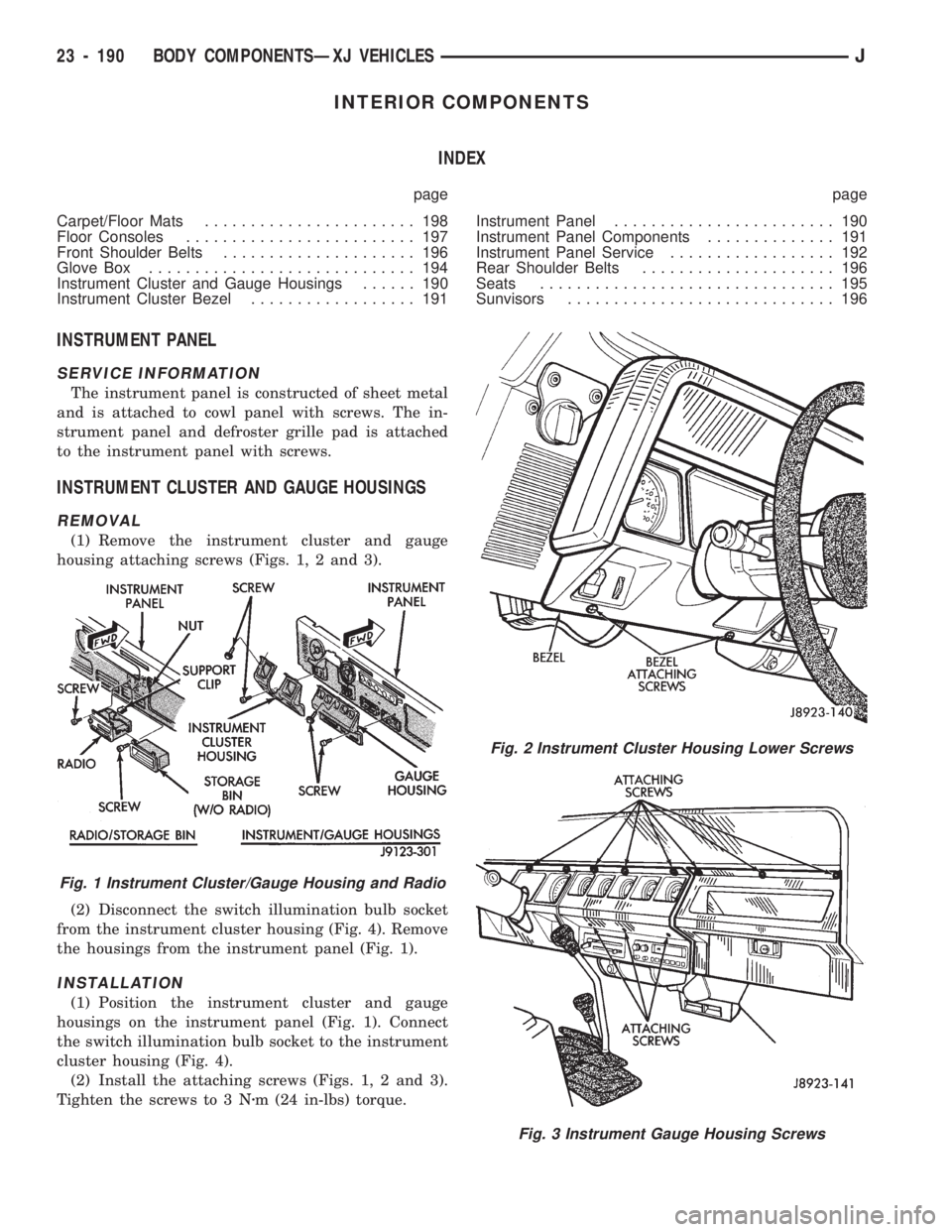

INSTRUMENT CLUSTER AND GAUGE HOUSINGS

REMOVAL

(1) Remove the instrument cluster and gauge

housing attaching screws (Figs. 1, 2 and 3).

(2) Disconnect the switch illumination bulb socket

from the instrument cluster housing (Fig. 4). Remove

the housings from the instrument panel (Fig. 1).

INSTALLATION

(1) Position the instrument cluster and gauge

housings on the instrument panel (Fig. 1). Connect

the switch illumination bulb socket to the instrument

cluster housing (Fig. 4).

(2) Install the attaching screws (Figs. 1, 2 and 3).

Tighten the screws to 3 Nzm (24 in-lbs) torque.

Fig. 2 Instrument Cluster Housing Lower Screws

Fig. 3 Instrument Gauge Housing Screws

Fig. 1 Instrument Cluster/Gauge Housing and Radio

23 - 190 BODY COMPONENTSÐXJ VEHICLESJ

Page 1648 of 1784

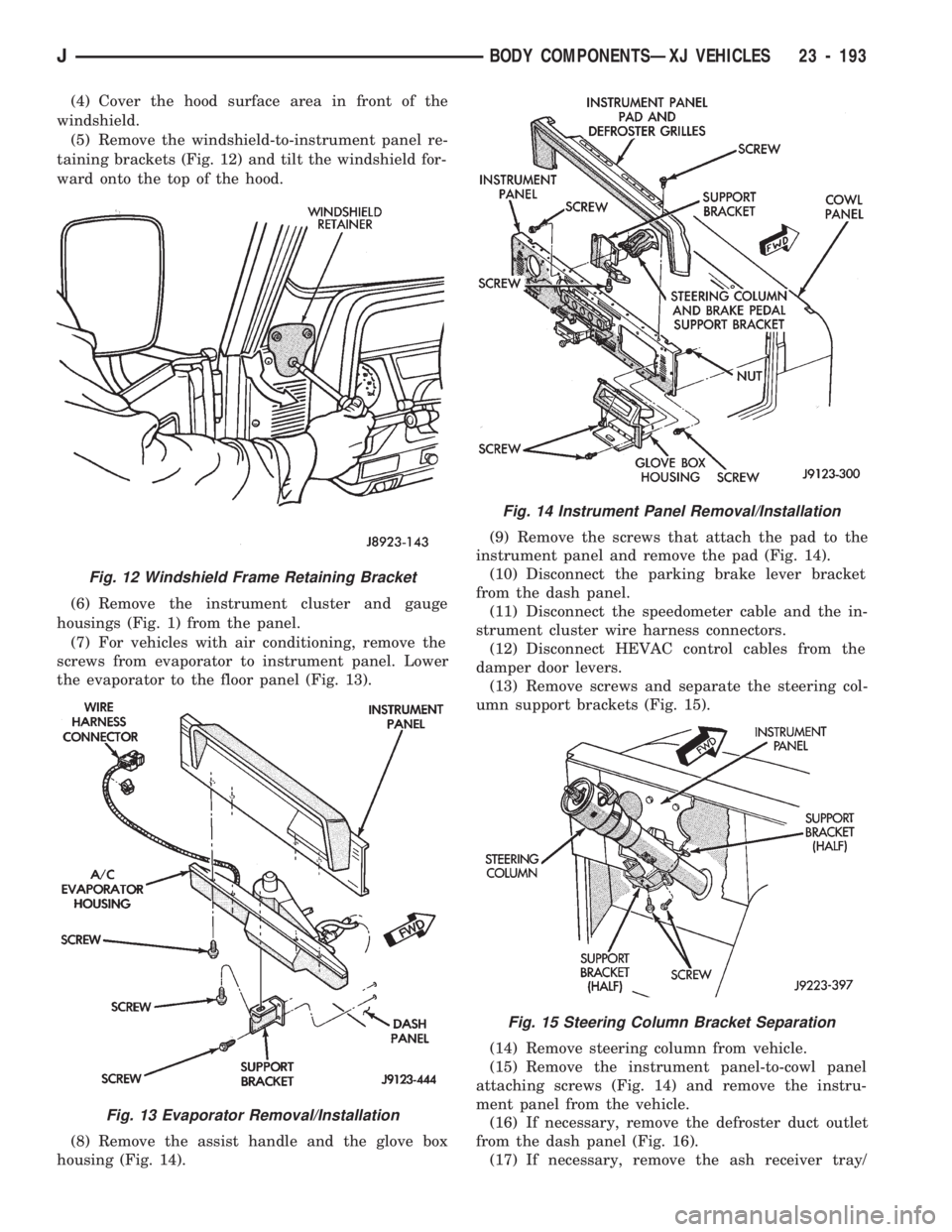

(4) Cover the hood surface area in front of the

windshield.

(5) Remove the windshield-to-instrument panel re-

taining brackets (Fig. 12) and tilt the windshield for-

ward onto the top of the hood.

(6) Remove the instrument cluster and gauge

housings (Fig. 1) from the panel.

(7) For vehicles with air conditioning, remove the

screws from evaporator to instrument panel. Lower

the evaporator to the floor panel (Fig. 13).

(8) Remove the assist handle and the glove box

housing (Fig. 14).(9) Remove the screws that attach the pad to the

instrument panel and remove the pad (Fig. 14).

(10) Disconnect the parking brake lever bracket

from the dash panel.

(11) Disconnect the speedometer cable and the in-

strument cluster wire harness connectors.

(12) Disconnect HEVAC control cables from the

damper door levers.

(13) Remove screws and separate the steering col-

umn support brackets (Fig. 15).

(14) Remove steering column from vehicle.

(15) Remove the instrument panel-to-cowl panel

attaching screws (Fig. 14) and remove the instru-

ment panel from the vehicle.

(16) If necessary, remove the defroster duct outlet

from the dash panel (Fig. 16).

(17) If necessary, remove the ash receiver tray/

Fig. 12 Windshield Frame Retaining Bracket

Fig. 13 Evaporator Removal/Installation

Fig. 14 Instrument Panel Removal/Installation

Fig. 15 Steering Column Bracket Separation

JBODY COMPONENTSÐXJ VEHICLES 23 - 193

Page 1650 of 1784

(3) If necessary, remove the retaining screws and

the hinge from the glove box door.

INSTALLATION

(1) If removed, install the hinge on the glove box

door with screws. Tighten the screws securely.

(2) Position the glove box door and hinge on the

glove box housing.

(3) Install the hinge-to-glove box housing screws

and adjust the door for proper fit within the opening.

Tighten the screws securely.

DOOR LATCH STRIKER ADJUSTMENT

The glove box door lock cylinder latch striker is at-

tached to the glove box housing opening with screws.

The striker can be moved in or out for adjustment.

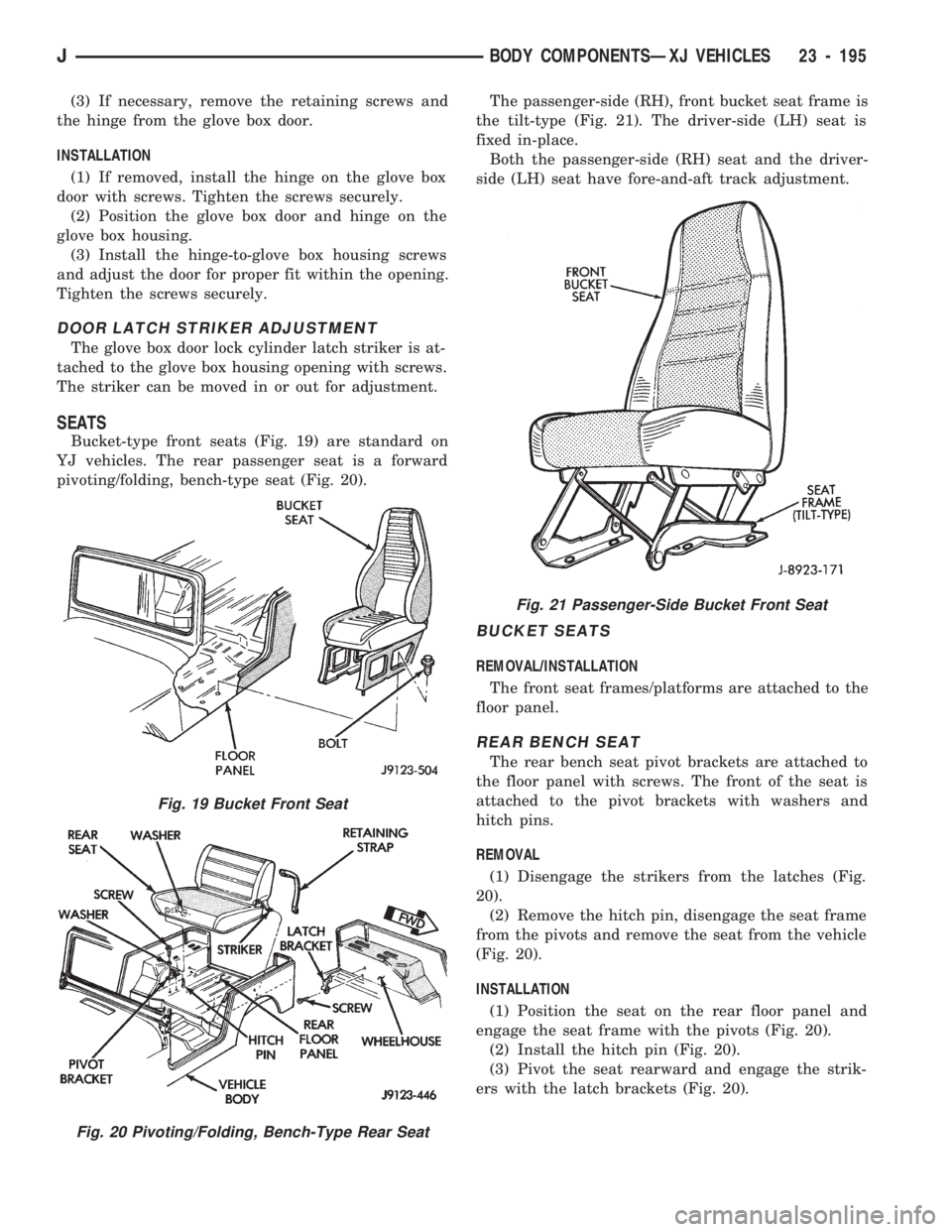

SEATS

Bucket-type front seats (Fig. 19) are standard on

YJ vehicles. The rear passenger seat is a forward

pivoting/folding, bench-type seat (Fig. 20).The passenger-side (RH), front bucket seat frame is

the tilt-type (Fig. 21). The driver-side (LH) seat is

fixed in-place.

Both the passenger-side (RH) seat and the driver-

side (LH) seat have fore-and-aft track adjustment.

BUCKET SEATS

REMOVAL/INSTALLATION

The front seat frames/platforms are attached to the

floor panel.

REAR BENCH SEAT

The rear bench seat pivot brackets are attached to

the floor panel with screws. The front of the seat is

attached to the pivot brackets with washers and

hitch pins.

REMOVAL

(1) Disengage the strikers from the latches (Fig.

20).

(2) Remove the hitch pin, disengage the seat frame

from the pivots and remove the seat from the vehicle

(Fig. 20).

INSTALLATION

(1) Position the seat on the rear floor panel and

engage the seat frame with the pivots (Fig. 20).

(2) Install the hitch pin (Fig. 20).

(3) Pivot the seat rearward and engage the strik-

ers with the latch brackets (Fig. 20).

Fig. 19 Bucket Front Seat

Fig. 20 Pivoting/Folding, Bench-Type Rear Seat

Fig. 21 Passenger-Side Bucket Front Seat

JBODY COMPONENTSÐXJ VEHICLES 23 - 195

Page 1651 of 1784

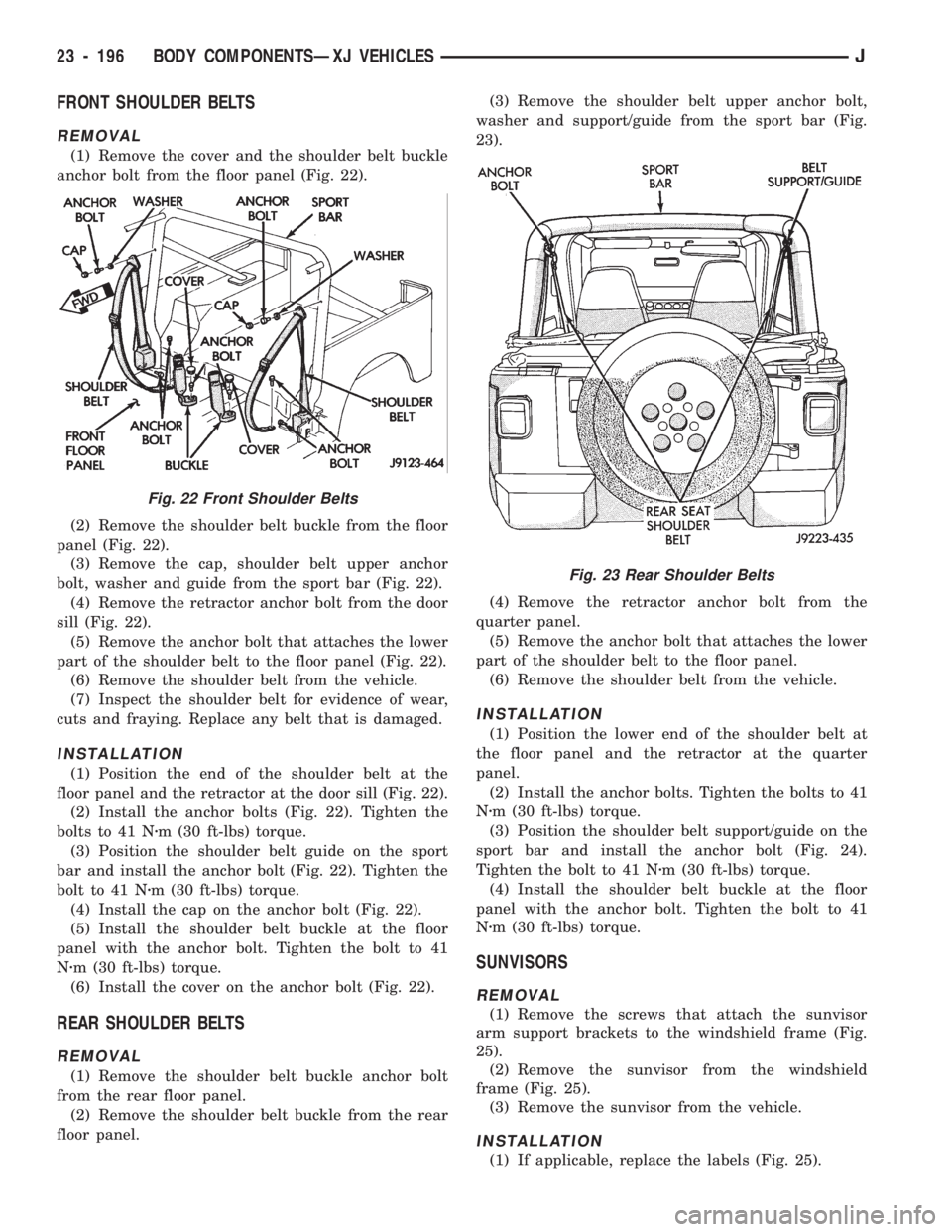

FRONT SHOULDER BELTS

REMOVAL

(1) Remove the cover and the shoulder belt buckle

anchor bolt from the floor panel (Fig. 22).

(2) Remove the shoulder belt buckle from the floor

panel (Fig. 22).

(3) Remove the cap, shoulder belt upper anchor

bolt, washer and guide from the sport bar (Fig. 22).

(4) Remove the retractor anchor bolt from the door

sill (Fig. 22).

(5) Remove the anchor bolt that attaches the lower

part of the shoulder belt to the floor panel (Fig. 22).

(6) Remove the shoulder belt from the vehicle.

(7) Inspect the shoulder belt for evidence of wear,

cuts and fraying. Replace any belt that is damaged.

INSTALLATION

(1) Position the end of the shoulder belt at the

floor panel and the retractor at the door sill (Fig. 22).

(2) Install the anchor bolts (Fig. 22). Tighten the

bolts to 41 Nzm (30 ft-lbs) torque.

(3) Position the shoulder belt guide on the sport

bar and install the anchor bolt (Fig. 22). Tighten the

bolt to 41 Nzm (30 ft-lbs) torque.

(4) Install the cap on the anchor bolt (Fig. 22).

(5) Install the shoulder belt buckle at the floor

panel with the anchor bolt. Tighten the bolt to 41

Nzm (30 ft-lbs) torque.

(6) Install the cover on the anchor bolt (Fig. 22).

REAR SHOULDER BELTS

REMOVAL

(1) Remove the shoulder belt buckle anchor bolt

from the rear floor panel.

(2) Remove the shoulder belt buckle from the rear

floor panel.(3) Remove the shoulder belt upper anchor bolt,

washer and support/guide from the sport bar (Fig.

23).

(4) Remove the retractor anchor bolt from the

quarter panel.

(5) Remove the anchor bolt that attaches the lower

part of the shoulder belt to the floor panel.

(6) Remove the shoulder belt from the vehicle.

INSTALLATION

(1) Position the lower end of the shoulder belt at

the floor panel and the retractor at the quarter

panel.

(2) Install the anchor bolts. Tighten the bolts to 41

Nzm (30 ft-lbs) torque.

(3) Position the shoulder belt support/guide on the

sport bar and install the anchor bolt (Fig. 24).

Tighten the bolt to 41 Nzm (30 ft-lbs) torque.

(4) Install the shoulder belt buckle at the floor

panel with the anchor bolt. Tighten the bolt to 41

Nzm (30 ft-lbs) torque.

SUNVISORS

REMOVAL

(1) Remove the screws that attach the sunvisor

arm support brackets to the windshield frame (Fig.

25).

(2) Remove the sunvisor from the windshield

frame (Fig. 25).

(3) Remove the sunvisor from the vehicle.

INSTALLATION

(1) If applicable, replace the labels (Fig. 25).

Fig. 22 Front Shoulder Belts

Fig. 23 Rear Shoulder Belts

23 - 196 BODY COMPONENTSÐXJ VEHICLESJ

Page 1653 of 1784

(5) Insert the key and cylinder into the lock and

turn clockwise. Release the lock latch and remove

the key.

(6) Insert the assembled lock in the console cover

hole (Fig. 28) and install the retainer with the at-

taching screw.

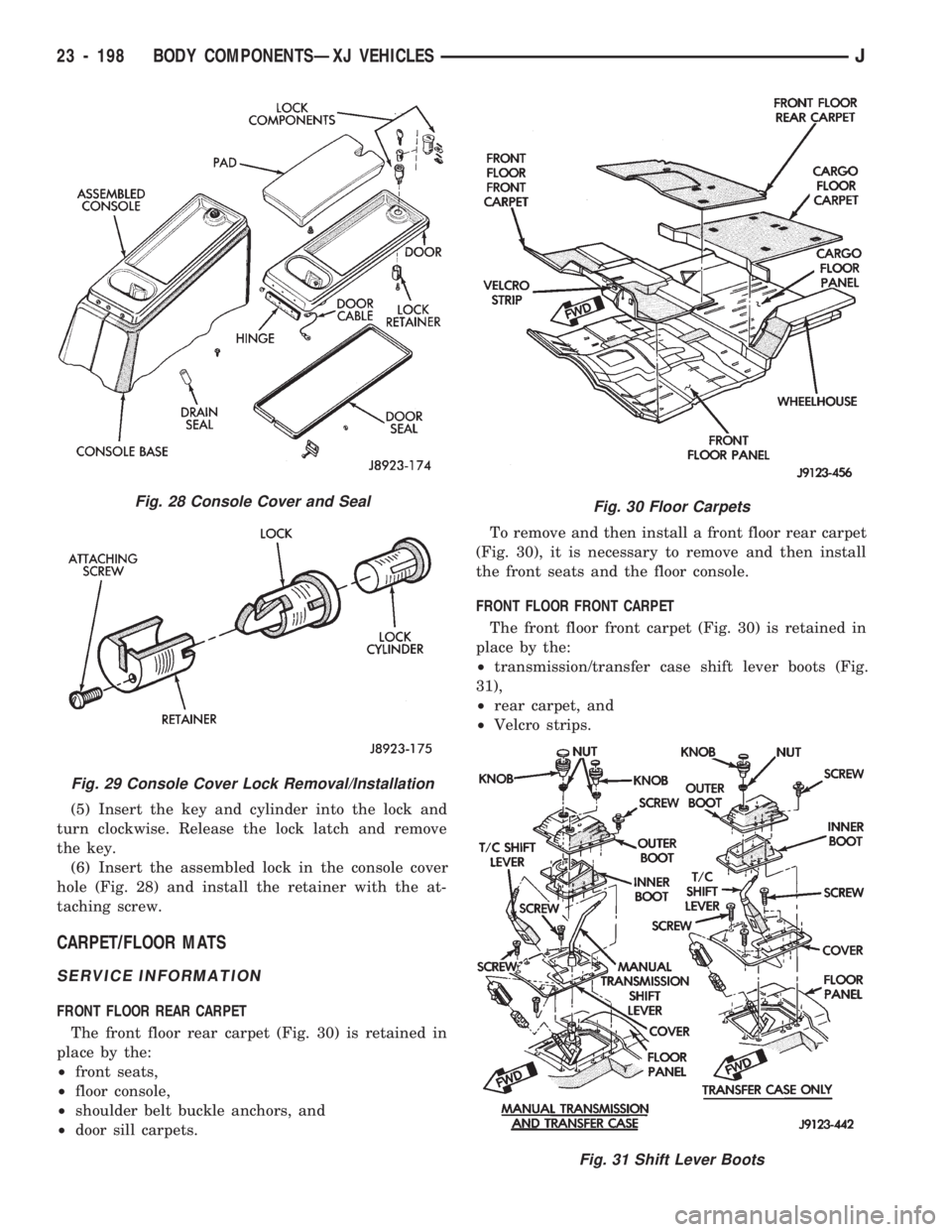

CARPET/FLOOR MATS

SERVICE INFORMATION

FRONT FLOOR REAR CARPET

The front floor rear carpet (Fig. 30) is retained in

place by the:

²front seats,

²floor console,

²shoulder belt buckle anchors, and

²door sill carpets.To remove and then install a front floor rear carpet

(Fig. 30), it is necessary to remove and then install

the front seats and the floor console.

FRONT FLOOR FRONT CARPET

The front floor front carpet (Fig. 30) is retained in

place by the:

²transmission/transfer case shift lever boots (Fig.

31),

²rear carpet, and

²Velcro strips.

Fig. 28 Console Cover and Seal

Fig. 29 Console Cover Lock Removal/Installation

Fig. 30 Floor Carpets

Fig. 31 Shift Lever Boots

23 - 198 BODY COMPONENTSÐXJ VEHICLESJ

Page 1654 of 1784

To remove and install a front floor front carpet

(Fig. 30), it is necessary to remove and then install

the shift lever boots (Fig. 31).

When replacing a front carpet, position and cut

openings in carpet with a razor knife for shift levers

and boots (Fig. 31).

CARGO FLOOR CARPET

The cargo floor carpet (Fig. 30) is retained in place

by the:

²rear seat,

²shoulder belt buckle anchors, and

²wheelhouse carpets.

To remove and then install a cargo floor carpet

(Fig. 30), it is necessary to remove and then install

the rear seat.

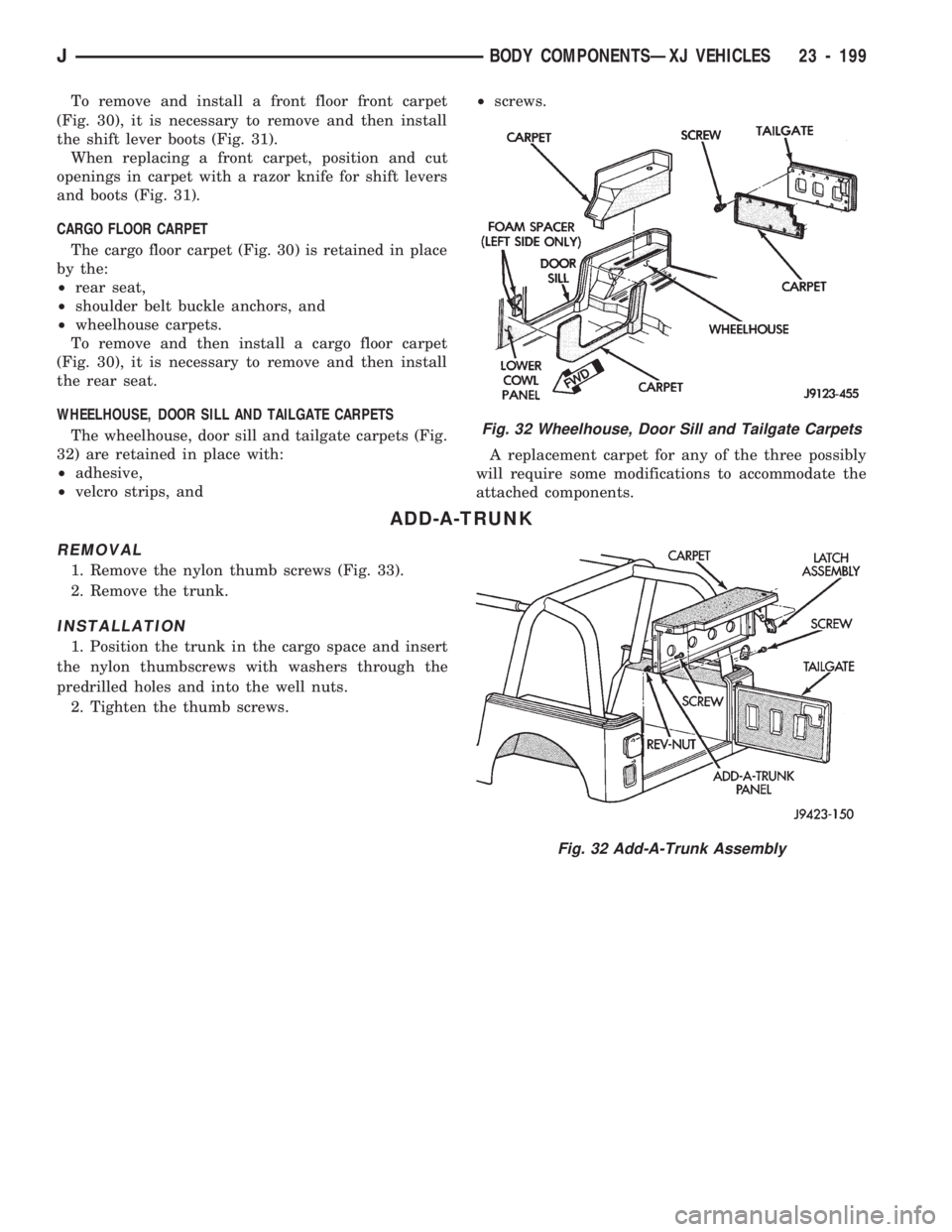

WHEELHOUSE, DOOR SILL AND TAILGATE CARPETS

The wheelhouse, door sill and tailgate carpets (Fig.

32) are retained in place with:

²adhesive,

²velcro strips, and²screws.

A replacement carpet for any of the three possibly

will require some modifications to accommodate the

attached components.

ADD-A-TRUNK

REMOVAL

1. Remove the nylon thumb screws (Fig. 33).

2. Remove the trunk.

INSTALLATION

1. Position the trunk in the cargo space and insert

the nylon thumbscrews with washers through the

predrilled holes and into the well nuts.

2. Tighten the thumb screws.

Fig. 32 Wheelhouse, Door Sill and Tailgate Carpets

Fig. 32 Add-A-Trunk Assembly

JBODY COMPONENTSÐXJ VEHICLES 23 - 199

Page 1657 of 1784

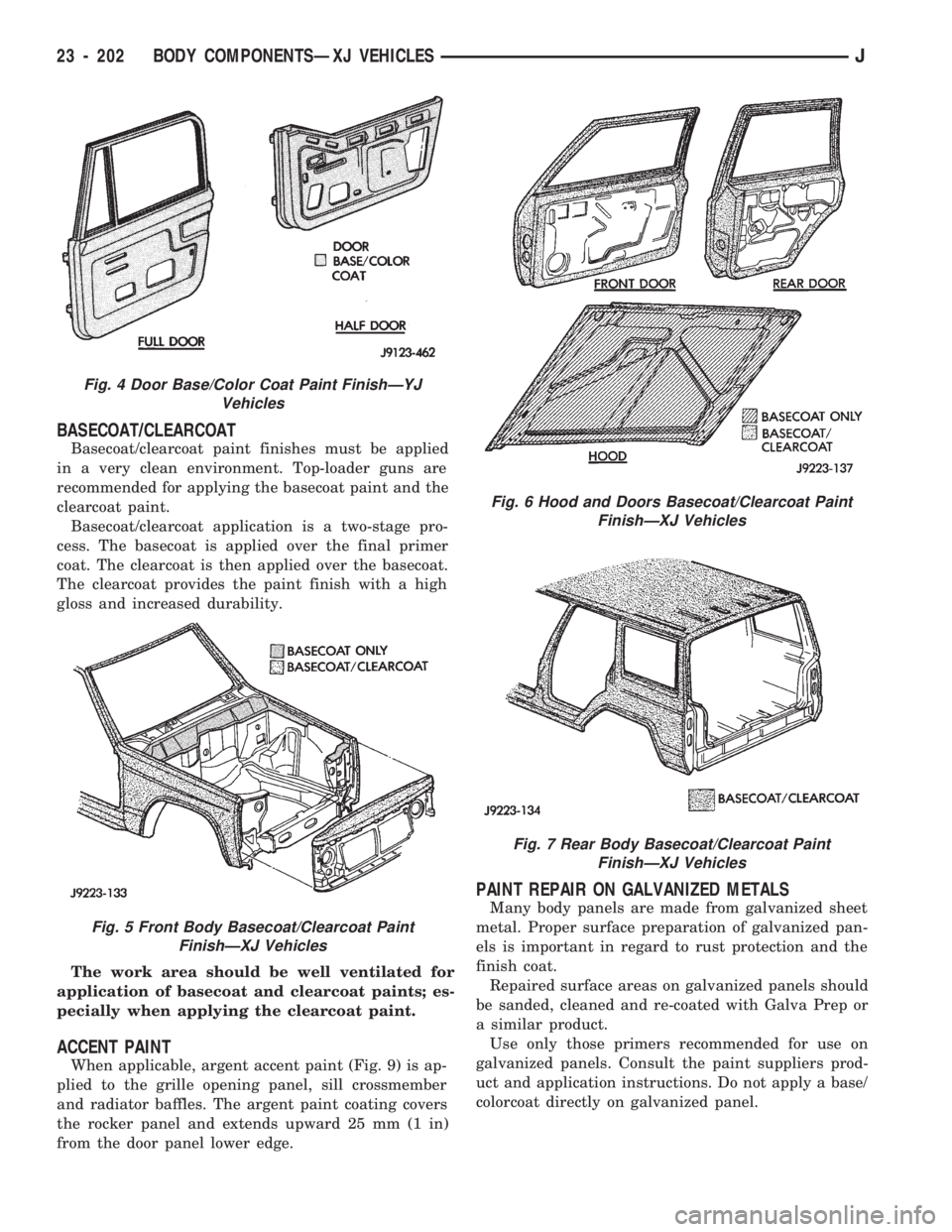

BASECOAT/CLEARCOAT

Basecoat/clearcoat paint finishes must be applied

in a very clean environment. Top-loader guns are

recommended for applying the basecoat paint and the

clearcoat paint.

Basecoat/clearcoat application is a two-stage pro-

cess. The basecoat is applied over the final primer

coat. The clearcoat is then applied over the basecoat.

The clearcoat provides the paint finish with a high

gloss and increased durability.

The work area should be well ventilated for

application of basecoat and clearcoat paints; es-

pecially when applying the clearcoat paint.

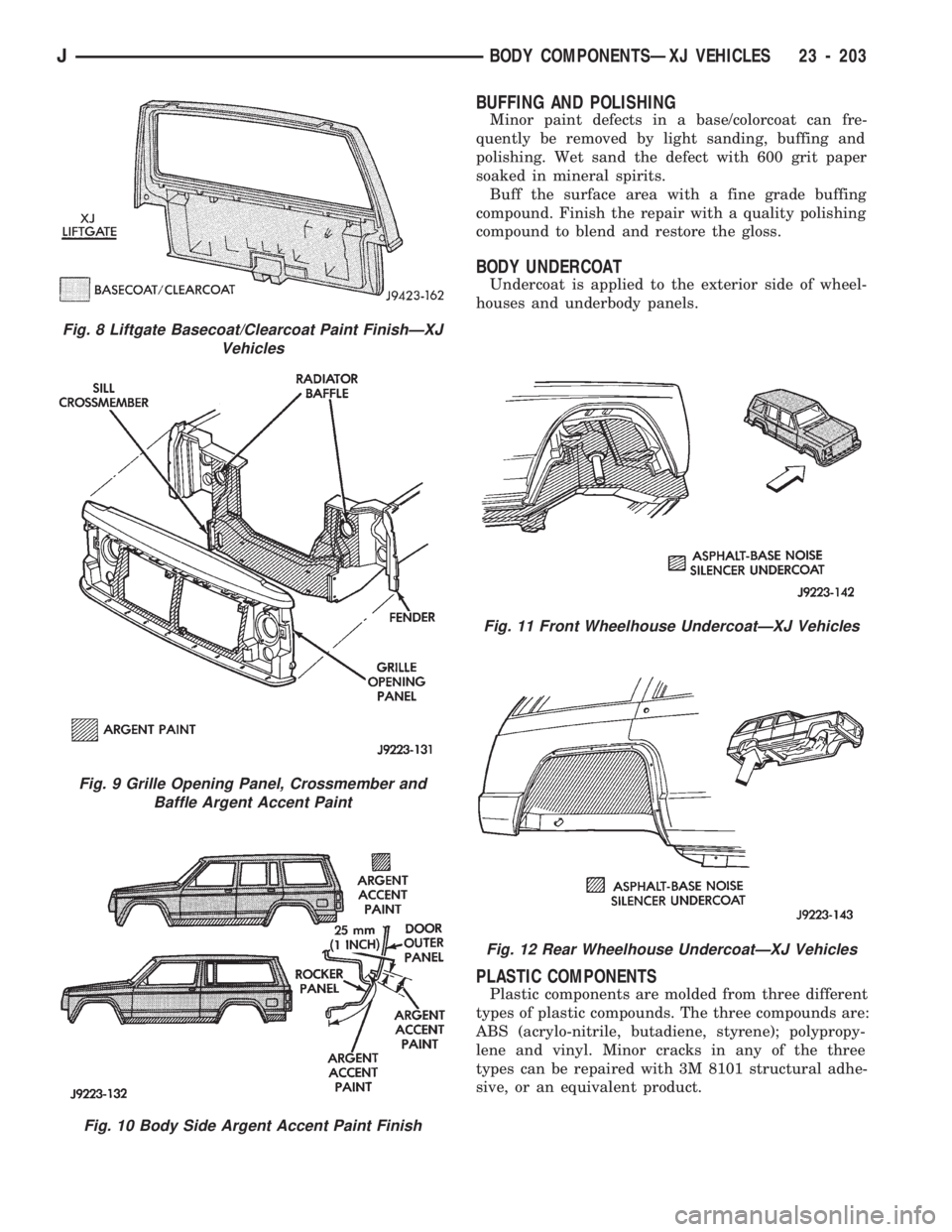

ACCENT PAINT

When applicable, argent accent paint (Fig. 9) is ap-

plied to the grille opening panel, sill crossmember

and radiator baffles. The argent paint coating covers

the rocker panel and extends upward 25 mm (1 in)

from the door panel lower edge.

PAINT REPAIR ON GALVANIZED METALS

Many body panels are made from galvanized sheet

metal. Proper surface preparation of galvanized pan-

els is important in regard to rust protection and the

finish coat.

Repaired surface areas on galvanized panels should

be sanded, cleaned and re-coated with Galva Prep or

a similar product.

Use only those primers recommended for use on

galvanized panels. Consult the paint suppliers prod-

uct and application instructions. Do not apply a base/

colorcoat directly on galvanized panel.

Fig. 4 Door Base/Color Coat Paint FinishÐYJ

Vehicles

Fig. 5 Front Body Basecoat/Clearcoat Paint

FinishÐXJ Vehicles

Fig. 6 Hood and Doors Basecoat/Clearcoat Paint

FinishÐXJ Vehicles

Fig. 7 Rear Body Basecoat/Clearcoat Paint

FinishÐXJ Vehicles

23 - 202 BODY COMPONENTSÐXJ VEHICLESJ

Page 1658 of 1784

BUFFING AND POLISHING

Minor paint defects in a base/colorcoat can fre-

quently be removed by light sanding, buffing and

polishing. Wet sand the defect with 600 grit paper

soaked in mineral spirits.

Buff the surface area with a fine grade buffing

compound. Finish the repair with a quality polishing

compound to blend and restore the gloss.

BODY UNDERCOAT

Undercoat is applied to the exterior side of wheel-

houses and underbody panels.

PLASTIC COMPONENTS

Plastic components are molded from three different

types of plastic compounds. The three compounds are:

ABS (acrylo-nitrile, butadiene, styrene); polypropy-

lene and vinyl. Minor cracks in any of the three

types can be repaired with 3M 8101 structural adhe-

sive, or an equivalent product.

Fig. 8 Liftgate Basecoat/Clearcoat Paint FinishÐXJ

Vehicles

Fig. 9 Grille Opening Panel, Crossmember and

Baffle Argent Accent Paint

Fig. 10 Body Side Argent Accent Paint Finish

Fig. 11 Front Wheelhouse UndercoatÐXJ Vehicles

Fig. 12 Rear Wheelhouse UndercoatÐXJ Vehicles

JBODY COMPONENTSÐXJ VEHICLES 23 - 203