front JEEP CHEROKEE 1994 Service Repair Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 1994, Model line: CHEROKEE, Model: JEEP CHEROKEE 1994Pages: 1784, PDF Size: 77.09 MB

Page 1602 of 1784

FENDER SPLASH APRONS

REMOVAL

(1) Remove the splash apron attaching screws (Fig.

41).

(2) Remove the aprons from the fender well (Fig.

41).

INSTALLATION

(1) Position the aprons in the fender well (Fig. 41).

(2) Install the screws to attach the splash aprons

to the fender well (Fig. 41).

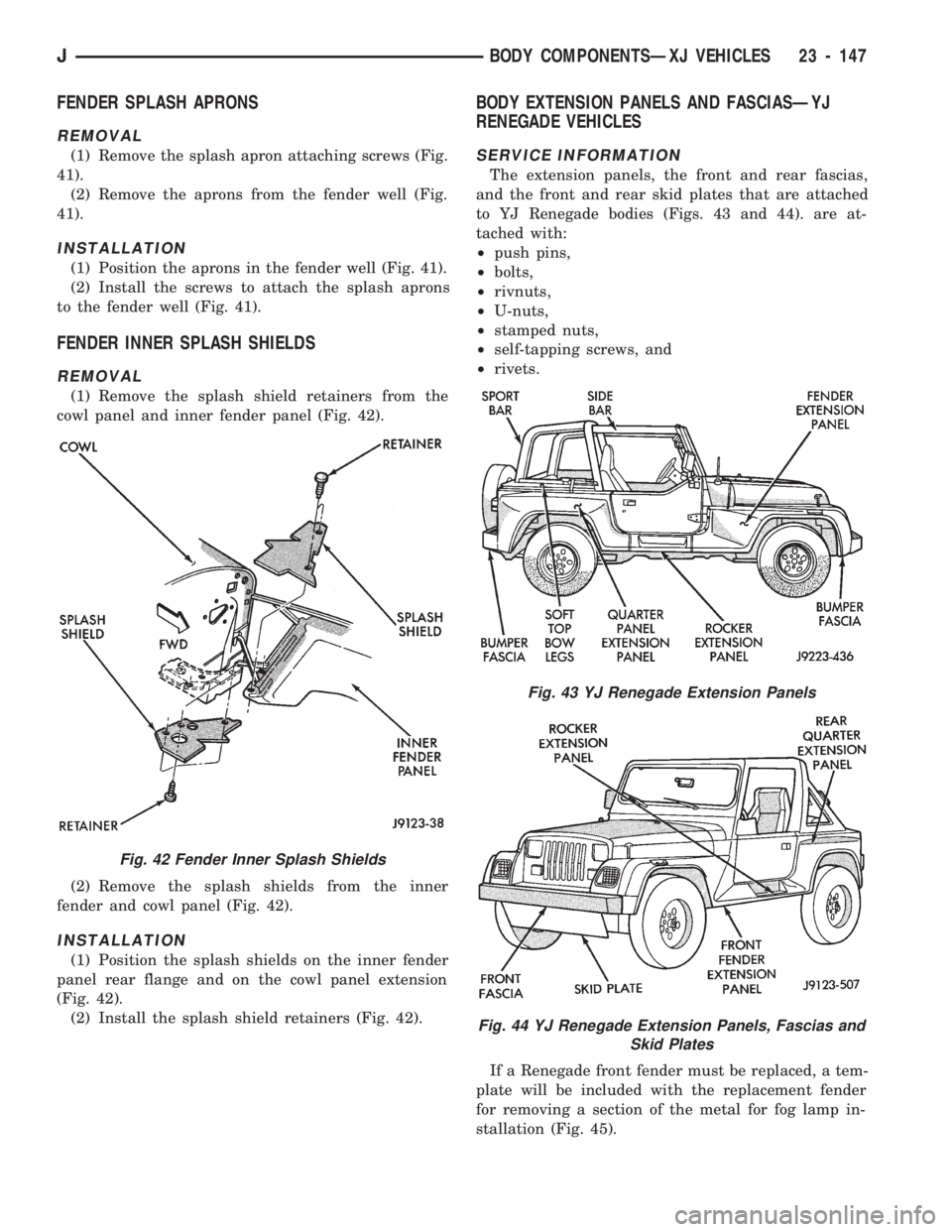

FENDER INNER SPLASH SHIELDS

REMOVAL

(1) Remove the splash shield retainers from the

cowl panel and inner fender panel (Fig. 42).

(2) Remove the splash shields from the inner

fender and cowl panel (Fig. 42).

INSTALLATION

(1) Position the splash shields on the inner fender

panel rear flange and on the cowl panel extension

(Fig. 42).

(2) Install the splash shield retainers (Fig. 42).

BODY EXTENSION PANELS AND FASCIASÐYJ

RENEGADE VEHICLES

SERVICE INFORMATION

The extension panels, the front and rear fascias,

and the front and rear skid plates that are attached

to YJ Renegade bodies (Figs. 43 and 44). are at-

tached with:

²push pins,

²bolts,

²rivnuts,

²U-nuts,

²stamped nuts,

²self-tapping screws, and

²rivets.

If a Renegade front fender must be replaced, a tem-

plate will be included with the replacement fender

for removing a section of the metal for fog lamp in-

stallation (Fig. 45).

Fig. 42 Fender Inner Splash Shields

Fig. 43 YJ Renegade Extension Panels

Fig. 44 YJ Renegade Extension Panels, Fascias and

Skid Plates

JBODY COMPONENTSÐXJ VEHICLES 23 - 147

Page 1603 of 1784

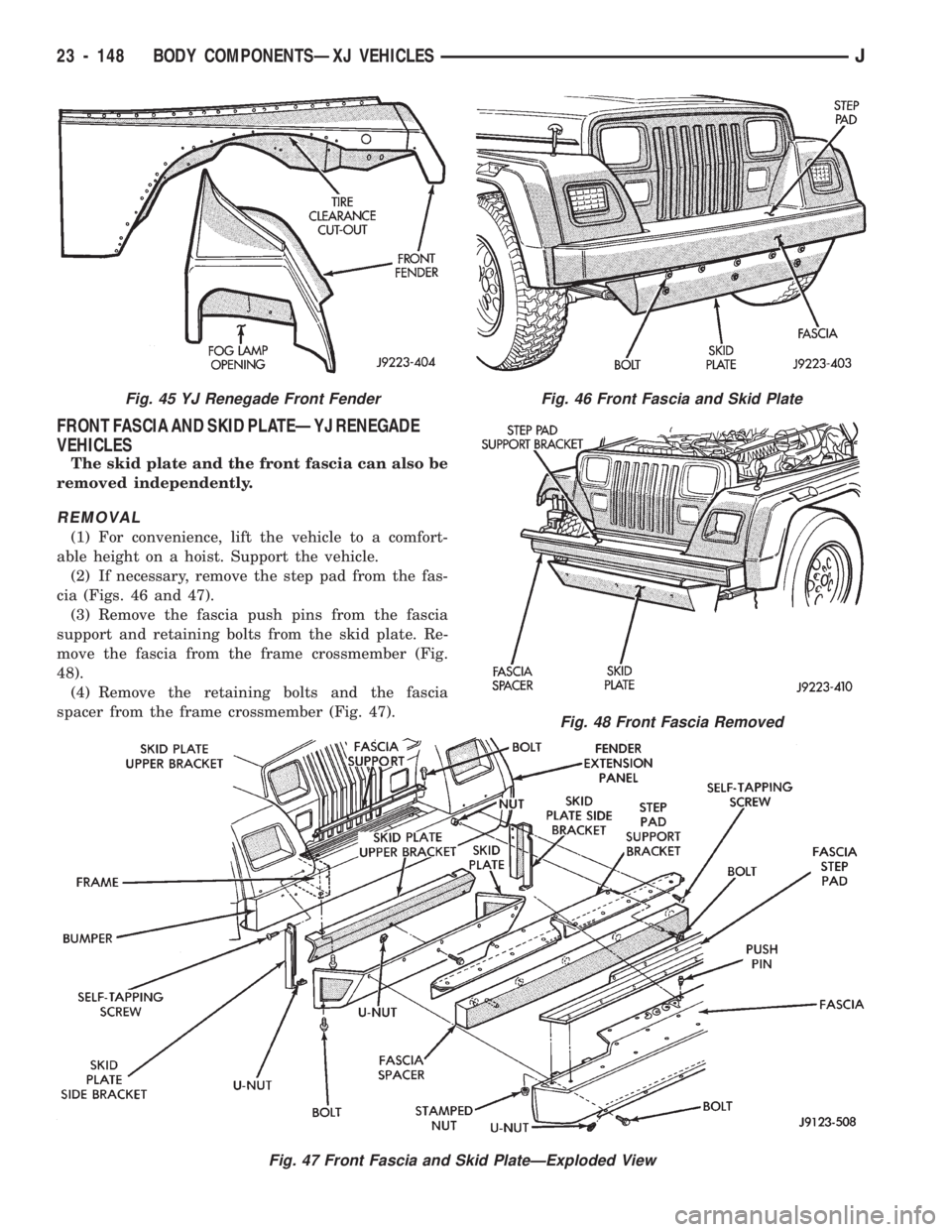

FRONT FASCIA AND SKID PLATEÐYJ RENEGADE

VEHICLES

The skid plate and the front fascia can also be

removed independently.

REMOVAL

(1) For convenience, lift the vehicle to a comfort-

able height on a hoist. Support the vehicle.

(2) If necessary, remove the step pad from the fas-

cia (Figs. 46 and 47).

(3) Remove the fascia push pins from the fascia

support and retaining bolts from the skid plate. Re-

move the fascia from the frame crossmember (Fig.

48).

(4) Remove the retaining bolts and the fascia

spacer from the frame crossmember (Fig. 47).

Fig. 46 Front Fascia and Skid Plate

Fig. 47 Front Fascia and Skid PlateÐExploded View

Fig. 48 Front Fascia Removed

Fig. 45 YJ Renegade Front Fender

23 - 148 BODY COMPONENTSÐXJ VEHICLESJ

Page 1604 of 1784

(5) Remove the retaining screws and the fascia

step pad support bracket from the frame crossmem-

ber (Fig. 47).

(6) Remove the retaining bolts from the skid plate.

Remove the skid plate from the brackets.

(7) Remove the retaining screws from the skid

plate brackets. Remove the brackets from the frame

rails.

(8) Remove the retaining bolts and the fascia sup-

port from the cover plate.

INSTALLATION

(1) Position the fascia support on the cover plate

and install the retaining bolts (Fig. 47). Tighten the

bolts to 5 Nzm (44 in-lbs) torque.

(2) Position the skid plate brackets at the frame

rails and install the retaining screws. Tighten the

screws to 25 Nzm (18 ft-lbs) torque.

(3) Position the skid plate at the brackets and in-

stall the retaining bolts. Tighten the bolts to 25 Nzm

(18 ft-lbs) torque.

(4) Position the fascia step pad support bracket at

the frame crossmember and install the retaining

screws. Tighten the screws to 25 Nzm (18 ft-lbs)

torque.

(5) Position the fascia spacer at the frame cross-

member and install the retaining bolts. Tighten the

nuts to 6 Nzm (53 in-lbs) torque.

(6) Position the fascia at the frame crossmember

and install the retaining bolts and push pins.

Tighten the bolts to 10 Nzm (7 ft-lbs) torque.

(7) Install the step pad on the fascia.

(8) If applicable, remove the support and lower the

vehicle.

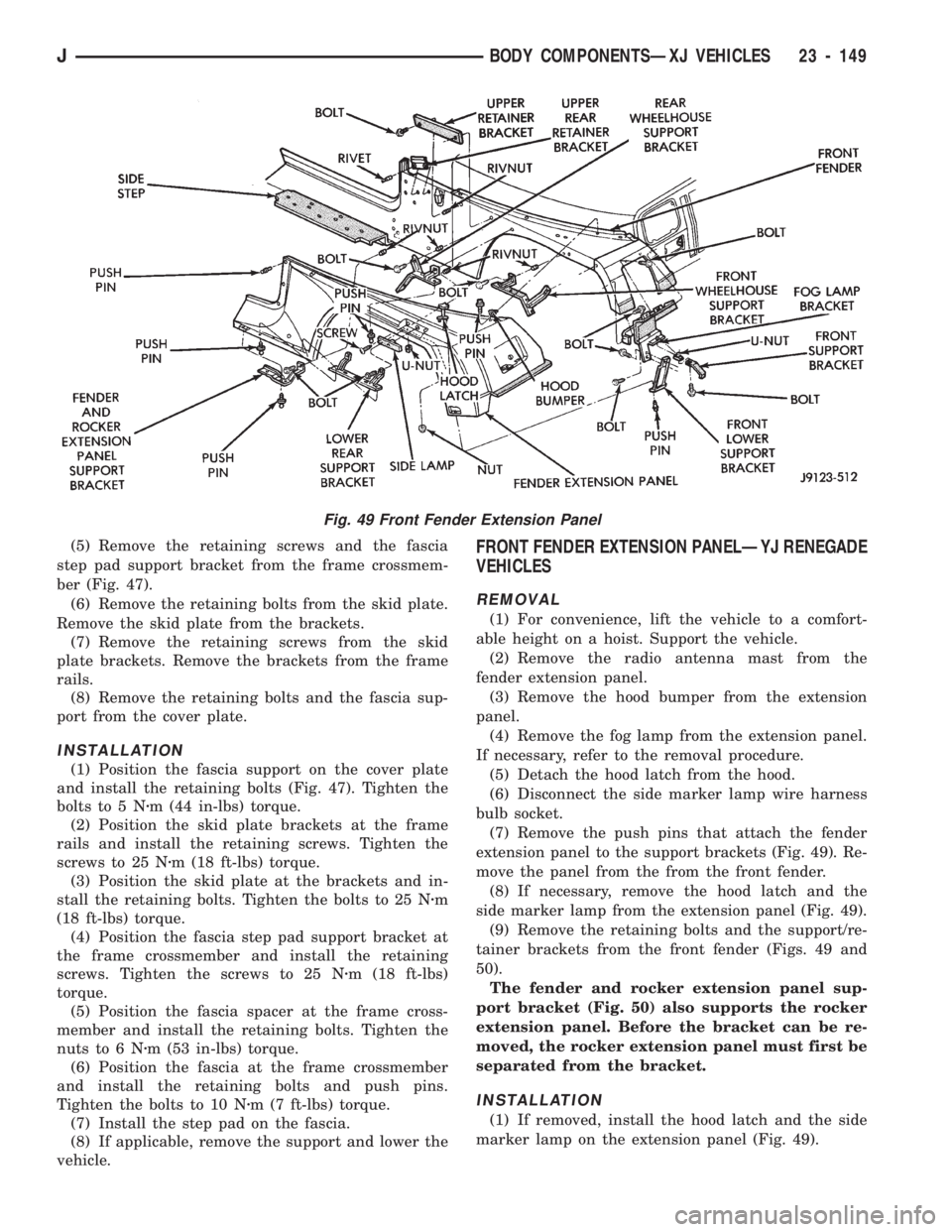

FRONT FENDER EXTENSION PANELÐYJ RENEGADE

VEHICLES

REMOVAL

(1) For convenience, lift the vehicle to a comfort-

able height on a hoist. Support the vehicle.

(2) Remove the radio antenna mast from the

fender extension panel.

(3) Remove the hood bumper from the extension

panel.

(4) Remove the fog lamp from the extension panel.

If necessary, refer to the removal procedure.

(5) Detach the hood latch from the hood.

(6) Disconnect the side marker lamp wire harness

bulb socket.

(7) Remove the push pins that attach the fender

extension panel to the support brackets (Fig. 49). Re-

move the panel from the from the front fender.

(8) If necessary, remove the hood latch and the

side marker lamp from the extension panel (Fig. 49).

(9) Remove the retaining bolts and the support/re-

tainer brackets from the front fender (Figs. 49 and

50).

The fender and rocker extension panel sup-

port bracket (Fig. 50) also supports the rocker

extension panel. Before the bracket can be re-

moved, the rocker extension panel must first be

separated from the bracket.

INSTALLATION

(1) If removed, install the hood latch and the side

marker lamp on the extension panel (Fig. 49).

Fig. 49 Front Fender Extension Panel

JBODY COMPONENTSÐXJ VEHICLES 23 - 149

Page 1605 of 1784

(2) If removed, install the fender and rocker exten-

sion panel support bracket (Fig. 50), and attach the

rocker extension panel to the bracket.

(3) Position the support/retainer brackets on the

front fender and install the retaining bolts. Tighten

the bolts to 10 Nzm (7 ft-lbs) torque.

(4) Position the extension panel on the brackets

and install the push pins (Fig. 49).

(5) Connect the side marker lamp wire harness

bulb socket.

(6) Install the fog lamp in the extension panel. If

necessary, refer to the installation procedure.

(7) Attach the hood latch to the hood.

(8) Install the radio antenna mast.

(9) Install the hood bumper on the extension panel.

(10) If applicable, remove the support and lower

the vehicle.

FOG LAMPÐYJ RENEGADE VEHICLES

REMOVAL

(1) Disconnect the wire harness connector.

(2) Remove the fog lamp retaining nut and washer

from the fog lamp and bracket (Fig. 51).

(3) Remove the bezel retaining screws (Fig. 51).

(4) Remove the fog lamp and the bezel from the

fender extension panel (Fig. 51).

If it is necessary to remove the fog lamp

bracket from the front fender, the fender exten-

sion panel must first be removed.

(5) With the fender extension panel removed, re-

move the fog lamp bracket retaining bolts from the

front fender (Fig. 51).

INSTALLATION

(1) If removed, install the fog lamp bracket and the

retaining bolts on the front fender (Fig. 51). Tighten

the bolts to 10 Nzm (7 ft-lbs) torque.

(2) If removed, install the fender extension panel.

If necessary, refer to the installation procedure.

(3) Position the bezel and the fog lamp in thefender extension panel (Fig. 51).

(4) Install the bezel retaining screws (Fig. 51).

Tighten the screws to 1.5 Nzm (13 in-lbs) torque.

(5) Install the fog lamp washer and retaining nut

on the fog lamp and bracket (Fig. 51). Tighten the

nut to 10 Nzm (7 ft-lbs) torque.

(6) Connect the fog lamp wire harness connector.

ROCKER EXTENSION PANELÐYJ RENEGADE

VEHICLES

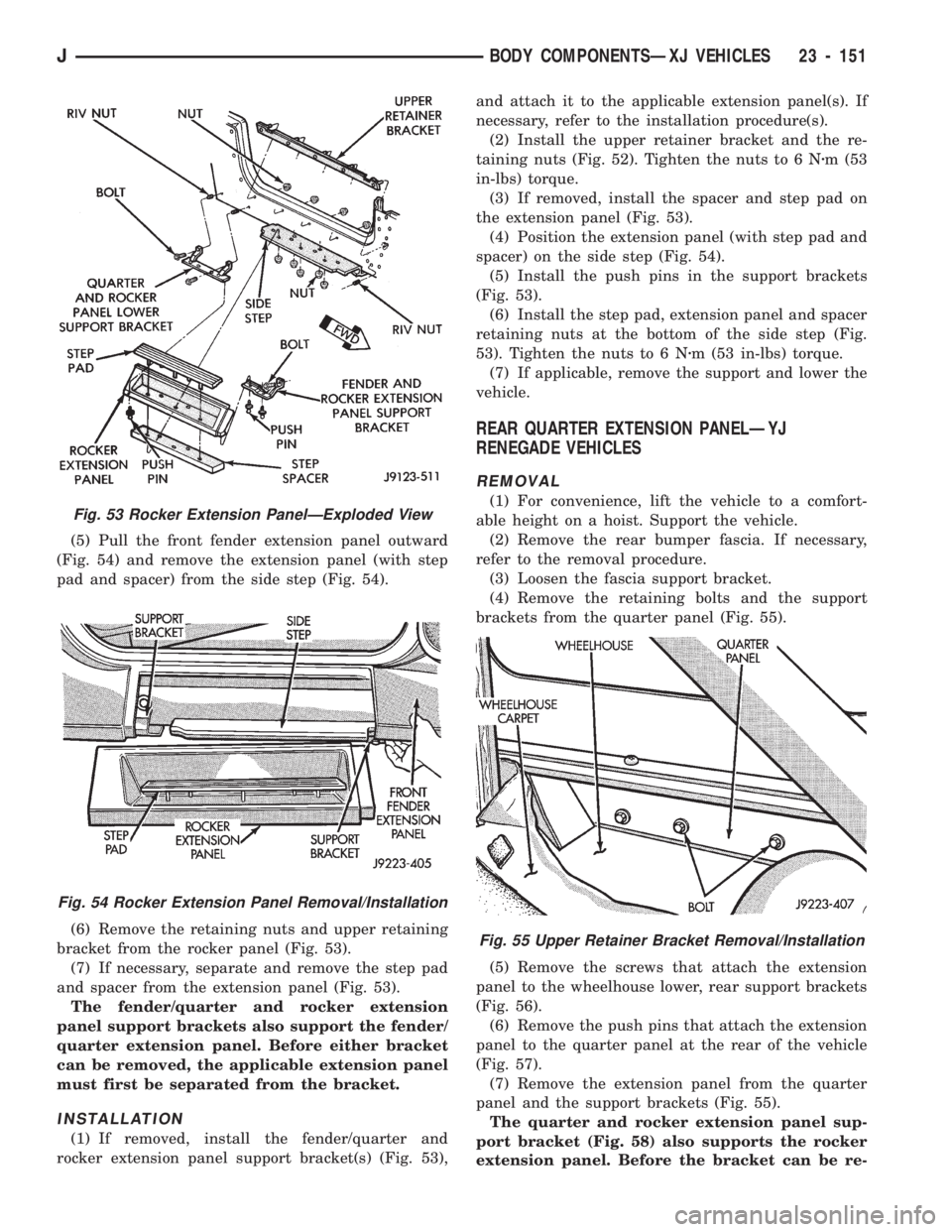

REMOVAL

(1) For convenience, lift the vehicle to a comfort-

able height on a hoist. Support the vehicle.

(2) From inside the vehicle, remove the nuts from

the upper retainer bracket studs (Fig. 52).

(3) Remove the push pins from the support brack-

ets (Fig. 53).

(4) Remove the step pad, extension panel and

spacer retaining nuts from the bottom of the side

step (Fig. 53).

Fig. 50 Front Fender Extension Panel RemovedFig. 51 Fog Lamp Removal/Installation

Fig. 52 Upper Retainer Bracket Stud Nuts Removal/

Installation

23 - 150 BODY COMPONENTSÐXJ VEHICLESJ

Page 1606 of 1784

(5) Pull the front fender extension panel outward

(Fig. 54) and remove the extension panel (with step

pad and spacer) from the side step (Fig. 54).

(6) Remove the retaining nuts and upper retaining

bracket from the rocker panel (Fig. 53).

(7) If necessary, separate and remove the step pad

and spacer from the extension panel (Fig. 53).

The fender/quarter and rocker extension

panel support brackets also support the fender/

quarter extension panel. Before either bracket

can be removed, the applicable extension panel

must first be separated from the bracket.

INSTALLATION

(1) If removed, install the fender/quarter and

rocker extension panel support bracket(s) (Fig. 53),and attach it to the applicable extension panel(s). If

necessary, refer to the installation procedure(s).

(2) Install the upper retainer bracket and the re-

taining nuts (Fig. 52). Tighten the nuts to 6 Nzm (53

in-lbs) torque.

(3) If removed, install the spacer and step pad on

the extension panel (Fig. 53).

(4) Position the extension panel (with step pad and

spacer) on the side step (Fig. 54).

(5) Install the push pins in the support brackets

(Fig. 53).

(6) Install the step pad, extension panel and spacer

retaining nuts at the bottom of the side step (Fig.

53). Tighten the nuts to 6 Nzm (53 in-lbs) torque.

(7) If applicable, remove the support and lower the

vehicle.

REAR QUARTER EXTENSION PANELÐYJ

RENEGADE VEHICLES

REMOVAL

(1) For convenience, lift the vehicle to a comfort-

able height on a hoist. Support the vehicle.

(2) Remove the rear bumper fascia. If necessary,

refer to the removal procedure.

(3) Loosen the fascia support bracket.

(4) Remove the retaining bolts and the support

brackets from the quarter panel (Fig. 55).

(5) Remove the screws that attach the extension

panel to the wheelhouse lower, rear support brackets

(Fig. 56).

(6) Remove the push pins that attach the extension

panel to the quarter panel at the rear of the vehicle

(Fig. 57).

(7) Remove the extension panel from the quarter

panel and the support brackets (Fig. 55).

The quarter and rocker extension panel sup-

port bracket (Fig. 58) also supports the rocker

extension panel. Before the bracket can be re-

Fig. 55 Upper Retainer Bracket Removal/Installation

Fig. 53 Rocker Extension PanelÐExploded View

Fig. 54 Rocker Extension Panel Removal/Installation

JBODY COMPONENTSÐXJ VEHICLES 23 - 151

Page 1622 of 1784

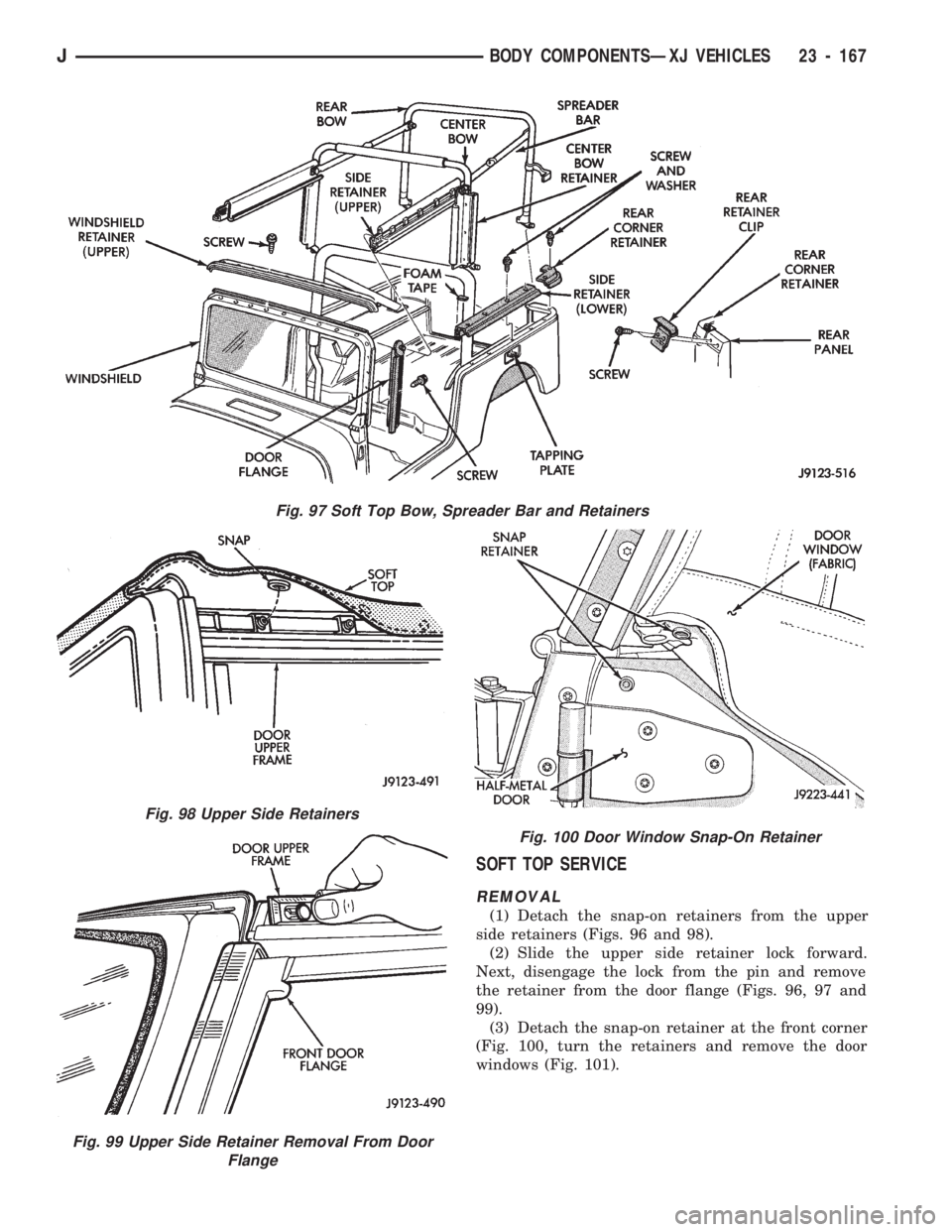

SOFT TOP SERVICE

REMOVAL

(1) Detach the snap-on retainers from the upper

side retainers (Figs. 96 and 98).

(2) Slide the upper side retainer lock forward.

Next, disengage the lock from the pin and remove

the retainer from the door flange (Figs. 96, 97 and

99).

(3) Detach the snap-on retainer at the front corner

(Fig. 100, turn the retainers and remove the door

windows (Fig. 101).

Fig. 97 Soft Top Bow, Spreader Bar and Retainers

Fig. 98 Upper Side Retainers

Fig. 99 Upper Side Retainer Removal From Door

Flange

Fig. 100 Door Window Snap-On Retainer

JBODY COMPONENTSÐXJ VEHICLES 23 - 167

Page 1623 of 1784

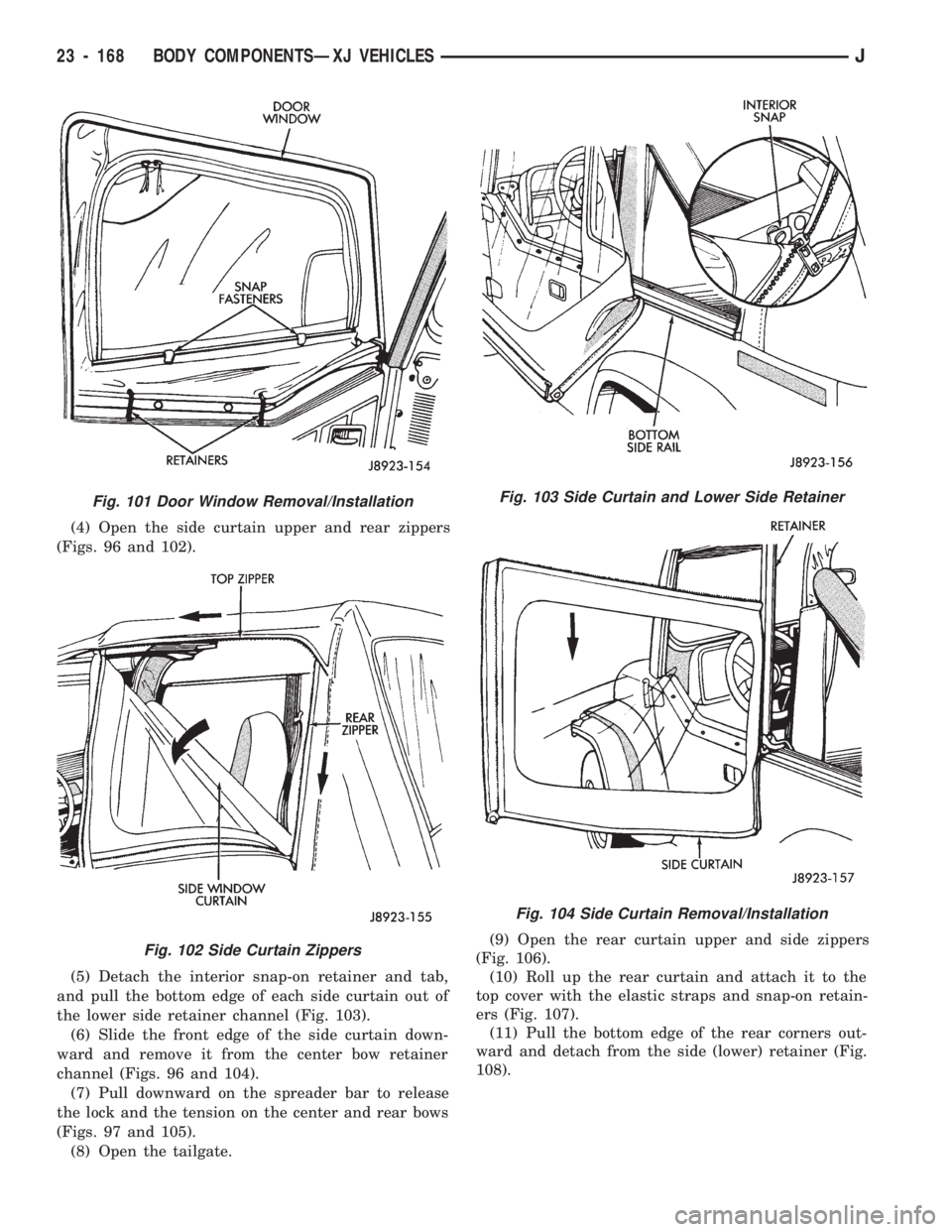

(4) Open the side curtain upper and rear zippers

(Figs. 96 and 102).

(5) Detach the interior snap-on retainer and tab,

and pull the bottom edge of each side curtain out of

the lower side retainer channel (Fig. 103).

(6) Slide the front edge of the side curtain down-

ward and remove it from the center bow retainer

channel (Figs. 96 and 104).

(7) Pull downward on the spreader bar to release

the lock and the tension on the center and rear bows

(Figs. 97 and 105).

(8) Open the tailgate.(9) Open the rear curtain upper and side zippers

(Fig. 106).

(10) Roll up the rear curtain and attach it to the

top cover with the elastic straps and snap-on retain-

ers (Fig. 107).

(11) Pull the bottom edge of the rear corners out-

ward and detach from the side (lower) retainer (Fig.

108).

Fig. 101 Door Window Removal/Installation

Fig. 102 Side Curtain Zippers

Fig. 103 Side Curtain and Lower Side Retainer

Fig. 104 Side Curtain Removal/Installation

23 - 168 BODY COMPONENTSÐXJ VEHICLESJ

Page 1626 of 1784

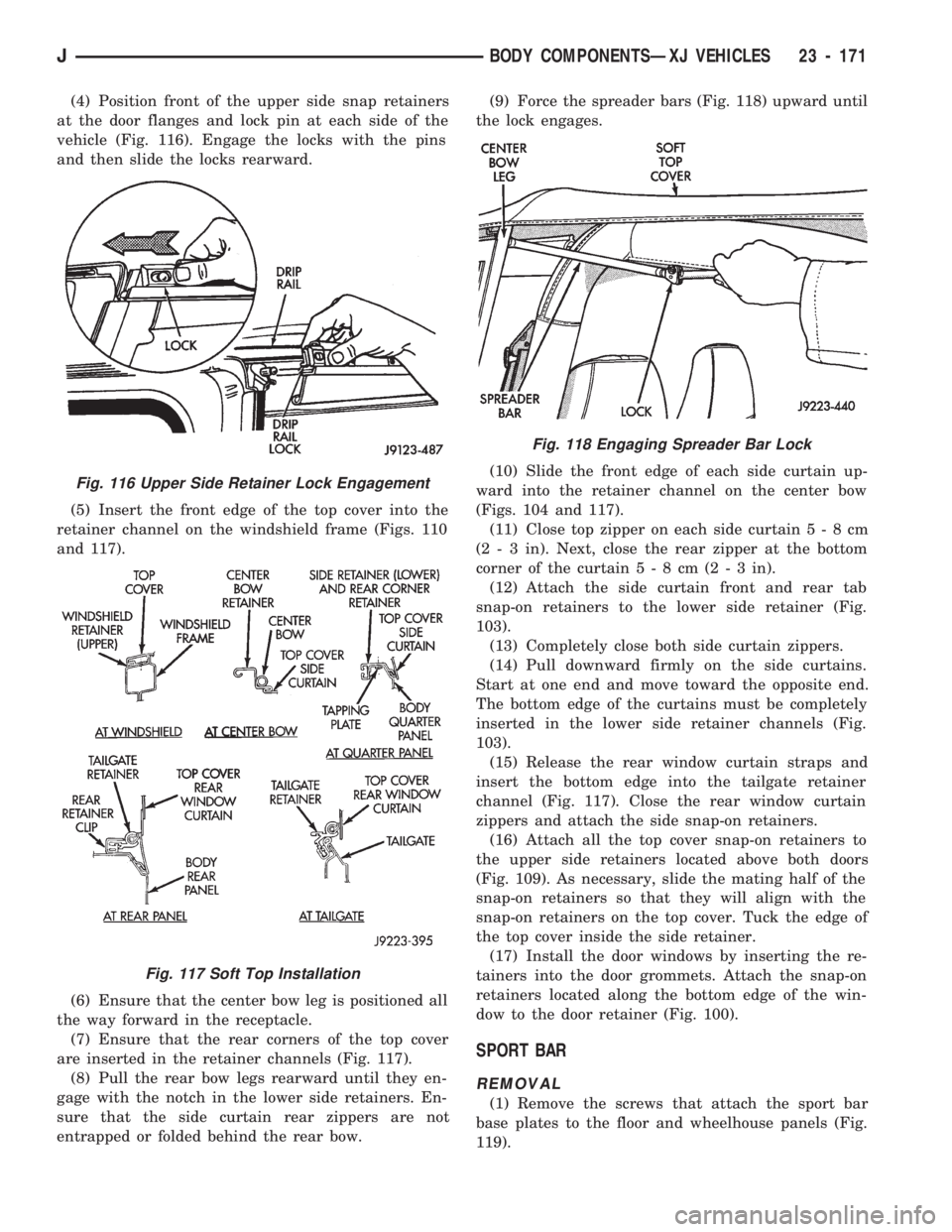

(4) Position front of the upper side snap retainers

at the door flanges and lock pin at each side of the

vehicle (Fig. 116). Engage the locks with the pins

and then slide the locks rearward.

(5) Insert the front edge of the top cover into the

retainer channel on the windshield frame (Figs. 110

and 117).

(6) Ensure that the center bow leg is positioned all

the way forward in the receptacle.

(7) Ensure that the rear corners of the top cover

are inserted in the retainer channels (Fig. 117).

(8) Pull the rear bow legs rearward until they en-

gage with the notch in the lower side retainers. En-

sure that the side curtain rear zippers are not

entrapped or folded behind the rear bow.(9) Force the spreader bars (Fig. 118) upward until

the lock engages.

(10) Slide the front edge of each side curtain up-

ward into the retainer channel on the center bow

(Figs. 104 and 117).

(11) Close top zipper on each side curtain5-8cm

(2 - 3 in). Next, close the rear zipper at the bottom

corner of the curtain5-8cm(2-3in).

(12) Attach the side curtain front and rear tab

snap-on retainers to the lower side retainer (Fig.

103).

(13) Completely close both side curtain zippers.

(14) Pull downward firmly on the side curtains.

Start at one end and move toward the opposite end.

The bottom edge of the curtains must be completely

inserted in the lower side retainer channels (Fig.

103).

(15) Release the rear window curtain straps and

insert the bottom edge into the tailgate retainer

channel (Fig. 117). Close the rear window curtain

zippers and attach the side snap-on retainers.

(16) Attach all the top cover snap-on retainers to

the upper side retainers located above both doors

(Fig. 109). As necessary, slide the mating half of the

snap-on retainers so that they will align with the

snap-on retainers on the top cover. Tuck the edge of

the top cover inside the side retainer.

(17) Install the door windows by inserting the re-

tainers into the door grommets. Attach the snap-on

retainers located along the bottom edge of the win-

dow to the door retainer (Fig. 100).

SPORT BAR

REMOVAL

(1) Remove the screws that attach the sport bar

base plates to the floor and wheelhouse panels (Fig.

119).

Fig. 116 Upper Side Retainer Lock Engagement

Fig. 117 Soft Top Installation

Fig. 118 Engaging Spreader Bar Lock

JBODY COMPONENTSÐXJ VEHICLES 23 - 171

Page 1632 of 1784

REMOVAL/INSTALLATION

(1) To remove a waterdam, insert a putty knife be-

tween it and the door inner panel.

(2) When installing a waterdam, ensure that lower

portion of waterdam is tucked inside the door panel

at the access opening.

FULL-METAL DOOR VENT WINDOW GLASS

REMOVAL

(1) Remove the door trim panel and the waterdam

(Figs. 8 and 9).

(2) Lower the door window glass to the ``down-

stop''.

(3) Remove the division channel upper attaching

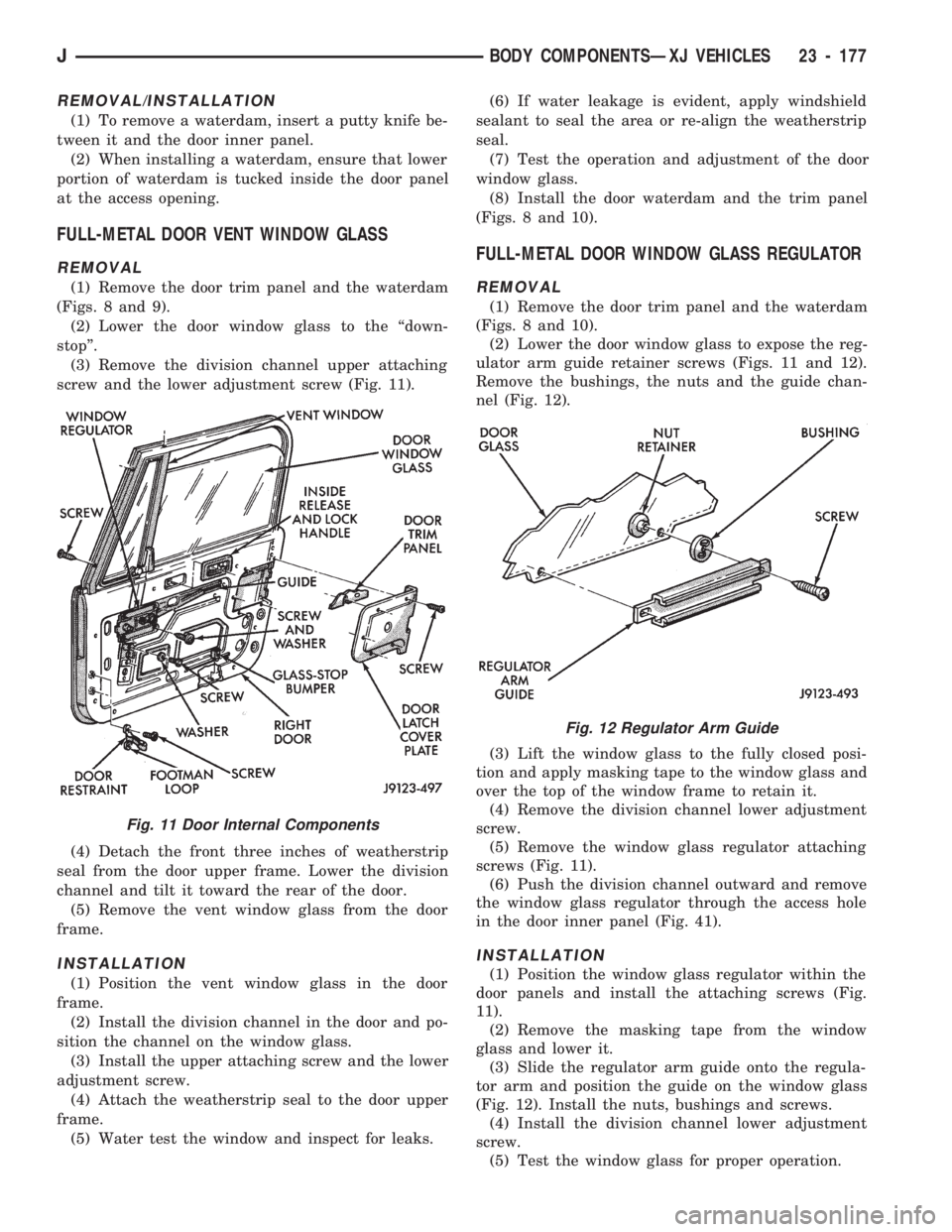

screw and the lower adjustment screw (Fig. 11).

(4) Detach the front three inches of weatherstrip

seal from the door upper frame. Lower the division

channel and tilt it toward the rear of the door.

(5) Remove the vent window glass from the door

frame.

INSTALLATION

(1) Position the vent window glass in the door

frame.

(2) Install the division channel in the door and po-

sition the channel on the window glass.

(3) Install the upper attaching screw and the lower

adjustment screw.

(4) Attach the weatherstrip seal to the door upper

frame.

(5) Water test the window and inspect for leaks.(6) If water leakage is evident, apply windshield

sealant to seal the area or re-align the weatherstrip

seal.

(7) Test the operation and adjustment of the door

window glass.

(8) Install the door waterdam and the trim panel

(Figs. 8 and 10).

FULL-METAL DOOR WINDOW GLASS REGULATOR

REMOVAL

(1) Remove the door trim panel and the waterdam

(Figs. 8 and 10).

(2) Lower the door window glass to expose the reg-

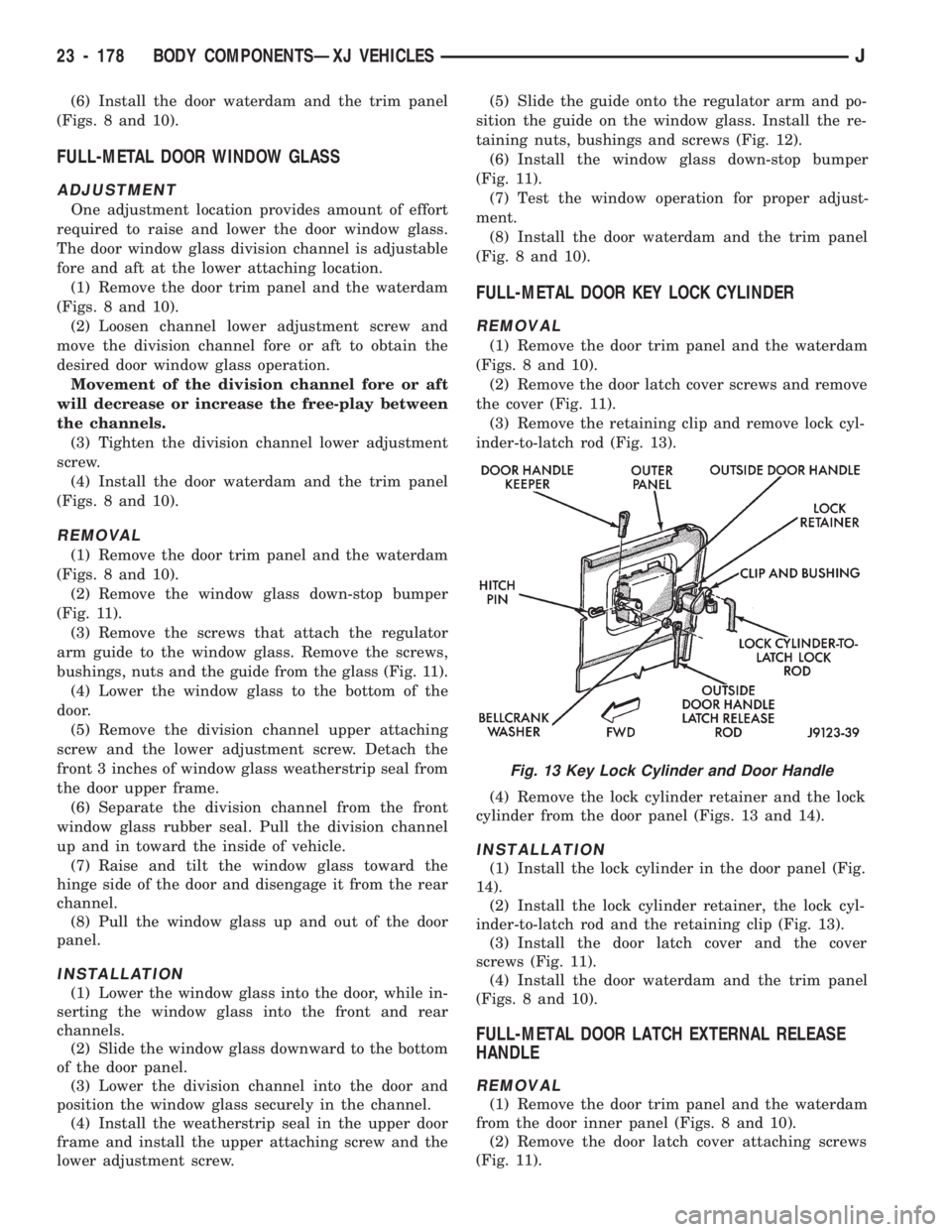

ulator arm guide retainer screws (Figs. 11 and 12).

Remove the bushings, the nuts and the guide chan-

nel (Fig. 12).

(3) Lift the window glass to the fully closed posi-

tion and apply masking tape to the window glass and

over the top of the window frame to retain it.

(4) Remove the division channel lower adjustment

screw.

(5) Remove the window glass regulator attaching

screws (Fig. 11).

(6) Push the division channel outward and remove

the window glass regulator through the access hole

in the door inner panel (Fig. 41).

INSTALLATION

(1) Position the window glass regulator within the

door panels and install the attaching screws (Fig.

11).

(2) Remove the masking tape from the window

glass and lower it.

(3) Slide the regulator arm guide onto the regula-

tor arm and position the guide on the window glass

(Fig. 12). Install the nuts, bushings and screws.

(4) Install the division channel lower adjustment

screw.

(5) Test the window glass for proper operation.

Fig. 11 Door Internal Components

Fig. 12 Regulator Arm Guide

JBODY COMPONENTSÐXJ VEHICLES 23 - 177

Page 1633 of 1784

(6) Install the door waterdam and the trim panel

(Figs. 8 and 10).

FULL-METAL DOOR WINDOW GLASS

ADJUSTMENT

One adjustment location provides amount of effort

required to raise and lower the door window glass.

The door window glass division channel is adjustable

fore and aft at the lower attaching location.

(1) Remove the door trim panel and the waterdam

(Figs. 8 and 10).

(2) Loosen channel lower adjustment screw and

move the division channel fore or aft to obtain the

desired door window glass operation.

Movement of the division channel fore or aft

will decrease or increase the free-play between

the channels.

(3) Tighten the division channel lower adjustment

screw.

(4) Install the door waterdam and the trim panel

(Figs. 8 and 10).

REMOVAL

(1) Remove the door trim panel and the waterdam

(Figs. 8 and 10).

(2) Remove the window glass down-stop bumper

(Fig. 11).

(3) Remove the screws that attach the regulator

arm guide to the window glass. Remove the screws,

bushings, nuts and the guide from the glass (Fig. 11).

(4) Lower the window glass to the bottom of the

door.

(5) Remove the division channel upper attaching

screw and the lower adjustment screw. Detach the

front 3 inches of window glass weatherstrip seal from

the door upper frame.

(6) Separate the division channel from the front

window glass rubber seal. Pull the division channel

up and in toward the inside of vehicle.

(7) Raise and tilt the window glass toward the

hinge side of the door and disengage it from the rear

channel.

(8) Pull the window glass up and out of the door

panel.

INSTALLATION

(1) Lower the window glass into the door, while in-

serting the window glass into the front and rear

channels.

(2) Slide the window glass downward to the bottom

of the door panel.

(3) Lower the division channel into the door and

position the window glass securely in the channel.

(4) Install the weatherstrip seal in the upper door

frame and install the upper attaching screw and the

lower adjustment screw.(5) Slide the guide onto the regulator arm and po-

sition the guide on the window glass. Install the re-

taining nuts, bushings and screws (Fig. 12).

(6) Install the window glass down-stop bumper

(Fig. 11).

(7) Test the window operation for proper adjust-

ment.

(8) Install the door waterdam and the trim panel

(Fig. 8 and 10).

FULL-METAL DOOR KEY LOCK CYLINDER

REMOVAL

(1) Remove the door trim panel and the waterdam

(Figs. 8 and 10).

(2) Remove the door latch cover screws and remove

the cover (Fig. 11).

(3) Remove the retaining clip and remove lock cyl-

inder-to-latch rod (Fig. 13).

(4) Remove the lock cylinder retainer and the lock

cylinder from the door panel (Figs. 13 and 14).

INSTALLATION

(1) Install the lock cylinder in the door panel (Fig.

14).

(2) Install the lock cylinder retainer, the lock cyl-

inder-to-latch rod and the retaining clip (Fig. 13).

(3) Install the door latch cover and the cover

screws (Fig. 11).

(4) Install the door waterdam and the trim panel

(Figs. 8 and 10).

FULL-METAL DOOR LATCH EXTERNAL RELEASE

HANDLE

REMOVAL

(1) Remove the door trim panel and the waterdam

from the door inner panel (Figs. 8 and 10).

(2) Remove the door latch cover attaching screws

(Fig. 11).

Fig. 13 Key Lock Cylinder and Door Handle

23 - 178 BODY COMPONENTSÐXJ VEHICLESJ