front JEEP CHEROKEE 1994 Service Repair Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 1994, Model line: CHEROKEE, Model: JEEP CHEROKEE 1994Pages: 1784, PDF Size: 77.09 MB

Page 1515 of 1784

92). Be careful not to bend the hinge when driving

the hinge pin, support may be required under the

hinge.

(8) Adjust/align latch striker and latch as neces-

sary.(9) Install the door restraint (check) retaining pin

with a punch.

FRONT DOOR SPACER BLOCKSÐTWO-DOOR

VEHICLES

REMOVAL

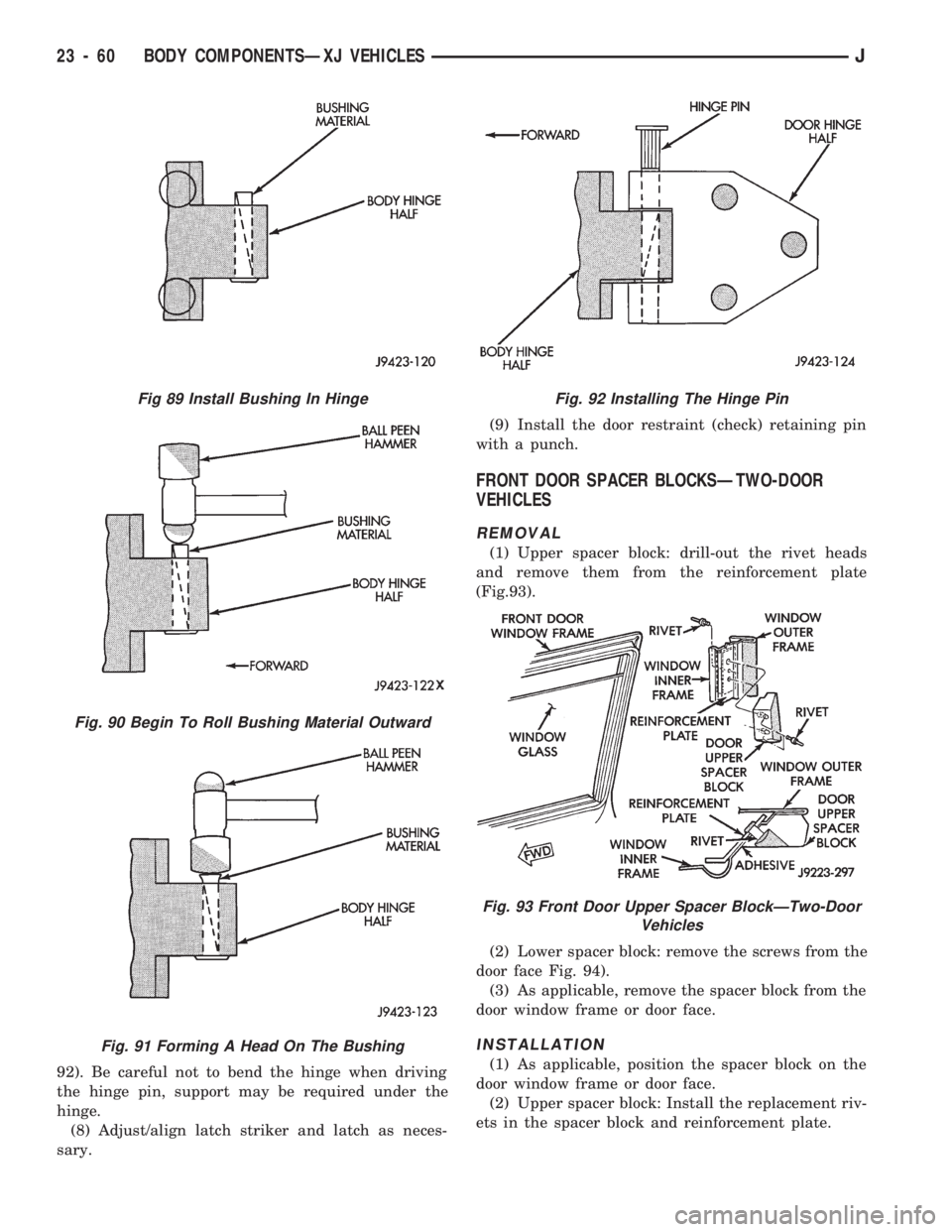

(1) Upper spacer block: drill-out the rivet heads

and remove them from the reinforcement plate

(Fig.93).

(2) Lower spacer block: remove the screws from the

door face Fig. 94).

(3) As applicable, remove the spacer block from the

door window frame or door face.

INSTALLATION

(1) As applicable, position the spacer block on the

door window frame or door face.

(2) Upper spacer block: Install the replacement riv-

ets in the spacer block and reinforcement plate.

Fig 89 Install Bushing In Hinge

Fig. 90 Begin To Roll Bushing Material Outward

Fig. 91 Forming A Head On The Bushing

Fig. 92 Installing The Hinge Pin

Fig. 93 Front Door Upper Spacer BlockÐTwo-Door

Vehicles

23 - 60 BODY COMPONENTSÐXJ VEHICLESJ

Page 1516 of 1784

(3) Lower spacer block: install the screws in the

door face. Tighten the screws to 1 Nzm (11 in-lbs)

torque.

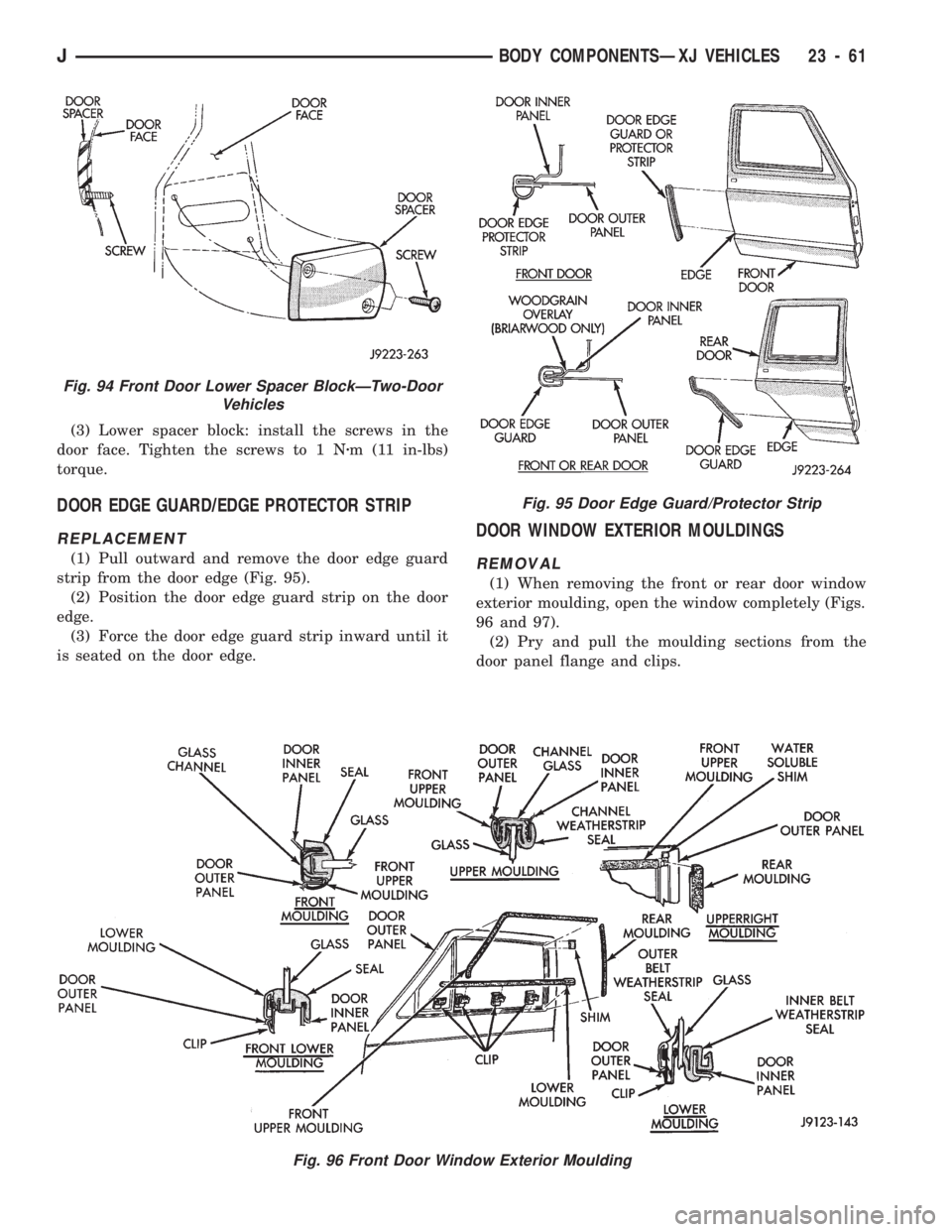

DOOR EDGE GUARD/EDGE PROTECTOR STRIP

REPLACEMENT

(1) Pull outward and remove the door edge guard

strip from the door edge (Fig. 95).

(2) Position the door edge guard strip on the door

edge.

(3) Force the door edge guard strip inward until it

is seated on the door edge.

DOOR WINDOW EXTERIOR MOULDINGS

REMOVAL

(1) When removing the front or rear door window

exterior moulding, open the window completely (Figs.

96 and 97).

(2) Pry and pull the moulding sections from the

door panel flange and clips.

Fig. 95 Door Edge Guard/Protector Strip

Fig. 96 Front Door Window Exterior Moulding

Fig. 94 Front Door Lower Spacer BlockÐTwo-Door

Vehicles

JBODY COMPONENTSÐXJ VEHICLES 23 - 61

Page 1517 of 1784

INSTALLATION

(1) When installing window mouldings, start at

the forward end of the upper moulding.

(2) Force the moulding onto the door panel and con-

tinue rearward until it is completely seated on the

flange.

(3) Mate the rear moulding with the upper mould-

ing and force the moulding edge inward.

(4) Continue pressing and moving downward to

complete the installation.

(5) Position the lower moulding on the clips and

force it downward.

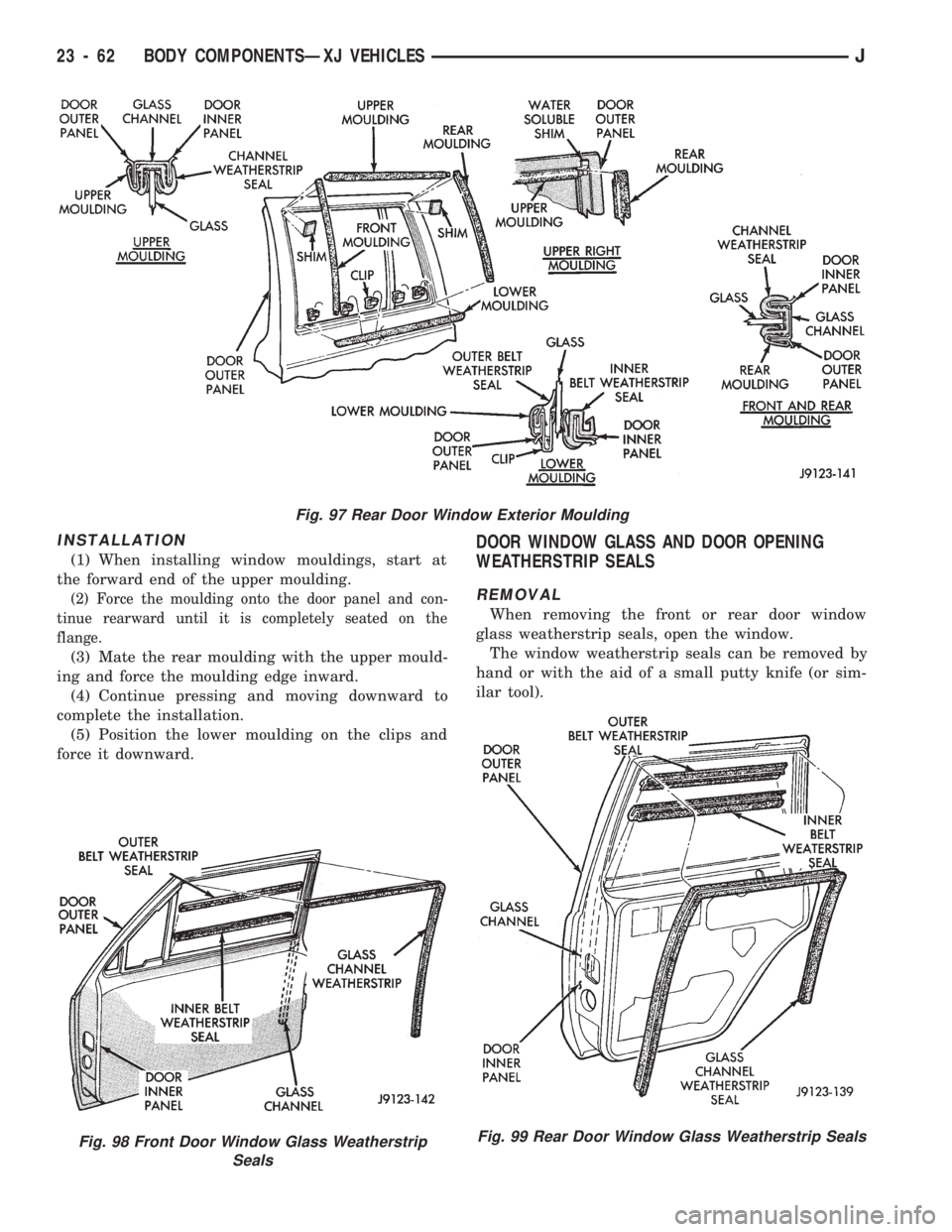

DOOR WINDOW GLASS AND DOOR OPENING

WEATHERSTRIP SEALS

REMOVAL

When removing the front or rear door window

glass weatherstrip seals, open the window.

The window weatherstrip seals can be removed by

hand or with the aid of a small putty knife (or sim-

ilar tool).

Fig. 97 Rear Door Window Exterior Moulding

Fig. 98 Front Door Window Glass Weatherstrip

SealsFig. 99 Rear Door Window Glass Weatherstrip Seals

23 - 62 BODY COMPONENTSÐXJ VEHICLESJ

Page 1518 of 1784

The door opening weatherstrip seal is attached to

the periphery of the door opening in the body. The

retaining push-studs can be removed with an appro-

priate pry tool. The front door secondary seal is at-

tached to the A-pillar with plastic blind rivets (Fig.

100).

The door-to-rocker panel seals are attached to the

door inner panels with rivets (Fig. 101). The rivets

can be removed with an appropriate pry tool.WINDOW GLASS WEATHERSTRIP SEAL

INSTALLATION

When installing front or rear door window glass

weatherstrip seals, open the window completely.

(1) To install a front door window glass channel

weatherstrip seal, start at the upper, rear corner

(Fig. 102).

(2) To install a rear door window glass channel

weatherstrip seal, start at the upper, front corner

(Fig. 103).

(3) A small amount of adhesive can be used to hold

the weatherstrip seal in-place, if necessary.

(4) As applicable, move forward or rearward and

downward evenly until the weatherstrip seal is fully

seated in the channel.

Fig. 100 Door Opening Weatherstrip Seals

Fig. 101 Door-To-Rocker Panel Seals

Fig. 102 Front Door Window Glass Channel

Weatherstrip Seal

Fig. 103 Rear Door Window Glass Channel

Weatherstrip Seal

JBODY COMPONENTSÐXJ VEHICLES 23 - 63

Page 1519 of 1784

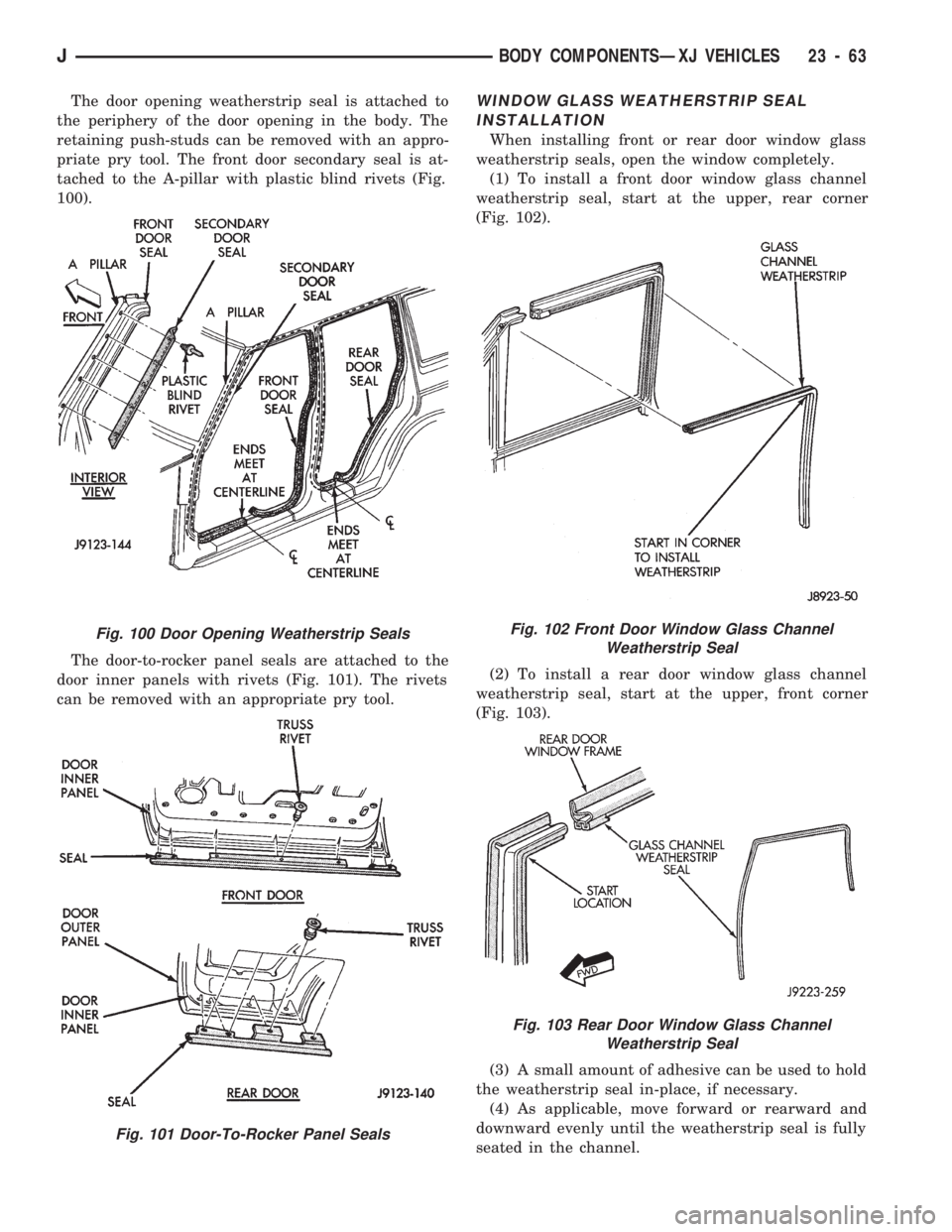

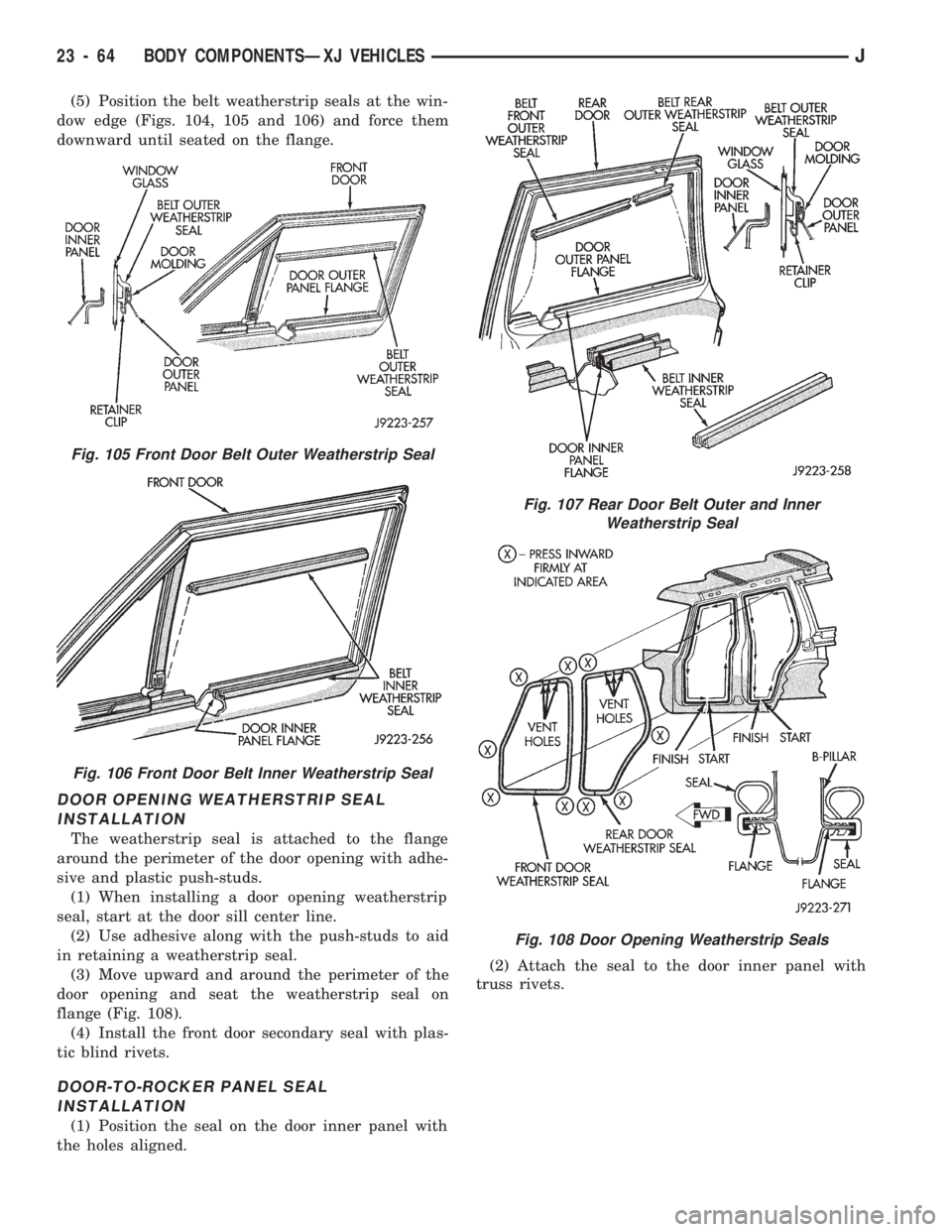

(5) Position the belt weatherstrip seals at the win-

dow edge (Figs. 104, 105 and 106) and force them

downward until seated on the flange.

DOOR OPENING WEATHERSTRIP SEAL

INSTALLATION

The weatherstrip seal is attached to the flange

around the perimeter of the door opening with adhe-

sive and plastic push-studs.

(1) When installing a door opening weatherstrip

seal, start at the door sill center line.

(2) Use adhesive along with the push-studs to aid

in retaining a weatherstrip seal.

(3) Move upward and around the perimeter of the

door opening and seat the weatherstrip seal on

flange (Fig. 108).

(4) Install the front door secondary seal with plas-

tic blind rivets.

DOOR-TO-ROCKER PANEL SEAL

INSTALLATION

(1) Position the seal on the door inner panel with

the holes aligned.(2) Attach the seal to the door inner panel with

truss rivets.

Fig. 105 Front Door Belt Outer Weatherstrip Seal

Fig. 106 Front Door Belt Inner Weatherstrip Seal

Fig. 107 Rear Door Belt Outer and Inner

Weatherstrip Seal

Fig. 108 Door Opening Weatherstrip Seals

23 - 64 BODY COMPONENTSÐXJ VEHICLESJ

Page 1539 of 1784

UNDERBODY COMPONENTS

INDEX

page page

Catalytic Converter/Muffler/Tailpipe Support

Brackets............................. 85

Front Skid Plate......................... 84

Fuel and Brake Fluid Tube Retainer Clip....... 86

Fuel Filler Hose Splash ShieldÐXJ Vehicles.... 86

Fuel Filter Bracket........................ 86Fuel Tank Skid Plate...................... 84

Fuel Tank Support Strap................... 86

Rear Tow HookÐXJ Vehicles............... 87

Service Information....................... 84

Trailer Hitches........................... 88

Transfer Case Skid Plate.................. 84

SERVICE INFORMATION

In some cases, components in the following proce-

dures either support, or are concealed by other com-

ponents. When necessary, refer to component

removal procedure for service access.

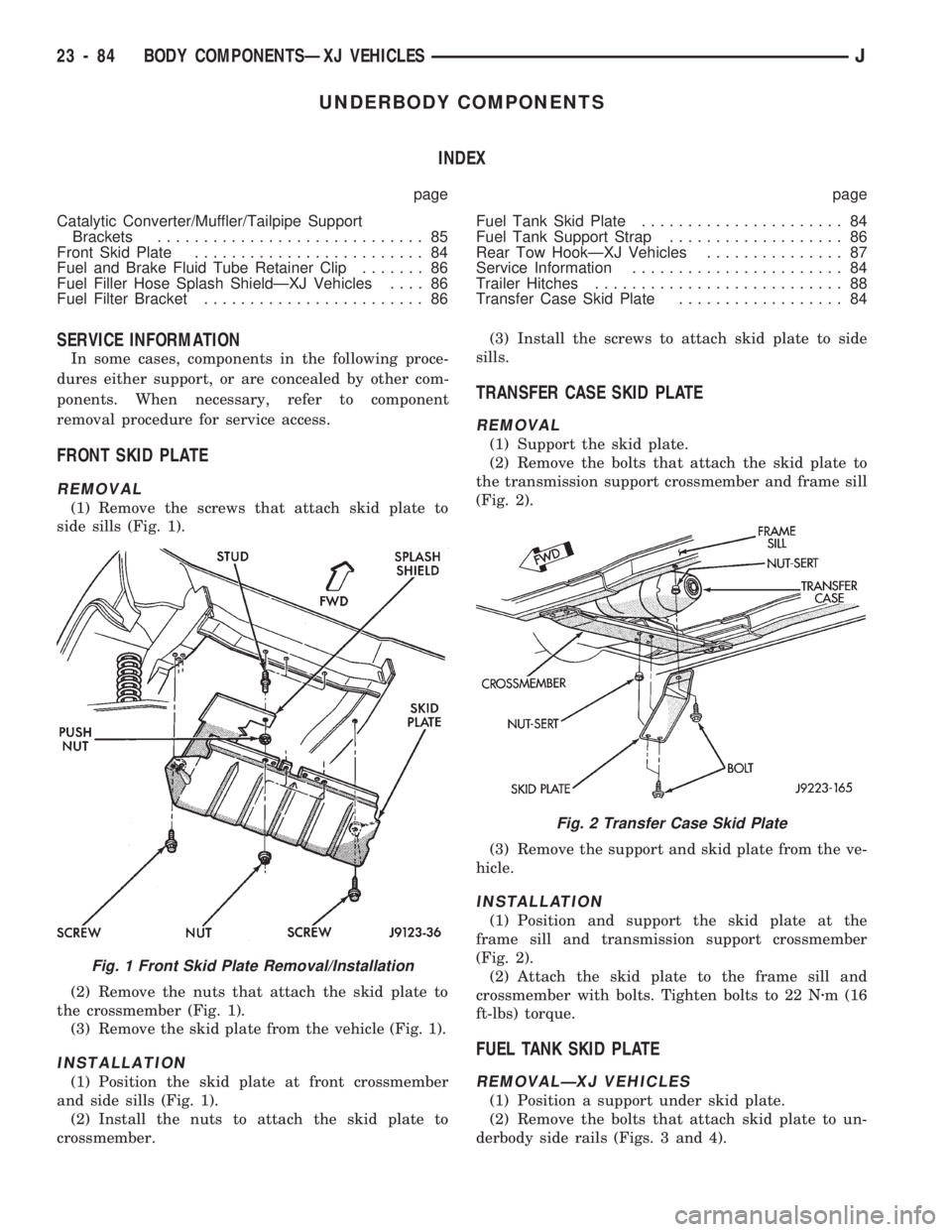

FRONT SKID PLATE

REMOVAL

(1) Remove the screws that attach skid plate to

side sills (Fig. 1).

(2) Remove the nuts that attach the skid plate to

the crossmember (Fig. 1).

(3) Remove the skid plate from the vehicle (Fig. 1).

INSTALLATION

(1) Position the skid plate at front crossmember

and side sills (Fig. 1).

(2) Install the nuts to attach the skid plate to

crossmember.(3) Install the screws to attach skid plate to side

sills.

TRANSFER CASE SKID PLATE

REMOVAL

(1) Support the skid plate.

(2) Remove the bolts that attach the skid plate to

the transmission support crossmember and frame sill

(Fig. 2).

(3) Remove the support and skid plate from the ve-

hicle.

INSTALLATION

(1) Position and support the skid plate at the

frame sill and transmission support crossmember

(Fig. 2).

(2) Attach the skid plate to the frame sill and

crossmember with bolts. Tighten bolts to 22 Nzm (16

ft-lbs) torque.

FUEL TANK SKID PLATE

REMOVALÐXJ VEHICLES

(1) Position a support under skid plate.

(2) Remove the bolts that attach skid plate to un-

derbody side rails (Figs. 3 and 4).

Fig. 1 Front Skid Plate Removal/Installation

Fig. 2 Transfer Case Skid Plate

23 - 84 BODY COMPONENTSÐXJ VEHICLESJ

Page 1546 of 1784

INTERIOR COMPONENTS

INDEX

page page

Assist HandleÐXJ Vehicles................ 118

B/C-Pillar and Liftgate Pillar Trim CoversÐ

XJ Vehicles.......................... 116

Bucket Seat Cushion and Cover............. 98

Bucket Seat Platform and Tracks........... 105

Bucket Seatback Cover and Frame.......... 100

Bucket Seatback Reconditioning............ 102

Carpets and Floor Mats................... 129

Dash Panel Insulation Panel................ 95

Front Bucket Seats....................... 97

Front Carpet/MatÐXJ Vehicles............. 129

Front Inner Scuff Plate/Cowl Side Trim PanelÐ

XJ Vehicles.......................... 114

Front Shoulder Belt/BuckleÐXJ Vehicles...... 119

Full Floor ConsoleÐXJ Vehicles............ 125

Headliner.............................. 121

I/P Ash Receiver Tray Lamp................ 92

I/P Tweeter Speaker/Courtesy Lamp Support

Bracket.............................. 95

Instrument Cluster Bezel................... 91

Instrument Cluster/Switch/Lighter/Radio/Hevac . . . 91

Instrument Panel......................... 93

Interior Trim Panels and Scuff PlatesÐXJ Vehicles. 112

Jack StorageÐXJ Vehicles................ 127

Mini-Floor ConsoleÐXJ Vehicles............ 124

Outer Scuff PlatesÐXJ Vehicles............ 118

Power Bucket Seat Components............ 106

Quarter and Wheelhouse Trim PanelsÐ

XJ Vehicles.......................... 115

Quarter Trim Panel ExtensionÐXJ Vehicles . . . 115

Rear Carpet/MatÐXJ Vehicles.............. 130

Rear Seat Cushion CoverÐXJ Vehicles...... 107

Rear Seat Cushion ReconditioningÐXJ Vehicles . 108

Rear Seat CushionÐXJ Vehicles............ 107

Rear Seatback CoverÐXJ Vehicles.......... 111

Rear Seatback Latch Striker and BumperÐ

XJ Vehicles.......................... 111

Rear Seatback ReconditioningÐXJ Vehicles . . . 111

Rear SeatbackÐXJ Vehicles............... 109

Rear Shoulder/Lap Belt/BuckleÐXJ Vehicles . . . 120

Spare Tire/Wheel Holddown and Floor BracketsÐ

XJ Vehicles.......................... 128

Sunvisors............................. 124

Windshield Side MouldingÐXJ Vehicles...... 114

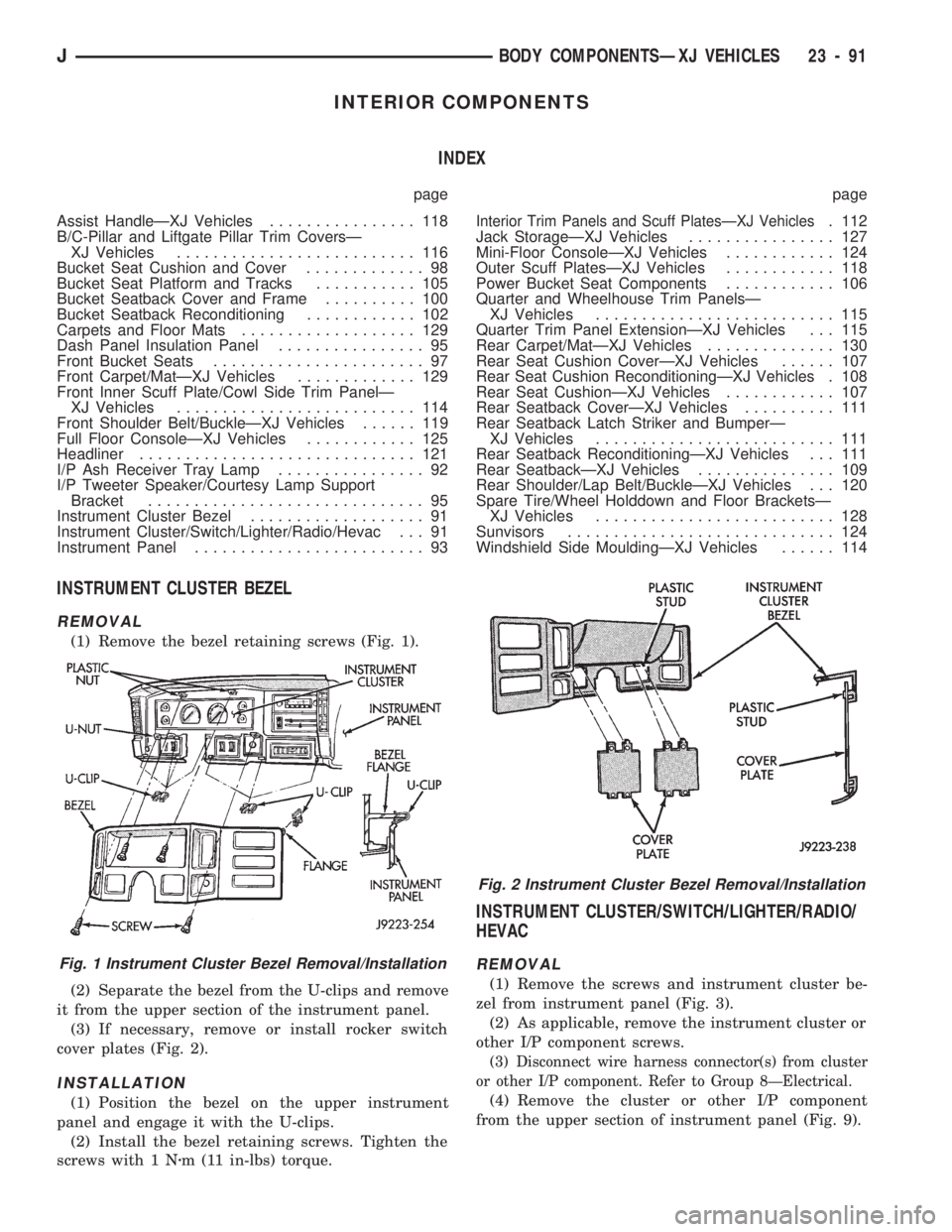

INSTRUMENT CLUSTER BEZEL

REMOVAL

(1) Remove the bezel retaining screws (Fig. 1).

(2) Separate the bezel from the U-clips and remove

it from the upper section of the instrument panel.

(3) If necessary, remove or install rocker switch

cover plates (Fig. 2).

INSTALLATION

(1) Position the bezel on the upper instrument

panel and engage it with the U-clips.

(2) Install the bezel retaining screws. Tighten the

screws with 1 Nzm (11 in-lbs) torque.

INSTRUMENT CLUSTER/SWITCH/LIGHTER/RADIO/

HEVAC

REMOVAL

(1) Remove the screws and instrument cluster be-

zel from instrument panel (Fig. 3).

(2) As applicable, remove the instrument cluster or

other I/P component screws.

(3) Disconnect wire harness connector(s) from cluster

or other I/P component. Refer to Group 8ÐElectrical.

(4) Remove the cluster or other I/P component

from the upper section of instrument panel (Fig. 9).

Fig. 1 Instrument Cluster Bezel Removal/Installation

Fig. 2 Instrument Cluster Bezel Removal/Installation

JBODY COMPONENTSÐXJ VEHICLES 23 - 91

Page 1552 of 1784

(5) Install the defroster tubes on the ducts.

(6) Install the instrument panel on the dash panel.

If necessary, refer to the installation procedure.

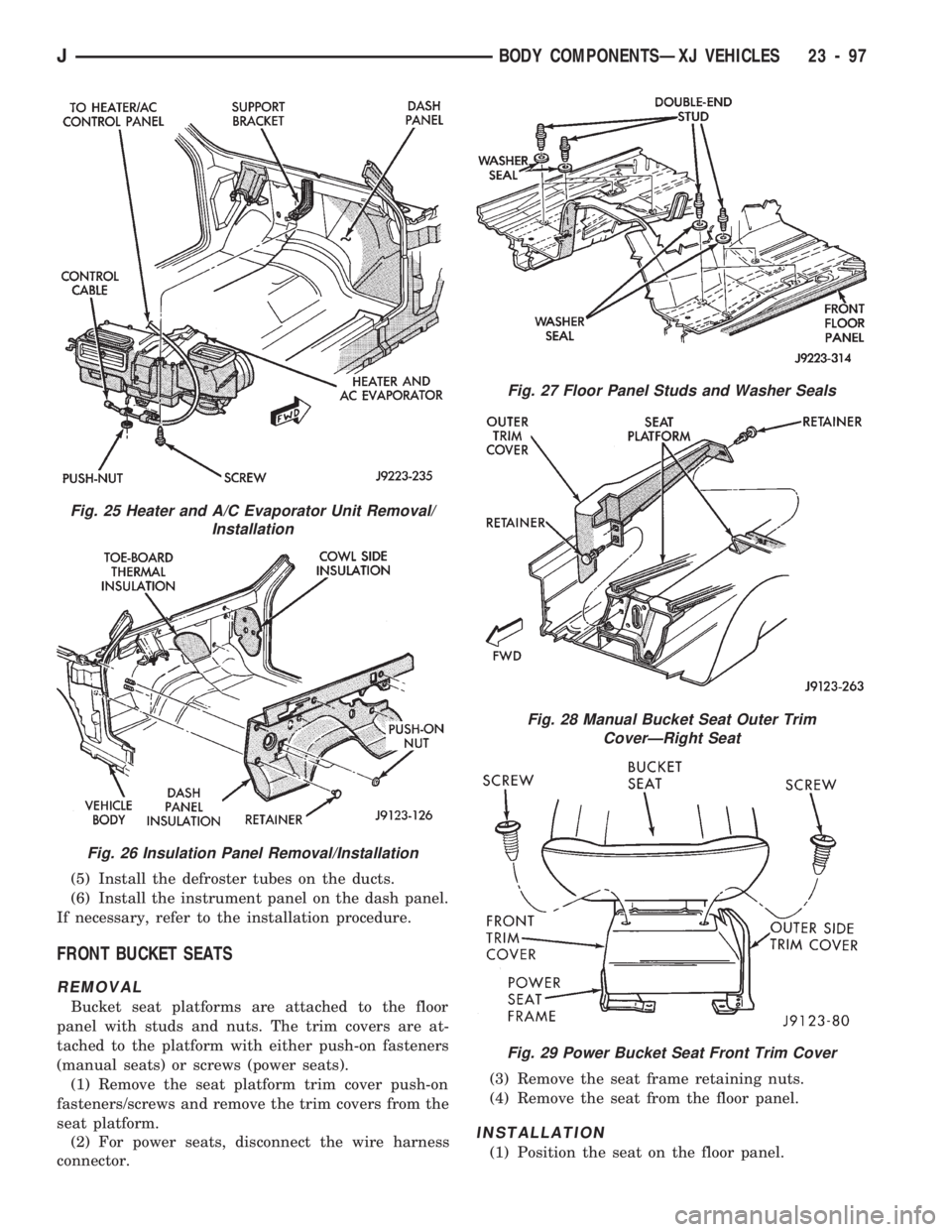

FRONT BUCKET SEATS

REMOVAL

Bucket seat platforms are attached to the floor

panel with studs and nuts. The trim covers are at-

tached to the platform with either push-on fasteners

(manual seats) or screws (power seats).

(1) Remove the seat platform trim cover push-on

fasteners/screws and remove the trim covers from the

seat platform.

(2) For power seats, disconnect the wire harness

connector.(3) Remove the seat frame retaining nuts.

(4) Remove the seat from the floor panel.

INSTALLATION

(1) Position the seat on the floor panel.

Fig. 25 Heater and A/C Evaporator Unit Removal/

Installation

Fig. 26 Insulation Panel Removal/Installation

Fig. 27 Floor Panel Studs and Washer Seals

Fig. 28 Manual Bucket Seat Outer Trim

CoverÐRight Seat

Fig. 29 Power Bucket Seat Front Trim Cover

JBODY COMPONENTSÐXJ VEHICLES 23 - 97

Page 1556 of 1784

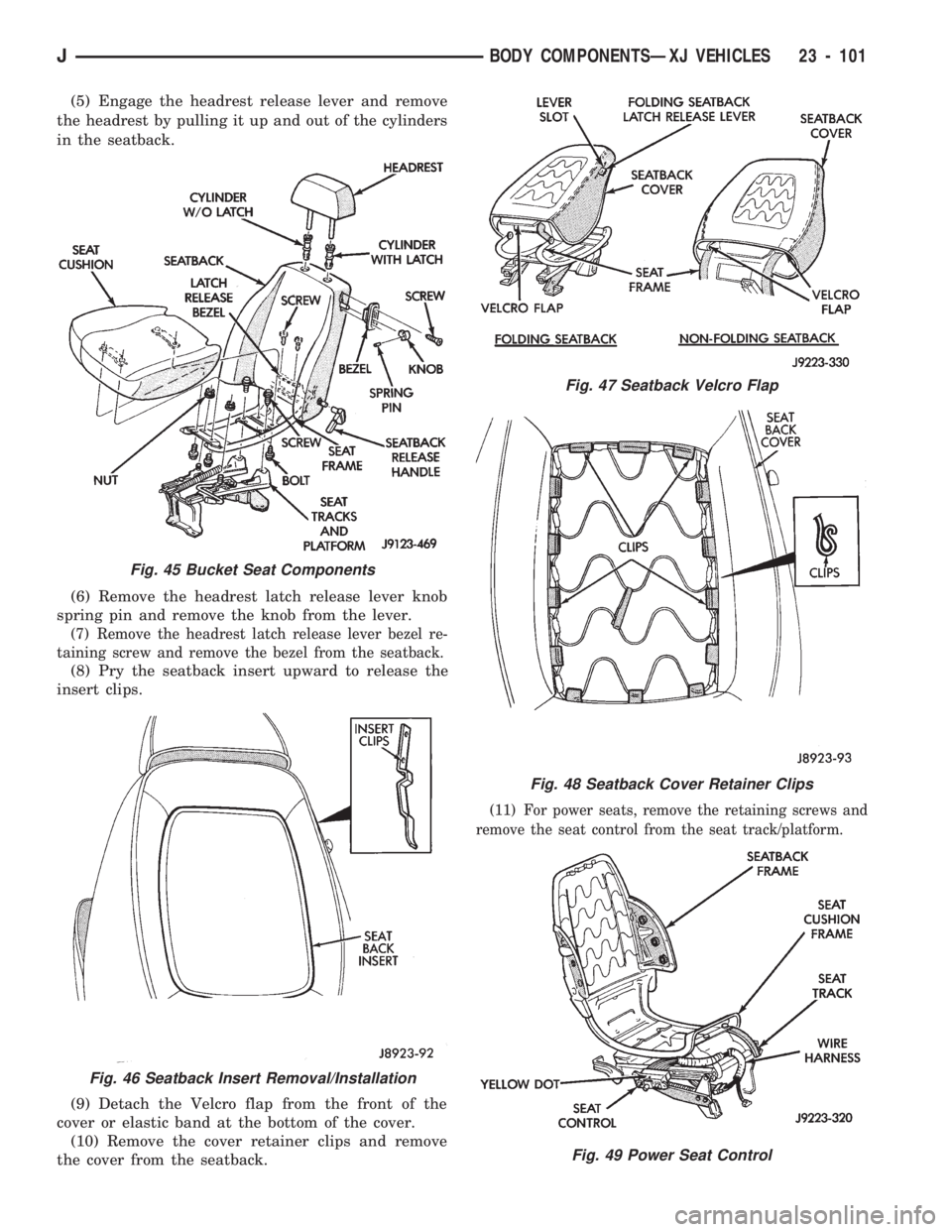

(5) Engage the headrest release lever and remove

the headrest by pulling it up and out of the cylinders

in the seatback.

(6) Remove the headrest latch release lever knob

spring pin and remove the knob from the lever.

(7) Remove the headrest latch release lever bezel re-

taining screw and remove the bezel from the seatback.

(8) Pry the seatback insert upward to release the

insert clips.

(9) Detach the Velcro flap from the front of the

cover or elastic band at the bottom of the cover.

(10) Remove the cover retainer clips and remove

the cover from the seatback.

(11) For power seats, remove the retaining screws and

remove the seat control from the seat track/platform.

Fig. 45 Bucket Seat Components

Fig. 46 Seatback Insert Removal/Installation

Fig. 47 Seatback Velcro Flap

Fig. 48 Seatback Cover Retainer Clips

Fig. 49 Power Seat Control

JBODY COMPONENTSÐXJ VEHICLES 23 - 101

Page 1557 of 1784

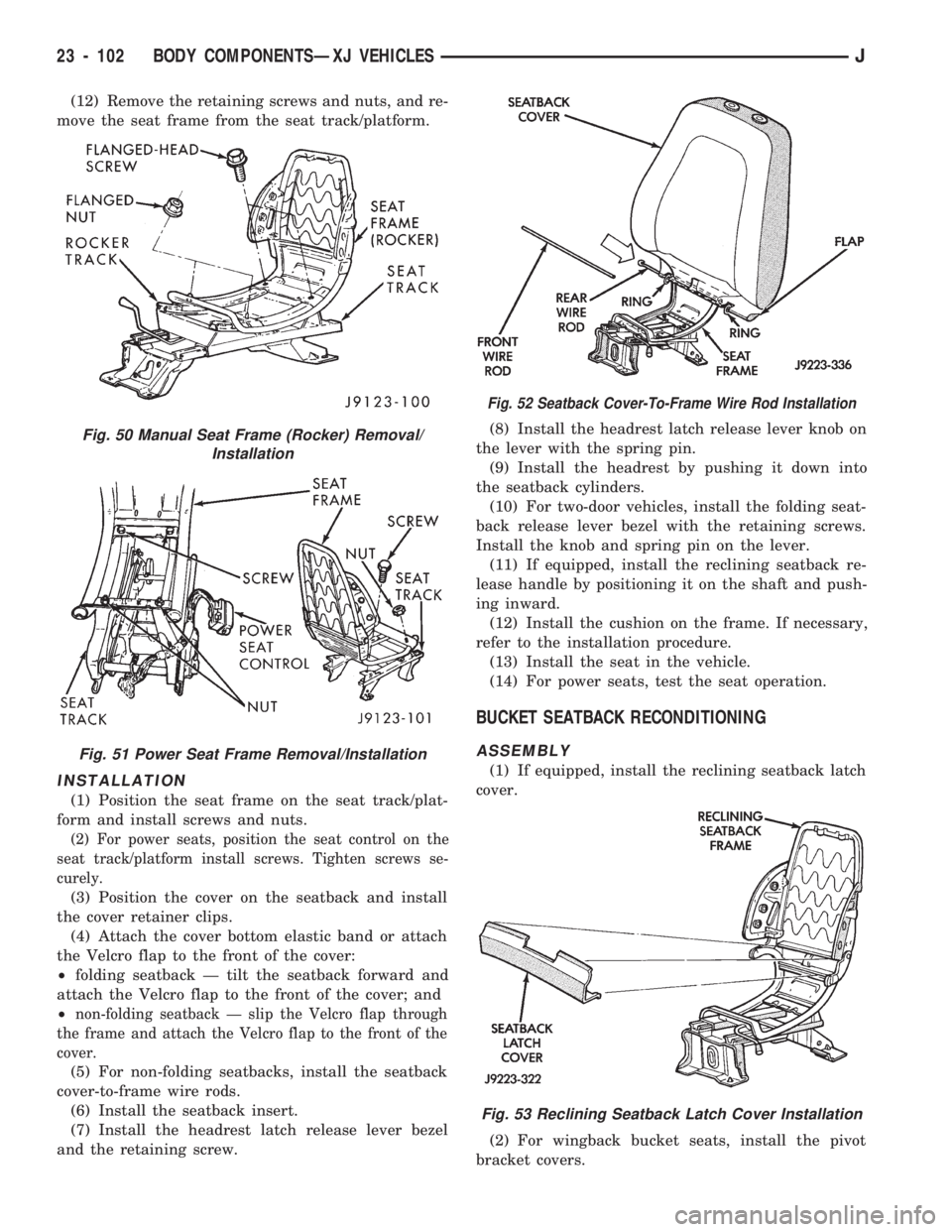

(12) Remove the retaining screws and nuts, and re-

move the seat frame from the seat track/platform.

INSTALLATION

(1) Position the seat frame on the seat track/plat-

form and install screws and nuts.

(2) For power seats, position the seat control on the

seat track/platform install screws. Tighten screws se-

curely.

(3) Position the cover on the seatback and install

the cover retainer clips.

(4) Attach the cover bottom elastic band or attach

the Velcro flap to the front of the cover:

²folding seatback Ð tilt the seatback forward and

attach the Velcro flap to the front of the cover; and

²

non-folding seatback Ð slip the Velcro flap through

the frame and attach the Velcro flap to the front of the

cover.

(5) For non-folding seatbacks, install the seatback

cover-to-frame wire rods.

(6) Install the seatback insert.

(7) Install the headrest latch release lever bezel

and the retaining screw.(8) Install the headrest latch release lever knob on

the lever with the spring pin.

(9) Install the headrest by pushing it down into

the seatback cylinders.

(10) For two-door vehicles, install the folding seat-

back release lever bezel with the retaining screws.

Install the knob and spring pin on the lever.

(11) If equipped, install the reclining seatback re-

lease handle by positioning it on the shaft and push-

ing inward.

(12) Install the cushion on the frame. If necessary,

refer to the installation procedure.

(13) Install the seat in the vehicle.

(14) For power seats, test the seat operation.

BUCKET SEATBACK RECONDITIONING

ASSEMBLY

(1) If equipped, install the reclining seatback latch

cover.

(2) For wingback bucket seats, install the pivot

bracket covers.

Fig. 50 Manual Seat Frame (Rocker) Removal/

Installation

Fig. 51 Power Seat Frame Removal/Installation

Fig. 52 Seatback Cover-To-Frame Wire Rod Installation

Fig. 53 Reclining Seatback Latch Cover Installation

23 - 102 BODY COMPONENTSÐXJ VEHICLESJ