JEEP CHEROKEE 1994 Service Repair Manual

Manufacturer: JEEP, Model Year: 1994, Model line: CHEROKEE, Model: JEEP CHEROKEE 1994Pages: 1784, PDF Size: 77.09 MB

Page 431 of 1784

(3) Move vehicle with the headlamps located di-

rectly above the 7.62-meters (25-feet) reference line.

(4) Equalize all the tire pressures.

(5) Rock vehicle from side to side to stabilize the

springs and shock absorbers.

(6) Use tape to attach a vehicle centerline on the

screen/wall (6). Ensure that it is aligned with and

represents the centerline of the vehicle.

(7) Measure distance between the vehicle head-

lamp centers. Divide this distance by two. Measure

the one/half distance outward from each side of the

vehicle centerline (6). Use tape to attach the right

and left lamp vertical centerline (4 and 5) on the

screen/wall (6).

(8) Measure the distance from the center of each

headlamp to the floor.

(9) Measure the lamp-to-floor distance upward

from the floor at each lamp vertical centerline (4 and

5). Use tape to attach the lamp horizontal centerline

(3) on the screen/wall.

ADJUSTMENT

(1) Remove screws and both headlamp bezels.

(2) Clean front of the headlamps.

(3) Place headlamps on LOW beam.

(4) Cover front of the headlamp that is not being

adjusted.

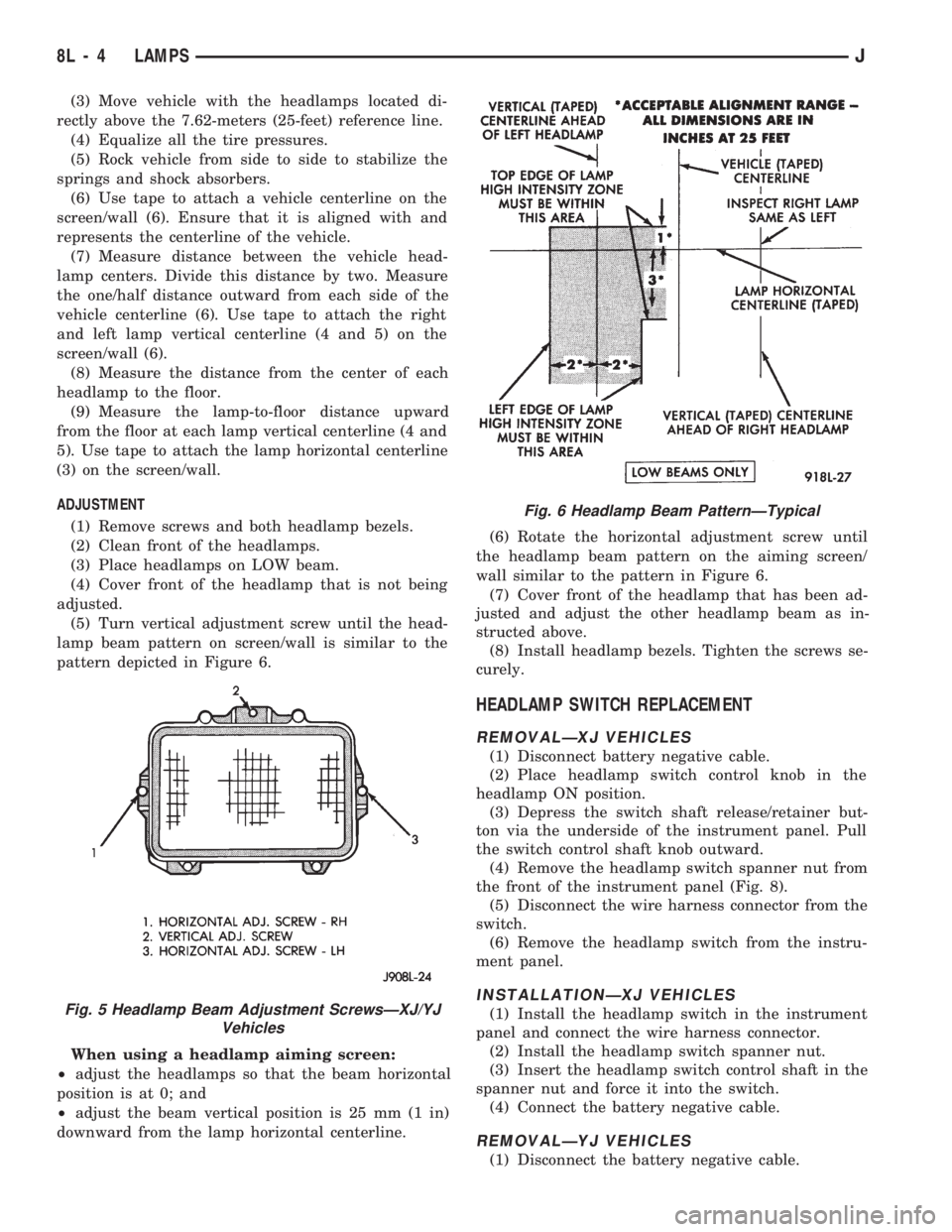

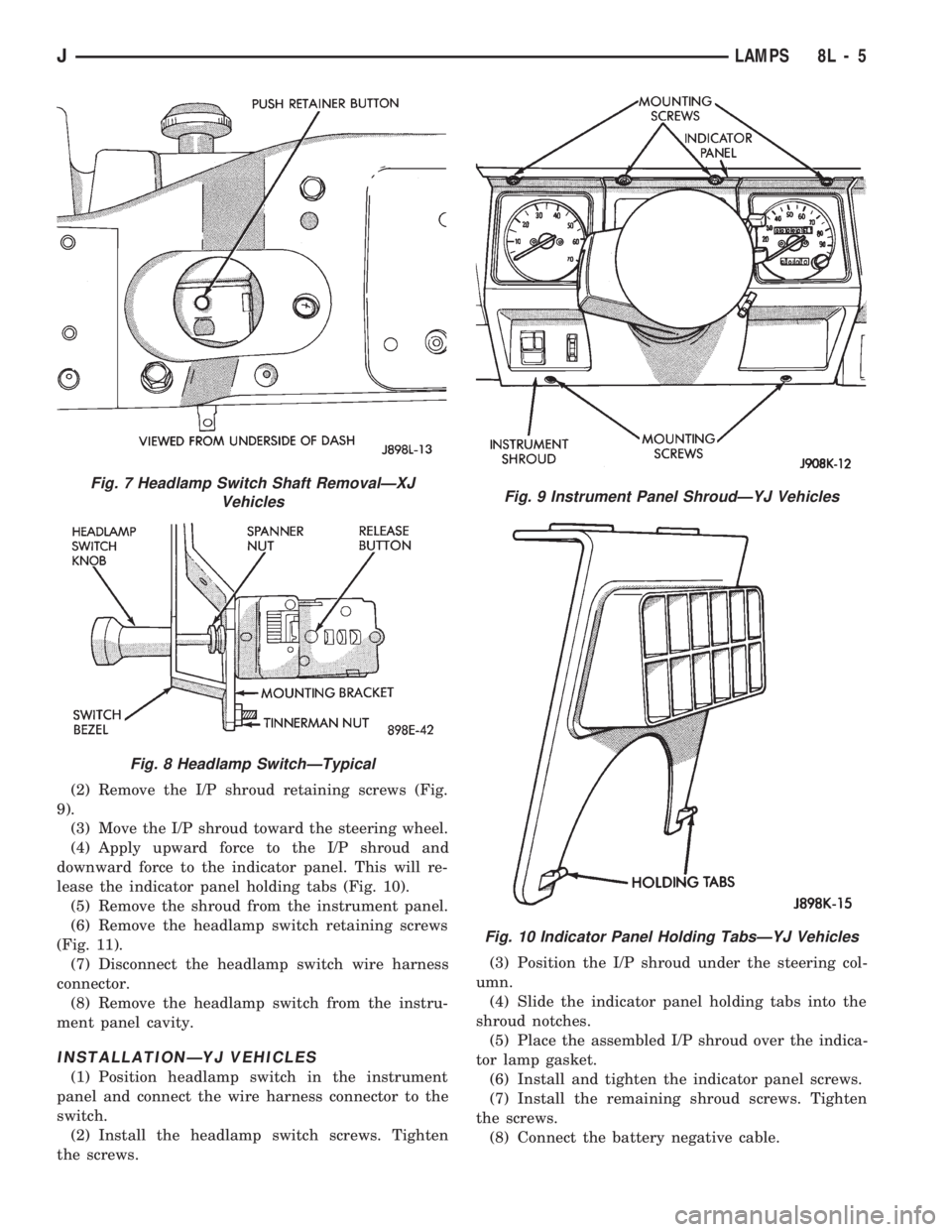

(5) Turn vertical adjustment screw until the head-

lamp beam pattern on screen/wall is similar to the

pattern depicted in Figure 6.

When using a headlamp aiming screen:

²adjust the headlamps so that the beam horizontal

position is at 0; and

²adjust the beam vertical position is 25 mm (1 in)

downward from the lamp horizontal centerline.(6) Rotate the horizontal adjustment screw until

the headlamp beam pattern on the aiming screen/

wall similar to the pattern in Figure 6.

(7) Cover front of the headlamp that has been ad-

justed and adjust the other headlamp beam as in-

structed above.

(8) Install headlamp bezels. Tighten the screws se-

curely.

HEADLAMP SWITCH REPLACEMENT

REMOVALÐXJ VEHICLES

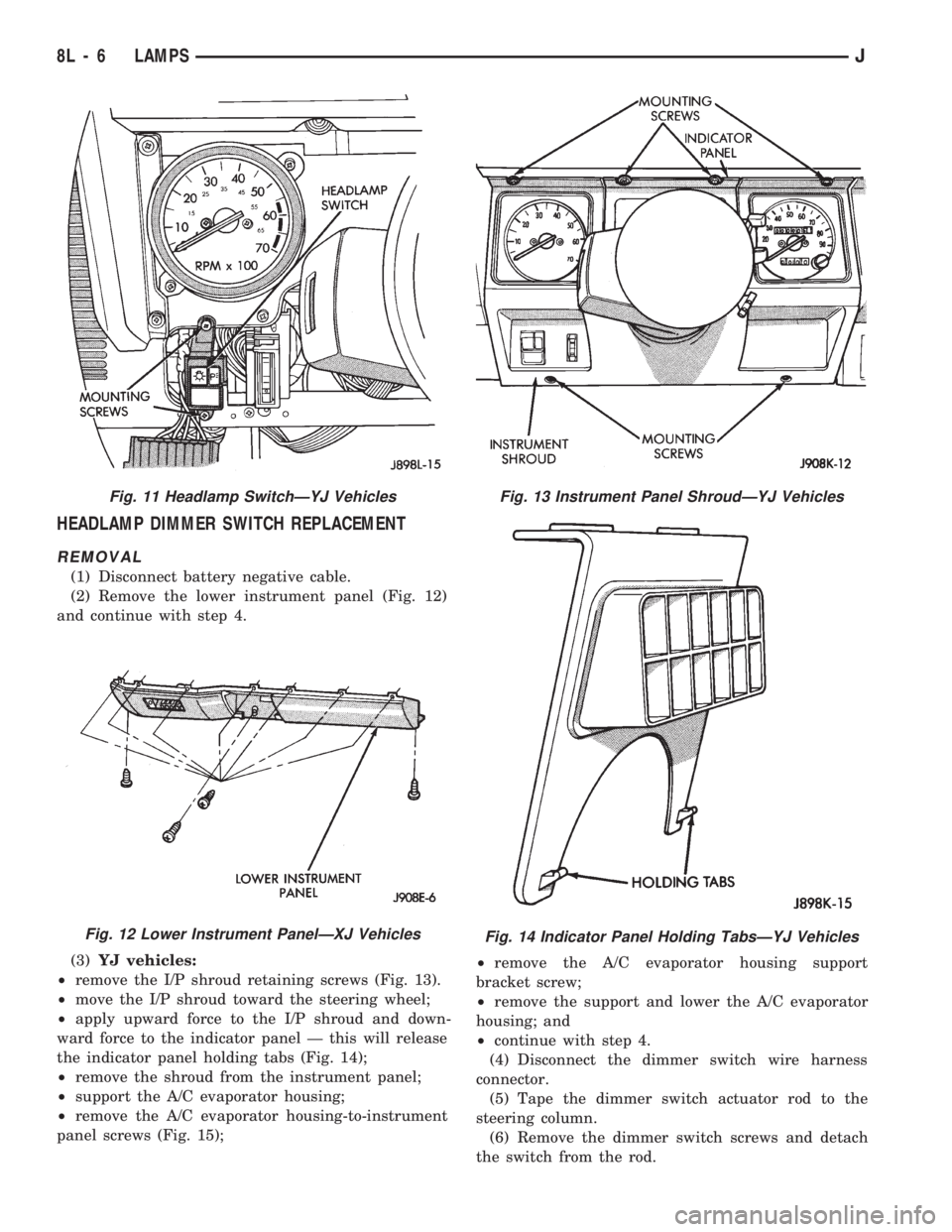

(1) Disconnect battery negative cable.

(2) Place headlamp switch control knob in the

headlamp ON position.

(3) Depress the switch shaft release/retainer but-

ton via the underside of the instrument panel. Pull

the switch control shaft knob outward.

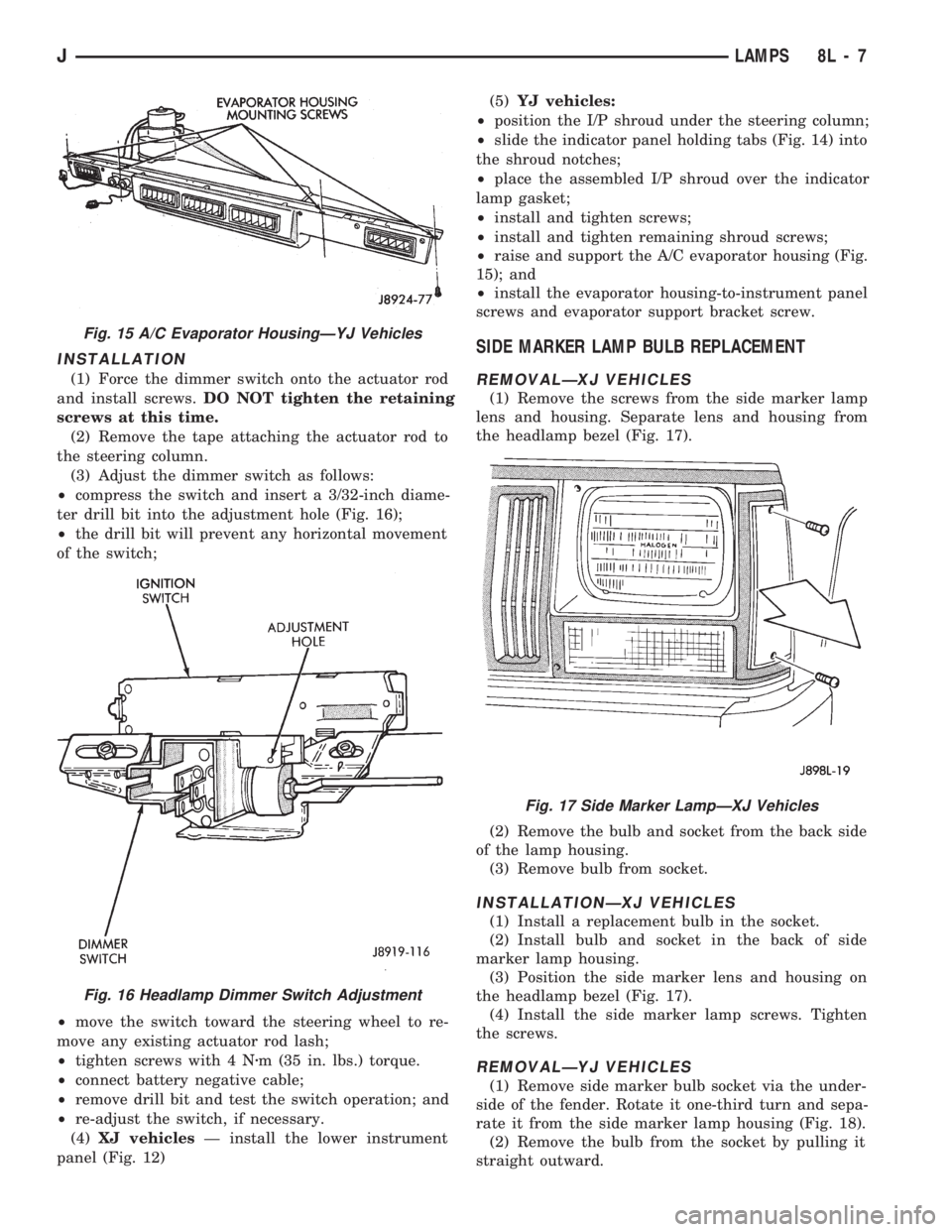

(4) Remove the headlamp switch spanner nut from

the front of the instrument panel (Fig. 8).

(5) Disconnect the wire harness connector from the

switch.

(6) Remove the headlamp switch from the instru-

ment panel.

INSTALLATIONÐXJ VEHICLES

(1) Install the headlamp switch in the instrument

panel and connect the wire harness connector.

(2) Install the headlamp switch spanner nut.

(3) Insert the headlamp switch control shaft in the

spanner nut and force it into the switch.

(4) Connect the battery negative cable.

REMOVALÐYJ VEHICLES

(1) Disconnect the battery negative cable.

Fig. 5 Headlamp Beam Adjustment ScrewsÐXJ/YJ

Vehicles

Fig. 6 Headlamp Beam PatternÐTypical

8L - 4 LAMPSJ

Page 432 of 1784

(2) Remove the I/P shroud retaining screws (Fig.

9).

(3) Move the I/P shroud toward the steering wheel.

(4) Apply upward force to the I/P shroud and

downward force to the indicator panel. This will re-

lease the indicator panel holding tabs (Fig. 10).

(5) Remove the shroud from the instrument panel.

(6) Remove the headlamp switch retaining screws

(Fig. 11).

(7) Disconnect the headlamp switch wire harness

connector.

(8) Remove the headlamp switch from the instru-

ment panel cavity.

INSTALLATIONÐYJ VEHICLES

(1) Position headlamp switch in the instrument

panel and connect the wire harness connector to the

switch.

(2) Install the headlamp switch screws. Tighten

the screws.(3) Position the I/P shroud under the steering col-

umn.

(4) Slide the indicator panel holding tabs into the

shroud notches.

(5) Place the assembled I/P shroud over the indica-

tor lamp gasket.

(6) Install and tighten the indicator panel screws.

(7) Install the remaining shroud screws. Tighten

the screws.

(8) Connect the battery negative cable.

Fig. 7 Headlamp Switch Shaft RemovalÐXJ

Vehicles

Fig. 8 Headlamp SwitchÐTypical

Fig. 9 Instrument Panel ShroudÐYJ Vehicles

Fig. 10 Indicator Panel Holding TabsÐYJ Vehicles

JLAMPS 8L - 5

Page 433 of 1784

HEADLAMP DIMMER SWITCH REPLACEMENT

REMOVAL

(1) Disconnect battery negative cable.

(2) Remove the lower instrument panel (Fig. 12)

and continue with step 4.

(3)YJ vehicles:

²remove the I/P shroud retaining screws (Fig. 13).

²move the I/P shroud toward the steering wheel;

²apply upward force to the I/P shroud and down-

ward force to the indicator panel Ð this will release

the indicator panel holding tabs (Fig. 14);

²remove the shroud from the instrument panel;

²support the A/C evaporator housing;

²remove the A/C evaporator housing-to-instrument

panel screws (Fig. 15);²remove the A/C evaporator housing support

bracket screw;

²remove the support and lower the A/C evaporator

housing; and

²continue with step 4.

(4) Disconnect the dimmer switch wire harness

connector.

(5) Tape the dimmer switch actuator rod to the

steering column.

(6) Remove the dimmer switch screws and detach

the switch from the rod.

Fig. 11 Headlamp SwitchÐYJ Vehicles

Fig. 12 Lower Instrument PanelÐXJ Vehicles

Fig. 13 Instrument Panel ShroudÐYJ Vehicles

Fig. 14 Indicator Panel Holding TabsÐYJ Vehicles

8L - 6 LAMPSJ

Page 434 of 1784

INSTALLATION

(1) Force the dimmer switch onto the actuator rod

and install screws.DO NOT tighten the retaining

screws at this time.

(2) Remove the tape attaching the actuator rod to

the steering column.

(3) Adjust the dimmer switch as follows:

²compress the switch and insert a 3/32-inch diame-

ter drill bit into the adjustment hole (Fig. 16);

²the drill bit will prevent any horizontal movement

of the switch;

²move the switch toward the steering wheel to re-

move any existing actuator rod lash;

²tighten screws with 4 Nzm (35 in. lbs.) torque.

²connect battery negative cable;

²remove drill bit and test the switch operation; and

²re-adjust the switch, if necessary.

(4)XJ vehiclesÐ install the lower instrument

panel (Fig. 12)(5)YJ vehicles:

²position the I/P shroud under the steering column;

²slide the indicator panel holding tabs (Fig. 14) into

the shroud notches;

²place the assembled I/P shroud over the indicator

lamp gasket;

²install and tighten screws;

²install and tighten remaining shroud screws;

²raise and support the A/C evaporator housing (Fig.

15); and

²install the evaporator housing-to-instrument panel

screws and evaporator support bracket screw.

SIDE MARKER LAMP BULB REPLACEMENT

REMOVALÐXJ VEHICLES

(1) Remove the screws from the side marker lamp

lens and housing. Separate lens and housing from

the headlamp bezel (Fig. 17).

(2) Remove the bulb and socket from the back side

of the lamp housing.

(3) Remove bulb from socket.

INSTALLATIONÐXJ VEHICLES

(1) Install a replacement bulb in the socket.

(2) Install bulb and socket in the back of side

marker lamp housing.

(3) Position the side marker lens and housing on

the headlamp bezel (Fig. 17).

(4) Install the side marker lamp screws. Tighten

the screws.

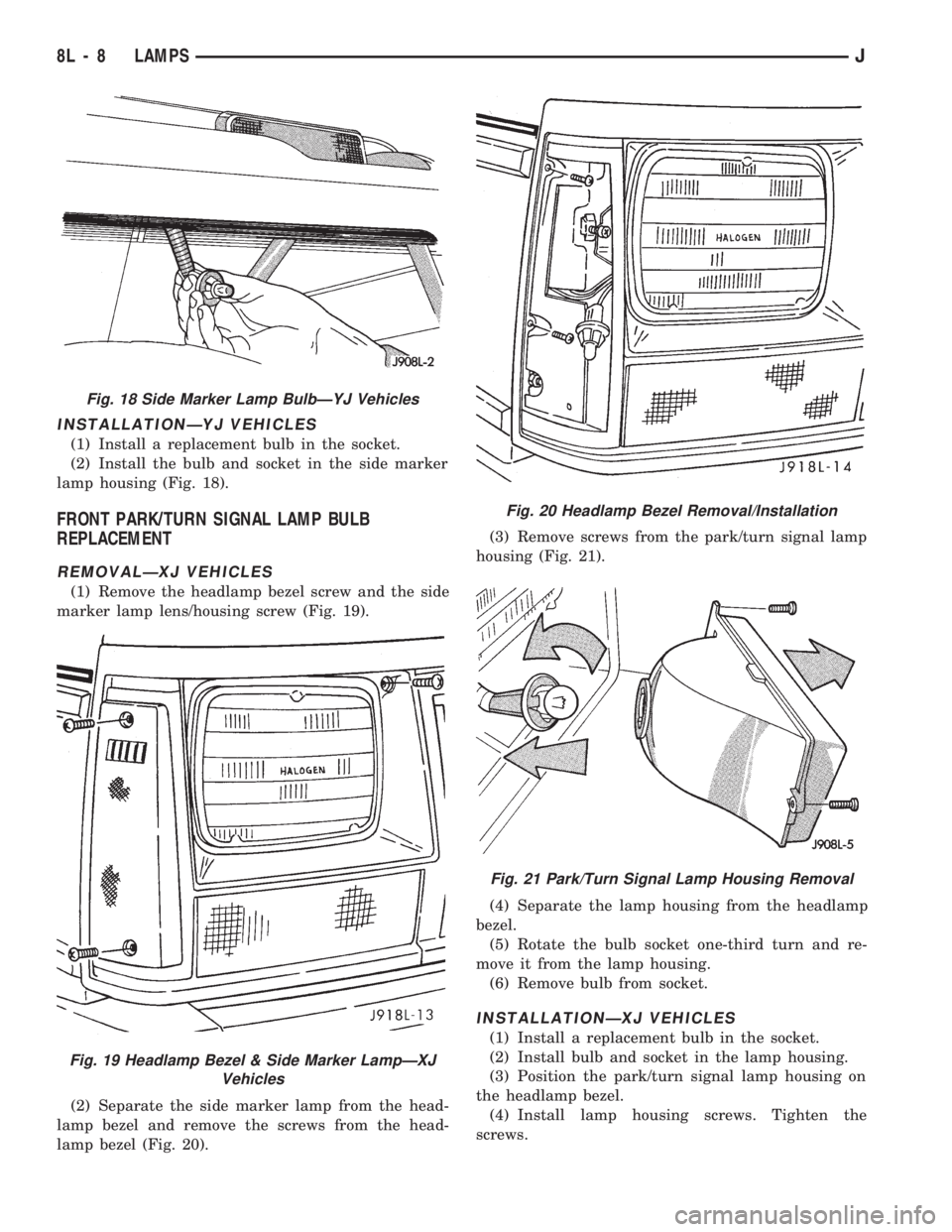

REMOVALÐYJ VEHICLES

(1) Remove side marker bulb socket via the under-

side of the fender. Rotate it one-third turn and sepa-

rate it from the side marker lamp housing (Fig. 18).

(2) Remove the bulb from the socket by pulling it

straight outward.

Fig. 15 A/C Evaporator HousingÐYJ Vehicles

Fig. 16 Headlamp Dimmer Switch Adjustment

Fig. 17 Side Marker LampÐXJ Vehicles

JLAMPS 8L - 7

Page 435 of 1784

INSTALLATIONÐYJ VEHICLES

(1) Install a replacement bulb in the socket.

(2) Install the bulb and socket in the side marker

lamp housing (Fig. 18).

FRONT PARK/TURN SIGNAL LAMP BULB

REPLACEMENT

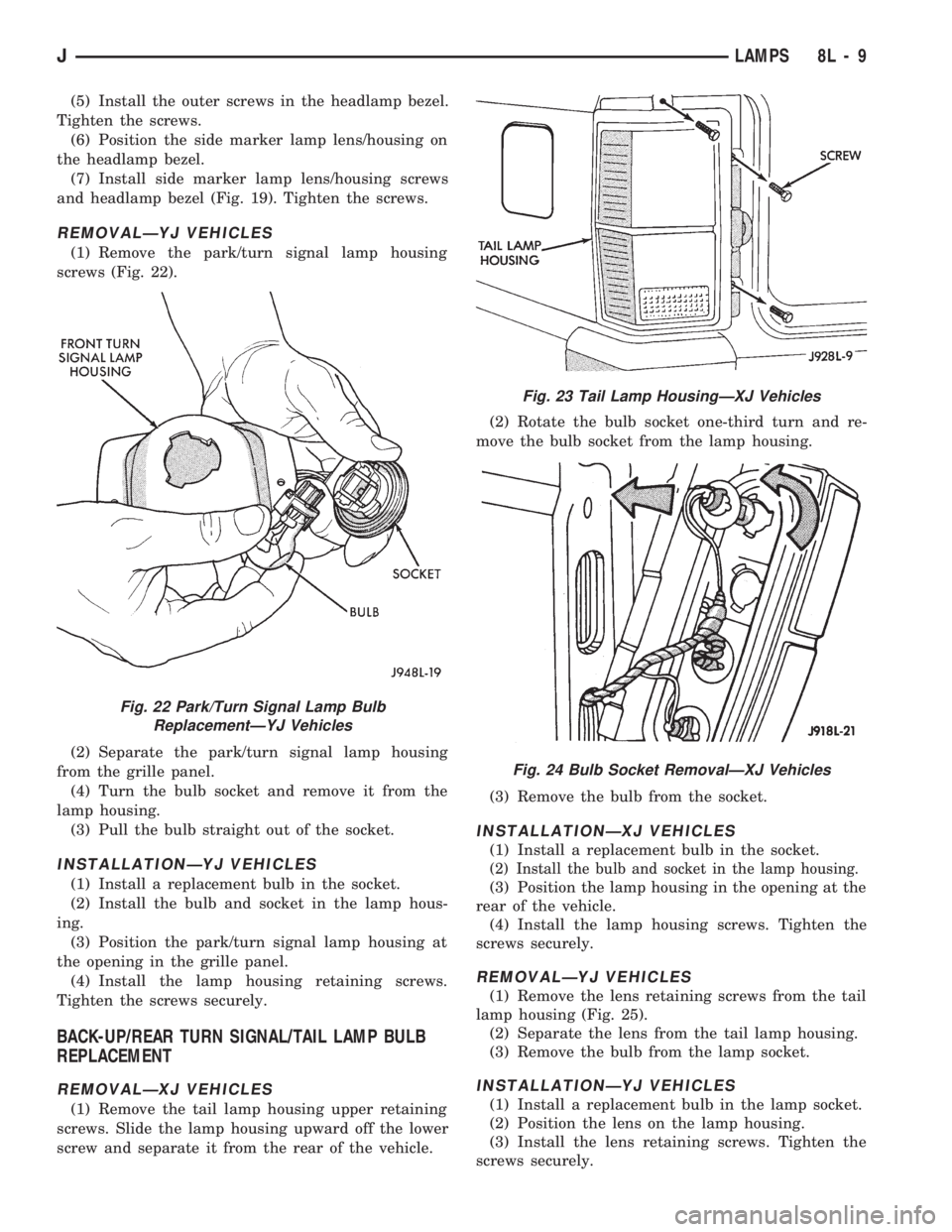

REMOVALÐXJ VEHICLES

(1) Remove the headlamp bezel screw and the side

marker lamp lens/housing screw (Fig. 19).

(2) Separate the side marker lamp from the head-

lamp bezel and remove the screws from the head-

lamp bezel (Fig. 20).(3) Remove screws from the park/turn signal lamp

housing (Fig. 21).

(4) Separate the lamp housing from the headlamp

bezel.

(5) Rotate the bulb socket one-third turn and re-

move it from the lamp housing.

(6) Remove bulb from socket.

INSTALLATIONÐXJ VEHICLES

(1) Install a replacement bulb in the socket.

(2) Install bulb and socket in the lamp housing.

(3) Position the park/turn signal lamp housing on

the headlamp bezel.

(4) Install lamp housing screws. Tighten the

screws.

Fig. 18 Side Marker Lamp BulbÐYJ Vehicles

Fig. 19 Headlamp Bezel & Side Marker LampÐXJ

Vehicles

Fig. 20 Headlamp Bezel Removal/Installation

Fig. 21 Park/Turn Signal Lamp Housing Removal

8L - 8 LAMPSJ

Page 436 of 1784

(5) Install the outer screws in the headlamp bezel.

Tighten the screws.

(6) Position the side marker lamp lens/housing on

the headlamp bezel.

(7) Install side marker lamp lens/housing screws

and headlamp bezel (Fig. 19). Tighten the screws.

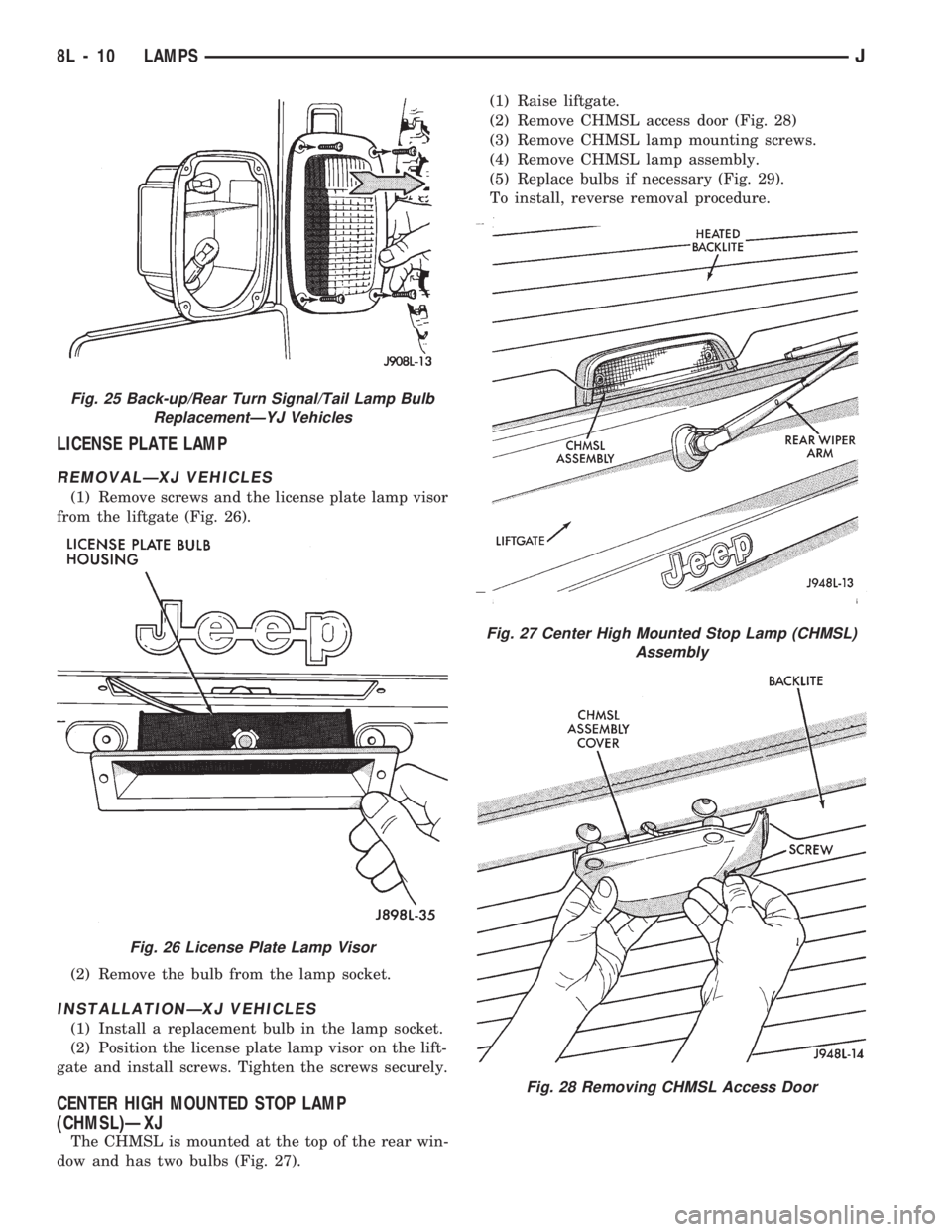

REMOVALÐYJ VEHICLES

(1) Remove the park/turn signal lamp housing

screws (Fig. 22).

(2) Separate the park/turn signal lamp housing

from the grille panel.

(4) Turn the bulb socket and remove it from the

lamp housing.

(3) Pull the bulb straight out of the socket.

INSTALLATIONÐYJ VEHICLES

(1) Install a replacement bulb in the socket.

(2) Install the bulb and socket in the lamp hous-

ing.

(3) Position the park/turn signal lamp housing at

the opening in the grille panel.

(4) Install the lamp housing retaining screws.

Tighten the screws securely.

BACK-UP/REAR TURN SIGNAL/TAIL LAMP BULB

REPLACEMENT

REMOVALÐXJ VEHICLES

(1) Remove the tail lamp housing upper retaining

screws. Slide the lamp housing upward off the lower

screw and separate it from the rear of the vehicle.(2) Rotate the bulb socket one-third turn and re-

move the bulb socket from the lamp housing.

(3) Remove the bulb from the socket.

INSTALLATIONÐXJ VEHICLES

(1) Install a replacement bulb in the socket.

(2) Install the bulb and socket in the lamp housing.

(3) Position the lamp housing in the opening at the

rear of the vehicle.

(4) Install the lamp housing screws. Tighten the

screws securely.

REMOVALÐYJ VEHICLES

(1) Remove the lens retaining screws from the tail

lamp housing (Fig. 25).

(2) Separate the lens from the tail lamp housing.

(3) Remove the bulb from the lamp socket.

INSTALLATIONÐYJ VEHICLES

(1) Install a replacement bulb in the lamp socket.

(2) Position the lens on the lamp housing.

(3) Install the lens retaining screws. Tighten the

screws securely.

Fig. 22 Park/Turn Signal Lamp Bulb

ReplacementÐYJ Vehicles

Fig. 23 Tail Lamp HousingÐXJ Vehicles

Fig. 24 Bulb Socket RemovalÐXJ Vehicles

JLAMPS 8L - 9

Page 437 of 1784

LICENSE PLATE LAMP

REMOVALÐXJ VEHICLES

(1) Remove screws and the license plate lamp visor

from the liftgate (Fig. 26).

(2) Remove the bulb from the lamp socket.

INSTALLATIONÐXJ VEHICLES

(1) Install a replacement bulb in the lamp socket.

(2) Position the license plate lamp visor on the lift-

gate and install screws. Tighten the screws securely.

CENTER HIGH MOUNTED STOP LAMP

(CHMSL)ÐXJ

The CHMSL is mounted at the top of the rear win-

dow and has two bulbs (Fig. 27).(1) Raise liftgate.

(2) Remove CHMSL access door (Fig. 28)

(3) Remove CHMSL lamp mounting screws.

(4) Remove CHMSL lamp assembly.

(5) Replace bulbs if necessary (Fig. 29).

To install, reverse removal procedure.

Fig. 25 Back-up/Rear Turn Signal/Tail Lamp Bulb

ReplacementÐYJ Vehicles

Fig. 26 License Plate Lamp Visor

Fig. 27 Center High Mounted Stop Lamp (CHMSL)

Assembly

Fig. 28 Removing CHMSL Access Door

8L - 10 LAMPSJ

Page 438 of 1784

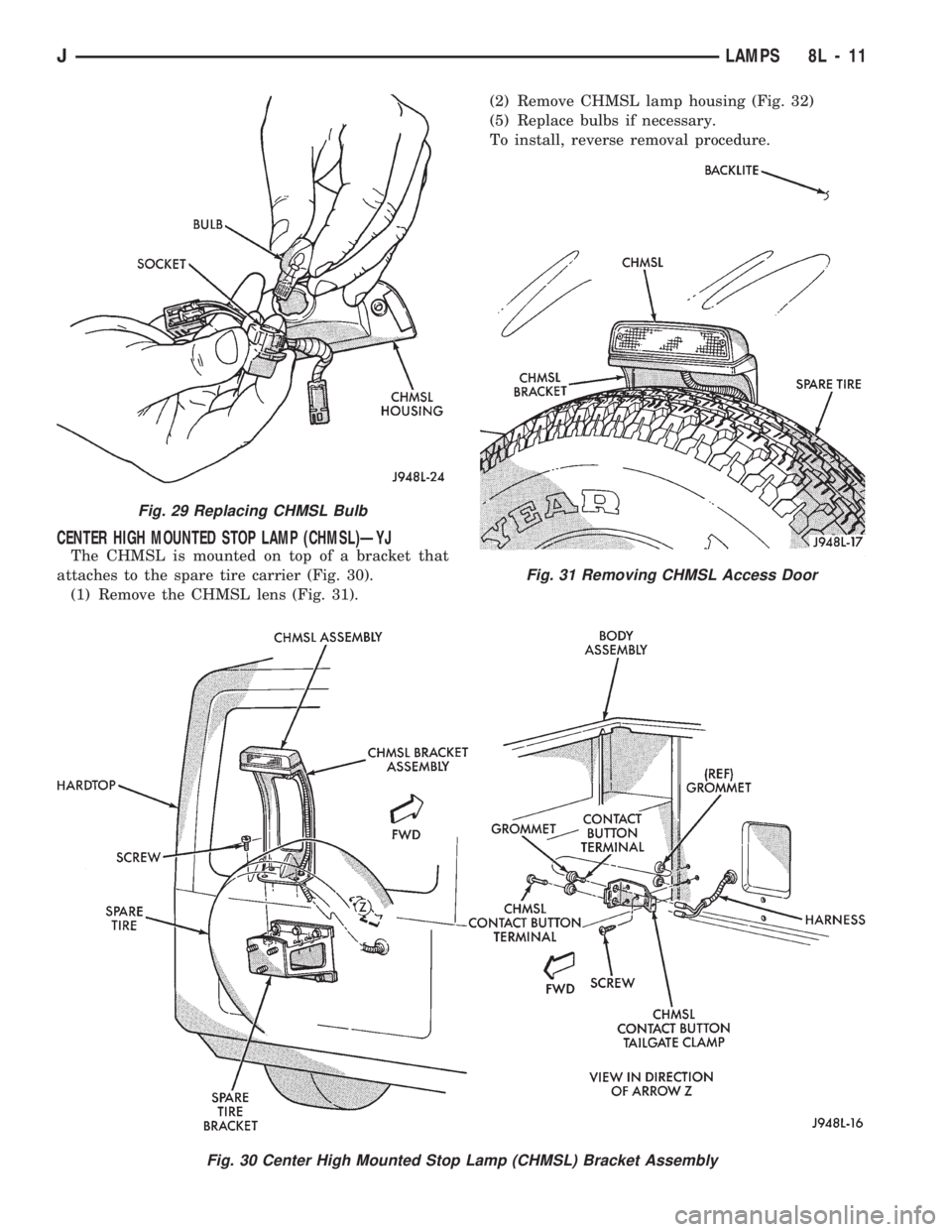

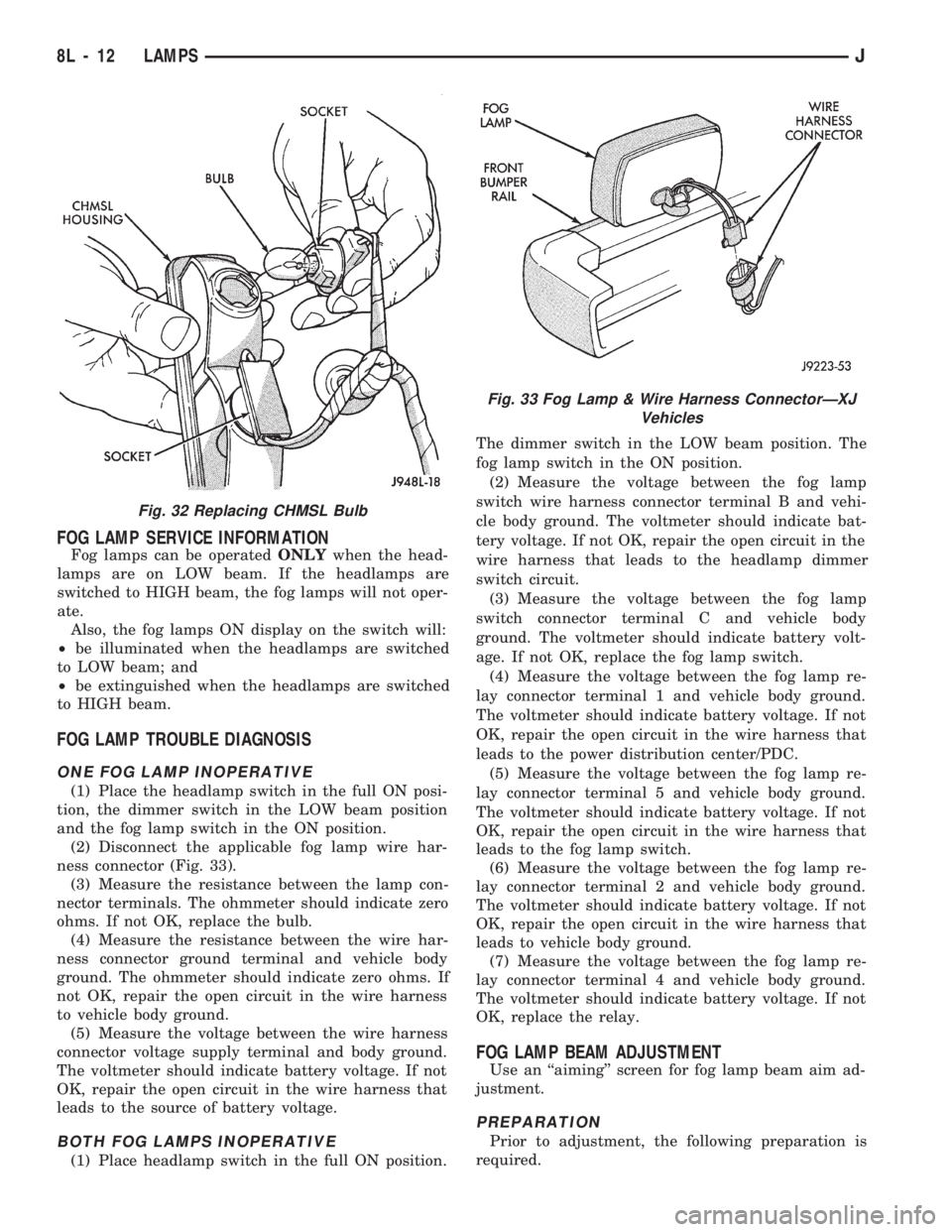

CENTER HIGH MOUNTED STOP LAMP (CHMSL)ÐYJ

The CHMSL is mounted on top of a bracket that

attaches to the spare tire carrier (Fig. 30).

(1) Remove the CHMSL lens (Fig. 31).(2) Remove CHMSL lamp housing (Fig. 32)

(5) Replace bulbs if necessary.

To install, reverse removal procedure.

Fig. 30 Center High Mounted Stop Lamp (CHMSL) Bracket Assembly

Fig. 29 Replacing CHMSL Bulb

Fig. 31 Removing CHMSL Access Door

JLAMPS 8L - 11

Page 439 of 1784

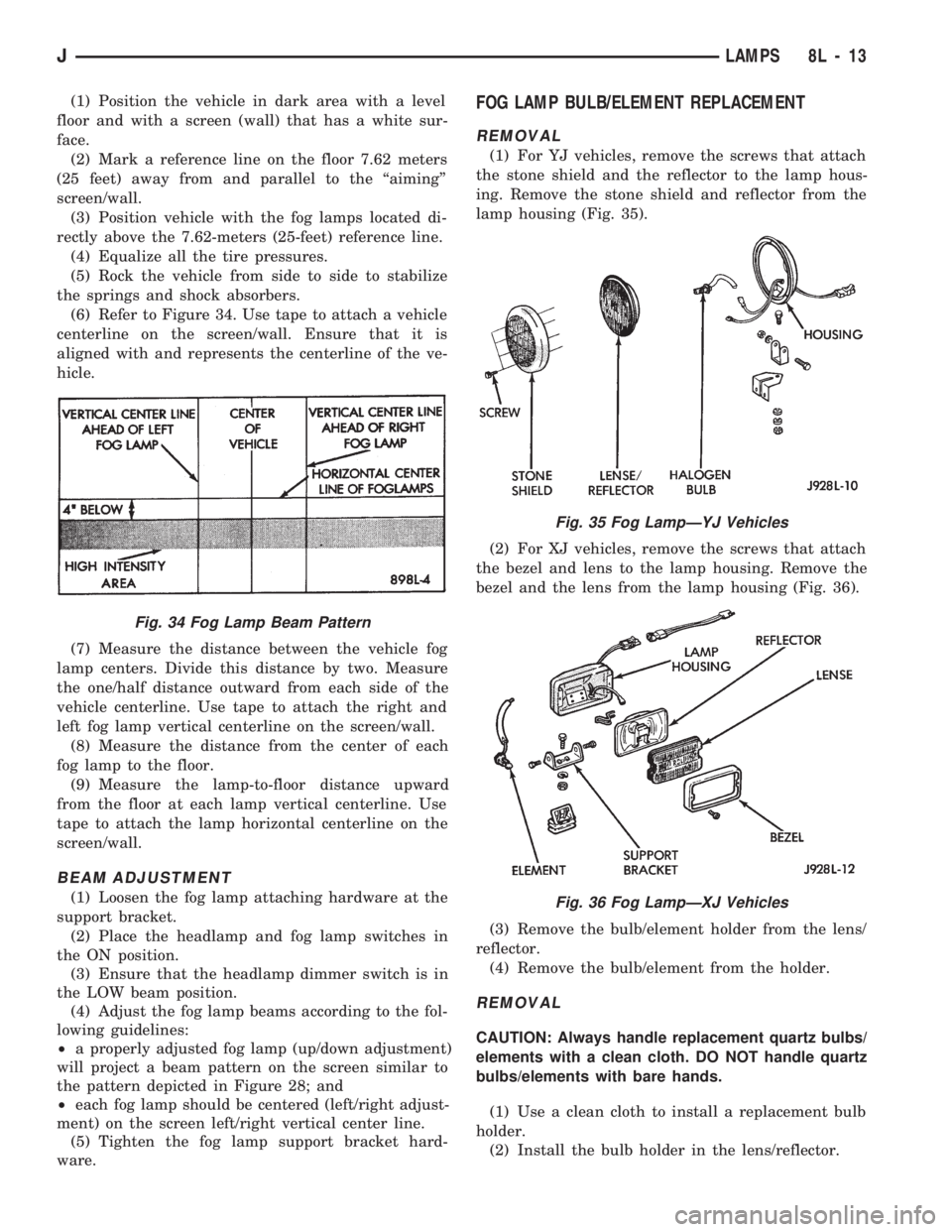

FOG LAMP SERVICE INFORMATION

Fog lamps can be operatedONLYwhen the head-

lamps are on LOW beam. If the headlamps are

switched to HIGH beam, the fog lamps will not oper-

ate.

Also, the fog lamps ON display on the switch will:

²be illuminated when the headlamps are switched

to LOW beam; and

²be extinguished when the headlamps are switched

to HIGH beam.

FOG LAMP TROUBLE DIAGNOSIS

ONE FOG LAMP INOPERATIVE

(1) Place the headlamp switch in the full ON posi-

tion, the dimmer switch in the LOW beam position

and the fog lamp switch in the ON position.

(2) Disconnect the applicable fog lamp wire har-

ness connector (Fig. 33).

(3) Measure the resistance between the lamp con-

nector terminals. The ohmmeter should indicate zero

ohms. If not OK, replace the bulb.

(4) Measure the resistance between the wire har-

ness connector ground terminal and vehicle body

ground. The ohmmeter should indicate zero ohms. If

not OK, repair the open circuit in the wire harness

to vehicle body ground.

(5) Measure the voltage between the wire harness

connector voltage supply terminal and body ground.

The voltmeter should indicate battery voltage. If not

OK, repair the open circuit in the wire harness that

leads to the source of battery voltage.

BOTH FOG LAMPS INOPERATIVE

(1) Place headlamp switch in the full ON position.The dimmer switch in the LOW beam position. The

fog lamp switch in the ON position.

(2) Measure the voltage between the fog lamp

switch wire harness connector terminal B and vehi-

cle body ground. The voltmeter should indicate bat-

tery voltage. If not OK, repair the open circuit in the

wire harness that leads to the headlamp dimmer

switch circuit.

(3) Measure the voltage between the fog lamp

switch connector terminal C and vehicle body

ground. The voltmeter should indicate battery volt-

age. If not OK, replace the fog lamp switch.

(4) Measure the voltage between the fog lamp re-

lay connector terminal 1 and vehicle body ground.

The voltmeter should indicate battery voltage. If not

OK, repair the open circuit in the wire harness that

leads to the power distribution center/PDC.

(5) Measure the voltage between the fog lamp re-

lay connector terminal 5 and vehicle body ground.

The voltmeter should indicate battery voltage. If not

OK, repair the open circuit in the wire harness that

leads to the fog lamp switch.

(6) Measure the voltage between the fog lamp re-

lay connector terminal 2 and vehicle body ground.

The voltmeter should indicate battery voltage. If not

OK, repair the open circuit in the wire harness that

leads to vehicle body ground.

(7) Measure the voltage between the fog lamp re-

lay connector terminal 4 and vehicle body ground.

The voltmeter should indicate battery voltage. If not

OK, replace the relay.

FOG LAMP BEAM ADJUSTMENT

Use an ``aiming'' screen for fog lamp beam aim ad-

justment.

PREPARATION

Prior to adjustment, the following preparation is

required.

Fig. 32 Replacing CHMSL Bulb

Fig. 33 Fog Lamp & Wire Harness ConnectorÐXJ

Vehicles

8L - 12 LAMPSJ

Page 440 of 1784

(1) Position the vehicle in dark area with a level

floor and with a screen (wall) that has a white sur-

face.

(2) Mark a reference line on the floor 7.62 meters

(25 feet) away from and parallel to the ``aiming''

screen/wall.

(3) Position vehicle with the fog lamps located di-

rectly above the 7.62-meters (25-feet) reference line.

(4) Equalize all the tire pressures.

(5) Rock the vehicle from side to side to stabilize

the springs and shock absorbers.

(6) Refer to Figure 34. Use tape to attach a vehicle

centerline on the screen/wall. Ensure that it is

aligned with and represents the centerline of the ve-

hicle.

(7) Measure the distance between the vehicle fog

lamp centers. Divide this distance by two. Measure

the one/half distance outward from each side of the

vehicle centerline. Use tape to attach the right and

left fog lamp vertical centerline on the screen/wall.

(8) Measure the distance from the center of each

fog lamp to the floor.

(9) Measure the lamp-to-floor distance upward

from the floor at each lamp vertical centerline. Use

tape to attach the lamp horizontal centerline on the

screen/wall.

BEAM ADJUSTMENT

(1) Loosen the fog lamp attaching hardware at the

support bracket.

(2) Place the headlamp and fog lamp switches in

the ON position.

(3) Ensure that the headlamp dimmer switch is in

the LOW beam position.

(4) Adjust the fog lamp beams according to the fol-

lowing guidelines:

²a properly adjusted fog lamp (up/down adjustment)

will project a beam pattern on the screen similar to

the pattern depicted in Figure 28; and

²each fog lamp should be centered (left/right adjust-

ment) on the screen left/right vertical center line.

(5) Tighten the fog lamp support bracket hard-

ware.

FOG LAMP BULB/ELEMENT REPLACEMENT

REMOVAL

(1) For YJ vehicles, remove the screws that attach

the stone shield and the reflector to the lamp hous-

ing. Remove the stone shield and reflector from the

lamp housing (Fig. 35).

(2) For XJ vehicles, remove the screws that attach

the bezel and lens to the lamp housing. Remove the

bezel and the lens from the lamp housing (Fig. 36).

(3) Remove the bulb/element holder from the lens/

reflector.

(4) Remove the bulb/element from the holder.

REMOVAL

CAUTION: Always handle replacement quartz bulbs/

elements with a clean cloth. DO NOT handle quartz

bulbs/elements with bare hands.

(1) Use a clean cloth to install a replacement bulb

holder.

(2) Install the bulb holder in the lens/reflector.

Fig. 34 Fog Lamp Beam Pattern

Fig. 35 Fog LampÐYJ Vehicles

Fig. 36 Fog LampÐXJ Vehicles

JLAMPS 8L - 13