maint JEEP CHEROKEE 1994 Service Manual PDF

[x] Cancel search | Manufacturer: JEEP, Model Year: 1994, Model line: CHEROKEE, Model: JEEP CHEROKEE 1994Pages: 1784, PDF Size: 77.09 MB

Page 271 of 1784

SPECIFICATIONS

GENERAL INFORMATION

The following specifications are published from the

latest information available at the time of publica-

tion.If anything differs between the specifica-

tions found on the Vehicle Emission Control

Information (VECI) label and the following

specifications, use specifications on VECI label.

The VECI label is located in the engine compart-

ment.

DRIVE BELT TENSION

Belt tension can be adjusted only on models

equipped with conventional left hand drive. Refer to

the following Belt TensionÐExcept RHD Models

chart for specifications.

It is not necessary to adjust belt tension on right

hand drive (RHD) vehicles if equipped with a 4.0L

engine. The engine is equipped with an automatic

belt tensioner. The tensioner maintains correct belt

tension at all times.Due to the use of this belt

tensioner, DO NOT attempt to use a belt ten-

sion gauge on this engine.Refer to Automatic Belt

Tensioner for additional information.

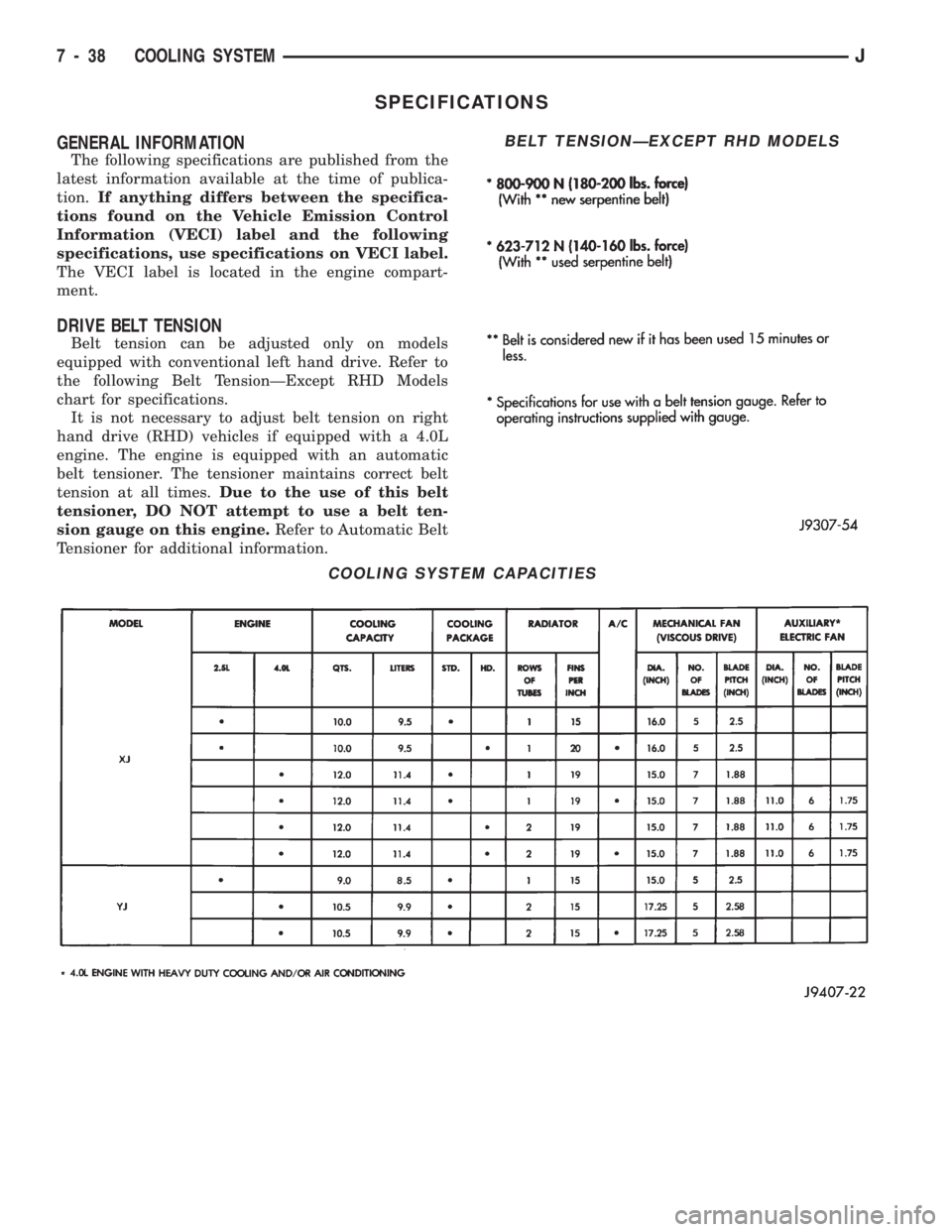

COOLING SYSTEM CAPACITIES

BELT TENSIONÐEXCEPT RHD MODELS

7 - 38 COOLING SYSTEMJ

Page 275 of 1784

BATTERY TEST PROCEDURES

INDEX

page page

Battery Charging.......................... 5

Battery Diagnostics Chart................... 7

Battery Load Test......................... 4

Battery Open Circuit Voltage Test............. 3Battery Testing General Information........... 3

General Information........................ 2

Hydrometer Test.......................... 3

Specifications............................ 8

GENERAL INFORMATION

The battery stores, stabilizes, and produces electri-

cal current. A battery must be able to accept a

charge and produce high-amperage current output

over an extended period. A chemical reaction occurs

between the sulfuric acid solution (electrolyte) and

the lead +/þ plates in each cell of the battery. As

the battery discharges, the plates collect the acid

from the electrolyte. When the charging system

charges the battery, water is converted to sulfuric

acid in the battery. The amount of acid (specific

gravity) in the electrolyte can be measured with a

hydrometer. The battery is vented to release gases

that are created when the battery is being charged.

The battery top,posts, and terminals should be cleaned when other

underhood maintenance is performed.

WARNING: DO NOT ATTEMPT TO ASSIST BOOST,

CHARGE, OR TEST BATTERY WHEN ELECTRO-

LYTE LEVEL IS BELOW THE TOP OF THE PLATES.

PERSONAL INJURY MAY OCCUR.

When the electrolyte level is below the top of the

plates distilled water should be added. The battery

must be completely charged. The top, posts, and ter-

minals should be properly cleaned before diagnostic

procedures are performed. See Group 8B - Battery/

Starter/Generator Service, for additional information.

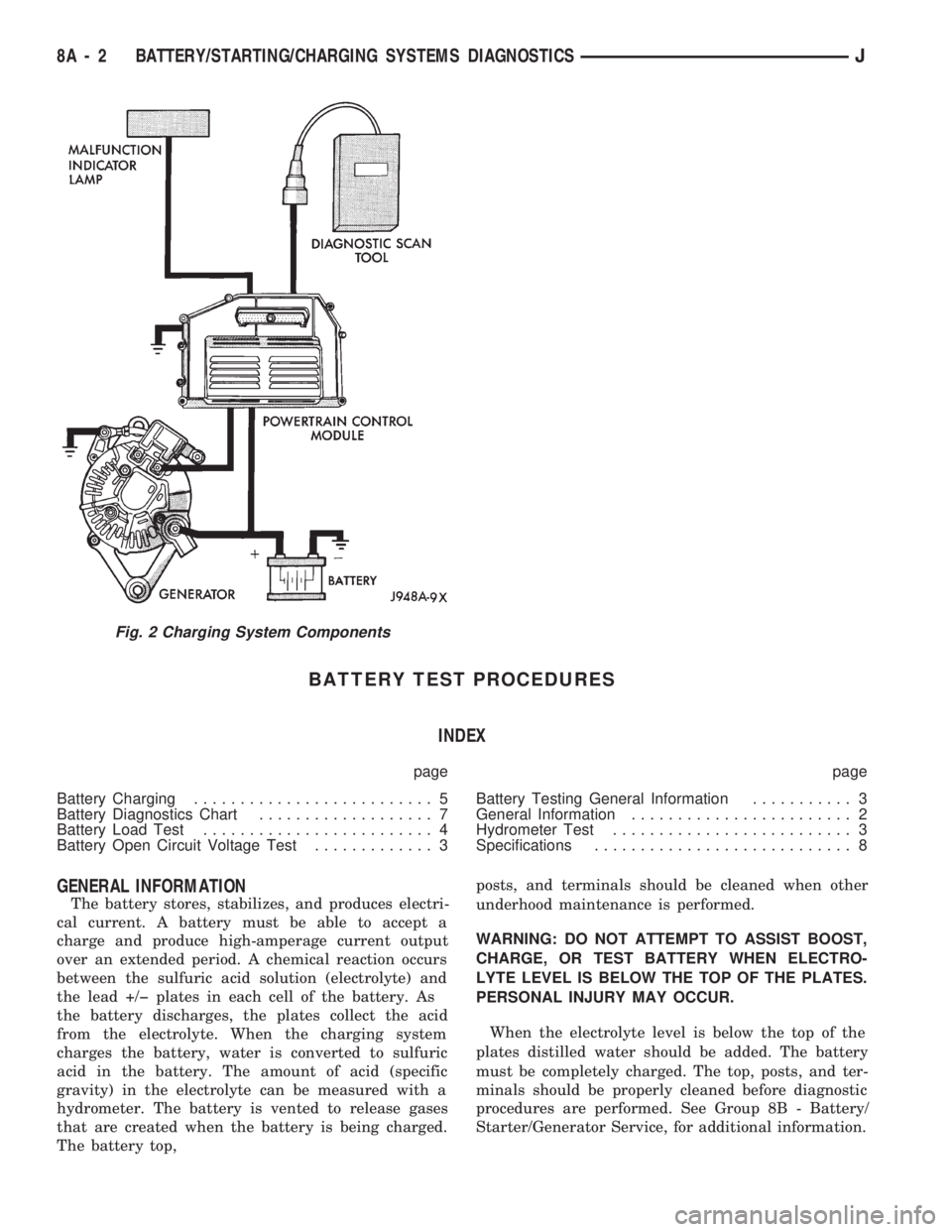

Fig. 2 Charging System Components

8A - 2 BATTERY/STARTING/CHARGING SYSTEMS DIAGNOSTICSJ

Page 277 of 1784

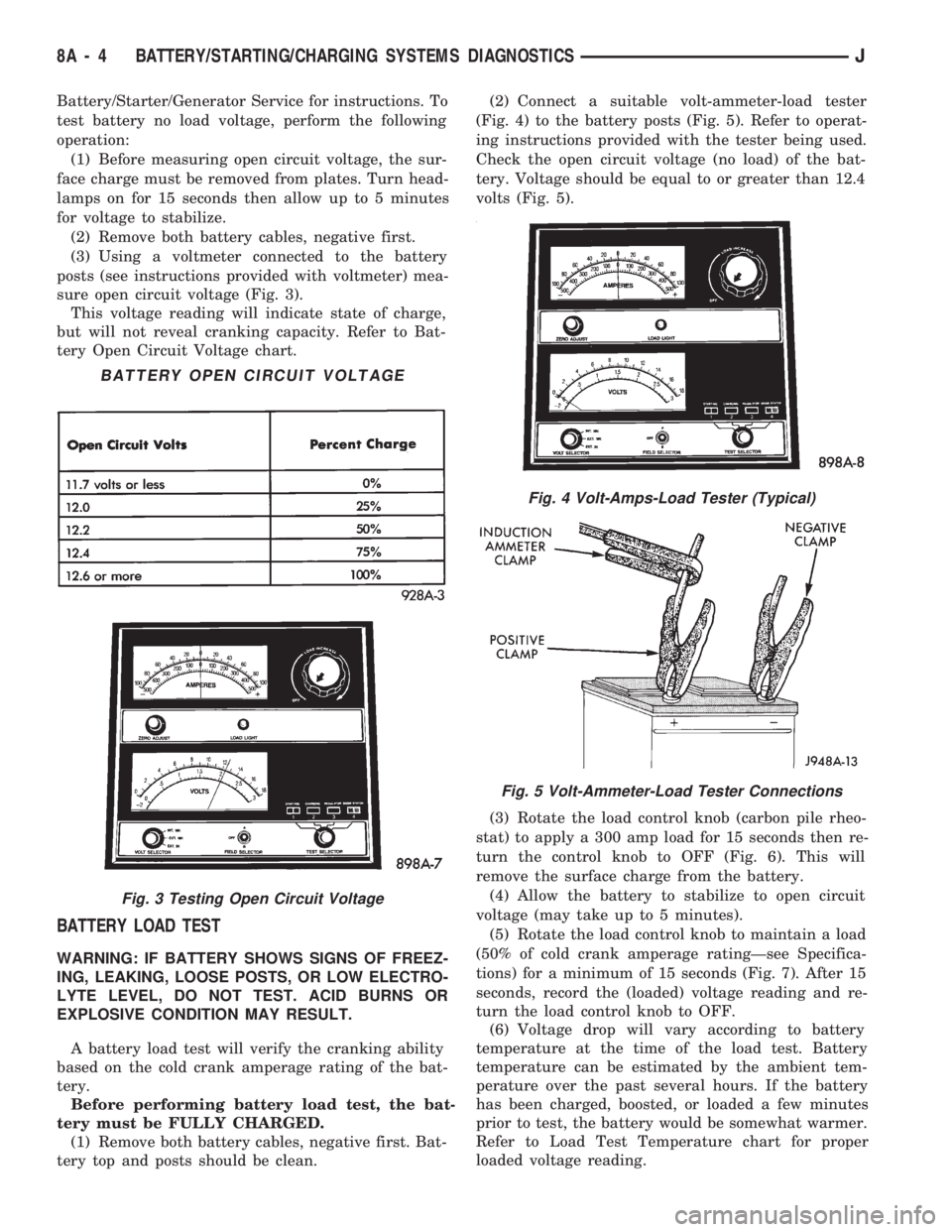

Battery/Starter/Generator Service for instructions. To

test battery no load voltage, perform the following

operation:

(1) Before measuring open circuit voltage, the sur-

face charge must be removed from plates. Turn head-

lamps on for 15 seconds then allow up to 5 minutes

for voltage to stabilize.

(2) Remove both battery cables, negative first.

(3) Using a voltmeter connected to the battery

posts (see instructions provided with voltmeter) mea-

sure open circuit voltage (Fig. 3).

This voltage reading will indicate state of charge,

but will not reveal cranking capacity. Refer to Bat-

tery Open Circuit Voltage chart.

BATTERY LOAD TEST

WARNING: IF BATTERY SHOWS SIGNS OF FREEZ-

ING, LEAKING, LOOSE POSTS, OR LOW ELECTRO-

LYTE LEVEL, DO NOT TEST. ACID BURNS OR

EXPLOSIVE CONDITION MAY RESULT.

A battery load test will verify the cranking ability

based on the cold crank amperage rating of the bat-

tery.

Before performing battery load test, the bat-

tery must be FULLY CHARGED.

(1) Remove both battery cables, negative first. Bat-

tery top and posts should be clean.(2) Connect a suitable volt-ammeter-load tester

(Fig. 4) to the battery posts (Fig. 5). Refer to operat-

ing instructions provided with the tester being used.

Check the open circuit voltage (no load) of the bat-

tery. Voltage should be equal to or greater than 12.4

volts (Fig. 5).

(3) Rotate the load control knob (carbon pile rheo-

stat) to apply a 300 amp load for 15 seconds then re-

turn the control knob to OFF (Fig. 6). This will

remove the surface charge from the battery.

(4) Allow the battery to stabilize to open circuit

voltage (may take up to 5 minutes).

(5) Rotate the load control knob to maintain a load

(50% of cold crank amperage ratingÐsee Specifica-

tions) for a minimum of 15 seconds (Fig. 7). After 15

seconds, record the (loaded) voltage reading and re-

turn the load control knob to OFF.

(6) Voltage drop will vary according to battery

temperature at the time of the load test. Battery

temperature can be estimated by the ambient tem-

perature over the past several hours. If the battery

has been charged, boosted, or loaded a few minutes

prior to test, the battery would be somewhat warmer.

Refer to Load Test Temperature chart for proper

loaded voltage reading.

Fig. 4 Volt-Amps-Load Tester (Typical)

Fig. 5 Volt-Ammeter-Load Tester Connections

BATTERY OPEN CIRCUIT VOLTAGE

Fig. 3 Testing Open Circuit Voltage

8A - 4 BATTERY/STARTING/CHARGING SYSTEMS DIAGNOSTICSJ

Page 294 of 1784

BATTERY/STARTER/GENERATOR SERVICE

CONTENTS

page page

BATTERY SERVICE PROCEDURES.......... 1

ENGINE STARTER MOTOR SERVICE

PROCEDURES......................... 4GENERATOR SERVICE PROCEDURES........ 7

SPECIFICATIONS....................... 10

BATTERY SERVICE PROCEDURES

GENERAL INFORMATION

This section covers battery removal and installa-

tion procedures only. For diagnostic procedures, refer

to Group 8A - Battery/Starting/Charging Systems Di-

agnostics.

BATTERY MAINTENANCE

(1) Inspect cable terminals for corrosion and dam-

age. Remove the corrosion using a wire brush, or

post and terminal cleaner, and a sodium bicarbonate/

water solution. Replace cables that have damaged or

deformed terminals.

Be sure filler caps or vents are installed when

washing battery to prevent solution from enter-

ing battery.

(2) Clean outside of battery case if the original

battery is to be installed. Clean top cover with di-

luted ammonia or a sodium bicarbonate/water solu-

tion to remove acid film. Flush with clean water.

Ensure that cleaning solution does not enter cells.

(3) Remove corrosion from the terminals with a

wire brush or post and terminal cleaner. Inspect the

case for cracks or other damage that would result in

leakage of electrolyte.

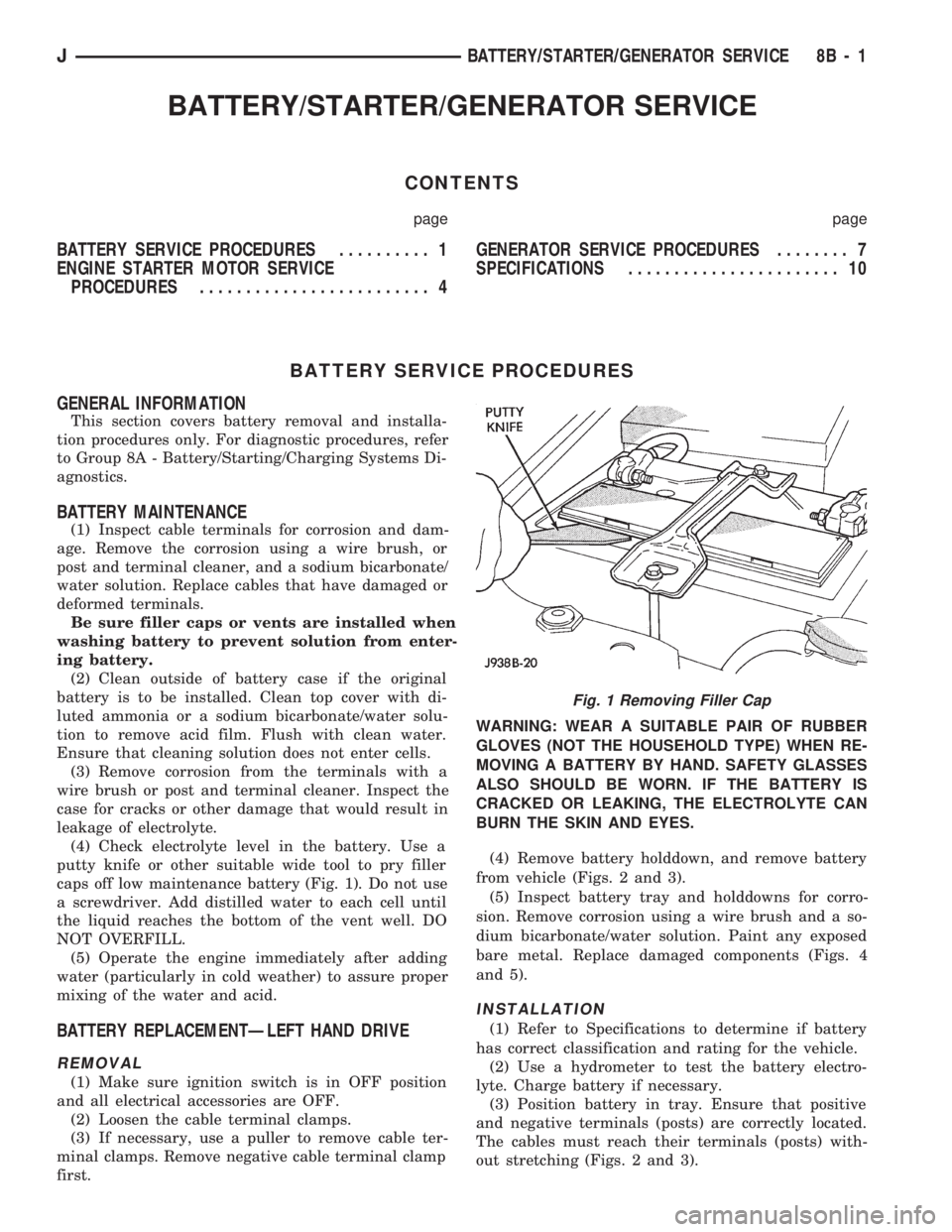

(4) Check electrolyte level in the battery. Use a

putty knife or other suitable wide tool to pry filler

caps off low maintenance battery (Fig. 1). Do not use

a screwdriver. Add distilled water to each cell until

the liquid reaches the bottom of the vent well. DO

NOT OVERFILL.

(5) Operate the engine immediately after adding

water (particularly in cold weather) to assure proper

mixing of the water and acid.

BATTERY REPLACEMENTÐLEFT HAND DRIVE

REMOVAL

(1) Make sure ignition switch is in OFF position

and all electrical accessories are OFF.

(2) Loosen the cable terminal clamps.

(3) If necessary, use a puller to remove cable ter-

minal clamps. Remove negative cable terminal clamp

first.WARNING: WEAR A SUITABLE PAIR OF RUBBER

GLOVES (NOT THE HOUSEHOLD TYPE) WHEN RE-

MOVING A BATTERY BY HAND. SAFETY GLASSES

ALSO SHOULD BE WORN. IF THE BATTERY IS

CRACKED OR LEAKING, THE ELECTROLYTE CAN

BURN THE SKIN AND EYES.

(4) Remove battery holddown, and remove battery

from vehicle (Figs. 2 and 3).

(5) Inspect battery tray and holddowns for corro-

sion. Remove corrosion using a wire brush and a so-

dium bicarbonate/water solution. Paint any exposed

bare metal. Replace damaged components (Figs. 4

and 5).

INSTALLATION

(1) Refer to Specifications to determine if battery

has correct classification and rating for the vehicle.

(2) Use a hydrometer to test the battery electro-

lyte. Charge battery if necessary.

(3) Position battery in tray. Ensure that positive

and negative terminals (posts) are correctly located.

The cables must reach their terminals (posts) with-

out stretching (Figs. 2 and 3).

Fig. 1 Removing Filler Cap

JBATTERY/STARTER/GENERATOR SERVICE 8B - 1

Page 314 of 1784

IGNITION SYSTEMS

CONTENTS

page page

COMPONENT IDENTIFICATION/SYSTEM

OPERATION.......................... 1

COMPONENT REMOVAL/INSTALLATION..... 20DIAGNOSTICS/SERVICE PROCEDURES....... 8

IGNITION SWITCH...................... 30

SPECIFICATIONS....................... 33

COMPONENT IDENTIFICATION/SYSTEM OPERATION

INDEX

page page

Automatic Shut Down (ASD) Relay............ 1

Camshaft Position Sensor................... 1

Crankshaft Position Sensor.................. 2

Distributors.............................. 3

Engine Coolant Temperature Sensor........... 4

General Information........................ 1Ignition Coil.............................. 4

Intake Manifold Air Temperature Sensor........ 5

Manifold Absolute Pressure (MAP) Sensor...... 5

Powertrain Control Module (PCM)............. 6

Throttle Position Sensor.................... 6

GENERAL INFORMATION

Throughout this group, references are made to par-

ticular vehicle models by alphabetical designation

(XJ or YJ) or by the particular vehicle nameplate. A

chart showing a breakdown of alphabetical designa-

tions is included in the Introduction group at the be-

ginning of this manual.

This section of the group, Component Identifica-

tion/System Operation, will discuss ignition system

operation and will identify ignition system compo-

nents.

For diagnostic procedures and adjustments, refer to

the Diagnostics/Service Procedures section of this

group.

For removal and installation of ignition system

components, refer to the Component Removal/Instal-

lation section of this group.

For other useful information, refer to On-Board Di-

agnostics in the General Diagnosis sections of Group

14, Fuel System in this manual.

For operation of the DRB Scan Tool, refer to the

appropriate Powertrain Diagnostic Procedures ser-

vice manual.

An Ignition specifications section is included at the

end of this group. A general Maintenance Schedule

(mileage intervals) for ignition related items can be

found in Group 0, Lubrication and Maintenance. This

schedule can also be found in the Owners Manual.

IGNITION SYSTEMS

A multi-port, fuel injected engine is used on all

models. The ignition system is controlled by the Pow-

ertrain Control Module (PCM) on all engines. The

PCM was formerly referred to as the SBEC or engine

controller.

The ignition system consists of:

²Spark Plugs

²Ignition Coil

²Secondary Ignition Cables

²Ignition distributor (contains rotor and camshaft

position sensor)

²Powertrain Control Module (PCM)

²Crankshaft Position Sensor

AUTOMATIC SHUT DOWN (ASD) RELAY

The automatic shut down (ASD) relay is located in

the Power Distribution Center (PDC) near the bat-

tery (Fig. 1 or 2). As one of its functions, it will sup-

ply battery voltage to the ignition coil. The ground

circuit for the ASD relay is controlled by the Power-

train Control Module (PCM). The PCM regulates

ASD relay operation by switching the ground circuit

on-and-off.

CAMSHAFT POSITION SENSOR

The camshaft position sensor is located in the igni-

tion distributor (Figs. 3 or 4) on all engines.

The camshaft position sensor contains a hall effect

device called a sync signal generator to generate a

fuel sync signal. This sync signal generator detects a

JIGNITION SYSTEMS 8D - 1

Page 329 of 1784

For diagnostics, refer to the appropriate Powertrain

Diagnostic Procedures service manual for operation

of the DRB scan tool.

SPARK PLUGS

For spark plug removal, cleaning, gap adjustment

and installation, refer to the Component Removal/In-

stallation section of this group.

Faulty carbon and/or gas fouled plugs generally

cause hard starting, but they will clean up at higher

engine speeds. Faulty plugs can be identified in a

number of ways: poor fuel economy, power loss, de-

crease in engine speed, hard starting and, in general,

poor engine performance.

Remove the spark plugs and examine them for

burned electrodes and fouled, cracked or broken por-

celain insulators. Keep plugs arranged in the order

in which they were removed from the engine. An iso-

lated plug displaying an abnormal condition indi-

cates that a problem exists in the corresponding

cylinder. Replace spark plugs at the intervals recom-

mended in the maintenance chart in Group 0, Lubri-

cation and Maintenance.

Spark plugs that have low mileage may be cleaned

and reused if not otherwise defective. Refer to the

following Spark Plug Condition section of this group.

CONDITION

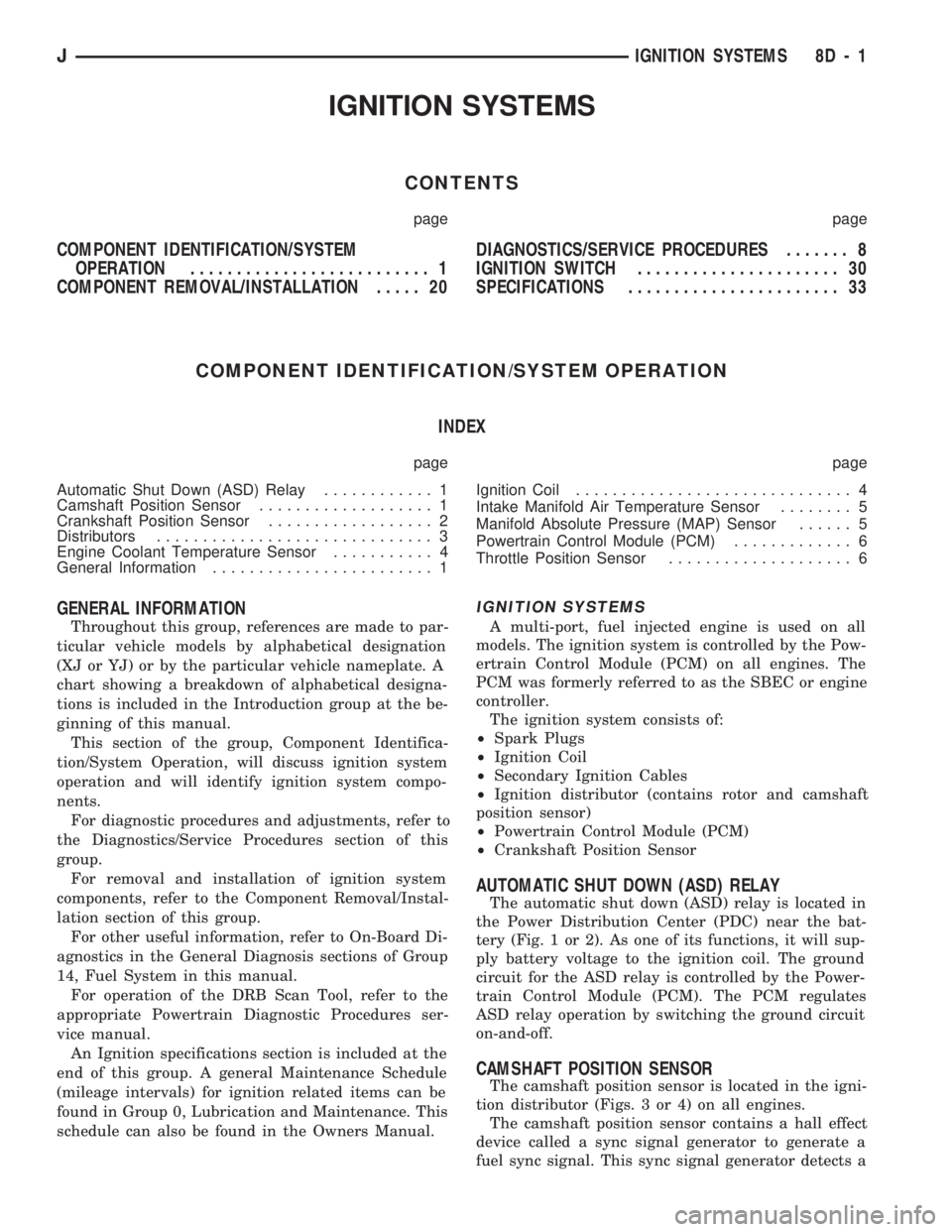

NORMAL OPERATING

The few deposits present on the spark plug will

probably be light tan or slightly gray in color. This is

evident with most grades of commercial gasoline

(Fig. 24). There will not be evidence of electrode

burning. Gap growth will not average more than ap-

proximately 0.025 mm (.001 in) per 1600 km (1000

miles) of operation. Spark plugs that have normal

wear can usually be cleaned, have the electrodes

filed, have the gap set and then be installed.Some fuel refiners in several areas of the United

States have introduced a manganese additive (MMT)

for unleaded fuel. During combustion, fuel with

MMT causes the entire tip of the spark plug to be

coated with a rust colored deposit. This rust color can

be misdiagnosed as being caused by coolant in the

combustion chamber. Spark plug performance is not

affected by MMT deposits.

COLD FOULING/CARBON FOULING

Cold fouling is sometimes referred to as carbon

fouling. The deposits that cause cold fouling are ba-

sically carbon (Fig. 24). A dry, black deposit on one

or two plugs in a set may be caused by sticking

valves or defective spark plug cables. Cold (carbon)

fouling of the entire set of spark plugs may be caused

by a clogged air filter or repeated short operating

times (short trips).

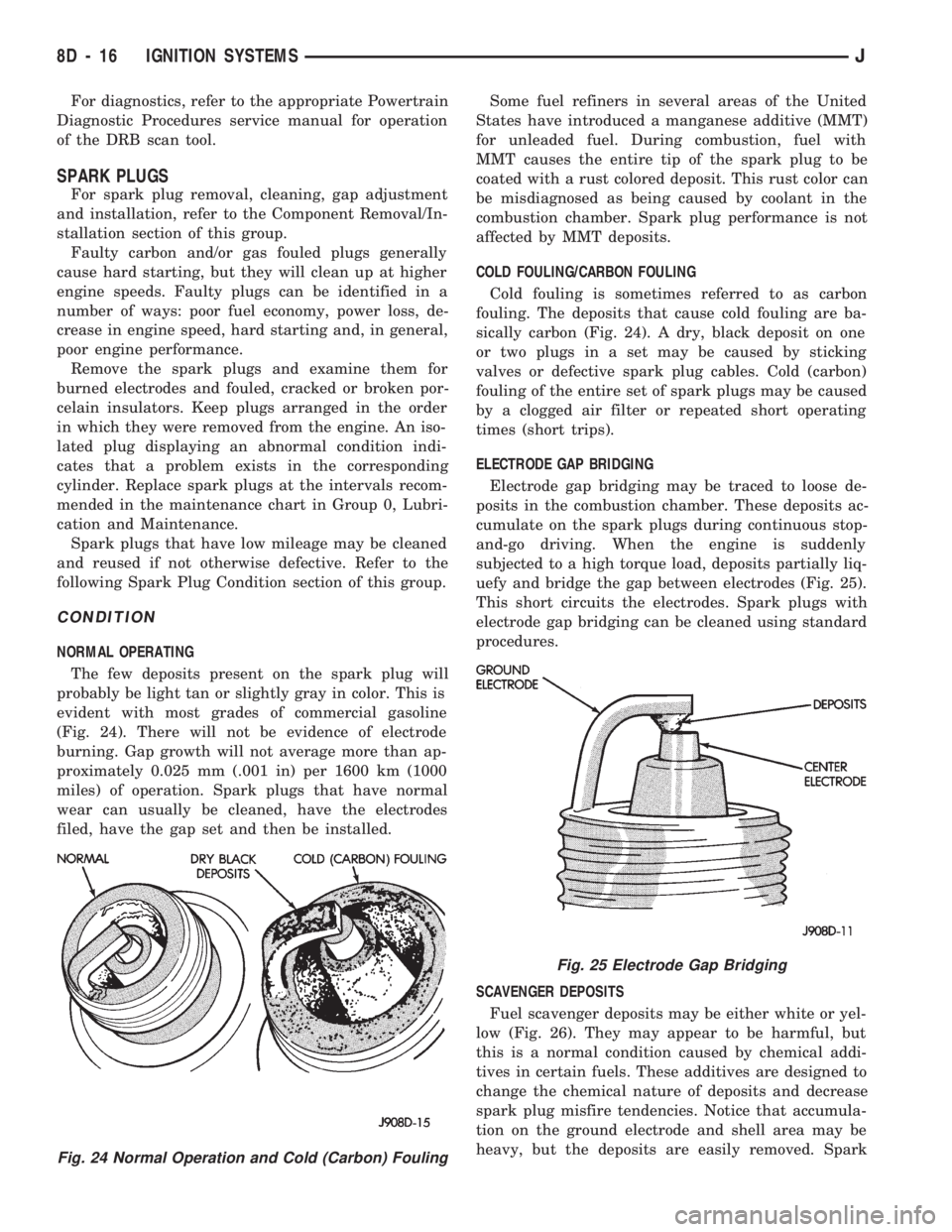

ELECTRODE GAP BRIDGING

Electrode gap bridging may be traced to loose de-

posits in the combustion chamber. These deposits ac-

cumulate on the spark plugs during continuous stop-

and-go driving. When the engine is suddenly

subjected to a high torque load, deposits partially liq-

uefy and bridge the gap between electrodes (Fig. 25).

This short circuits the electrodes. Spark plugs with

electrode gap bridging can be cleaned using standard

procedures.

SCAVENGER DEPOSITS

Fuel scavenger deposits may be either white or yel-

low (Fig. 26). They may appear to be harmful, but

this is a normal condition caused by chemical addi-

tives in certain fuels. These additives are designed to

change the chemical nature of deposits and decrease

spark plug misfire tendencies. Notice that accumula-

tion on the ground electrode and shell area may be

heavy, but the deposits are easily removed. Spark

Fig. 24 Normal Operation and Cold (Carbon) Fouling

Fig. 25 Electrode Gap Bridging

8D - 16 IGNITION SYSTEMSJ

Page 386 of 1784

HORNS

CONTENTS

page page

GENERAL INFORMATION.................. 1

HORN SWITCH (HORN PAD) REPLACEMENT . . 3

TORQUE SPECIFICATIONS................. 3XJ ..................................... 1

YJ ..................................... 2

GENERAL INFORMATION

For XJ/YJ vehicles battery voltage is applied to the

horn relay through a fuse.

When the horn switch is depressed, the horn relay

is grounded, pulling the contact closed and providing

battery voltage to the horns.

A slip ring and brush arrangement in the steering

wheel allows the switch circuit to maintain contact

while allowing rotation of the steering wheel.On XJ models, a cadmium-plated ground

screw is used to attach the horn(s) to the body.

Do not substitute other types of ground screws

as they may become corroded and cause a loss

of ground.

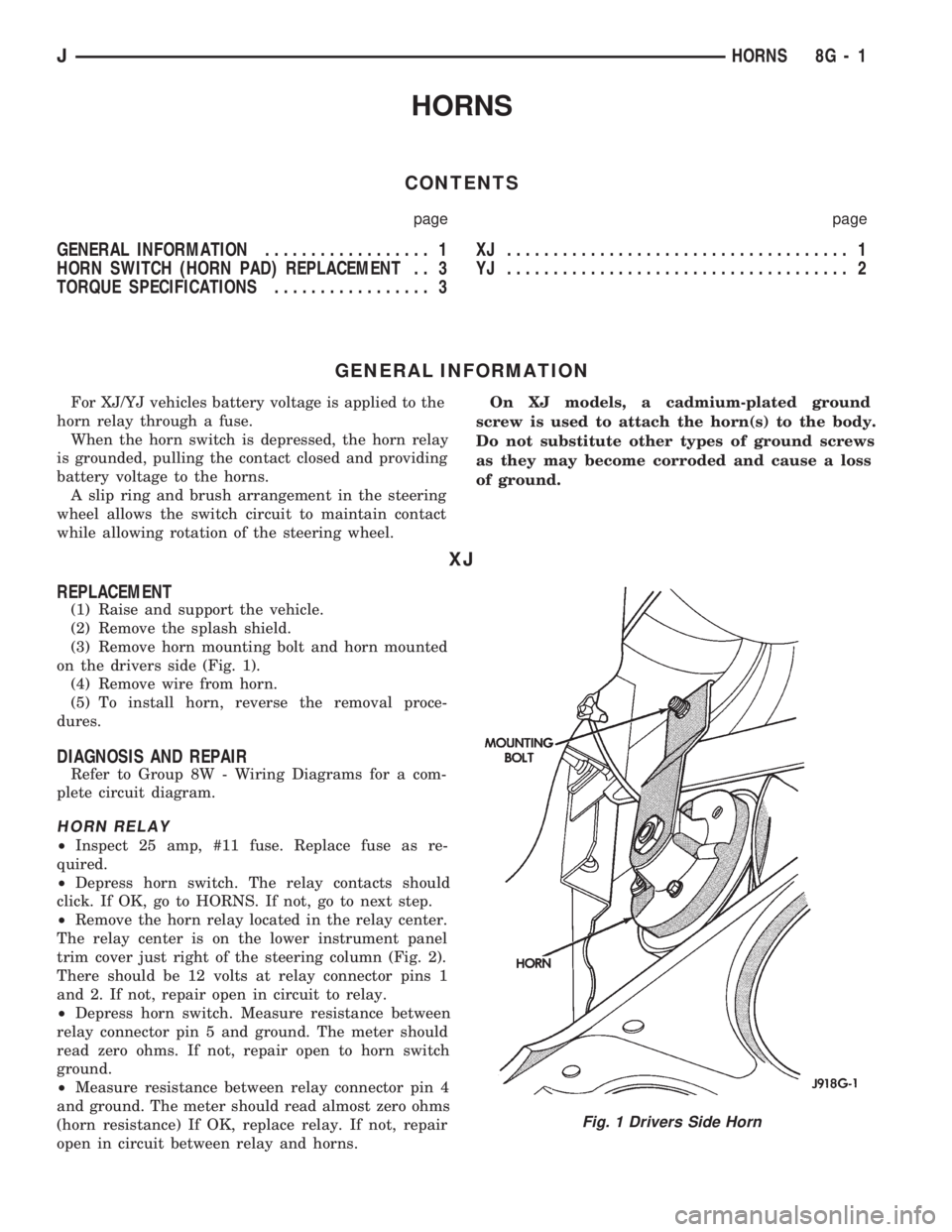

XJ

REPLACEMENT

(1) Raise and support the vehicle.

(2) Remove the splash shield.

(3) Remove horn mounting bolt and horn mounted

on the drivers side (Fig. 1).

(4) Remove wire from horn.

(5) To install horn, reverse the removal proce-

dures.

DIAGNOSIS AND REPAIR

Refer to Group 8W - Wiring Diagrams for a com-

plete circuit diagram.

HORN RELAY

²Inspect 25 amp, #11 fuse. Replace fuse as re-

quired.

²Depress horn switch. The relay contacts should

click. If OK, go to HORNS. If not, go to next step.

²Remove the horn relay located in the relay center.

The relay center is on the lower instrument panel

trim cover just right of the steering column (Fig. 2).

There should be 12 volts at relay connector pins 1

and 2. If not, repair open in circuit to relay.

²Depress horn switch. Measure resistance between

relay connector pin 5 and ground. The meter should

read zero ohms. If not, repair open to horn switch

ground.

²Measure resistance between relay connector pin 4

and ground. The meter should read almost zero ohms

(horn resistance) If OK, replace relay. If not, repair

open in circuit between relay and horns.

Fig. 1 Drivers Side Horn

JHORNS 8G - 1

Page 390 of 1784

VEHICLE SPEED CONTROL SYSTEM

CONTENTS

page page

SERVICE PROCEDURES................... 9TEST PROCEDURES...................... 5

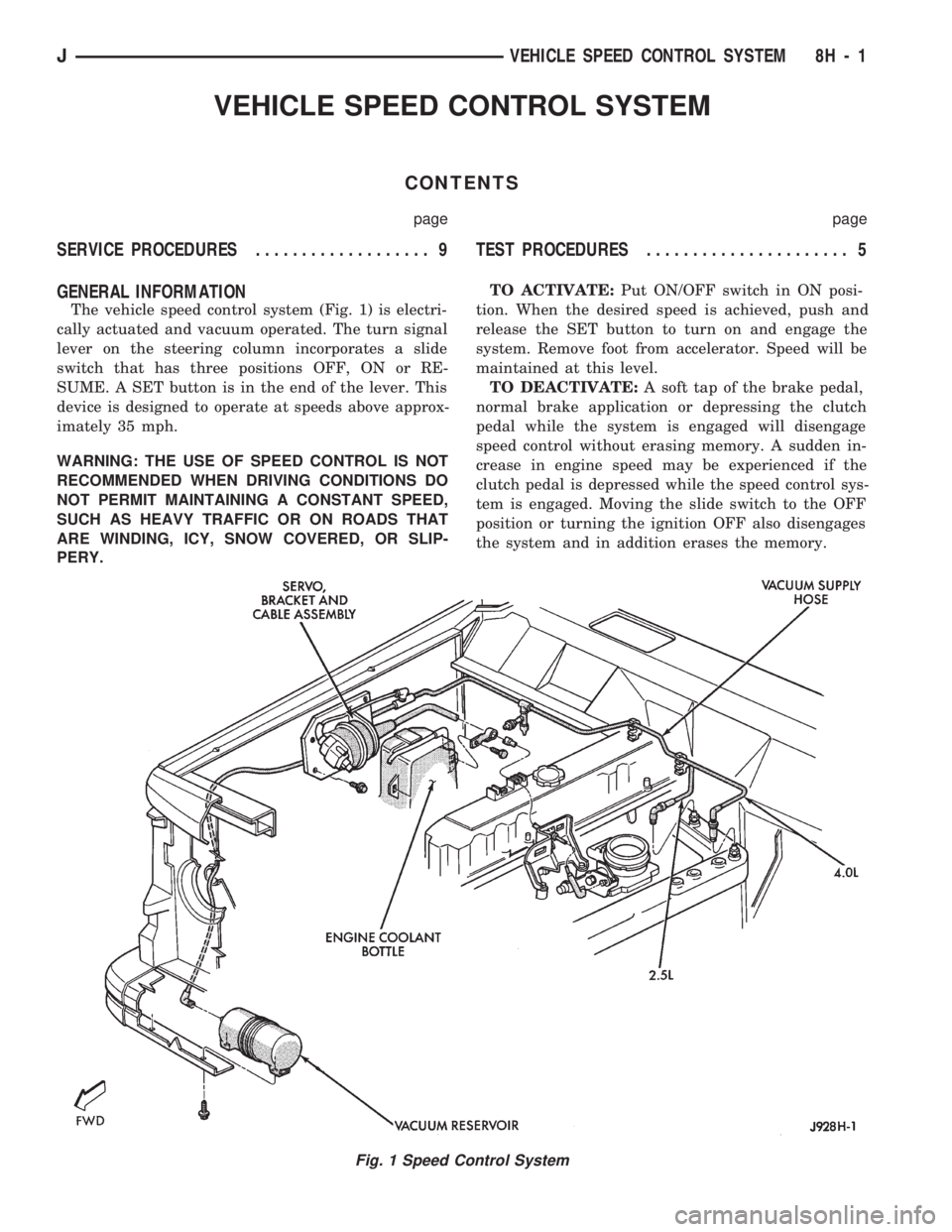

GENERAL INFORMATION

The vehicle speed control system (Fig. 1) is electri-

cally actuated and vacuum operated. The turn signal

lever on the steering column incorporates a slide

switch that has three positions OFF, ON or RE-

SUME. A SET button is in the end of the lever. This

device is designed to operate at speeds above approx-

imately 35 mph.

WARNING: THE USE OF SPEED CONTROL IS NOT

RECOMMENDED WHEN DRIVING CONDITIONS DO

NOT PERMIT MAINTAINING A CONSTANT SPEED,

SUCH AS HEAVY TRAFFIC OR ON ROADS THAT

ARE WINDING, ICY, SNOW COVERED, OR SLIP-

PERY.TO ACTIVATE:Put ON/OFF switch in ON posi-

tion. When the desired speed is achieved, push and

release the SET button to turn on and engage the

system. Remove foot from accelerator. Speed will be

maintained at this level.

TO DEACTIVATE:A soft tap of the brake pedal,

normal brake application or depressing the clutch

pedal while the system is engaged will disengage

speed control without erasing memory. A sudden in-

crease in engine speed may be experienced if the

clutch pedal is depressed while the speed control sys-

tem is engaged. Moving the slide switch to the OFF

position or turning the ignition OFF also disengages

the system and in addition erases the memory.

Fig. 1 Speed Control System

JVEHICLE SPEED CONTROL SYSTEM 8H - 1

Page 396 of 1784

perform the speed control switch test. If switch is not

at fault, then check main harness and repair as nec-

essary.

(8) Using an ohmmeter, connect one lead to a good

body ground and touch other lead to terminal in cav-

ity number 29. With brake pedal released, meter

should show continuity. When pedal is depressed,

meter should show open circuit.

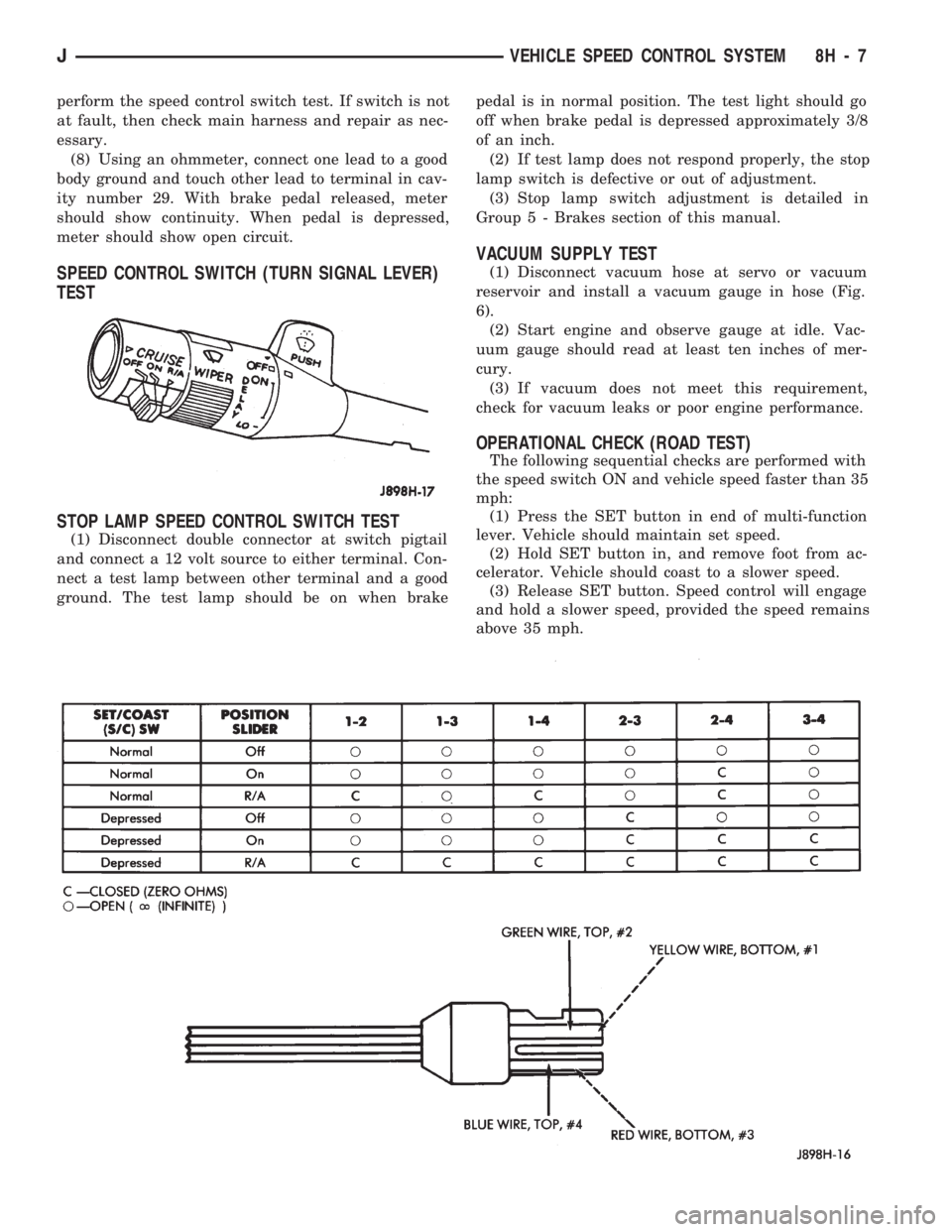

SPEED CONTROL SWITCH (TURN SIGNAL LEVER)

TEST

STOP LAMP SPEED CONTROL SWITCH TEST

(1) Disconnect double connector at switch pigtail

and connect a 12 volt source to either terminal. Con-

nect a test lamp between other terminal and a good

ground. The test lamp should be on when brakepedal is in normal position. The test light should go

off when brake pedal is depressed approximately 3/8

of an inch.

(2) If test lamp does not respond properly, the stop

lamp switch is defective or out of adjustment.

(3) Stop lamp switch adjustment is detailed in

Group 5 - Brakes section of this manual.

VACUUM SUPPLY TEST

(1) Disconnect vacuum hose at servo or vacuum

reservoir and install a vacuum gauge in hose (Fig.

6).

(2) Start engine and observe gauge at idle. Vac-

uum gauge should read at least ten inches of mer-

cury.

(3) If vacuum does not meet this requirement,

check for vacuum leaks or poor engine performance.

OPERATIONAL CHECK (ROAD TEST)

The following sequential checks are performed with

the speed switch ON and vehicle speed faster than 35

mph:

(1) Press the SET button in end of multi-function

lever. Vehicle should maintain set speed.

(2) Hold SET button in, and remove foot from ac-

celerator. Vehicle should coast to a slower speed.

(3) Release SET button. Speed control will engage

and hold a slower speed, provided the speed remains

above 35 mph.

JVEHICLE SPEED CONTROL SYSTEM 8H - 7

Page 408 of 1784

WINDSHIELD WIPERS

CONTENTS

page page

WIPER CONTROL SWITCH REPLACEMENT . . 15

WIPER SWITCH TESTING................ 19XJ .................................... 1

YJ .................................... 8

XJ

INDEX

page page

Diagnosing Rear Wiper..................... 6

Diagnosing Rear Wiper Washer.............. 6

Diagnosing Windshield Washer (Intermittent)..... 5

Diagnosing Windshield Washer (Non-Intermittent) . 4

Diagnosing Windshield Wipers............... 11

Front Wipers/Washers...................... 1

Intermittent Wiper Module................... 5

Liftgate Wiper............................ 5Liftgate Wiper Switch Replacement............ 6

Rear Wiper/Washer Switch Testing............ 7

Torque Specifications XJ.................... 7

Washer Pump Replacement................. 6

Washer Pump ReplacementÐLeft Hand Drive.... 2

Washer Pump ReplacementÐRight Hand Drive . . 3

Windshield Wiper Motor.................... 2

FRONT WIPERS/WASHERS

GENERAL

Two-speed electric windshield wipers and electric

washers are standard equipment. An optional inter-

mittent wiper system provides a pause between wipe

cycles for use during conditions of very light precipi-

tation.

The windshield wipers can be operated with the

windshield wiper switch only when the ignition

switch is in the ON or ACCESSORY position. A cir-

cuit breaker located in the fuse block protects the cir-

cuitry of the wiper system.

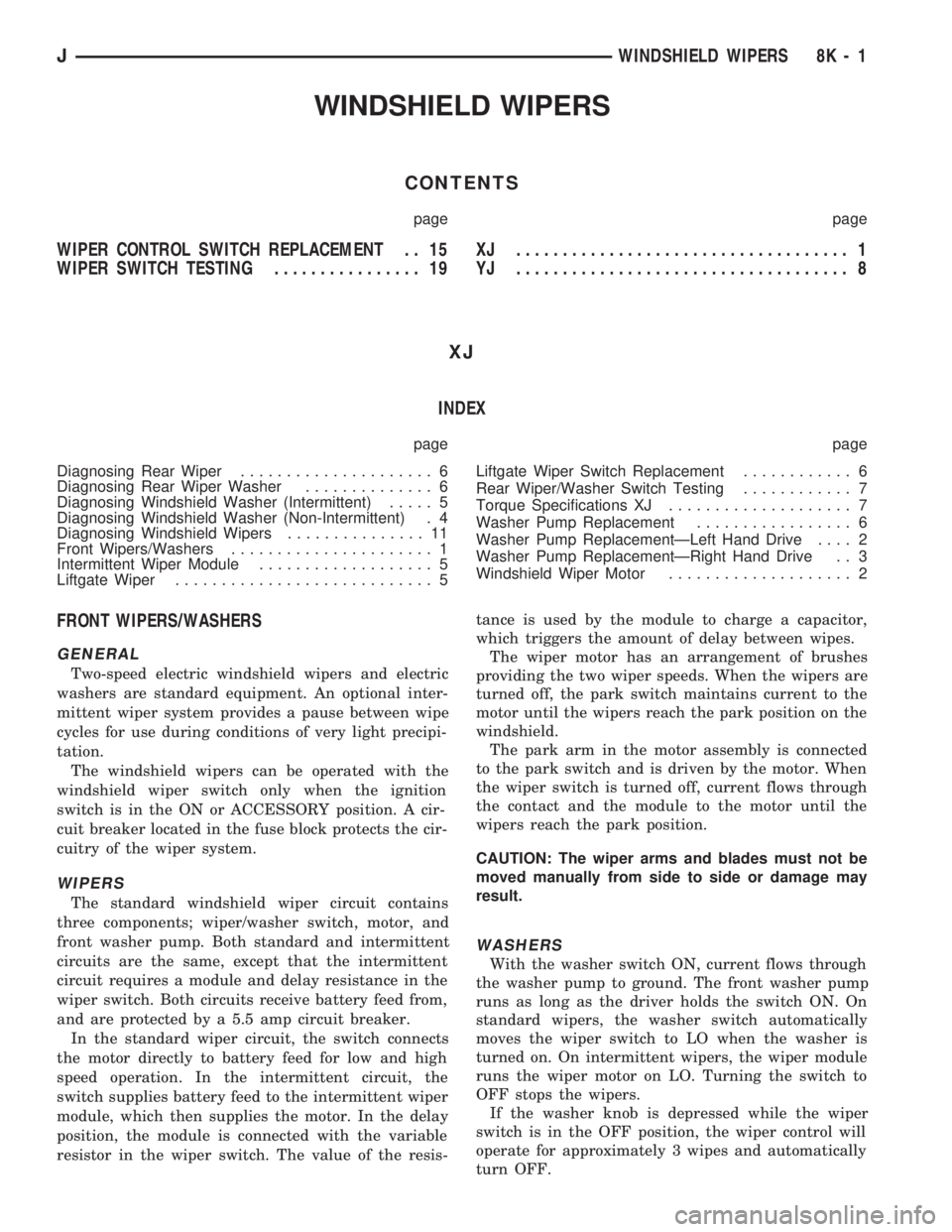

WIPERS

The standard windshield wiper circuit contains

three components; wiper/washer switch, motor, and

front washer pump. Both standard and intermittent

circuits are the same, except that the intermittent

circuit requires a module and delay resistance in the

wiper switch. Both circuits receive battery feed from,

and are protected by a 5.5 amp circuit breaker.

In the standard wiper circuit, the switch connects

the motor directly to battery feed for low and high

speed operation. In the intermittent circuit, the

switch supplies battery feed to the intermittent wiper

module, which then supplies the motor. In the delay

position, the module is connected with the variable

resistor in the wiper switch. The value of the resis-tance is used by the module to charge a capacitor,

which triggers the amount of delay between wipes.

The wiper motor has an arrangement of brushes

providing the two wiper speeds. When the wipers are

turned off, the park switch maintains current to the

motor until the wipers reach the park position on the

windshield.

The park arm in the motor assembly is connected

to the park switch and is driven by the motor. When

the wiper switch is turned off, current flows through

the contact and the module to the motor until the

wipers reach the park position.

CAUTION: The wiper arms and blades must not be

moved manually from side to side or damage may

result.

WASHERS

With the washer switch ON, current flows through

the washer pump to ground. The front washer pump

runs as long as the driver holds the switch ON. On

standard wipers, the washer switch automatically

moves the wiper switch to LO when the washer is

turned on. On intermittent wipers, the wiper module

runs the wiper motor on LO. Turning the switch to

OFF stops the wipers.

If the washer knob is depressed while the wiper

switch is in the OFF position, the wiper control will

operate for approximately 3 wipes and automatically

turn OFF.

JWINDSHIELD WIPERS 8K - 1