ABS JEEP CHEROKEE 1994 Service Manual Online

[x] Cancel search | Manufacturer: JEEP, Model Year: 1994, Model line: CHEROKEE, Model: JEEP CHEROKEE 1994Pages: 1784, PDF Size: 77.09 MB

Page 405 of 1784

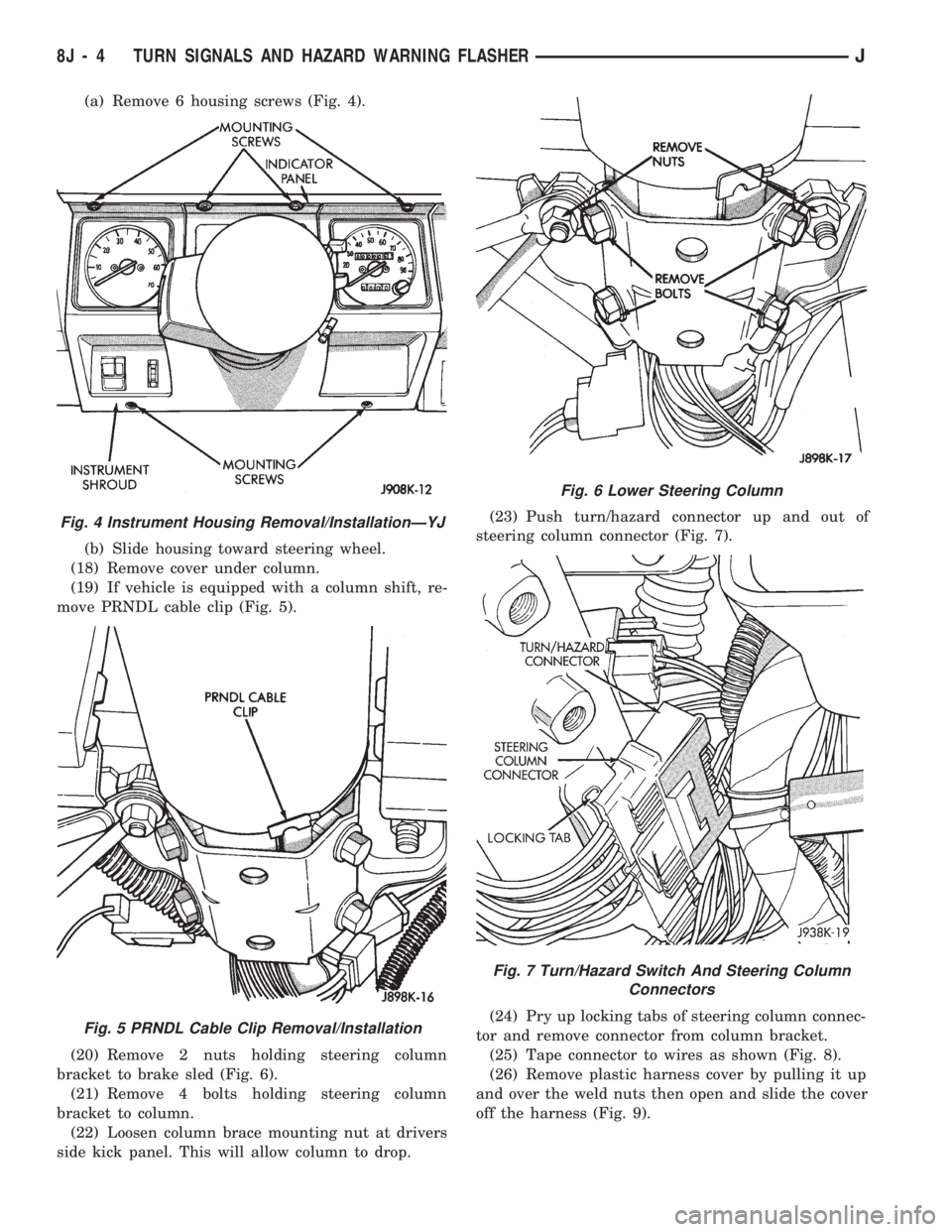

(a) Remove 6 housing screws (Fig. 4).

(b) Slide housing toward steering wheel.

(18) Remove cover under column.

(19) If vehicle is equipped with a column shift, re-

move PRNDL cable clip (Fig. 5).

(20) Remove 2 nuts holding steering column

bracket to brake sled (Fig. 6).

(21) Remove 4 bolts holding steering column

bracket to column.

(22) Loosen column brace mounting nut at drivers

side kick panel. This will allow column to drop.(23) Push turn/hazard connector up and out of

steering column connector (Fig. 7).

(24) Pry up locking tabs of steering column connec-

tor and remove connector from column bracket.

(25) Tape connector to wires as shown (Fig. 8).

(26) Remove plastic harness cover by pulling it up

and over the weld nuts then open and slide the cover

off the harness (Fig. 9).

Fig. 4 Instrument Housing Removal/InstallationÐYJ

Fig. 5 PRNDL Cable Clip Removal/Installation

Fig. 6 Lower Steering Column

Fig. 7 Turn/Hazard Switch And Steering Column

Connectors

8J - 4 TURN SIGNALS AND HAZARD WARNING FLASHERJ

Page 413 of 1784

(2) Install the mounting screws.

(3) Connect the wiring harness.

(4) Install the pivot pin, seal, bezel and attaching

nut (Fig. 2). Torque nut to 4 Nzm (32 in. lbs.).

(5) Connect interior washer hose.

Lubricate the bezel nipples with a small amount

of water and then install the washer hoses.

(6) Install the liftgate trim panel.

(7) Install the wiper arm assembly and connect the

external washer hose to the bezel.

(8) Slide the clip along the hose until it is over

hose mount.

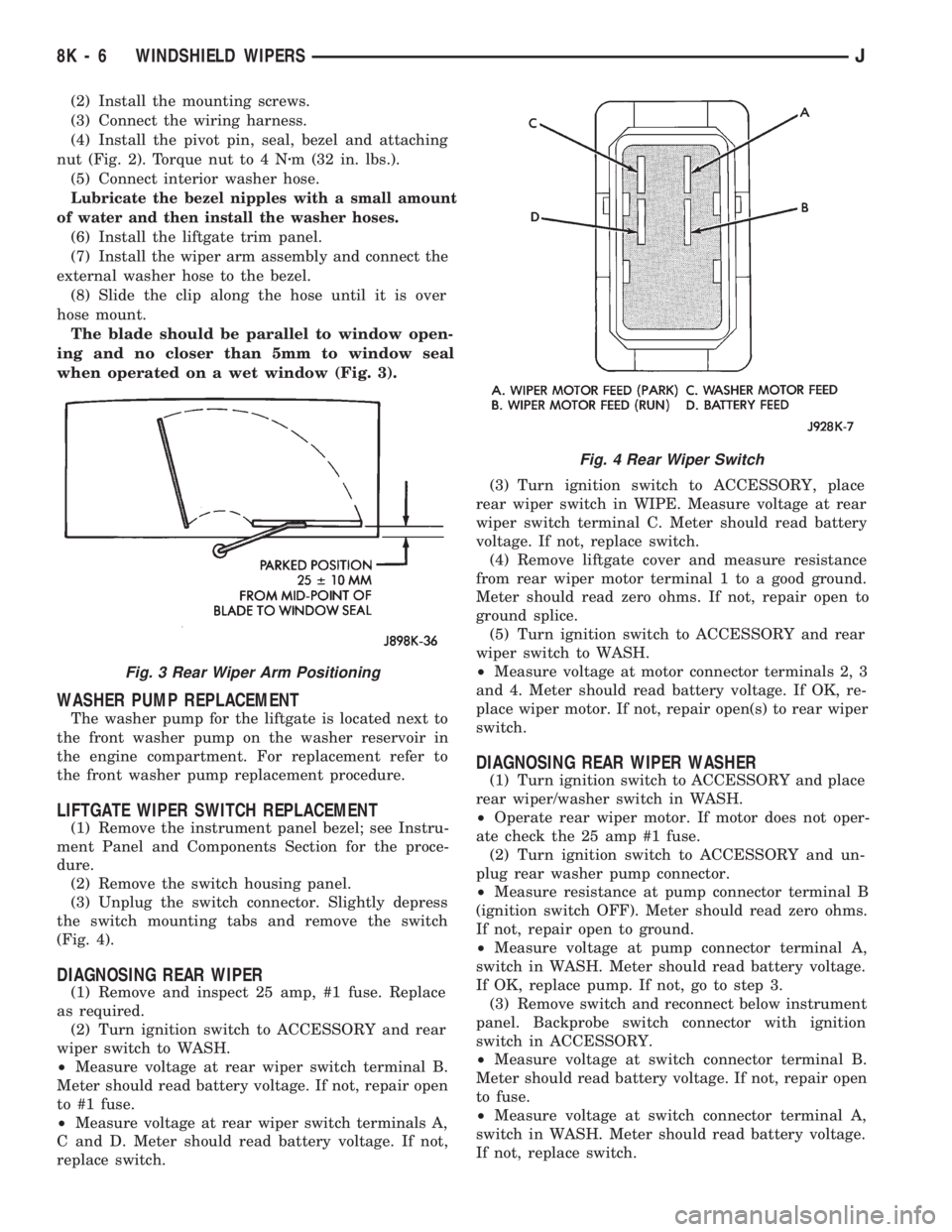

The blade should be parallel to window open-

ing and no closer than 5mm to window seal

when operated on a wet window (Fig. 3).

WASHER PUMP REPLACEMENT

The washer pump for the liftgate is located next to

the front washer pump on the washer reservoir in

the engine compartment. For replacement refer to

the front washer pump replacement procedure.

LIFTGATE WIPER SWITCH REPLACEMENT

(1) Remove the instrument panel bezel; see Instru-

ment Panel and Components Section for the proce-

dure.

(2) Remove the switch housing panel.

(3) Unplug the switch connector. Slightly depress

the switch mounting tabs and remove the switch

(Fig. 4).

DIAGNOSING REAR WIPER

(1) Remove and inspect 25 amp, #1 fuse. Replace

as required.

(2) Turn ignition switch to ACCESSORY and rear

wiper switch to WASH.

²Measure voltage at rear wiper switch terminal B.

Meter should read battery voltage. If not, repair open

to #1 fuse.

²Measure voltage at rear wiper switch terminals A,

C and D. Meter should read battery voltage. If not,

replace switch.(3) Turn ignition switch to ACCESSORY, place

rear wiper switch in WIPE. Measure voltage at rear

wiper switch terminal C. Meter should read battery

voltage. If not, replace switch.

(4) Remove liftgate cover and measure resistance

from rear wiper motor terminal 1 to a good ground.

Meter should read zero ohms. If not, repair open to

ground splice.

(5) Turn ignition switch to ACCESSORY and rear

wiper switch to WASH.

²Measure voltage at motor connector terminals 2, 3

and 4. Meter should read battery voltage. If OK, re-

place wiper motor. If not, repair open(s) to rear wiper

switch.

DIAGNOSING REAR WIPER WASHER

(1) Turn ignition switch to ACCESSORY and place

rear wiper/washer switch in WASH.

²Operate rear wiper motor. If motor does not oper-

ate check the 25 amp #1 fuse.

(2) Turn ignition switch to ACCESSORY and un-

plug rear washer pump connector.

²Measure resistance at pump connector terminal B

(ignition switch OFF). Meter should read zero ohms.

If not, repair open to ground.

²Measure voltage at pump connector terminal A,

switch in WASH. Meter should read battery voltage.

If OK, replace pump. If not, go to step 3.

(3) Remove switch and reconnect below instrument

panel. Backprobe switch connector with ignition

switch in ACCESSORY.

²Measure voltage at switch connector terminal B.

Meter should read battery voltage. If not, repair open

to fuse.

²Measure voltage at switch connector terminal A,

switch in WASH. Meter should read battery voltage.

If not, replace switch.

Fig. 3 Rear Wiper Arm Positioning

Fig. 4 Rear Wiper Switch

8K - 6 WINDSHIELD WIPERSJ

Page 420 of 1784

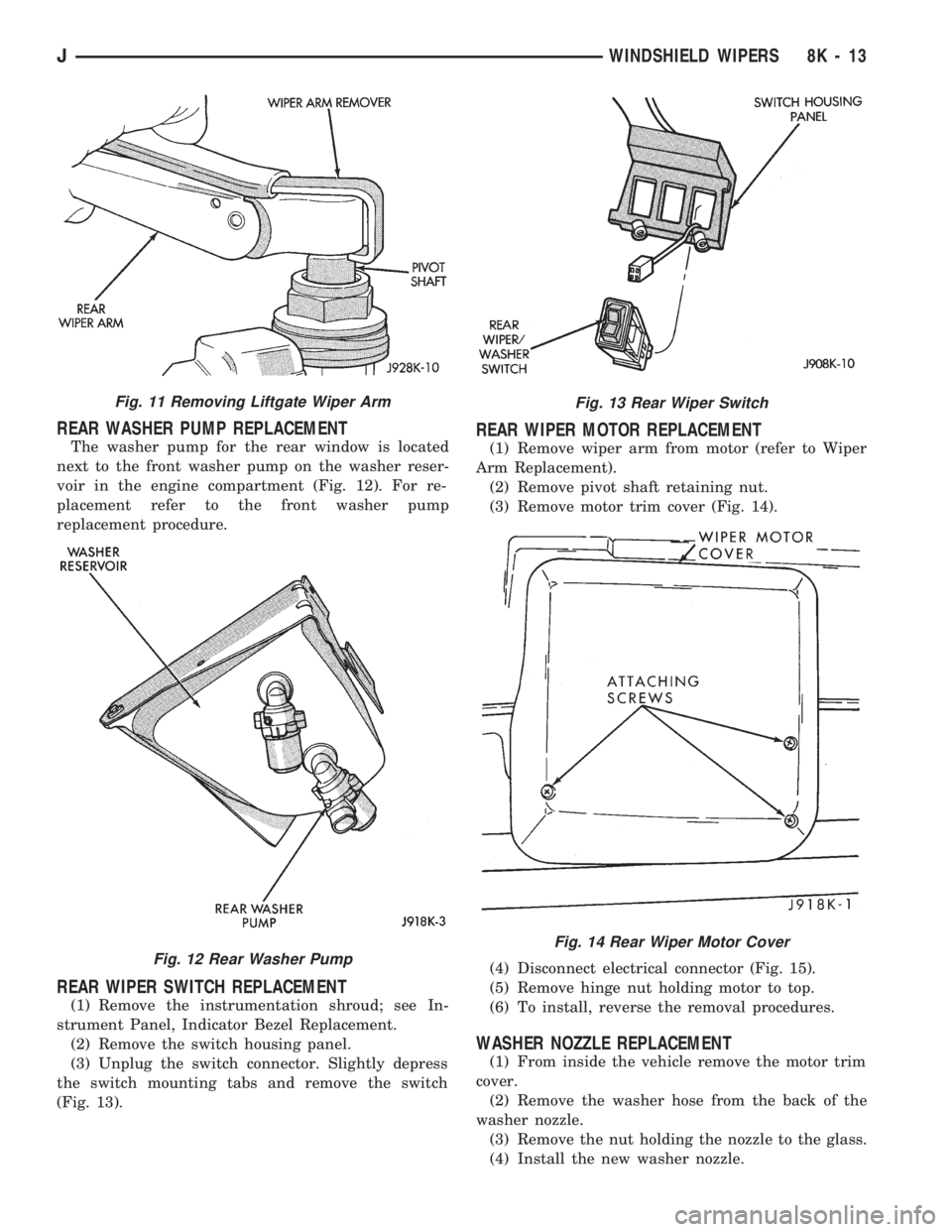

REAR WASHER PUMP REPLACEMENT

The washer pump for the rear window is located

next to the front washer pump on the washer reser-

voir in the engine compartment (Fig. 12). For re-

placement refer to the front washer pump

replacement procedure.

REAR WIPER SWITCH REPLACEMENT

(1) Remove the instrumentation shroud; see In-

strument Panel, Indicator Bezel Replacement.

(2) Remove the switch housing panel.

(3) Unplug the switch connector. Slightly depress

the switch mounting tabs and remove the switch

(Fig. 13).

REAR WIPER MOTOR REPLACEMENT

(1) Remove wiper arm from motor (refer to Wiper

Arm Replacement).

(2) Remove pivot shaft retaining nut.

(3) Remove motor trim cover (Fig. 14).

(4) Disconnect electrical connector (Fig. 15).

(5) Remove hinge nut holding motor to top.

(6) To install, reverse the removal procedures.

WASHER NOZZLE REPLACEMENT

(1) From inside the vehicle remove the motor trim

cover.

(2) Remove the washer hose from the back of the

washer nozzle.

(3) Remove the nut holding the nozzle to the glass.

(4) Install the new washer nozzle.

Fig. 11 Removing Liftgate Wiper Arm

Fig. 12 Rear Washer Pump

Fig. 13 Rear Wiper Switch

Fig. 14 Rear Wiper Motor Cover

JWINDSHIELD WIPERS 8K - 13

Page 424 of 1784

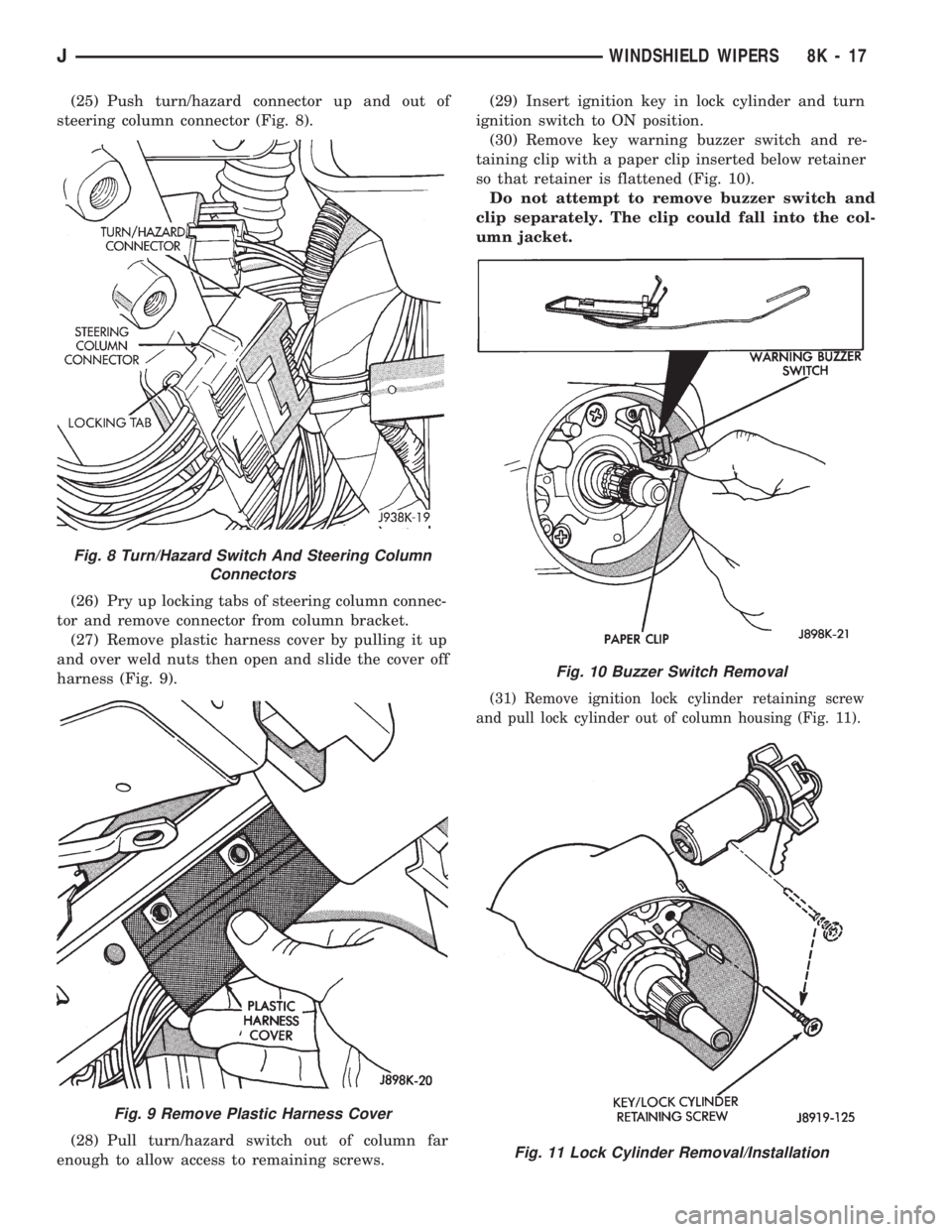

(25) Push turn/hazard connector up and out of

steering column connector (Fig. 8).

(26) Pry up locking tabs of steering column connec-

tor and remove connector from column bracket.

(27) Remove plastic harness cover by pulling it up

and over weld nuts then open and slide the cover off

harness (Fig. 9).

(28) Pull turn/hazard switch out of column far

enough to allow access to remaining screws.(29) Insert ignition key in lock cylinder and turn

ignition switch to ON position.

(30) Remove key warning buzzer switch and re-

taining clip with a paper clip inserted below retainer

so that retainer is flattened (Fig. 10).

Do not attempt to remove buzzer switch and

clip separately. The clip could fall into the col-

umn jacket.

(31) Remove ignition lock cylinder retaining screw

and pull lock cylinder out of column housing (Fig. 11).

Fig. 8 Turn/Hazard Switch And Steering Column

Connectors

Fig. 9 Remove Plastic Harness Cover

Fig. 10 Buzzer Switch Removal

Fig. 11 Lock Cylinder Removal/Installation

JWINDSHIELD WIPERS 8K - 17

Page 431 of 1784

(3) Move vehicle with the headlamps located di-

rectly above the 7.62-meters (25-feet) reference line.

(4) Equalize all the tire pressures.

(5) Rock vehicle from side to side to stabilize the

springs and shock absorbers.

(6) Use tape to attach a vehicle centerline on the

screen/wall (6). Ensure that it is aligned with and

represents the centerline of the vehicle.

(7) Measure distance between the vehicle head-

lamp centers. Divide this distance by two. Measure

the one/half distance outward from each side of the

vehicle centerline (6). Use tape to attach the right

and left lamp vertical centerline (4 and 5) on the

screen/wall (6).

(8) Measure the distance from the center of each

headlamp to the floor.

(9) Measure the lamp-to-floor distance upward

from the floor at each lamp vertical centerline (4 and

5). Use tape to attach the lamp horizontal centerline

(3) on the screen/wall.

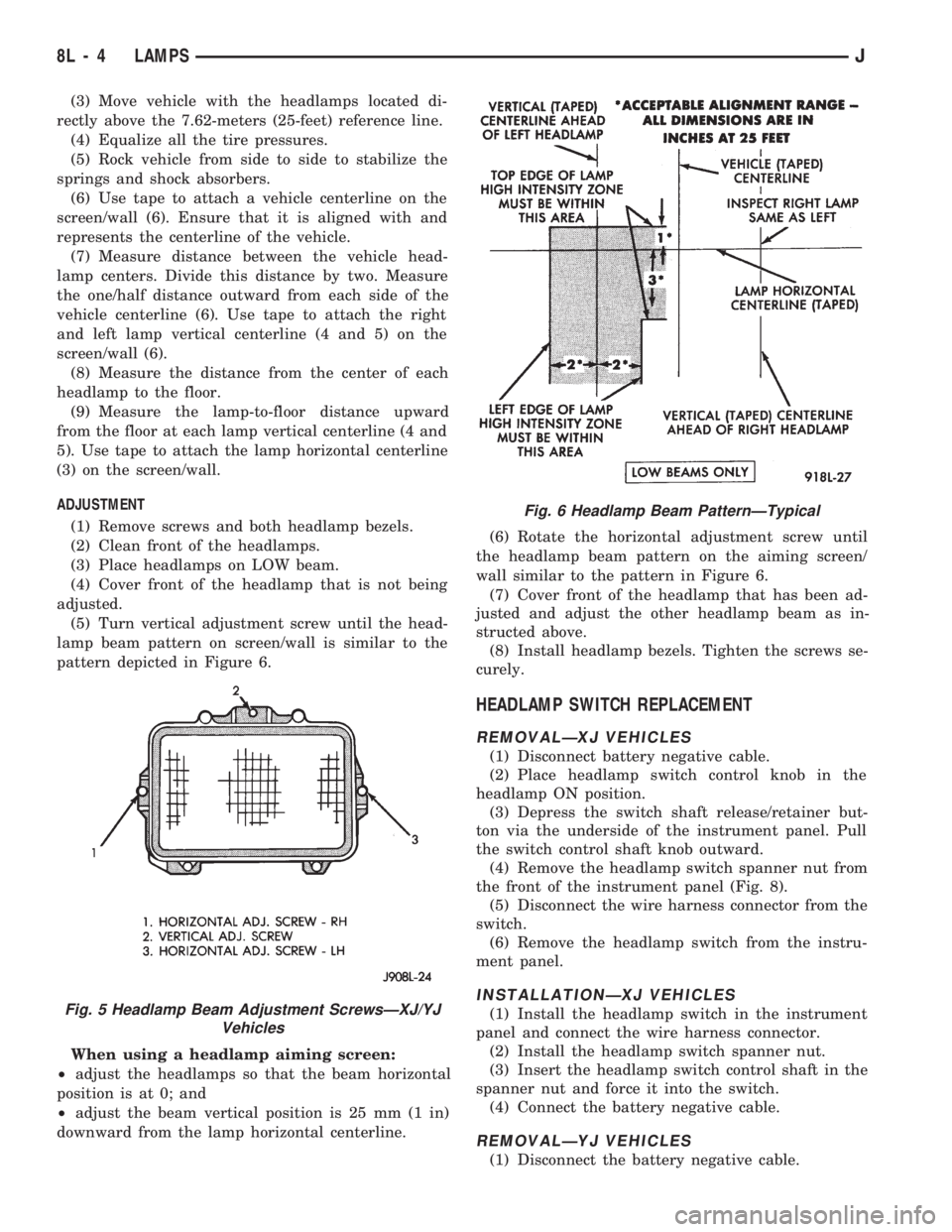

ADJUSTMENT

(1) Remove screws and both headlamp bezels.

(2) Clean front of the headlamps.

(3) Place headlamps on LOW beam.

(4) Cover front of the headlamp that is not being

adjusted.

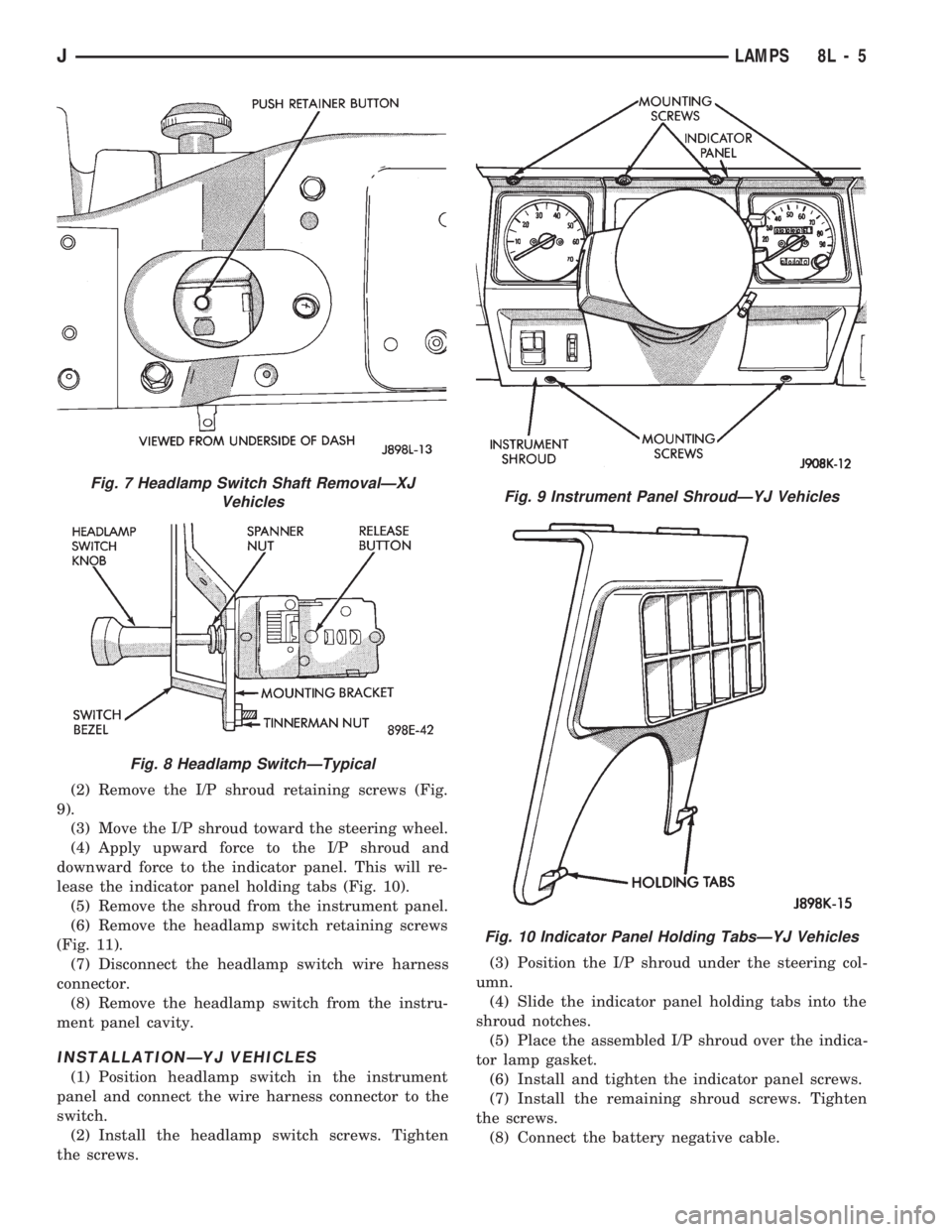

(5) Turn vertical adjustment screw until the head-

lamp beam pattern on screen/wall is similar to the

pattern depicted in Figure 6.

When using a headlamp aiming screen:

²adjust the headlamps so that the beam horizontal

position is at 0; and

²adjust the beam vertical position is 25 mm (1 in)

downward from the lamp horizontal centerline.(6) Rotate the horizontal adjustment screw until

the headlamp beam pattern on the aiming screen/

wall similar to the pattern in Figure 6.

(7) Cover front of the headlamp that has been ad-

justed and adjust the other headlamp beam as in-

structed above.

(8) Install headlamp bezels. Tighten the screws se-

curely.

HEADLAMP SWITCH REPLACEMENT

REMOVALÐXJ VEHICLES

(1) Disconnect battery negative cable.

(2) Place headlamp switch control knob in the

headlamp ON position.

(3) Depress the switch shaft release/retainer but-

ton via the underside of the instrument panel. Pull

the switch control shaft knob outward.

(4) Remove the headlamp switch spanner nut from

the front of the instrument panel (Fig. 8).

(5) Disconnect the wire harness connector from the

switch.

(6) Remove the headlamp switch from the instru-

ment panel.

INSTALLATIONÐXJ VEHICLES

(1) Install the headlamp switch in the instrument

panel and connect the wire harness connector.

(2) Install the headlamp switch spanner nut.

(3) Insert the headlamp switch control shaft in the

spanner nut and force it into the switch.

(4) Connect the battery negative cable.

REMOVALÐYJ VEHICLES

(1) Disconnect the battery negative cable.

Fig. 5 Headlamp Beam Adjustment ScrewsÐXJ/YJ

Vehicles

Fig. 6 Headlamp Beam PatternÐTypical

8L - 4 LAMPSJ

Page 432 of 1784

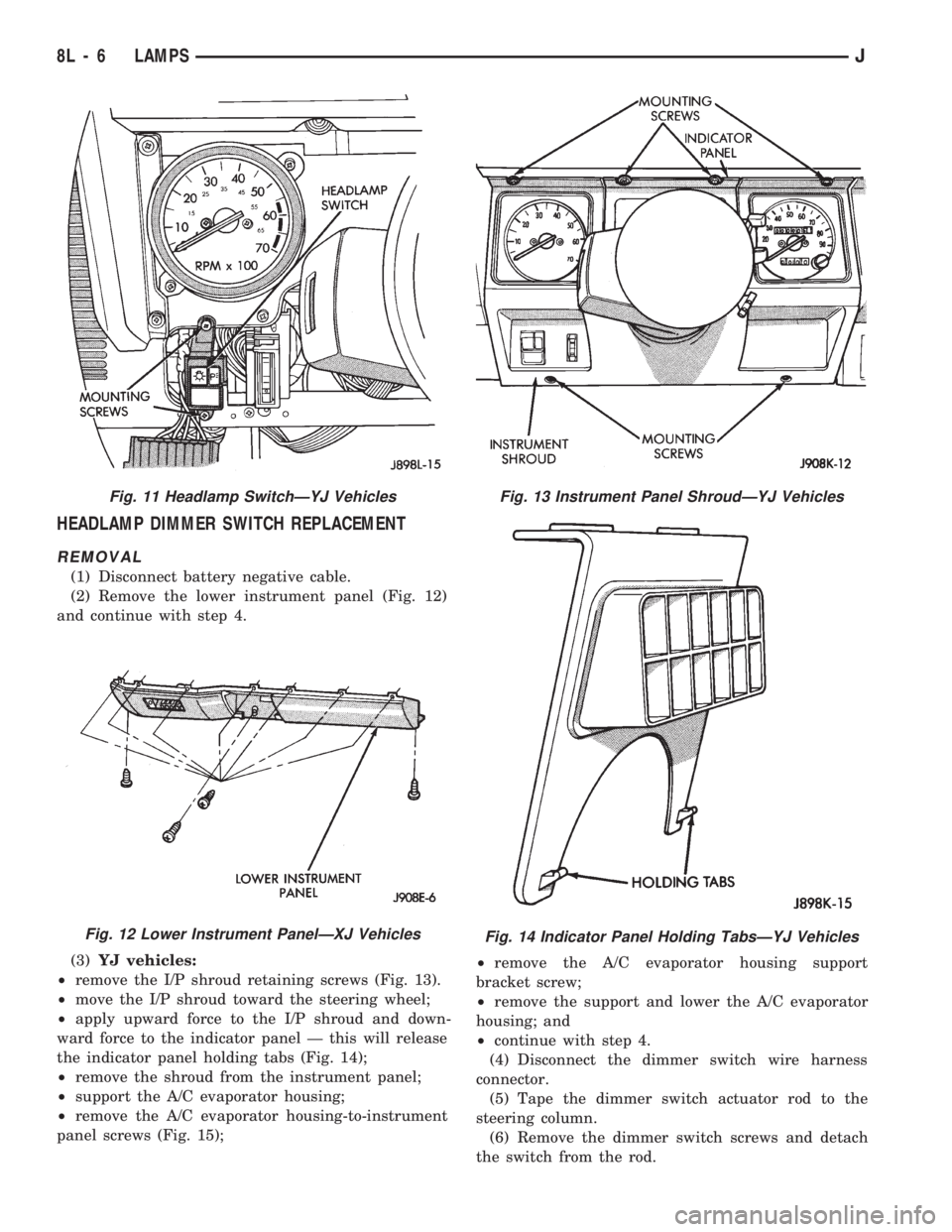

(2) Remove the I/P shroud retaining screws (Fig.

9).

(3) Move the I/P shroud toward the steering wheel.

(4) Apply upward force to the I/P shroud and

downward force to the indicator panel. This will re-

lease the indicator panel holding tabs (Fig. 10).

(5) Remove the shroud from the instrument panel.

(6) Remove the headlamp switch retaining screws

(Fig. 11).

(7) Disconnect the headlamp switch wire harness

connector.

(8) Remove the headlamp switch from the instru-

ment panel cavity.

INSTALLATIONÐYJ VEHICLES

(1) Position headlamp switch in the instrument

panel and connect the wire harness connector to the

switch.

(2) Install the headlamp switch screws. Tighten

the screws.(3) Position the I/P shroud under the steering col-

umn.

(4) Slide the indicator panel holding tabs into the

shroud notches.

(5) Place the assembled I/P shroud over the indica-

tor lamp gasket.

(6) Install and tighten the indicator panel screws.

(7) Install the remaining shroud screws. Tighten

the screws.

(8) Connect the battery negative cable.

Fig. 7 Headlamp Switch Shaft RemovalÐXJ

Vehicles

Fig. 8 Headlamp SwitchÐTypical

Fig. 9 Instrument Panel ShroudÐYJ Vehicles

Fig. 10 Indicator Panel Holding TabsÐYJ Vehicles

JLAMPS 8L - 5

Page 433 of 1784

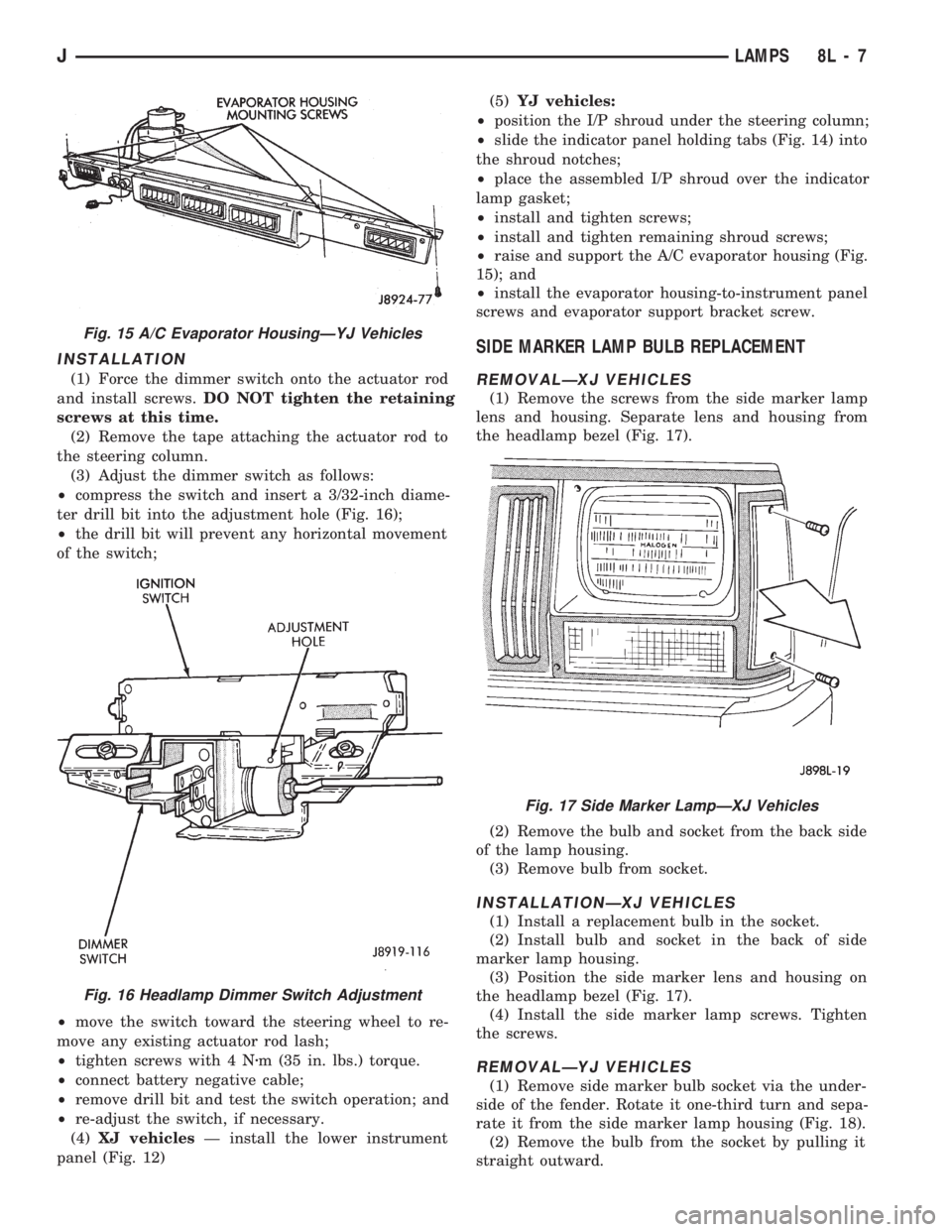

HEADLAMP DIMMER SWITCH REPLACEMENT

REMOVAL

(1) Disconnect battery negative cable.

(2) Remove the lower instrument panel (Fig. 12)

and continue with step 4.

(3)YJ vehicles:

²remove the I/P shroud retaining screws (Fig. 13).

²move the I/P shroud toward the steering wheel;

²apply upward force to the I/P shroud and down-

ward force to the indicator panel Ð this will release

the indicator panel holding tabs (Fig. 14);

²remove the shroud from the instrument panel;

²support the A/C evaporator housing;

²remove the A/C evaporator housing-to-instrument

panel screws (Fig. 15);²remove the A/C evaporator housing support

bracket screw;

²remove the support and lower the A/C evaporator

housing; and

²continue with step 4.

(4) Disconnect the dimmer switch wire harness

connector.

(5) Tape the dimmer switch actuator rod to the

steering column.

(6) Remove the dimmer switch screws and detach

the switch from the rod.

Fig. 11 Headlamp SwitchÐYJ Vehicles

Fig. 12 Lower Instrument PanelÐXJ Vehicles

Fig. 13 Instrument Panel ShroudÐYJ Vehicles

Fig. 14 Indicator Panel Holding TabsÐYJ Vehicles

8L - 6 LAMPSJ

Page 434 of 1784

INSTALLATION

(1) Force the dimmer switch onto the actuator rod

and install screws.DO NOT tighten the retaining

screws at this time.

(2) Remove the tape attaching the actuator rod to

the steering column.

(3) Adjust the dimmer switch as follows:

²compress the switch and insert a 3/32-inch diame-

ter drill bit into the adjustment hole (Fig. 16);

²the drill bit will prevent any horizontal movement

of the switch;

²move the switch toward the steering wheel to re-

move any existing actuator rod lash;

²tighten screws with 4 Nzm (35 in. lbs.) torque.

²connect battery negative cable;

²remove drill bit and test the switch operation; and

²re-adjust the switch, if necessary.

(4)XJ vehiclesÐ install the lower instrument

panel (Fig. 12)(5)YJ vehicles:

²position the I/P shroud under the steering column;

²slide the indicator panel holding tabs (Fig. 14) into

the shroud notches;

²place the assembled I/P shroud over the indicator

lamp gasket;

²install and tighten screws;

²install and tighten remaining shroud screws;

²raise and support the A/C evaporator housing (Fig.

15); and

²install the evaporator housing-to-instrument panel

screws and evaporator support bracket screw.

SIDE MARKER LAMP BULB REPLACEMENT

REMOVALÐXJ VEHICLES

(1) Remove the screws from the side marker lamp

lens and housing. Separate lens and housing from

the headlamp bezel (Fig. 17).

(2) Remove the bulb and socket from the back side

of the lamp housing.

(3) Remove bulb from socket.

INSTALLATIONÐXJ VEHICLES

(1) Install a replacement bulb in the socket.

(2) Install bulb and socket in the back of side

marker lamp housing.

(3) Position the side marker lens and housing on

the headlamp bezel (Fig. 17).

(4) Install the side marker lamp screws. Tighten

the screws.

REMOVALÐYJ VEHICLES

(1) Remove side marker bulb socket via the under-

side of the fender. Rotate it one-third turn and sepa-

rate it from the side marker lamp housing (Fig. 18).

(2) Remove the bulb from the socket by pulling it

straight outward.

Fig. 15 A/C Evaporator HousingÐYJ Vehicles

Fig. 16 Headlamp Dimmer Switch Adjustment

Fig. 17 Side Marker LampÐXJ Vehicles

JLAMPS 8L - 7

Page 440 of 1784

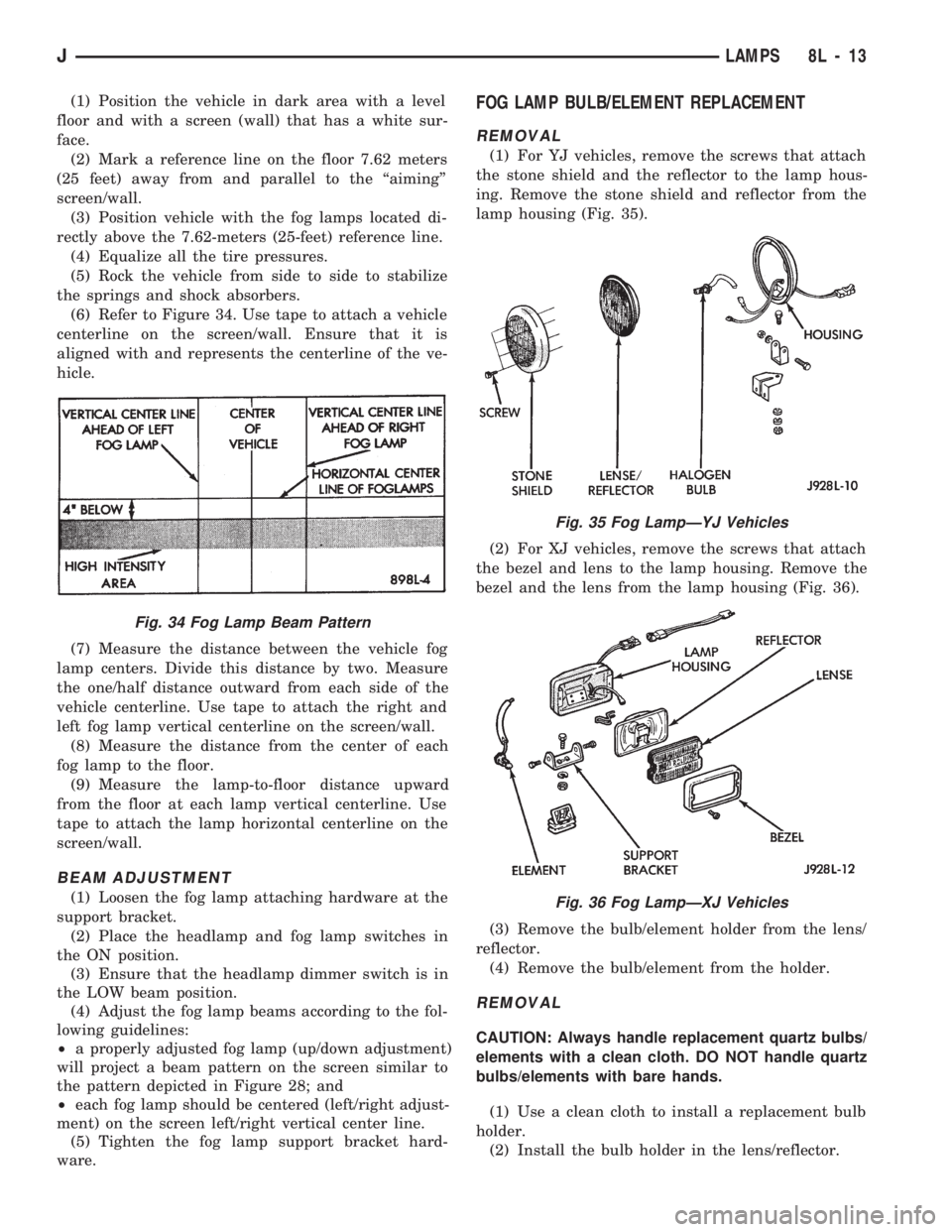

(1) Position the vehicle in dark area with a level

floor and with a screen (wall) that has a white sur-

face.

(2) Mark a reference line on the floor 7.62 meters

(25 feet) away from and parallel to the ``aiming''

screen/wall.

(3) Position vehicle with the fog lamps located di-

rectly above the 7.62-meters (25-feet) reference line.

(4) Equalize all the tire pressures.

(5) Rock the vehicle from side to side to stabilize

the springs and shock absorbers.

(6) Refer to Figure 34. Use tape to attach a vehicle

centerline on the screen/wall. Ensure that it is

aligned with and represents the centerline of the ve-

hicle.

(7) Measure the distance between the vehicle fog

lamp centers. Divide this distance by two. Measure

the one/half distance outward from each side of the

vehicle centerline. Use tape to attach the right and

left fog lamp vertical centerline on the screen/wall.

(8) Measure the distance from the center of each

fog lamp to the floor.

(9) Measure the lamp-to-floor distance upward

from the floor at each lamp vertical centerline. Use

tape to attach the lamp horizontal centerline on the

screen/wall.

BEAM ADJUSTMENT

(1) Loosen the fog lamp attaching hardware at the

support bracket.

(2) Place the headlamp and fog lamp switches in

the ON position.

(3) Ensure that the headlamp dimmer switch is in

the LOW beam position.

(4) Adjust the fog lamp beams according to the fol-

lowing guidelines:

²a properly adjusted fog lamp (up/down adjustment)

will project a beam pattern on the screen similar to

the pattern depicted in Figure 28; and

²each fog lamp should be centered (left/right adjust-

ment) on the screen left/right vertical center line.

(5) Tighten the fog lamp support bracket hard-

ware.

FOG LAMP BULB/ELEMENT REPLACEMENT

REMOVAL

(1) For YJ vehicles, remove the screws that attach

the stone shield and the reflector to the lamp hous-

ing. Remove the stone shield and reflector from the

lamp housing (Fig. 35).

(2) For XJ vehicles, remove the screws that attach

the bezel and lens to the lamp housing. Remove the

bezel and the lens from the lamp housing (Fig. 36).

(3) Remove the bulb/element holder from the lens/

reflector.

(4) Remove the bulb/element from the holder.

REMOVAL

CAUTION: Always handle replacement quartz bulbs/

elements with a clean cloth. DO NOT handle quartz

bulbs/elements with bare hands.

(1) Use a clean cloth to install a replacement bulb

holder.

(2) Install the bulb holder in the lens/reflector.

Fig. 34 Fog Lamp Beam Pattern

Fig. 35 Fog LampÐYJ Vehicles

Fig. 36 Fog LampÐXJ Vehicles

JLAMPS 8L - 13

Page 441 of 1784

(3) For XJ vehicles, position the bezel and the lens

on the lamp housing. Install the screws that attach

the bezel and lens to the lamp housing. Tighten the

screws securely.

(4) For YJ vehicles, position the stone shield and

reflector on the lamp housing. Install the screws that

attach the stone shield and the reflector to the lamp

housing. Tighten the screws securely.

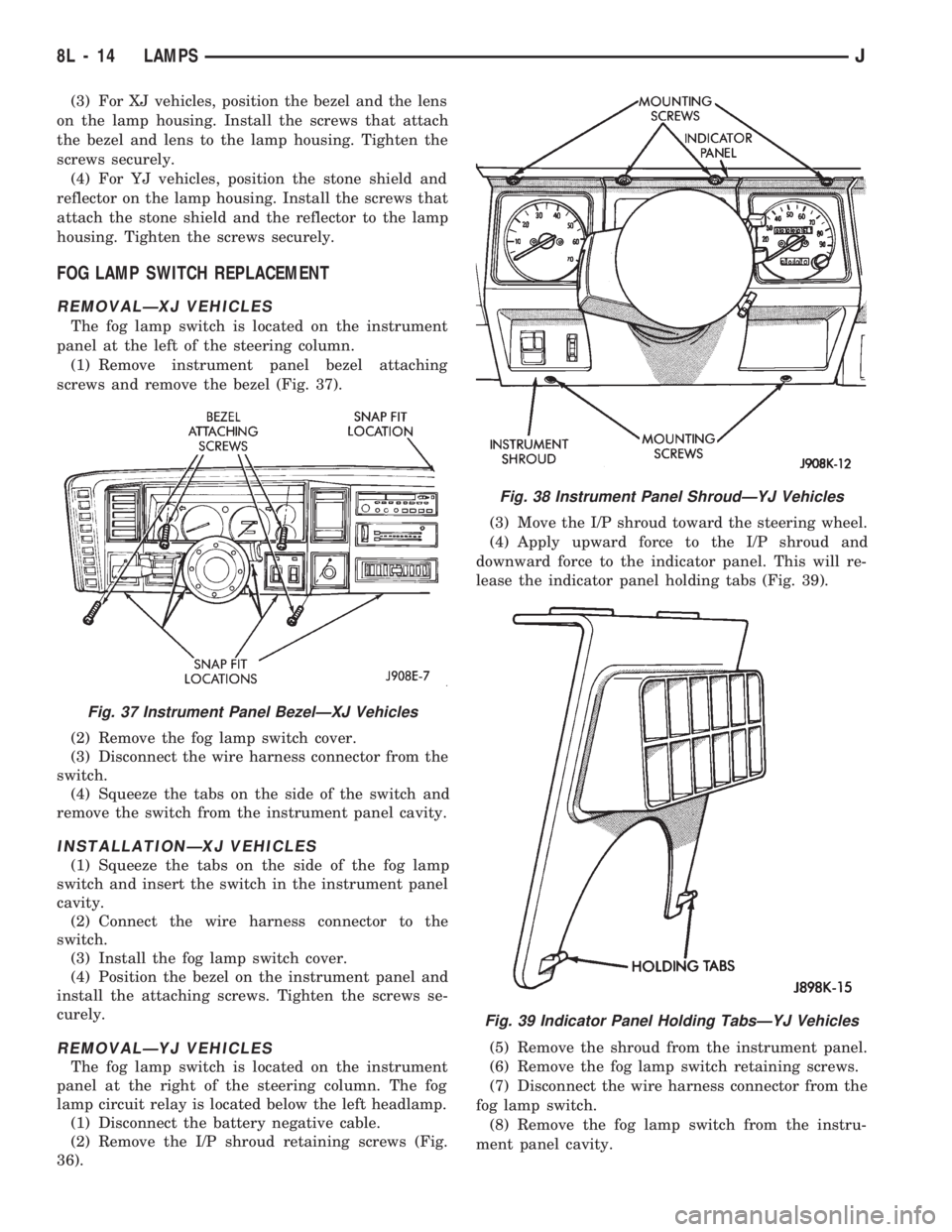

FOG LAMP SWITCH REPLACEMENT

REMOVALÐXJ VEHICLES

The fog lamp switch is located on the instrument

panel at the left of the steering column.

(1) Remove instrument panel bezel attaching

screws and remove the bezel (Fig. 37).

(2) Remove the fog lamp switch cover.

(3) Disconnect the wire harness connector from the

switch.

(4) Squeeze the tabs on the side of the switch and

remove the switch from the instrument panel cavity.

INSTALLATIONÐXJ VEHICLES

(1) Squeeze the tabs on the side of the fog lamp

switch and insert the switch in the instrument panel

cavity.

(2) Connect the wire harness connector to the

switch.

(3) Install the fog lamp switch cover.

(4) Position the bezel on the instrument panel and

install the attaching screws. Tighten the screws se-

curely.

REMOVALÐYJ VEHICLES

The fog lamp switch is located on the instrument

panel at the right of the steering column. The fog

lamp circuit relay is located below the left headlamp.

(1) Disconnect the battery negative cable.

(2) Remove the I/P shroud retaining screws (Fig.

36).(3) Move the I/P shroud toward the steering wheel.

(4) Apply upward force to the I/P shroud and

downward force to the indicator panel. This will re-

lease the indicator panel holding tabs (Fig. 39).

(5) Remove the shroud from the instrument panel.

(6) Remove the fog lamp switch retaining screws.

(7) Disconnect the wire harness connector from the

fog lamp switch.

(8) Remove the fog lamp switch from the instru-

ment panel cavity.

Fig. 37 Instrument Panel BezelÐXJ Vehicles

Fig. 38 Instrument Panel ShroudÐYJ Vehicles

Fig. 39 Indicator Panel Holding TabsÐYJ Vehicles

8L - 14 LAMPSJ