JEEP CHEROKEE 1994 Service Repair Manual

Manufacturer: JEEP, Model Year: 1994, Model line: CHEROKEE, Model: JEEP CHEROKEE 1994Pages: 1784, PDF Size: 77.09 MB

Page 951 of 1784

CONSTRUCTION

The frame is constructed of high-strength channel

steel siderails and crossmembers. The crossmembers

join the siderails and retain them in alignment in re-

lation to each other. This provides resistance to

frame twists and strains.

FRAME ALIGNMENT

INCORRECT ALIGNMENT

Incorrect frame alignment is usually a result of:

²collision impact, or

²the vehicle being operated with excessive loads, or

²loads not positioned in a properly distributed man-

ner on the vehicle.

A mis-aligned frame will affect front axle and/or

rear axle alignment. It can cause excessive wear and

mechanical failures in the powertrain. Window glass

cracks and door opening/closing problems. Vehicle

performance can also be impaired.

RE-ALIGNMENT

With collision damage, it is important that the ex-

istence of any frame alignment damage be deter-

mined. If necessary, the frame should be correctly re-

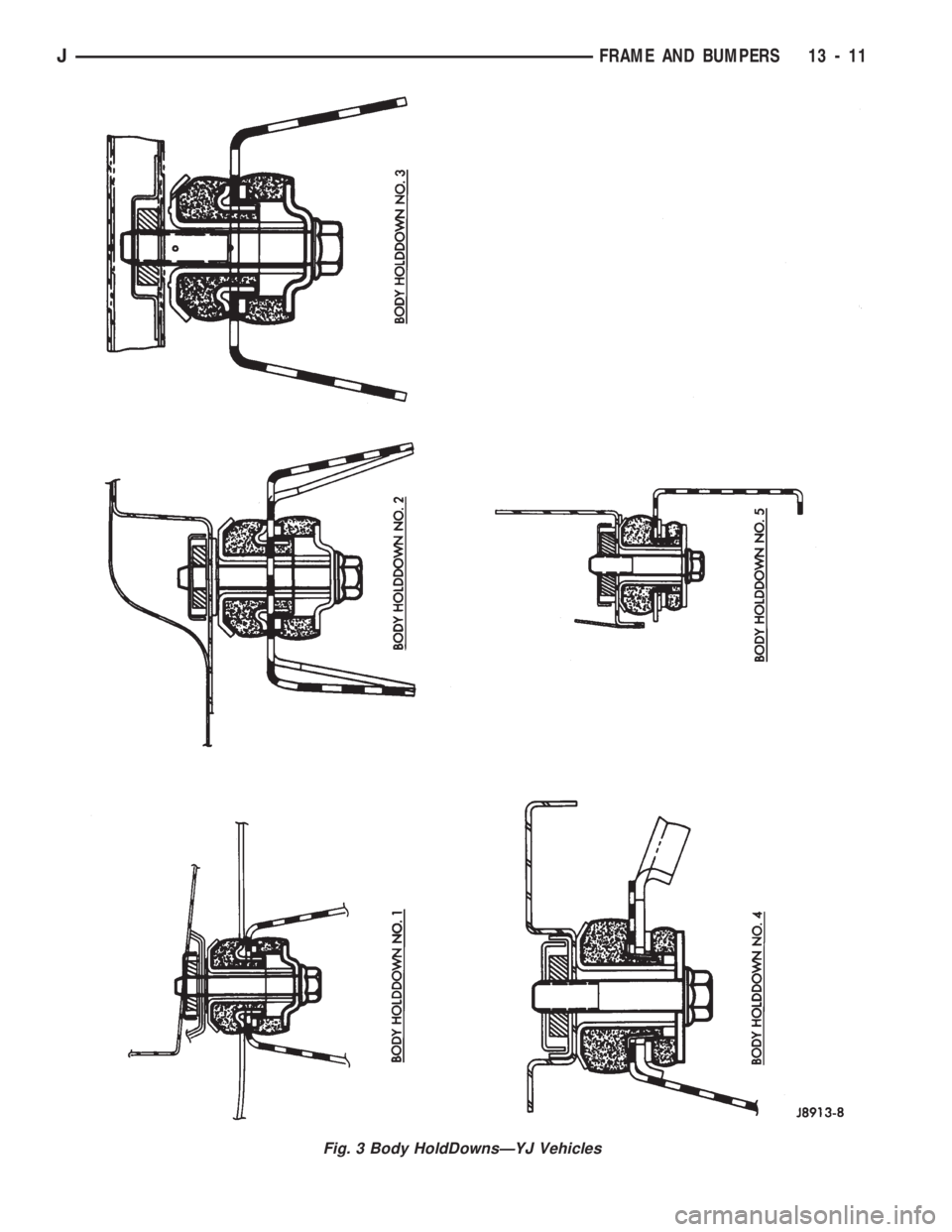

aligned. Refer to the reference dimensions listed on

frame alignment dimension chart (Fig. 4).

FRAME INSPECTION/MEASUREMENTS

INSPECTION

Before proceeding with measurements, inspect all

components for visible damage and other metal dam-

age. Also, inspect all connections for loose and miss-

ing hardware.

All damaged areas must be repaired and/or the

components replaced, as necessary.

MEASUREMENTS

Measure the frame for mis-alignment with the

body attached to the frame. Figure 4 provides the

alignment reference dimensions. The following infor-

mation applies to all measurements.

(1) Place the vehicle on a level surface.

(2) If the vehicle is loaded, ensure that the vehicle

weight plus the payload does not exceed the gross ve-

hicle weight rating. Also, ensure that the load is dis-

tributed in the vehicle as evenly as possible.

(3) Measure the tire inflation pressures and adjust

the pressure, if necessary.

HORIZONTAL OR DIAGONAL FRAME MEASUREMENTS

Determine the frame horizontal non-square devia-

tion(s) according to the following procedure.

(1) Select several reference points along one frame

siderail, preferably at the crossmember junctions.(2) Transfer these reference points to the surface/

floor with a plumb bob. Paper sheets can be attached

to the surface below the reference points for better

measurement accuracy.

(3) Locate the reference points on the other frame

siderail and transfer them to the surface/floor with

the same procedure as above.

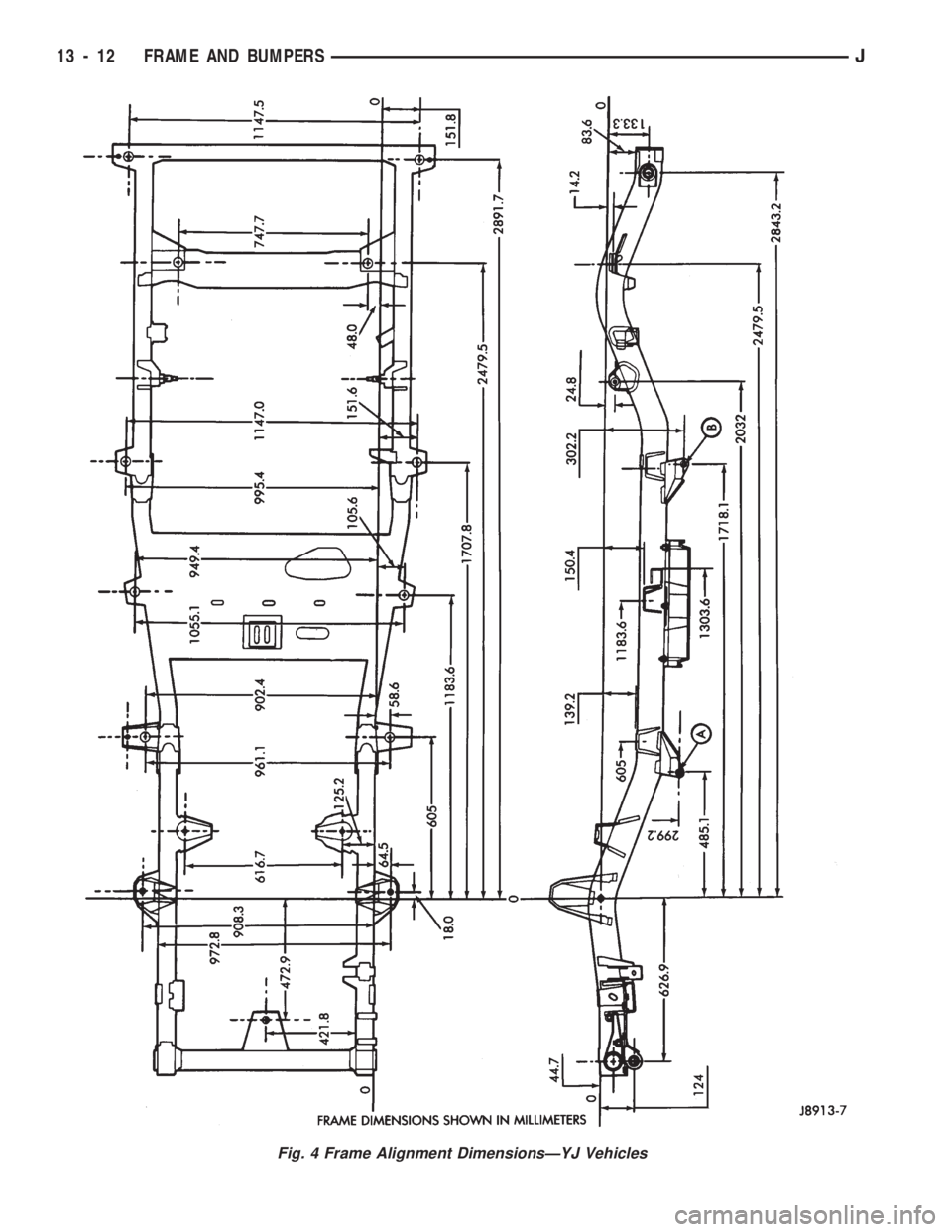

(4) Move the vehicle away and measure between

all the reference points diagonally from and parallel

to the siderails (Fig. 5). The measurements should

not differ by more than 6 mm (1/4 in).

(5) Measure the distance between the two front

reference points and the distance between the two

rear reference points. Divide each distance in half

and indicate the two half-way points on the surface/

floor. Designate the front point as ``1'' and the rear

point as ``2'' (Fig. 5).

(6) Place a chalk-line between points 1 and 2 and

``snap'' the string.

(7) Determine how close the center line is to the

diagonal intersection points A, B, C, D, E, and F in

Figure 5.

(8) The reference marks on the surface/floor will

provide an illustrated indication of the degree of

frame misalignment.

(9) A reference point transferred from one frame

siderail may be 3 mm (1/8 in) ahead or behind the

reference point from the opposite siderail.

(10) Frame bow to the side should not exceed 3

mm per 2,540 mm (1/8 inch per 100 inches) in

length.

(11) The overall width of the frame should not

vary more than 3 mm (1/8 in) from reference point-

to-reference point.

(12) Repeat steps (1) through (11) after straighten-

ing the frame to evaluate the effectiveness.

TWIST AND PARALLEL FRAME MEASUREMENTS

Determine the amount of frame twist and siderail

deviation according to the following procedure.

(1) Mark the vertical measurement reference

points under the frame siderails at 305-mm (12-in)

intervals starting at the rear frame crossmember.

(2) Measure the vertical distance up from a level

surface to each reference point located under the left

and right frame siderails.

(3) The distance to a reference point under one

frame siderail should be 3 mm (1/8 in) greater or less

than the point under the opposite siderail.

(4) Plot the measured vertical distances to scale on

a sheet of graph paper. Plot the distances so that the

frame siderails are located adjacent to each other.

Join the vertical distance points.

13 - 10 FRAME AND BUMPERSJ

Page 952 of 1784

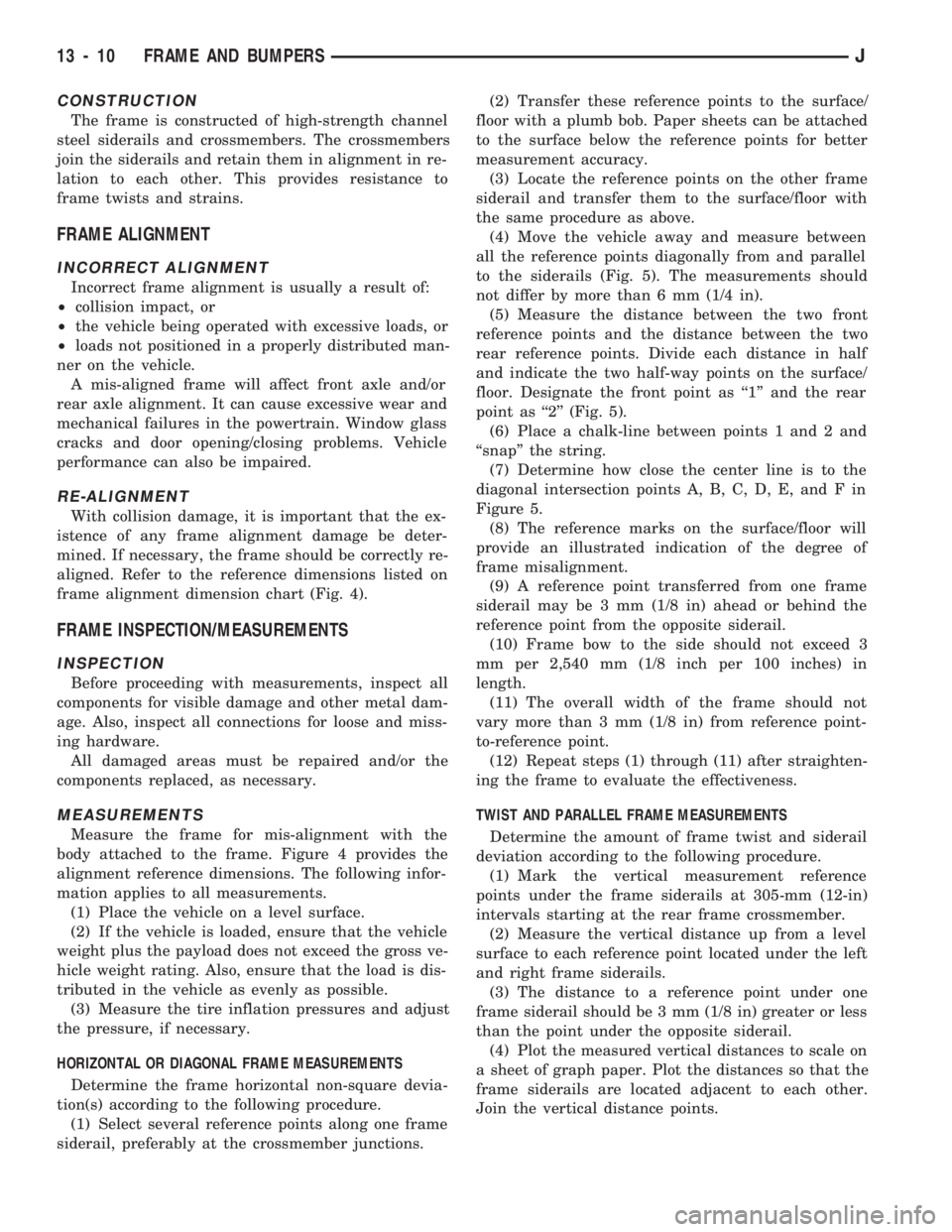

Fig. 3 Body HoldDownsÐYJ Vehicles

JFRAME AND BUMPERS 13 - 11

Page 953 of 1784

Fig. 4 Frame Alignment DimensionsÐYJ Vehicles

13 - 12 FRAME AND BUMPERSJ

Page 954 of 1784

FRAME REPAIR SERVICE

When necessary, conventional vehicle frames that

are bent or twisted can be straightened by applica-

tion of heat. The temperature must not exceed 566ÉC/

1050ÉF.

Damaged frame siderails, crossmembers, and

brackets are repaired either by straightening or by

replacement.

Welded joints between the frame siderails and

crossmembers are not recommended.

FRAME STRAIGHTENING

A straightening repair process should be limited to

frame components that are not severely damaged.

The bolts, nuts and rivets should conform to the spec-

ifications as the original.

FRAME COMPONENT REPLACEMENT

An improperly straightened frame component will

have harmful effects on the overall frame alignment.

FRAME COMPONENT REPAIRS

DRILLING HOLES

Holesshould notbe drilled in frame siderail

flanges because this will severely reduce the frame

strength. Holes drilled in the frame siderail vertical

webs must be 38 mm (1 and 1/2 in) minimum from

the top and bottom flanges.

Newly drilled holes should be located an acceptable

distance away from any existing holes.WELDING

It is recommended that electric welding equipment

be used to weld frame siderails and crossmembers.

A damaged frame component should be closely ex-

amined for hairline cracks. Repair frame component

cracks according to the following procedure.

(1) Drill a hole at each end of the crack with a

3-mm (1/8-in) diameter drill bit.

(2) ``V-groove'' the crack to allow good weld pene-

tration.

(3) Weld the crack.

(4) Grind the weld surface area smooth and install

a reinforcement section at the welded area.

The flanges on reinforcement channel should

be less in width than the siderail flanges. Other-

wise, longitudinal welds are very acceptable.

Complete transverse welds should be avoided.

FRAME REPAIR HARDWARE

Bolts, nuts and rivets can be used to repair frames

or to install a reinforcement section on the frame.

When it is more practical to substitute a bolt for a

rivet, install the next-larger-size diameter bolt to

prevent the bolt from loosening.

Conical-type lockwashers are preferred over the

split-ring type lockwashers. Normally, grade-5 bolts

are adequate for frame repair.Grade-3 bolts (or

less) should not be used.Tightening bolts/nuts

with the correct torque is mandatory to adequately

``lock'' the bolt, lockwasher and nut together, and to

prevent them from loosening.

Fig. 5 Frame Alignment Reference PointsÐTypical

JFRAME AND BUMPERS 13 - 13

Page 955 of 1784

YJ BUMPERS AND FRAME ATTACHED COMPONENTS

INDEX

page page

Generator Splash Shield................... 14

Body.................................. 18

Engine Front Support Cushion............... 15

Frame Crossmember Cover................. 14

Front Bumper........................... 14

Fuel and Brake Fluid Tube Retainer Clip....... 16

Fuel Filter Shield and Bracket............... 17

Fuel Tank Skid Plate...................... 16Muffler and Tailpipe Heat Shields............ 17

Muffler/Tailpipe Hanger Bracket.............. 16

Rear Bumper............................ 18

Rear Jounce Bumper..................... 18

Service Information....................... 14

Tow Hooks............................. 14

Transfer Case Skid Plate.................. 15

SERVICE INFORMATION

In some cases, components in the following proce-

dures either support, or are hidden by other compo-

nents.

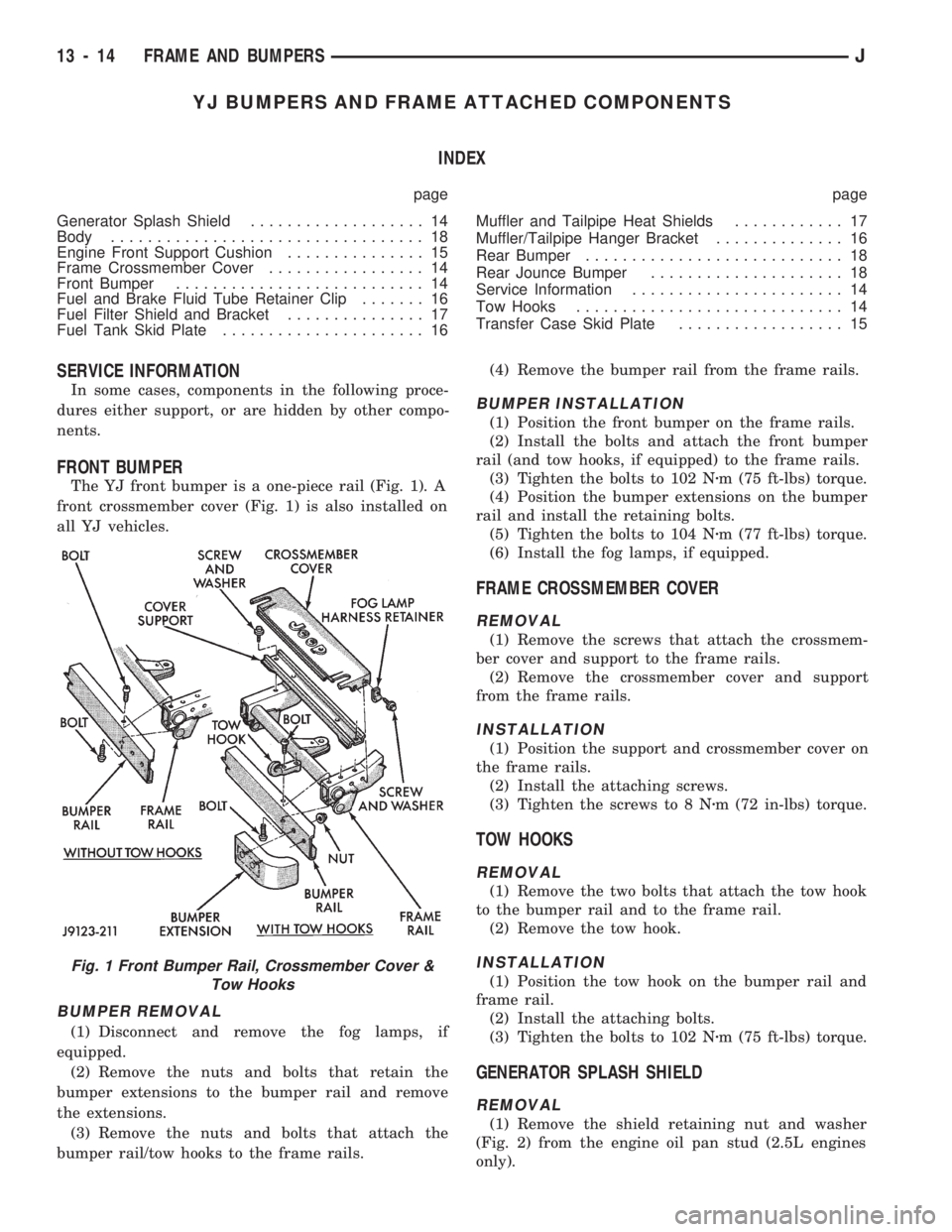

FRONT BUMPER

The YJ front bumper is a one-piece rail (Fig. 1). A

front crossmember cover (Fig. 1) is also installed on

all YJ vehicles.

BUMPER REMOVAL

(1) Disconnect and remove the fog lamps, if

equipped.

(2) Remove the nuts and bolts that retain the

bumper extensions to the bumper rail and remove

the extensions.

(3) Remove the nuts and bolts that attach the

bumper rail/tow hooks to the frame rails.(4) Remove the bumper rail from the frame rails.

BUMPER INSTALLATION

(1) Position the front bumper on the frame rails.

(2) Install the bolts and attach the front bumper

rail (and tow hooks, if equipped) to the frame rails.

(3) Tighten the bolts to 102 Nzm (75 ft-lbs) torque.

(4) Position the bumper extensions on the bumper

rail and install the retaining bolts.

(5) Tighten the bolts to 104 Nzm (77 ft-lbs) torque.

(6) Install the fog lamps, if equipped.

FRAME CROSSMEMBER COVER

REMOVAL

(1) Remove the screws that attach the crossmem-

ber cover and support to the frame rails.

(2) Remove the crossmember cover and support

from the frame rails.

INSTALLATION

(1) Position the support and crossmember cover on

the frame rails.

(2) Install the attaching screws.

(3) Tighten the screws to 8 Nzm (72 in-lbs) torque.

TOW HOOKS

REMOVAL

(1) Remove the two bolts that attach the tow hook

to the bumper rail and to the frame rail.

(2) Remove the tow hook.

INSTALLATION

(1) Position the tow hook on the bumper rail and

frame rail.

(2) Install the attaching bolts.

(3) Tighten the bolts to 102 Nzm (75 ft-lbs) torque.

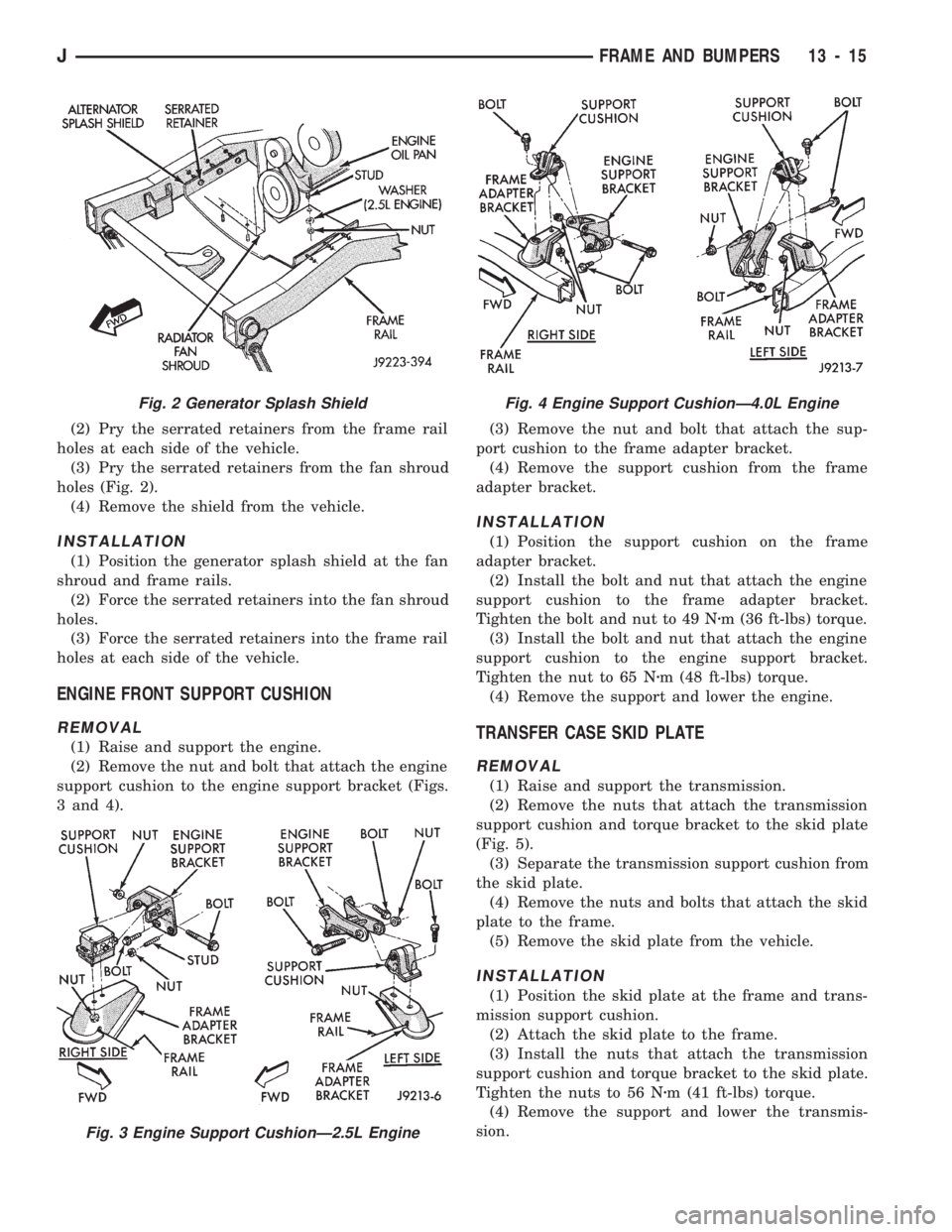

GENERATOR SPLASH SHIELD

REMOVAL

(1) Remove the shield retaining nut and washer

(Fig. 2) from the engine oil pan stud (2.5L engines

only).

Fig. 1 Front Bumper Rail, Crossmember Cover &

Tow Hooks

13 - 14 FRAME AND BUMPERSJ

Page 956 of 1784

(2) Pry the serrated retainers from the frame rail

holes at each side of the vehicle.

(3) Pry the serrated retainers from the fan shroud

holes (Fig. 2).

(4) Remove the shield from the vehicle.

INSTALLATION

(1) Position the generator splash shield at the fan

shroud and frame rails.

(2) Force the serrated retainers into the fan shroud

holes.

(3) Force the serrated retainers into the frame rail

holes at each side of the vehicle.

ENGINE FRONT SUPPORT CUSHION

REMOVAL

(1) Raise and support the engine.

(2) Remove the nut and bolt that attach the engine

support cushion to the engine support bracket (Figs.

3 and 4).(3) Remove the nut and bolt that attach the sup-

port cushion to the frame adapter bracket.

(4) Remove the support cushion from the frame

adapter bracket.

INSTALLATION

(1) Position the support cushion on the frame

adapter bracket.

(2) Install the bolt and nut that attach the engine

support cushion to the frame adapter bracket.

Tighten the bolt and nut to 49 Nzm (36 ft-lbs) torque.

(3) Install the bolt and nut that attach the engine

support cushion to the engine support bracket.

Tighten the nut to 65 Nzm (48 ft-lbs) torque.

(4) Remove the support and lower the engine.

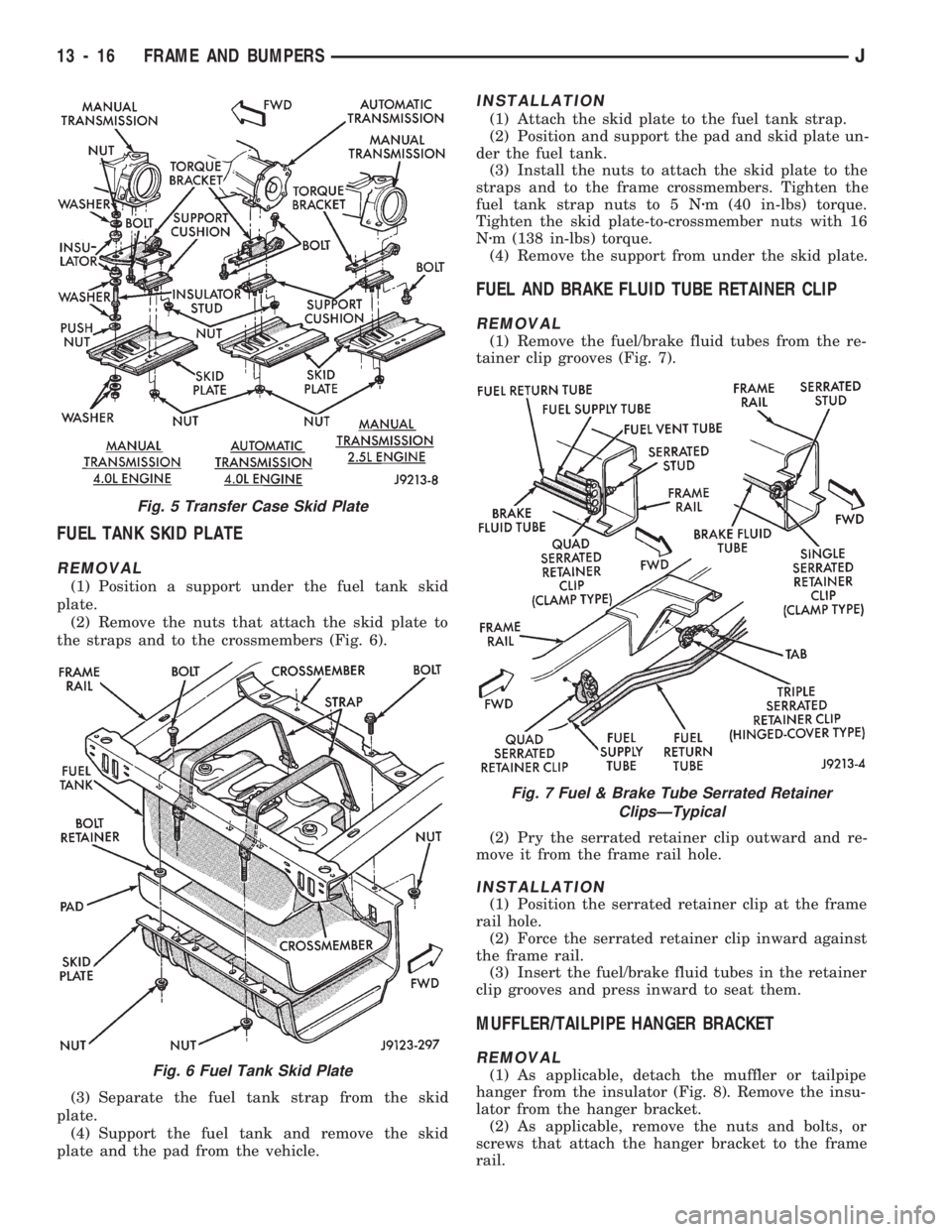

TRANSFER CASE SKID PLATE

REMOVAL

(1) Raise and support the transmission.

(2) Remove the nuts that attach the transmission

support cushion and torque bracket to the skid plate

(Fig. 5).

(3) Separate the transmission support cushion from

the skid plate.

(4) Remove the nuts and bolts that attach the skid

plate to the frame.

(5) Remove the skid plate from the vehicle.

INSTALLATION

(1) Position the skid plate at the frame and trans-

mission support cushion.

(2) Attach the skid plate to the frame.

(3) Install the nuts that attach the transmission

support cushion and torque bracket to the skid plate.

Tighten the nuts to 56 Nzm (41 ft-lbs) torque.

(4) Remove the support and lower the transmis-

sion.

Fig. 2 Generator Splash Shield

Fig. 3 Engine Support CushionÐ2.5L Engine

Fig. 4 Engine Support CushionÐ4.0L Engine

JFRAME AND BUMPERS 13 - 15

Page 957 of 1784

FUEL TANK SKID PLATE

REMOVAL

(1) Position a support under the fuel tank skid

plate.

(2) Remove the nuts that attach the skid plate to

the straps and to the crossmembers (Fig. 6).

(3) Separate the fuel tank strap from the skid

plate.

(4) Support the fuel tank and remove the skid

plate and the pad from the vehicle.

INSTALLATION

(1) Attach the skid plate to the fuel tank strap.

(2) Position and support the pad and skid plate un-

der the fuel tank.

(3) Install the nuts to attach the skid plate to the

straps and to the frame crossmembers. Tighten the

fuel tank strap nuts to 5 Nzm (40 in-lbs) torque.

Tighten the skid plate-to-crossmember nuts with 16

Nzm (138 in-lbs) torque.

(4) Remove the support from under the skid plate.

FUEL AND BRAKE FLUID TUBE RETAINER CLIP

REMOVAL

(1) Remove the fuel/brake fluid tubes from the re-

tainer clip grooves (Fig. 7).

(2) Pry the serrated retainer clip outward and re-

move it from the frame rail hole.

INSTALLATION

(1) Position the serrated retainer clip at the frame

rail hole.

(2) Force the serrated retainer clip inward against

the frame rail.

(3) Insert the fuel/brake fluid tubes in the retainer

clip grooves and press inward to seat them.

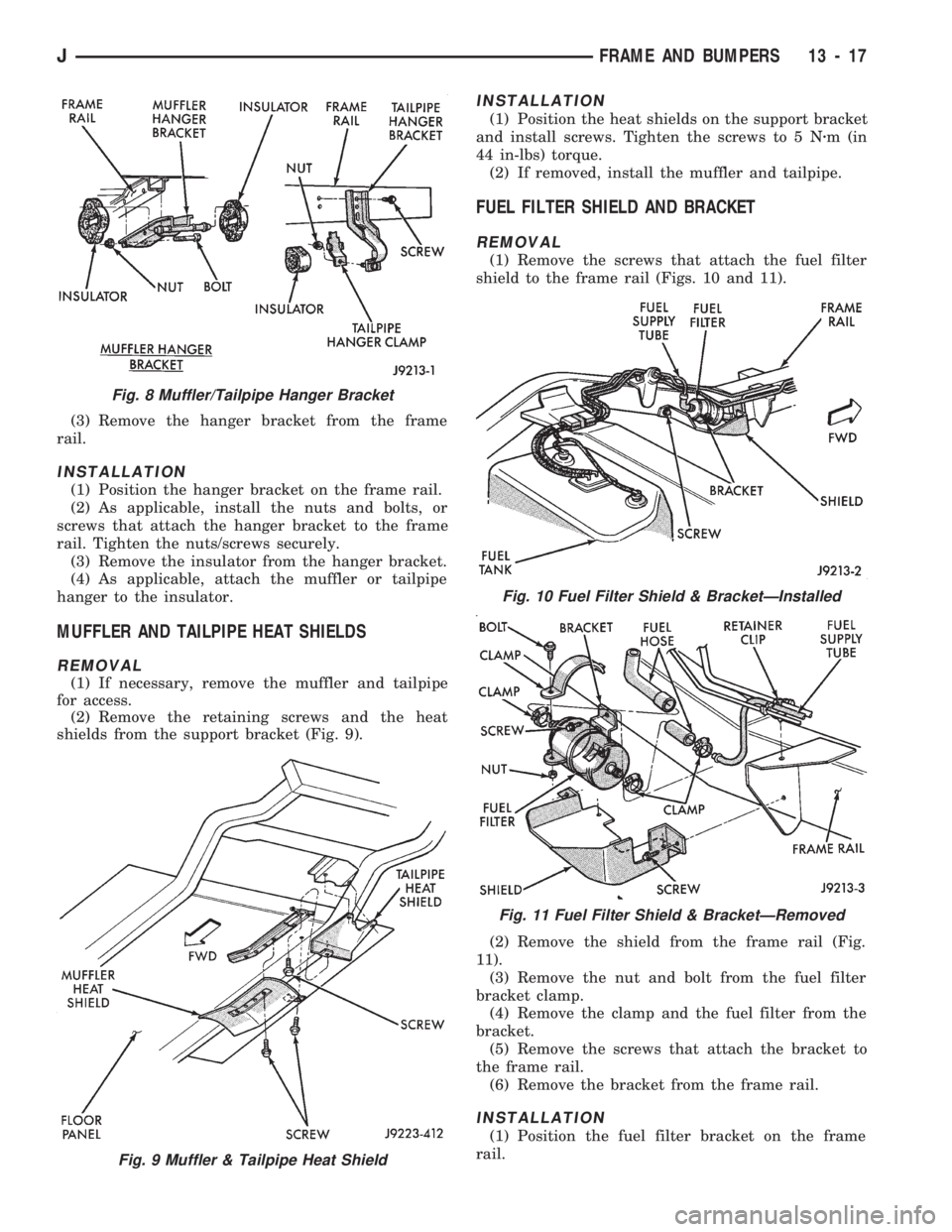

MUFFLER/TAILPIPE HANGER BRACKET

REMOVAL

(1) As applicable, detach the muffler or tailpipe

hanger from the insulator (Fig. 8). Remove the insu-

lator from the hanger bracket.

(2) As applicable, remove the nuts and bolts, or

screws that attach the hanger bracket to the frame

rail.

Fig. 5 Transfer Case Skid Plate

Fig. 6 Fuel Tank Skid Plate

Fig. 7 Fuel & Brake Tube Serrated Retainer

ClipsÐTypical

13 - 16 FRAME AND BUMPERSJ

Page 958 of 1784

(3) Remove the hanger bracket from the frame

rail.

INSTALLATION

(1) Position the hanger bracket on the frame rail.

(2) As applicable, install the nuts and bolts, or

screws that attach the hanger bracket to the frame

rail. Tighten the nuts/screws securely.

(3) Remove the insulator from the hanger bracket.

(4) As applicable, attach the muffler or tailpipe

hanger to the insulator.

MUFFLER AND TAILPIPE HEAT SHIELDS

REMOVAL

(1) If necessary, remove the muffler and tailpipe

for access.

(2) Remove the retaining screws and the heat

shields from the support bracket (Fig. 9).

INSTALLATION

(1) Position the heat shields on the support bracket

and install screws. Tighten the screws to 5 Nzm (in

44 in-lbs) torque.

(2) If removed, install the muffler and tailpipe.

FUEL FILTER SHIELD AND BRACKET

REMOVAL

(1) Remove the screws that attach the fuel filter

shield to the frame rail (Figs. 10 and 11).

(2) Remove the shield from the frame rail (Fig.

11).

(3) Remove the nut and bolt from the fuel filter

bracket clamp.

(4) Remove the clamp and the fuel filter from the

bracket.

(5) Remove the screws that attach the bracket to

the frame rail.

(6) Remove the bracket from the frame rail.

INSTALLATION

(1) Position the fuel filter bracket on the frame

rail.

Fig. 8 Muffler/Tailpipe Hanger Bracket

Fig. 9 Muffler & Tailpipe Heat Shield

Fig. 10 Fuel Filter Shield & BracketÐInstalled

Fig. 11 Fuel Filter Shield & BracketÐRemoved

JFRAME AND BUMPERS 13 - 17

Page 959 of 1784

(2) Install the screws that attach the bracket to

the frame rail. Tighten the screws to 42 Nzm (31 ft-

lbs) torque.

(3) Install the fuel filter in the bracket.

(4) Position the clamp on the bracket and install

bolt and nut. Tighten the nut to 8 Nzm (72 in-lbs)

torque.

(5) Position the fuel filter shield from the frame

rail.

(6) Install the screws that attach the fuel filter

shield to the frame rail. Tighten the screws to 42

Nzm (31 ft-lbs) torque.

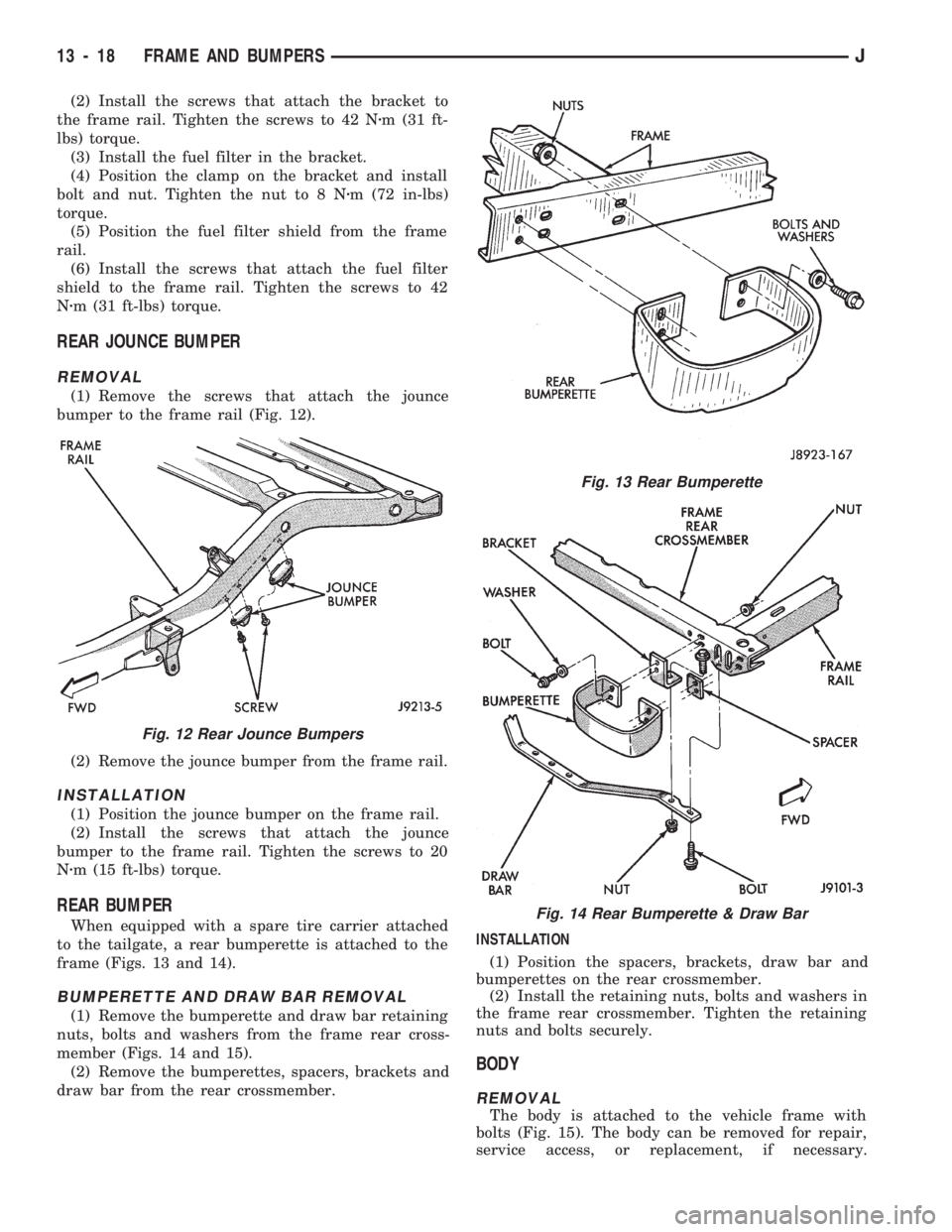

REAR JOUNCE BUMPER

REMOVAL

(1) Remove the screws that attach the jounce

bumper to the frame rail (Fig. 12).

(2) Remove the jounce bumper from the frame rail.

INSTALLATION

(1) Position the jounce bumper on the frame rail.

(2) Install the screws that attach the jounce

bumper to the frame rail. Tighten the screws to 20

Nzm (15 ft-lbs) torque.

REAR BUMPER

When equipped with a spare tire carrier attached

to the tailgate, a rear bumperette is attached to the

frame (Figs. 13 and 14).

BUMPERETTE AND DRAW BAR REMOVAL

(1) Remove the bumperette and draw bar retaining

nuts, bolts and washers from the frame rear cross-

member (Figs. 14 and 15).

(2) Remove the bumperettes, spacers, brackets and

draw bar from the rear crossmember.INSTALLATION

(1) Position the spacers, brackets, draw bar and

bumperettes on the rear crossmember.

(2) Install the retaining nuts, bolts and washers in

the frame rear crossmember. Tighten the retaining

nuts and bolts securely.

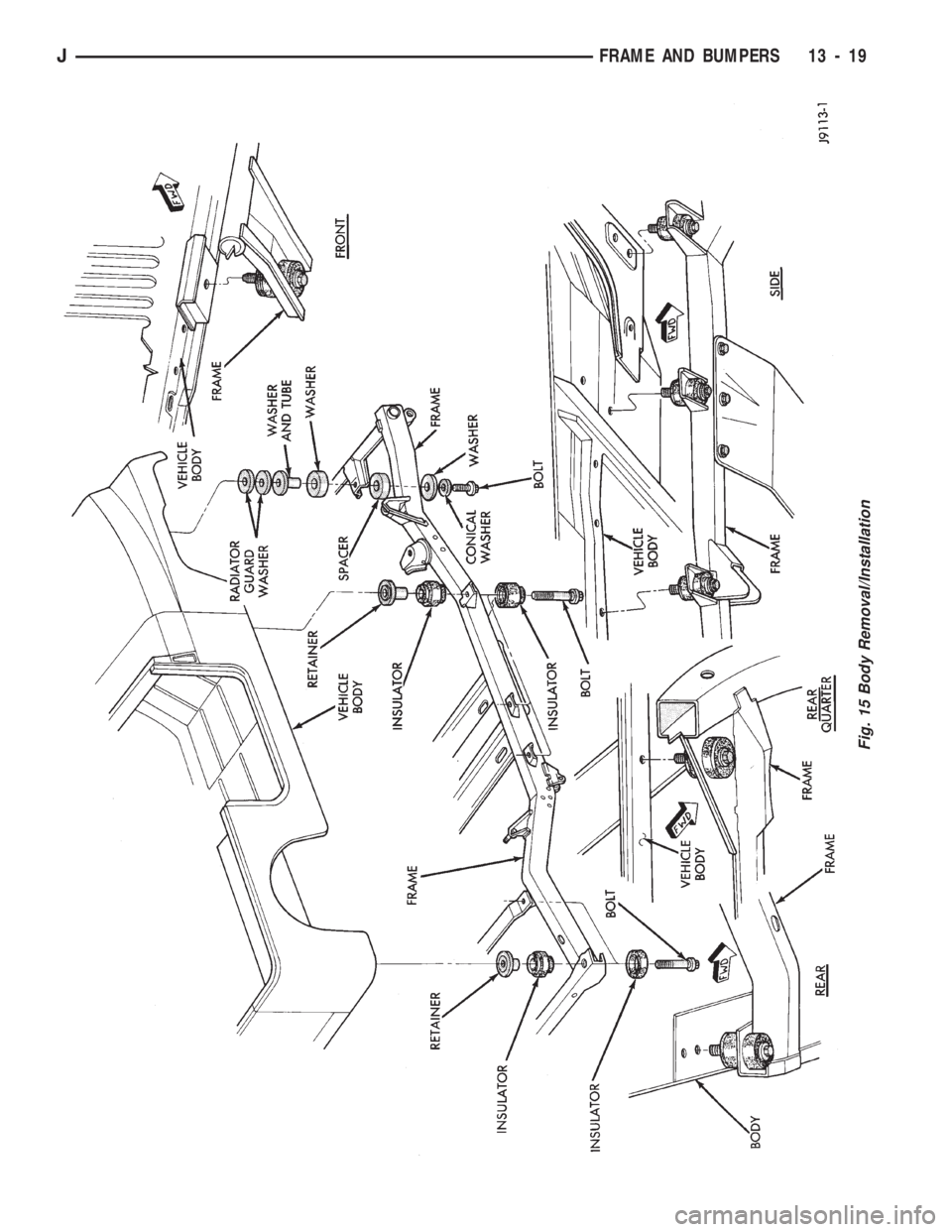

BODY

REMOVAL

The body is attached to the vehicle frame with

bolts (Fig. 15). The body can be removed for repair,

service access, or replacement, if necessary.

Fig. 12 Rear Jounce Bumpers

Fig. 13 Rear Bumperette

Fig. 14 Rear Bumperette & Draw Bar

13 - 18 FRAME AND BUMPERSJ

Page 960 of 1784

Fig. 15 Body Removal/Installation

JFRAME AND BUMPERS 13 - 19