tow JEEP CHEROKEE 1994 Service Repair Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 1994, Model line: CHEROKEE, Model: JEEP CHEROKEE 1994Pages: 1784, PDF Size: 77.09 MB

Page 2 of 1784

LUBRICATION AND MAINTENANCE

CONTENTS

page page

CHASSIS AND BODY COMPONENTS....... 30

DRIVETRAIN........................... 22

ENGINE MAINTENANCE.................. 13GENERAL INFORMATION.................. 1

JUMP STARTING, HOISTING AND TOWING . . 7

MAINTENANCE SCHEDULES............... 5

GENERAL INFORMATION

INDEX

page page

Classification of Lubricants.................. 2

Components Requiring No Lubrication.......... 3

Fluid Capacities.......................... 4

Fuel Requirements........................ 2Introduction.............................. 1

Recommended Lubricant and Replacement Parts . 3

Routine Service........................... 2

INTRODUCTION

Jeeptlubrication and maintenance is divided into

required and recommended service tasks.

The recommendations and procedures listed in this

group are intended for JeeptDealer Service Personnel.

Because conditions vary, it is necessary to schedule

service tasks according to a time interval as well as a

distance interval.

It is the owner's responsibility to have vehicle ser-

viced. Owner is to pay for labor and necessary parts

that are not covered by the warranty.

Additional lubrication and maintenance informa-

tion is listed in the Owner's Manual, which is in-

cluded with the vehicle.

SEVERE DRIVING CONDITIONS

When a vehicle is subjected to a severe driving con-

dition, time between recommended maintenance

should be decreased.

Refer to Engine Maintenance for the engine oil and

filter maintenance interval when involved with a se-

vere driving condition.

A severe driving condition is defined as either:

²frequent short trip driving less than 24 km (15

miles);

²frequent driving in a dusty environment;

²trailer towing;

²extensive engine idling;

²sustained high-speed operation;

²desert operation;

²frequent starting and stopping;²cold-climate operation;

²off-road driving; or

²commercial service.

To service a Jeeptvehicle for a severe driving con-

dition, change all the lubricating fluids and lubricate:

²the body components,

²all the driveline coupling joints, and

²the steering linkage

more often than for a normal driving condition to

prevent excessive wear of the components.

DUSTY AREAS

Driving in an area with dust-filled air increases the

risk of particles entering the engine and crankcase.

With this type of severe driving condition, attention

should be given to the engine and crankcase compo-

nents.

OFF-ROAD (4WD) OPERATION

After completion of off-road (4WD) operation, the

underside of the vehicle should be thoroughly in-

spected. Examine threaded fasteners for looseness.

HARSH SURFACE ENVIRONMENTS

After vehicle operation in a harsh surface environ-

ment, the following components should be inspected

and cleaned as soon as possible:

²brake drums,

²brake linings,

²front wheel bearings (2WD vehicles only), and

²axle coupling joints.

This will prevent wear and/or unpredictable brake

action.

JLUBRICATION AND MAINTENANCE 0 - 1

Page 6 of 1784

MAINTENANCE SCHEDULES

INTRODUCTION

Chrysler Corporation has compiled recommended

lubrication and maintenance schedules and proce-

dures to help reduce premature wear or failure over

a broad range of operating conditions.

SEVERE SERVICE MAINTENANCE

If the vehicle is involved with a severe driving con-

dition, after each 4 800-km (3,000-miles)/3-month in-

terval. A severe driving condition includes:

²frequent short trip driving less than 24 km (15

miles);

²frequent driving in a dusty environment;

²trailer towing;

²extensive engine idling;

²sustained high-speed operation;

²desert operation;

²frequent starting and stopping;

²cold-climate operation;

²off-road driving; or

²commercial service.

MAINTENANCE SCHEDULES

AT EACH STOP FOR FUEL

²Check engine oil level, add as required.

²

Check windshield washer solvent and add if required.

ONCE A MONTH

²Check tire pressure and look for unusual wear or

damage.

²Inspect battery and clean and tighten terminals as

required.

²Check electrolyte level and add water as needed.

²Check fluid levels of coolant reservoir, power steer-

ing and transmission and add as needed.

²Check all lights and all other electrical items for

correct operation.

²Check rubber seals on each side of the radiator for

proper fit.

7,500 MILES (12 000 KM) OR AT 6 MONTHS

²Check engine coolant level, hoses and clamps.

²Change engine oil.

²Replace engine oil filter.

²Check exhaust system.

²Lubricate steering linkage (4x4 models).

²Lubricate propeller shaft universal joints.

²Rotate Tires.

15,000 MILES (24 000 KM) OR AT 12 MONTHS

²Check engine coolant level, hoses and clamps.

²Change engine oil.

²Replace engine oil filter.

²Check exhaust system.

²Lubricate steering linkage (4x4 models).

²Lubricate propeller shaft universal joints.²Check fluid level in battery.

²Rotate Tires.

22,500 MILES (36 000 KM) OR AT 18 MONTHS

²Check engine coolant level, hoses and clamps.

²Change engine oil.

²Replace engine oil filter.

²Check exhaust system.

²Lubricate steering linkage (4x4 models).

²Lubricate propeller shaft universal joints.

²Rotate Tires.

30,000 MILES (48 000 KM) OR AT 24 MONTHS

²Replace air cleaner filter.

²Replace spark plugs.

²Adjust drive belt.

²Check engine coolant level, hoses and clamps.

²Change engine oil.

²Replace engine oil filter.

²Check exhaust system.

²Lubricate steering linkage (4x4 models).

²Lubricate propeller shaft universal joints.

²Check fluid level in battery.

²Drain and refill automatic transmission.

²Drain and refill transfer case.

²Rotate Tires.

37,500 MILES (60 000 KM) OR AT 30 MONTHS

²Check engine coolant level, hoses and clamps.

²Change engine oil.

²Replace engine oil filter.

²Check exhaust system.

²Lubricate steering linkage (4x4 models).

²Lubricate propeller shaft universal joints.

²Drain and refill manual transmission.

²Rotate Tires.

45,000 MILES (72 500 KM) OR AT 36 MONTHS

²Check engine coolant level, hoses and clamps.

²Change engine oil.

²Replace engine oil filter.

²Check exhaust system.

²Lubricate steering linkage (4x4 models).

²Lubricate propeller shaft universal joints.

²Check fluid level in battery.

²Rotate Tires.

52,500 MILES (84 500 KM) OR AT 42 MONTHS

²Flush and replace engine coolant.

²Check engine coolant system hoses and clamps.

²Change engine oil.

²Replace engine oil filter.

²Check exhaust system.

²Lubricate steering linkage (4x4 models).

²Lubricate propeller shaft universal joints.

²Rotate Tires.

JLUBRICATION AND MAINTENANCE 0 - 5

Page 8 of 1784

JUMP STARTING, HOISTING AND TOWING

JUMP STARTING

WARNING: DO NOT ATTEMPT TO PUSH OR TOW A

VEHICLE TO START THE ENGINE. UNBURNED

FUEL COULD ENTER THE EXHAUST CATALYTIC

CONVERTER AND IGNITE AFTER THE ENGINE IS

STARTED. THIS COULD CAUSE THE CONVERTER

TO OVERHEAT AND RUPTURE.

BOOSTER BATTERY

WARNING: TO PREVENT PERSONAL INJURY OR

CLOTHING DAMAGE, DO NOT ALLOW BATTERY

(ACID) TO CONTACT EYES, SKIN OR CLOTHING.

DO NOT LEAN OVER A BATTERY WHEN CON-

NECTING JUMPER CABLES. DO NOT ALLOW THE

POSITIVE AND NEGATIVE CABLE CONNECTOR

CLAMPS TO CONTACT EACH OTHER. KEEP OPEN

FLAMES AND SPARKS AWAY FROM THE BATTERY

VENT HOLES. ALWAYS WEAR EYE PROTECTION

WHEN INVOLVED WITH BATTERIES.

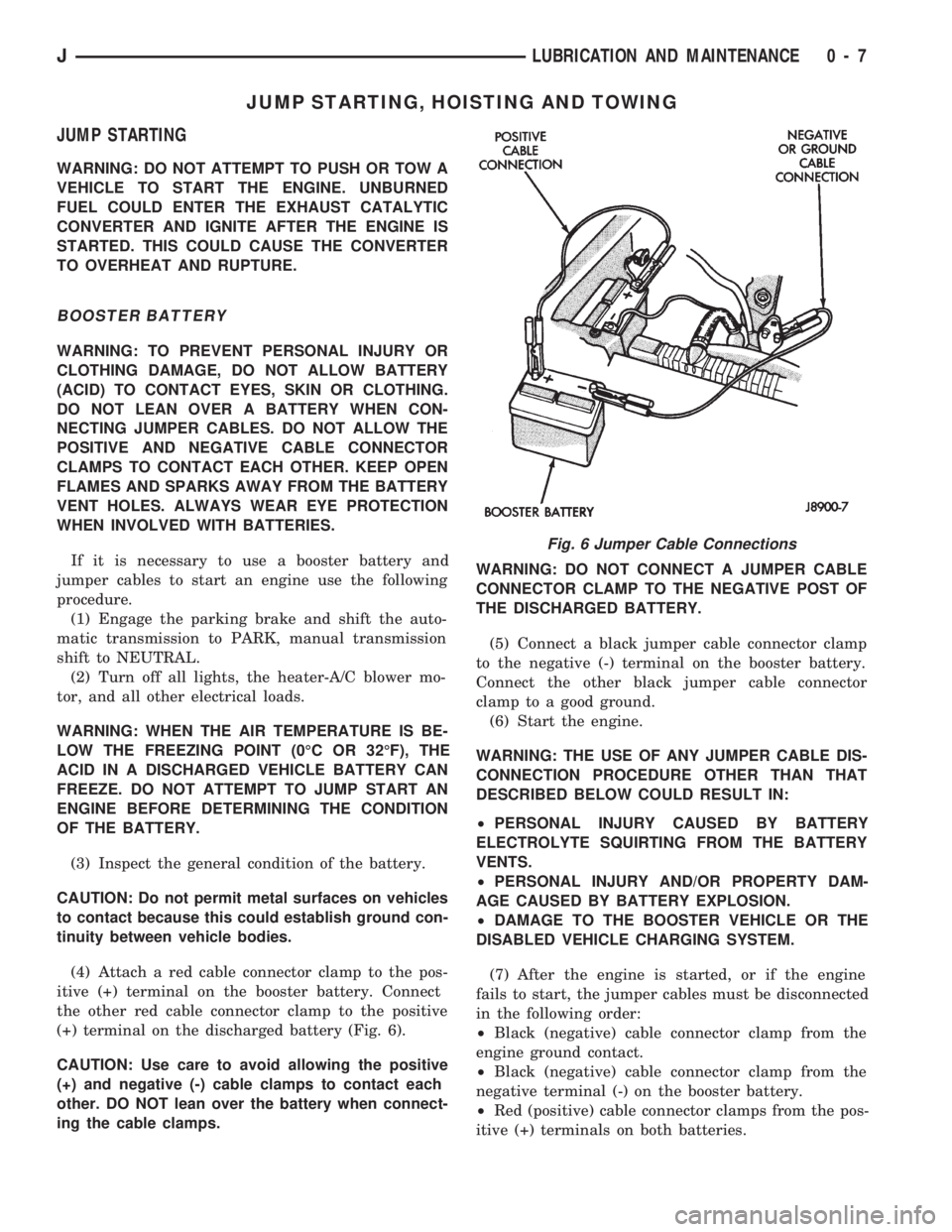

If it is necessary to use a booster battery and

jumper cables to start an engine use the following

procedure.

(1) Engage the parking brake and shift the auto-

matic transmission to PARK, manual transmission

shift to NEUTRAL.

(2) Turn off all lights, the heater-A/C blower mo-

tor, and all other electrical loads.

WARNING: WHEN THE AIR TEMPERATURE IS BE-

LOW THE FREEZING POINT (0ÉC OR 32ÉF), THE

ACID IN A DISCHARGED VEHICLE BATTERY CAN

FREEZE. DO NOT ATTEMPT TO JUMP START AN

ENGINE BEFORE DETERMINING THE CONDITION

OF THE BATTERY.

(3) Inspect the general condition of the battery.

CAUTION: Do not permit metal surfaces on vehicles

to contact because this could establish ground con-

tinuity between vehicle bodies.

(4) Attach a red cable connector clamp to the pos-

itive (+) terminal on the booster battery. Connect

the other red cable connector clamp to the positive

(+) terminal on the discharged battery (Fig. 6).

CAUTION: Use care to avoid allowing the positive

(+) and negative (-) cable clamps to contact each

other. DO NOT lean over the battery when connect-

ing the cable clamps.WARNING: DO NOT CONNECT A JUMPER CABLE

CONNECTOR CLAMP TO THE NEGATIVE POST OF

THE DISCHARGED BATTERY.

(5) Connect a black jumper cable connector clamp

to the negative (-) terminal on the booster battery.

Connect the other black jumper cable connector

clamp to a good ground.

(6) Start the engine.

WARNING: THE USE OF ANY JUMPER CABLE DIS-

CONNECTION PROCEDURE OTHER THAN THAT

DESCRIBED BELOW COULD RESULT IN:

²PERSONAL INJURY CAUSED BY BATTERY

ELECTROLYTE SQUIRTING FROM THE BATTERY

VENTS.

²PERSONAL INJURY AND/OR PROPERTY DAM-

AGE CAUSED BY BATTERY EXPLOSION.

²DAMAGE TO THE BOOSTER VEHICLE OR THE

DISABLED VEHICLE CHARGING SYSTEM.

(7) After the engine is started, or if the engine

fails to start, the jumper cables must be disconnected

in the following order:

²Black (negative) cable connector clamp from the

engine ground contact.

²Black (negative) cable connector clamp from the

negative terminal (-) on the booster battery.

²Red (positive) cable connector clamps from the pos-

itive (+) terminals on both batteries.

Fig. 6 Jumper Cable Connections

JLUBRICATION AND MAINTENANCE 0 - 7

Page 9 of 1784

PORTABLE STARTING UNIT

There are many types of portable starting units

available for starting engines. Follow the manufac-

turer's instructions when involved in any engine

starting procedure.

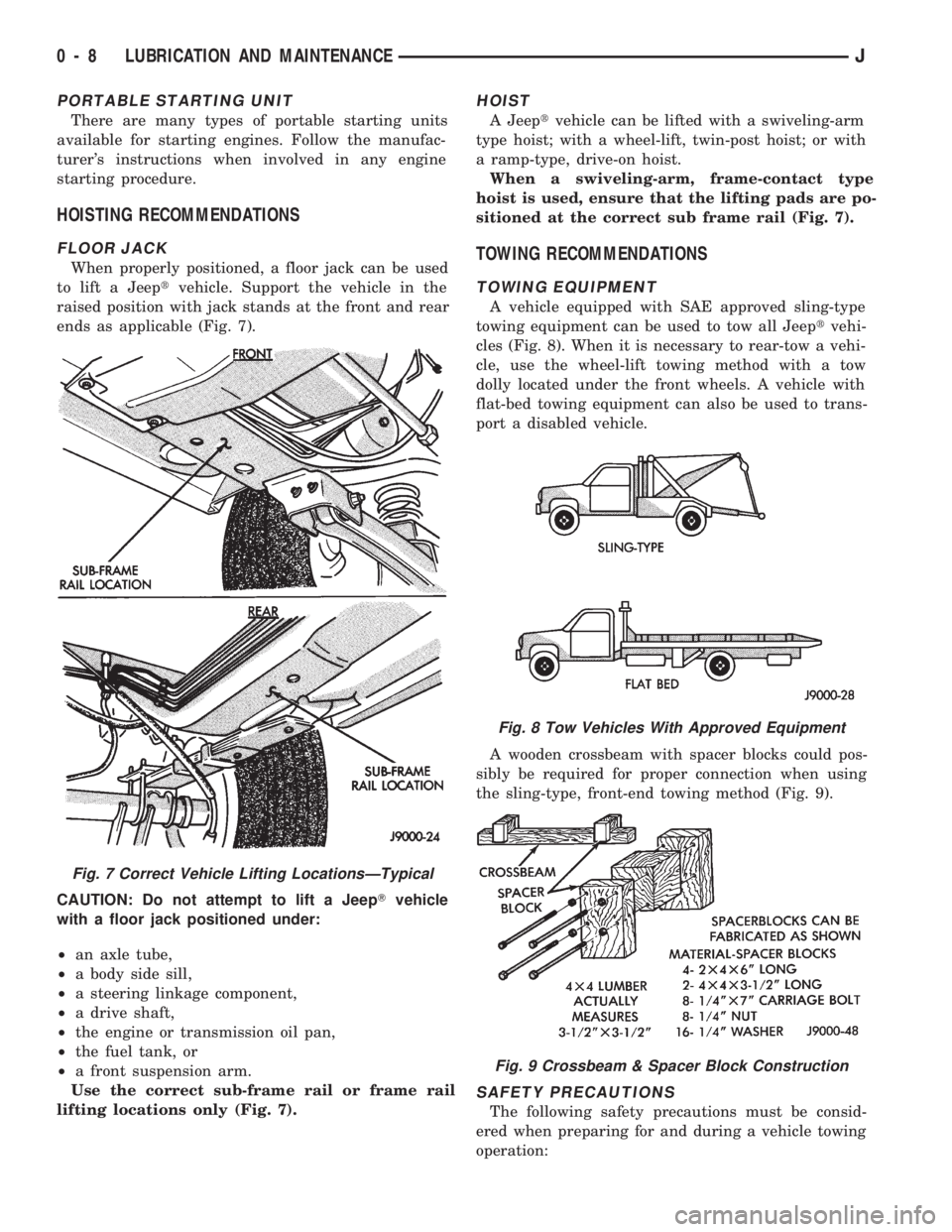

HOISTING RECOMMENDATIONS

FLOOR JACK

When properly positioned, a floor jack can be used

to lift a Jeeptvehicle. Support the vehicle in the

raised position with jack stands at the front and rear

ends as applicable (Fig. 7).

CAUTION: Do not attempt to lift a JeepTvehicle

with a floor jack positioned under:

²an axle tube,

²a body side sill,

²a steering linkage component,

²a drive shaft,

²the engine or transmission oil pan,

²the fuel tank, or

²a front suspension arm.

Use the correct sub-frame rail or frame rail

lifting locations only (Fig. 7).

HOIST

A Jeeptvehicle can be lifted with a swiveling-arm

type hoist; with a wheel-lift, twin-post hoist; or with

a ramp-type, drive-on hoist.

When a swiveling-arm, frame-contact type

hoist is used, ensure that the lifting pads are po-

sitioned at the correct sub frame rail (Fig. 7).

TOWING RECOMMENDATIONS

TOWING EQUIPMENT

A vehicle equipped with SAE approved sling-type

towing equipment can be used to tow all Jeeptvehi-

cles (Fig. 8). When it is necessary to rear-tow a vehi-

cle, use the wheel-lift towing method with a tow

dolly located under the front wheels. A vehicle with

flat-bed towing equipment can also be used to trans-

port a disabled vehicle.

A wooden crossbeam with spacer blocks could pos-

sibly be required for proper connection when using

the sling-type, front-end towing method (Fig. 9).

SAFETY PRECAUTIONS

The following safety precautions must be consid-

ered when preparing for and during a vehicle towing

operation:

Fig. 7 Correct Vehicle Lifting LocationsÐTypical

Fig. 8 Tow Vehicles With Approved Equipment

Fig. 9 Crossbeam & Spacer Block Construction

0 - 8 LUBRICATION AND MAINTENANCEJ

Page 10 of 1784

²if the vehicle is damaged, secure the loose and pro-

truding parts;

²always use a safety chain system that is indepen-

dent of the lifting and towing equipment;

²do not allow any of the towing equipment to con-

tact the disabled vehicle's fuel tank;

²do not allow anyone to be under the disabled vehi-

cle while it is lifted by the towing equipment;

²do not allow passengers to ride in a vehicle being

towed;

²always observe all state and local laws involving

warning signals, night illumination, speed, etc.

²do not attempt a towing operation that could jeop-

ardize the safety of the operator, bystanders or other

motorists;

²do not exceed a towing speed of 48 km/h (30 mph);

²avoid towing distances of more than 24 km (15

miles) whenever possible; and

²do not attach tow chains or a tow sling to a

bumper, the steering linkage, the universal joints,

the constant velocity (CV) joints, or a drive shaft.

CLEARANCES AND RAMP ANGLE

SURFACE CLEARANCE

The end of the disabled vehicle that is attached to

the tow vehicle should be lifted a minimum of 10 cm

or four inches off the surface. Inspect to ensure that

the opposite end of the disabled vehicle has clearance

from the surface.

RAMP ANGLEÐFLAT-BED TOWING

If a vehicle with flat-bed towing equipment is used,

the approach ramp angle should not exceed 15 de-

grees.

SLING-TYPE, FRONT-END TOWING

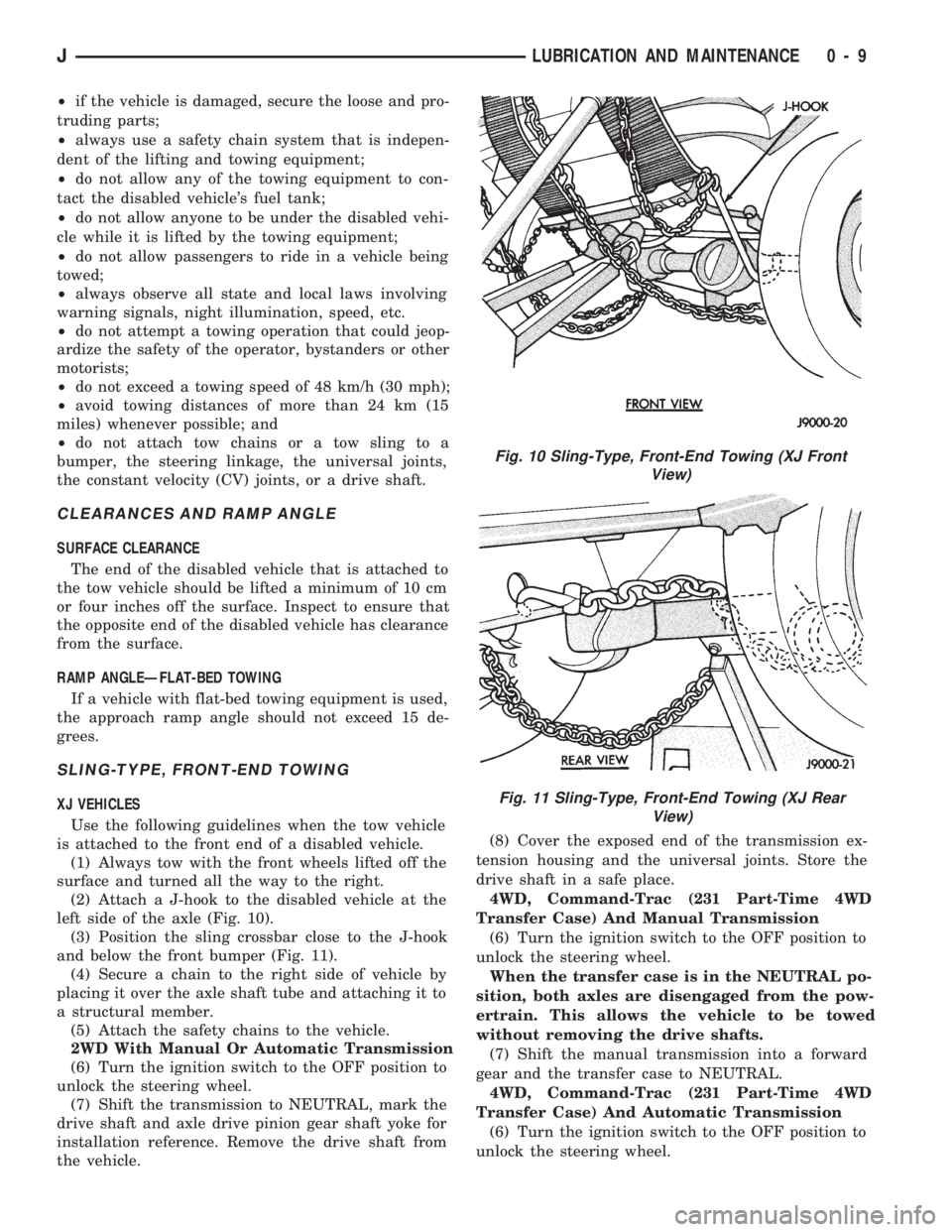

XJ VEHICLES

Use the following guidelines when the tow vehicle

is attached to the front end of a disabled vehicle.

(1) Always tow with the front wheels lifted off the

surface and turned all the way to the right.

(2) Attach a J-hook to the disabled vehicle at the

left side of the axle (Fig. 10).

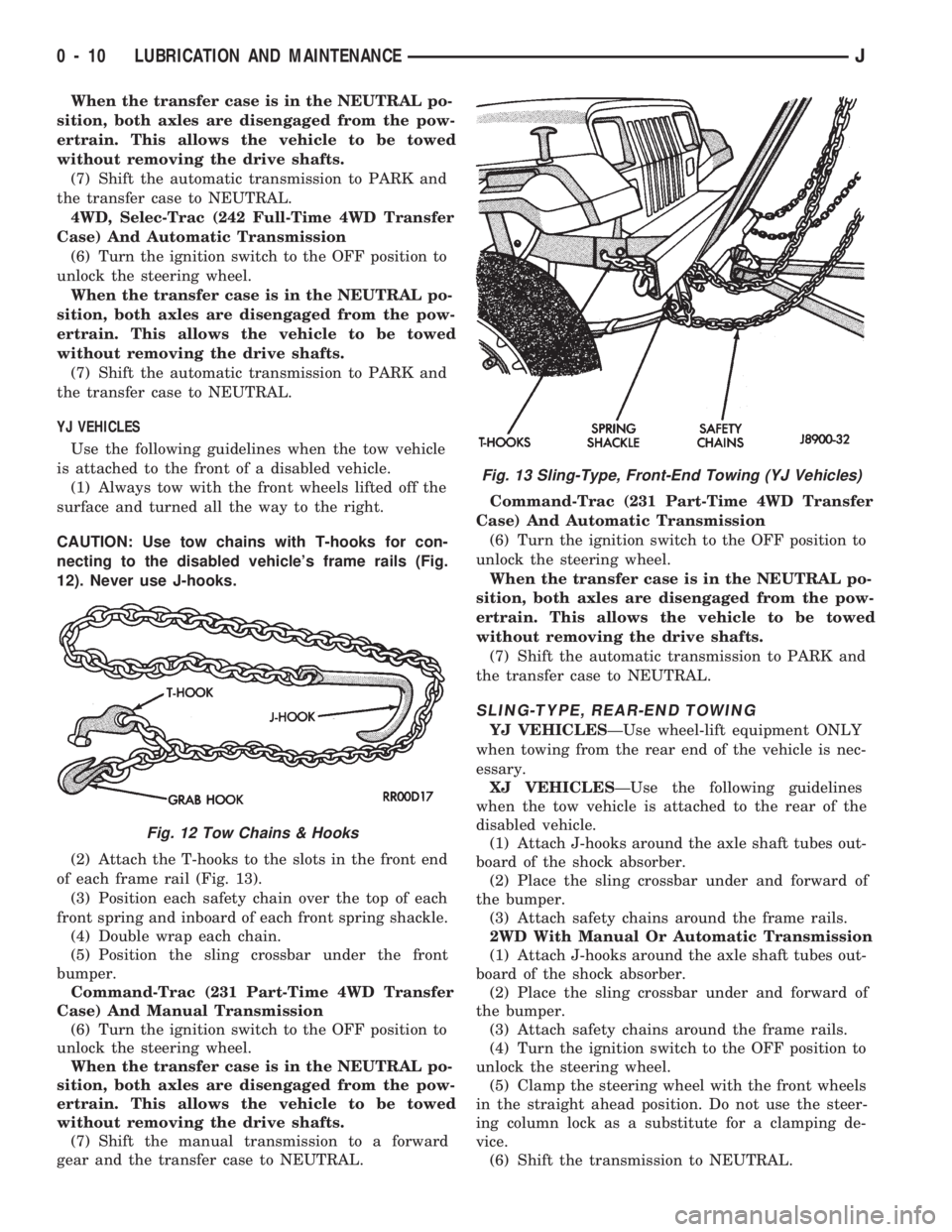

(3) Position the sling crossbar close to the J-hook

and below the front bumper (Fig. 11).

(4) Secure a chain to the right side of vehicle by

placing it over the axle shaft tube and attaching it to

a structural member.

(5) Attach the safety chains to the vehicle.

2WD With Manual Or Automatic Transmission

(6) Turn the ignition switch to the OFF position to

unlock the steering wheel.

(7) Shift the transmission to NEUTRAL, mark the

drive shaft and axle drive pinion gear shaft yoke for

installation reference. Remove the drive shaft from

the vehicle.(8) Cover the exposed end of the transmission ex-

tension housing and the universal joints. Store the

drive shaft in a safe place.

4WD, Command-Trac (231 Part-Time 4WD

Transfer Case) And Manual Transmission

(6) Turn the ignition switch to the OFF position to

unlock the steering wheel.

When the transfer case is in the NEUTRAL po-

sition, both axles are disengaged from the pow-

ertrain. This allows the vehicle to be towed

without removing the drive shafts.

(7) Shift the manual transmission into a forward

gear and the transfer case to NEUTRAL.

4WD, Command-Trac (231 Part-Time 4WD

Transfer Case) And Automatic Transmission

(6) Turn the ignition switch to the OFF position to

unlock the steering wheel.

Fig. 10 Sling-Type, Front-End Towing (XJ Front

View)

Fig. 11 Sling-Type, Front-End Towing (XJ Rear

View)

JLUBRICATION AND MAINTENANCE 0 - 9

Page 11 of 1784

When the transfer case is in the NEUTRAL po-

sition, both axles are disengaged from the pow-

ertrain. This allows the vehicle to be towed

without removing the drive shafts.

(7) Shift the automatic transmission to PARK and

the transfer case to NEUTRAL.

4WD, Selec-Trac (242 Full-Time 4WD Transfer

Case) And Automatic Transmission

(6) Turn the ignition switch to the OFF position to

unlock the steering wheel.

When the transfer case is in the NEUTRAL po-

sition, both axles are disengaged from the pow-

ertrain. This allows the vehicle to be towed

without removing the drive shafts.

(7) Shift the automatic transmission to PARK and

the transfer case to NEUTRAL.

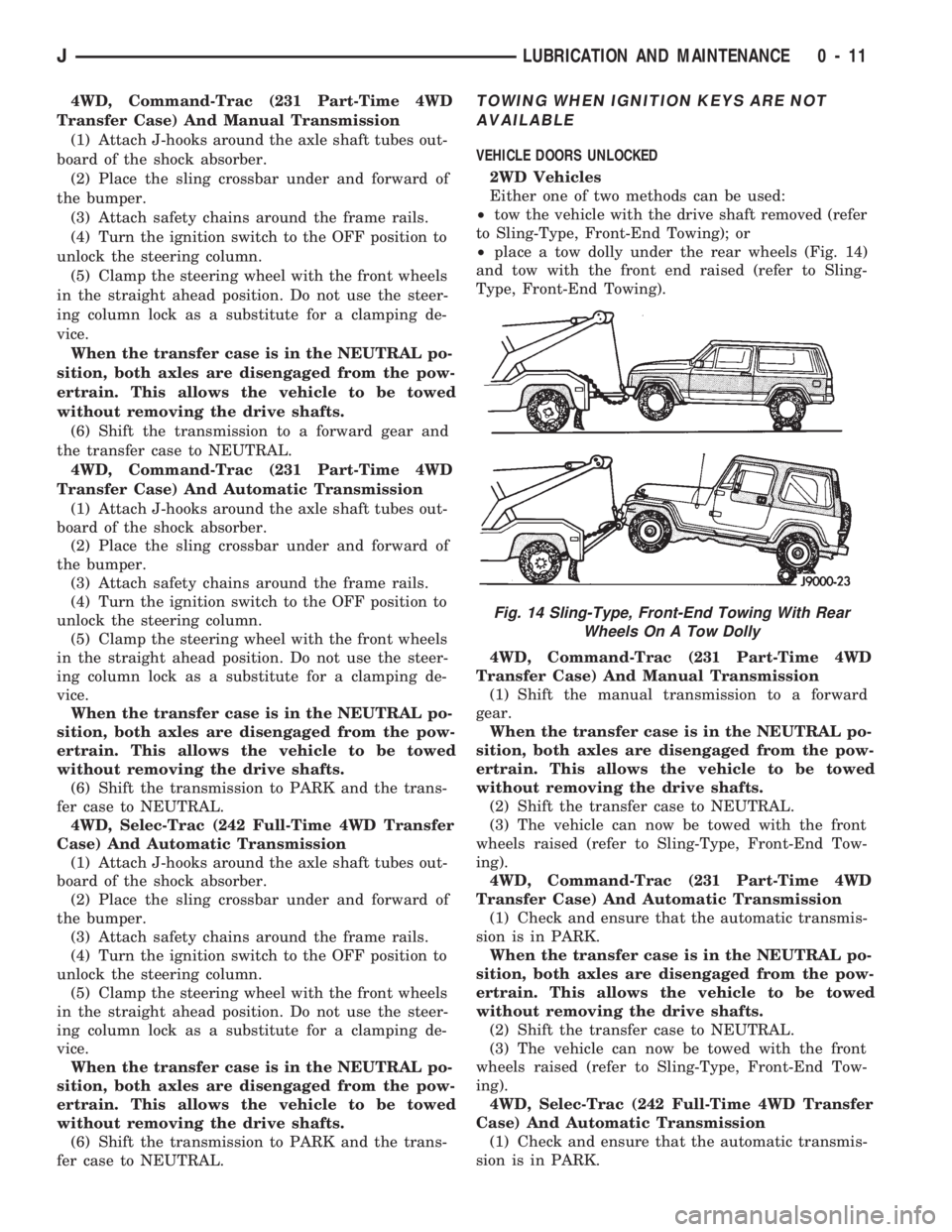

YJ VEHICLES

Use the following guidelines when the tow vehicle

is attached to the front of a disabled vehicle.

(1) Always tow with the front wheels lifted off the

surface and turned all the way to the right.

CAUTION: Use tow chains with T-hooks for con-

necting to the disabled vehicle's frame rails (Fig.

12). Never use J-hooks.

(2) Attach the T-hooks to the slots in the front end

of each frame rail (Fig. 13).

(3) Position each safety chain over the top of each

front spring and inboard of each front spring shackle.

(4) Double wrap each chain.

(5) Position the sling crossbar under the front

bumper.

Command-Trac (231 Part-Time 4WD Transfer

Case) And Manual Transmission

(6) Turn the ignition switch to the OFF position to

unlock the steering wheel.

When the transfer case is in the NEUTRAL po-

sition, both axles are disengaged from the pow-

ertrain. This allows the vehicle to be towed

without removing the drive shafts.

(7) Shift the manual transmission to a forward

gear and the transfer case to NEUTRAL.Command-Trac (231 Part-Time 4WD Transfer

Case) And Automatic Transmission

(6) Turn the ignition switch to the OFF position to

unlock the steering wheel.

When the transfer case is in the NEUTRAL po-

sition, both axles are disengaged from the pow-

ertrain. This allows the vehicle to be towed

without removing the drive shafts.

(7) Shift the automatic transmission to PARK and

the transfer case to NEUTRAL.

SLING-TYPE, REAR-END TOWING

YJ VEHICLESÐUse wheel-lift equipment ONLY

when towing from the rear end of the vehicle is nec-

essary.

XJ VEHICLESÐUse the following guidelines

when the tow vehicle is attached to the rear of the

disabled vehicle.

(1) Attach J-hooks around the axle shaft tubes out-

board of the shock absorber.

(2) Place the sling crossbar under and forward of

the bumper.

(3) Attach safety chains around the frame rails.

2WD With Manual Or Automatic Transmission

(1) Attach J-hooks around the axle shaft tubes out-

board of the shock absorber.

(2) Place the sling crossbar under and forward of

the bumper.

(3) Attach safety chains around the frame rails.

(4) Turn the ignition switch to the OFF position to

unlock the steering wheel.

(5) Clamp the steering wheel with the front wheels

in the straight ahead position. Do not use the steer-

ing column lock as a substitute for a clamping de-

vice.

(6) Shift the transmission to NEUTRAL.

Fig. 12 Tow Chains & Hooks

Fig. 13 Sling-Type, Front-End Towing (YJ Vehicles)

0 - 10 LUBRICATION AND MAINTENANCEJ

Page 12 of 1784

4WD, Command-Trac (231 Part-Time 4WD

Transfer Case) And Manual Transmission

(1) Attach J-hooks around the axle shaft tubes out-

board of the shock absorber.

(2) Place the sling crossbar under and forward of

the bumper.

(3) Attach safety chains around the frame rails.

(4) Turn the ignition switch to the OFF position to

unlock the steering column.

(5) Clamp the steering wheel with the front wheels

in the straight ahead position. Do not use the steer-

ing column lock as a substitute for a clamping de-

vice.

When the transfer case is in the NEUTRAL po-

sition, both axles are disengaged from the pow-

ertrain. This allows the vehicle to be towed

without removing the drive shafts.

(6) Shift the transmission to a forward gear and

the transfer case to NEUTRAL.

4WD, Command-Trac (231 Part-Time 4WD

Transfer Case) And Automatic Transmission

(1) Attach J-hooks around the axle shaft tubes out-

board of the shock absorber.

(2) Place the sling crossbar under and forward of

the bumper.

(3) Attach safety chains around the frame rails.

(4) Turn the ignition switch to the OFF position to

unlock the steering column.

(5) Clamp the steering wheel with the front wheels

in the straight ahead position. Do not use the steer-

ing column lock as a substitute for a clamping de-

vice.

When the transfer case is in the NEUTRAL po-

sition, both axles are disengaged from the pow-

ertrain. This allows the vehicle to be towed

without removing the drive shafts.

(6) Shift the transmission to PARK and the trans-

fer case to NEUTRAL.

4WD, Selec-Trac (242 Full-Time 4WD Transfer

Case) And Automatic Transmission

(1) Attach J-hooks around the axle shaft tubes out-

board of the shock absorber.

(2) Place the sling crossbar under and forward of

the bumper.

(3) Attach safety chains around the frame rails.

(4) Turn the ignition switch to the OFF position to

unlock the steering column.

(5) Clamp the steering wheel with the front wheels

in the straight ahead position. Do not use the steer-

ing column lock as a substitute for a clamping de-

vice.

When the transfer case is in the NEUTRAL po-

sition, both axles are disengaged from the pow-

ertrain. This allows the vehicle to be towed

without removing the drive shafts.

(6) Shift the transmission to PARK and the trans-

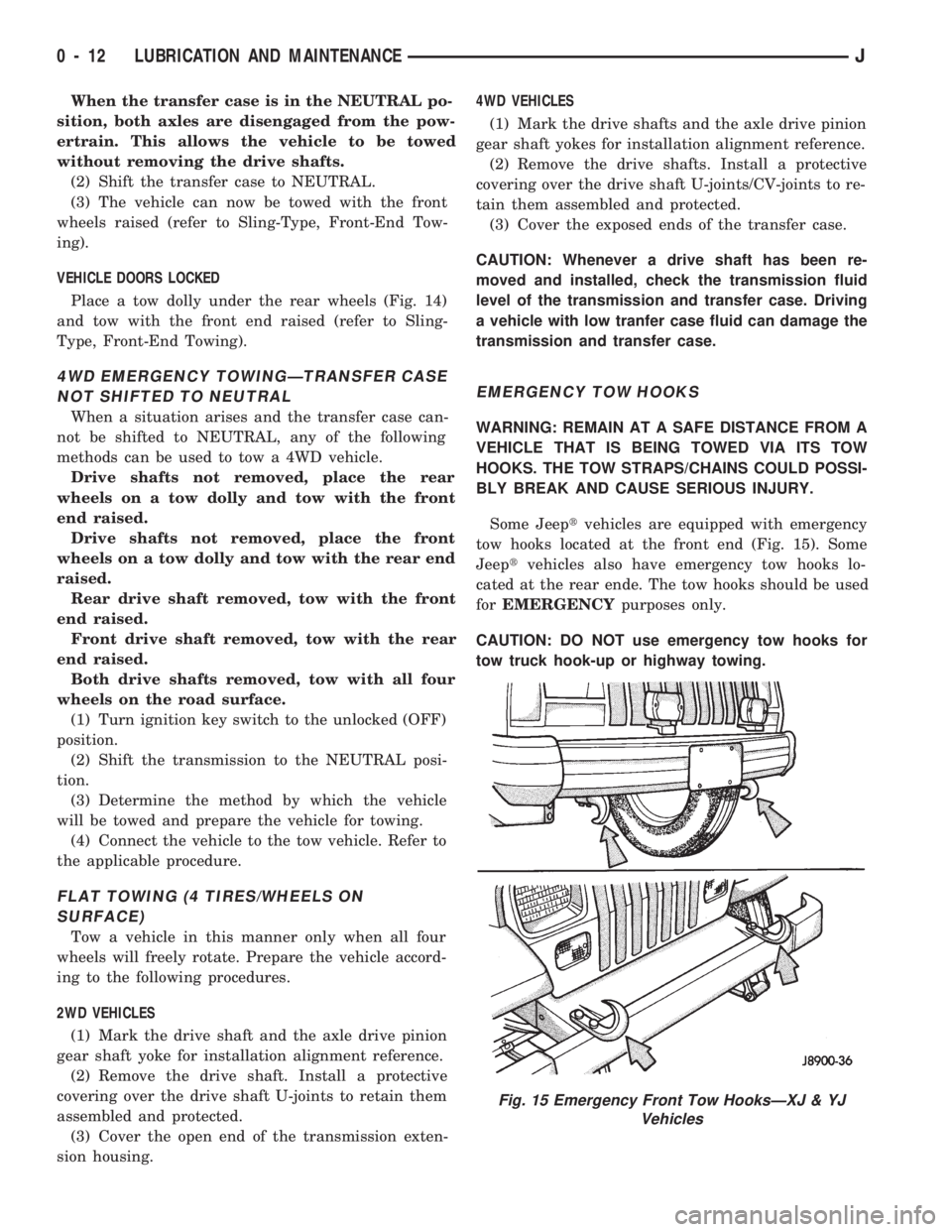

fer case to NEUTRAL.TOWING WHEN IGNITION KEYS ARE NOT

AVAILABLE

VEHICLE DOORS UNLOCKED

2WD Vehicles

Either one of two methods can be used:

²tow the vehicle with the drive shaft removed (refer

to Sling-Type, Front-End Towing); or

²place a tow dolly under the rear wheels (Fig. 14)

and tow with the front end raised (refer to Sling-

Type, Front-End Towing).

4WD, Command-Trac (231 Part-Time 4WD

Transfer Case) And Manual Transmission

(1) Shift the manual transmission to a forward

gear.

When the transfer case is in the NEUTRAL po-

sition, both axles are disengaged from the pow-

ertrain. This allows the vehicle to be towed

without removing the drive shafts.

(2) Shift the transfer case to NEUTRAL.

(3) The vehicle can now be towed with the front

wheels raised (refer to Sling-Type, Front-End Tow-

ing).

4WD, Command-Trac (231 Part-Time 4WD

Transfer Case) And Automatic Transmission

(1) Check and ensure that the automatic transmis-

sion is in PARK.

When the transfer case is in the NEUTRAL po-

sition, both axles are disengaged from the pow-

ertrain. This allows the vehicle to be towed

without removing the drive shafts.

(2) Shift the transfer case to NEUTRAL.

(3) The vehicle can now be towed with the front

wheels raised (refer to Sling-Type, Front-End Tow-

ing).

4WD, Selec-Trac (242 Full-Time 4WD Transfer

Case) And Automatic Transmission

(1) Check and ensure that the automatic transmis-

sion is in PARK.

Fig. 14 Sling-Type, Front-End Towing With Rear

Wheels On A Tow Dolly

JLUBRICATION AND MAINTENANCE 0 - 11

Page 13 of 1784

When the transfer case is in the NEUTRAL po-

sition, both axles are disengaged from the pow-

ertrain. This allows the vehicle to be towed

without removing the drive shafts.

(2) Shift the transfer case to NEUTRAL.

(3) The vehicle can now be towed with the front

wheels raised (refer to Sling-Type, Front-End Tow-

ing).

VEHICLE DOORS LOCKED

Place a tow dolly under the rear wheels (Fig. 14)

and tow with the front end raised (refer to Sling-

Type, Front-End Towing).

4WD EMERGENCY TOWINGÐTRANSFER CASE

NOT SHIFTED TO NEUTRAL

When a situation arises and the transfer case can-

not be shifted to NEUTRAL, any of the following

methods can be used to tow a 4WD vehicle.

Drive shafts not removed, place the rear

wheels on a tow dolly and tow with the front

end raised.

Drive shafts not removed, place the front

wheels on a tow dolly and tow with the rear end

raised.

Rear drive shaft removed, tow with the front

end raised.

Front drive shaft removed, tow with the rear

end raised.

Both drive shafts removed, tow with all four

wheels on the road surface.

(1) Turn ignition key switch to the unlocked (OFF)

position.

(2) Shift the transmission to the NEUTRAL posi-

tion.

(3) Determine the method by which the vehicle

will be towed and prepare the vehicle for towing.

(4) Connect the vehicle to the tow vehicle. Refer to

the applicable procedure.

FLAT TOWING (4 TIRES/WHEELS ON

SURFACE)

Tow a vehicle in this manner only when all four

wheels will freely rotate. Prepare the vehicle accord-

ing to the following procedures.

2WD VEHICLES

(1) Mark the drive shaft and the axle drive pinion

gear shaft yoke for installation alignment reference.

(2) Remove the drive shaft. Install a protective

covering over the drive shaft U-joints to retain them

assembled and protected.

(3) Cover the open end of the transmission exten-

sion housing.4WD VEHICLES

(1) Mark the drive shafts and the axle drive pinion

gear shaft yokes for installation alignment reference.

(2) Remove the drive shafts. Install a protective

covering over the drive shaft U-joints/CV-joints to re-

tain them assembled and protected.

(3) Cover the exposed ends of the transfer case.

CAUTION: Whenever a drive shaft has been re-

moved and installed, check the transmission fluid

level of the transmission and transfer case. Driving

a vehicle with low tranfer case fluid can damage the

transmission and transfer case.

EMERGENCY TOW HOOKS

WARNING: REMAIN AT A SAFE DISTANCE FROM A

VEHICLE THAT IS BEING TOWED VIA ITS TOW

HOOKS. THE TOW STRAPS/CHAINS COULD POSSI-

BLY BREAK AND CAUSE SERIOUS INJURY.

Some Jeeptvehicles are equipped with emergency

tow hooks located at the front end (Fig. 15). Some

Jeeptvehicles also have emergency tow hooks lo-

cated at the rear ende. The tow hooks should be used

forEMERGENCYpurposes only.

CAUTION: DO NOT use emergency tow hooks for

tow truck hook-up or highway towing.

Fig. 15 Emergency Front Tow HooksÐXJ & YJ

Vehicles

0 - 12 LUBRICATION AND MAINTENANCEJ

Page 16 of 1784

ENGINE OIL CHANGE AND FILTER REPLACEMENT

WARNING: CARE SHOULD BE TAKEN WHEN

CHANGING OIL. PROTECTIVE CLOTHING AND

GLOVES SHOULD BE WORN. EXPOSED SKIN

SHOULD BE WASHED WITH SOAP AND WATER TO

REMOVE ANY ENGINE OIL. DO NOT USE GASO-

LINE, THINNER, OR SOLVENTS TO REMOVE EN-

GINE OIL FROM SKIN.

REQUIRED MAINTENANCE

With normal driving conditions, engine oil and fil-

ter must be changed after each 12 000-km (7,500-

miles)/12-month interval. If the vehicle is involved

with a severe driving condition, after each 4 800-km

(3,000-miles)/3-month interval. A severe driving con-

dition includes:

²frequent short trip driving less than 24 km (15

miles);

²frequent driving in a dusty environment;

²trailer towing;

²extensive engine idling;

²sustained high-speed operation;

²desert operation;

²frequent starting and stopping;

²cold-climate operation;

²off-road driving; or

²commercial service.

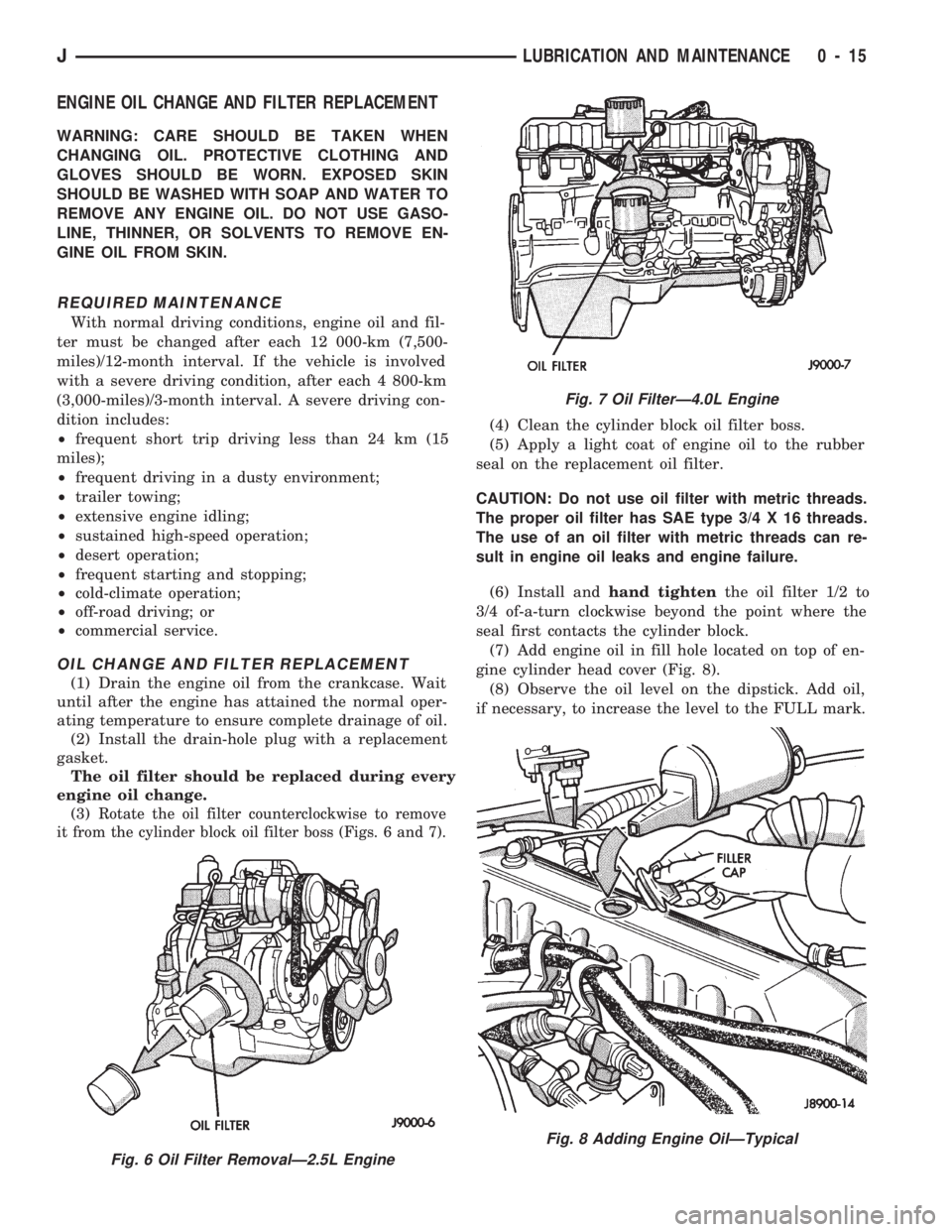

OIL CHANGE AND FILTER REPLACEMENT

(1) Drain the engine oil from the crankcase. Wait

until after the engine has attained the normal oper-

ating temperature to ensure complete drainage of oil.

(2) Install the drain-hole plug with a replacement

gasket.

The oil filter should be replaced during every

engine oil change.

(3)

Rotate the oil filter counterclockwise to remove

it from the cylinder block oil filter boss (Figs. 6 and 7).

(4) Clean the cylinder block oil filter boss.

(5) Apply a light coat of engine oil to the rubber

seal on the replacement oil filter.

CAUTION: Do not use oil filter with metric threads.

The proper oil filter has SAE type 3/4 X 16 threads.

The use of an oil filter with metric threads can re-

sult in engine oil leaks and engine failure.

(6) Install andhand tightenthe oil filter 1/2 to

3/4 of-a-turn clockwise beyond the point where the

seal first contacts the cylinder block.

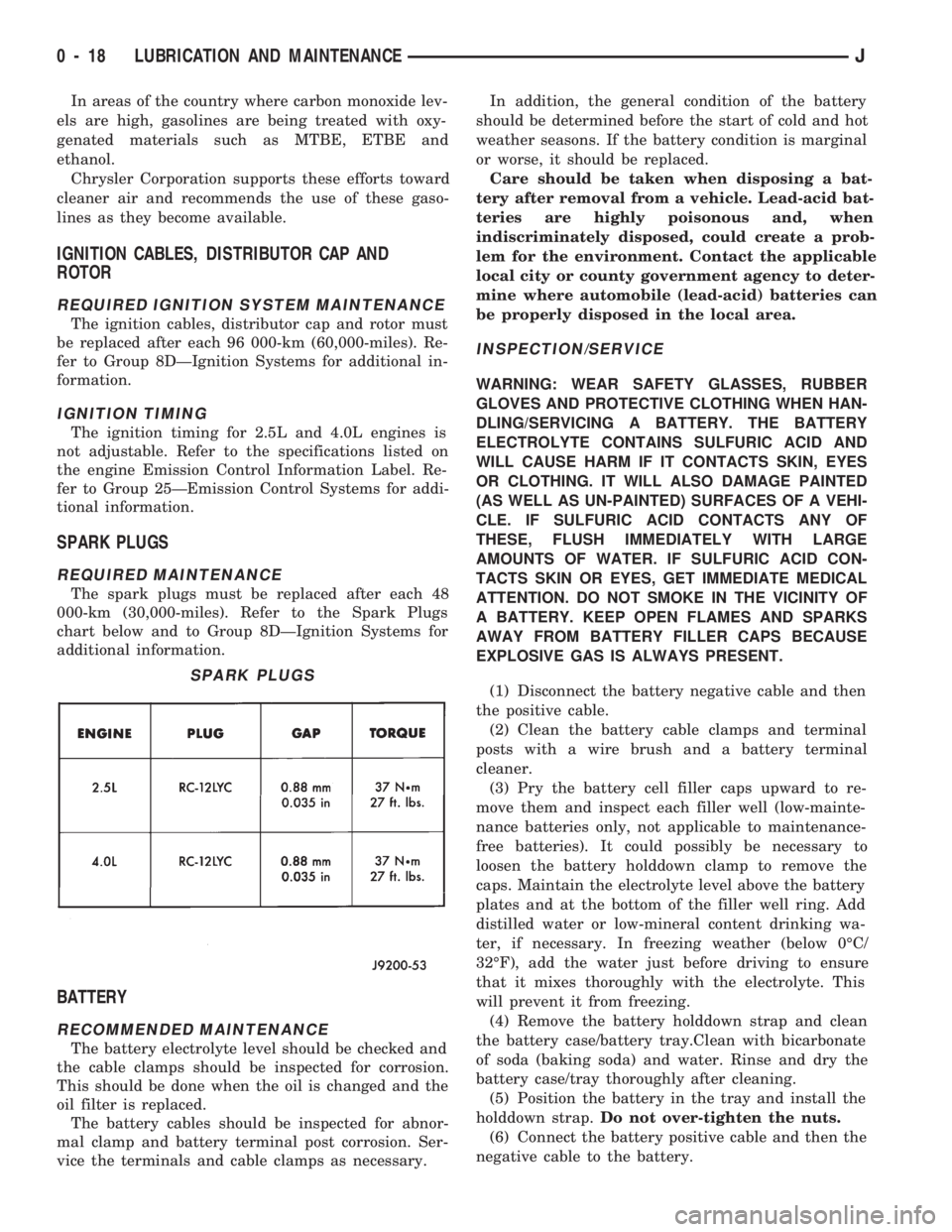

(7) Add engine oil in fill hole located on top of en-

gine cylinder head cover (Fig. 8).

(8) Observe the oil level on the dipstick. Add oil,

if necessary, to increase the level to the FULL mark.

Fig. 6 Oil Filter RemovalÐ2.5L Engine

Fig. 7 Oil FilterÐ4.0L Engine

Fig. 8 Adding Engine OilÐTypical

JLUBRICATION AND MAINTENANCE 0 - 15

Page 19 of 1784

In areas of the country where carbon monoxide lev-

els are high, gasolines are being treated with oxy-

genated materials such as MTBE, ETBE and

ethanol.

Chrysler Corporation supports these efforts toward

cleaner air and recommends the use of these gaso-

lines as they become available.

IGNITION CABLES, DISTRIBUTOR CAP AND

ROTOR

REQUIRED IGNITION SYSTEM MAINTENANCE

The ignition cables, distributor cap and rotor must

be replaced after each 96 000-km (60,000-miles). Re-

fer to Group 8DÐIgnition Systems for additional in-

formation.

IGNITION TIMING

The ignition timing for 2.5L and 4.0L engines is

not adjustable. Refer to the specifications listed on

the engine Emission Control Information Label. Re-

fer to Group 25ÐEmission Control Systems for addi-

tional information.

SPARK PLUGS

REQUIRED MAINTENANCE

The spark plugs must be replaced after each 48

000-km (30,000-miles). Refer to the Spark Plugs

chart below and to Group 8DÐIgnition Systems for

additional information.

BATTERY

RECOMMENDED MAINTENANCE

The battery electrolyte level should be checked and

the cable clamps should be inspected for corrosion.

This should be done when the oil is changed and the

oil filter is replaced.

The battery cables should be inspected for abnor-

mal clamp and battery terminal post corrosion. Ser-

vice the terminals and cable clamps as necessary.In addition, the general condition of the battery

should be determined before the start of cold and hot

weather seasons. If the battery condition is marginal

or worse, it should be replaced.

Care should be taken when disposing a bat-

tery after removal from a vehicle. Lead-acid bat-

teries are highly poisonous and, when

indiscriminately disposed, could create a prob-

lem for the environment. Contact the applicable

local city or county government agency to deter-

mine where automobile (lead-acid) batteries can

be properly disposed in the local area.

INSPECTION/SERVICE

WARNING: WEAR SAFETY GLASSES, RUBBER

GLOVES AND PROTECTIVE CLOTHING WHEN HAN-

DLING/SERVICING A BATTERY. THE BATTERY

ELECTROLYTE CONTAINS SULFURIC ACID AND

WILL CAUSE HARM IF IT CONTACTS SKIN, EYES

OR CLOTHING. IT WILL ALSO DAMAGE PAINTED

(AS WELL AS UN-PAINTED) SURFACES OF A VEHI-

CLE. IF SULFURIC ACID CONTACTS ANY OF

THESE, FLUSH IMMEDIATELY WITH LARGE

AMOUNTS OF WATER. IF SULFURIC ACID CON-

TACTS SKIN OR EYES, GET IMMEDIATE MEDICAL

ATTENTION. DO NOT SMOKE IN THE VICINITY OF

A BATTERY. KEEP OPEN FLAMES AND SPARKS

AWAY FROM BATTERY FILLER CAPS BECAUSE

EXPLOSIVE GAS IS ALWAYS PRESENT.

(1) Disconnect the battery negative cable and then

the positive cable.

(2) Clean the battery cable clamps and terminal

posts with a wire brush and a battery terminal

cleaner.

(3) Pry the battery cell filler caps upward to re-

move them and inspect each filler well (low-mainte-

nance batteries only, not applicable to maintenance-

free batteries). It could possibly be necessary to

loosen the battery holddown clamp to remove the

caps. Maintain the electrolyte level above the battery

plates and at the bottom of the filler well ring. Add

distilled water or low-mineral content drinking wa-

ter, if necessary. In freezing weather (below 0ÉC/

32ÉF), add the water just before driving to ensure

that it mixes thoroughly with the electrolyte. This

will prevent it from freezing.

(4) Remove the battery holddown strap and clean

the battery case/battery tray.Clean with bicarbonate

of soda (baking soda) and water. Rinse and dry the

battery case/tray thoroughly after cleaning.

(5) Position the battery in the tray and install the

holddown strap.Do not over-tighten the nuts.

(6) Connect the battery positive cable and then the

negative cable to the battery.

SPARK PLUGS

0 - 18 LUBRICATION AND MAINTENANCEJ