JEEP CHEROKEE 1995 Service Repair Manual

Manufacturer: JEEP, Model Year: 1995, Model line: CHEROKEE, Model: JEEP CHEROKEE 1995Pages: 2198, PDF Size: 82.83 MB

Page 1101 of 2198

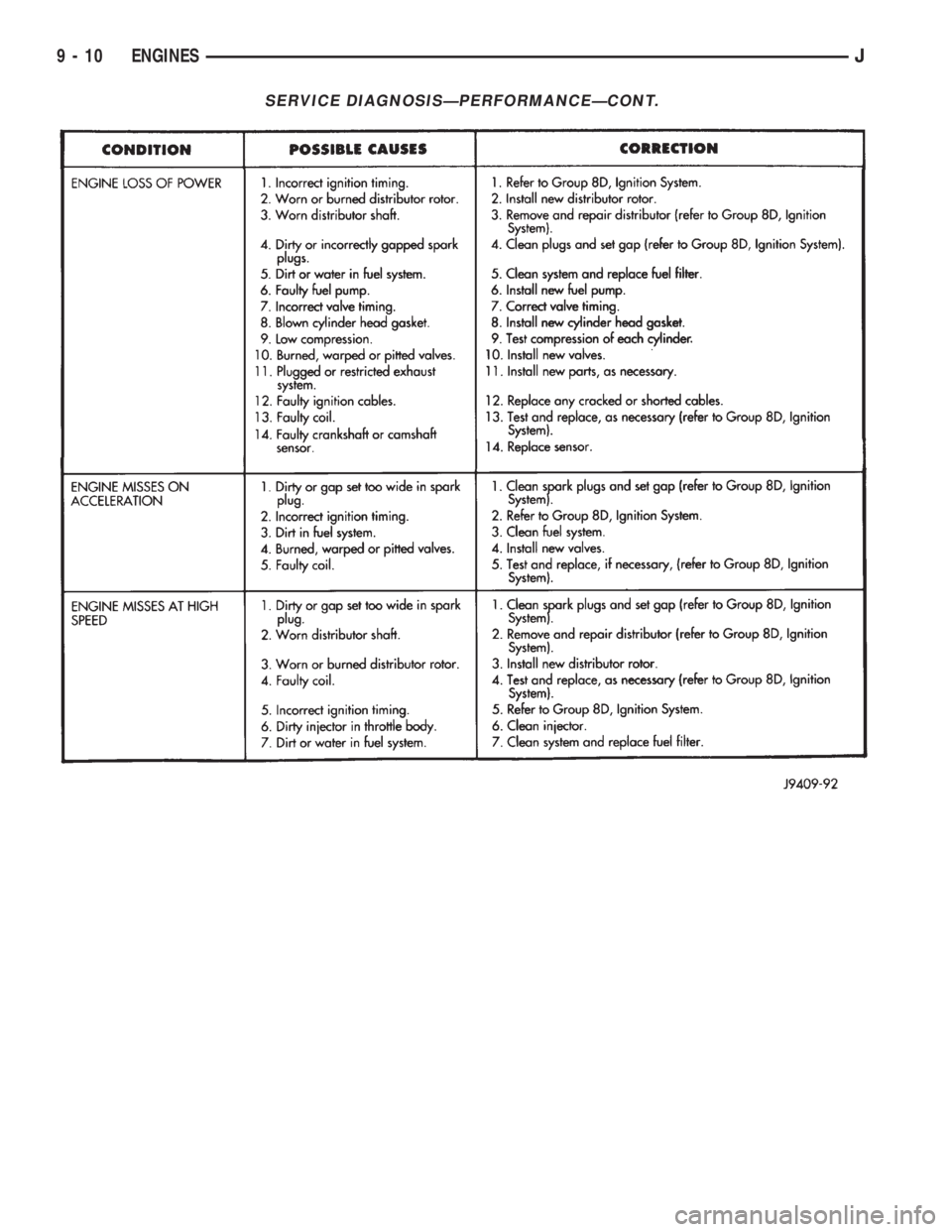

SERVICE DIAGNOSISÐPERFORMANCEÐCONT.

9 - 10 ENGINESJ

Page 1102 of 2198

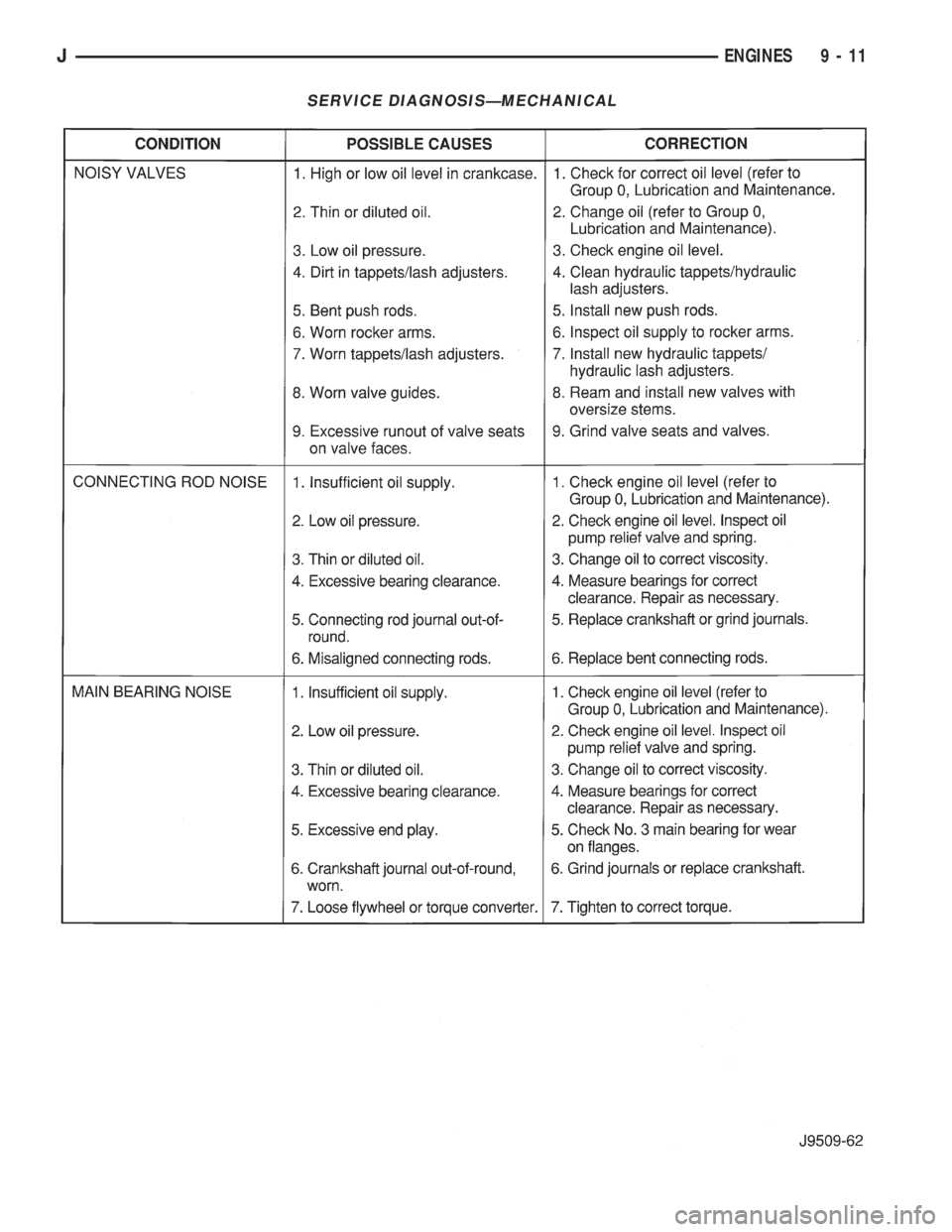

SERVICE DIAGNOSISÐMECHANICAL

JENGINES 9 - 11

Page 1103 of 2198

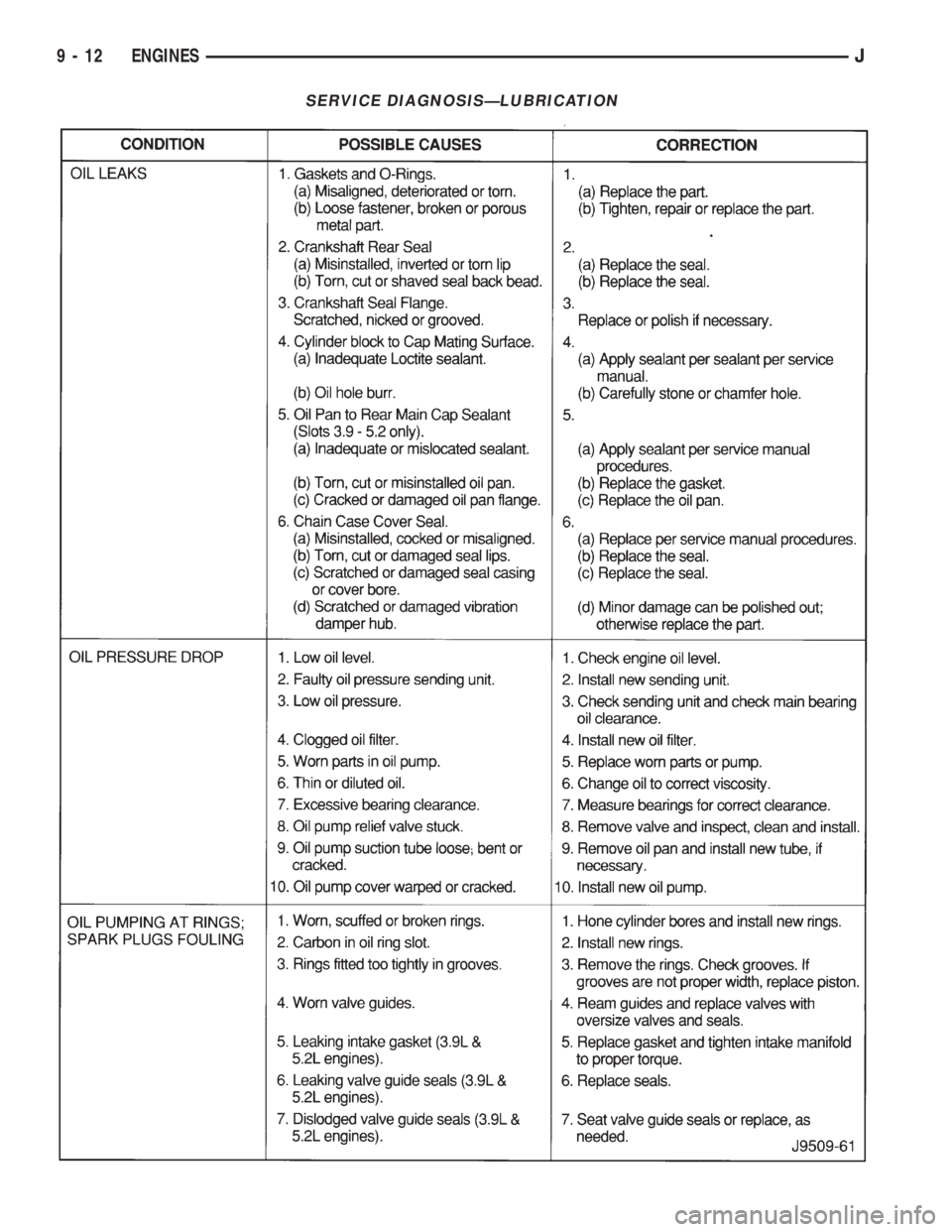

SERVICE DIAGNOSISÐLUBRICATION

9 - 12 ENGINESJ

Page 1104 of 2198

2.5L ENGINE SERVICE PROCEDURES

INDEX

page page

Camshaft............................... 32

Camshaft Pin Replacement.................. 34

Engine AssemblyÐXJ Vehicles............... 18

Engine AssemblyÐYJ Vehicles............... 20

Engine Cylinder Head...................... 25

Engine Cylinder Head Cover................. 22

Engine Damper........................... 17

Engine MountÐRear....................... 16

Engine MountsÐFront..................... 14

General Information....................... 13

Hydraulic Tappets......................... 24OilPan ................................. 36

Rocker Arms and Push Rods................ 23

Timing Case Cover........................ 31

Timing Case Cover Oil Seal Replacement....... 30

Timing Chain and Sprockets................. 31

Valve Component ReplaceÐCylinder Head Not

Removed.............................. 23

Valve Springs and Oil Seals................. 23

Valve Timing............................. 30

Valves and Valve Springs................... 27

Vibration Damper......................... 30

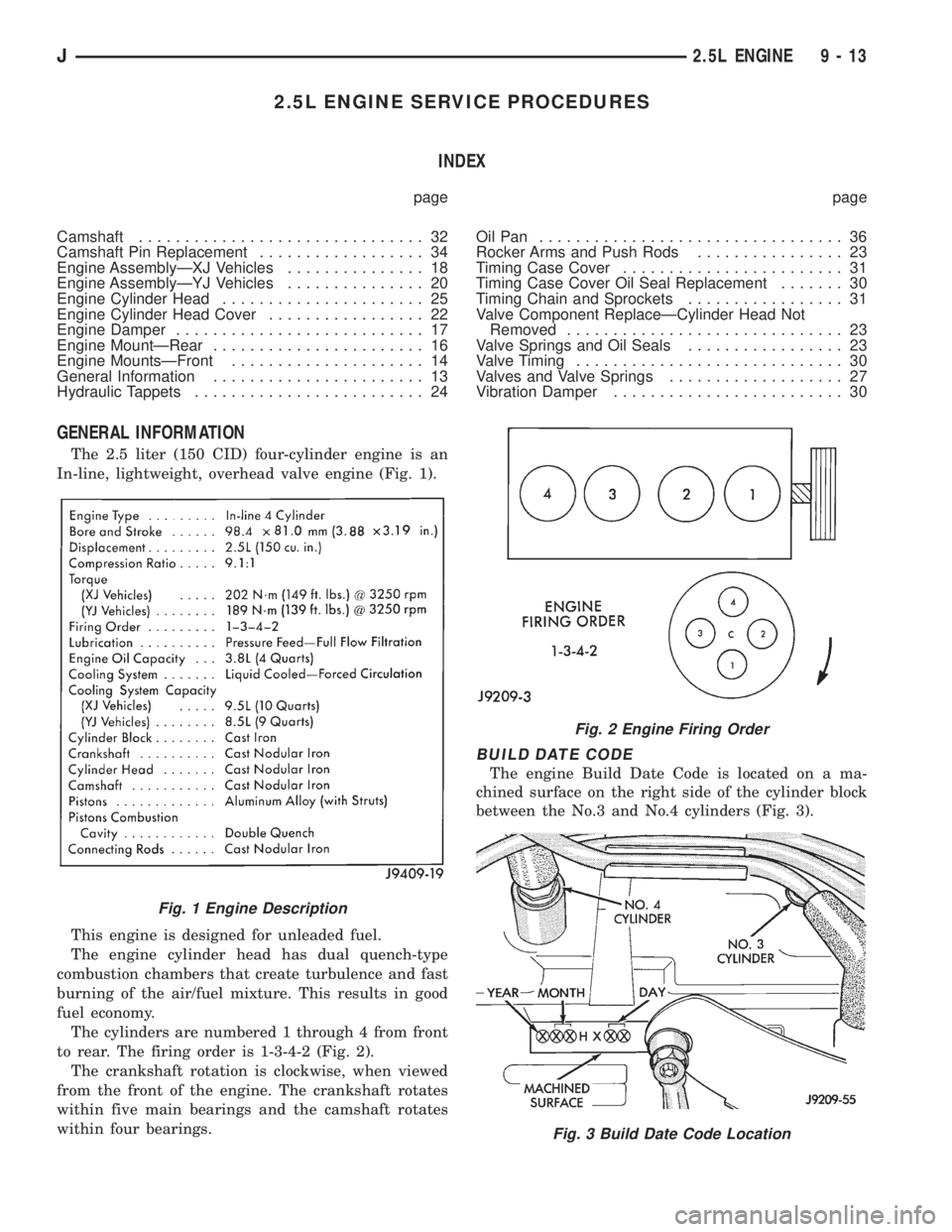

GENERAL INFORMATION

The 2.5 liter (150 CID) four-cylinder engine is an

In-line, lightweight, overhead valve engine (Fig. 1).

This engine is designed for unleaded fuel.

The engine cylinder head has dual quench-type

combustion chambers that create turbulence and fast

burning of the air/fuel mixture. This results in good

fuel economy.

The cylinders are numbered 1 through 4 from front

to rear. The firing order is 1-3-4-2 (Fig. 2).

The crankshaft rotation is clockwise, when viewed

from the front of the engine. The crankshaft rotates

within five main bearings and the camshaft rotates

within four bearings.

BUILD DATE CODE

The engine Build Date Code is located on a ma-

chined surface on the right side of the cylinder block

between the No.3 and No.4 cylinders (Fig. 3).

Fig. 1 Engine Description

Fig. 2 Engine Firing Order

Fig. 3 Build Date Code Location

J2.5L ENGINE 9 - 13

Page 1105 of 2198

The digits of the code identify:

(1) 1st DigitÐThe year (4 = 1994).

(2) 2nd & 3rd DigitsÐThe month (01 - 12).

(3) 4th & 5th DigitsÐThe engine type/fuel system/

compression ratio (HX = A 2.5 liter (150 CID) 9.1:1

compression ratio engine with a multi-point fuel in-

jection system).

(4) 6th & 7th DigitsÐThe day of engine build (01 -

31).

FOR EXAMPLE:Code * 401HX23 * identifies a

2.5 liter (150 CID) engine with a multi-point fuel in-

jection system, 9.1:1 compression ratio and built on

January 23, 1994.

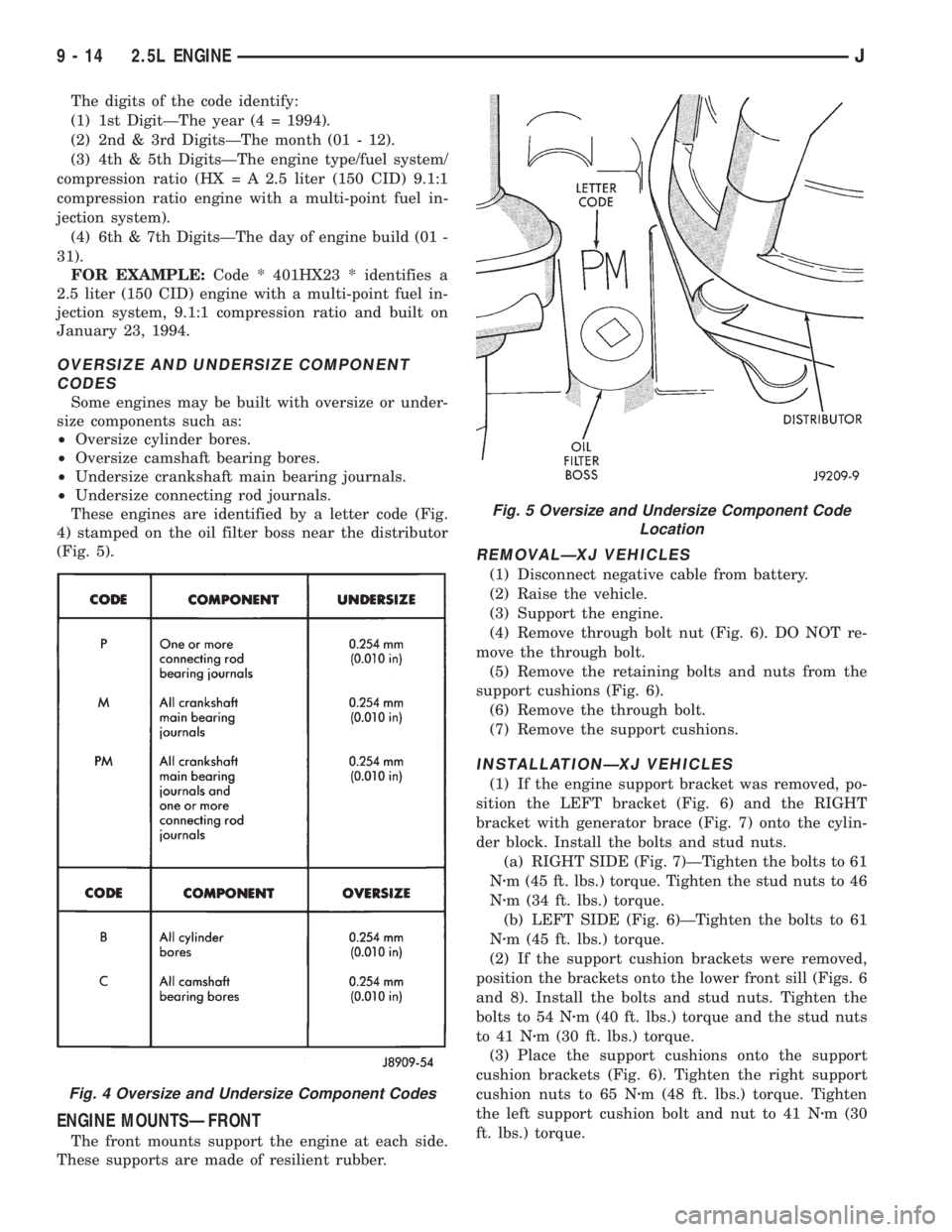

OVERSIZE AND UNDERSIZE COMPONENT

CODES

Some engines may be built with oversize or under-

size components such as:

²Oversize cylinder bores.

²Oversize camshaft bearing bores.

²Undersize crankshaft main bearing journals.

²Undersize connecting rod journals.

These engines are identified by a letter code (Fig.

4) stamped on the oil filter boss near the distributor

(Fig. 5).

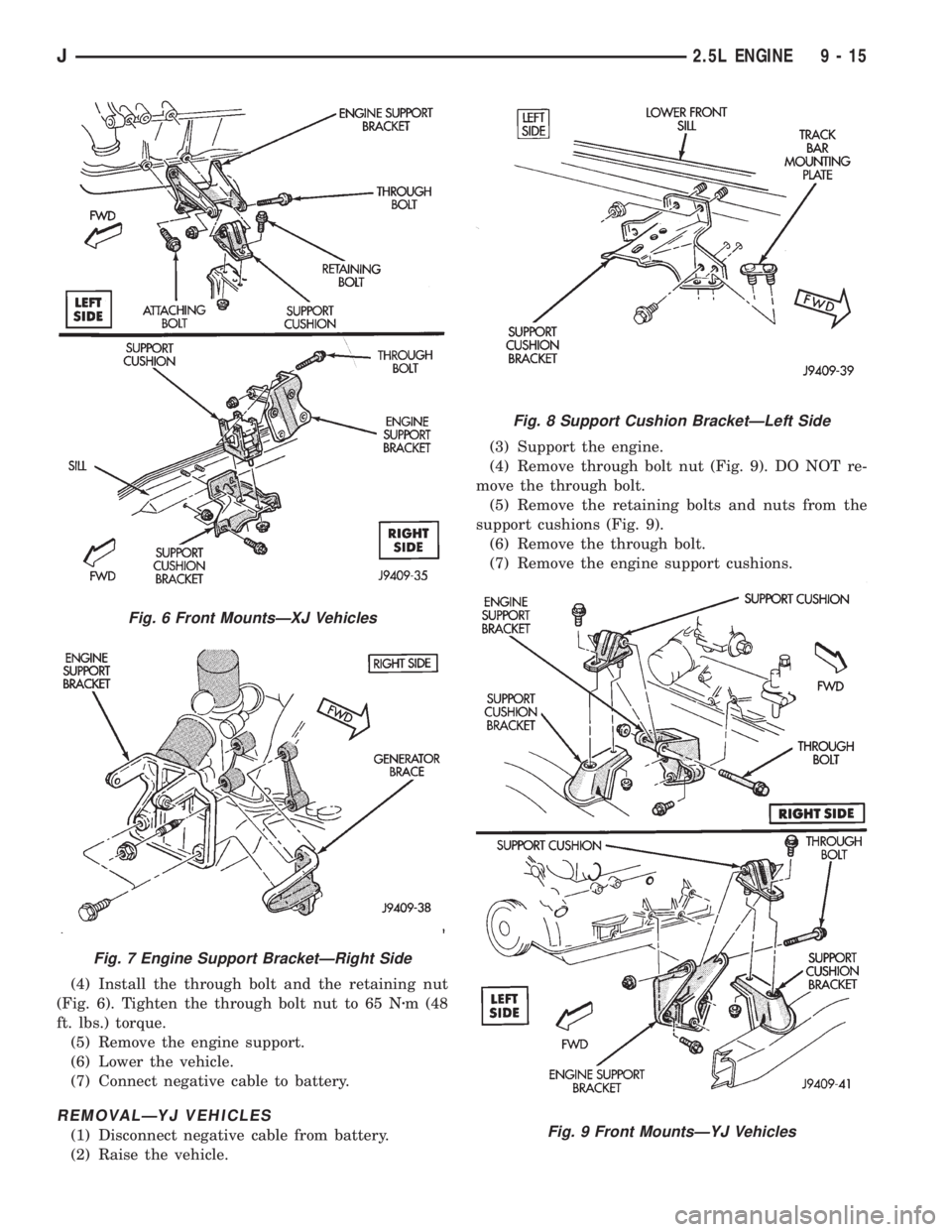

ENGINE MOUNTSÐFRONT

The front mounts support the engine at each side.

These supports are made of resilient rubber.

REMOVALÐXJ VEHICLES

(1) Disconnect negative cable from battery.

(2) Raise the vehicle.

(3) Support the engine.

(4) Remove through bolt nut (Fig. 6). DO NOT re-

move the through bolt.

(5) Remove the retaining bolts and nuts from the

support cushions (Fig. 6).

(6) Remove the through bolt.

(7) Remove the support cushions.

INSTALLATIONÐXJ VEHICLES

(1) If the engine support bracket was removed, po-

sition the LEFT bracket (Fig. 6) and the RIGHT

bracket with generator brace (Fig. 7) onto the cylin-

der block. Install the bolts and stud nuts.

(a) RIGHT SIDE (Fig. 7)ÐTighten the bolts to 61

Nzm (45 ft. lbs.) torque. Tighten the stud nuts to 46

Nzm (34 ft. lbs.) torque.

(b) LEFT SIDE (Fig. 6)ÐTighten the bolts to 61

Nzm (45 ft. lbs.) torque.

(2) If the support cushion brackets were removed,

position the brackets onto the lower front sill (Figs. 6

and 8). Install the bolts and stud nuts. Tighten the

bolts to 54 Nzm (40 ft. lbs.) torque and the stud nuts

to 41 Nzm (30 ft. lbs.) torque.

(3) Place the support cushions onto the support

cushion brackets (Fig. 6). Tighten the right support

cushion nuts to 65 Nzm (48 ft. lbs.) torque. Tighten

the left support cushion bolt and nut to 41 Nzm (30

ft. lbs.) torque.

Fig. 4 Oversize and Undersize Component Codes

Fig. 5 Oversize and Undersize Component Code

Location

9 - 14 2.5L ENGINEJ

Page 1106 of 2198

(4) Install the through bolt and the retaining nut

(Fig. 6). Tighten the through bolt nut to 65 Nzm (48

ft. lbs.) torque.

(5) Remove the engine support.

(6) Lower the vehicle.

(7) Connect negative cable to battery.

REMOVALÐYJ VEHICLES

(1) Disconnect negative cable from battery.

(2) Raise the vehicle.(3) Support the engine.

(4) Remove through bolt nut (Fig. 9). DO NOT re-

move the through bolt.

(5) Remove the retaining bolts and nuts from the

support cushions (Fig. 9).

(6) Remove the through bolt.

(7) Remove the engine support cushions.

Fig. 6 Front MountsÐXJ Vehicles

Fig. 7 Engine Support BracketÐRight Side

Fig. 8 Support Cushion BracketÐLeft Side

Fig. 9 Front MountsÐYJ Vehicles

J2.5L ENGINE 9 - 15

Page 1107 of 2198

INSTALLATIONÐYJ VEHICLES

(1) If the engine support bracket was removed, po-

sition the bracket onto the block and install the at-

taching bolts (Fig. 9). Tighten the bolts to 62 Nzm (46

ft. lbs.) torque.

(2) Place the support cushion on the support cush-

ion bracket (Fig. 9). Install the support cushion re-

taining bolts and nuts. Tighten the bolts and nuts to

52 Nzm (38 ft. lbs.) torque.

(3) Install the through bolt and the retaining nut

(Fig. 9). Tighten the through bolt nut to 69 Nzm (51

ft. lbs.) torque.

(4) Remove the engine support.

(5) Lower the vehicle.

(6) Connect negative cable to battery.

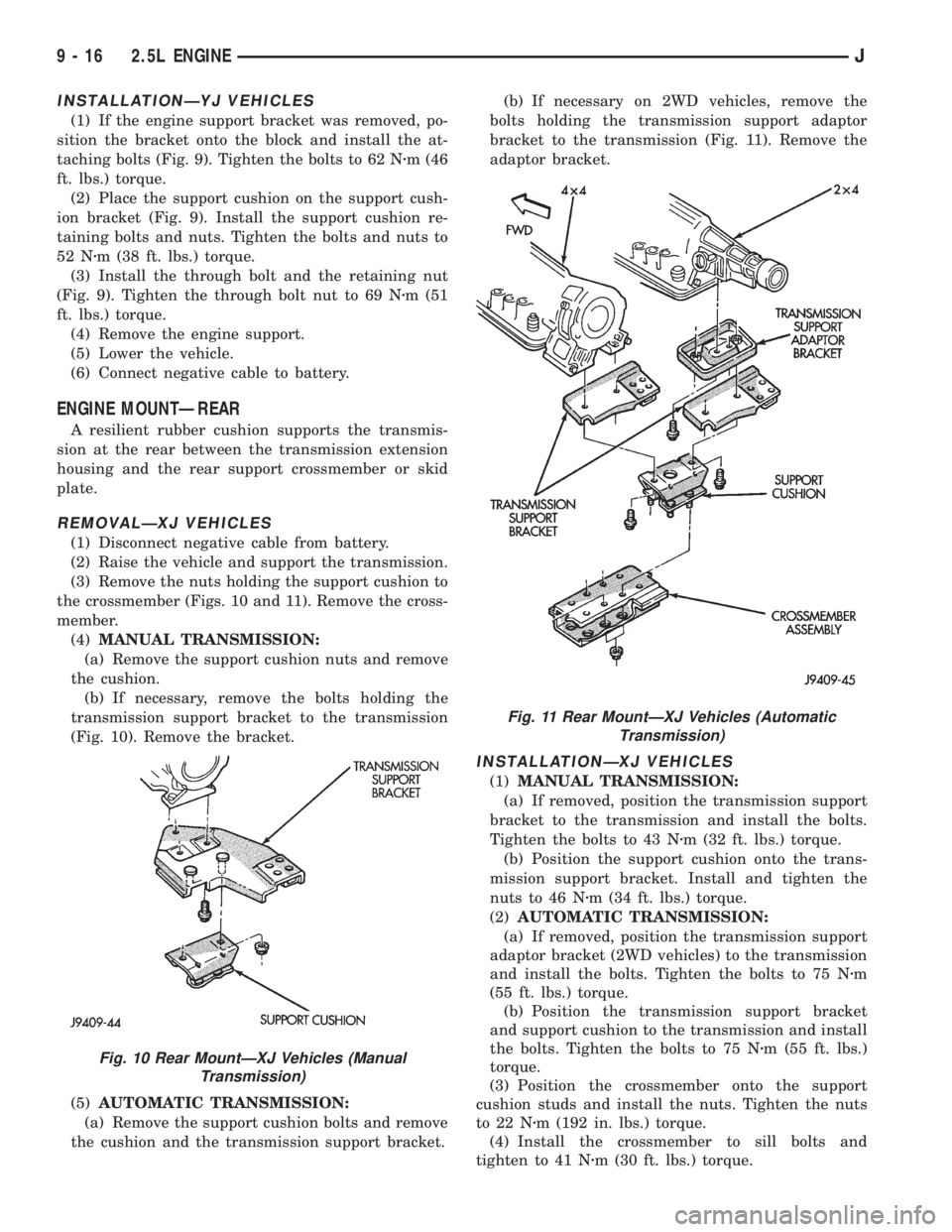

ENGINE MOUNTÐREAR

A resilient rubber cushion supports the transmis-

sion at the rear between the transmission extension

housing and the rear support crossmember or skid

plate.

REMOVALÐXJ VEHICLES

(1) Disconnect negative cable from battery.

(2) Raise the vehicle and support the transmission.

(3) Remove the nuts holding the support cushion to

the crossmember (Figs. 10 and 11). Remove the cross-

member.

(4)MANUAL TRANSMISSION:

(a) Remove the support cushion nuts and remove

the cushion.

(b) If necessary, remove the bolts holding the

transmission support bracket to the transmission

(Fig. 10). Remove the bracket.

(5)AUTOMATIC TRANSMISSION:

(a) Remove the support cushion bolts and remove

the cushion and the transmission support bracket.(b) If necessary on 2WD vehicles, remove the

bolts holding the transmission support adaptor

bracket to the transmission (Fig. 11). Remove the

adaptor bracket.

INSTALLATIONÐXJ VEHICLES

(1)MANUAL TRANSMISSION:

(a) If removed, position the transmission support

bracket to the transmission and install the bolts.

Tighten the bolts to 43 Nzm (32 ft. lbs.) torque.

(b) Position the support cushion onto the trans-

mission support bracket. Install and tighten the

nuts to 46 Nzm (34 ft. lbs.) torque.

(2)AUTOMATIC TRANSMISSION:

(a) If removed, position the transmission support

adaptor bracket (2WD vehicles) to the transmission

and install the bolts. Tighten the bolts to 75 Nzm

(55 ft. lbs.) torque.

(b) Position the transmission support bracket

and support cushion to the transmission and install

the bolts. Tighten the bolts to 75 Nzm (55 ft. lbs.)

torque.

(3) Position the crossmember onto the support

cushion studs and install the nuts. Tighten the nuts

to 22 Nzm (192 in. lbs.) torque.

(4) Install the crossmember to sill bolts and

tighten to 41 Nzm (30 ft. lbs.) torque.

Fig. 10 Rear MountÐXJ Vehicles (Manual

Transmission)

Fig. 11 Rear MountÐXJ Vehicles (Automatic

Transmission)

9 - 16 2.5L ENGINEJ

Page 1108 of 2198

(5) Remove the transmission support.

(6) Lower the vehicle.

(7) Connect negative cable to battery.

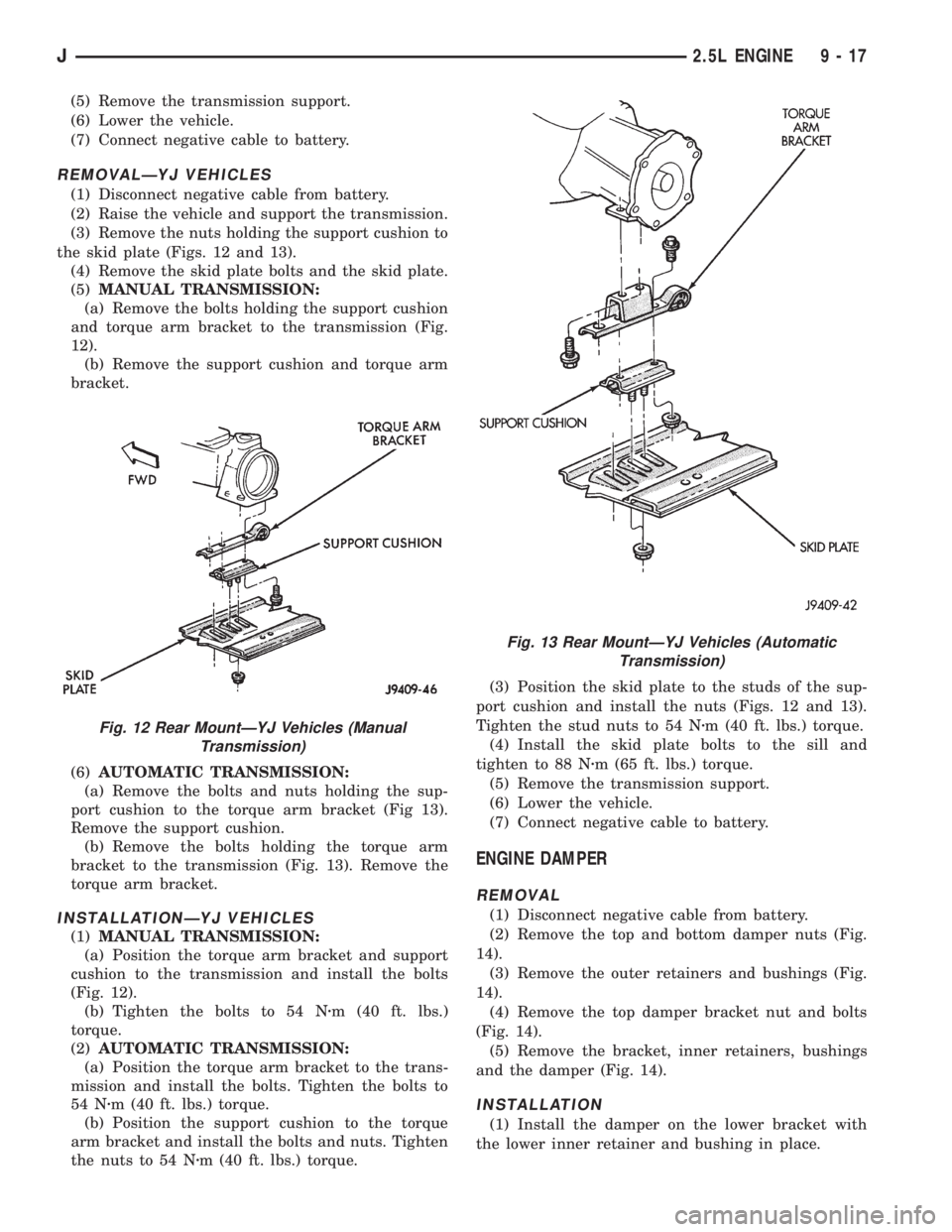

REMOVALÐYJ VEHICLES

(1) Disconnect negative cable from battery.

(2) Raise the vehicle and support the transmission.

(3) Remove the nuts holding the support cushion to

the skid plate (Figs. 12 and 13).

(4) Remove the skid plate bolts and the skid plate.

(5)MANUAL TRANSMISSION:

(a) Remove the bolts holding the support cushion

and torque arm bracket to the transmission (Fig.

12).

(b) Remove the support cushion and torque arm

bracket.

(6)AUTOMATIC TRANSMISSION:

(a) Remove the bolts and nuts holding the sup-

port cushion to the torque arm bracket (Fig 13).

Remove the support cushion.

(b) Remove the bolts holding the torque arm

bracket to the transmission (Fig. 13). Remove the

torque arm bracket.

INSTALLATIONÐYJ VEHICLES

(1)MANUAL TRANSMISSION:

(a) Position the torque arm bracket and support

cushion to the transmission and install the bolts

(Fig. 12).

(b) Tighten the bolts to 54 Nzm (40 ft. lbs.)

torque.

(2)AUTOMATIC TRANSMISSION:

(a) Position the torque arm bracket to the trans-

mission and install the bolts. Tighten the bolts to

54 Nzm (40 ft. lbs.) torque.

(b) Position the support cushion to the torque

arm bracket and install the bolts and nuts. Tighten

the nuts to 54 Nzm (40 ft. lbs.) torque.(3) Position the skid plate to the studs of the sup-

port cushion and install the nuts (Figs. 12 and 13).

Tighten the stud nuts to 54 Nzm (40 ft. lbs.) torque.

(4) Install the skid plate bolts to the sill and

tighten to 88 Nzm (65 ft. lbs.) torque.

(5) Remove the transmission support.

(6) Lower the vehicle.

(7) Connect negative cable to battery.

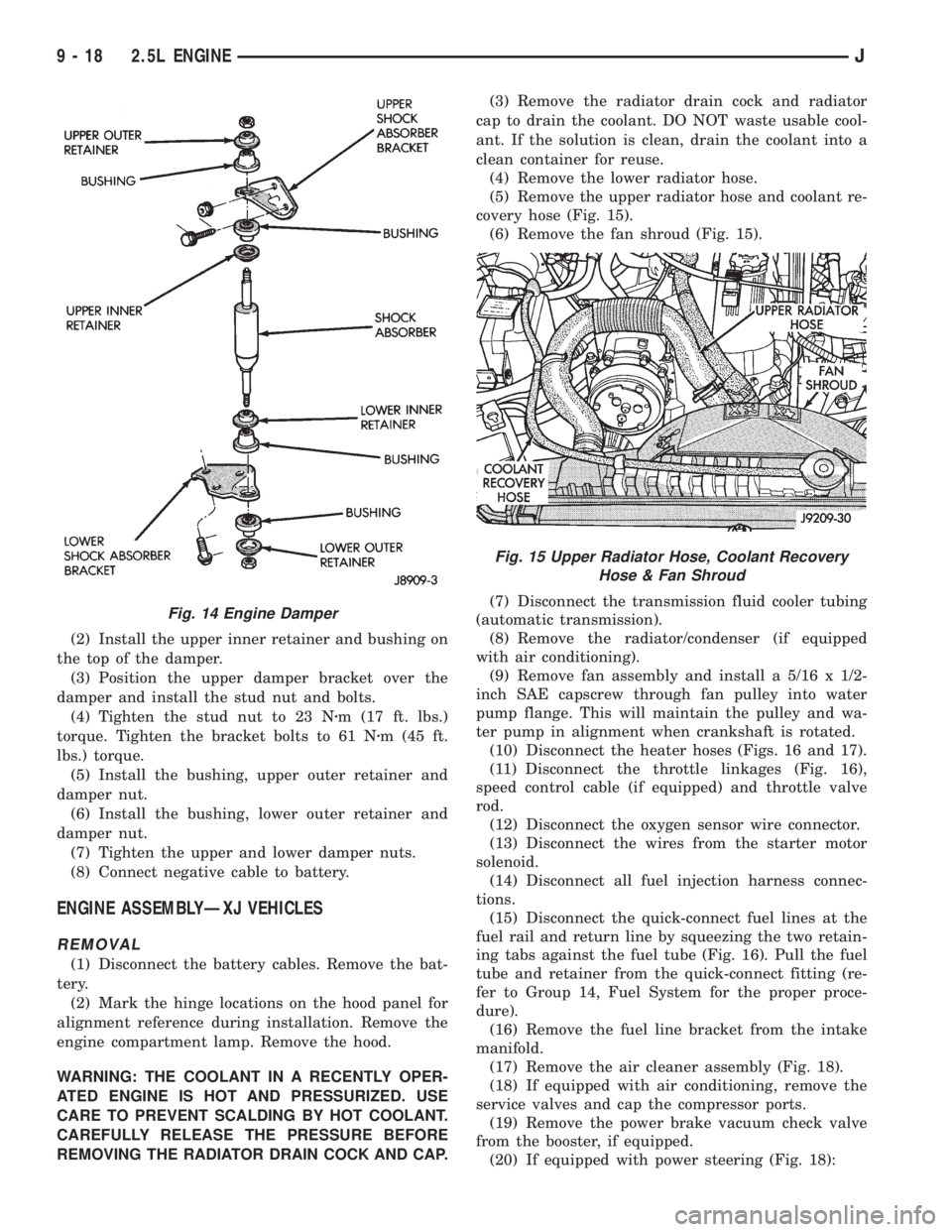

ENGINE DAMPER

REMOVAL

(1) Disconnect negative cable from battery.

(2) Remove the top and bottom damper nuts (Fig.

14).

(3) Remove the outer retainers and bushings (Fig.

14).

(4) Remove the top damper bracket nut and bolts

(Fig. 14).

(5) Remove the bracket, inner retainers, bushings

and the damper (Fig. 14).

INSTALLATION

(1) Install the damper on the lower bracket with

the lower inner retainer and bushing in place.

Fig. 12 Rear MountÐYJ Vehicles (Manual

Transmission)

Fig. 13 Rear MountÐYJ Vehicles (Automatic

Transmission)

J2.5L ENGINE 9 - 17

Page 1109 of 2198

(2) Install the upper inner retainer and bushing on

the top of the damper.

(3) Position the upper damper bracket over the

damper and install the stud nut and bolts.

(4) Tighten the stud nut to 23 Nzm (17 ft. lbs.)

torque. Tighten the bracket bolts to 61 Nzm (45 ft.

lbs.) torque.

(5) Install the bushing, upper outer retainer and

damper nut.

(6) Install the bushing, lower outer retainer and

damper nut.

(7) Tighten the upper and lower damper nuts.

(8) Connect negative cable to battery.

ENGINE ASSEMBLYÐXJ VEHICLES

REMOVAL

(1) Disconnect the battery cables. Remove the bat-

tery.

(2) Mark the hinge locations on the hood panel for

alignment reference during installation. Remove the

engine compartment lamp. Remove the hood.

WARNING: THE COOLANT IN A RECENTLY OPER-

ATED ENGINE IS HOT AND PRESSURIZED. USE

CARE TO PREVENT SCALDING BY HOT COOLANT.

CAREFULLY RELEASE THE PRESSURE BEFORE

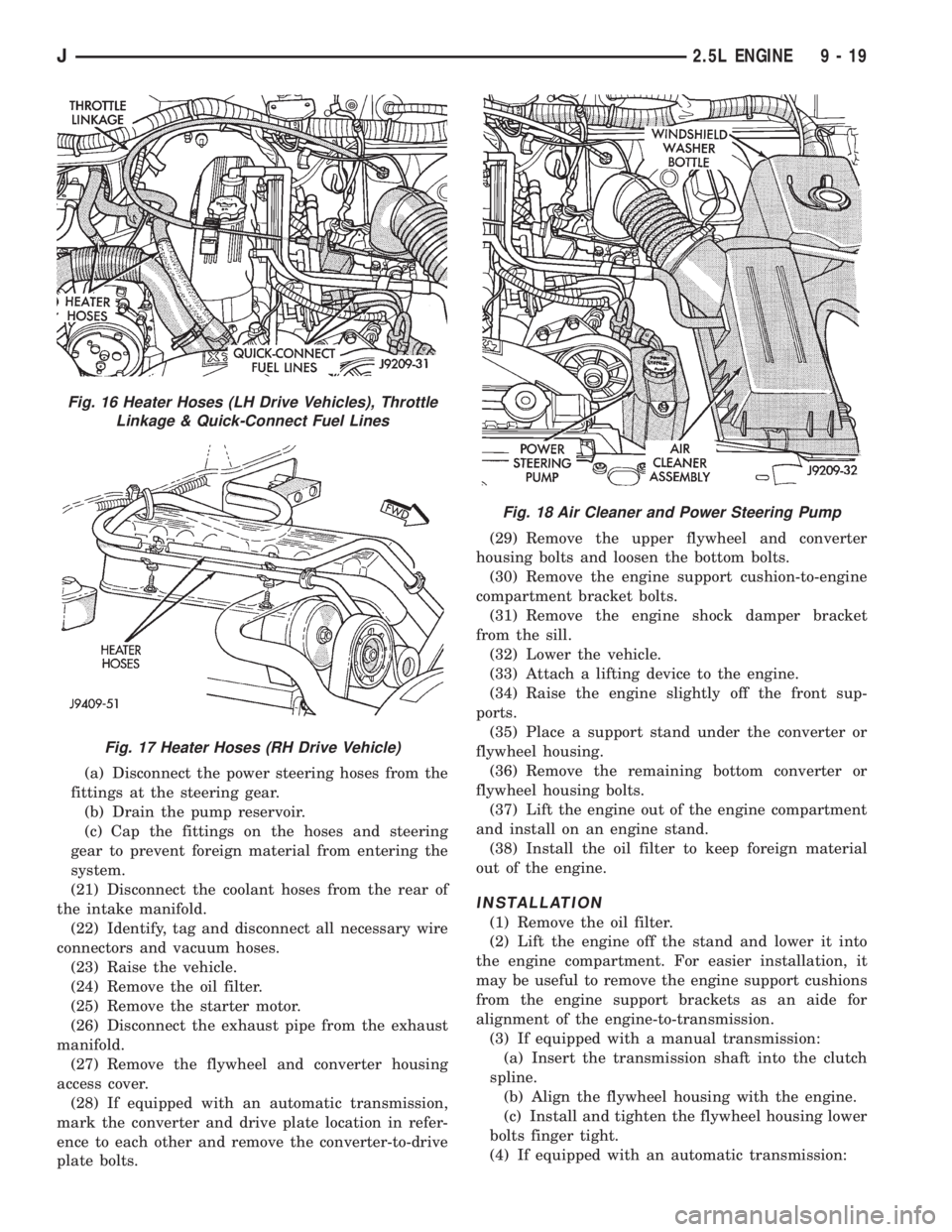

REMOVING THE RADIATOR DRAIN COCK AND CAP.(3) Remove the radiator drain cock and radiator

cap to drain the coolant. DO NOT waste usable cool-

ant. If the solution is clean, drain the coolant into a

clean container for reuse.

(4) Remove the lower radiator hose.

(5) Remove the upper radiator hose and coolant re-

covery hose (Fig. 15).

(6) Remove the fan shroud (Fig. 15).

(7) Disconnect the transmission fluid cooler tubing

(automatic transmission).

(8) Remove the radiator/condenser (if equipped

with air conditioning).

(9) Remove fan assembly and install a 5/16 x 1/2-

inch SAE capscrew through fan pulley into water

pump flange. This will maintain the pulley and wa-

ter pump in alignment when crankshaft is rotated.

(10) Disconnect the heater hoses (Figs. 16 and 17).

(11) Disconnect the throttle linkages (Fig. 16),

speed control cable (if equipped) and throttle valve

rod.

(12) Disconnect the oxygen sensor wire connector.

(13) Disconnect the wires from the starter motor

solenoid.

(14) Disconnect all fuel injection harness connec-

tions.

(15) Disconnect the quick-connect fuel lines at the

fuel rail and return line by squeezing the two retain-

ing tabs against the fuel tube (Fig. 16). Pull the fuel

tube and retainer from the quick-connect fitting (re-

fer to Group 14, Fuel System for the proper proce-

dure).

(16) Remove the fuel line bracket from the intake

manifold.

(17) Remove the air cleaner assembly (Fig. 18).

(18) If equipped with air conditioning, remove the

service valves and cap the compressor ports.

(19) Remove the power brake vacuum check valve

from the booster, if equipped.

(20) If equipped with power steering (Fig. 18):

Fig. 14 Engine Damper

Fig. 15 Upper Radiator Hose, Coolant Recovery

Hose & Fan Shroud

9 - 18 2.5L ENGINEJ

Page 1110 of 2198

(a) Disconnect the power steering hoses from the

fittings at the steering gear.

(b) Drain the pump reservoir.

(c) Cap the fittings on the hoses and steering

gear to prevent foreign material from entering the

system.

(21) Disconnect the coolant hoses from the rear of

the intake manifold.

(22) Identify, tag and disconnect all necessary wire

connectors and vacuum hoses.

(23) Raise the vehicle.

(24) Remove the oil filter.

(25) Remove the starter motor.

(26) Disconnect the exhaust pipe from the exhaust

manifold.

(27) Remove the flywheel and converter housing

access cover.

(28) If equipped with an automatic transmission,

mark the converter and drive plate location in refer-

ence to each other and remove the converter-to-drive

plate bolts.(29) Remove the upper flywheel and converter

housing bolts and loosen the bottom bolts.

(30) Remove the engine support cushion-to-engine

compartment bracket bolts.

(31) Remove the engine shock damper bracket

from the sill.

(32) Lower the vehicle.

(33) Attach a lifting device to the engine.

(34) Raise the engine slightly off the front sup-

ports.

(35) Place a support stand under the converter or

flywheel housing.

(36) Remove the remaining bottom converter or

flywheel housing bolts.

(37) Lift the engine out of the engine compartment

and install on an engine stand.

(38) Install the oil filter to keep foreign material

out of the engine.

INSTALLATION

(1) Remove the oil filter.

(2) Lift the engine off the stand and lower it into

the engine compartment. For easier installation, it

may be useful to remove the engine support cushions

from the engine support brackets as an aide for

alignment of the engine-to-transmission.

(3) If equipped with a manual transmission:

(a) Insert the transmission shaft into the clutch

spline.

(b) Align the flywheel housing with the engine.

(c) Install and tighten the flywheel housing lower

bolts finger tight.

(4) If equipped with an automatic transmission:

Fig. 16 Heater Hoses (LH Drive Vehicles), Throttle

Linkage & Quick-Connect Fuel Lines

Fig. 17 Heater Hoses (RH Drive Vehicle)

Fig. 18 Air Cleaner and Power Steering Pump

J2.5L ENGINE 9 - 19