JEEP CHEROKEE 1995 Service Repair Manual

Manufacturer: JEEP, Model Year: 1995, Model line: CHEROKEE, Model: JEEP CHEROKEE 1995Pages: 2198, PDF Size: 82.83 MB

Page 1211 of 2198

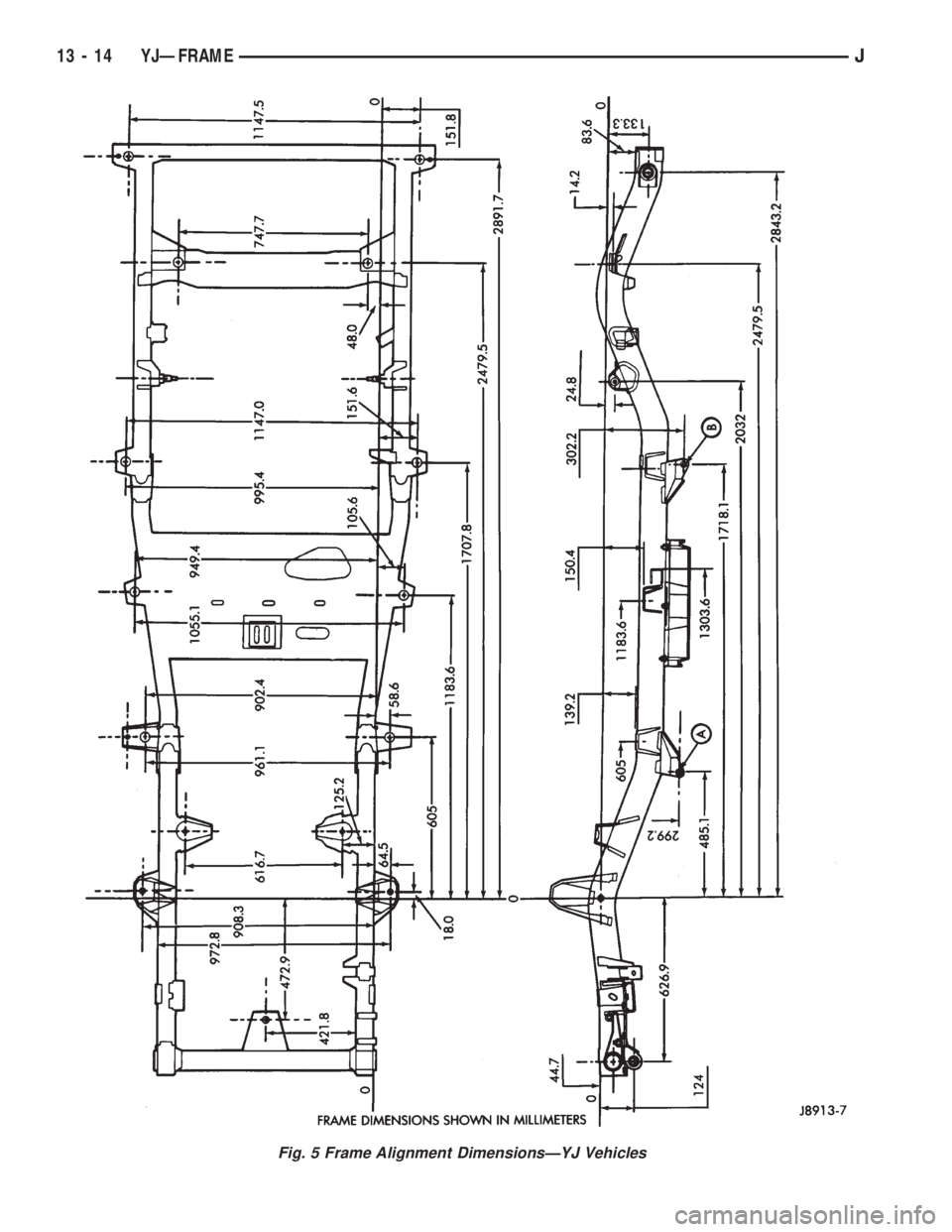

Fig. 5 Frame Alignment DimensionsÐYJ Vehicles

13 - 14 YJÐFRAMEJ

Page 1212 of 2198

INSTALLATION

(1) Position the generator splash shield at the fan

shroud and frame rails.

(2) Force the serrated retainers into the fan shroud

holes.

(3) Force the serrated retainers into the frame rail

holes at each side of the vehicle.

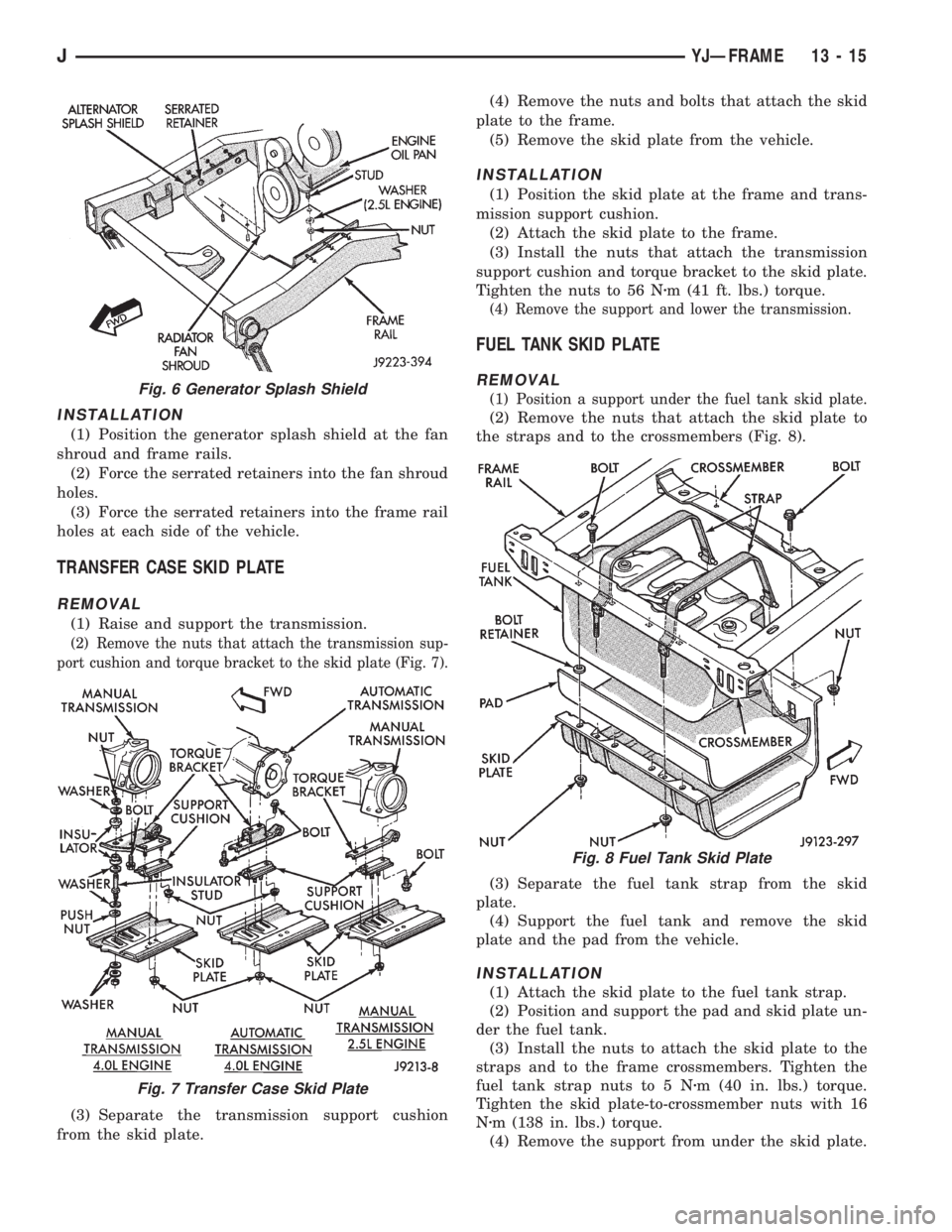

TRANSFER CASE SKID PLATE

REMOVAL

(1) Raise and support the transmission.

(2) Remove the nuts that attach the transmission sup-

port cushion and torque bracket to the skid plate (Fig. 7).

(3) Separate the transmission support cushion

from the skid plate.(4) Remove the nuts and bolts that attach the skid

plate to the frame.

(5) Remove the skid plate from the vehicle.

INSTALLATION

(1) Position the skid plate at the frame and trans-

mission support cushion.

(2) Attach the skid plate to the frame.

(3) Install the nuts that attach the transmission

support cushion and torque bracket to the skid plate.

Tighten the nuts to 56 Nzm (41 ft. lbs.) torque.

(4) Remove the support and lower the transmission.

FUEL TANK SKID PLATE

REMOVAL

(1) Position a support under the fuel tank skid plate.

(2) Remove the nuts that attach the skid plate to

the straps and to the crossmembers (Fig. 8).

(3) Separate the fuel tank strap from the skid

plate.

(4) Support the fuel tank and remove the skid

plate and the pad from the vehicle.

INSTALLATION

(1) Attach the skid plate to the fuel tank strap.

(2) Position and support the pad and skid plate un-

der the fuel tank.

(3) Install the nuts to attach the skid plate to the

straps and to the frame crossmembers. Tighten the

fuel tank strap nuts to 5 Nzm (40 in. lbs.) torque.

Tighten the skid plate-to-crossmember nuts with 16

Nzm (138 in. lbs.) torque.

(4) Remove the support from under the skid plate.

Fig. 6 Generator Splash Shield

Fig. 7 Transfer Case Skid Plate

Fig. 8 Fuel Tank Skid Plate

JYJÐFRAME 13 - 15

Page 1213 of 2198

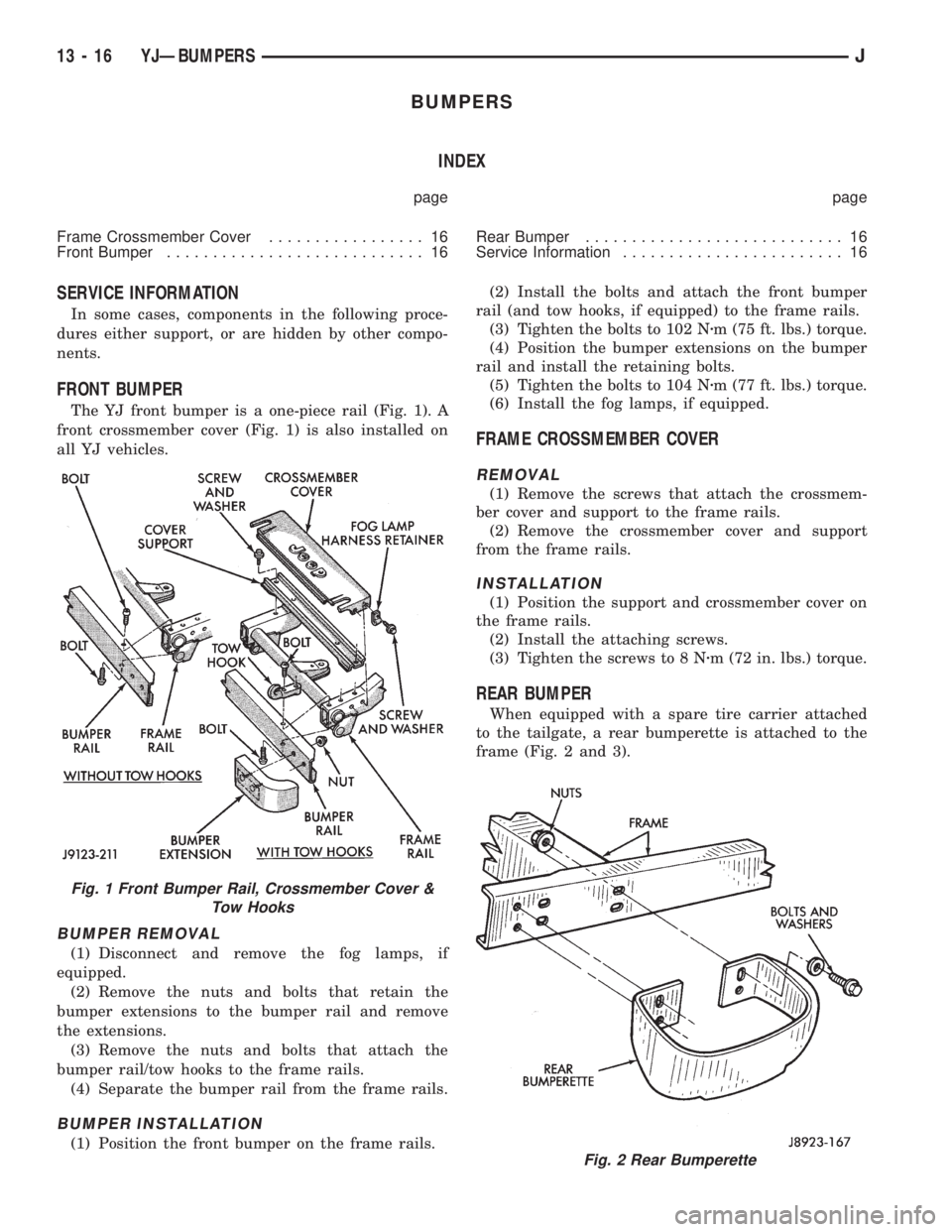

BUMPERS

INDEX

page page

Frame Crossmember Cover................. 16

Front Bumper............................ 16Rear Bumper............................ 16

Service Information........................ 16

SERVICE INFORMATION

In some cases, components in the following proce-

dures either support, or are hidden by other compo-

nents.

FRONT BUMPER

The YJ front bumper is a one-piece rail (Fig. 1). A

front crossmember cover (Fig. 1) is also installed on

all YJ vehicles.

BUMPER REMOVAL

(1) Disconnect and remove the fog lamps, if

equipped.

(2) Remove the nuts and bolts that retain the

bumper extensions to the bumper rail and remove

the extensions.

(3) Remove the nuts and bolts that attach the

bumper rail/tow hooks to the frame rails.

(4) Separate the bumper rail from the frame rails.

BUMPER INSTALLATION

(1) Position the front bumper on the frame rails.(2) Install the bolts and attach the front bumper

rail (and tow hooks, if equipped) to the frame rails.

(3) Tighten the bolts to 102 Nzm (75 ft. lbs.) torque.

(4) Position the bumper extensions on the bumper

rail and install the retaining bolts.

(5) Tighten the bolts to 104 Nzm (77 ft. lbs.) torque.

(6) Install the fog lamps, if equipped.

FRAME CROSSMEMBER COVER

REMOVAL

(1) Remove the screws that attach the crossmem-

ber cover and support to the frame rails.

(2) Remove the crossmember cover and support

from the frame rails.

INSTALLATION

(1) Position the support and crossmember cover on

the frame rails.

(2) Install the attaching screws.

(3) Tighten the screws to 8 Nzm (72 in. lbs.) torque.

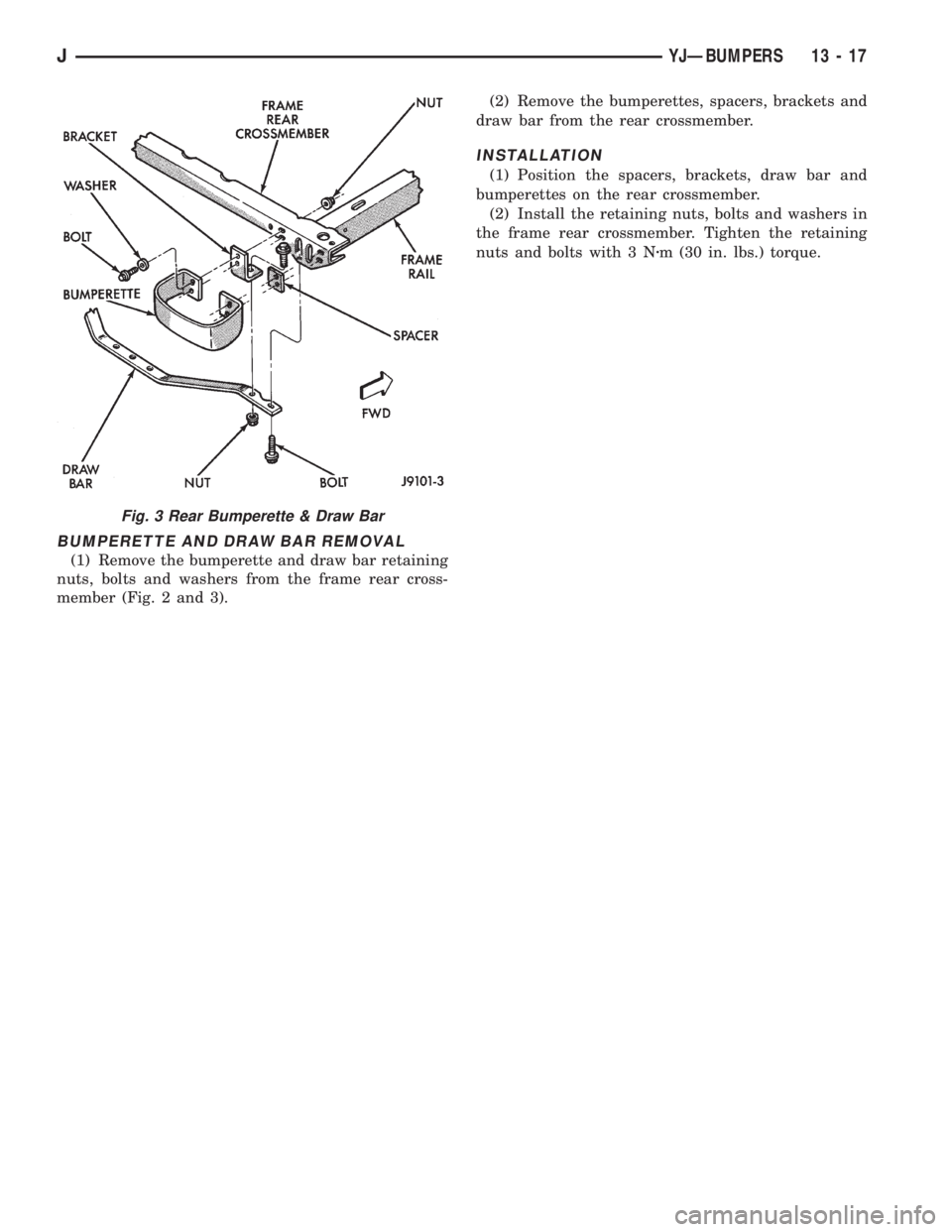

REAR BUMPER

When equipped with a spare tire carrier attached

to the tailgate, a rear bumperette is attached to the

frame (Fig. 2 and 3).

Fig. 2 Rear Bumperette

Fig. 1 Front Bumper Rail, Crossmember Cover &

Tow Hooks

13 - 16 YJÐBUMPERSJ

Page 1214 of 2198

BUMPERETTE AND DRAW BAR REMOVAL

(1) Remove the bumperette and draw bar retaining

nuts, bolts and washers from the frame rear cross-

member (Fig. 2 and 3).(2) Remove the bumperettes, spacers, brackets and

draw bar from the rear crossmember.

INSTALLATION

(1) Position the spacers, brackets, draw bar and

bumperettes on the rear crossmember.

(2) Install the retaining nuts, bolts and washers in

the frame rear crossmember. Tighten the retaining

nuts and bolts with 3 Nzm (30 in. lbs.) torque.

Fig. 3 Rear Bumperette & Draw Bar

JYJÐBUMPERS 13 - 17

Page 1215 of 2198

Page 1216 of 2198

FUEL SYSTEM

CONTENTS

page page

ACCELERATOR PEDAL AND THROTTLE CABLE.17

FUEL DELIVERY SYSTEM.................. 3

FUEL TANKS........................... 13

GENERAL INFORMATION.................. 1

MULTI-PORT FUEL INJECTION (MFI)Ð

COMPONENT DESCRIPTION/SYSTEMOPERATION.......................... 19

MULTI-PORT FUEL INJECTION (MFI)Ð

COMPONENT REMOVAL/INSTALLATION.... 58

MULTI-PORT FUEL INJECTION (MFI)Ð

GENERAL DIAGNOSIS.................. 35

SPECIFICATIONS........................ 67

GENERAL INFORMATION

Throughout this group, references are made to par-

ticular vehicle models by alphabetical designation

(XJ or YJ) or by the particular vehicle nameplate. A

chart showing a breakdown of the alphabetical desig-

nations is included in the Introduction section at the

beginning of this manual.

TheFuel Systemconsists of: the fuel tank, an

electric (fuel tank mounted) fuel pump and a fuel fil-

ter. It also consists of fuel tubes/lines/hoses, vacuum

hoses, throttle body and fuel injectors.

TheFuel Delivery Systemconsists of: the electric

fuel pump, fuel filter, fuel tubes/lines/hoses, fuel rail,

fuel injectors and fuel pressure regulator.

AFuel Return Systemis used on all vehicles.

The system consists of: the fuel tubes/lines/hoses that

route fuel back to the fuel tank.

TheFuel Tank Assemblyconsists of: the fuel

tank, filler tube, fuel fill and vent hoses, fuel gauge

sending unit/electric fuel pump module, a pressure

relief/rollover valve and a pressure-vacuum filler cap.

Also to be considered part of the fuel system is the

Evaporation Control System.This is designed to

reduce the emission of fuel vapors into the atmo-

sphere. The description and function of the Evapora-

tive Control System is found in Group 25, Emission

Control Systems.

FUEL USAGE STATEMENT

Your vehicle was designed to meet all emission reg-

ulations and provide excellent fuel economy using

high quality unleaded gasoline. Only use unleaded

gasolines having a minimum posted octane of 87.

If your vehicle develops occasional light spark

knock (ping) at low engine speeds, this is not harm-

ful. However,continued heavy knock at high

speeds can cause damage and should be re-

ported to your dealer immediately.Engine dam-

age as a result of heavy knock operation may not becovered by the new vehicle warranty.

In addition to using unleaded gasoline with the

proper octane rating,those that contain deter-

gents, corrosion and stability additives are rec-

ommended.Using gasolines that have these

additives will help improve fuel economy, reduce

emissions and maintain vehicle performance.

Poor quality gasolinecan cause problems such

as hard starting, stalling and stumble. If you experi-

ence these problems, use another brand of gasoline

before considering service for the vehicle.

GASOLINE/OXYGENATE BLENDS

Some fuel suppliers blend unleaded gasoline with

materials that contain oxygen such as alcohol, MTBE

and ETBE. The type and amount of oxygenate used

in the blend is important. The following are generally

used in gasoline blends:

ETHANOL

Ethanol (Ethyl or Grain Alcohol) properly blended,

is used as a mixture of 10 percent ethanol and 90

percent gasoline.Gasoline with ethanol may be

used in your vehicle.

METHANOL

CAUTION: DO NOT USE GASOLINES CONTAINING

METHANOL.Use of methanol/gasoline blends may re-

sult in starting and driveability problems. In addition,

damage may be done to critical fuel system compo-

nents.

Methanol (Methyl or Wood Alcohol) is used in a va-

riety of concentrations blended with unleaded gaso-

JFUEL SYSTEM 14 - 1

Page 1217 of 2198

line. You may encounter fuels containing 3 percent or

more methanol along with other alcohols called cosol-

vents.

Problems that are the result of using methanol/gas-

oline blends are not the responsibility of Chrysler

Corporation. They may not be covered by the vehicle

warranty.

MTBE/ETBE

Gasoline and MTBE (Methyl Tertiary Butyl Ether)

blends are a mixture of unleaded gasoline and up to

15 percent MTBE. Gasoline and ETBE (Ethyl Ter-

tiary Butyl Ether) are blends of gasoline and up to

17 percent ETBE. Gasoline blended with MTBE or

ETBE may be used in your vehicle.CLEAN AIR GASOLINE

Many gasolines are now being blended that con-

tribute to cleaner air, especially in those areas of the

country where air pollution levels are high. These

new blends provide a cleaner burning fuel and some

are referred to asReformulated Gasoline.

In areas of the country where carbon monoxide lev-

els are high, gasolines are being treated with oxygen-

ated materials such as MTBE, ETBE and ethanol.

Chrysler Corporation supports these efforts toward

cleaner air and recommends that you use these gaso-

lines as they become available.

14 - 2 FUEL SYSTEMJ

Page 1218 of 2198

FUEL DELIVERY SYSTEM

INDEX

page page

Fuel Filter................................ 9

Fuel Pressure Leak Down Test................ 8

Fuel Pressure Release Procedure.............. 6

Fuel Pump Capacity Test.................... 7

Fuel Pump Electrical Control.................. 5Fuel Pump Module......................... 3

Fuel System Pressure Test................... 6

Fuel Tubes/Lines/Hoses and Clamps............ 9

Quick-Connect Fittings..................... 10

FUEL PUMP MODULE

The fuel pump module is installed in the top of the

fuel tank. The fuel pump module contains the follow-

ing components:

²Electric fuel pump

²Fuel pump reservoir

²In-tank fuel filter

²Fuel gauge sending unit

²Fuel supply and return tube connections

The fuel pump used on all vehicles is a turbine

type pump. It is driven by a permanent magnet 12

volt electric motor that is immersed in the fuel tank.

The electrical pump is integral with the fuel sender

unit. The pump/sender assembly is installed inside

the fuel tank.

The fuel pump has a check valve at the outlet end

that consists of a ball held against a seat by force ap-

plied from a spring. When the pump is operating,

fuel pressure overcomes spring pressure and forces

the ball off its seat, allowing fuel to flow. When the

pump is not operating, spring pressure forces the ball

back against the seat preventing fuel backflow

through the pump.

Fuel system pressure is maintained at approxi-

mately 214 kPa (31 psi). This is when the pump is

operating and vacuum is supplied to the fuel pres-

sure regulator. If vacuum is not supplied to the pres-

sure regulator, fuel pressure will be approximately

55-69 kPa (8-10 psi) higher. This may be due to a

broken or clogged vacuum line. When the fuel pump

is not operating, fuel system pressure of 131-269 kPa

(19-39 psi) is maintained for approximately 2 to 6

hours. This is done by the fuel pump outlet check

valve and the vacuum assisted fuel pressure regula-

tor.

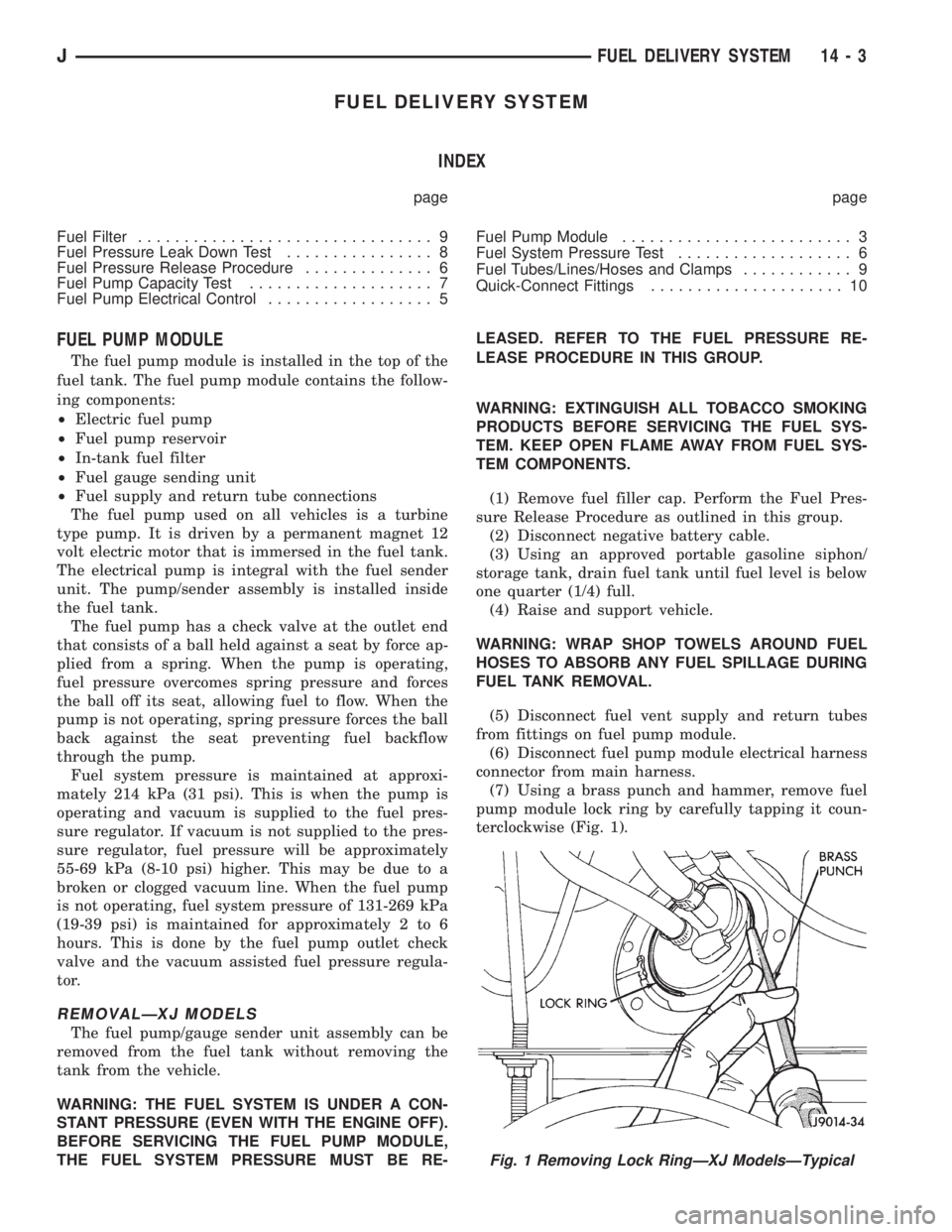

REMOVALÐXJ MODELS

The fuel pump/gauge sender unit assembly can be

removed from the fuel tank without removing the

tank from the vehicle.

WARNING: THE FUEL SYSTEM IS UNDER A CON-

STANT PRESSURE (EVEN WITH THE ENGINE OFF).

BEFORE SERVICING THE FUEL PUMP MODULE,

THE FUEL SYSTEM PRESSURE MUST BE RE-LEASED. REFER TO THE FUEL PRESSURE RE-

LEASE PROCEDURE IN THIS GROUP.

WARNING: EXTINGUISH ALL TOBACCO SMOKING

PRODUCTS BEFORE SERVICING THE FUEL SYS-

TEM. KEEP OPEN FLAME AWAY FROM FUEL SYS-

TEM COMPONENTS.

(1) Remove fuel filler cap. Perform the Fuel Pres-

sure Release Procedure as outlined in this group.

(2) Disconnect negative battery cable.

(3) Using an approved portable gasoline siphon/

storage tank, drain fuel tank until fuel level is below

one quarter (1/4) full.

(4) Raise and support vehicle.

WARNING: WRAP SHOP TOWELS AROUND FUEL

HOSES TO ABSORB ANY FUEL SPILLAGE DURING

FUEL TANK REMOVAL.

(5) Disconnect fuel vent supply and return tubes

from fittings on fuel pump module.

(6) Disconnect fuel pump module electrical harness

connector from main harness.

(7) Using a brass punch and hammer, remove fuel

pump module lock ring by carefully tapping it coun-

terclockwise (Fig. 1).

Fig. 1 Removing Lock RingÐXJ ModelsÐTypical

JFUEL DELIVERY SYSTEM 14 - 3

Page 1219 of 2198

(8) Remove fuel pump module and O-ring seal.

Discard old O-ring and fuel pump module inlet filter.

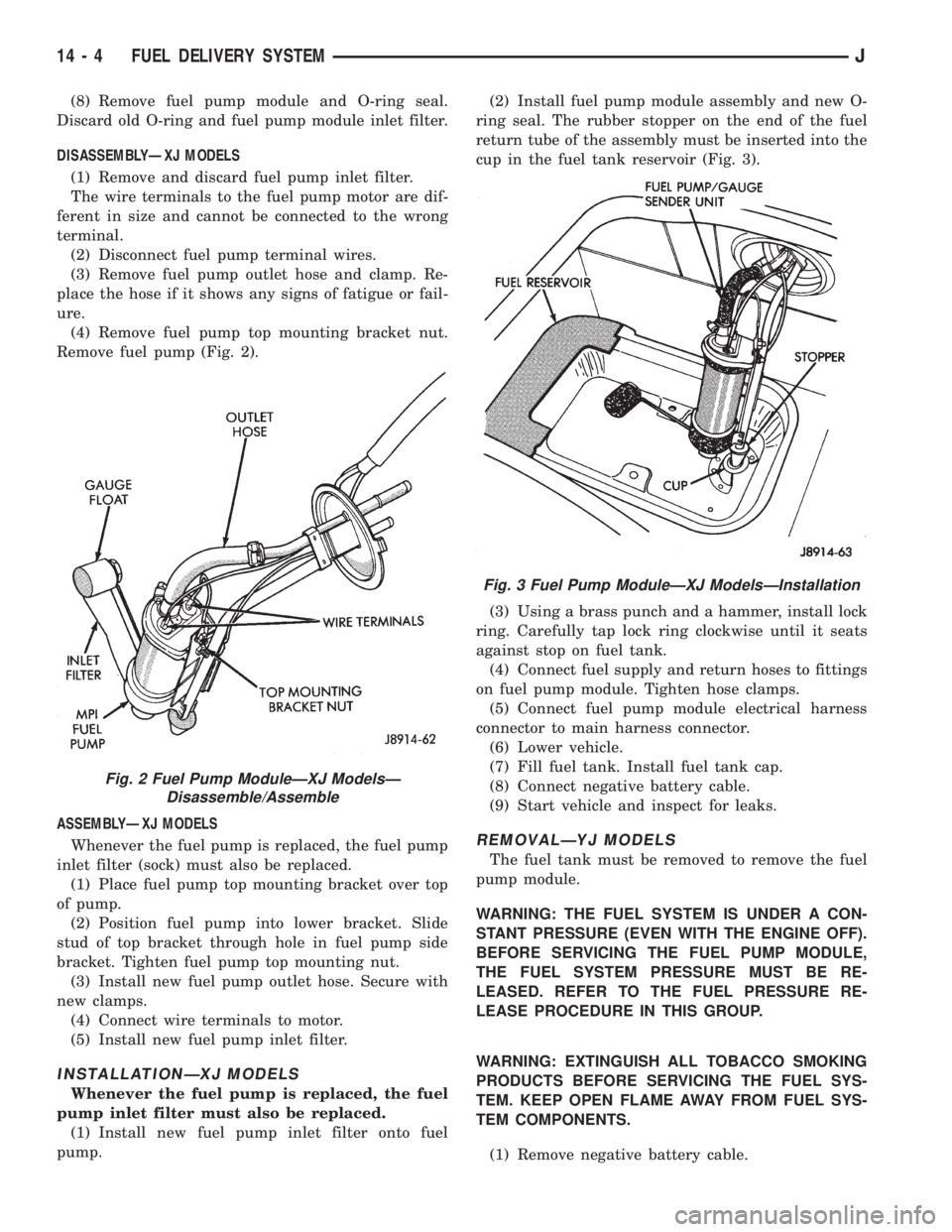

DISASSEMBLYÐXJ MODELS

(1) Remove and discard fuel pump inlet filter.

The wire terminals to the fuel pump motor are dif-

ferent in size and cannot be connected to the wrong

terminal.

(2) Disconnect fuel pump terminal wires.

(3) Remove fuel pump outlet hose and clamp. Re-

place the hose if it shows any signs of fatigue or fail-

ure.

(4) Remove fuel pump top mounting bracket nut.

Remove fuel pump (Fig. 2).

ASSEMBLYÐXJ MODELS

Whenever the fuel pump is replaced, the fuel pump

inlet filter (sock) must also be replaced.

(1) Place fuel pump top mounting bracket over top

of pump.

(2) Position fuel pump into lower bracket. Slide

stud of top bracket through hole in fuel pump side

bracket. Tighten fuel pump top mounting nut.

(3) Install new fuel pump outlet hose. Secure with

new clamps.

(4) Connect wire terminals to motor.

(5) Install new fuel pump inlet filter.

INSTALLATIONÐXJ MODELS

Whenever the fuel pump is replaced, the fuel

pump inlet filter must also be replaced.

(1) Install new fuel pump inlet filter onto fuel

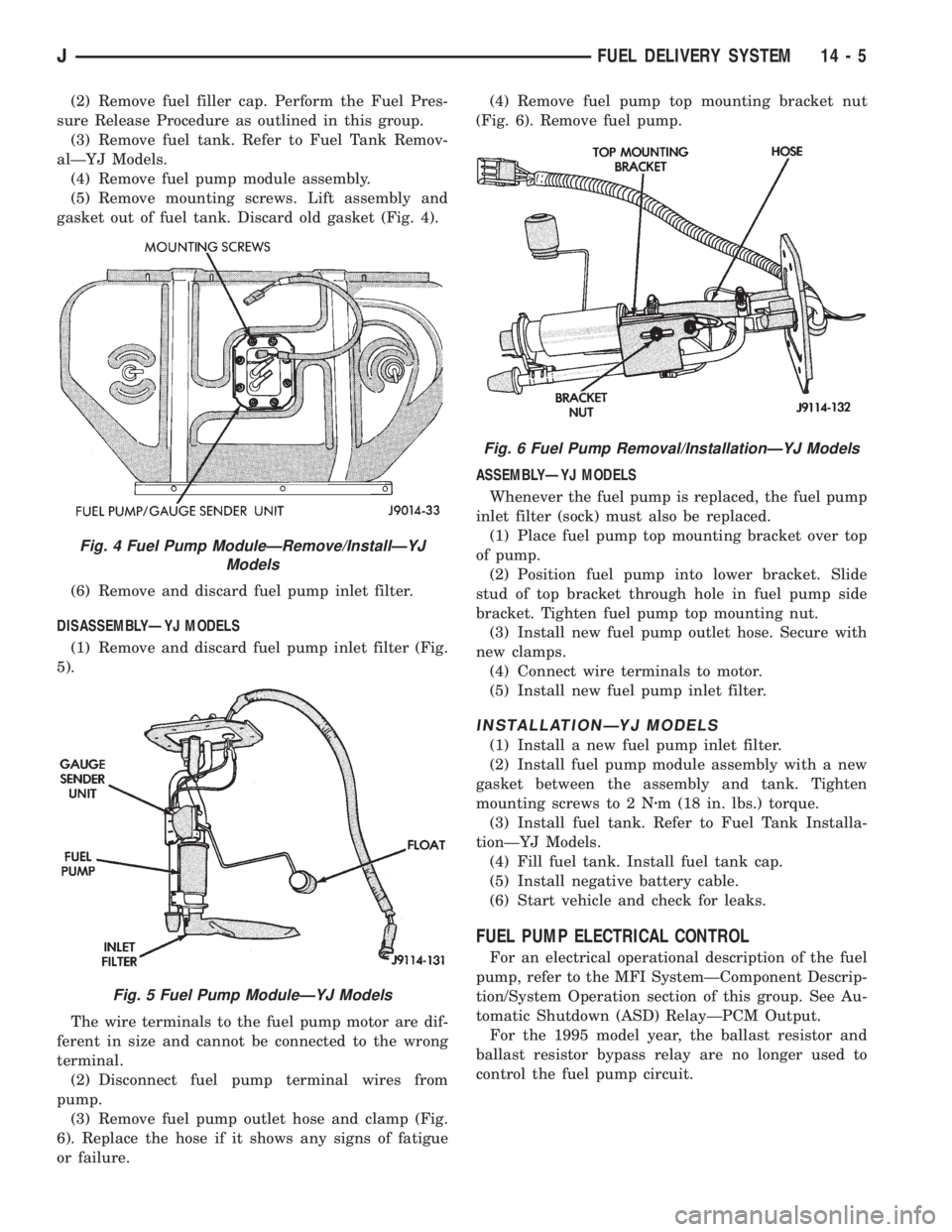

pump.(2) Install fuel pump module assembly and new O-

ring seal. The rubber stopper on the end of the fuel

return tube of the assembly must be inserted into the

cup in the fuel tank reservoir (Fig. 3).

(3) Using a brass punch and a hammer, install lock

ring. Carefully tap lock ring clockwise until it seats

against stop on fuel tank.

(4) Connect fuel supply and return hoses to fittings

on fuel pump module. Tighten hose clamps.

(5) Connect fuel pump module electrical harness

connector to main harness connector.

(6) Lower vehicle.

(7) Fill fuel tank. Install fuel tank cap.

(8) Connect negative battery cable.

(9) Start vehicle and inspect for leaks.

REMOVALÐYJ MODELS

The fuel tank must be removed to remove the fuel

pump module.

WARNING: THE FUEL SYSTEM IS UNDER A CON-

STANT PRESSURE (EVEN WITH THE ENGINE OFF).

BEFORE SERVICING THE FUEL PUMP MODULE,

THE FUEL SYSTEM PRESSURE MUST BE RE-

LEASED. REFER TO THE FUEL PRESSURE RE-

LEASE PROCEDURE IN THIS GROUP.

WARNING: EXTINGUISH ALL TOBACCO SMOKING

PRODUCTS BEFORE SERVICING THE FUEL SYS-

TEM. KEEP OPEN FLAME AWAY FROM FUEL SYS-

TEM COMPONENTS.

(1) Remove negative battery cable.

Fig. 2 Fuel Pump ModuleÐXJ ModelsÐ

Disassemble/Assemble

Fig. 3 Fuel Pump ModuleÐXJ ModelsÐInstallation

14 - 4 FUEL DELIVERY SYSTEMJ

Page 1220 of 2198

(2) Remove fuel filler cap. Perform the Fuel Pres-

sure Release Procedure as outlined in this group.

(3) Remove fuel tank. Refer to Fuel Tank Remov-

alÐYJ Models.

(4) Remove fuel pump module assembly.

(5) Remove mounting screws. Lift assembly and

gasket out of fuel tank. Discard old gasket (Fig. 4).

(6) Remove and discard fuel pump inlet filter.

DISASSEMBLYÐYJ MODELS

(1) Remove and discard fuel pump inlet filter (Fig.

5).

The wire terminals to the fuel pump motor are dif-

ferent in size and cannot be connected to the wrong

terminal.

(2) Disconnect fuel pump terminal wires from

pump.

(3) Remove fuel pump outlet hose and clamp (Fig.

6). Replace the hose if it shows any signs of fatigue

or failure.(4) Remove fuel pump top mounting bracket nut

(Fig. 6). Remove fuel pump.

ASSEMBLYÐYJ MODELS

Whenever the fuel pump is replaced, the fuel pump

inlet filter (sock) must also be replaced.

(1) Place fuel pump top mounting bracket over top

of pump.

(2) Position fuel pump into lower bracket. Slide

stud of top bracket through hole in fuel pump side

bracket. Tighten fuel pump top mounting nut.

(3) Install new fuel pump outlet hose. Secure with

new clamps.

(4) Connect wire terminals to motor.

(5) Install new fuel pump inlet filter.

INSTALLATIONÐYJ MODELS

(1) Install a new fuel pump inlet filter.

(2) Install fuel pump module assembly with a new

gasket between the assembly and tank. Tighten

mounting screws to 2 Nzm (18 in. lbs.) torque.

(3) Install fuel tank. Refer to Fuel Tank Installa-

tionÐYJ Models.

(4) Fill fuel tank. Install fuel tank cap.

(5) Install negative battery cable.

(6) Start vehicle and check for leaks.

FUEL PUMP ELECTRICAL CONTROL

For an electrical operational description of the fuel

pump, refer to the MFI SystemÐComponent Descrip-

tion/System Operation section of this group. See Au-

tomatic Shutdown (ASD) RelayÐPCM Output.

For the 1995 model year, the ballast resistor and

ballast resistor bypass relay are no longer used to

control the fuel pump circuit.

Fig. 4 Fuel Pump ModuleÐRemove/InstallÐYJ

Models

Fig. 5 Fuel Pump ModuleÐYJ Models

Fig. 6 Fuel Pump Removal/InstallationÐYJ Models

JFUEL DELIVERY SYSTEM 14 - 5