JEEP CHEROKEE 1995 Service Repair Manual

CHEROKEE 1995

JEEP

JEEP

https://www.carmanualsonline.info/img/16/57039/w960_57039-0.png

JEEP CHEROKEE 1995 Service Repair Manual

Trending: oil temperature, electrical, wiper blades, headrest, interior, brake rotor, OBD port

Page 1251 of 2198

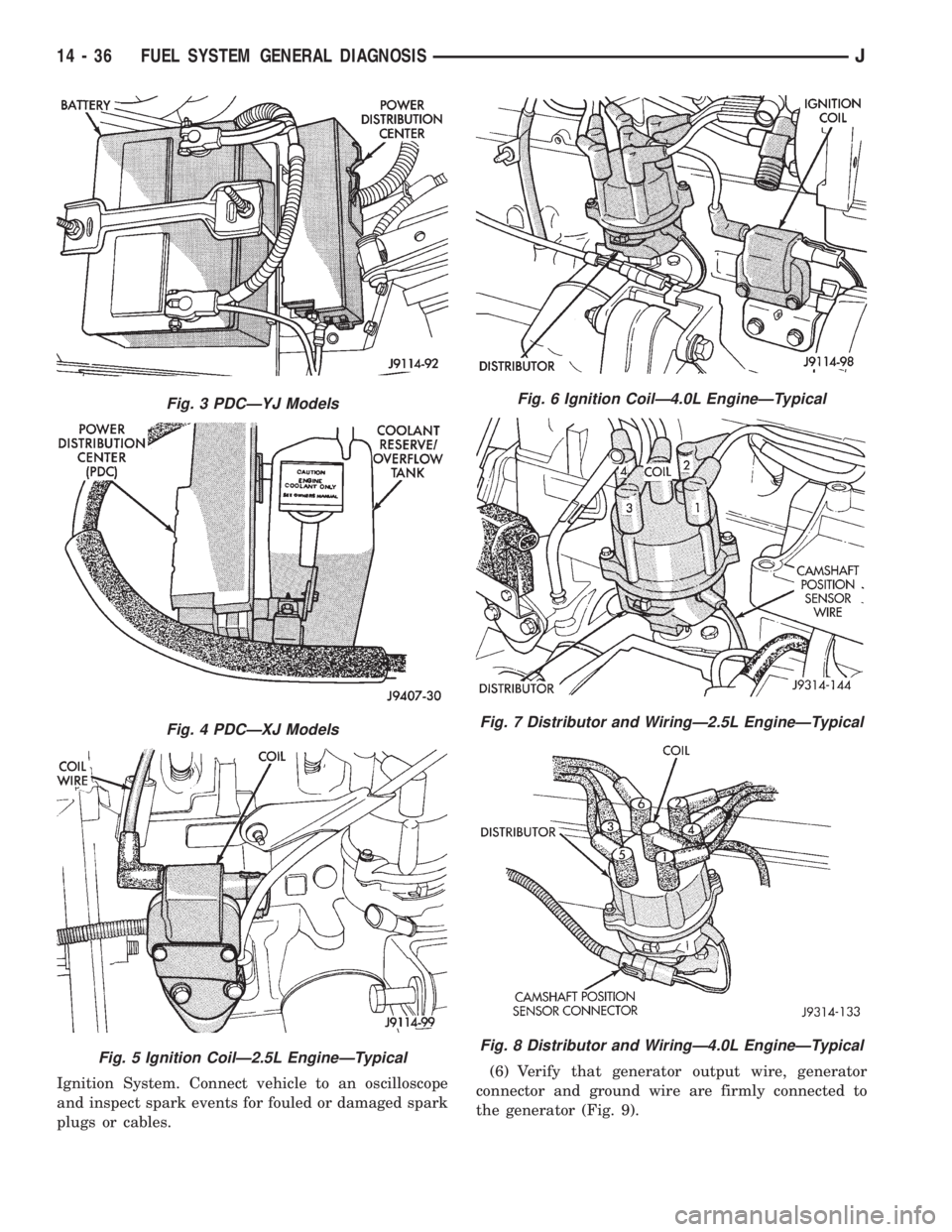

Ignition System. Connect vehicle to an oscilloscope

and inspect spark events for fouled or damaged spark

plugs or cables.(6) Verify that generator output wire, generator

connector and ground wire are firmly connected to

the generator (Fig. 9).

Fig. 3 PDCÐYJ Models

Fig. 4 PDCÐXJ Models

Fig. 5 Ignition CoilÐ2.5L EngineÐTypical

Fig. 6 Ignition CoilÐ4.0L EngineÐTypical

Fig. 7 Distributor and WiringÐ2.5L EngineÐTypical

Fig. 8 Distributor and WiringÐ4.0L EngineÐTypical

14 - 36 FUEL SYSTEM GENERAL DIAGNOSISJ

Page 1252 of 2198

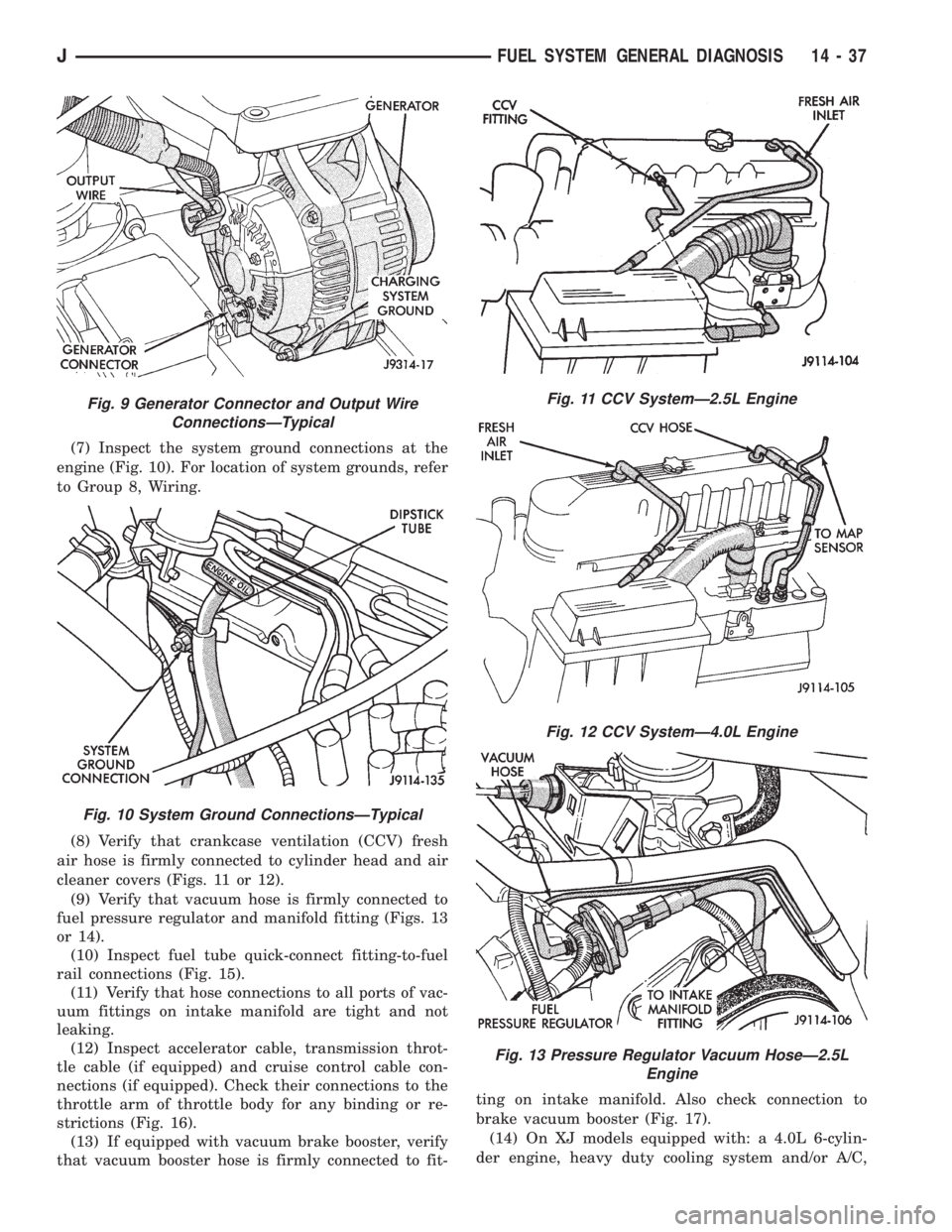

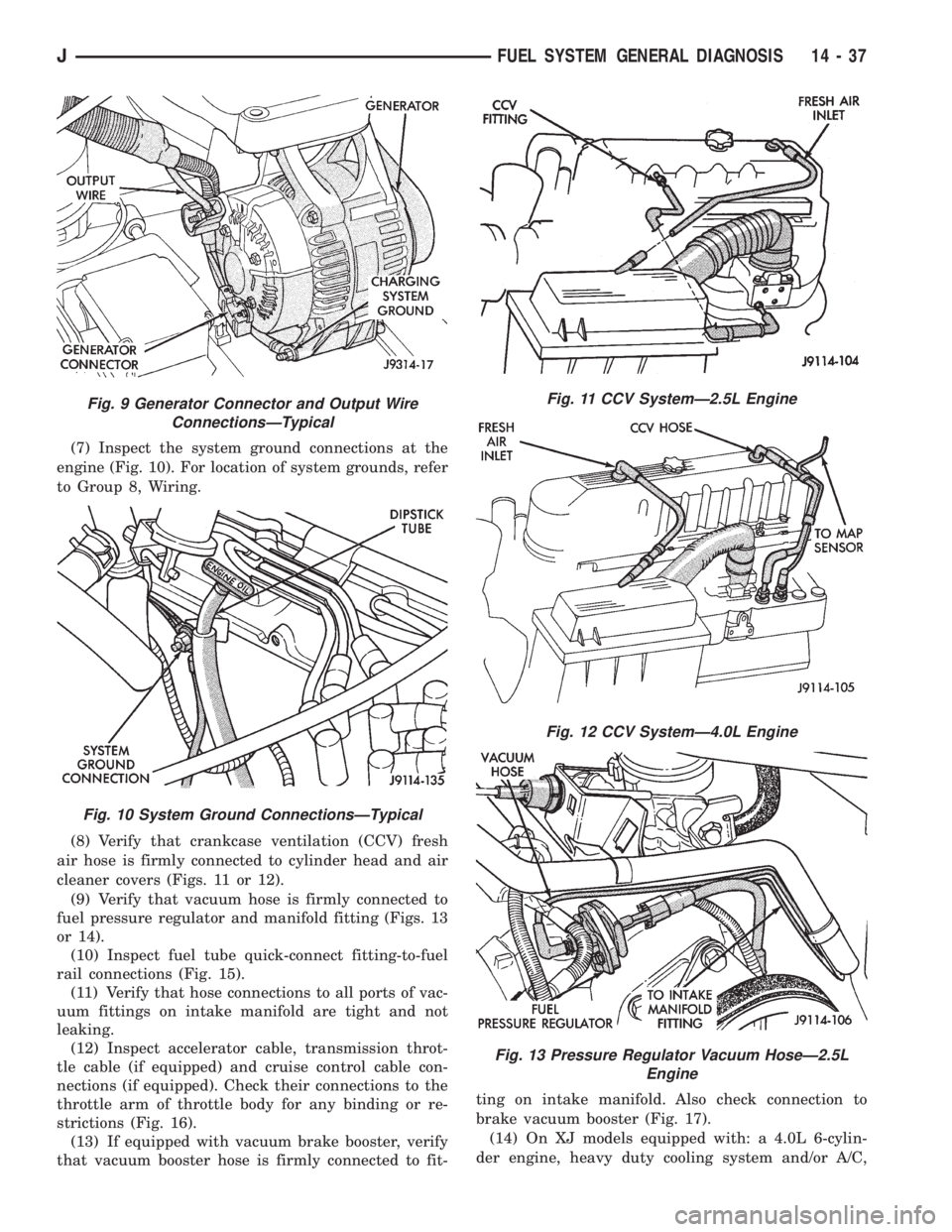

(7) Inspect the system ground connections at the

engine (Fig. 10). For location of system grounds, refer

to Group 8, Wiring.

(8) Verify that crankcase ventilation (CCV) fresh

air hose is firmly connected to cylinder head and air

cleaner covers (Figs. 11 or 12).

(9) Verify that vacuum hose is firmly connected to

fuel pressure regulator and manifold fitting (Figs. 13

or 14).

(10) Inspect fuel tube quick-connect fitting-to-fuel

rail connections (Fig. 15).

(11) Verify that hose connections to all ports of vac-

uum fittings on intake manifold are tight and not

leaking.

(12) Inspect accelerator cable, transmission throt-

tle cable (if equipped) and cruise control cable con-

nections (if equipped). Check their connections to the

throttle arm of throttle body for any binding or re-

strictions (Fig. 16).

(13) If equipped with vacuum brake booster, verify

that vacuum booster hose is firmly connected to fit-ting on intake manifold. Also check connection to

brake vacuum booster (Fig. 17).

(14) On XJ models equipped with: a 4.0L 6-cylin-

der engine, heavy duty cooling system and/or A/C,

Fig. 9 Generator Connector and Output Wire

ConnectionsÐTypical

Fig. 10 System Ground ConnectionsÐTypical

Fig. 11 CCV SystemÐ2.5L Engine

Fig. 12 CCV SystemÐ4.0L Engine

Fig. 13 Pressure Regulator Vacuum HoseÐ2.5L

Engine

JFUEL SYSTEM GENERAL DIAGNOSIS 14 - 37

Page 1253 of 2198

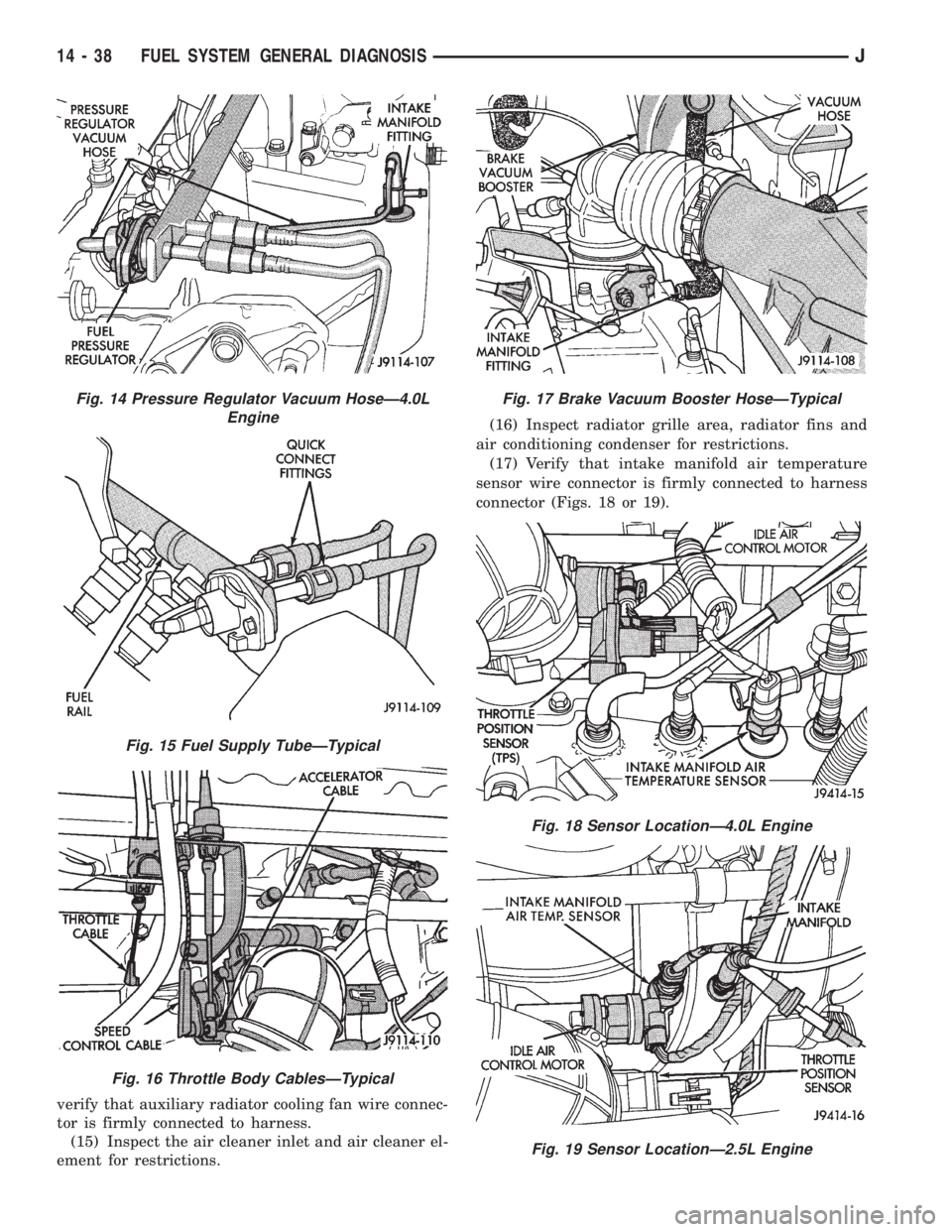

verify that auxiliary radiator cooling fan wire connec-

tor is firmly connected to harness.

(15) Inspect the air cleaner inlet and air cleaner el-

ement for restrictions.(16) Inspect radiator grille area, radiator fins and

air conditioning condenser for restrictions.

(17) Verify that intake manifold air temperature

sensor wire connector is firmly connected to harness

connector (Figs. 18 or 19).

Fig. 14 Pressure Regulator Vacuum HoseÐ4.0L

Engine

Fig. 15 Fuel Supply TubeÐTypical

Fig. 16 Throttle Body CablesÐTypical

Fig. 17 Brake Vacuum Booster HoseÐTypical

Fig. 18 Sensor LocationÐ4.0L Engine

Fig. 19 Sensor LocationÐ2.5L Engine

14 - 38 FUEL SYSTEM GENERAL DIAGNOSISJ

Page 1254 of 2198

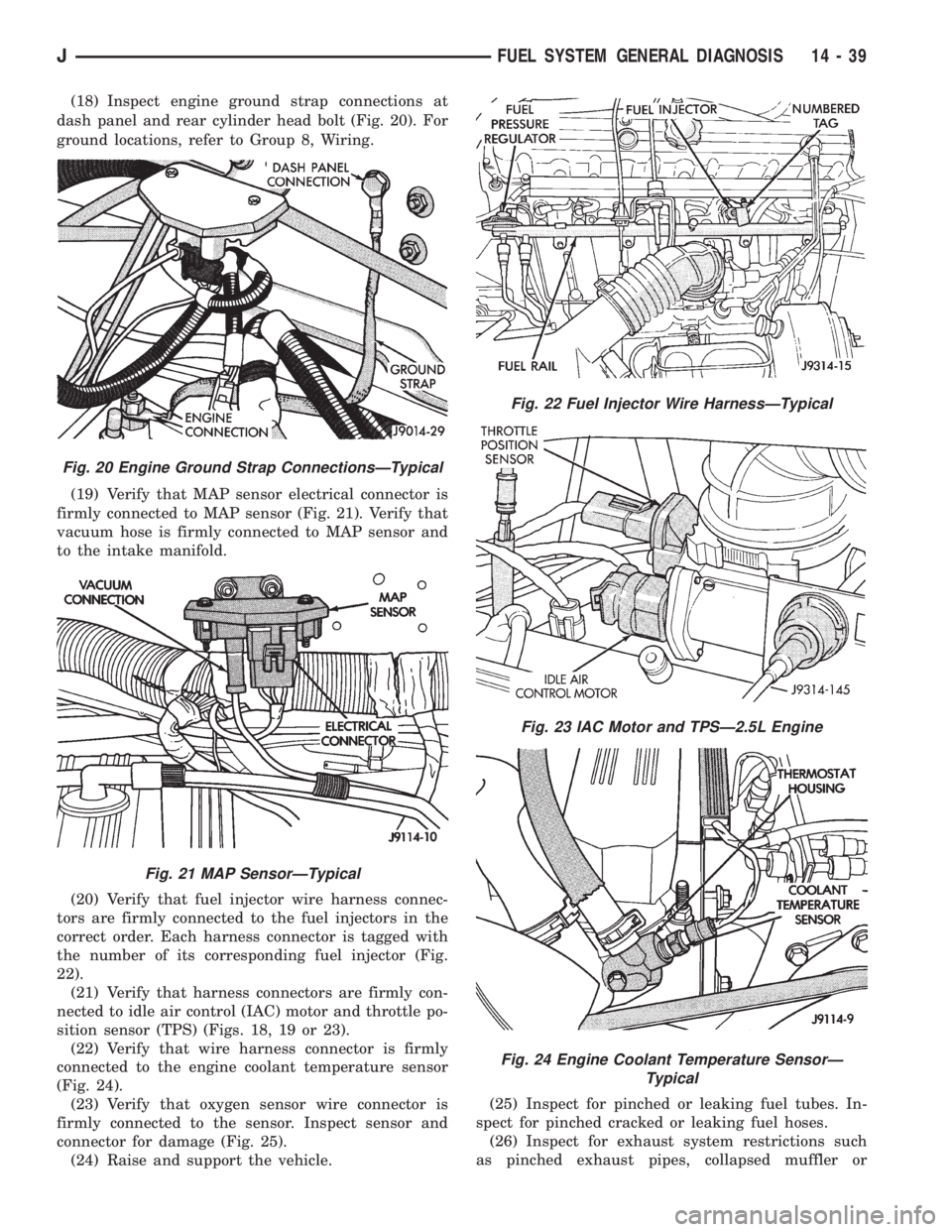

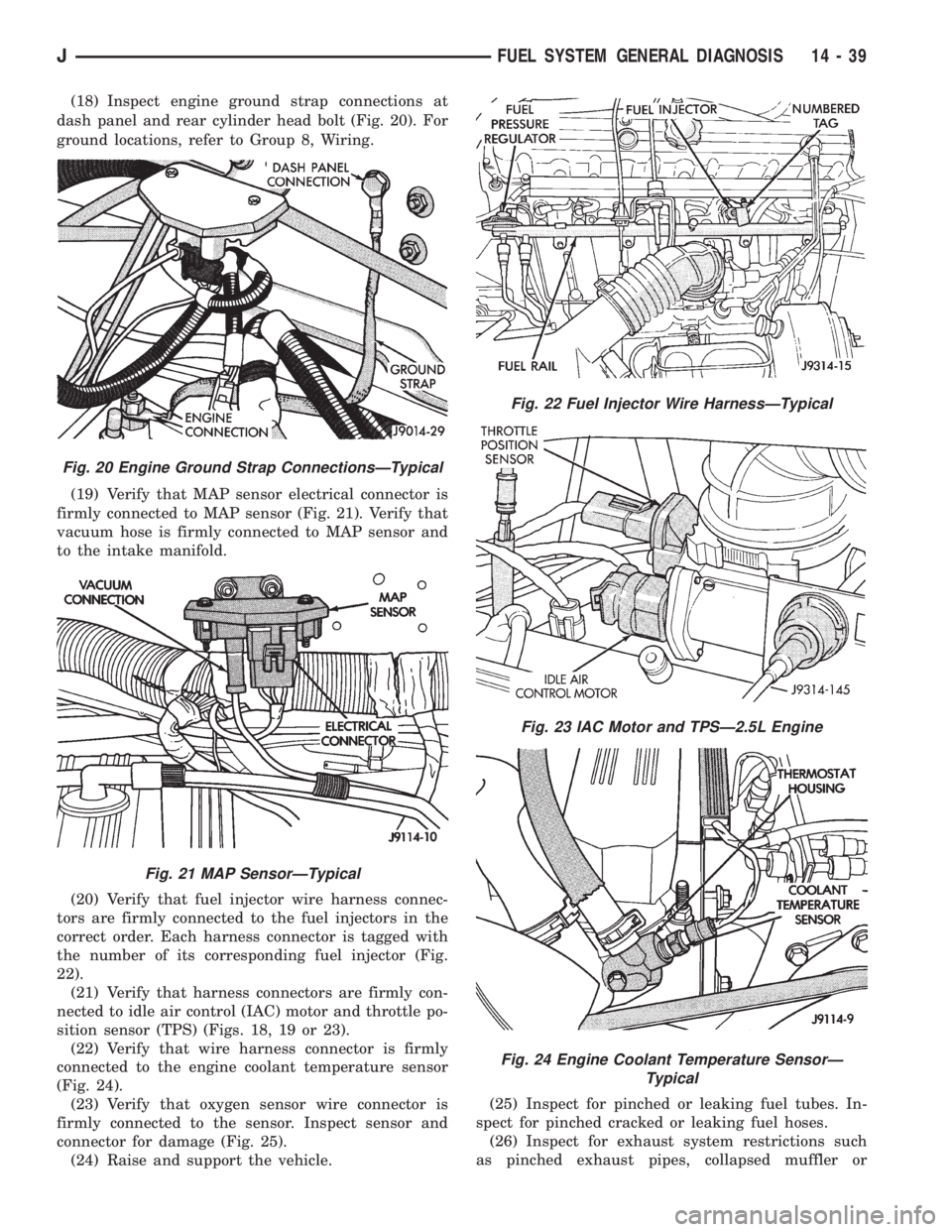

(18) Inspect engine ground strap connections at

dash panel and rear cylinder head bolt (Fig. 20). For

ground locations, refer to Group 8, Wiring.

(19) Verify that MAP sensor electrical connector is

firmly connected to MAP sensor (Fig. 21). Verify that

vacuum hose is firmly connected to MAP sensor and

to the intake manifold.

(20) Verify that fuel injector wire harness connec-

tors are firmly connected to the fuel injectors in the

correct order. Each harness connector is tagged with

the number of its corresponding fuel injector (Fig.

22).

(21) Verify that harness connectors are firmly con-

nected to idle air control (IAC) motor and throttle po-

sition sensor (TPS) (Figs. 18, 19 or 23).

(22) Verify that wire harness connector is firmly

connected to the engine coolant temperature sensor

(Fig. 24).

(23) Verify that oxygen sensor wire connector is

firmly connected to the sensor. Inspect sensor and

connector for damage (Fig. 25).

(24) Raise and support the vehicle.(25) Inspect for pinched or leaking fuel tubes. In-

spect for pinched cracked or leaking fuel hoses.

(26) Inspect for exhaust system restrictions such

as pinched exhaust pipes, collapsed muffler or

Fig. 20 Engine Ground Strap ConnectionsÐTypical

Fig. 21 MAP SensorÐTypical

Fig. 22 Fuel Injector Wire HarnessÐTypical

Fig. 23 IAC Motor and TPSÐ2.5L Engine

Fig. 24 Engine Coolant Temperature SensorÐ

Typical

JFUEL SYSTEM GENERAL DIAGNOSIS 14 - 39

Page 1255 of 2198

plugged catalytic convertor.

(27) If equipped with automatic transmission, ver-

ify that electrical harness is firmly connected to park/

neutral safety switch. Refer to Automatic

Transmission section of Group 21.

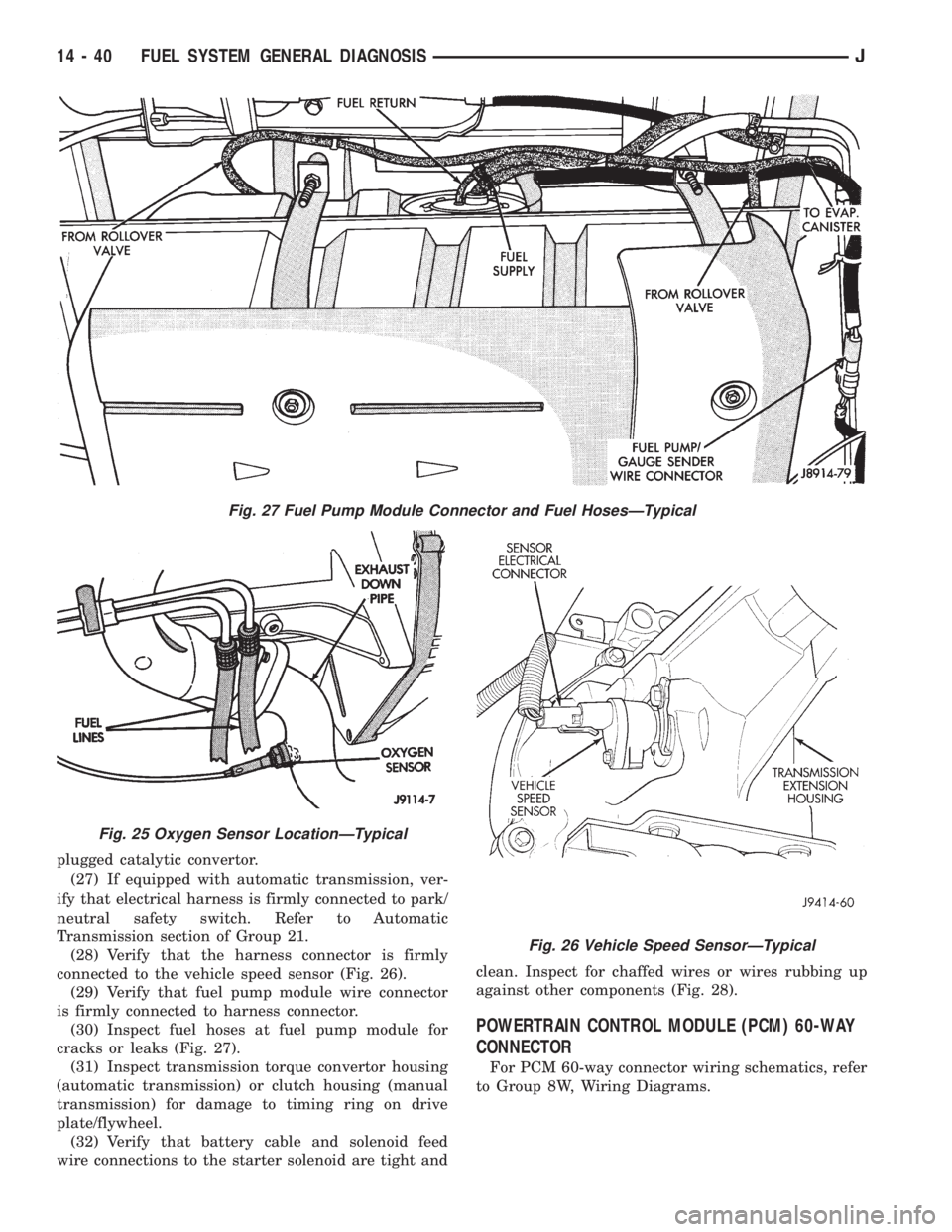

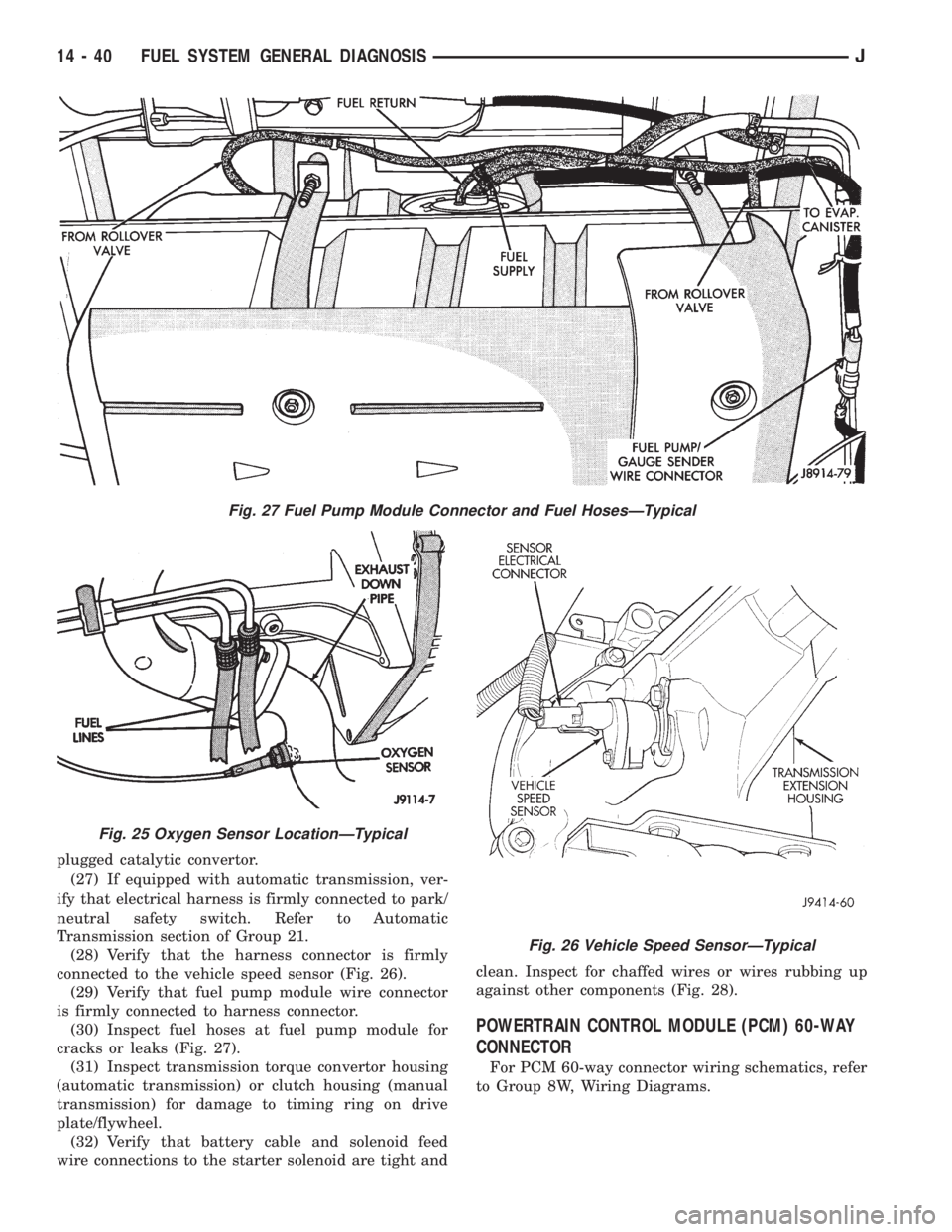

(28) Verify that the harness connector is firmly

connected to the vehicle speed sensor (Fig. 26).

(29) Verify that fuel pump module wire connector

is firmly connected to harness connector.

(30) Inspect fuel hoses at fuel pump module for

cracks or leaks (Fig. 27).

(31) Inspect transmission torque convertor housing

(automatic transmission) or clutch housing (manual

transmission) for damage to timing ring on drive

plate/flywheel.

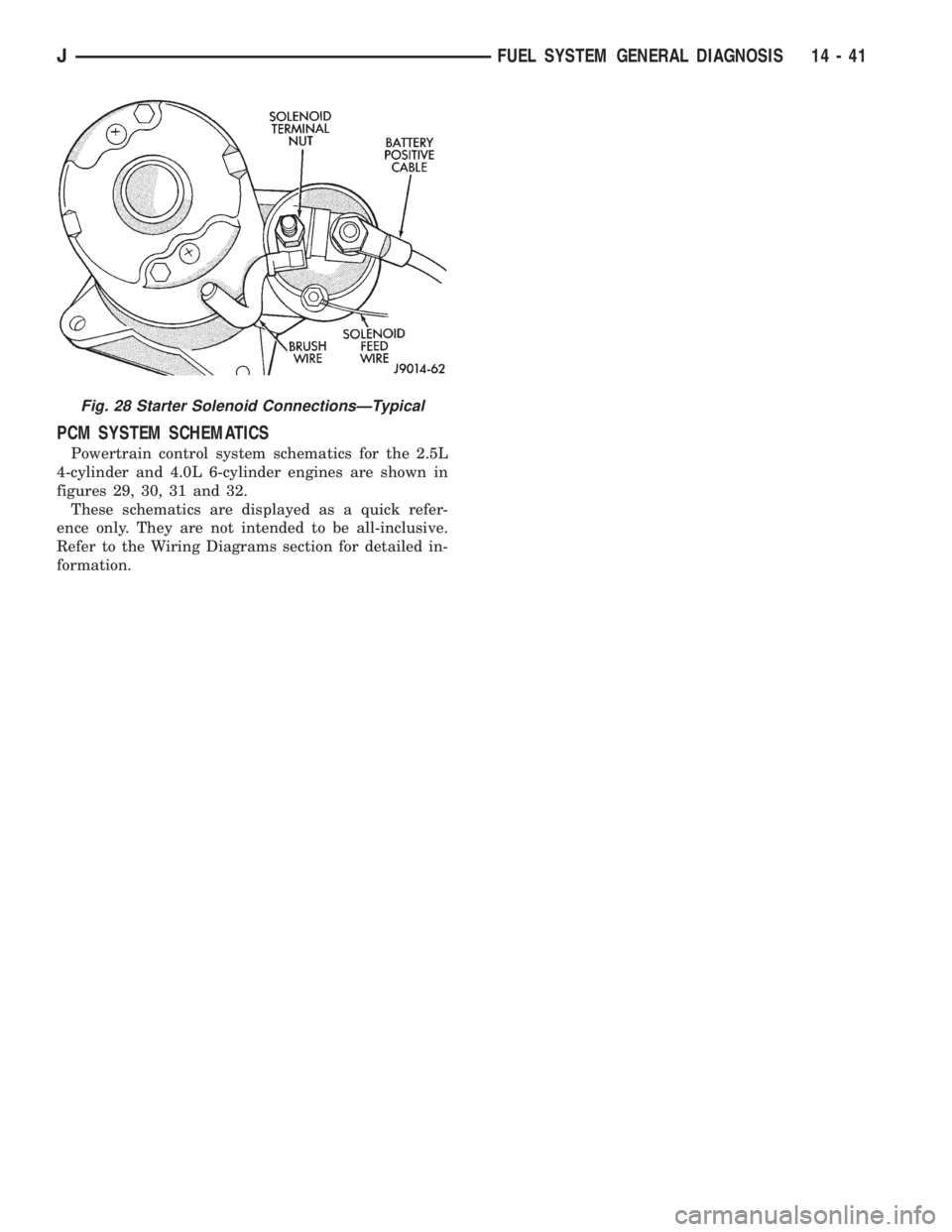

(32) Verify that battery cable and solenoid feed

wire connections to the starter solenoid are tight andclean. Inspect for chaffed wires or wires rubbing up

against other components (Fig. 28).

POWERTRAIN CONTROL MODULE (PCM) 60-WAY

CONNECTOR

For PCM 60-way connector wiring schematics, refer

to Group 8W, Wiring Diagrams.

Fig. 27 Fuel Pump Module Connector and Fuel HosesÐTypical

Fig. 25 Oxygen Sensor LocationÐTypical

Fig. 26 Vehicle Speed SensorÐTypical

14 - 40 FUEL SYSTEM GENERAL DIAGNOSISJ

Page 1256 of 2198

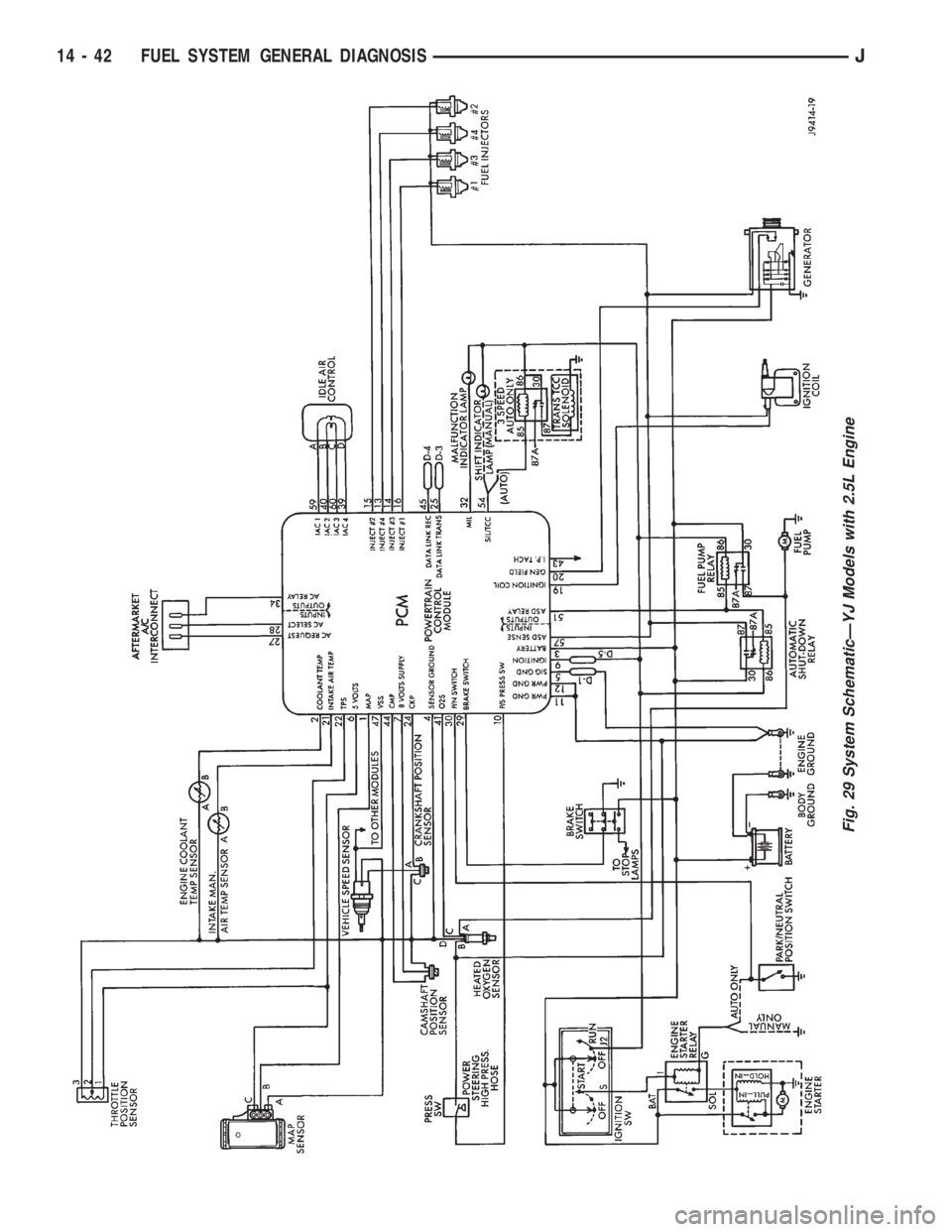

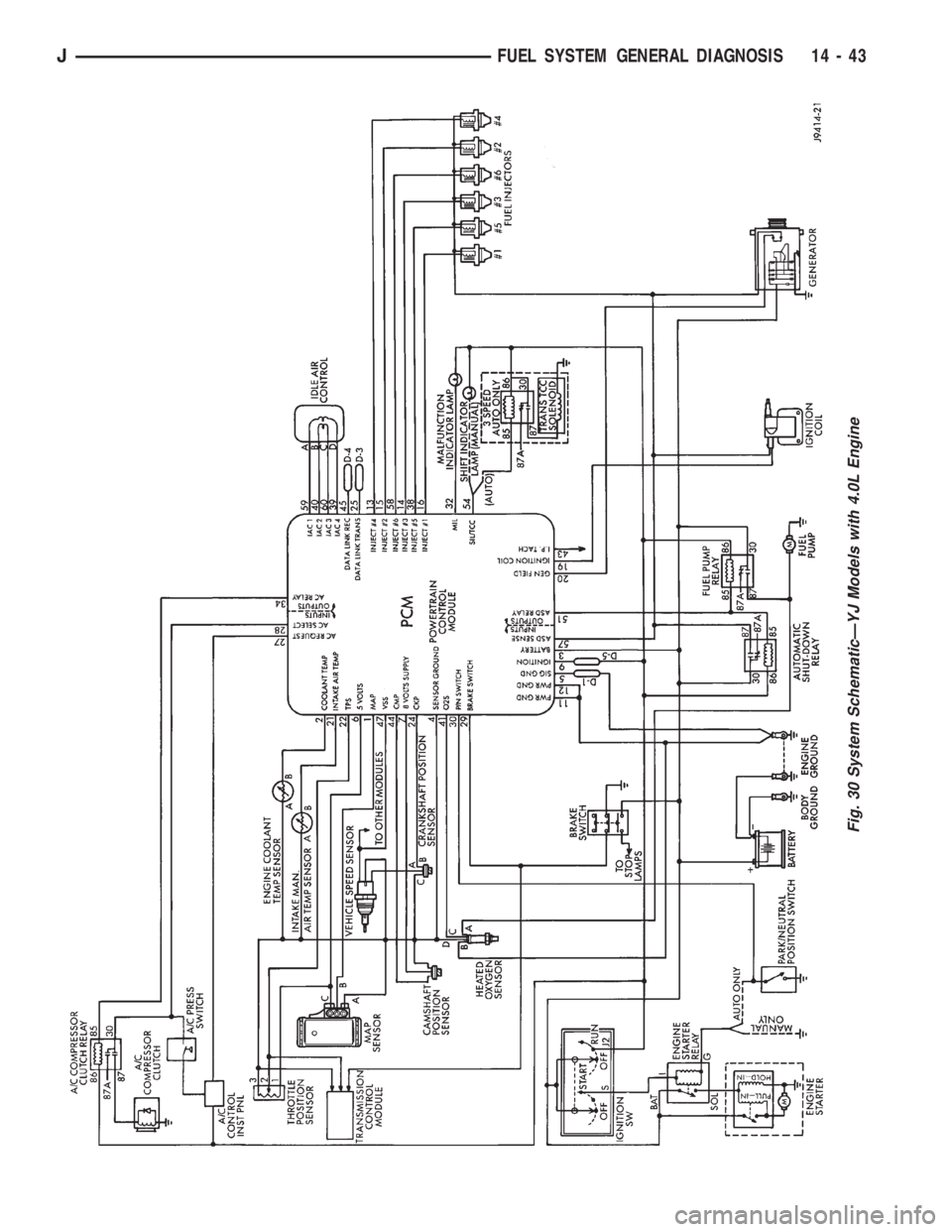

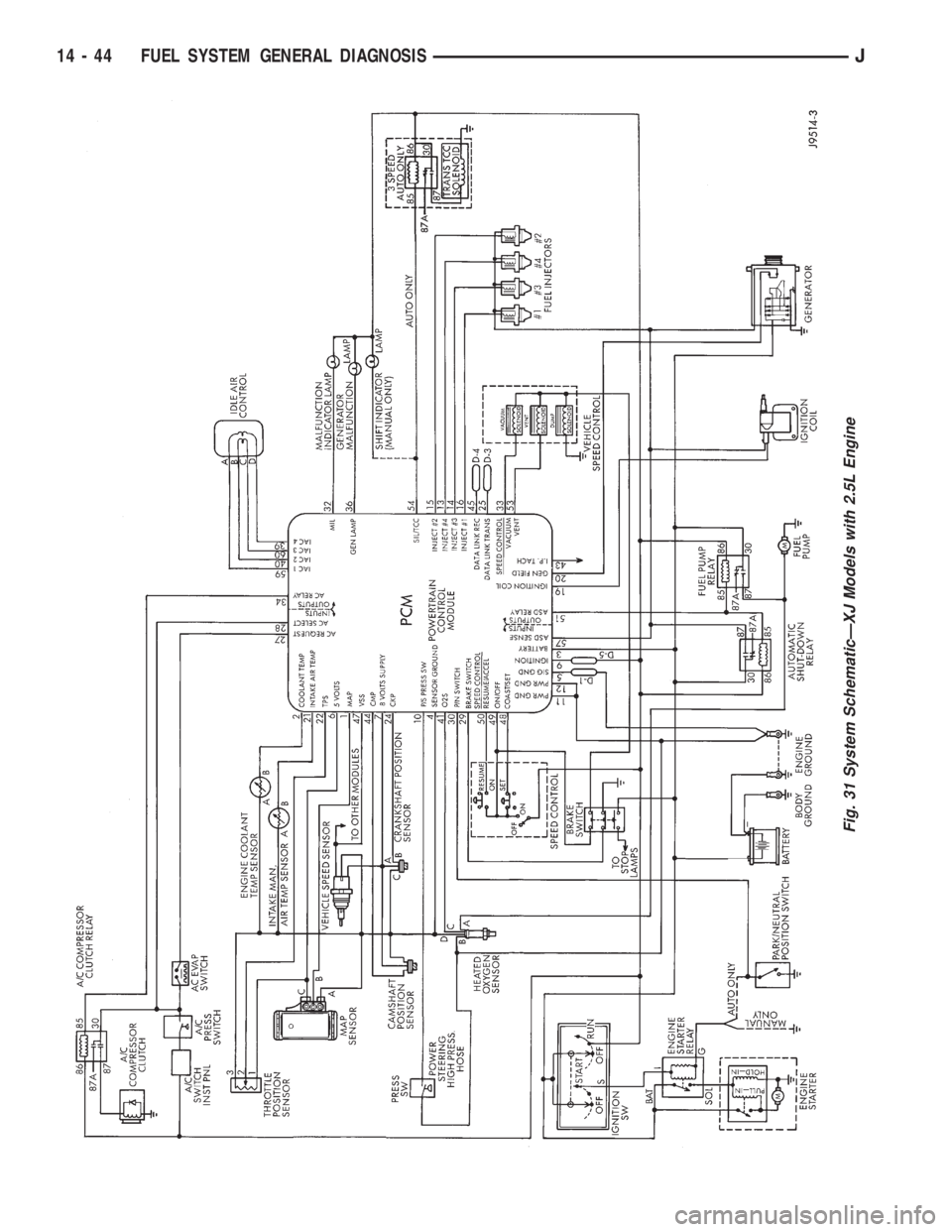

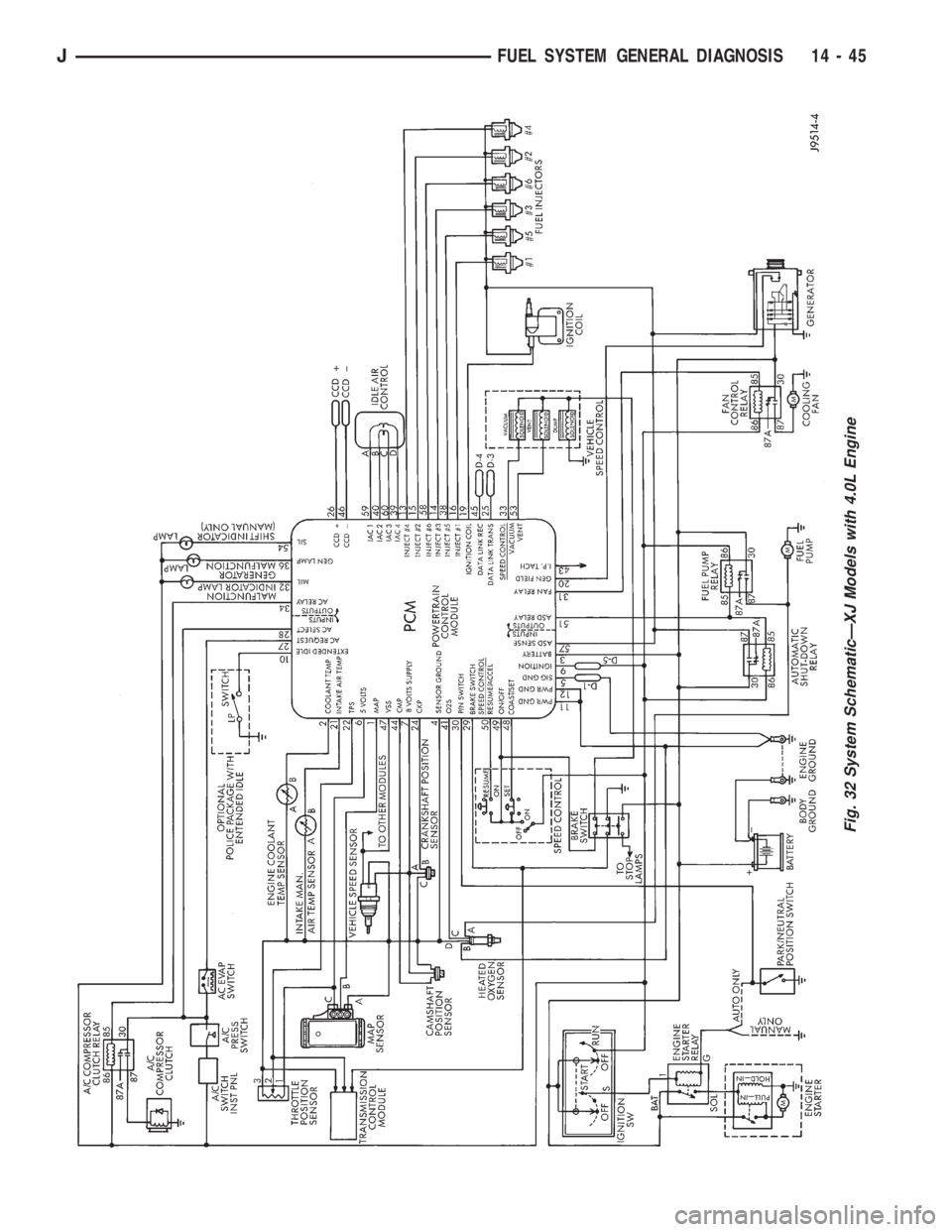

PCM SYSTEM SCHEMATICS

Powertrain control system schematics for the 2.5L

4-cylinder and 4.0L 6-cylinder engines are shown in

figures 29, 30, 31 and 32.

These schematics are displayed as a quick refer-

ence only. They are not intended to be all-inclusive.

Refer to the Wiring Diagrams section for detailed in-

formation.

Fig. 28 Starter Solenoid ConnectionsÐTypical

JFUEL SYSTEM GENERAL DIAGNOSIS 14 - 41

Page 1257 of 2198

Fig. 29 System SchematicÐYJ Models with 2.5L Engine

14 - 42 FUEL SYSTEM GENERAL DIAGNOSISJ

Page 1258 of 2198

Fig. 30 System SchematicÐYJ Models with 4.0L Engine

JFUEL SYSTEM GENERAL DIAGNOSIS 14 - 43

Page 1259 of 2198

Fig. 31 System SchematicÐXJ Models with 2.5L Engine

14 - 44 FUEL SYSTEM GENERAL DIAGNOSISJ

Page 1260 of 2198

Fig. 32 System SchematicÐXJ Models with 4.0L Engine

JFUEL SYSTEM GENERAL DIAGNOSIS 14 - 45

Trending: load capacity, oil level, dash panel, oil temperature, buttons, four wheel drive, radio controls