4WD JEEP CHEROKEE 1995 Service User Guide

[x] Cancel search | Manufacturer: JEEP, Model Year: 1995, Model line: CHEROKEE, Model: JEEP CHEROKEE 1995Pages: 2198, PDF Size: 82.83 MB

Page 29 of 2198

CHASSIS AND BODY COMPONENTS

INDEX

page page

Body Components........................ 32

Chassis Component and Wheel Bearing

Lubricants............................. 28

Front Wheel Bearings...................... 28

Headlamps.............................. 33

Manual Steering Gear...................... 30Power Brake System....................... 30

Power Steering System..................... 29

Speedometer Cable....................... 33

Steering Linkage.......................... 28

Tires................................... 32

CHASSIS COMPONENT AND WHEEL BEARING

LUBRICANTS

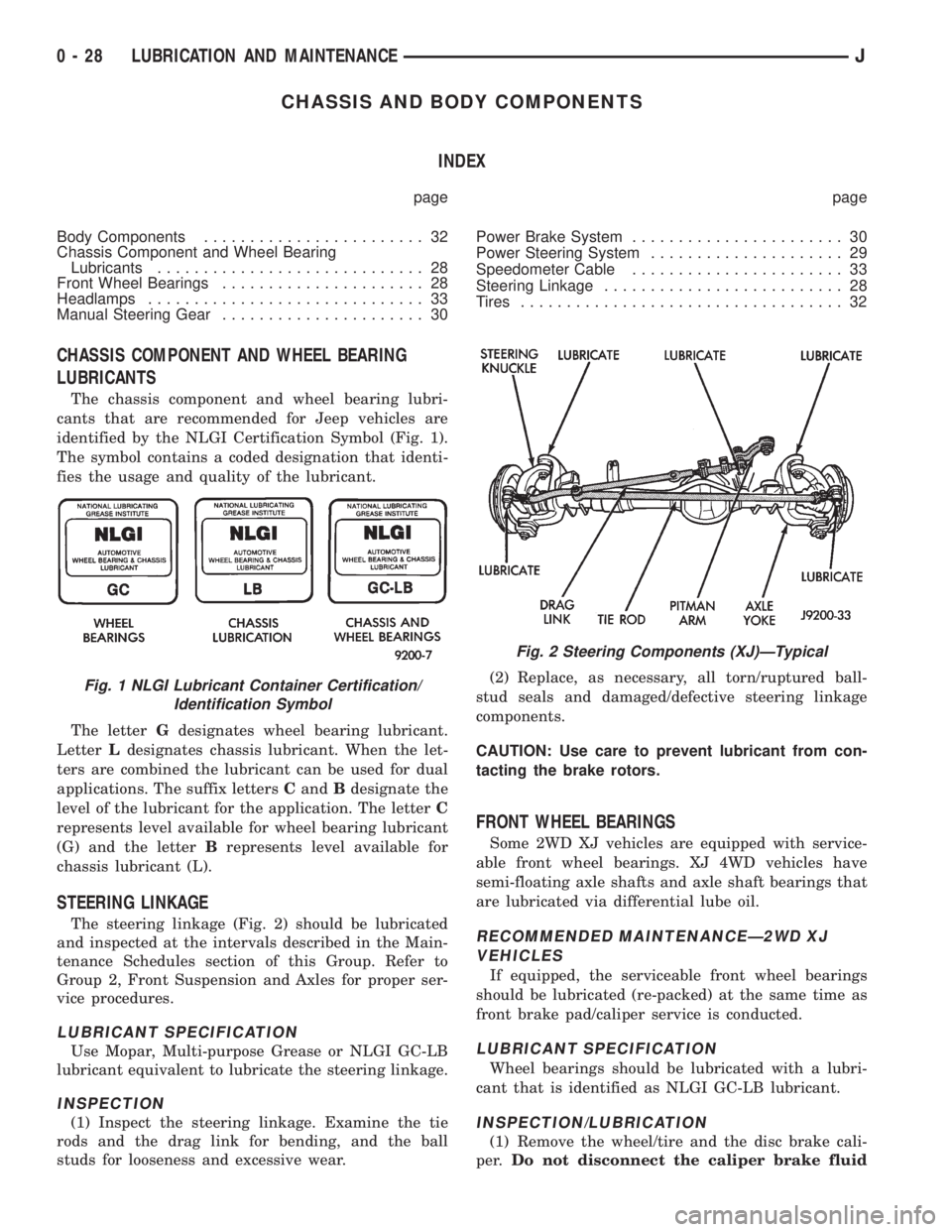

The chassis component and wheel bearing lubri-

cants that are recommended for Jeep vehicles are

identified by the NLGI Certification Symbol (Fig. 1).

The symbol contains a coded designation that identi-

fies the usage and quality of the lubricant.

The letterGdesignates wheel bearing lubricant.

LetterLdesignates chassis lubricant. When the let-

ters are combined the lubricant can be used for dual

applications. The suffix lettersCandBdesignate the

level of the lubricant for the application. The letterC

represents level available for wheel bearing lubricant

(G) and the letterBrepresents level available for

chassis lubricant (L).

STEERING LINKAGE

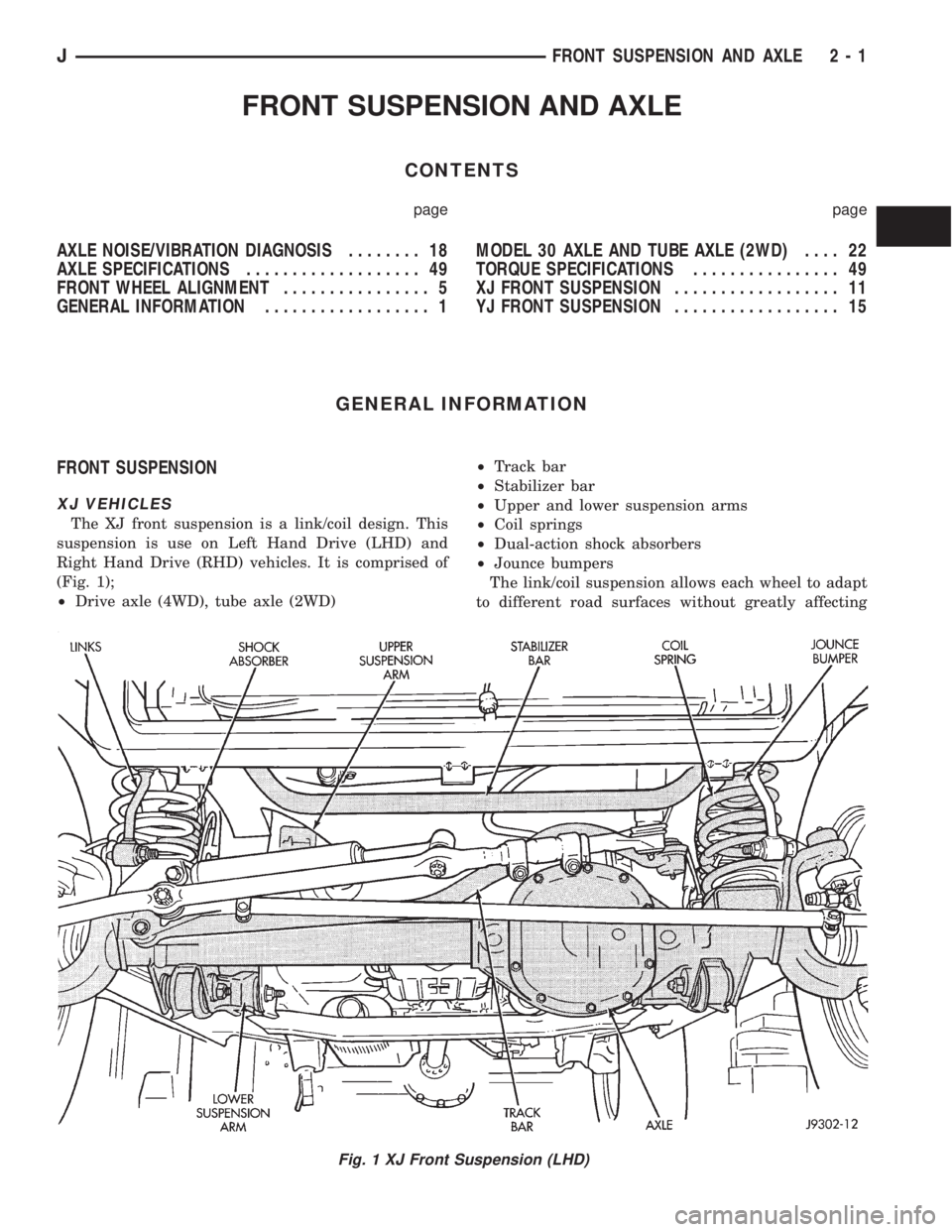

The steering linkage (Fig. 2) should be lubricated

and inspected at the intervals described in the Main-

tenance Schedules section of this Group. Refer to

Group 2, Front Suspension and Axles for proper ser-

vice procedures.

LUBRICANT SPECIFICATION

Use Mopar, Multi-purpose Grease or NLGI GC-LB

lubricant equivalent to lubricate the steering linkage.

INSPECTION

(1) Inspect the steering linkage. Examine the tie

rods and the drag link for bending, and the ball

studs for looseness and excessive wear.(2) Replace, as necessary, all torn/ruptured ball-

stud seals and damaged/defective steering linkage

components.

CAUTION: Use care to prevent lubricant from con-

tacting the brake rotors.

FRONT WHEEL BEARINGS

Some 2WD XJ vehicles are equipped with service-

able front wheel bearings. XJ 4WD vehicles have

semi-floating axle shafts and axle shaft bearings that

are lubricated via differential lube oil.

RECOMMENDED MAINTENANCEÐ2WD XJ

VEHICLES

If equipped, the serviceable front wheel bearings

should be lubricated (re-packed) at the same time as

front brake pad/caliper service is conducted.

LUBRICANT SPECIFICATION

Wheel bearings should be lubricated with a lubri-

cant that is identified as NLGI GC-LB lubricant.

INSPECTION/LUBRICATION

(1) Remove the wheel/tire and the disc brake cali-

per.Do not disconnect the caliper brake fluid

Fig. 1 NLGI Lubricant Container Certification/

Identification Symbol

Fig. 2 Steering Components (XJ)ÐTypical

0 - 28 LUBRICATION AND MAINTENANCEJ

Page 36 of 2198

FRONT SUSPENSION AND AXLE

CONTENTS

page page

AXLE NOISE/VIBRATION DIAGNOSIS........ 18

AXLE SPECIFICATIONS................... 49

FRONT WHEEL ALIGNMENT................ 5

GENERAL INFORMATION.................. 1MODEL 30 AXLE AND TUBE AXLE (2WD).... 22

TORQUE SPECIFICATIONS................ 49

XJ FRONT SUSPENSION.................. 11

YJ FRONT SUSPENSION.................. 15

GENERAL INFORMATION

FRONT SUSPENSION

XJ VEHICLES

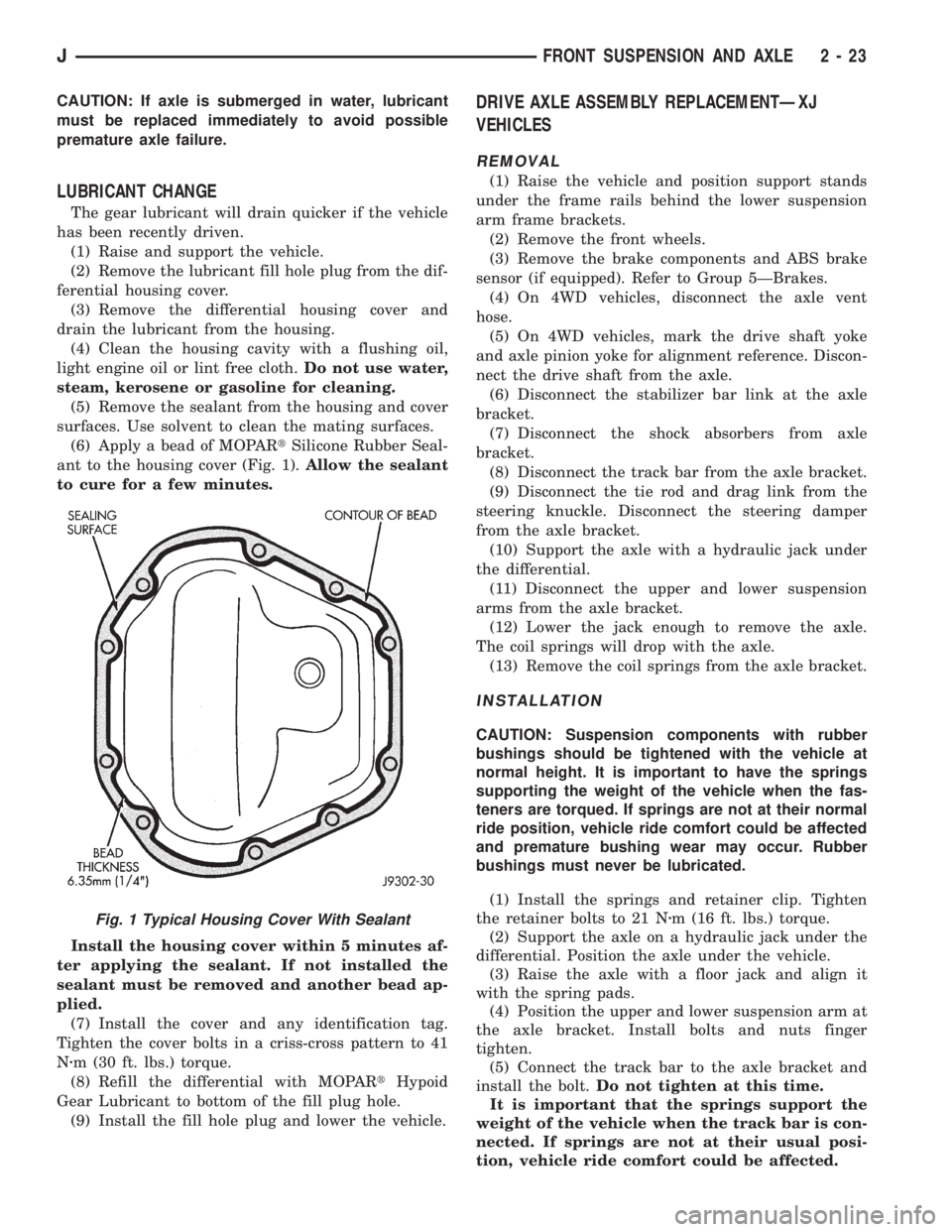

The XJ front suspension is a link/coil design. This

suspension is use on Left Hand Drive (LHD) and

Right Hand Drive (RHD) vehicles. It is comprised of

(Fig. 1);

²Drive axle (4WD), tube axle (2WD)²Track bar

²Stabilizer bar

²Upper and lower suspension arms

²Coil springs

²Dual-action shock absorbers

²Jounce bumpers

The link/coil suspension allows each wheel to adapt

to different road surfaces without greatly affecting

Fig. 1 XJ Front Suspension (LHD)

JFRONT SUSPENSION AND AXLE 2 - 1

Page 58 of 2198

CAUTION: If axle is submerged in water, lubricant

must be replaced immediately to avoid possible

premature axle failure.

LUBRICANT CHANGE

The gear lubricant will drain quicker if the vehicle

has been recently driven.

(1) Raise and support the vehicle.

(2) Remove the lubricant fill hole plug from the dif-

ferential housing cover.

(3) Remove the differential housing cover and

drain the lubricant from the housing.

(4) Clean the housing cavity with a flushing oil,

light engine oil or lint free cloth.Do not use water,

steam, kerosene or gasoline for cleaning.

(5) Remove the sealant from the housing and cover

surfaces. Use solvent to clean the mating surfaces.

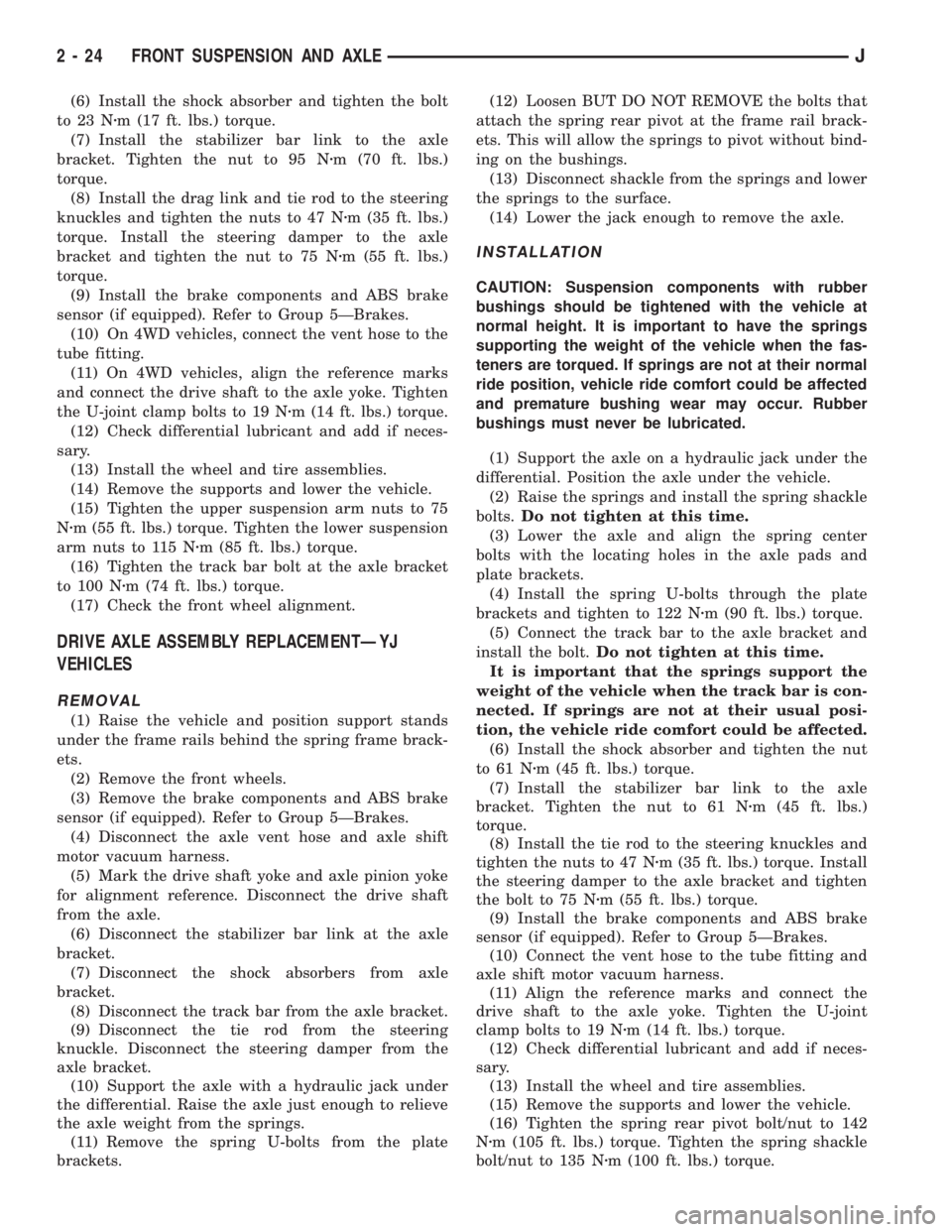

(6) Apply a bead of MOPARtSilicone Rubber Seal-

ant to the housing cover (Fig. 1).Allow the sealant

to cure for a few minutes.

Install the housing cover within 5 minutes af-

ter applying the sealant. If not installed the

sealant must be removed and another bead ap-

plied.

(7) Install the cover and any identification tag.

Tighten the cover bolts in a criss-cross pattern to 41

Nzm (30 ft. lbs.) torque.

(8) Refill the differential with MOPARtHypoid

Gear Lubricant to bottom of the fill plug hole.

(9) Install the fill hole plug and lower the vehicle.

DRIVE AXLE ASSEMBLY REPLACEMENTÐXJ

VEHICLES

REMOVAL

(1) Raise the vehicle and position support stands

under the frame rails behind the lower suspension

arm frame brackets.

(2) Remove the front wheels.

(3) Remove the brake components and ABS brake

sensor (if equipped). Refer to Group 5ÐBrakes.

(4) On 4WD vehicles, disconnect the axle vent

hose.

(5) On 4WD vehicles, mark the drive shaft yoke

and axle pinion yoke for alignment reference. Discon-

nect the drive shaft from the axle.

(6) Disconnect the stabilizer bar link at the axle

bracket.

(7) Disconnect the shock absorbers from axle

bracket.

(8) Disconnect the track bar from the axle bracket.

(9) Disconnect the tie rod and drag link from the

steering knuckle. Disconnect the steering damper

from the axle bracket.

(10) Support the axle with a hydraulic jack under

the differential.

(11) Disconnect the upper and lower suspension

arms from the axle bracket.

(12) Lower the jack enough to remove the axle.

The coil springs will drop with the axle.

(13) Remove the coil springs from the axle bracket.

INSTALLATION

CAUTION: Suspension components with rubber

bushings should be tightened with the vehicle at

normal height. It is important to have the springs

supporting the weight of the vehicle when the fas-

teners are torqued. If springs are not at their normal

ride position, vehicle ride comfort could be affected

and premature bushing wear may occur. Rubber

bushings must never be lubricated.

(1) Install the springs and retainer clip. Tighten

the retainer bolts to 21 Nzm (16 ft. lbs.) torque.

(2) Support the axle on a hydraulic jack under the

differential. Position the axle under the vehicle.

(3) Raise the axle with a floor jack and align it

with the spring pads.

(4) Position the upper and lower suspension arm at

the axle bracket. Install bolts and nuts finger

tighten.

(5) Connect the track bar to the axle bracket and

install the bolt.Do not tighten at this time.

It is important that the springs support the

weight of the vehicle when the track bar is con-

nected. If springs are not at their usual posi-

tion, vehicle ride comfort could be affected.

Fig. 1 Typical Housing Cover With Sealant

JFRONT SUSPENSION AND AXLE 2 - 23

Page 59 of 2198

(6) Install the shock absorber and tighten the bolt

to 23 Nzm (17 ft. lbs.) torque.

(7) Install the stabilizer bar link to the axle

bracket. Tighten the nut to 95 Nzm (70 ft. lbs.)

torque.

(8) Install the drag link and tie rod to the steering

knuckles and tighten the nuts to 47 Nzm (35 ft. lbs.)

torque. Install the steering damper to the axle

bracket and tighten the nut to 75 Nzm (55 ft. lbs.)

torque.

(9) Install the brake components and ABS brake

sensor (if equipped). Refer to Group 5ÐBrakes.

(10) On 4WD vehicles, connect the vent hose to the

tube fitting.

(11) On 4WD vehicles, align the reference marks

and connect the drive shaft to the axle yoke. Tighten

the U-joint clamp bolts to 19 Nzm (14 ft. lbs.) torque.

(12) Check differential lubricant and add if neces-

sary.

(13) Install the wheel and tire assemblies.

(14) Remove the supports and lower the vehicle.

(15) Tighten the upper suspension arm nuts to 75

Nzm (55 ft. lbs.) torque. Tighten the lower suspension

arm nuts to 115 Nzm (85 ft. lbs.) torque.

(16) Tighten the track bar bolt at the axle bracket

to 100 Nzm (74 ft. lbs.) torque.

(17) Check the front wheel alignment.

DRIVE AXLE ASSEMBLY REPLACEMENTÐYJ

VEHICLES

REMOVAL

(1) Raise the vehicle and position support stands

under the frame rails behind the spring frame brack-

ets.

(2) Remove the front wheels.

(3) Remove the brake components and ABS brake

sensor (if equipped). Refer to Group 5ÐBrakes.

(4) Disconnect the axle vent hose and axle shift

motor vacuum harness.

(5) Mark the drive shaft yoke and axle pinion yoke

for alignment reference. Disconnect the drive shaft

from the axle.

(6) Disconnect the stabilizer bar link at the axle

bracket.

(7) Disconnect the shock absorbers from axle

bracket.

(8) Disconnect the track bar from the axle bracket.

(9) Disconnect the tie rod from the steering

knuckle. Disconnect the steering damper from the

axle bracket.

(10) Support the axle with a hydraulic jack under

the differential. Raise the axle just enough to relieve

the axle weight from the springs.

(11) Remove the spring U-bolts from the plate

brackets.(12) Loosen BUT DO NOT REMOVE the bolts that

attach the spring rear pivot at the frame rail brack-

ets. This will allow the springs to pivot without bind-

ing on the bushings.

(13) Disconnect shackle from the springs and lower

the springs to the surface.

(14) Lower the jack enough to remove the axle.

INSTALLATION

CAUTION: Suspension components with rubber

bushings should be tightened with the vehicle at

normal height. It is important to have the springs

supporting the weight of the vehicle when the fas-

teners are torqued. If springs are not at their normal

ride position, vehicle ride comfort could be affected

and premature bushing wear may occur. Rubber

bushings must never be lubricated.

(1) Support the axle on a hydraulic jack under the

differential. Position the axle under the vehicle.

(2) Raise the springs and install the spring shackle

bolts.Do not tighten at this time.

(3) Lower the axle and align the spring center

bolts with the locating holes in the axle pads and

plate brackets.

(4) Install the spring U-bolts through the plate

brackets and tighten to 122 Nzm (90 ft. lbs.) torque.

(5) Connect the track bar to the axle bracket and

install the bolt.Do not tighten at this time.

It is important that the springs support the

weight of the vehicle when the track bar is con-

nected. If springs are not at their usual posi-

tion, the vehicle ride comfort could be affected.

(6) Install the shock absorber and tighten the nut

to 61 Nzm (45 ft. lbs.) torque.

(7) Install the stabilizer bar link to the axle

bracket. Tighten the nut to 61 Nzm (45 ft. lbs.)

torque.

(8) Install the tie rod to the steering knuckles and

tighten the nuts to 47 Nzm (35 ft. lbs.) torque. Install

the steering damper to the axle bracket and tighten

the bolt to 75 Nzm (55 ft. lbs.) torque.

(9) Install the brake components and ABS brake

sensor (if equipped). Refer to Group 5ÐBrakes.

(10) Connect the vent hose to the tube fitting and

axle shift motor vacuum harness.

(11) Align the reference marks and connect the

drive shaft to the axle yoke. Tighten the U-joint

clamp bolts to 19 Nzm (14 ft. lbs.) torque.

(12) Check differential lubricant and add if neces-

sary.

(13) Install the wheel and tire assemblies.

(15) Remove the supports and lower the vehicle.

(16) Tighten the spring rear pivot bolt/nut to 142

Nzm (105 ft. lbs.) torque. Tighten the spring shackle

bolt/nut to 135 Nzm (100 ft. lbs.) torque.

2 - 24 FRONT SUSPENSION AND AXLEJ

Page 346 of 2198

TACHOMETER

The tachometer gives an indication of engine speed

in Revolutions-Per-Minute (RPM). With the engine

running, the tachometer receives an engine speed

pulse signal from the Powertrain Control Module

(PCM). An electronic integrated circuit contained

within the tachometer reads and analyzes the pulse

signal. It then adjusts the ground path resistance of

one electromagnet in the gauge to control needle

movement. Frequency values for the pulse signal are

shown in a chart in Specifications.

TRIP ODOMETER

The trip odometer is driven by the same electronic

integrated circuit as the speedometer/odometer. How-

ever, by depressing the trip odometer reset knob on

the face of the speedometer, the trip odometer can be

reset to zero. The trip odometer is serviced only as a

part of the speedometer/odometer gauge assembly.

VOLTMETER

The voltmeter is connected in parallel with the bat-

tery. With the ignition switch ON, the voltmeter in-

dicates battery or generator output voltage,

whichever is greater.

INDICATOR LAMPS

Indicator lamps are located in two areas within the

cluster. Each of these areas is served by a separate

printed circuit and cluster connector. Those lamps in

the gauge area of the cluster share the gauge area

printed circuit and cluster connector A. Those lamps

in the tell-tale area of the cluster use the tell-tale

printed circuit and cluster (tell-tale) connector B.

Up to ten indicator lamps can be found in the tell-

tale area of the cluster. These lamps are arranged in

five stacked rows with two lamps in each row, located

to the driver's side of the main cluster.

ANTI-LOCK BRAKE SYSTEM LAMP

The Anti-Lock Brake System (ABS) lamp is

switched to ground by the ABS module. The module

lights the lamp when the ignition switch is turned to

the START position as a bulb test. The lamp will

stay on for 3 to 5 seconds after vehicle start-up to in-

dicate a system self-test is in process. If the lamp re-

mains on after start-up, or comes on and stays on

while driving, it may indicate that the ABS module

has detected a system malfunction or that the system

has become inoperative. Refer to Group 5 - Brakes

for more information.

BRAKE WARNING LAMP

The brake warning lamp warns the driver that the

parking brake is applied or that the pressures in the

two halves of the split brake hydraulic system are

unequal. With the ignition switch turned ON, batteryvoltage is supplied to one side of the indicator bulb. A

ground path for the bulb is provided by 3 switches.

The bulb will light when:

²the brake warning switch is closed (indicating un-

equal brake system hydraulic pressures possibly due

to brake fluid leakage)

²the ignition switch is in the START position (bulb

test)

²the parking brake switch is closed (parking brake

is applied).

Refer to Group 5 - Brakes for more information.

COOLANT TEMPERATURE WARNING LAMP

The coolant temperature warning lamp lights

whenever engine coolant temperature is too high.

Battery voltage is supplied to one side of the indica-

tor bulb when the ignition switch is turned ON. The

normally open coolant temperature switch is con-

nected to the other side of the bulb. When coolant

temperature is too high, the switch closes. This pro-

vides a ground path for the indicator bulb, which

causes it to light. The lamp is also grounded and

should light with the ignition switch in the START

position as a bulb test.

FOUR-WHEEL DRIVE INDICATOR LAMPS

PART TIME

On vehicles with Command-Trac 4WD, the Part

Time lamp lights when the transfer case is engaged

in the 4H or 4L position. On vehicles with Selec-Trac

4WD, the Part Time lamp lights when the transfer

case is engaged in the4X4PARTTIME or 4 LO po-

sition. Voltage is supplied to one side of the indicator

bulb. A switch in the transfer case is connected to the

other side of the indicator bulb. When the switch is

closed, a path to ground is provided and the indicator

bulb lights.

FULL TIME

The Full Time lamp is only operational on vehicles

equipped with Selec-Trac 4WD. The Full Time lamp

lights when the transfer case is engaged in the4X4

Full Time position. Voltage is supplied to one side of

the indicator bulb. A switch in the transfer case is

connected to the other side of the indicator bulb.

When the switch is closed, a path to ground is pro-

vided and the indicator bulb lights.

GENERATOR WARNING LAMP

The generator warning lamp lights with the igni-

tion switch turned to ON, but should go out when-

ever the engine is running. If the lamp comes on and

stays on while the engine is running, it indicates

that a charging system malfunction exists. One side

of the bulb is connected to ignition-switched battery

feed. The other side of the bulb is switched to ground

by the Powertrain Control Module (PCM).

JINSTRUMENT PANEL AND GAUGESÐXJ 8E - 3

Page 356 of 2198

Connect battery negative cable and turn ignition

switch to ON. Lamp should light. If OK, repair open

circuit to brake warning switch. If not OK, replace

bulb.

(5) Turn ignition switch to OFF and remove

jumper wire. Disconnect battery negative cable.

Check for continuity between cavity A (cavity B -

RHD) of brake warning switch connector and a good

ground with ignition switch in START position.

There should be continuity. If not OK, go to next

step.

(6) Turn ignition switch to OFF and remove

jumper wire. Disconnect battery negative cable. Un-

plug ignition switch connector. Check for continuity

between ignition switch connector cavity 3 and a

good ground. There should be no continuity. If OK, go

to next step. If not OK, repair short circuit between

ignition switch and brake warning switch connectors

as required.

(7) Check for continuity between ignition switch

connector cavity 3 and brake warning switch connec-

tor cavity A (cavity B - RHD). There should be conti-

nuity. If OK, go to next step. If not OK, repair open

circuit as required.

(8) Check for continuity between metal steering

column jacket and a good ground. There should be

continuity. If OK, go to next step. If not OK, refer to

Group 19 - Steering to check steering column ground

clip installation.

(9) Turn ignition switch to START position and

hold there. Check for continuity between terminal 3

of ignition switch and a good ground. There should

be continuity. If not OK, replace ignition switch.

(10) Unplug brake warning switch connector.

Check for continuity between parking brake switch

connector and a good ground. There should be no

continuity. If OK, go to next step. If not OK, repair

short circuit as required.

(11) Check for continuity between parking brake

switch connector and cavity B (cavity A - RHD) of

brake warning switch connector. There should be

continuity. If OK, replace parking brake switch. If

not OK, repair open circuit to brake warning switch

as required.

COOLANT TEMPERATURE WARNING LAMP

The diagnosis found here addresses an inoperative

lamp condition. If the problem being diagnosed is re-

lated to lamp accuracy, be certain to confirm that

problem is with lamp and not with cooling system

performance. Actual engine coolant temperature

should be checked with a test gauge or thermometer

before proceeding with lamp diagnosis. Refer to

Group 7 - Cooling System for more information.

(1) Turn ignition switch to START position. Lamp

should light. If OK, go to next step. If not OK, go to

step 3.(2) Turn ignition switch to ON. Disconnect coolant

temperature switch connector (Fig. 1). Jump switch

connector to ground. Lamp should light. If OK, re-

place switch. If not OK, go to next step.

(3) Turn ignition switch to OFF. Disconnect battery

negative cable. Unplug coolant temperature switch

connector. Remove instrument cluster bezel and clus-

ter assembly. Disconnect cluster connector A and

probe cavity A1. Check for continuity to a good

ground. There should be no continuity. If OK, go to

next step. If not OK, repair short circuit to coolant

temperature switch or ignition switch as required.

(4) Connect cluster connector A to cluster. Install a

jumper wire from cavity A1 of cluster connector A to

a good ground. Connect battery negative cable and

turn ignition switch to ON. Lamp should light. If OK,

repair open circuit to coolant temperature switch or

ignition switch as required. If not OK, replace bulb.

FOUR-WHEEL DRIVE INDICATOR LAMPS

(1) Apply parking brake, start engine, vehicle in

4WD Lock or 4WD.

(2) Unplug switch and touch harness side of wire

to ground. Lamp should light. If OK, check switch

operation, replace if bad. If bulb is OK, repair open

to indicator.

GENERATOR WARNING LAMP

(1) Disconnect battery negative cable and unplug

PCM connector. Install a jumper wire between cavity

36 of PCM connector (Fig. 5) and a good ground. Con-

nect battery negative cable and turn ignition switch

to ON. Lamp should light. Unplug jumper wire and

lamp should go off. If OK, refer to Powertrain Diag-

nostic Procedures to check PCM. If not OK, go to

next step.

(2) Turn ignition switch to OFF and disconnect

battery negative cable. Remove instrument cluster

bezel and cluster assembly. Install a jumper wire be-

tween cavity B8 of cluster connector A and a good

ground. Connect battery negative cable and turn ig-

nition switch to ON. Lamp should light. If OK, go to

next step. If not OK, replace bulb.

(3) Turn ignition switch to OFF and disconnect

battery negative cable. Unplug cluster connector A.

Probe cavity B8 of cluster connector A and check for

continuity to a good ground. There should be no con-

tinuity. If OK, go to next step. If not OK, repair short

circuit as required.

(4) Check for continuity between cavity B8 of clus-

ter connector A and cavity 36 of PCM connector.

There should be continuity. If not OK, repair open

circuit as required.

HEADLAMP HIGH BEAM INDICATOR LAMP

(1) Check that headlamp high beams are func-

tional. If OK, go to next step. If not OK, refer to

Group 8L - Lamps for diagnosis of headlamp system.

JINSTRUMENT PANEL AND GAUGESÐXJ 8E - 13

Page 376 of 2198

(9) Turn ignition switch to START position and

hold there. Check for continuity between terminal for

circuit G11 of ignition switch and a good ground.

There should be continuity. If not OK, replace igni-

tion switch.

(10) Unplug brake warning switch connector.

Check for continuity between parking brake switch

connector and a good ground. There should be no

continuity. If OK, go to next step. If not OK, repair

short circuit as required.

(11) Check for continuity between parking brake

switch connector and brake warning switch connector

cavity for circuit G11. There should be continuity. If

OK, replace parking brake switch. If not OK, repair

open circuit to brake warning switch as required.

FOUR-WHEEL DRIVE INDICATOR LAMP

(1) Apply parking brake, start engine, vehicle in

4WD Lock or 4WD.

(2) Unplug switch and touch harness side of wire

to ground. Lamp should light. If OK, check switch

operation, replace if bad. If bulb is OK, repair open

to indicator.

HEADLAMP HIGH BEAM INDICATOR LAMP

(1) Check that headlamp high beams are func-

tional. If OK, go to next step. If not OK, refer to

Group 8L - Lamps for diagnosis of headlamp system.

(2) Disconnect battery negative cable. Remove left

instrument cluster bezel and main cluster assembly.

Unplug cluster connector. Connect battery negative

cable. Turn headlamps on and select high beam.

Check for battery voltage at cavity 17 of cluster con-

nector. If OK, replace indicator bulb. If not OK, re-

pair circuit to headlamp dimmer switch as required.

MALFUNCTION INDICATOR LAMP

The diagnosis found here addresses an inoperative

lamp condition. If the lamp comes on and stays on

with engine running, refer to Group 14 - Fuel System

for diagnosis. If no fuel or emission system problem

is found, the following procedure will help locate a

short or open in the lamp circuit.

(1) Disconnect battery negative cable. Unplug PCM

connector. Install a jumper wire from cavity 32 of

PCM connector (Fig. 5) to a good ground. Connect

battery negative cable. Turn ignition switch to ON.

Lamp should light. Remove jumper wire and lamp

should go OFF. If OK, refer to Powertrain Diagnostic

Procedures to check PCM. If not OK, go to next step.

(2) Turn ignition switch to OFF. Disconnect battery

negative cable. Remove left instrument cluster bezel

and main cluster assembly. Install a jumper wire

from cavity 2 of cluster connector to a good ground.

Connect battery negative cable. Turn ignition switch

to ON. Lamp should light. If OK, go to next step. If

not OK, replace bulb.(3) Turn ignition switch to OFF. Disconnect battery

negative cable. Unplug cluster connector. Check for

continuity between cavity 2 of cluster connector and

a good ground. There should be no continuity. If OK,

go to next step. If not OK, repair short circuit to

PCM as required.

(4) Check continuity between cavity 2 of cluster

connector and cavity 32 of PCM connector. There

should be continuity. If not OK, repair open circuit to

PCM as required.

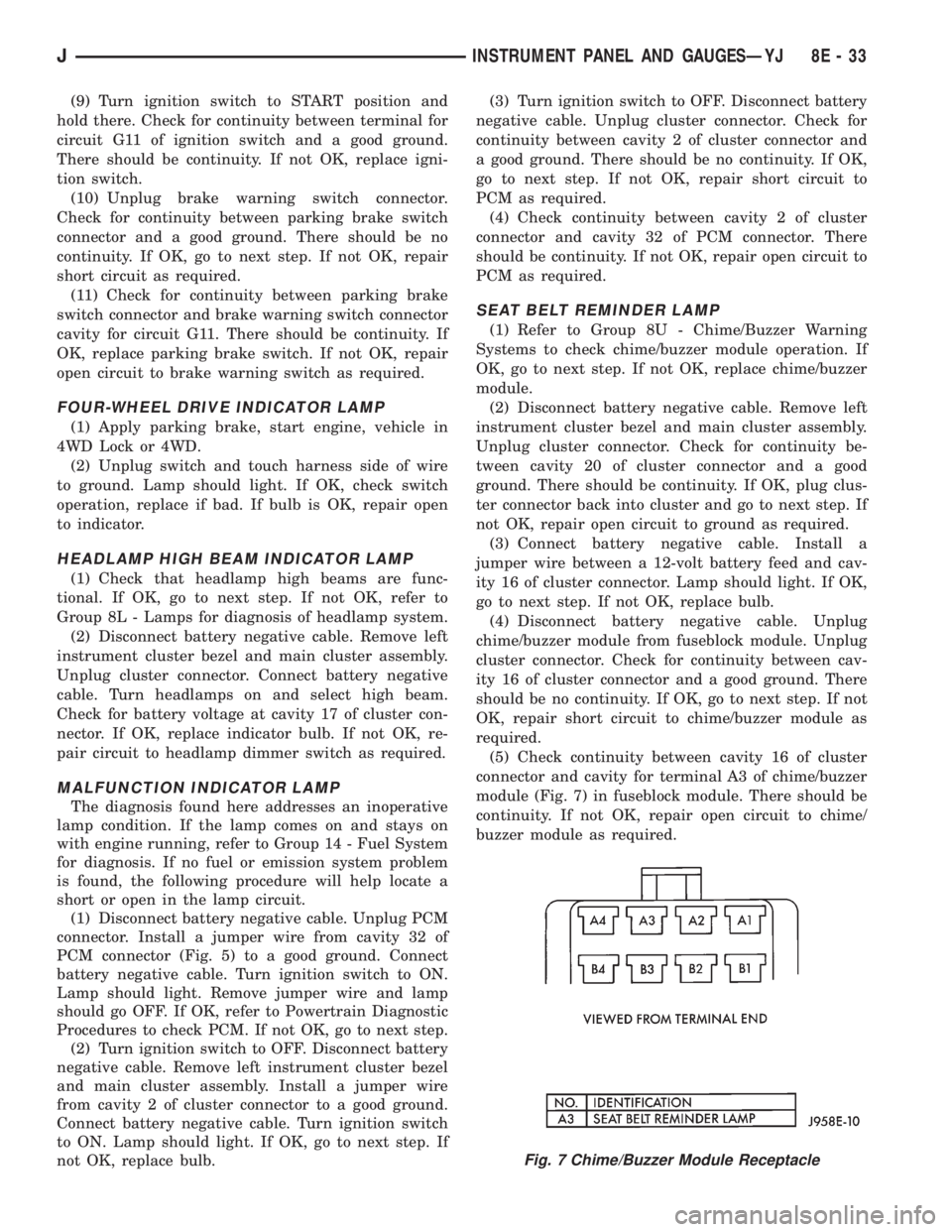

SEAT BELT REMINDER LAMP

(1) Refer to Group 8U - Chime/Buzzer Warning

Systems to check chime/buzzer module operation. If

OK, go to next step. If not OK, replace chime/buzzer

module.

(2) Disconnect battery negative cable. Remove left

instrument cluster bezel and main cluster assembly.

Unplug cluster connector. Check for continuity be-

tween cavity 20 of cluster connector and a good

ground. There should be continuity. If OK, plug clus-

ter connector back into cluster and go to next step. If

not OK, repair open circuit to ground as required.

(3) Connect battery negative cable. Install a

jumper wire between a 12-volt battery feed and cav-

ity 16 of cluster connector. Lamp should light. If OK,

go to next step. If not OK, replace bulb.

(4) Disconnect battery negative cable. Unplug

chime/buzzer module from fuseblock module. Unplug

cluster connector. Check for continuity between cav-

ity 16 of cluster connector and a good ground. There

should be no continuity. If OK, go to next step. If not

OK, repair short circuit to chime/buzzer module as

required.

(5) Check continuity between cavity 16 of cluster

connector and cavity for terminal A3 of chime/buzzer

module (Fig. 7) in fuseblock module. There should be

continuity. If not OK, repair open circuit to chime/

buzzer module as required.

Fig. 7 Chime/Buzzer Module Receptacle

JINSTRUMENT PANEL AND GAUGESÐYJ 8E - 33

Page 596 of 2198

TRANSMISSION CONTROLS

UPSHIFT LAMP

On vehicles equipped with a manual transmission,

the PCM grounds the up-shift lamp on circuit K54.

Circuit K54 connects to cavity 54 of the PCM.

FOUR-WHEEL DRIVE (4WD) SWITCH

When the 4WD switch closes, circuit Z1 provides

ground for the 4WD indicator lamp in the instrument

cluster. Circuit F87 connects to the instrument clus-

ter and supplies battery voltage to the 4WD indicator

lamp. Circuit 107 connects the indicator lamp to the

4WD switch. Circuit 106 connects the lamp to the in-

strument cluster and circuit F87.

TRANSMISSION CONTROL MODULEÐ4.0L

ENGINE ONLY

Vehicles equipped with the 4.0L engine have elec-

tronically controlled solenoids in the automatic trans-

mission valve body.

The Transmission Control Module (TCM) receives

inputs from the Throttle Position Sensor (TPS) on

circuit K22 and the stop lamp switch on circuit K29.

Circuit K4 connects to the TCM to provide ground for

the TPS signal. The TCM receives the transmission

output speed sensor signal on circuit T505. Circuit

A14 from fuse 2 in the Power Distribution Center

supplies battery voltage to the TCM. Circuit Z12 pro-

vides ground for the TCM.

The TCM powers the S1 solenoid on circuit T510,

the S2 solenoid on circuit T509, and the S3 solenoid

on circuit T508. Circuit Z12 provides ground for the

S1, S2, and S3 solenoids.

TORQUE CONVERTER CLUTCH (TCC) SOLENOID

AND RELAYÐ2.5L ENGINE ONLY

The TCC solenoid is only used on 2.5L engines

with the three-speed automatic transmissions. The

Powertrain Control Module (PCM) operates the TCC

solenoid by energizing the TCC relay.

Circuit T17 from fuse 12 in the Power Distribution

Center (PDC) supplies voltage to the coil and contact

sides of the TCC relay. When the PCM provides a

ground path on circuit K54 for the coil side of the re-

lay, the relay contacts close.

When the relay contacts close, they connect circuit

T17 with circuit T22. Circuit T22 supplies battery

voltage to the case grounded TCC solenoid. Circuit

K54 connects to PCM cavity 54.

HELPFUL INFORMATION

²In the RUN or START position, the ignition switch

connects circuit A1 from fuse 6 in the PDC to circuit

A21.

DIAGRAM INDEX

Component Page

4-WD Indicator Lamp......................8W-31-4

4-WD Indicator Switch.....................8W-31-4

Back-Up Lamp Switch.....................8W-31-3

Fuse 2 (PDC)...........................8W-31-4

Fuse 6 (PDC).........................8W-31-2, 3

Fuse 11 (PDC)..........................8W-31-3

Fuse 12 (PDC)..........................8W-31-2

Ignition Switch........................8W-31-2, 3

Powertrain Control Module..................8W-31-2

Park/Neutral Position Switch.................8W-31-3

TCC Relay.............................8W-31-2

TCC Solenoid...........................8W-31-2

Transmission Control Module.................8W-31-2

J8W-31 TRANSMISSION CONTROLSÐXJ VEHICLES 8W - 31 - 1

Page 614 of 2198

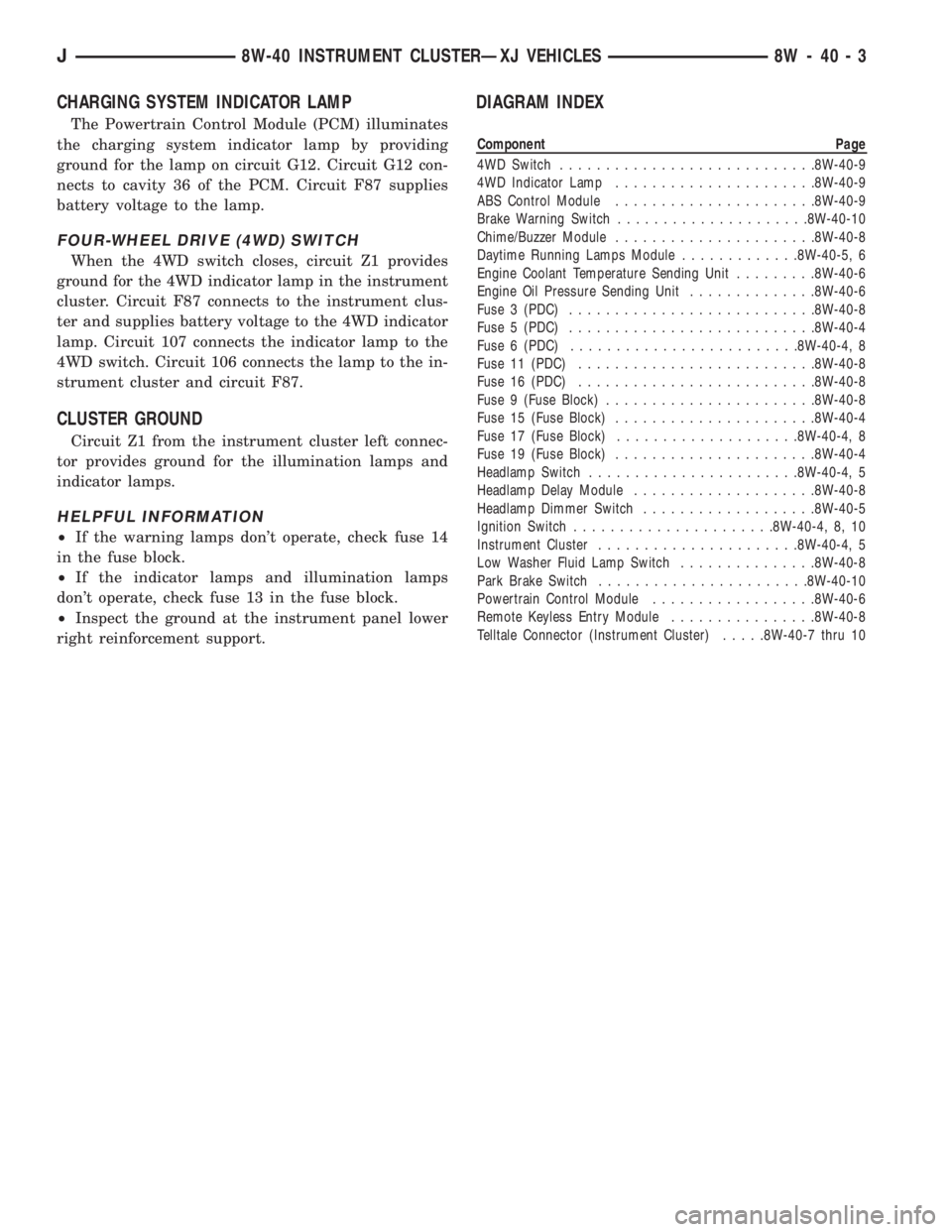

CHARGING SYSTEM INDICATOR LAMP

The Powertrain Control Module (PCM) illuminates

the charging system indicator lamp by providing

ground for the lamp on circuit G12. Circuit G12 con-

nects to cavity 36 of the PCM. Circuit F87 supplies

battery voltage to the lamp.

FOUR-WHEEL DRIVE (4WD) SWITCH

When the 4WD switch closes, circuit Z1 provides

ground for the 4WD indicator lamp in the instrument

cluster. Circuit F87 connects to the instrument clus-

ter and supplies battery voltage to the 4WD indicator

lamp. Circuit 107 connects the indicator lamp to the

4WD switch. Circuit 106 connects the lamp to the in-

strument cluster and circuit F87.

CLUSTER GROUND

Circuit Z1 from the instrument cluster left connec-

tor provides ground for the illumination lamps and

indicator lamps.

HELPFUL INFORMATION

²If the warning lamps don't operate, check fuse 14

in the fuse block.

²If the indicator lamps and illumination lamps

don't operate, check fuse 13 in the fuse block.

²Inspect the ground at the instrument panel lower

right reinforcement support.

DIAGRAM INDEX

Component Page

4WD Switch............................8W-40-9

4WD Indicator Lamp......................8W-40-9

ABS Control Module......................8W-40-9

Brake Warning Switch.....................8W-40-10

Chime/Buzzer Module......................8W-40-8

Daytime Running Lamps Module.............8W-40-5, 6

Engine Coolant Temperature Sending Unit.........8W-40-6

Engine Oil Pressure Sending Unit..............8W-40-6

Fuse 3 (PDC)...........................8W-40-8

Fuse 5 (PDC)...........................8W-40-4

Fuse 6 (PDC).........................8W-40-4, 8

Fuse 11 (PDC)..........................8W-40-8

Fuse 16 (PDC)..........................8W-40-8

Fuse 9 (Fuse Block).......................8W-40-8

Fuse 15 (Fuse Block)......................8W-40-4

Fuse 17 (Fuse Block)....................8W-40-4, 8

Fuse 19 (Fuse Block)......................8W-40-4

Headlamp Switch.......................8W-40-4, 5

Headlamp Delay Module....................8W-40-8

Headlamp Dimmer Switch...................8W-40-5

Ignition Switch......................8W-40-4, 8, 10

Instrument Cluster......................8W-40-4, 5

Low Washer Fluid Lamp Switch...............8W-40-8

Park Brake Switch.......................8W-40-10

Powertrain Control Module..................8W-40-6

Remote Keyless Entry Module................8W-40-8

Telltale Connector (Instrument Cluster).....8W-40-7 thru 10

J8W-40 INSTRUMENT CLUSTERÐXJ VEHICLES 8W - 40 - 3

Page 781 of 2198

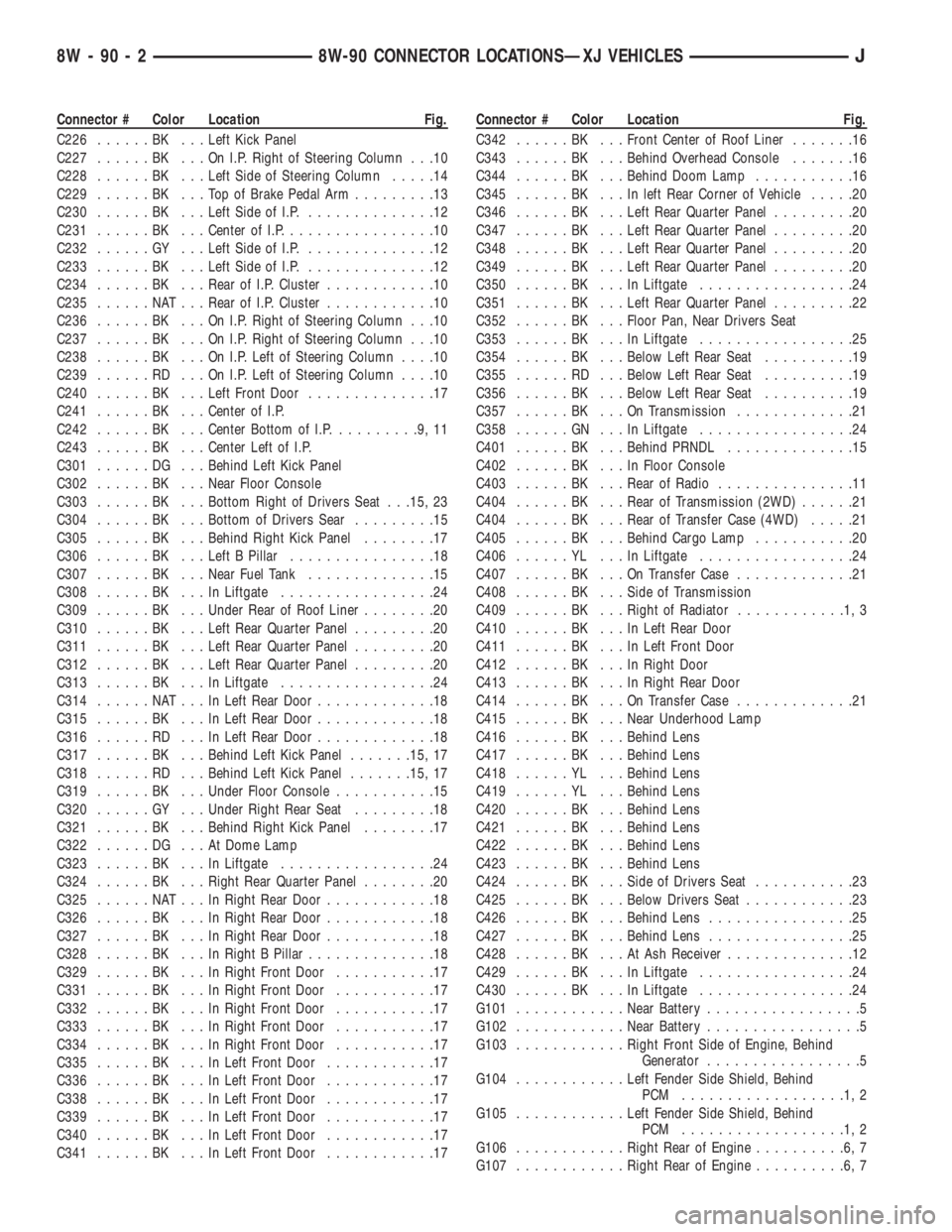

Connector # Color Location Fig.

C226......BK ...Left Kick Panel

C227......BK ...OnI.P.Right of Steering Column . . .10

C228......BK ...Left Side of Steering Column.....14

C229......BK ...TopofBrake Pedal Arm.........13

C230......BK ...Left Side of I.P...............12

C231......BK ...Center of I.P.................10

C232......GY ...Left Side of I.P...............12

C233......BK ...Left Side of I.P...............12

C234......BK ...Rear of I.P. Cluster............10

C235......NAT...Rear of I.P. Cluster............10

C236......BK ...OnI.P.Right of Steering Column . . .10

C237......BK ...OnI.P.Right of Steering Column . . .10

C238......BK ...OnI.P.Left of Steering Column....10

C239......RD ...OnI.P.Left of Steering Column....10

C240......BK ...Left Front Door..............17

C241......BK ...Center of I.P.

C242......BK ...Center Bottom of I.P..........9,11

C243......BK ...Center Left of I.P.

C301......DG ...Behind Left Kick Panel

C302......BK ...Near Floor Console

C303......BK ...Bottom Right of Drivers Seat . . .15, 23

C304......BK ...Bottom of Drivers Sear.........15

C305......BK ...Behind Right Kick Panel........17

C306......BK ...Left B Pillar................18

C307......BK ...Near Fuel Tank..............15

C308......BK ...InLiftgate.................24

C309......BK ...Under Rear of Roof Liner........20

C310......BK ...Left Rear Quarter Panel.........20

C311......BK ...Left Rear Quarter Panel.........20

C312......BK ...Left Rear Quarter Panel.........20

C313......BK ...InLiftgate.................24

C314......NAT...InLeft Rear Door.............18

C315......BK ...InLeft Rear Door.............18

C316......RD ...InLeft Rear Door.............18

C317......BK ...Behind Left Kick Panel.......15, 17

C318......RD ...Behind Left Kick Panel.......15, 17

C319......BK ...Under Floor Console...........15

C320......GY ...Under Right Rear Seat.........18

C321......BK ...Behind Right Kick Panel........17

C322......DG ...AtDome Lamp

C323......BK ...InLiftgate.................24

C324......BK ...Right Rear Quarter Panel........20

C325......NAT...InRight Rear Door............18

C326......BK ...InRight Rear Door............18

C327......BK ...InRight Rear Door............18

C328......BK ...InRight B Pillar..............18

C329......BK ...InRight Front Door...........17

C331......BK ...InRight Front Door...........17

C332......BK ...InRight Front Door...........17

C333......BK ...InRight Front Door...........17

C334......BK ...InRight Front Door...........17

C335......BK ...InLeft Front Door............17

C336......BK ...InLeft Front Door............17

C338......BK ...InLeft Front Door............17

C339......BK ...InLeft Front Door............17

C340......BK ...InLeft Front Door............17

C341......BK ...InLeft Front Door............17Connector # Color Location Fig.

C342......BK ...Front Center of Roof Liner.......16

C343......BK ...Behind Overhead Console.......16

C344......BK ...Behind Doom Lamp...........16

C345......BK ...Inleft Rear Corner of Vehicle.....20

C346......BK ...Left Rear Quarter Panel.........20

C347......BK ...Left Rear Quarter Panel.........20

C348......BK ...Left Rear Quarter Panel.........20

C349......BK ...Left Rear Quarter Panel.........20

C350......BK ...InLiftgate.................24

C351......BK ...Left Rear Quarter Panel.........22

C352......BK ...Floor Pan, Near Drivers Seat

C353......BK ...InLiftgate.................25

C354......BK ...Below Left Rear Seat..........19

C355......RD ...Below Left Rear Seat..........19

C356......BK ...Below Left Rear Seat..........19

C357......BK ...OnTransmission.............21

C358......GN ...InLiftgate.................24

C401......BK ...Behind PRNDL..............15

C402......BK ...InFloor Console

C403......BK ...Rear of Radio...............11

C404......BK ...Rear of Transmission (2WD)......21

C404......BK ...Rear of Transfer Case (4WD).....21

C405......BK ...Behind Cargo Lamp...........20

C406......YL ...InLiftgate.................24

C407......BK ...OnTransfer Case.............21

C408......BK ...Side of Transmission

C409......BK ...Right of Radiator............1,3

C410......BK ...InLeft Rear Door

C411......BK ...InLeft Front Door

C412......BK ...InRight Door

C413......BK ...InRight Rear Door

C414......BK ...OnTransfer Case.............21

C415......BK ...Near Underhood Lamp

C416......BK ...Behind Lens

C417......BK ...Behind Lens

C418......YL ...Behind Lens

C419......YL ...Behind Lens

C420......BK ...Behind Lens

C421......BK ...Behind Lens

C422......BK ...Behind Lens

C423......BK ...Behind Lens

C424......BK ...Side of Drivers Seat...........23

C425......BK ...Below Drivers Seat............23

C426......BK ...Behind Lens................25

C427......BK ...Behind Lens................25

C428......BK ...AtAshReceiver..............12

C429......BK ...InLiftgate.................24

C430......BK ...InLiftgate.................24

G101............Near Battery.................5

G102............Near Battery.................5

G103............Right Front Side of Engine, Behind

Generator.................5

G104............Left Fender Side Shield, Behind

PCM ..................1,2

G105............Left Fender Side Shield, Behind

PCM ..................1,2

G106............Right Rear of Engine..........6,7

G107............Right Rear of Engine..........6,7

8W - 90 - 2 8W-90 CONNECTOR LOCATIONSÐXJ VEHICLESJ