ECO mode JEEP CHEROKEE 1995 Service User Guide

[x] Cancel search | Manufacturer: JEEP, Model Year: 1995, Model line: CHEROKEE, Model: JEEP CHEROKEE 1995Pages: 2198, PDF Size: 82.83 MB

Page 198 of 2198

secondary brakeshoes move the shoes directly into

contact with the drum braking surface. The actuating

levers are interconnected by a system of cables and a

tensioner mechanism. The tensioner mechanism con-

trols parking brake adjustment.

A parking brake switch is used on all models. It is

mounted on the parking brake lever or foot pedal and

is actuated by movement of the lever/pedal. The

switch, which is in circuit with the red warning light

in the dash, will illuminate the warning light when-

ever the parking brakes are applied.

On XJ models, the cable tensioner is part of the lever

assembly. On YJ models, the tensioner and equalizer

are mounted in a bracket attached to the underbody.

On YJ models, the parking brake front cable is at-

tached to the foot pedal and cable tensioner. The ten-

sioner and rear cables are connected to the equalizer

(Fig. 1).

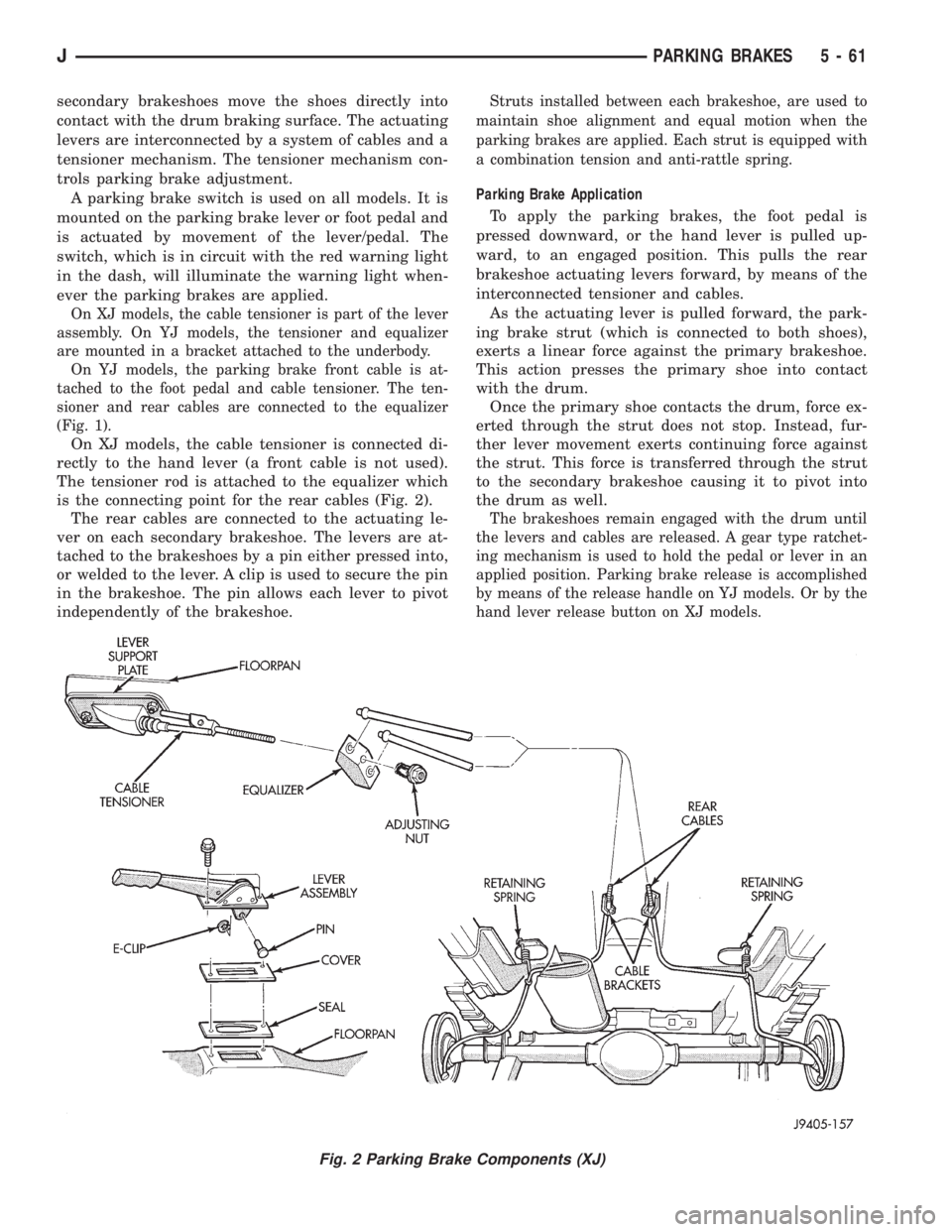

On XJ models, the cable tensioner is connected di-

rectly to the hand lever (a front cable is not used).

The tensioner rod is attached to the equalizer which

is the connecting point for the rear cables (Fig. 2).

The rear cables are connected to the actuating le-

ver on each secondary brakeshoe. The levers are at-

tached to the brakeshoes by a pin either pressed into,

or welded to the lever. A clip is used to secure the pin

in the brakeshoe. The pin allows each lever to pivot

independently of the brakeshoe.

Struts installed between each brakeshoe, are used to

maintain shoe alignment and equal motion when the

parking brakes are applied. Each strut is equipped with

a combination tension and anti-rattle spring.

Parking Brake Application

To apply the parking brakes, the foot pedal is

pressed downward, or the hand lever is pulled up-

ward, to an engaged position. This pulls the rear

brakeshoe actuating levers forward, by means of the

interconnected tensioner and cables.

As the actuating lever is pulled forward, the park-

ing brake strut (which is connected to both shoes),

exerts a linear force against the primary brakeshoe.

This action presses the primary shoe into contact

with the drum.

Once the primary shoe contacts the drum, force ex-

erted through the strut does not stop. Instead, fur-

ther lever movement exerts continuing force against

the strut. This force is transferred through the strut

to the secondary brakeshoe causing it to pivot into

the drum as well.

The brakeshoes remain engaged with the drum until

the levers and cables are released. A gear type ratchet-

ing mechanism is used to hold the pedal or lever in an

applied position. Parking brake release is accomplished

by means of the release handle on YJ models. Or by the

hand lever release button on XJ models.

Fig. 2 Parking Brake Components (XJ)

JPARKING BRAKES 5 - 61

Page 205 of 2198

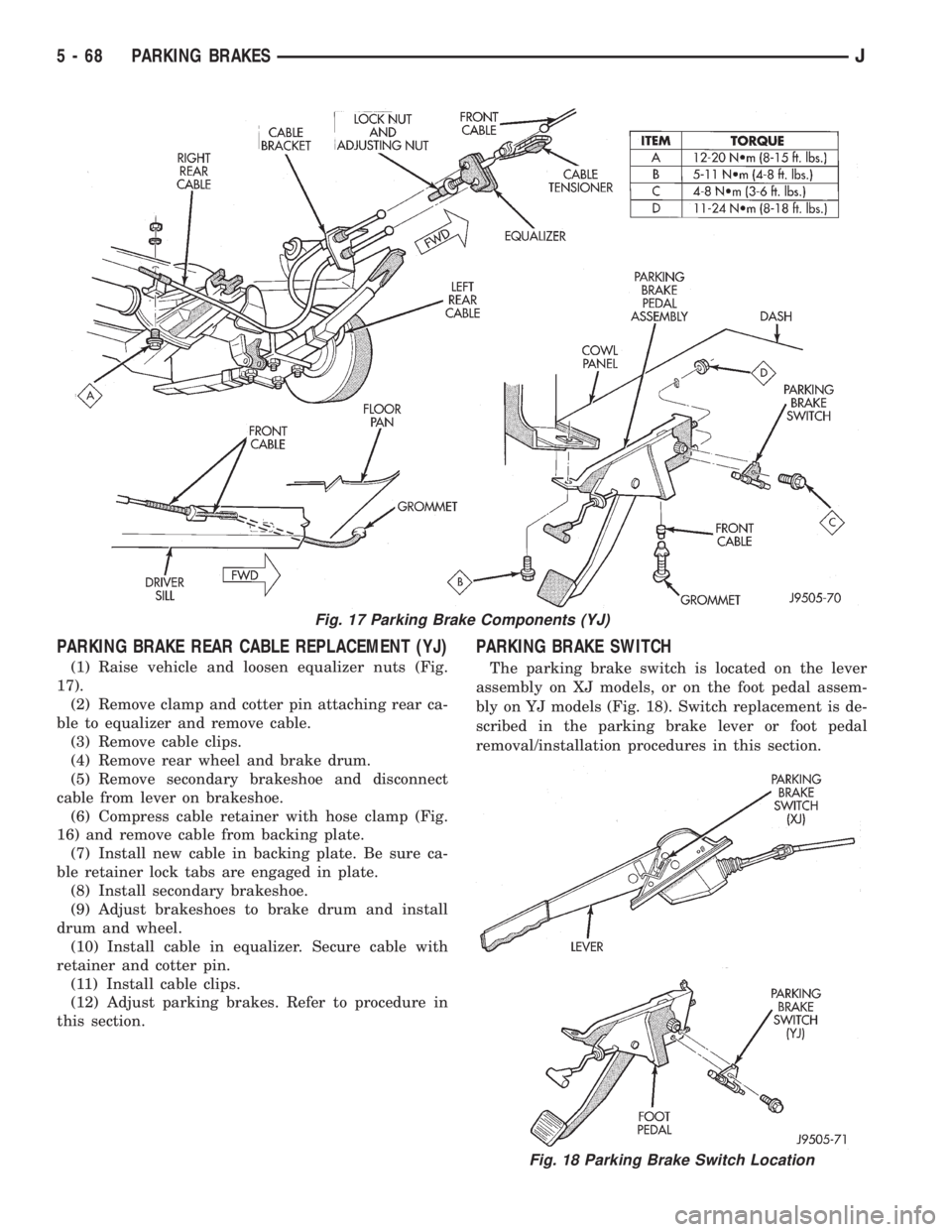

PARKING BRAKE REAR CABLE REPLACEMENT (YJ)

(1) Raise vehicle and loosen equalizer nuts (Fig.

17).

(2) Remove clamp and cotter pin attaching rear ca-

ble to equalizer and remove cable.

(3) Remove cable clips.

(4) Remove rear wheel and brake drum.

(5) Remove secondary brakeshoe and disconnect

cable from lever on brakeshoe.

(6) Compress cable retainer with hose clamp (Fig.

16) and remove cable from backing plate.

(7) Install new cable in backing plate. Be sure ca-

ble retainer lock tabs are engaged in plate.

(8) Install secondary brakeshoe.

(9) Adjust brakeshoes to brake drum and install

drum and wheel.

(10) Install cable in equalizer. Secure cable with

retainer and cotter pin.

(11) Install cable clips.

(12) Adjust parking brakes. Refer to procedure in

this section.

PARKING BRAKE SWITCH

The parking brake switch is located on the lever

assembly on XJ models, or on the foot pedal assem-

bly on YJ models (Fig. 18). Switch replacement is de-

scribed in the parking brake lever or foot pedal

removal/installation procedures in this section.

Fig. 17 Parking Brake Components (YJ)

Fig. 18 Parking Brake Switch Location

5 - 68 PARKING BRAKESJ

Page 220 of 2198

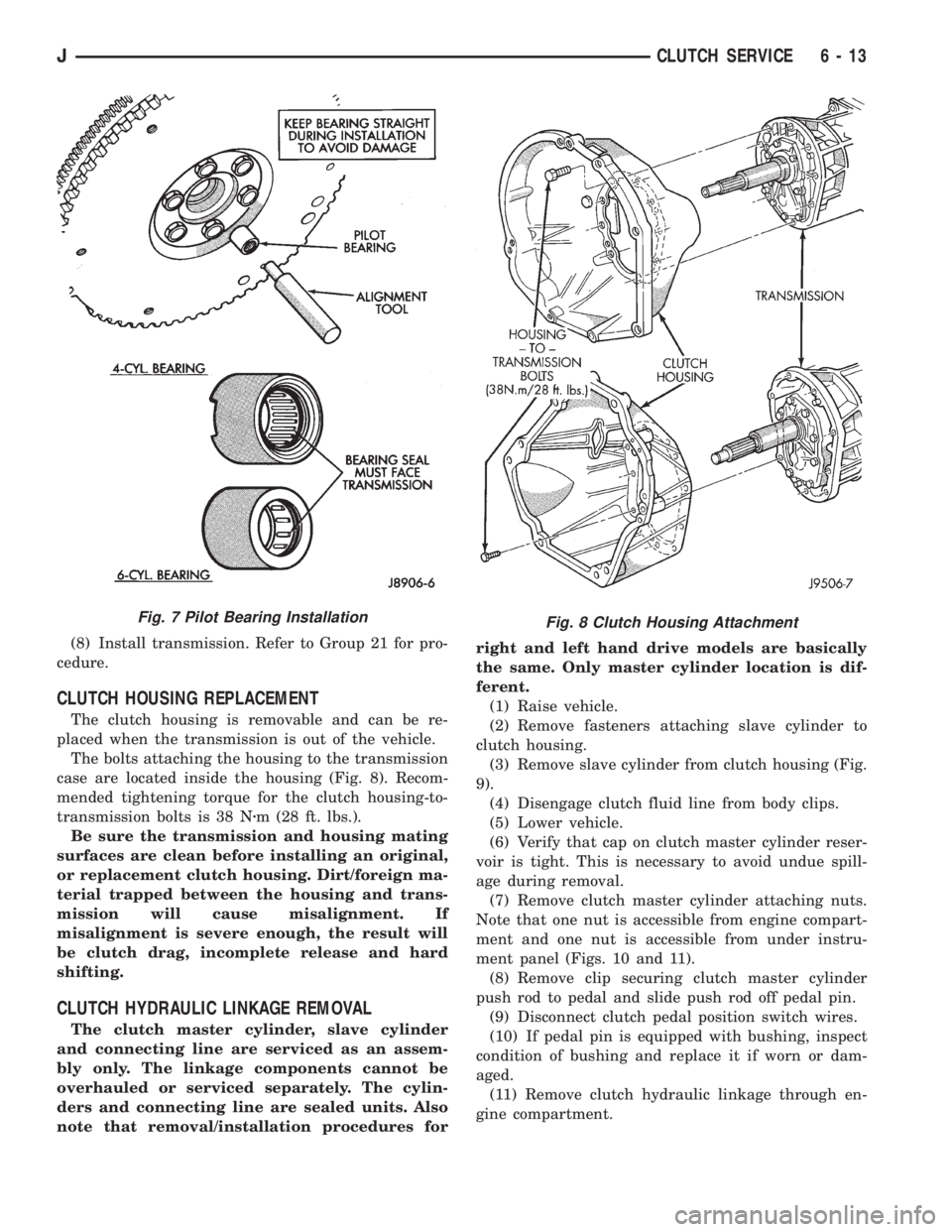

(8) Install transmission. Refer to Group 21 for pro-

cedure.

CLUTCH HOUSING REPLACEMENT

The clutch housing is removable and can be re-

placed when the transmission is out of the vehicle.

The bolts attaching the housing to the transmission

case are located inside the housing (Fig. 8). Recom-

mended tightening torque for the clutch housing-to-

transmission bolts is 38 Nzm (28 ft. lbs.).

Be sure the transmission and housing mating

surfaces are clean before installing an original,

or replacement clutch housing. Dirt/foreign ma-

terial trapped between the housing and trans-

mission will cause misalignment. If

misalignment is severe enough, the result will

be clutch drag, incomplete release and hard

shifting.

CLUTCH HYDRAULIC LINKAGE REMOVAL

The clutch master cylinder, slave cylinder

and connecting line are serviced as an assem-

bly only. The linkage components cannot be

overhauled or serviced separately. The cylin-

ders and connecting line are sealed units. Also

note that removal/installation procedures forright and left hand drive models are basically

the same. Only master cylinder location is dif-

ferent.

(1) Raise vehicle.

(2) Remove fasteners attaching slave cylinder to

clutch housing.

(3) Remove slave cylinder from clutch housing (Fig.

9).

(4) Disengage clutch fluid line from body clips.

(5) Lower vehicle.

(6) Verify that cap on clutch master cylinder reser-

voir is tight. This is necessary to avoid undue spill-

age during removal.

(7) Remove clutch master cylinder attaching nuts.

Note that one nut is accessible from engine compart-

ment and one nut is accessible from under instru-

ment panel (Figs. 10 and 11).

(8) Remove clip securing clutch master cylinder

push rod to pedal and slide push rod off pedal pin.

(9) Disconnect clutch pedal position switch wires.

(10) If pedal pin is equipped with bushing, inspect

condition of bushing and replace it if worn or dam-

aged.

(11) Remove clutch hydraulic linkage through en-

gine compartment.

Fig. 8 Clutch Housing AttachmentFig. 7 Pilot Bearing Installation

JCLUTCH SERVICE 6 - 13

Page 229 of 2198

DIAGNOSIS

INDEX

page page

DRB Scan Tool............................ 5

On-Board Diagnostics (OBD).................. 4Preliminary Checks......................... 5

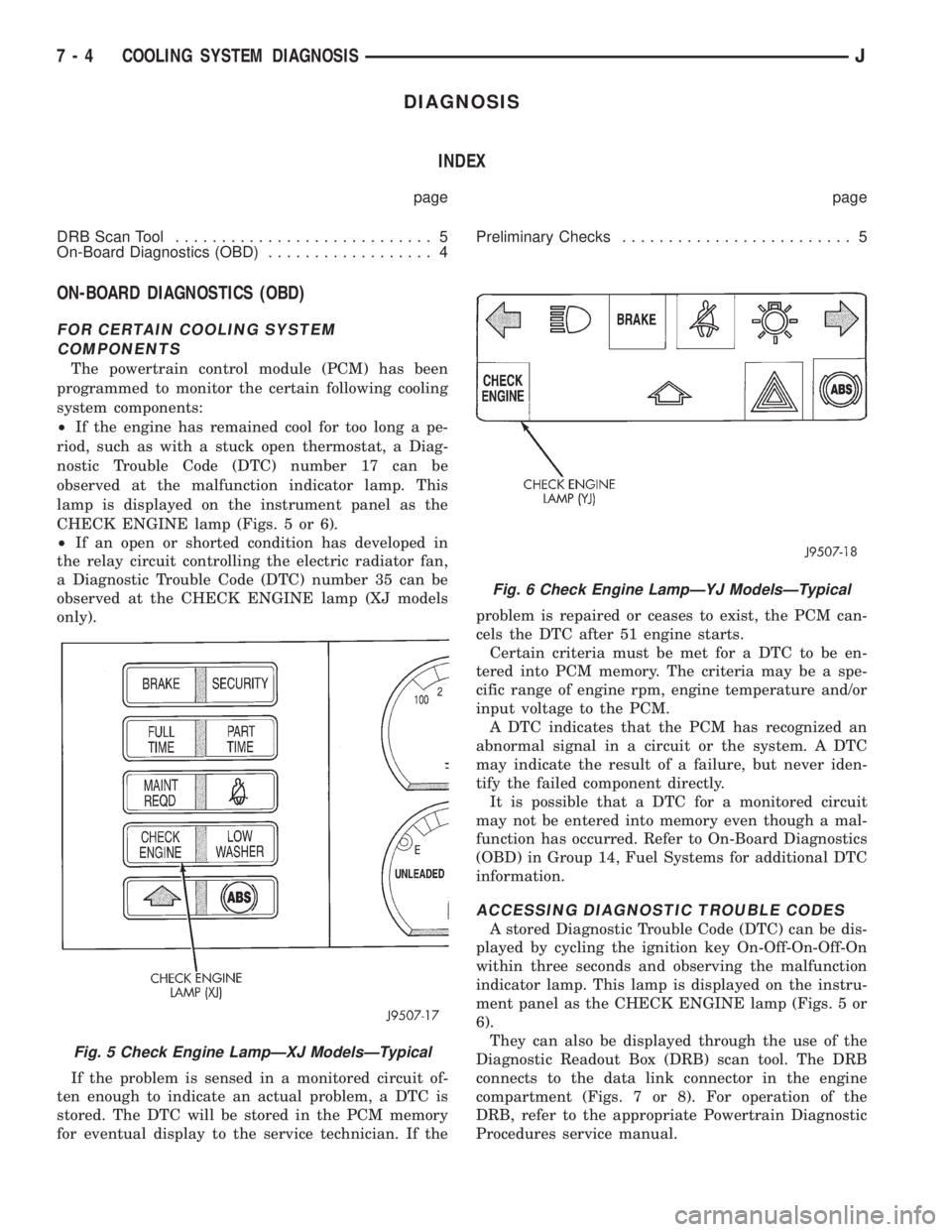

ON-BOARD DIAGNOSTICS (OBD)

FOR CERTAIN COOLING SYSTEM

COMPONENTS

The powertrain control module (PCM) has been

programmed to monitor the certain following cooling

system components:

²If the engine has remained cool for too long a pe-

riod, such as with a stuck open thermostat, a Diag-

nostic Trouble Code (DTC) number 17 can be

observed at the malfunction indicator lamp. This

lamp is displayed on the instrument panel as the

CHECK ENGINE lamp (Figs. 5 or 6).

²If an open or shorted condition has developed in

the relay circuit controlling the electric radiator fan,

a Diagnostic Trouble Code (DTC) number 35 can be

observed at the CHECK ENGINE lamp (XJ models

only).

If the problem is sensed in a monitored circuit of-

ten enough to indicate an actual problem, a DTC is

stored. The DTC will be stored in the PCM memory

for eventual display to the service technician. If theproblem is repaired or ceases to exist, the PCM can-

cels the DTC after 51 engine starts.

Certain criteria must be met for a DTC to be en-

tered into PCM memory. The criteria may be a spe-

cific range of engine rpm, engine temperature and/or

input voltage to the PCM.

A DTC indicates that the PCM has recognized an

abnormal signal in a circuit or the system. A DTC

may indicate the result of a failure, but never iden-

tify the failed component directly.

It is possible that a DTC for a monitored circuit

may not be entered into memory even though a mal-

function has occurred. Refer to On-Board Diagnostics

(OBD) in Group 14, Fuel Systems for additional DTC

information.

ACCESSING DIAGNOSTIC TROUBLE CODES

A stored Diagnostic Trouble Code (DTC) can be dis-

played by cycling the ignition key On-Off-On-Off-On

within three seconds and observing the malfunction

indicator lamp. This lamp is displayed on the instru-

ment panel as the CHECK ENGINE lamp (Figs. 5 or

6).

They can also be displayed through the use of the

Diagnostic Readout Box (DRB) scan tool. The DRB

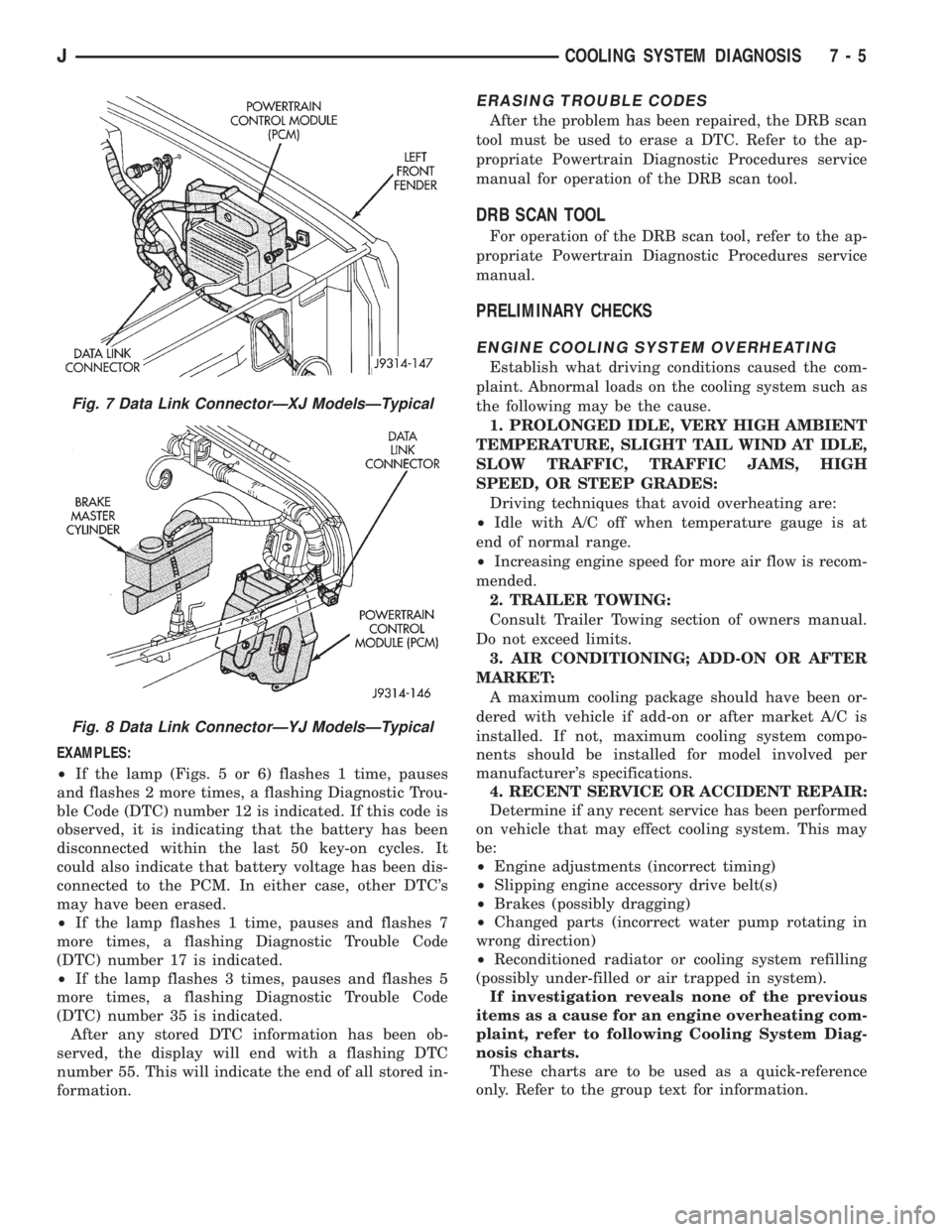

connects to the data link connector in the engine

compartment (Figs. 7 or 8). For operation of the

DRB, refer to the appropriate Powertrain Diagnostic

Procedures service manual.

Fig. 5 Check Engine LampÐXJ ModelsÐTypical

Fig. 6 Check Engine LampÐYJ ModelsÐTypical

7 - 4 COOLING SYSTEM DIAGNOSISJ

Page 230 of 2198

EXAMPLES:

²If the lamp (Figs. 5 or 6) flashes 1 time, pauses

and flashes 2 more times, a flashing Diagnostic Trou-

ble Code (DTC) number 12 is indicated. If this code is

observed, it is indicating that the battery has been

disconnected within the last 50 key-on cycles. It

could also indicate that battery voltage has been dis-

connected to the PCM. In either case, other DTC's

may have been erased.

²If the lamp flashes 1 time, pauses and flashes 7

more times, a flashing Diagnostic Trouble Code

(DTC) number 17 is indicated.

²If the lamp flashes 3 times, pauses and flashes 5

more times, a flashing Diagnostic Trouble Code

(DTC) number 35 is indicated.

After any stored DTC information has been ob-

served, the display will end with a flashing DTC

number 55. This will indicate the end of all stored in-

formation.

ERASING TROUBLE CODES

After the problem has been repaired, the DRB scan

tool must be used to erase a DTC. Refer to the ap-

propriate Powertrain Diagnostic Procedures service

manual for operation of the DRB scan tool.

DRB SCAN TOOL

For operation of the DRB scan tool, refer to the ap-

propriate Powertrain Diagnostic Procedures service

manual.

PRELIMINARY CHECKS

ENGINE COOLING SYSTEM OVERHEATING

Establish what driving conditions caused the com-

plaint. Abnormal loads on the cooling system such as

the following may be the cause.

1. PROLONGED IDLE, VERY HIGH AMBIENT

TEMPERATURE, SLIGHT TAIL WIND AT IDLE,

SLOW TRAFFIC, TRAFFIC JAMS, HIGH

SPEED, OR STEEP GRADES:

Driving techniques that avoid overheating are:

²Idle with A/C off when temperature gauge is at

end of normal range.

²Increasing engine speed for more air flow is recom-

mended.

2. TRAILER TOWING:

Consult Trailer Towing section of owners manual.

Do not exceed limits.

3. AIR CONDITIONING; ADD-ON OR AFTER

MARKET:

A maximum cooling package should have been or-

dered with vehicle if add-on or after market A/C is

installed. If not, maximum cooling system compo-

nents should be installed for model involved per

manufacturer's specifications.

4. RECENT SERVICE OR ACCIDENT REPAIR:

Determine if any recent service has been performed

on vehicle that may effect cooling system. This may

be:

²Engine adjustments (incorrect timing)

²Slipping engine accessory drive belt(s)

²Brakes (possibly dragging)

²Changed parts (incorrect water pump rotating in

wrong direction)

²Reconditioned radiator or cooling system refilling

(possibly under-filled or air trapped in system).

If investigation reveals none of the previous

items as a cause for an engine overheating com-

plaint, refer to following Cooling System Diag-

nosis charts.

These charts are to be used as a quick-reference

only. Refer to the group text for information.

Fig. 7 Data Link ConnectorÐXJ ModelsÐTypical

Fig. 8 Data Link ConnectorÐYJ ModelsÐTypical

JCOOLING SYSTEM DIAGNOSIS 7 - 5

Page 243 of 2198

temperature, coolant is allowed to flow to the radia-

tor. This provides quick engine warmup and overall

temperature control.

An arrow plus the wordUPis stamped on the

front flange next to the air bleed. The wordsTO

RADare stamped on one arm of the thermostat.

They indicate the proper installed position.

The same thermostat is used for winter and sum-

mer seasons. An engine should not be operated with-

out a thermostat, except for servicing or testing.

Operating without a thermostat causes other prob-

lems. These are: longer engine warmup time, unreli-

able warmup performance, increased exhaust

emissions and crankcase condensation. This conden-

sation can result in sludge formation.

CAUTION: Do not operate an engine without a ther-

mostat, except for servicing or testing.

ON-BOARD DIAGNOSTICS

XJ and YJ models are equipped with On-Board Di-

agnostics for certain cooling system components. Re-

fer to On-Board Diagnostics (OBD) in the Diagnosis

section of this group for additional information. If the

powertrain control module (PCM) detects low engine

coolant temperature, it will record a Diagnostic Trou-

ble Code (DTC) in the PCM memory. The DTC num-

ber for low coolant temperature is 17. Do not change

a thermostat for lack of heat as indicated by the in-

strument panel gauge or heater performance unless a

DTC number 17 is present. Refer to the Diagnosis

section of this group for other probable causes. For

other DTC numbers, refer to On-Board Diagnostics

in the General Diagnosis section of Group 14, Fuel

Systems.

The DTC can also be accessed through the DRB

scan tool. Refer to the appropriate Powertrain Diag-

nostic Procedures manual for diagnostic information

and operation of the DRB scan tool.

REMOVAL

WARNING: DO NOT LOOSEN THE RADIATOR

DRAINCOCK WITH THE SYSTEM HOT AND PRES-

SURIZED. SERIOUS BURNS FROM THE COOLANT

CAN OCCUR.

DO NOT WASTE reusable coolant. If the solution

is clean, drain the coolant into a clean container for

reuse.

(1) Drain the coolant from the radiator until the

level is below the thermostat housing.

WARNING: CONSTANT TENSION HOSE CLAMPS

ARE USED ON MOST COOLING SYSTEM HOSES.

WHEN REMOVING OR INSTALLING, USE ONLY

TOOLS DESIGNED FOR SERVICING THIS TYPE OF

CLAMP, SUCH AS SPECIAL CLAMP TOOL (NUMBER

6094) (FIG. 15). SNAP-ON CLAMP TOOL (NUMBER

HPC-20) MAY BE USED FOR LARGER CLAMPS. AL-

WAYS WEAR SAFETY GLASSES WHEN SERVICING

CONSTANT TENSION CLAMPS.

CAUTION: A number or letter is stamped into the

tongue of constant tension clamps (Fig. 16). If re-

placement is necessary, use only an original equip-

ment clamp with matching number or letter.

(2) Remove radiator upper hose and heater hose at

thermostat housing.

(3) Disconnect wiring connector at engine coolant

temperature sensor.

(4) Remove thermostat housing mounting bolts,

thermostat housing, gasket and thermostat (Fig. 17).

Discard old gasket.

(5) Clean the gasket mating surfaces.

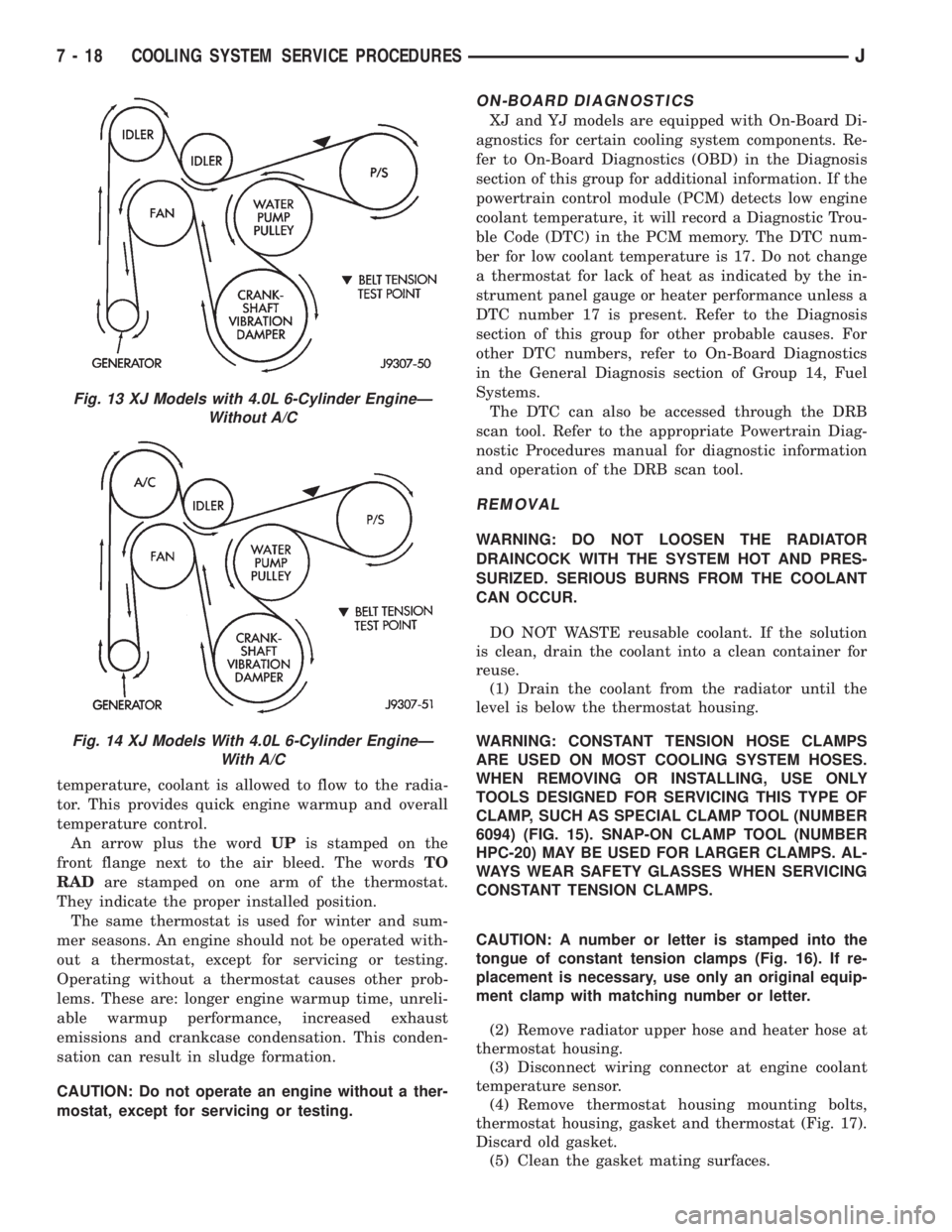

Fig. 13 XJ Models with 4.0L 6-Cylinder EngineÐ

Without A/C

Fig. 14 XJ Models With 4.0L 6-Cylinder EngineÐ

With A/C

7 - 18 COOLING SYSTEM SERVICE PROCEDURESJ

Page 251 of 2198

(4) When checking for vacuum leaks.

WARNING: IF VEHICLE HAS BEEN RUN RECENTLY,

WAIT AT LEAST 15 MINUTES BEFORE REMOVING

RADIATOR CAP. WITH A RAG, SQUEEZE RADIATOR

UPPER HOSE TO CHECK IF SYSTEM IS UNDER

PRESSURE. PLACE A RAG OVER THE CAP AND

WITHOUT PUSHING DOWN, ROTATE CAP

COUNTER-CLOCKWISE TO THE FIRST STOP. AL-

LOW FLUID TO ESCAPE THROUGH OVERFLOW

HOSE INTO COOLANT RESERVE/OVERFLOW

TANK. SQUEEZE RADIATOR UPPER HOSE TO DE-

TERMINE WHEN PRESSURE HAS BEEN RE-

LEASED. WHEN COOLANT AND STEAM STOP

BEING PUSHED INTO TANK AND SYSTEM PRES-

SURE DROPS, REMOVE RADIATOR CAP COM-

PLETELY.

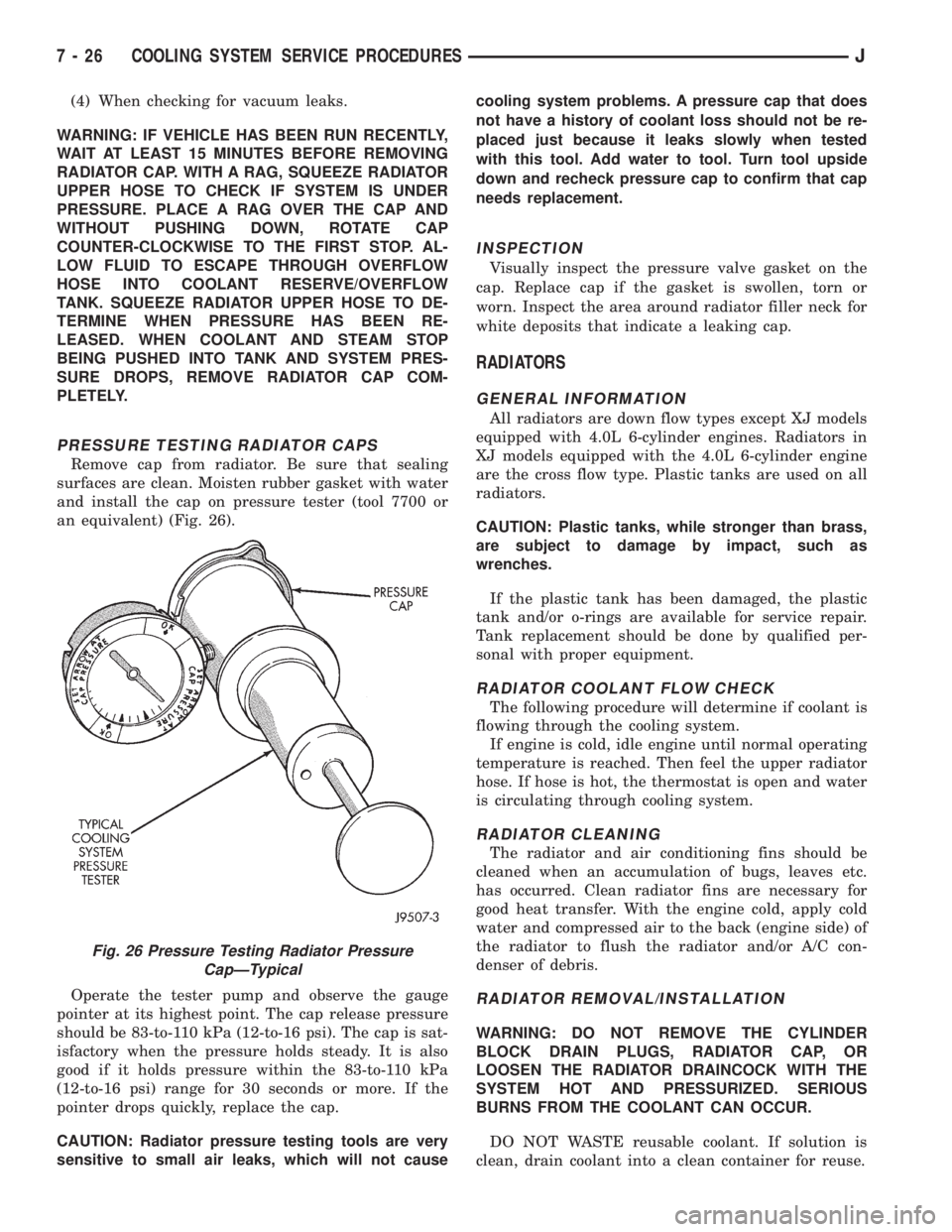

PRESSURE TESTING RADIATOR CAPS

Remove cap from radiator. Be sure that sealing

surfaces are clean. Moisten rubber gasket with water

and install the cap on pressure tester (tool 7700 or

an equivalent) (Fig. 26).

Operate the tester pump and observe the gauge

pointer at its highest point. The cap release pressure

should be 83-to-110 kPa (12-to-16 psi). The cap is sat-

isfactory when the pressure holds steady. It is also

good if it holds pressure within the 83-to-110 kPa

(12-to-16 psi) range for 30 seconds or more. If the

pointer drops quickly, replace the cap.

CAUTION: Radiator pressure testing tools are very

sensitive to small air leaks, which will not causecooling system problems. A pressure cap that does

not have a history of coolant loss should not be re-

placed just because it leaks slowly when tested

with this tool. Add water to tool. Turn tool upside

down and recheck pressure cap to confirm that cap

needs replacement.

INSPECTION

Visually inspect the pressure valve gasket on the

cap. Replace cap if the gasket is swollen, torn or

worn. Inspect the area around radiator filler neck for

white deposits that indicate a leaking cap.

RADIATORS

GENERAL INFORMATION

All radiators are down flow types except XJ models

equipped with 4.0L 6-cylinder engines. Radiators in

XJ models equipped with the 4.0L 6-cylinder engine

are the cross flow type. Plastic tanks are used on all

radiators.

CAUTION: Plastic tanks, while stronger than brass,

are subject to damage by impact, such as

wrenches.

If the plastic tank has been damaged, the plastic

tank and/or o-rings are available for service repair.

Tank replacement should be done by qualified per-

sonal with proper equipment.

RADIATOR COOLANT FLOW CHECK

The following procedure will determine if coolant is

flowing through the cooling system.

If engine is cold, idle engine until normal operating

temperature is reached. Then feel the upper radiator

hose. If hose is hot, the thermostat is open and water

is circulating through cooling system.

RADIATOR CLEANING

The radiator and air conditioning fins should be

cleaned when an accumulation of bugs, leaves etc.

has occurred. Clean radiator fins are necessary for

good heat transfer. With the engine cold, apply cold

water and compressed air to the back (engine side) of

the radiator to flush the radiator and/or A/C con-

denser of debris.

RADIATOR REMOVAL/INSTALLATION

WARNING: DO NOT REMOVE THE CYLINDER

BLOCK DRAIN PLUGS, RADIATOR CAP, OR

LOOSEN THE RADIATOR DRAINCOCK WITH THE

SYSTEM HOT AND PRESSURIZED. SERIOUS

BURNS FROM THE COOLANT CAN OCCUR.

DO NOT WASTE reusable coolant. If solution is

clean, drain coolant into a clean container for reuse.

Fig. 26 Pressure Testing Radiator Pressure

CapÐTypical

7 - 26 COOLING SYSTEM SERVICE PROCEDURESJ

Page 261 of 2198

nostic Procedures manual for diagnostic information

and operation of the DRB scan tool.

To test operation of the fan relay only, refer to Re-

laysÐOperation/Testing. This can be found in Group

14, Fuel Systems.

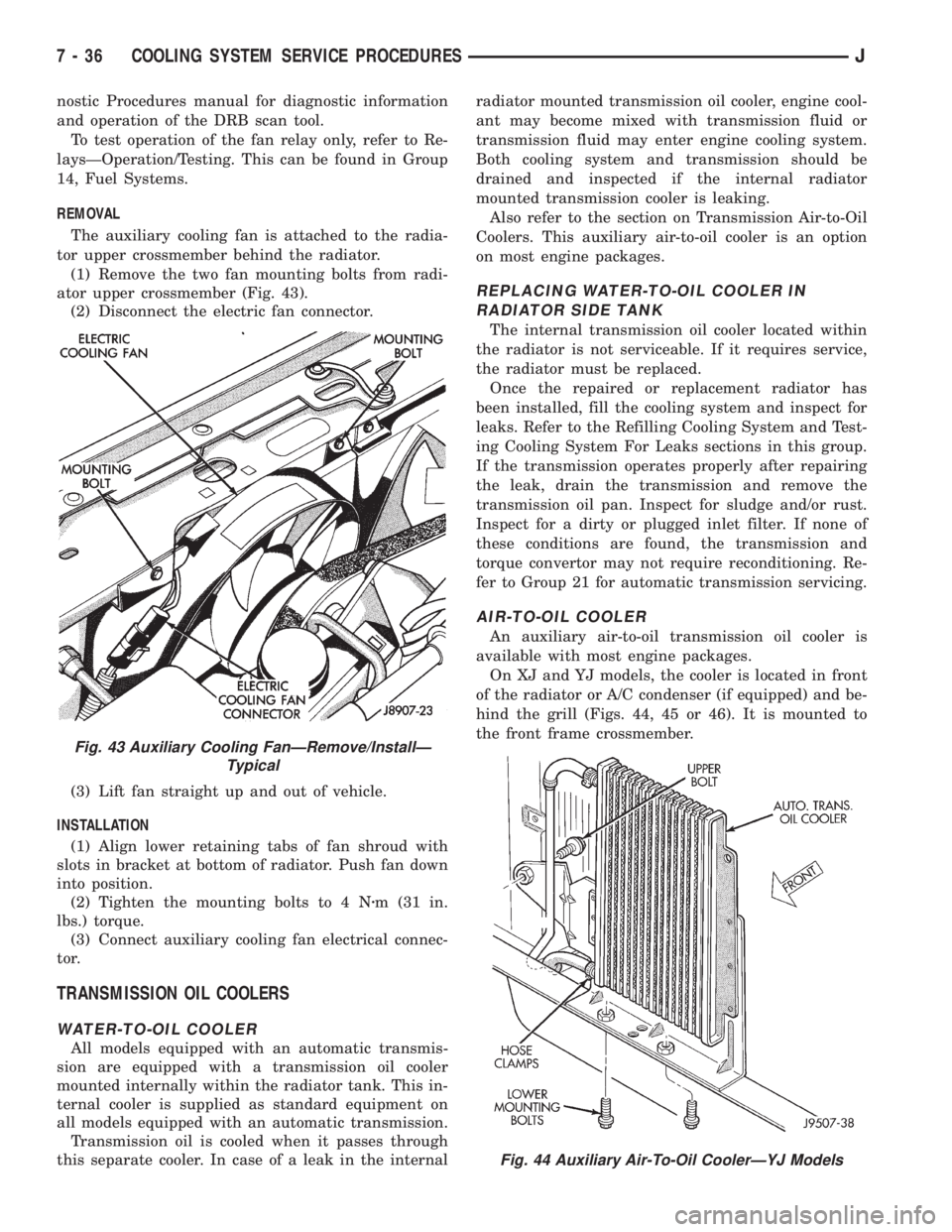

REMOVAL

The auxiliary cooling fan is attached to the radia-

tor upper crossmember behind the radiator.

(1) Remove the two fan mounting bolts from radi-

ator upper crossmember (Fig. 43).

(2) Disconnect the electric fan connector.

(3) Lift fan straight up and out of vehicle.

INSTALLATION

(1) Align lower retaining tabs of fan shroud with

slots in bracket at bottom of radiator. Push fan down

into position.

(2) Tighten the mounting bolts to 4 Nzm (31 in.

lbs.) torque.

(3) Connect auxiliary cooling fan electrical connec-

tor.

TRANSMISSION OIL COOLERS

WATER-TO-OIL COOLER

All models equipped with an automatic transmis-

sion are equipped with a transmission oil cooler

mounted internally within the radiator tank. This in-

ternal cooler is supplied as standard equipment on

all models equipped with an automatic transmission.

Transmission oil is cooled when it passes through

this separate cooler. In case of a leak in the internalradiator mounted transmission oil cooler, engine cool-

ant may become mixed with transmission fluid or

transmission fluid may enter engine cooling system.

Both cooling system and transmission should be

drained and inspected if the internal radiator

mounted transmission cooler is leaking.

Also refer to the section on Transmission Air-to-Oil

Coolers. This auxiliary air-to-oil cooler is an option

on most engine packages.

REPLACING WATER-TO-OIL COOLER IN

RADIATOR SIDE TANK

The internal transmission oil cooler located within

the radiator is not serviceable. If it requires service,

the radiator must be replaced.

Once the repaired or replacement radiator has

been installed, fill the cooling system and inspect for

leaks. Refer to the Refilling Cooling System and Test-

ing Cooling System For Leaks sections in this group.

If the transmission operates properly after repairing

the leak, drain the transmission and remove the

transmission oil pan. Inspect for sludge and/or rust.

Inspect for a dirty or plugged inlet filter. If none of

these conditions are found, the transmission and

torque convertor may not require reconditioning. Re-

fer to Group 21 for automatic transmission servicing.

AIR-TO-OIL COOLER

An auxiliary air-to-oil transmission oil cooler is

available with most engine packages.

On XJ and YJ models, the cooler is located in front

of the radiator or A/C condenser (if equipped) and be-

hind the grill (Figs. 44, 45 or 46). It is mounted to

the front frame crossmember.

Fig. 43 Auxiliary Cooling FanÐRemove/InstallÐ

Typical

Fig. 44 Auxiliary Air-To-Oil CoolerÐYJ Models

7 - 36 COOLING SYSTEM SERVICE PROCEDURESJ

Page 288 of 2198

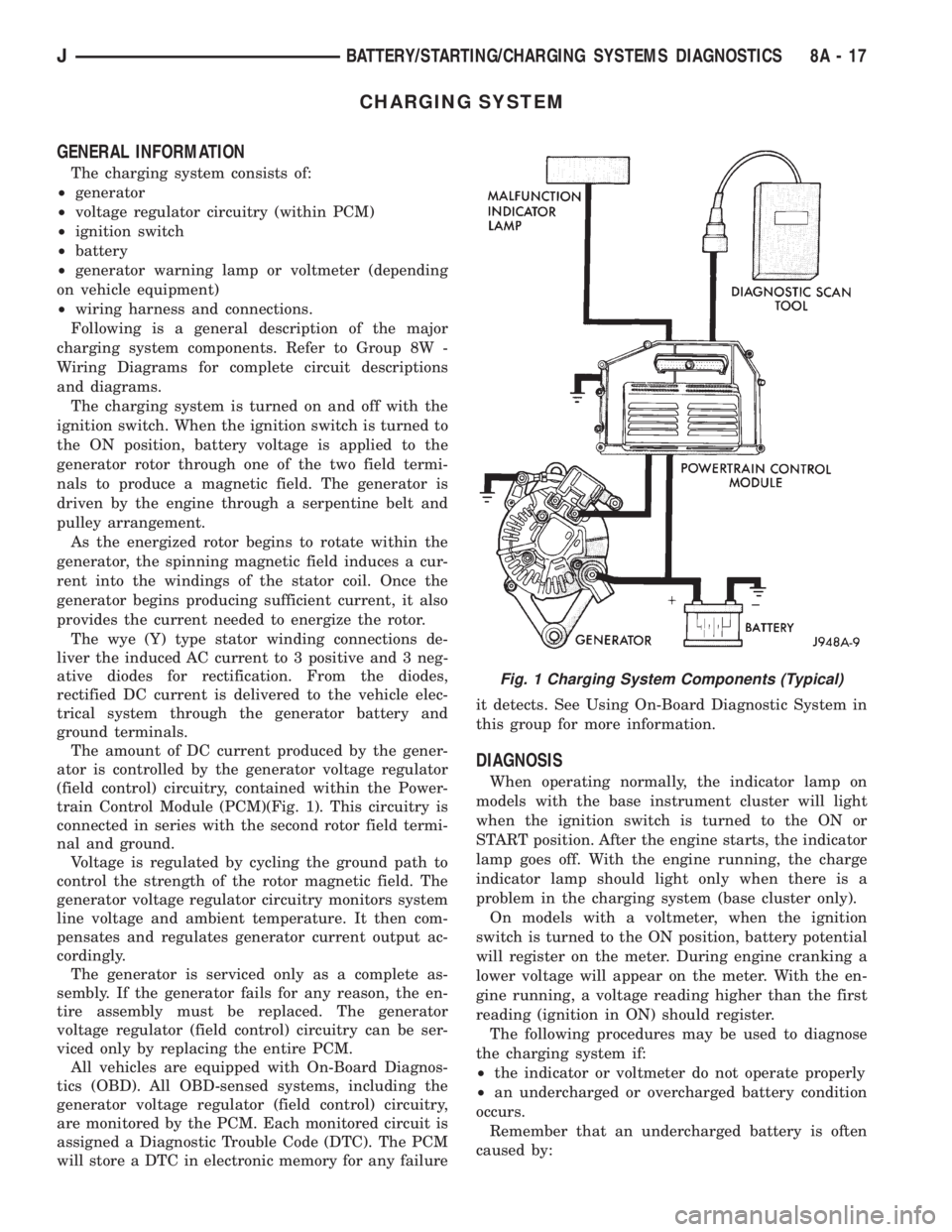

CHARGING SYSTEM

GENERAL INFORMATION

The charging system consists of:

²generator

²voltage regulator circuitry (within PCM)

²ignition switch

²battery

²generator warning lamp or voltmeter (depending

on vehicle equipment)

²wiring harness and connections.

Following is a general description of the major

charging system components. Refer to Group 8W -

Wiring Diagrams for complete circuit descriptions

and diagrams.

The charging system is turned on and off with the

ignition switch. When the ignition switch is turned to

the ON position, battery voltage is applied to the

generator rotor through one of the two field termi-

nals to produce a magnetic field. The generator is

driven by the engine through a serpentine belt and

pulley arrangement.

As the energized rotor begins to rotate within the

generator, the spinning magnetic field induces a cur-

rent into the windings of the stator coil. Once the

generator begins producing sufficient current, it also

provides the current needed to energize the rotor.

The wye (Y) type stator winding connections de-

liver the induced AC current to 3 positive and 3 neg-

ative diodes for rectification. From the diodes,

rectified DC current is delivered to the vehicle elec-

trical system through the generator battery and

ground terminals.

The amount of DC current produced by the gener-

ator is controlled by the generator voltage regulator

(field control) circuitry, contained within the Power-

train Control Module (PCM)(Fig. 1). This circuitry is

connected in series with the second rotor field termi-

nal and ground.

Voltage is regulated by cycling the ground path to

control the strength of the rotor magnetic field. The

generator voltage regulator circuitry monitors system

line voltage and ambient temperature. It then com-

pensates and regulates generator current output ac-

cordingly.

The generator is serviced only as a complete as-

sembly. If the generator fails for any reason, the en-

tire assembly must be replaced. The generator

voltage regulator (field control) circuitry can be ser-

viced only by replacing the entire PCM.

All vehicles are equipped with On-Board Diagnos-

tics (OBD). All OBD-sensed systems, including the

generator voltage regulator (field control) circuitry,

are monitored by the PCM. Each monitored circuit is

assigned a Diagnostic Trouble Code (DTC). The PCM

will store a DTC in electronic memory for any failureit detects. See Using On-Board Diagnostic System in

this group for more information.

DIAGNOSIS

When operating normally, the indicator lamp on

models with the base instrument cluster will light

when the ignition switch is turned to the ON or

START position. After the engine starts, the indicator

lamp goes off. With the engine running, the charge

indicator lamp should light only when there is a

problem in the charging system (base cluster only).

On models with a voltmeter, when the ignition

switch is turned to the ON position, battery potential

will register on the meter. During engine cranking a

lower voltage will appear on the meter. With the en-

gine running, a voltage reading higher than the first

reading (ignition in ON) should register.

The following procedures may be used to diagnose

the charging system if:

²the indicator or voltmeter do not operate properly

²an undercharged or overcharged battery condition

occurs.

Remember that an undercharged battery is often

caused by:

Fig. 1 Charging System Components (Typical)

JBATTERY/STARTING/CHARGING SYSTEMS DIAGNOSTICS 8A - 17

Page 304 of 2198

OVERHEAD CONSOLE

CONTENTS

page page

DIAGNOSIS............................. 2

GENERAL INFORMATION.................. 1SERVICE PROCEDURES................... 5

GENERAL INFORMATION

An overhead console featuring an electronic com-

pass and thermometer is an available option for XJ

(Cherokee) models. Following are general descrip-

tions of major components used in the overhead con-

sole. Refer to Group 8W - Wiring Diagrams for

complete circuit descriptions and diagrams.

COMPASS

The compass will display the direction in which the

vehicle is pointed using the eight major compass

headings (Examples: north is N, northeast is NE). It

does not display the headings in actual degrees. The

display is turned on or off using the COMP/TEMP

button to the left of the display.

The self-calibrating compass unit requires no ad-

justing in normal use. The only calibration that may

prove necessary is to drive the vehicle in 3 complete

circles, on level ground, in not less than 48 seconds.

This will reorient the unit to its vehicle.

The unit also will compensate for magnetism the

body of the vehicle may acquire during normal use.

However, avoid placing anything magnetic directly on

the roof of the vehicle. Magnetic mounts for an an-

tenna, a repair order hat or a funeral procession flag

can exceed the compensating ability of the compass

unit if placed on the roof panel. Magnetic bit drivers

used on the fasteners that hold the assembly to the

roof header can also affect compass operation.

If the vehicle roof should become magnetized, the

demagnetizing and calibration procedures may be re-

quired to restore proper operation.

THERMOMETER

The thermometer displays the outside ambient

temperature. The temperature displayed can be

changed from Fahrenheit to Celsius using the US/

METRIC button. The displayed temperature is not

an instant reading of conditions, but an average tem-

perature. It may take the unit several minutes to re-

act to a major temperature change such as driving

out of a heated garage into winter temperatures.

When the ignition switch is turned OFF, the lastdisplayed temperature reading stays in memory.

When the ignition switch is turned ON again, the

thermometer will display the memory temperature

for one minute; then update the display to the cur-

rent average temperature reading within five min-

utes.

READING AND COURTESY LAMPS

All reading and courtesy lamps in the overhead

console are activated by the door jamb switches.

When all doors and the liftgate are closed, the lamps

can be individually activated by depressing the corre-

sponding lens. When a door and/or the liftgate is

open, depressing the lamp lens switches will not turn

the lamps off. Refer to Group 8L - Lamps, for diag-

nosis and service of these lamps.

KEYLESS ENTRY RECEIVER

The overhead console houses the keyless entry re-

ceiver. Refer to Group 8P - Power Locks, for diagno-

sis and service of this component.

REMOTE GARAGE DOOR OPENER STORAGE

A compartment in the overhead console is designed

to hold most remote garage door opener transmitters.

The transmitter is mounted within the compartment

with an adhesive-backed hook and loop fastener

patch. Then one to three pegs are selected and

mounted on a post on the inside of the storage com-

partment door. The pegs may be stacked, if neces-

sary. The peg(s) selected must be long enough to

activate the button of the transmitter each time the

storage compartment door is depressed.

SUNGLASSES STORAGE

A flocked storage compartment for sunglasses is in-

cluded in the overhead console. This compartment

features a push/push-type latch and a viscous damp-

ening system for a fluid opening motion.

JOVERHEAD CONSOLE 8C - 1