keyless JEEP CHEROKEE 1995 Service User Guide

[x] Cancel search | Manufacturer: JEEP, Model Year: 1995, Model line: CHEROKEE, Model: JEEP CHEROKEE 1995Pages: 2198, PDF Size: 82.83 MB

Page 532 of 2198

FUSE/FUSE BLOCK

GENERAL INFORMATION

This section covers the Fuse Block and all circuits

involved with it. For additional information on sys-

tem operation, refer to the appropriate section of the

wiring diagrams.

DIAGRAM INDEX

Component Page

ABS Control Module......................8W-10-4

ABS Warning Lamp Relay...................8W-10-2

Chime/Buzzer Module.................8W-10-2, 9, 10

Circuit Breaker Cavity 16...................8W-10-12

In-Line Circuit Breaker (Wipers)...............8W-10-5

In-Line Circuit Breaker (Stop Lamp Relay)........8W-10-12

Daytime Running Lamps Module..............8W-10-8

Fuse 1 (Fuse Block).......................8W-10-4

Fuse 2 (Fuse Block).......................8W-10-5

Fuse 3 (Fuse Block).....................8W-10-4, 8

Fuse 3 (PDC)........................8W-10-6, 12

Fuse 4 (Fuse Block).......................8W-10-7

Fuse 5 (Fuse Block).......................8W-10-5

Fuse 5 (PDC)........................8W-10-7, 10

Fuse 6 (Fuse Block).......................8W-10-4

Fuse 6 (PDC).........................8W-10-4, 8

Fuse 7 (Fuse Block)....................8W-10-4, 10

Fuse 8 (Fuse Block).......................8W-10-5

Fuse 9 (Fuse Block).......................8W-10-6

Fuse 10 (Fuse Block)......................8W-10-4

Fuse 11 (Fuse Block)......................8W-10-9

Fuse 11 (PDC)..........................8W-10-8

Fuse 12 (PDC)..........................8W-10-8

Fuse 13 (Fuse Block)......................8W-10-9

Fuse 14 (Fuse Block)......................8W-10-9

Fuse 15 (Fuse Block)......................8W-10-7

Fuse 15 (PDC)..........................8W-10-6

Fuse 17 (Fuse Block)......................8W-10-9

Fuse Block.............................8W-10-2

Headlamp Delay Module....................8W-10-9

Headlamp Switch......................8W-10-7, 10

Heated Rear Window Relay.................8W-10-10

Ignition Switch........................8W-10-4, 8

Instrument Cluster.......................8W-10-11

Overhead Console.....................8W-10-9, 11

Powertrain Control Module..................8W-10-8

Remote Keyless Entry Module................8W-10-9

J8W-10 FUSE/FUSE BLOCKÐXJ VEHICLES 8W - 10 - 1

Page 544 of 2198

POWER DISTRIBUTION

GENERAL INFORMATION

This section covers the Power Distribution Center

(PDC) and all circuits involved with it. For additional

information on system operation, refer to the appro-

priate section of the wiring diagrams.

DIAGRAM INDEX

Component Page

A/C Compressor Clutch Relay..............8W-11-3, 11

ABS Control Module.....................8W-11-6, 7

ABS Power Relay......................8W-11-3, 6

ABS Pump Motor Relay..................8W-11-3, 7

Automatic Shut Down Relay................8W-11-3, 9

Chime/Buzzer Module..................8W-11-10, 14

Circuit Breaker Cavity 16 (Fuse Block)..........8W-11-13

Combination Flasher......................8W-11-17

Daytime Running Lamp Module.............8W-11-5, 10

Diode D101............................8W-11-6

Engine Starter Motor Relay................8W-11-3, 4

Fuel Pump Relay.......................8W-11-3, 8

Fuse 1 (PDC)..........................8W-11-13

Fuse 3 (PDC)..........................8W-11-12

Fuse 4 (Fuse Block)......................8W-11-14

Fuse 4 (PDC)..........................8W-11-15

Fuse 5 (PDC)..........................8W-11-14

Fuse 6 (PDC)....................8W-11-4, 7, 10, 15

Fuse 7 (Fuse Block).......................8W-11-7

Fuse 7 (PDC)...........................8W-11-4

Fuse 8 (PDC)...........................8W-11-7

Fuse 9 (Fuse Block)......................8W-11-12

Fuse 9 (PDC)..........................8W-11-13

Fuse 10 (PDC)........................8W-11-6, 8

Fuse 11 (Fuse Block).....................8W-11-13

Fuse 11 (PDC).........................8W-11-10

Fuse 12 (PDC).........................8W-11-15Component Page

Fuse 13 (PDC)..........................8W-11-4

Fuse 14 (PDC)..........................8W-11-8

Fuse 15 (Fuse Block).....................8W-11-14

Fuse 15 (PDC)..........................8W-11-8

Fuse 16 (PDC).........................8W-11-12

Fuse 17 (Fuse Block).....................8W-11-10

Headlamp Delay Module.................8W-11-10, 14

Headlamp Switch........................8W-11-14

Headlamp Dimmer Switch..................8W-11-14

Horn Rear Window Relay..................8W-11-17

Horn Relay............................8W-11-17

Ignition Switch...................8W-11-4, 7, 10, 15

In-Line Circuit Breaker (Stop Lamp Relay)........8W-11-13

LCD Illumination Relay....................8W-11-17

Overhead Console.....................8W-11-10, 14

Powertrain Control Module..........8W-11-4, 5, 8, 9, 11

Power Distribution Center...................8W-11-2

Power Door Lock Relay...................8W-11-16

Power Door Unlock Relay..................8W-11-16

Radiator Fan Control Relay................8W-11-3, 11

Remote Keyless Entry Module.............8W-11-10, 12

Relay Center...........................8W-11-16

Telltale Connector (I.P. Cluster)..........8W-11-6, 10, 12

Torque Converter Clutch (TCC) Relay...........8W-11-15

Transmission Control Module...............8W-11-5, 8

J8W-11 POWER DISTRIBUTIONÐXJ VEHICLES 8W - 11 - 1

Page 614 of 2198

CHARGING SYSTEM INDICATOR LAMP

The Powertrain Control Module (PCM) illuminates

the charging system indicator lamp by providing

ground for the lamp on circuit G12. Circuit G12 con-

nects to cavity 36 of the PCM. Circuit F87 supplies

battery voltage to the lamp.

FOUR-WHEEL DRIVE (4WD) SWITCH

When the 4WD switch closes, circuit Z1 provides

ground for the 4WD indicator lamp in the instrument

cluster. Circuit F87 connects to the instrument clus-

ter and supplies battery voltage to the 4WD indicator

lamp. Circuit 107 connects the indicator lamp to the

4WD switch. Circuit 106 connects the lamp to the in-

strument cluster and circuit F87.

CLUSTER GROUND

Circuit Z1 from the instrument cluster left connec-

tor provides ground for the illumination lamps and

indicator lamps.

HELPFUL INFORMATION

²If the warning lamps don't operate, check fuse 14

in the fuse block.

²If the indicator lamps and illumination lamps

don't operate, check fuse 13 in the fuse block.

²Inspect the ground at the instrument panel lower

right reinforcement support.

DIAGRAM INDEX

Component Page

4WD Switch............................8W-40-9

4WD Indicator Lamp......................8W-40-9

ABS Control Module......................8W-40-9

Brake Warning Switch.....................8W-40-10

Chime/Buzzer Module......................8W-40-8

Daytime Running Lamps Module.............8W-40-5, 6

Engine Coolant Temperature Sending Unit.........8W-40-6

Engine Oil Pressure Sending Unit..............8W-40-6

Fuse 3 (PDC)...........................8W-40-8

Fuse 5 (PDC)...........................8W-40-4

Fuse 6 (PDC).........................8W-40-4, 8

Fuse 11 (PDC)..........................8W-40-8

Fuse 16 (PDC)..........................8W-40-8

Fuse 9 (Fuse Block).......................8W-40-8

Fuse 15 (Fuse Block)......................8W-40-4

Fuse 17 (Fuse Block)....................8W-40-4, 8

Fuse 19 (Fuse Block)......................8W-40-4

Headlamp Switch.......................8W-40-4, 5

Headlamp Delay Module....................8W-40-8

Headlamp Dimmer Switch...................8W-40-5

Ignition Switch......................8W-40-4, 8, 10

Instrument Cluster......................8W-40-4, 5

Low Washer Fluid Lamp Switch...............8W-40-8

Park Brake Switch.......................8W-40-10

Powertrain Control Module..................8W-40-6

Remote Keyless Entry Module................8W-40-8

Telltale Connector (Instrument Cluster).....8W-40-7 thru 10

J8W-40 INSTRUMENT CLUSTERÐXJ VEHICLES 8W - 40 - 3

Page 632 of 2198

INTERIOR LIGHTING

INDEX

page page

Cargo Lamp, Courtesy Lamps and Dome Lamp.... 1

Chime/Buzzer Module....................... 2

Diagram Index............................ 2

General Information........................ 1

Glove Box Lamp........................... 1

Ignition Switch Lamp........................ 1Instrument Panel Illumination Lamps............ 1

Reading Lamps........................... 2

Time Delay Relay.......................... 1

Underhood Lamp.......................... 2

Visor Vanity Mirror Lamps.................... 2

GENERAL INFORMATION

Circuit M1 supplies power to the glove box lamp,

left courtesy lamp, right courtesy lamp, dome lamp,

and cargo lamp. The M1 circuit also connects to the

remote keyless entry module. Circuit M1 is protected

by the ignition off draw (IOD) fuse (fuse 9) in the fuse

block.

Circuit E2 supplies power for the instrument panel

illumination lamps.

INSTRUMENT PANEL ILLUMINATION LAMPS

Circuit E2 from the headlamp switch splices to

supply power to the following illumination lamps:

²Ash receiver lamp

²Cigar lighter lamp

²Transmission range indicator lamp

²Transfer case range indicator lamp

²A/C-Heater switch lamp

²Heated rear window lamp

²Rear wiper switch lamp

²Fog lamp switch lamp

Fuse 19 in the fuse block protects circuit E2. Circuit

Z1 provides ground for all of the illumination lamps

except for the cigar lighter lamp. The cigar lighter

lamp is case grounded.

HELPFUL INFORMATION

Circuit E2 also supplies power to the radio, LCD

relay and the illumination lamps in the instrument

cluster.

IGNITION SWITCH LAMP

The time delay relay is used to allow a time-ON

function for the ignition switch lamp and the courtesy

lamp. Power for the relay is received on the M1

circuit from the IOD fuse (fuse F9) in the fuse block.

Circuit M2 provides ground for the time delay relay

through the right and left door ajar switches and the

headlamp switch. When a door is opened, or the

headlamp switch is moved to the dome lamp position,a ground path is provided for the relay on circuit M2.

This energizes the relay, causing the contacts to close.

When the relay contacts close, power is provided

through the relay to circuit M50. The M50 circuit

supplies current to the ignition switch lamp. Circuit

Z1 provides ground for the lamp.

GLOVE BOX LAMP

Circuit M1 from the IOD fuse (fuse F9) in the fuse

block powers the glove box lamp. A case grounded

switch, in series after the lamp, closes when the glove

box door is opened. The switch completes a path to

ground on circuit Z1.

CARGO LAMP, COURTESY LAMPS AND DOME

LAMP

Circuit M1 from the IOD fuse (fuse F9) in the fuse

block supplies power to the cargo, courtesy lamps and

dome lamp. This circuit is HOT at all times. The

ground path for the lamp is provided in three differ-

ent ways.

One way is through the door jamb switches. Circuit

M2 connects to the door jamb switches from the cour-

tesy and dome lamps. The switches are connected to

ground circuit Z1. When a door is opened, the plunger

in the switch closes, completing a path to ground.

The second way is through the liftgate switch. Cir-

cuit M2 connects to circuit M4 at the cargo lamp.

Circuit M4 connects to the liftgate switch. The lift-

gate switch connects to ground circuit Z1. When the

lift gate opens, the plunger in the switch closes, com-

pleting a path to ground.

The third ground path is through the headlamp

switch. Circuit M2 is spliced in with the headlamp

switch. When the operator turns the headlamp switch

to the dome lamp ON position, a ground path is

provided through the switch.

J8W-44 INTERIOR LIGHTINGÐXJ VEHICLES 8W - 44 - 1

Page 633 of 2198

READING LAMPS

Circuit M1 from the IOD fuse (fuse F9) in the fuse

block supplies power to the reading lamps. Circuit

M1 is HOT at all times. When the operator depresses

the reading lamp, the reading lamp switch closes and

supplies ground on circuit Z1.

VISOR VANITY MIRROR LAMPS

Circuit M1 from the IOD fuse (fuse F9) in the fuse

block supplies power to the vanity lamps. Circuit M1

is HOT at all times. When the vanity lamps switch

closes, voltage flows to vanity mirror lamps. The van-

ity mirror is case grounded.

UNDERHOOD LAMP

Circuit A6 from fuse 16 in the Power Distribution

Center (PDC) supplies battery voltage for the under-

hood lamp. A mercury switch, in series after the

lamp, connects the lamp to ground on circuit Z1.

When the hood is raised, mercury inside the switch

moves to a position where it connects circuit M1 to

ground circuit Z1, illuminating the lamp.

CHIME/BUZZER MODULE

The buzzer or optional chime module sounds an au-

dible warning tone. The tone sounds for seat belt

warning and when the ignition key is in the ignition

switch while the drivers door is open. The tone also

sounds when the ignition key is in the ON position

while the drivers side seat belt is not buckled. Lastly,

the tone sounds when the headlamps are ON when

the ignition is OFF. Refer to Group 8U for system op-

eration.

When the ignition switch is in the RUN or START

position, circuit F87 from fuse 17 in the fuse block

supplies power to the chime/buzzer module. Circuit

A21 from the ignition switch supplies power to fuse

17.

Circuit L7 from fuse 15 in the fuse block also sup-

plies power to the chime/buzzer module. Circuit A3

from fuse 5 in the Power Distribution Center (PDC)

powers fuse 15.

When the parking lamps or headlamps are ON, the

headlamp switch connects circuit G26 with the driv-

ers side door jamb switch. Circuit G26 also connects

to the key-in switch. Circuit M11 connects the key-in

switch to the chime/buzzer module and the headlamp

switch.

If the headlamps are ON, and the drivers door

opens, ground for the chime/buzzer is on circuit C26

from the headlamp switch through the door jamb

switch to circuit Z1.

If the headlamps are OFF with the key in the ig-

nition while the drivers side door is open, ground forthe chime/buzzer is supplied through the key-in

switch. The ground path is over circuit M11, through

the closed key-in switch to circuit C26. From circuit

C26, the ground path continues through the drivers

door jamb switch to circuit Z1.

Circuit G11 from the buzzer powers the seat belt

warning lamp in the instrument cluster. Circuit Z1

at the instrument cluster provides ground for the

lamp.

Circuit G10 from the buzzer connects to the seat

belt switch. When the seat belt switch closes a path

to ground is completed on circuit Z1 and the tone

sounds momentarily.

Circuit Z1 also grounds the chime\buzzer module.

HELPFUL INFORMATION

Circuit F87 also powers the instrument cluster and

the headlamp delay module.

DIAGRAM INDEX

Component Page

Cargo Lamp............................8W-44-6

Chime/Buzzer Module......................8W-44-3

Courtesy Lamps.........................8W-44-5

Dome Lamp............................8W-44-7

Door Jamb Switches.....................8W-44-10

Fuse 3 (PDC).........................8W-44-4, 6

Fuse 5 (PDC).........................8W-44-3, 8

Fuse 6 (PDC)...........................8W-44-3

Fuse 9 (Fuse Block).....................8W-44-4, 6

Fuse 15 (Fuse Block)....................8W-44-3, 8

Fuse 16 (PDC)........................8W-44-4, 6

Fuse 17 (Fuse Block)......................8W-44-3

Fuse 19 (Fuse Block)......................8W-44-8

Glove Box Lamp and Switch.................8W-44-5

Headlamp Switch...................8W-44-3, 4, 5, 8

Headlamp Delay Module....................8W-44-4

Headlamp Delay Relay.....................8W-44-3

Ignition Switch..........................8W-44-3

Instrument Cluster........................8W-44-3

Instrument Panel Illumination Lamps..........8W-44-8, 9

Intermittent Wiper Control Module.............8W-44-4

Key-In Switch...........................8W-44-4

Liftgate Switch..........................8W-44-6

Reading Lamps..........................8W-44-7

Remote Keyless Entry Module................8W-44-7

Seat Belt Switch.........................8W-44-3

Telltale Connector (Instrument Cluster)...........8W-44-3

Time Delay Relay........................8W-44-4

Underhood Lamp.........................8W-44-4

Vanity Lamps...........................8W-44-7

8W - 44 - 2 8W-44 INTERIOR LIGHTINGÐXJ VEHICLESJ

Page 694 of 2198

POWER DOOR LOCKS

POWER DOOR LOCKS

Two relays provide power for the power door lock

motors. The Unlock relay provides power for the un-

lock circuits while the Lock relay powers the lock cir-

cuits. Either the power door lock switches or the

remote keyless entry module operate the Unlock and

Lock relays.

LOCK RELAY

Circuit M1 from fuse 9 in the fuse block powers cir-

cuit P38. When either power door lock switch is put

in the LOCK position, the switch connects circuit P38

to circuit P35. If the operator uses Remote Keyless

Entry (RKE), the RKE module powers circuit P35. In

either case, circuit P35 supplies power to the coil side

of the lock relay, causing the relay contacts to close.

Circuit Z1 provides ground for the coil side of the

lock relay.

When the lock relay contacts close, they connect

battery voltage from circuit P37 to circuit P2. Circuit

P2 then supplies battery voltage to the power door

lock motors to LOCK the doors.

When the power doors LOCK, ground for the mo-

tors is on circuit P34 through the normally closed

contacts in the door unlock relay to ground on circuit

Z1.

UNLOCK RELAY

Circuit M1 from fuse 9 in the fuse block powers cir-

cuit P38. When either power door lock switch is put

in the UNLOCK position, the switch connects circuit

P38 to circuit P36. If the operator uses Remote Key-

less Entry (RKE), the RKE module powers circuit

P36. In either case, circuit P36 supplies power to the

coil side of the unlock relay, causing the relay con-

tacts to close. Circuit Z1 provides ground for the coil

side of the unlock relay.

When the unlock relay contacts close, they connect

battery voltage from circuit P37 to circuit P34. Cir-

cuit P34 then supplies battery voltage to the power

door lock motors to UNLOCK the doors.

When the power doors UNLOCK, ground for the

motors is on circuit P2 through the normally closed

contacts in the door lock relay to ground on circuit

Z1.

REMOTE KEYLESS ENTRY MODULE

Circuit M1 from the ignition off draw (IOD) fuse in

cavity 9 of the fuse block supplies power to the Re-

mote Keyless Entry (RKE) module. Circuit F87 from

fuse 17 in the fuse block supplies power to the RKE

module when the ignition switch is in the START or

RUN position. Circuit Z1 provides ground for the

RKE module.

The RKE module UNLOCKS the doors by energiz-

ing the unlock relay on circuit P36. Refer to Unlock

Relay.

The module LOCKS the doors by energizing the

lock relay on circuit P35. Refer to Lock Relay.

HELPFUL INFORMATION

²Fuse 13 in the fuse block powers circuit P37. Cir-

cuit A7 from fuse 3 in the PDC feeds fuse 13 in the

fuse block.

²Circuit A7 from fuse 3 in the PDC also feeds fuse

16 in the PDC. PDC fuse 16 powers fuse 9 in the

fuse block. Fuse 9 protects the M1 circuit.

DIAGRAM INDEX

Component Page

Chime/Buzzer Module......................8W-61-5

Fuse 3 (PDC).........................8W-61-2, 6

Fuse 6 (PDC)...........................8W-61-5

Fuse 9 (Fuse Block).......................8W-61-2

Fuse 11 (Fuse Block)......................8W-61-2

Fuse 13 (Fuse Block)......................8W-61-2

Fuse 14 (Fuse Block)......................8W-61-2

Fuse 16 (PDC)........................8W-61-2, 6

Fuse 17 (Fuse Block)......................8W-61-5

Headlamp Delay Module....................8W-61-5

Ignition Switch..........................8W-61-5

Liftgate Lock Motor.......................8W-61-4

Power Door Lock Motors...................8W-61-4

Power Door Lock Relay....................8W-61-3

Power Door Lock Switches..................8W-61-2

Power Door Unlock Relay...................8W-61-3

Remote Keyless Entry (RKE) Module............8W-61-6

Telltale Connector........................8W-61-5

J8W-61 POWER DOOR LOCKSÐXJ VEHICLES 8W - 61 - 1

Page 1813 of 2198

INTERIOR COMPONENTS

INDEX

page page

Assist HandleÐXJ........................ 89

B/C-Pillar and Liftgate Pillar Trim CoversÐXJ.... 88

Bucket Seat Cushion and CoverÐXJ........... 81

Bucket Seat PlatformÐXJ................... 82

Bucket Seatback Cover and FrameÐXJ........ 81

Cargo BarrierÐXJ........................ 101

Cargo LampÐXJ......................... 94

Carpets and Floor MatsÐXJ................. 99

Dome LampÐXJ......................... 93

Front Bucket SeatsÐXJ.................... 81

Front Carpet/MatÐXJ...................... 99

Front Inner Scuff Plate/Cowl Side Trim PanelÐXJ . 86

Front Shoulder Belt/BuckleÐXJ............... 90

Full Floor ConsoleÐXJ..................... 95

HeadlinerÐXJ............................ 92

I/P Ash Receiver Tray LampÐXJ.............. 80

Instrument Cluster BezelÐXJ................ 80

Interior Trim Panels and Scuff PlatesÐXJ....... 84

Jack StorageÐXJ......................... 97

Keyless Entry ReceiverÐXJ................. 93Mini-Console with Floor ShiftÐXJ............. 94

Mini-Floor ConsoleÐXJ..................... 94

Outer Scuff PlatesÐXJ..................... 89

Overhead ConsoleÐXJ..................... 93

Parking Brake Handle CoverÐXJ............. 94

Quarter and Wheelhouse Trim PanelsÐXJ...... 87

Quarter Trim Panel ExtensionÐXJ............. 87

Rear Carpet/MatÐXJ..................... 100

Rear Seat Cushion CoverÐXJ............... 82

Rear Seat CushionÐXJ.................... 82

Rear Seatback CoverÐXJ................... 84

Rear Seatback Latch Striker and BumperÐXJ.... 84

Rear SeatbackÐXJ........................ 83

Rear Shoulder/Lap Belt/BuckleÐXJ............ 91

Sound BarÐXJ........................... 94

Spare Tire/Wheel Holddown and Floor

BracketsÐXJ........................... 98

SunvisorsÐXJ........................... 93

Windshield Side MoldingÐXJ................ 86

INSTRUMENT CLUSTER BEZELÐXJ

REMOVAL

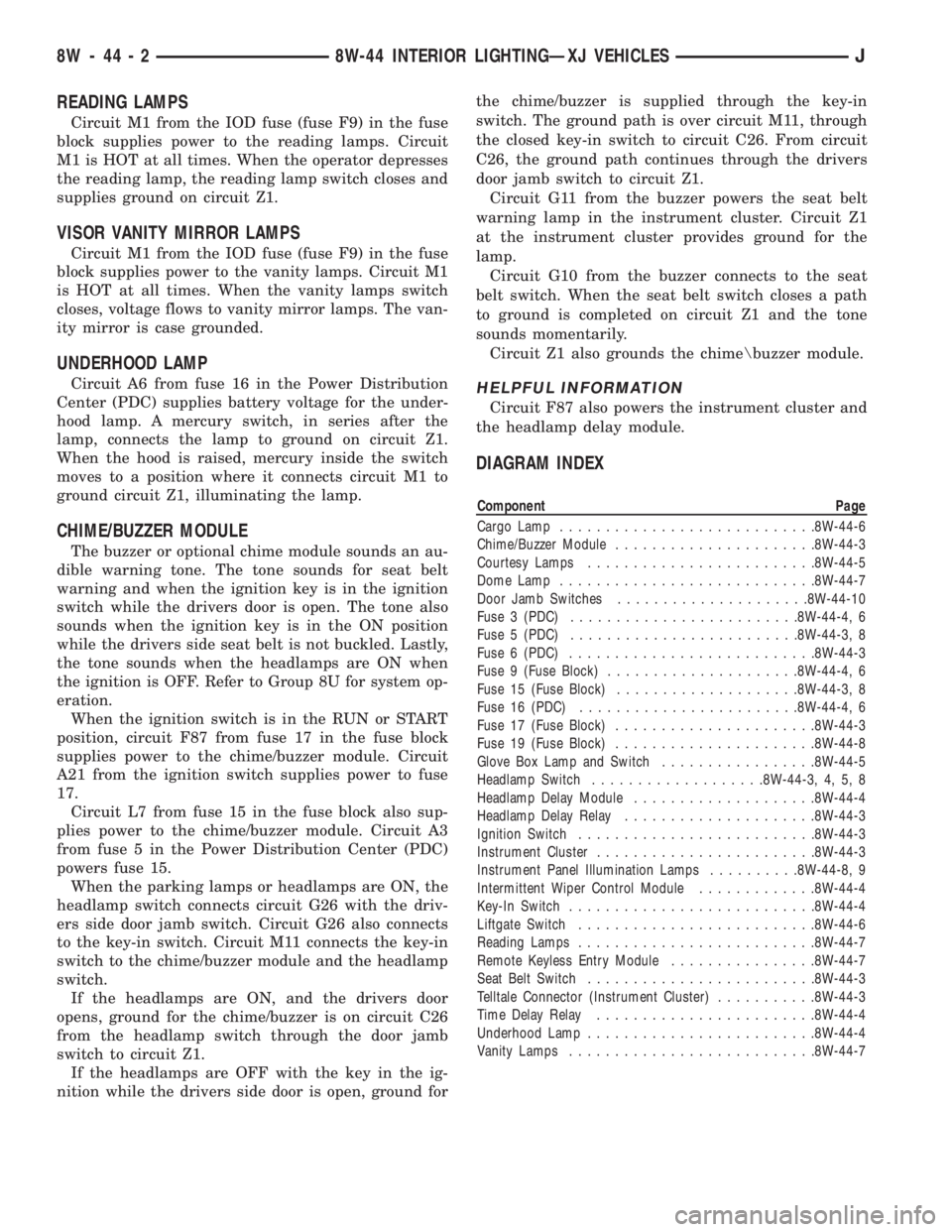

(1) Remove the bezel retaining screws (Fig. 1).

(2) Separate the bezel from the U-clips and remove

it from the upper section of the instrument panel.

(3) If necessary, remove or install rocker switch

cover plates.

INSTALLATION

(1) Position the bezel on the upper instrument

panel and engage it with the U-clips.

(2) Install the bezel retaining screws. Tighten thescrews with 1 Nzm (11 in-lbs) torque.

For service procedures regarding individual I/P

components refer to Group 8, Electrical.

I/P ASH RECEIVER TRAY LAMPÐXJ

REMOVAL

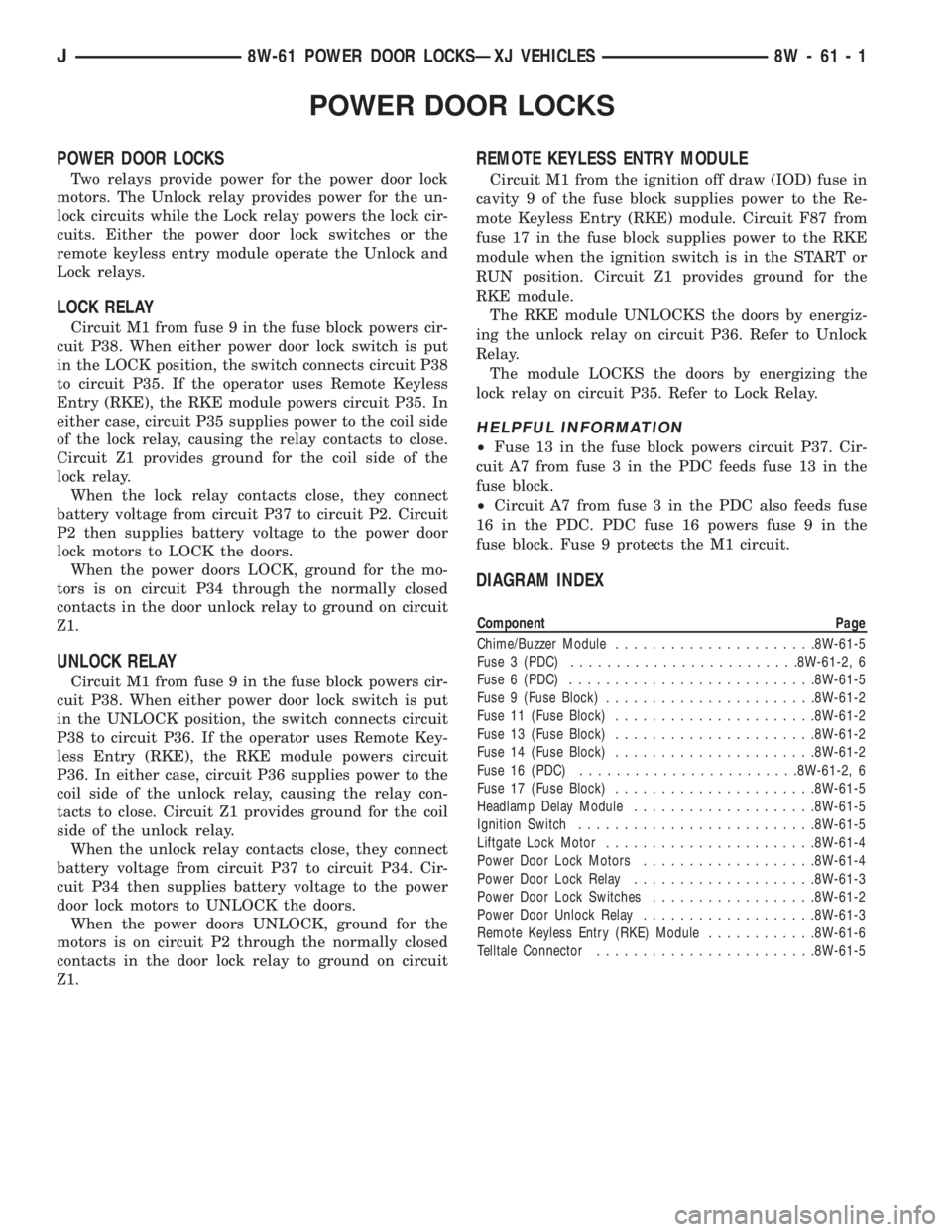

(1) Remove the ash receiver tray from instrument

panel (Fig. 2).

(2) Remove the lamp retaining screw from the ash

receiver tray cavity (Fig. 3).

(3) Disconnect the lamp wire harness connector

and remove the lamp from the instrument panel.

Fig. 1 Instrument Bezel Removal/Installation

Fig. 2 Ash Receiver Tray

23 - 80 INTERIOR COMPONENTSÐXJJ

Page 1825 of 2198

INSPECTION

Inspect the rear shoulder/lap belts and buckles. Re-

place any belt that is either cut, frayed, torn or dam-

aged in any way. Replace the shoulder belt if the

retractor is damaged or inoperative.

INSTALLATION

(1) Position the shoulder belt buckle and the lap

belt/buckle anchor plates on the floor panel.

(2) Install the anchor bolts. Tighten the bolts to 37

Nzm (27 ft-lbs) torque.

(3) Position the shoulder belt at the roof rail and

install the upper anchor bolt. Tighten the bolt to 37

Nzm (27 ft-lbs) torque.

(4) Route the shoulder belt through the quarter

trim panel slot. Install the retractor support on the

rear quarter rail. Tighten the screw to 5 Nzm (45 in-

lbs) torque.

(5) Install the quarter trim panel.

(6) Install the shoulder belt lower anchor bolt.

Tighten the bolt to 37 Nzm (27 ft-lbs) torque.

(7) Return the rear seat to the normal position and

engage the latch.

HEADLINERÐXJ

The upper trim moldings and the headliner are at-

tached to the roof rail with a combination of screws,

velcro strips, clip retainers and rail retainers (Fig. 1).

To remove a headliner, all of the upper trim mold-

ings must be removed from the perimeter of the

headliner along with (as applicable):

²Assist handles.

²Sunvisors.

²Dome/cargo lamps.

²Overhead console.

²Keyless entry receiver module.

²Sound bar.

²All other attached/overlapping components.

Refer to the appropriate removal and installation pro-

cedure locate in this section or in Group 8, Electrical.

REMOVAL

CAUTION: The headliner is a one-piece, molded

component. It has limited flexibility and must not be

bent during removal/installation.

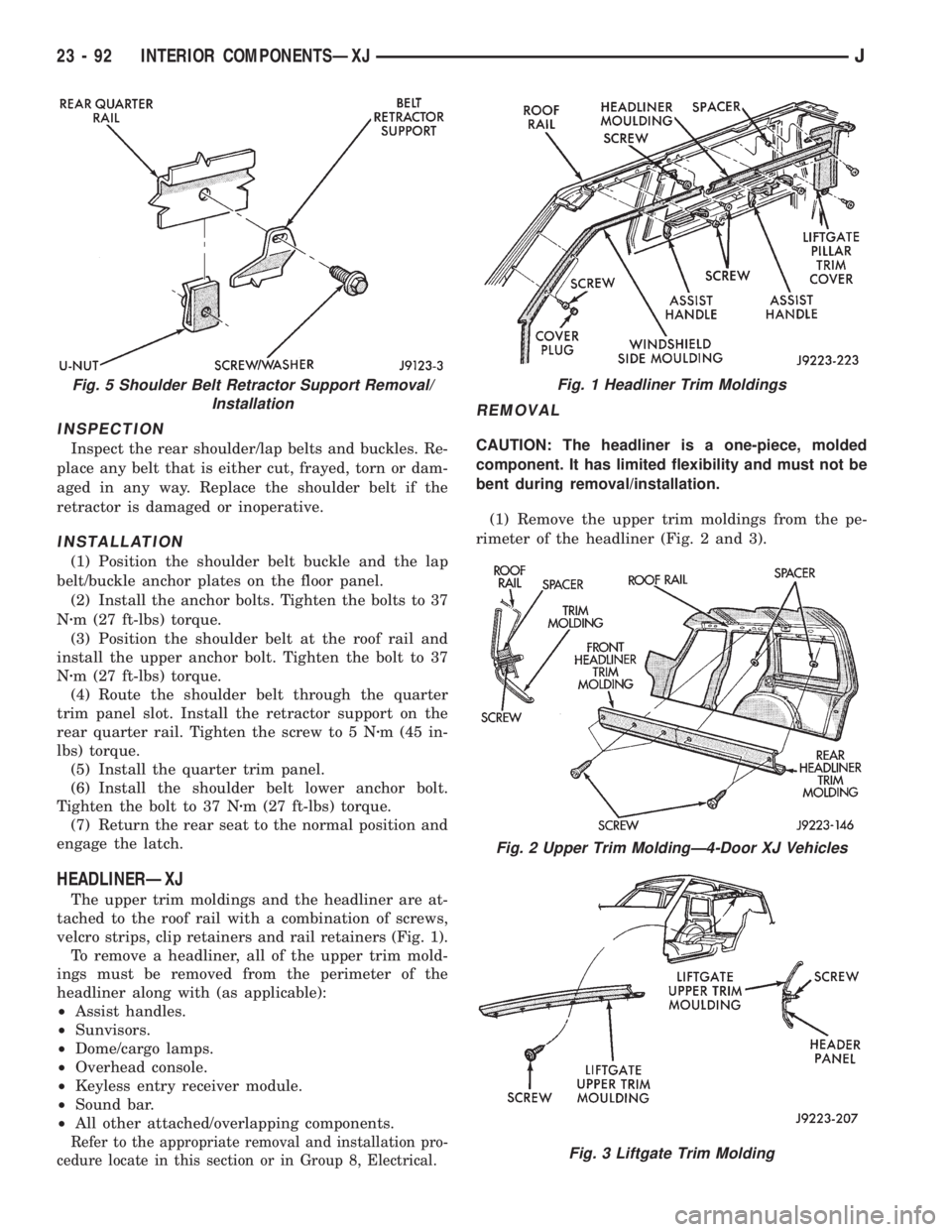

(1) Remove the upper trim moldings from the pe-

rimeter of the headliner (Fig. 2 and 3).

Fig. 5 Shoulder Belt Retractor Support Removal/

InstallationFig. 1 Headliner Trim Moldings

Fig. 2 Upper Trim MoldingÐ4-Door XJ Vehicles

Fig. 3 Liftgate Trim Molding

23 - 92 INTERIOR COMPONENTSÐXJJ

Page 1826 of 2198

(2) Ensure that all the retainer clips, screws and

Velcro strips are disengaged before removing the

headliner.

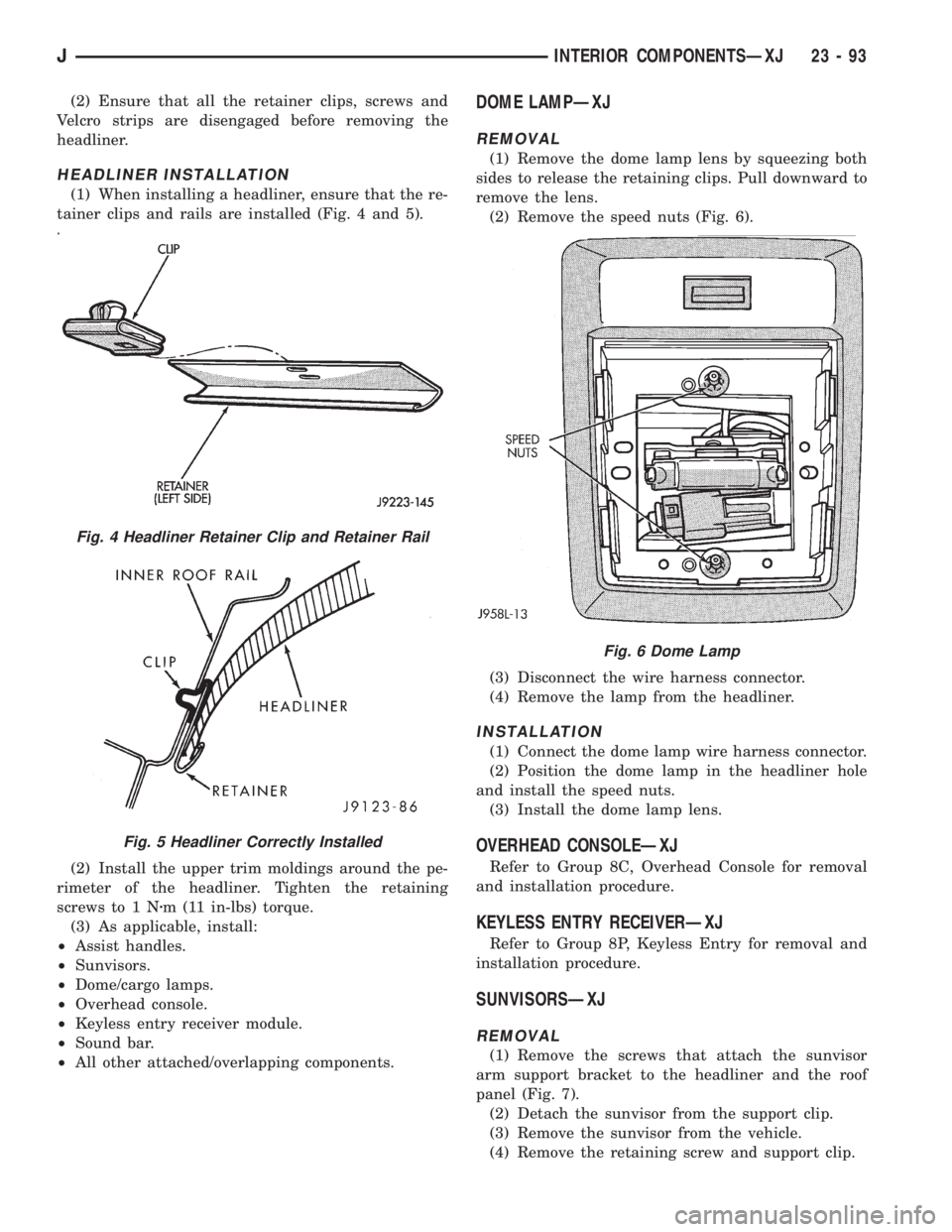

HEADLINER INSTALLATION

(1) When installing a headliner, ensure that the re-

tainer clips and rails are installed (Fig. 4 and 5).

(2) Install the upper trim moldings around the pe-

rimeter of the headliner. Tighten the retaining

screws to 1 Nzm (11 in-lbs) torque.

(3) As applicable, install:

²Assist handles.

²Sunvisors.

²Dome/cargo lamps.

²Overhead console.

²Keyless entry receiver module.

²Sound bar.

²All other attached/overlapping components.

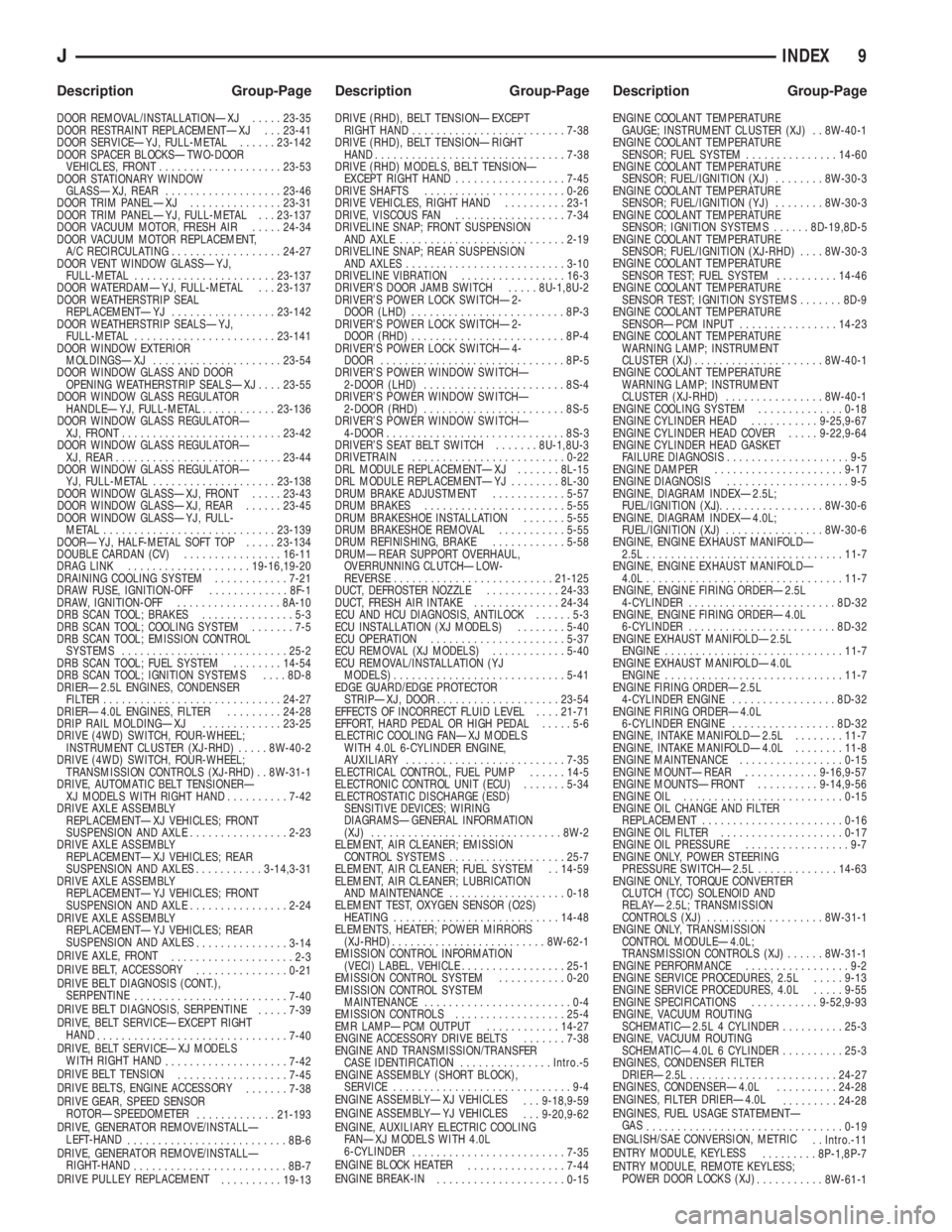

DOME LAMPÐXJ

REMOVAL

(1) Remove the dome lamp lens by squeezing both

sides to release the retaining clips. Pull downward to

remove the lens.

(2) Remove the speed nuts (Fig. 6).

(3) Disconnect the wire harness connector.

(4) Remove the lamp from the headliner.

INSTALLATION

(1) Connect the dome lamp wire harness connector.

(2) Position the dome lamp in the headliner hole

and install the speed nuts.

(3) Install the dome lamp lens.

OVERHEAD CONSOLEÐXJ

Refer to Group 8C, Overhead Console for removal

and installation procedure.

KEYLESS ENTRY RECEIVERÐXJ

Refer to Group 8P, Keyless Entry for removal and

installation procedure.

SUNVISORSÐXJ

REMOVAL

(1) Remove the screws that attach the sunvisor

arm support bracket to the headliner and the roof

panel (Fig. 7).

(2) Detach the sunvisor from the support clip.

(3) Remove the sunvisor from the vehicle.

(4) Remove the retaining screw and support clip.

Fig. 4 Headliner Retainer Clip and Retainer Rail

Fig. 5 Headliner Correctly Installed

Fig. 6 Dome Lamp

JINTERIOR COMPONENTSÐXJ 23 - 93

Page 1970 of 2198

DOOR REMOVAL/INSTALLATIONÐXJ.....23-35

DOOR RESTRAINT REPLACEMENTÐXJ . . . 23-41

DOOR SERVICEÐYJ, FULL-METAL......23-142

DOOR SPACER BLOCKSÐTWO-DOOR

VEHICLES, FRONT....................23-53

DOOR STATIONARY WINDOW

GLASSÐXJ, REAR...................23-46

DOOR TRIM PANELÐXJ...............23-31

DOOR TRIM PANELÐYJ, FULL-METAL . . . 23-137

DOOR VACUUM MOTOR, FRESH AIR.....24-34

DOOR VACUUM MOTOR REPLACEMENT,

A/C RECIRCULATING..................24-27

DOOR VENT WINDOW GLASSÐYJ,

FULL-METAL.......................23-137

DOOR WATERDAMÐYJ, FULL-METAL . . . 23-137

DOOR WEATHERSTRIP SEAL

REPLACEMENTÐYJ.................23-142

DOOR WEATHERSTRIP SEALSÐYJ,

FULL-METAL.......................23-141

DOOR WINDOW EXTERIOR

MOLDINGSÐXJ.....................23-54

DOOR WINDOW GLASS AND DOOR

OPENING WEATHERSTRIP SEALSÐXJ....23-55

DOOR WINDOW GLASS REGULATOR

HANDLEÐYJ, FULL-METAL............23-136

DOOR WINDOW GLASS REGULATORÐ

XJ, FRONT..........................23-42

DOOR WINDOW GLASS REGULATORÐ

XJ, REAR...........................23-44

DOOR WINDOW GLASS REGULATORÐ

YJ, FULL-METAL....................23-138

DOOR WINDOW GLASSÐXJ, FRONT.....23-43

DOOR WINDOW GLASSÐXJ, REAR......23-45

DOOR WINDOW GLASSÐYJ, FULL-

METAL............................23-139

DOORÐYJ, HALF-METAL SOFT TOP.....23-134

DOUBLE CARDAN (CV)................16-11

DRAG LINK....................19-16,19-20

DRAINING COOLING SYSTEM............7-21

DRAW FUSE, IGNITION-OFF.............8F-1

DRAW, IGNITION-OFF.................8A-10

DRB SCAN TOOL; BRAKES...............5-3

DRB SCAN TOOL; COOLING SYSTEM.......7-5

DRB SCAN TOOL; EMISSION CONTROL

SYSTEMS...........................25-2

DRB SCAN TOOL; FUEL SYSTEM........14-54

DRB SCAN TOOL; IGNITION SYSTEMS....8D-8

DRIERÐ2.5L ENGINES, CONDENSER

FILTER.............................24-27

DRIERÐ4.0L ENGINES, FILTER.........24-28

DRIP RAIL MOLDINGÐXJ.............23-25

DRIVE (4WD) SWITCH, FOUR-WHEEL;

INSTRUMENT CLUSTER (XJ-RHD).....8W-40-2

DRIVE (4WD) SWITCH, FOUR-WHEEL;

TRANSMISSION CONTROLS (XJ-RHD) . . 8W-31-1

DRIVE, AUTOMATIC BELT TENSIONERÐ

XJ MODELS WITH RIGHT HAND..........7-42

DRIVE AXLE ASSEMBLY

REPLACEMENTÐXJ VEHICLES; FRONT

SUSPENSION AND AXLE................2-23

DRIVE AXLE ASSEMBLY

REPLACEMENTÐXJ VEHICLES; REAR

SUSPENSION AND AXLES...........3-14,3-31

DRIVE AXLE ASSEMBLY

REPLACEMENTÐYJ VEHICLES; FRONT

SUSPENSION AND AXLE................2-24

DRIVE AXLE ASSEMBLY

REPLACEMENTÐYJ VEHICLES; REAR

SUSPENSION AND AXLES

...............3-14

DRIVE AXLE, FRONT

....................2-3

DRIVE BELT, ACCESSORY

...............0-21

DRIVE BELT DIAGNOSIS (CONT.),

SERPENTINE

.........................7-40

DRIVE BELT DIAGNOSIS, SERPENTINE

.....7-39

DRIVE, BELT SERVICEÐEXCEPT RIGHT

HAND

...............................7-40

DRIVE, BELT SERVICEÐXJ MODELS

WITH RIGHT HAND

....................7-42

DRIVE BELT TENSION

..................7-45

DRIVE BELTS, ENGINE ACCESSORY

.......7-38

DRIVE GEAR, SPEED SENSOR

ROTORÐSPEEDOMETER

.............21-193

DRIVE, GENERATOR REMOVE/INSTALLÐ

LEFT-HAND

..........................8B-6

DRIVE, GENERATOR REMOVE/INSTALLÐ

RIGHT-HAND

.........................8B-7

DRIVE PULLEY REPLACEMENT

..........19-13DRIVE (RHD), BELT TENSIONÐEXCEPT

RIGHT HAND.........................7-38

DRIVE (RHD), BELT TENSIONÐRIGHT

HAND...............................7-38

DRIVE (RHD) MODELS, BELT TENSIONÐ

EXCEPT RIGHT HAND..................7-45

DRIVE SHAFTS.......................0-26

DRIVE VEHICLES, RIGHT HAND..........23-1

DRIVE, VISCOUS FAN..................7-34

DRIVELINE SNAP; FRONT SUSPENSION

AND AXLE...........................2-19

DRIVELINE SNAP; REAR SUSPENSION

AND AXLES..........................3-10

DRIVELINE VIBRATION.................16-3

DRIVER'S DOOR JAMB SWITCH.....8U-1,8U-2

DRIVER'S POWER LOCK SWITCHÐ2-

DOOR (LHD).........................8P-3

DRIVER'S POWER LOCK SWITCHÐ2-

DOOR (RHD).........................8P-4

DRIVER'S POWER LOCK SWITCHÐ4-

DOOR..............................8P-5

DRIVER'S POWER WINDOW SWITCHÐ

2-DOOR (LHD).......................8S-4

DRIVER'S POWER WINDOW SWITCHÐ

2-DOOR (RHD).......................8S-5

DRIVER'S POWER WINDOW SWITCHÐ

4-DOOR.............................8S-3

DRIVER'S SEAT BELT SWITCH.......8U-1,8U-3

DRIVETRAIN.........................0-22

DRL MODULE REPLACEMENTÐXJ.......8L-15

DRL MODULE REPLACEMENTÐYJ........8L-30

DRUM BRAKE ADJUSTMENT............5-57

DRUM BRAKES.......................5-55

DRUM BRAKESHOE INSTALLATION.......5-55

DRUM BRAKESHOE REMOVAL...........5-55

DRUM REFINISHING, BRAKE............5-58

DRUMÐREAR SUPPORT OVERHAUL,

OVERRUNNING CLUTCHÐLOW-

REVERSE..........................21-125

DUCT, DEFROSTER NOZZLE............24-33

DUCT, FRESH AIR INTAKE..............24-34

ECU AND HCU DIAGNOSIS, ANTILOCK......5-3

ECU INSTALLATION (XJ MODELS)........5-40

ECU OPERATION......................5-37

ECU REMOVAL (XJ MODELS)............5-40

ECU REMOVAL/INSTALLATION (YJ

MODELS)............................5-41

EDGE GUARD/EDGE PROTECTOR

STRIPÐXJ, DOOR....................23-54

EFFECTS OF INCORRECT FLUID LEVEL....21-71

EFFORT, HARD PEDAL OR HIGH PEDAL.....5-6

ELECTRIC COOLING FANÐXJ MODELS

WITH 4.0L 6-CYLINDER ENGINE,

AUXILIARY..........................7-35

ELECTRICAL CONTROL, FUEL PUMP......14-5

ELECTRONIC CONTROL UNIT (ECU).......5-34

ELECTROSTATIC DISCHARGE (ESD)

SENSITIVE DEVICES; WIRING

DIAGRAMSÐGENERAL INFORMATION

(XJ)...............................8W-2

ELEMENT, AIR CLEANER; EMISSION

CONTROL SYSTEMS...................25-7

ELEMENT, AIR CLEANER; FUEL SYSTEM . . 14-59

ELEMENT, AIR CLEANER; LUBRICATION

AND MAINTENANCE...................0-18

ELEMENT TEST, OXYGEN SENSOR (O2S)

HEATING...........................14-48

ELEMENTS, HEATER; POWER MIRRORS

(XJ-RHD).........................8W-62-1

EMISSION CONTROL INFORMATION

(VECI) LABEL, VEHICLE.................25-1

EMISSION CONTROL SYSTEM...........0-20

EMISSION CONTROL SYSTEM

MAINTENANCE........................0-4

EMISSION CONTROLS..................25-4

EMR LAMPÐPCM OUTPUT............14-27

ENGINE ACCESSORY DRIVE BELTS.......7-38

ENGINE AND TRANSMISSION/TRANSFER

CASE IDENTIFICATION...............Intro.-5

ENGINE ASSEMBLY (SHORT BLOCK),

SERVICE.............................9-4

ENGINE ASSEMBLYÐXJ VEHICLES

. . . 9-18,9-59

ENGINE ASSEMBLYÐYJ VEHICLES

. . . 9-20,9-62

ENGINE, AUXILIARY ELECTRIC COOLING

FANÐXJ MODELS WITH 4.0L

6-CYLINDER

.........................7-35

ENGINE BLOCK HEATER

................7-44

ENGINE BREAK-IN

.....................0-15ENGINE COOLANT TEMPERATURE

GAUGE; INSTRUMENT CLUSTER (XJ) . . 8W-40-1

ENGINE COOLANT TEMPERATURE

SENSOR; FUEL SYSTEM...............14-60

ENGINE COOLANT TEMPERATURE

SENSOR; FUEL/IGNITION (XJ)........8W-30-3

ENGINE COOLANT TEMPERATURE

SENSOR; FUEL/IGNITION (YJ)........8W-30-3

ENGINE COOLANT TEMPERATURE

SENSOR; IGNITION SYSTEMS......8D-19,8D-5

ENGINE COOLANT TEMPERATURE

SENSOR; FUEL/IGNITION (XJ-RHD)....8W-30-3

ENGINE COOLANT TEMPERATURE

SENSOR TEST; FUEL SYSTEM..........14-46

ENGINE COOLANT TEMPERATURE

SENSOR TEST; IGNITION SYSTEMS.......8D-9

ENGINE COOLANT TEMPERATURE

SENSORÐPCM INPUT................14-23

ENGINE COOLANT TEMPERATURE

WARNING LAMP; INSTRUMENT

CLUSTER (XJ).....................8W-40-1

ENGINE COOLANT TEMPERATURE

WARNING LAMP; INSTRUMENT

CLUSTER (XJ-RHD)................8W-40-1

ENGINE COOLING SYSTEM..............0-18

ENGINE CYLINDER HEAD...........9-25,9-67

ENGINE CYLINDER HEAD COVER.....9-22,9-64

ENGINE CYLINDER HEAD GASKET

FAILURE DIAGNOSIS....................9-5

ENGINE DAMPER.....................9-17

ENGINE DIAGNOSIS....................9-5

ENGINE, DIAGRAM INDEXÐ2.5L;

FUEL/IGNITION (XJ)..................8W-30-6

ENGINE, DIAGRAM INDEXÐ4.0L;

FUEL/IGNITION (XJ)................8W-30-6

ENGINE, ENGINE EXHAUST MANIFOLDÐ

2.5L................................11-7

ENGINE, ENGINE EXHAUST MANIFOLDÐ

4.0L................................11-7

ENGINE, ENGINE FIRING ORDERÐ2.5L

4-CYLINDER........................8D-32

ENGINE, ENGINE FIRING ORDERÐ4.0L

6-CYLINDER........................8D-32

ENGINE EXHAUST MANIFOLDÐ2.5L

ENGINE.............................11-7

ENGINE EXHAUST MANIFOLDÐ4.0L

ENGINE.............................11-7

ENGINE FIRING ORDERÐ2.5L

4-CYLINDER ENGINE.................8D-32

ENGINE FIRING ORDERÐ4.0L

6-CYLINDER ENGINE.................8D-32

ENGINE, INTAKE MANIFOLDÐ2.5L........11-7

ENGINE, INTAKE MANIFOLDÐ4.0L........11-8

ENGINE MAINTENANCE.................0-15

ENGINE MOUNTÐREAR............9-16,9-57

ENGINE MOUNTSÐFRONT..........9-14,9-56

ENGINE OIL..........................0-15

ENGINE OIL CHANGE AND FILTER

REPLACEMENT.......................0-16

ENGINE OIL FILTER....................0-17

ENGINE OIL PRESSURE.................9-7

ENGINE ONLY, POWER STEERING

PRESSURE SWITCHÐ2.5L.............14-63

ENGINE ONLY, TORQUE CONVERTER

CLUTCH (TCC) SOLENOID AND

RELAYÐ2.5L; TRANSMISSION

CONTROLS (XJ)...................8W-31-1

ENGINE ONLY, TRANSMISSION

CONTROL MODULEÐ4.0L;

TRANSMISSION CONTROLS (XJ)......8W-31-1

ENGINE PERFORMANCE.................9-2

ENGINE SERVICE PROCEDURES, 2.5L.....9-13

ENGINE SERVICE PROCEDURES, 4.0L.....9-55

ENGINE SPECIFICATIONS...........9-52,9-93

ENGINE, VACUUM ROUTING

SCHEMATICÐ2.5L 4 CYLINDER..........25-3

ENGINE, VACUUM ROUTING

SCHEMATICÐ4.0L 6 CYLINDER..........25-3

ENGINES, CONDENSER FILTER

DRIERÐ2.5L........................24-27

ENGINES, CONDENSERÐ4.0L..........24-28

ENGINES, FILTER DRIERÐ4.0L

.........24-28

ENGINES, FUEL USAGE STATEMENTÐ

GAS

................................0-19

ENGLISH/SAE CONVERSION, METRIC

. . Intro.-11

ENTRY MODULE, KEYLESS

.........8P-1,8P-7

ENTRY MODULE, REMOTE KEYLESS;

POWER DOOR LOCKS (XJ)

...........8W-61-1

JINDEX 9

Description Group-Page Description Group-Page Description Group-Page