clock JEEP CHEROKEE 1995 Service Owner's Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 1995, Model line: CHEROKEE, Model: JEEP CHEROKEE 1995Pages: 2198, PDF Size: 82.83 MB

Page 463 of 2198

INTERIOR LAMPS

INDEX

page page

Dome Lamp ReplacementÐXJ............... 17

Dome/Courtesy Lamp Service InformationÐXJ . . . 16

Dome/Courtesy Lamp Trouble DiagnosisÐXJ.... 16Lighted Vanity Mirror Trouble DiagnosisÐXJ..... 16

Lighted Vanity MirrorÐXJ................... 16

Overhead ConsoleÐXJ..................... 17

DOME/COURTESY LAMP SERVICE

INFORMATIONÐXJ

Voltage is applied at all times via the dome lamp

fuse to each of the interior lamp bulbs. The interior

lamp bulbs illuminate when they are connected to

body ground via the switch:

²Headlamp switch.

²Glove box switch.

²Door pillar switch.

²Liftgate switch (if the cargo lamp is ON).

If equipped with Security Alarm Module, refer to

Group 8Q, Vehicle Theft Security System.

DOME/COURTESY LAMP TROUBLE DIAGNOSISÐ

XJ

ALL LAMPS INOPERATIVE

(1) Rotate the headlamp switch rheostat clockwise.

The lamps should light. If not OK, remove, inspect

and test the dome lamp fuse. Replace if bad.

(2) If the fuse is OK, repair the open circuit in the

wire harness to vehicle body ground.

ONE LAMP INOPERATIVE

(1) Measure the resistance across the bulb holder

terminals. The ohmmeter should indicate zero ohms.

If not, replace the bulb.

(2) Measure the voltage between the voltage side

of the bulb holder and vehicle body ground. The volt-

meter should indicate battery voltage. If not, repair

the open circuit in the wire harness to the splice.

LAMPS INOPERATIVE WITH ONE OR MORE

DOORS OPENED

(1) Remove the inoperative switch from the door

pillar and connect the switch wire directly to ground.

The lamp should light.

(2) If not, check for an open circuit in black

(ground) wire. Repair as necessary. If lamps still do

not light, replace the switch.

LIGHTED VANITY MIRRORÐXJ

SERVICE INFORMATION

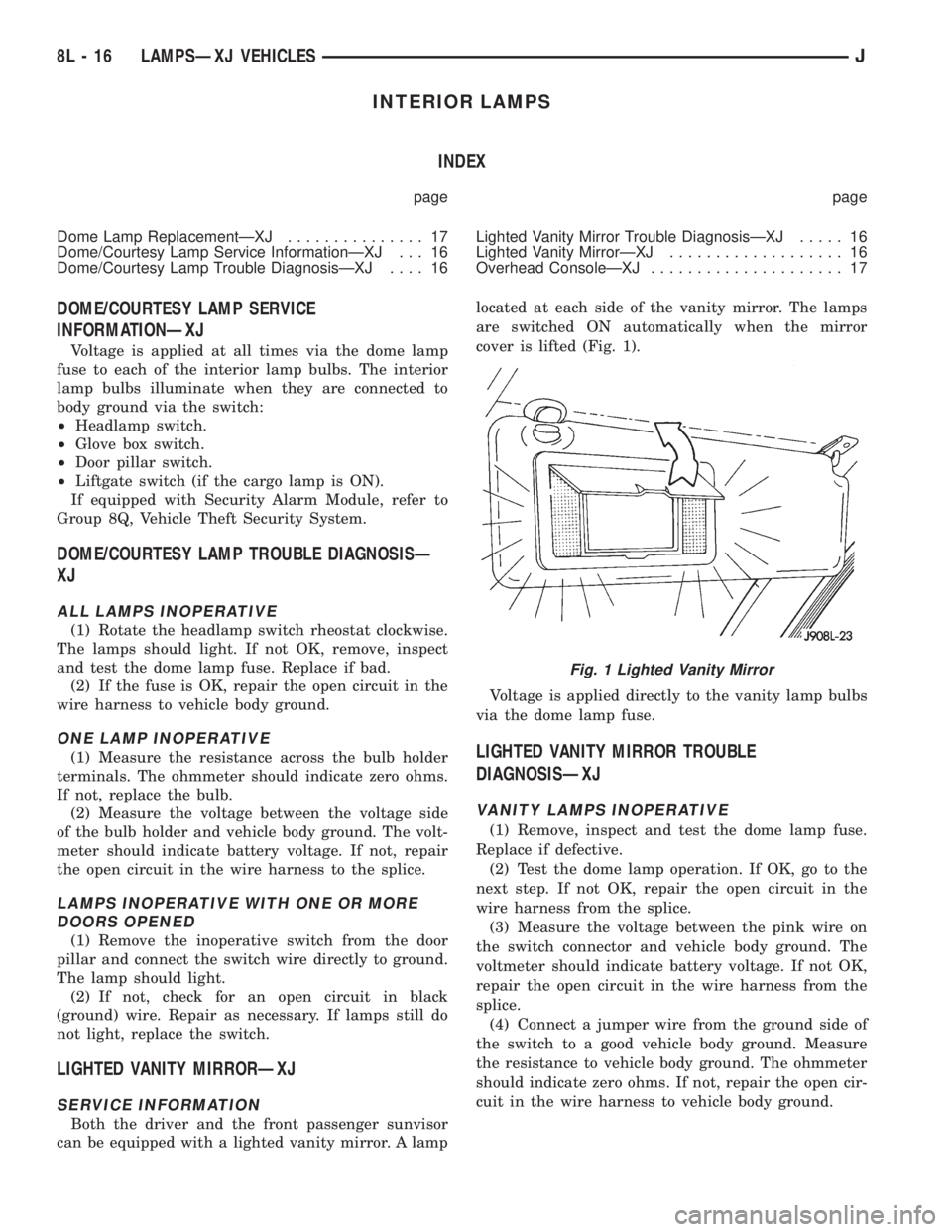

Both the driver and the front passenger sunvisor

can be equipped with a lighted vanity mirror. A lamplocated at each side of the vanity mirror. The lamps

are switched ON automatically when the mirror

cover is lifted (Fig. 1).

Voltage is applied directly to the vanity lamp bulbs

via the dome lamp fuse.

LIGHTED VANITY MIRROR TROUBLE

DIAGNOSISÐXJ

VANITY LAMPS INOPERATIVE

(1) Remove, inspect and test the dome lamp fuse.

Replace if defective.

(2) Test the dome lamp operation. If OK, go to the

next step. If not OK, repair the open circuit in the

wire harness from the splice.

(3) Measure the voltage between the pink wire on

the switch connector and vehicle body ground. The

voltmeter should indicate battery voltage. If not OK,

repair the open circuit in the wire harness from the

splice.

(4) Connect a jumper wire from the ground side of

the switch to a good vehicle body ground. Measure

the resistance to vehicle body ground. The ohmmeter

should indicate zero ohms. If not, repair the open cir-

cuit in the wire harness to vehicle body ground.

Fig. 1 Lighted Vanity Mirror

8L - 16 LAMPSÐXJ VEHICLESJ

Page 476 of 2198

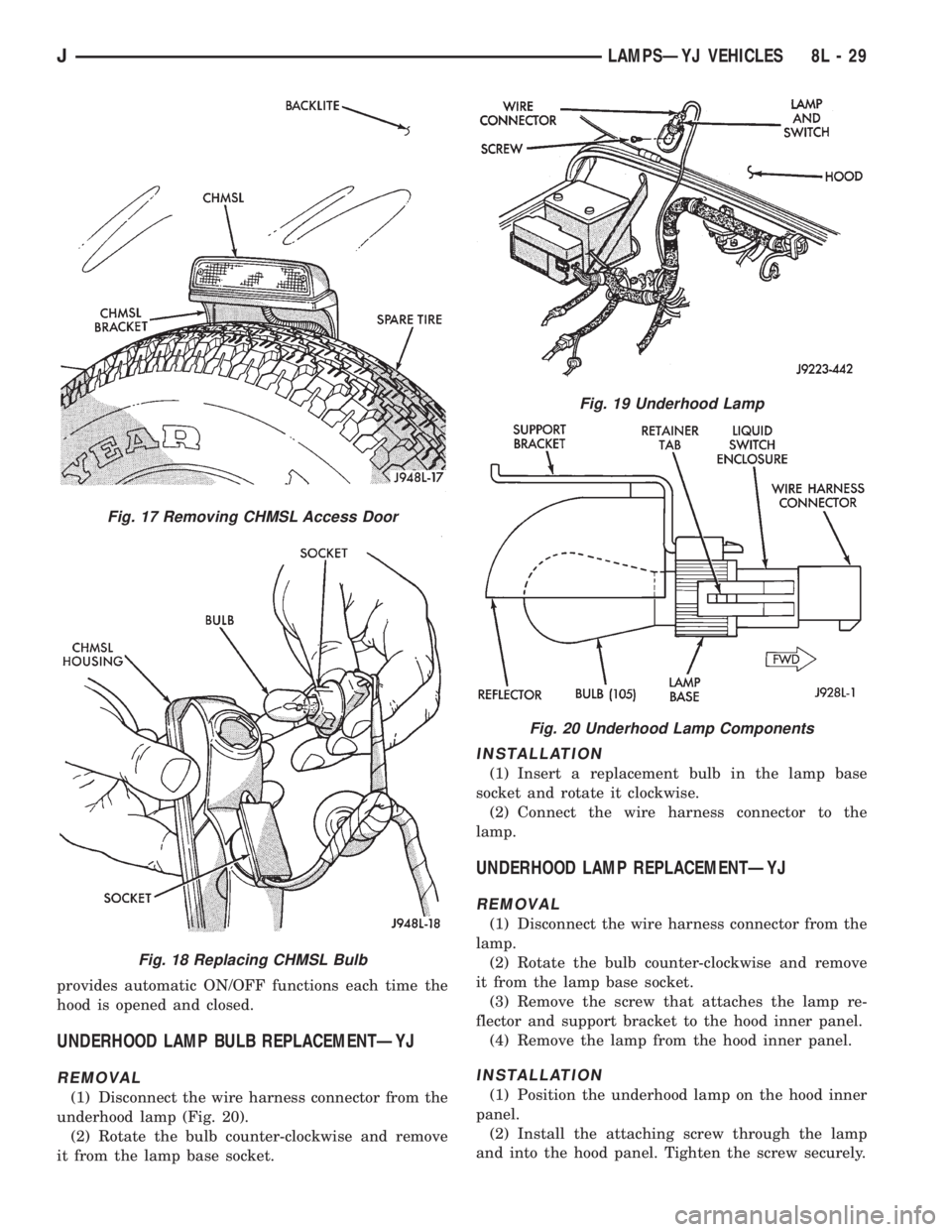

provides automatic ON/OFF functions each time the

hood is opened and closed.

UNDERHOOD LAMP BULB REPLACEMENTÐYJ

REMOVAL

(1) Disconnect the wire harness connector from the

underhood lamp (Fig. 20).

(2) Rotate the bulb counter-clockwise and remove

it from the lamp base socket.

INSTALLATION

(1) Insert a replacement bulb in the lamp base

socket and rotate it clockwise.

(2) Connect the wire harness connector to the

lamp.

UNDERHOOD LAMP REPLACEMENTÐYJ

REMOVAL

(1) Disconnect the wire harness connector from the

lamp.

(2) Rotate the bulb counter-clockwise and remove

it from the lamp base socket.

(3) Remove the screw that attaches the lamp re-

flector and support bracket to the hood inner panel.

(4) Remove the lamp from the hood inner panel.

INSTALLATION

(1) Position the underhood lamp on the hood inner

panel.

(2) Install the attaching screw through the lamp

and into the hood panel. Tighten the screw securely.

Fig. 17 Removing CHMSL Access Door

Fig. 18 Replacing CHMSL Bulb

Fig. 19 Underhood Lamp

Fig. 20 Underhood Lamp Components

JLAMPSÐYJ VEHICLES 8L - 29

Page 477 of 2198

(3) Insert a replacement bulb in the lamp base

socket and rotate it clockwise.

(4) Connect the wire harness connector to the

lamp.

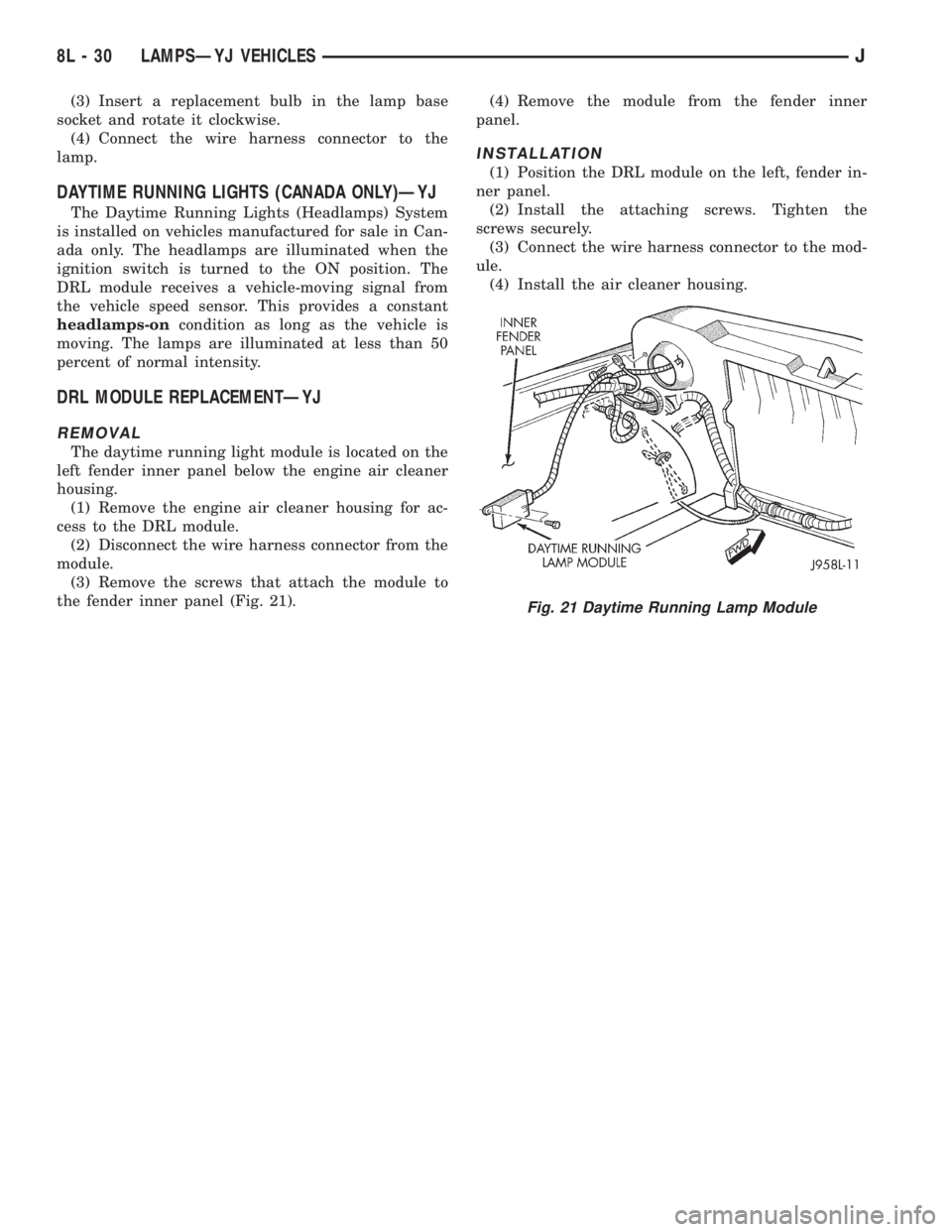

DAYTIME RUNNING LIGHTS (CANADA ONLY)ÐYJ

The Daytime Running Lights (Headlamps) System

is installed on vehicles manufactured for sale in Can-

ada only. The headlamps are illuminated when the

ignition switch is turned to the ON position. The

DRL module receives a vehicle-moving signal from

the vehicle speed sensor. This provides a constant

headlamps-oncondition as long as the vehicle is

moving. The lamps are illuminated at less than 50

percent of normal intensity.

DRL MODULE REPLACEMENTÐYJ

REMOVAL

The daytime running light module is located on the

left fender inner panel below the engine air cleaner

housing.

(1) Remove the engine air cleaner housing for ac-

cess to the DRL module.

(2) Disconnect the wire harness connector from the

module.

(3) Remove the screws that attach the module to

the fender inner panel (Fig. 21).(4) Remove the module from the fender inner

panel.

INSTALLATION

(1) Position the DRL module on the left, fender in-

ner panel.

(2) Install the attaching screws. Tighten the

screws securely.

(3) Connect the wire harness connector to the mod-

ule.

(4) Install the air cleaner housing.

Fig. 21 Daytime Running Lamp Module

8L - 30 LAMPSÐYJ VEHICLESJ

Page 482 of 2198

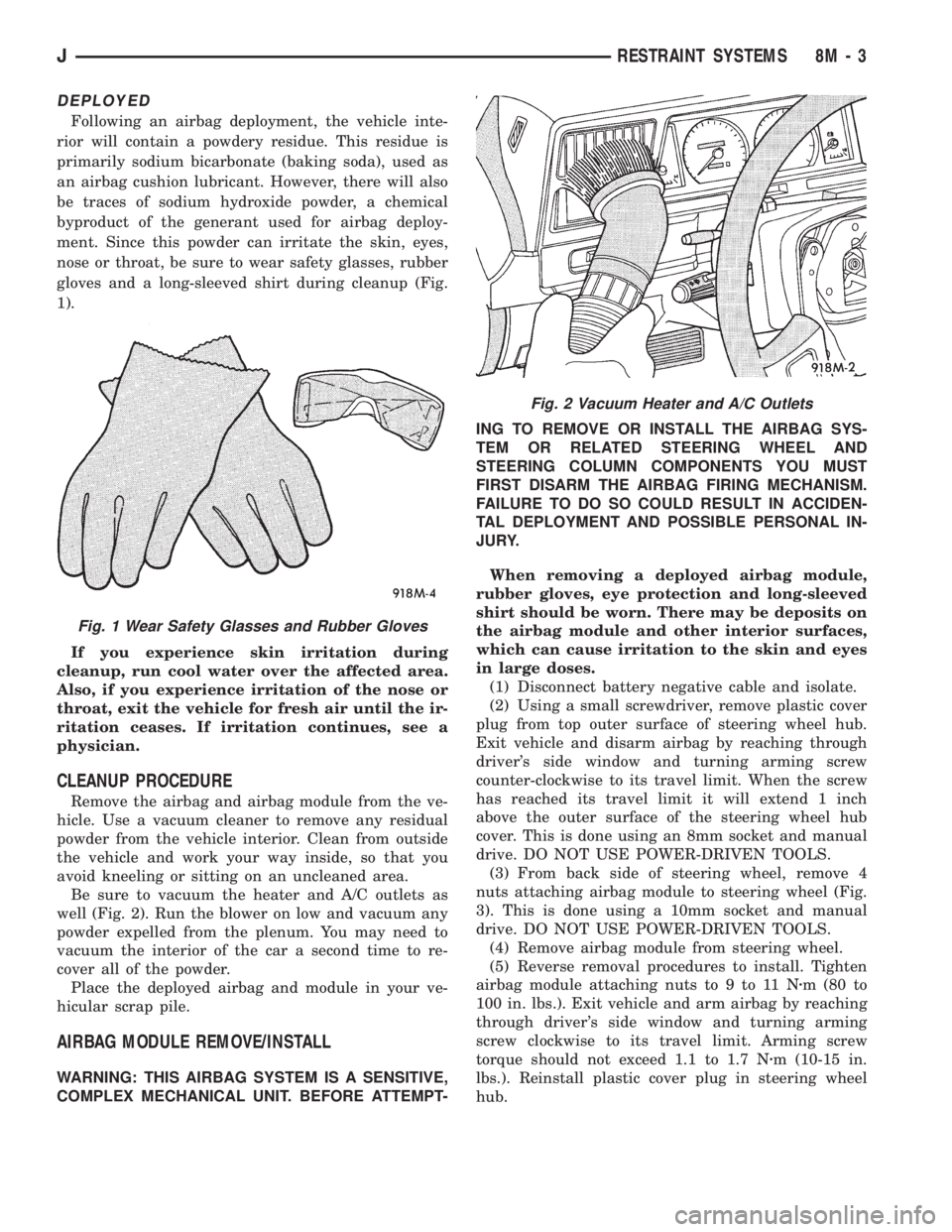

DEPLOYED

Following an airbag deployment, the vehicle inte-

rior will contain a powdery residue. This residue is

primarily sodium bicarbonate (baking soda), used as

an airbag cushion lubricant. However, there will also

be traces of sodium hydroxide powder, a chemical

byproduct of the generant used for airbag deploy-

ment. Since this powder can irritate the skin, eyes,

nose or throat, be sure to wear safety glasses, rubber

gloves and a long-sleeved shirt during cleanup (Fig.

1).

If you experience skin irritation during

cleanup, run cool water over the affected area.

Also, if you experience irritation of the nose or

throat, exit the vehicle for fresh air until the ir-

ritation ceases. If irritation continues, see a

physician.

CLEANUP PROCEDURE

Remove the airbag and airbag module from the ve-

hicle. Use a vacuum cleaner to remove any residual

powder from the vehicle interior. Clean from outside

the vehicle and work your way inside, so that you

avoid kneeling or sitting on an uncleaned area.

Be sure to vacuum the heater and A/C outlets as

well (Fig. 2). Run the blower on low and vacuum any

powder expelled from the plenum. You may need to

vacuum the interior of the car a second time to re-

cover all of the powder.

Place the deployed airbag and module in your ve-

hicular scrap pile.

AIRBAG MODULE REMOVE/INSTALL

WARNING: THIS AIRBAG SYSTEM IS A SENSITIVE,

COMPLEX MECHANICAL UNIT. BEFORE ATTEMPT-ING TO REMOVE OR INSTALL THE AIRBAG SYS-

TEM OR RELATED STEERING WHEEL AND

STEERING COLUMN COMPONENTS YOU MUST

FIRST DISARM THE AIRBAG FIRING MECHANISM.

FAILURE TO DO SO COULD RESULT IN ACCIDEN-

TAL DEPLOYMENT AND POSSIBLE PERSONAL IN-

JURY.

When removing a deployed airbag module,

rubber gloves, eye protection and long-sleeved

shirt should be worn. There may be deposits on

the airbag module and other interior surfaces,

which can cause irritation to the skin and eyes

in large doses.

(1) Disconnect battery negative cable and isolate.

(2) Using a small screwdriver, remove plastic cover

plug from top outer surface of steering wheel hub.

Exit vehicle and disarm airbag by reaching through

driver's side window and turning arming screw

counter-clockwise to its travel limit. When the screw

has reached its travel limit it will extend 1 inch

above the outer surface of the steering wheel hub

cover. This is done using an 8mm socket and manual

drive. DO NOT USE POWER-DRIVEN TOOLS.

(3) From back side of steering wheel, remove 4

nuts attaching airbag module to steering wheel (Fig.

3). This is done using a 10mm socket and manual

drive. DO NOT USE POWER-DRIVEN TOOLS.

(4) Remove airbag module from steering wheel.

(5) Reverse removal procedures to install. Tighten

airbag module attaching nuts to 9 to 11 Nzm (80 to

100 in. lbs.). Exit vehicle and arm airbag by reaching

through driver's side window and turning arming

screw clockwise to its travel limit. Arming screw

torque should not exceed 1.1 to 1.7 Nzm (10-15 in.

lbs.). Reinstall plastic cover plug in steering wheel

hub.

Fig. 1 Wear Safety Glasses and Rubber Gloves

Fig. 2 Vacuum Heater and A/C Outlets

JRESTRAINT SYSTEMS 8M - 3

Page 644 of 2198

AUDIO SYSTEM

RADIO

When the ignition switch is in the ACCESSORY or

RUN position, it connects circuit A1 from fuse 6 in the

Power Distribution Center (PDC) to circuit A48. Cir-

cuit A48 powers circuit F85 through fuse 2 in the fuse

block. Circuit F85 powers the radio.

Circuit Z1 provides ground for the radio. The an-

tenna connects to the rear of the radio.

RADIO MEMORY

Circuit M1 from the Ignition Off Draw (IOD) fuse

(fuse 9) in the fuse block supplies power for the radio

memory. The IOD fuse is removed during vehicle

shipping to prevent excessive battery draw.

Circuit A6 from fuse 16 in the Power Distribution

Center (PDC) supplies voltage to fuse 9. Circuit A7

from fuse 3 in the PDC powers circuit A6 through

fuse 16. Circuits A6, A7 and M1 are HOT at all times.

RADIO ILLUMINATION

Circuit E2 supplies battery voltage to the radio

illumination lamps when the headlamps or parking

lamps are on and the dimmer switch is in the LOW or

ON positions.

Circuit X5 supplies battery voltage for the radio

clock and station frequency display. Circuit X5 origi-

nates at the radio illumination relay and is fed by

either circuit F85 or circuit E2 depending on the

switch position inside the relay.

When the headlamps and parking lamps are off, the

radio illumination relay is in its normal At Rest posi-

tion. In the At Rest position, the relay connects circuit

F85 from fuse 2 in the fuse block to circuit X5.

When the headlamps or parking lamps are on, cir-

cuit L90 from the headlamp switch supplies battery

voltage to the coil side of the radio illumination relay.

Circuit Z1 provides ground for the coil side of the

relay.

When voltage is present on circuit L90, the radio

illumination relay switches from its At Rest position

to connect circuit E2 to circuit X5.

SPEAKERS

There are 3 different radio packages. The standard

radio package includes 2 speakers; one in each front

door. The four speaker system uses speakers in each

front door plus speakers in the rear sound bar. The six

speaker system has the front door speakers, sound bar

speakers and two speakers in the instrument panel.

BASE RADIO

Vehicles with the base radio have a jumper between

the radio and the instrument panel connectors. The

jumper simulates rear speaker load.Circuit X53 feeds the speaker in the left front door.

Circuit X55 is the return from the speaker to the

radio.

Circuit X54 feeds the right front door speaker. Cir-

cuit X56 is the return from the speaker to the radio.

FOUR SPEAKER SYSTEM

Circuit X53 feeds the speaker in the left front door.

Circuit X55 is the return from the speaker to the

radio.

Circuit X54 feeds the right front door speaker. Cir-

cuit X56 is the return from the speaker to the radio.

Circuit X51 feeds the left rear speaker. Circuit X57

is the return from the speaker to the radio.

Circuit X52 feeds the right rear speaker. Circuit

X58 is the return from the speaker to the radio.

SIX SPEAKER SYSTEM

Circuit X53 feeds the left speaker in the instrument

panel. The X53 circuit is double crimped at the in-

strument panel left speaker and branches to the left

front door speaker. Circuit X55 is the return to the

radio from the instrument panel left speaker and left

front door speaker. Circuit X55 is double crimped at

the instrument panel left speaker.

Circuit X54 feeds the right speaker in the instru-

ment panel. The X54 circuit is double crimped at the

instrument panel right speaker and branches to the

right front door speaker. Circuit X56 is the return to

the radio from the instrument panel left speaker and

left front door speaker. Circuit X56 is double crimped

at the instrument panel left speaker.

Circuit X51 feeds the left rear speaker. Circuit X57

is the return from the speaker to the radio.

Circuit X52 feeds the right rear speaker. Circuit

X58 is the return from the speaker to the radio.

DIAGRAM INDEX

Component Page

Fuse Block...........................8W-47-2, 3

Headlamp Switch.........................8W-47-2

Ignition Switch..........................8W-47-2

LCD Relay.............................8W-47-3

Power Distribution Center..................8W-47-2, 3

Radio............................8W-47-2 thru 7

Speakers (Six Speaker System)..............8W-47-4, 5

Speakers (Four Speaker System).............8W-47-6, 7

J8W-47 AUDIO SYSTEMÐXJ VEHICLES 8W -47 - 1

Page 918 of 2198

RADIO

RADIO

When the ignition switch is in the ACCESSORY or

RUN position, it connects circuit A1 from fuse 6 in

the Power Distribution Center (PDC) to circuit A48.

Circuit A48 powers circuit F85 through fuse 13 in the

fuse block. Circuit F85 powers the radio.

Circuit Z1 provides ground for the radio. The an-

tenna connects to the rear of the radio.

RADIO MEMORY

Circuit M1 from fuse 16 in the Power Distribution

Center (PDC) supplies power for the radio memory.

Circuit A7 from fuse 3 in the PDC supplies voltage

to fuse 16. Circuits A7 and M1 are HOT at all times.

RADIO ILLUMINATION

Circuit E2 supplies battery voltage to the radio il-

lumination lamps when the headlamps or parking

lamps are on and the dimmer switch is in the Low or

On positions.

Circuit X5 supplies battery voltage for the radio

clock and station frequency display. Circuit X5 origi-

nates at the radio illumination relay and is fed by ei-

ther circuit F85 or circuit E2 depending on the

switch position inside the relay.

When the headlamps and parking lamps are off,

the radio illumination relay is in its normal At Rest

position. In the At Rest position, the relay connects

circuit F85 from fuse 13 in the fuse block to circuit

X5.

When the headlamps or parking lamps are on, cir-

cuit L90 from the headlamp switch supplies battery

voltage to the coil side of the radio illumination relay.

Circuit Z1 provides ground for the coil side of the re-

lay.

When voltage is present on circuit L90, the radio

illumination relay switches from its At Rest position

to connect circuit E2 to circuit X5.

HELPFUL INFORMATION

²Circuit A48 supplies voltage to fuse 13 in the fuse

block for circuit F85 when the ignition switch is in

the ACCESSORY or RUN positions. In these posi-

tions, the ignition switch connects circuit A1 from

fuse 6 in the PDC to circuit A48.²Circuit A3 from fuse 5 in the PDC supplies power

to the fuse block for fuse 9. Fuse 9 protects circuit

L7. When the headlamps or parking lamps are ON,

the headlamp switch connects circuit L7 to circuit

L90. When the adjustable dimmer switch is in the

LOW to ON positions, it internally connects circuit

L7 to circuit E2. Circuit E2 powers fuse 25 in the

fuse block. Circuit E2 continues through fuse 25.

POWER ANTENNA

The Power Antenna Relay supplies power to raise

and lower the antenna. Circuit F60 from fuse 7 in

the fuse block powers the relay. Circuit Z1 provides

ground for the relay.

When the radio is turned on, circuit X60 from the

radio energizes the relay to raise the antenna.

SPEAKERS

Circuit X53 feeds the left front speakers. Circuit

X55 is the return from the speakers to the radio.

Circuit X54 feeds the right front speakers. Circuit

X56 is the return from the speakers to the radio.

Circuit X51 feeds the left rear speaker. Circuit X57

is the return from the speaker to the radio.

Circuit X52 feeds the right rear speaker. Circuit

X58 is the return from the speaker to the radio.

DIAGRAM INDEX

Component Page

Fuse 3 (PDC).........................8W-47-2, 4

Fuse 5 (PDC).......................8W-47-2, 4, 5

Fuse 6 (PDC).........................8W-47-2, 4

Fuse 7 (PDC).........................8W-47-2, 4

Fuse 9 (Fuse Block)...................8W-47-2, 4, 5

Fuse 13 (Fuse Block)....................8W-47-2, 4

Fuse 16 (PDC)........................8W-47-2, 4

Fuse 25 (Fuse Block)....................8W-47-2, 4

Headlamp Switch.......................8W-47-2, 4

Ignition Switch..........................8W-47-2

LCD Relay...........................8W-47-3, 5

Power Antenna..........................8W-47-6

Power Antenna Relay......................8W-47-6

Radio...........................8W-47-2 thru 8

Speakers............................8W-47-7, 8

J8W-47 AUDIO SYSTEMÐXJ-RHD 8W - 47 - 1

Page 1104 of 2198

2.5L ENGINE SERVICE PROCEDURES

INDEX

page page

Camshaft............................... 32

Camshaft Pin Replacement.................. 34

Engine AssemblyÐXJ Vehicles............... 18

Engine AssemblyÐYJ Vehicles............... 20

Engine Cylinder Head...................... 25

Engine Cylinder Head Cover................. 22

Engine Damper........................... 17

Engine MountÐRear....................... 16

Engine MountsÐFront..................... 14

General Information....................... 13

Hydraulic Tappets......................... 24OilPan ................................. 36

Rocker Arms and Push Rods................ 23

Timing Case Cover........................ 31

Timing Case Cover Oil Seal Replacement....... 30

Timing Chain and Sprockets................. 31

Valve Component ReplaceÐCylinder Head Not

Removed.............................. 23

Valve Springs and Oil Seals................. 23

Valve Timing............................. 30

Valves and Valve Springs................... 27

Vibration Damper......................... 30

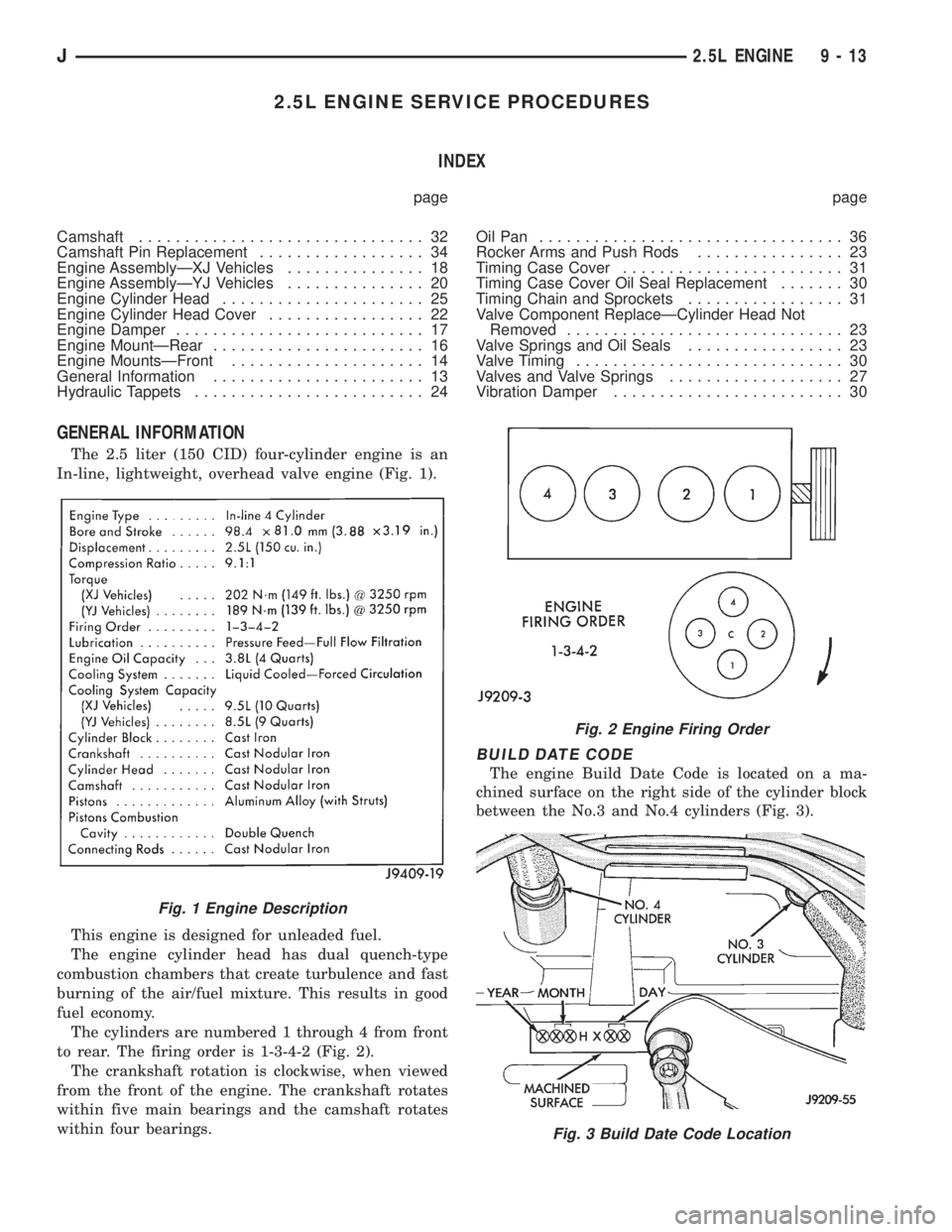

GENERAL INFORMATION

The 2.5 liter (150 CID) four-cylinder engine is an

In-line, lightweight, overhead valve engine (Fig. 1).

This engine is designed for unleaded fuel.

The engine cylinder head has dual quench-type

combustion chambers that create turbulence and fast

burning of the air/fuel mixture. This results in good

fuel economy.

The cylinders are numbered 1 through 4 from front

to rear. The firing order is 1-3-4-2 (Fig. 2).

The crankshaft rotation is clockwise, when viewed

from the front of the engine. The crankshaft rotates

within five main bearings and the camshaft rotates

within four bearings.

BUILD DATE CODE

The engine Build Date Code is located on a ma-

chined surface on the right side of the cylinder block

between the No.3 and No.4 cylinders (Fig. 3).

Fig. 1 Engine Description

Fig. 2 Engine Firing Order

Fig. 3 Build Date Code Location

J2.5L ENGINE 9 - 13

Page 1116 of 2198

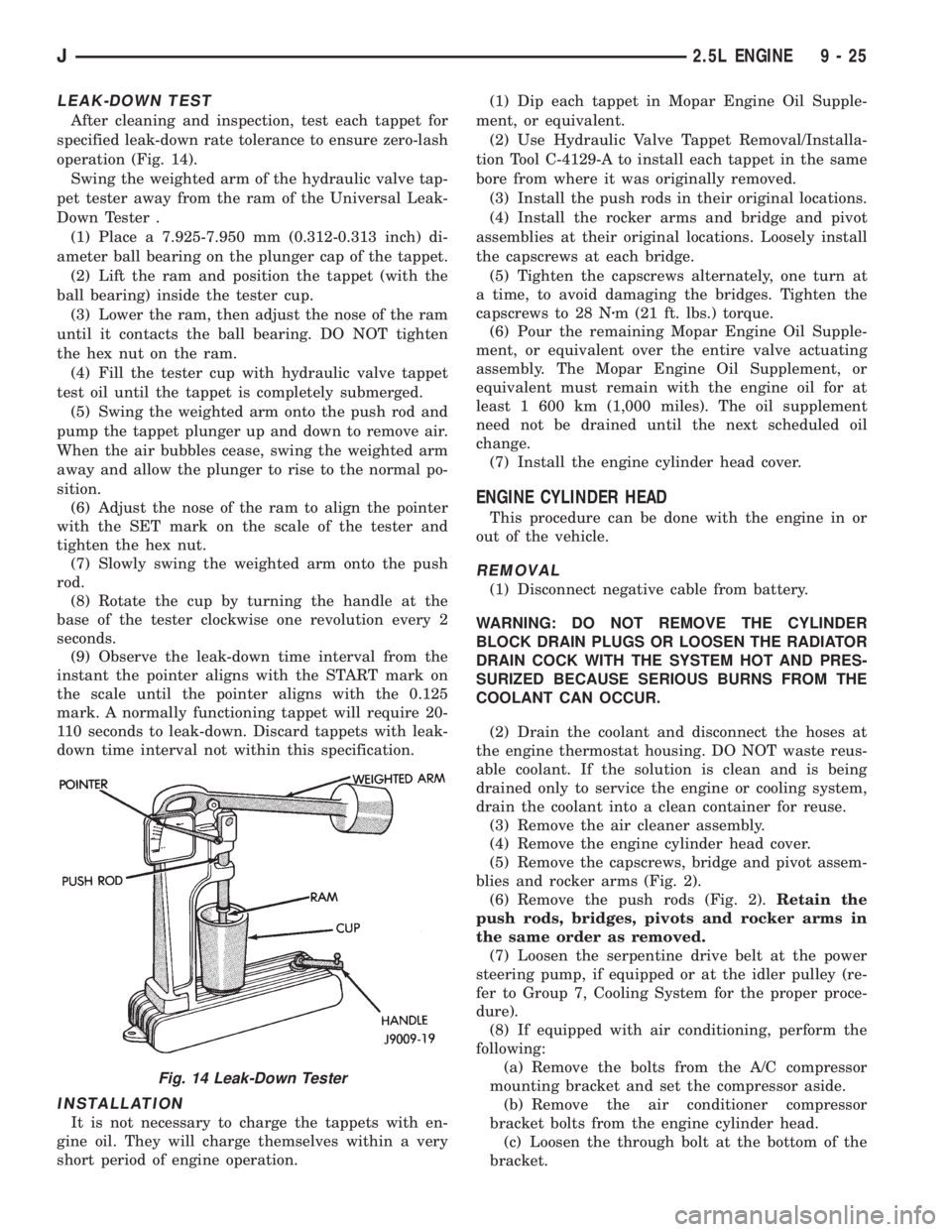

LEAK-DOWN TEST

After cleaning and inspection, test each tappet for

specified leak-down rate tolerance to ensure zero-lash

operation (Fig. 14).

Swing the weighted arm of the hydraulic valve tap-

pet tester away from the ram of the Universal Leak-

Down Tester .

(1) Place a 7.925-7.950 mm (0.312-0.313 inch) di-

ameter ball bearing on the plunger cap of the tappet.

(2) Lift the ram and position the tappet (with the

ball bearing) inside the tester cup.

(3) Lower the ram, then adjust the nose of the ram

until it contacts the ball bearing. DO NOT tighten

the hex nut on the ram.

(4) Fill the tester cup with hydraulic valve tappet

test oil until the tappet is completely submerged.

(5) Swing the weighted arm onto the push rod and

pump the tappet plunger up and down to remove air.

When the air bubbles cease, swing the weighted arm

away and allow the plunger to rise to the normal po-

sition.

(6) Adjust the nose of the ram to align the pointer

with the SET mark on the scale of the tester and

tighten the hex nut.

(7) Slowly swing the weighted arm onto the push

rod.

(8) Rotate the cup by turning the handle at the

base of the tester clockwise one revolution every 2

seconds.

(9) Observe the leak-down time interval from the

instant the pointer aligns with the START mark on

the scale until the pointer aligns with the 0.125

mark. A normally functioning tappet will require 20-

110 seconds to leak-down. Discard tappets with leak-

down time interval not within this specification.

INSTALLATION

It is not necessary to charge the tappets with en-

gine oil. They will charge themselves within a very

short period of engine operation.(1) Dip each tappet in Mopar Engine Oil Supple-

ment, or equivalent.

(2) Use Hydraulic Valve Tappet Removal/Installa-

tion Tool C-4129-A to install each tappet in the same

bore from where it was originally removed.

(3) Install the push rods in their original locations.

(4) Install the rocker arms and bridge and pivot

assemblies at their original locations. Loosely install

the capscrews at each bridge.

(5) Tighten the capscrews alternately, one turn at

a time, to avoid damaging the bridges. Tighten the

capscrews to 28 Nzm (21 ft. lbs.) torque.

(6) Pour the remaining Mopar Engine Oil Supple-

ment, or equivalent over the entire valve actuating

assembly. The Mopar Engine Oil Supplement, or

equivalent must remain with the engine oil for at

least 1 600 km (1,000 miles). The oil supplement

need not be drained until the next scheduled oil

change.

(7) Install the engine cylinder head cover.

ENGINE CYLINDER HEAD

This procedure can be done with the engine in or

out of the vehicle.

REMOVAL

(1) Disconnect negative cable from battery.

WARNING: DO NOT REMOVE THE CYLINDER

BLOCK DRAIN PLUGS OR LOOSEN THE RADIATOR

DRAIN COCK WITH THE SYSTEM HOT AND PRES-

SURIZED BECAUSE SERIOUS BURNS FROM THE

COOLANT CAN OCCUR.

(2) Drain the coolant and disconnect the hoses at

the engine thermostat housing. DO NOT waste reus-

able coolant. If the solution is clean and is being

drained only to service the engine or cooling system,

drain the coolant into a clean container for reuse.

(3) Remove the air cleaner assembly.

(4) Remove the engine cylinder head cover.

(5) Remove the capscrews, bridge and pivot assem-

blies and rocker arms (Fig. 2).

(6) Remove the push rods (Fig. 2).Retain the

push rods, bridges, pivots and rocker arms in

the same order as removed.

(7) Loosen the serpentine drive belt at the power

steering pump, if equipped or at the idler pulley (re-

fer to Group 7, Cooling System for the proper proce-

dure).

(8) If equipped with air conditioning, perform the

following:

(a) Remove the bolts from the A/C compressor

mounting bracket and set the compressor aside.

(b) Remove the air conditioner compressor

bracket bolts from the engine cylinder head.

(c) Loosen the through bolt at the bottom of the

bracket.

Fig. 14 Leak-Down Tester

J2.5L ENGINE 9 - 25

Page 1121 of 2198

at the engine cylinder head. Also tap the top of the

retainer to seat the valve locks.

(8) Install the engine cylinder head.

VALVE TIMING

Disconnect the spark plug wires and remove the

spark plugs.

Remove the engine cylinder head cover.

Remove the capscrews, bridge and pivot assembly,

and rocker arms from above the No.1 cylinder.

Alternately loosen each capscrew, one turn at a

time, to avoid damaging the bridge.

Rotate the crankshaft until the No.4 piston is at

top dead center (TDC) on the compression stroke.

Rotate the crankshaft counterclockwise (viewed

from the front of the engine) 90É.

Install a dial indicator on the end of the No.1 cyl-

inder intake valve push rod. Use rubber tubing to se-

cure the indicator stem on the push rod.

Set the dial indicator pointer at zero.

Rotate the crankshaft clockwise (viewed from the

front of the engine) until the dial indicator pointer

indicates 0.305 mm (0.012 inch) travel distance (lift).

The timing notch index on the vibration damper

should be aligned with the TDC mark on the timing

degree scale.

If the timing notch is more than 13 mm (1/2 inch)

away from the TDC mark in either direction, the

valve timing is incorrect.

If the valve timing is incorrect, the cause may be a

broken camshaft pin. It is not necessary to replace

the camshaft because of pin failure. A spring pin is

available for service replacement.

VIBRATION DAMPER

REMOVAL

(1) Disconnect negative cable from battery.

(2) Remove the serpentine drive belt and fan

shroud.

(3) Remove the vibration damper retaining bolt

and washer.

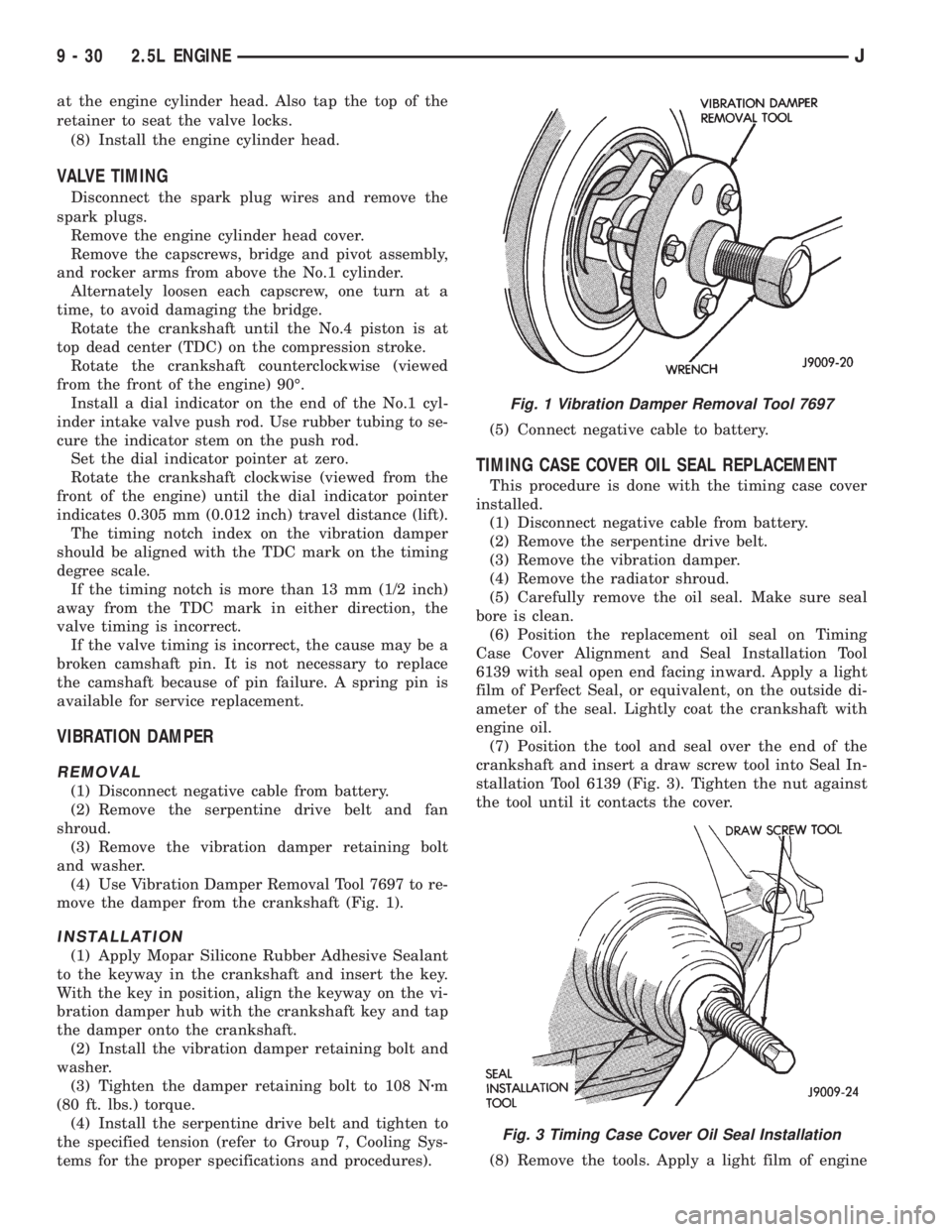

(4) Use Vibration Damper Removal Tool 7697 to re-

move the damper from the crankshaft (Fig. 1).

INSTALLATION

(1) Apply Mopar Silicone Rubber Adhesive Sealant

to the keyway in the crankshaft and insert the key.

With the key in position, align the keyway on the vi-

bration damper hub with the crankshaft key and tap

the damper onto the crankshaft.

(2) Install the vibration damper retaining bolt and

washer.

(3) Tighten the damper retaining bolt to 108 Nzm

(80 ft. lbs.) torque.

(4) Install the serpentine drive belt and tighten to

the specified tension (refer to Group 7, Cooling Sys-

tems for the proper specifications and procedures).(5) Connect negative cable to battery.

TIMING CASE COVER OIL SEAL REPLACEMENT

This procedure is done with the timing case cover

installed.

(1) Disconnect negative cable from battery.

(2) Remove the serpentine drive belt.

(3) Remove the vibration damper.

(4) Remove the radiator shroud.

(5) Carefully remove the oil seal. Make sure seal

bore is clean.

(6) Position the replacement oil seal on Timing

Case Cover Alignment and Seal Installation Tool

6139 with seal open end facing inward. Apply a light

film of Perfect Seal, or equivalent, on the outside di-

ameter of the seal. Lightly coat the crankshaft with

engine oil.

(7) Position the tool and seal over the end of the

crankshaft and insert a draw screw tool into Seal In-

stallation Tool 6139 (Fig. 3). Tighten the nut against

the tool until it contacts the cover.

(8) Remove the tools. Apply a light film of engine

Fig. 1 Vibration Damper Removal Tool 7697

Fig. 3 Timing Case Cover Oil Seal Installation

9 - 30 2.5L ENGINEJ

Page 1146 of 2198

4.0L ENGINE SERVICE PROCEDURES

INDEX

page page

Camshaft............................... 74

Camshaft Pin Replacement.................. 75

Engine AssemblyÐXJ Vehicles............... 59

Engine AssemblyÐYJ Vehicles............... 62

Engine Cylinder Head...................... 67

Engine Cylinder Head Cover................. 64

Engine MountÐRear....................... 57

Engine MountsÐFront..................... 56

General Information....................... 55

Hydraulic Tappets......................... 66

OilPan ................................. 77Rocker Arms and Push Rods................ 65

Timing Case Cover........................ 72

Timing Case Cover Oil Seal Replacement....... 73

Timing Chain and Sprockets................. 73

Valve Component ReplaceÐCylinder Head Not

Removed.............................. 65

Valve Stem Seal and Spring Replacement....... 65

Valve Timing............................. 71

Valves and Valve Springs................... 69

Vibration Damper......................... 72

GENERAL INFORMATION

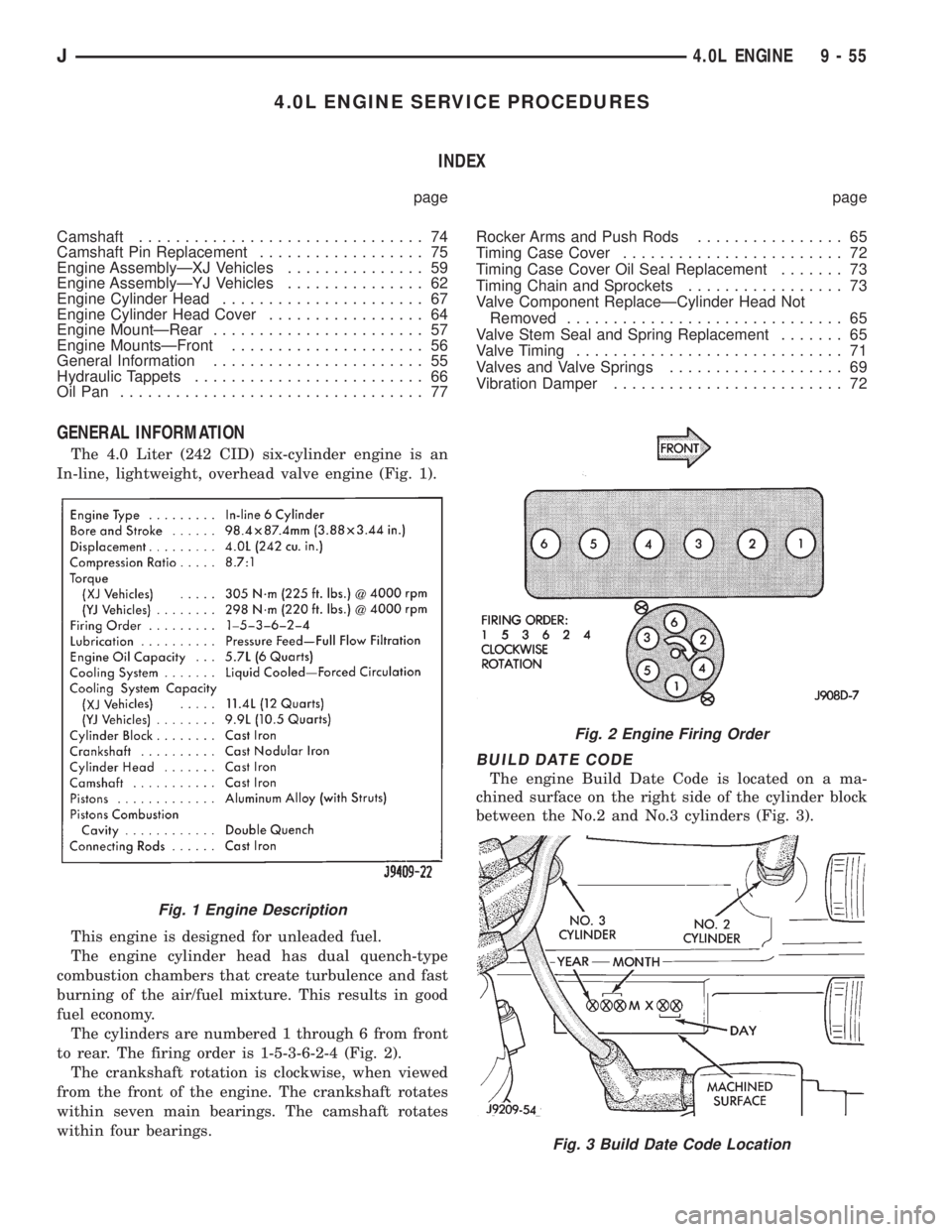

The 4.0 Liter (242 CID) six-cylinder engine is an

In-line, lightweight, overhead valve engine (Fig. 1).

This engine is designed for unleaded fuel.

The engine cylinder head has dual quench-type

combustion chambers that create turbulence and fast

burning of the air/fuel mixture. This results in good

fuel economy.

The cylinders are numbered 1 through 6 from front

to rear. The firing order is 1-5-3-6-2-4 (Fig. 2).

The crankshaft rotation is clockwise, when viewed

from the front of the engine. The crankshaft rotates

within seven main bearings. The camshaft rotates

within four bearings.

BUILD DATE CODE

The engine Build Date Code is located on a ma-

chined surface on the right side of the cylinder block

between the No.2 and No.3 cylinders (Fig. 3).

Fig. 1 Engine Description

Fig. 2 Engine Firing Order

Fig. 3 Build Date Code Location

J4.0L ENGINE 9 - 55