clock JEEP CHEROKEE 1995 Service Workshop Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 1995, Model line: CHEROKEE, Model: JEEP CHEROKEE 1995Pages: 2198, PDF Size: 82.83 MB

Page 1367 of 2198

(27) Position the steering column in the center,

non-tilt position.

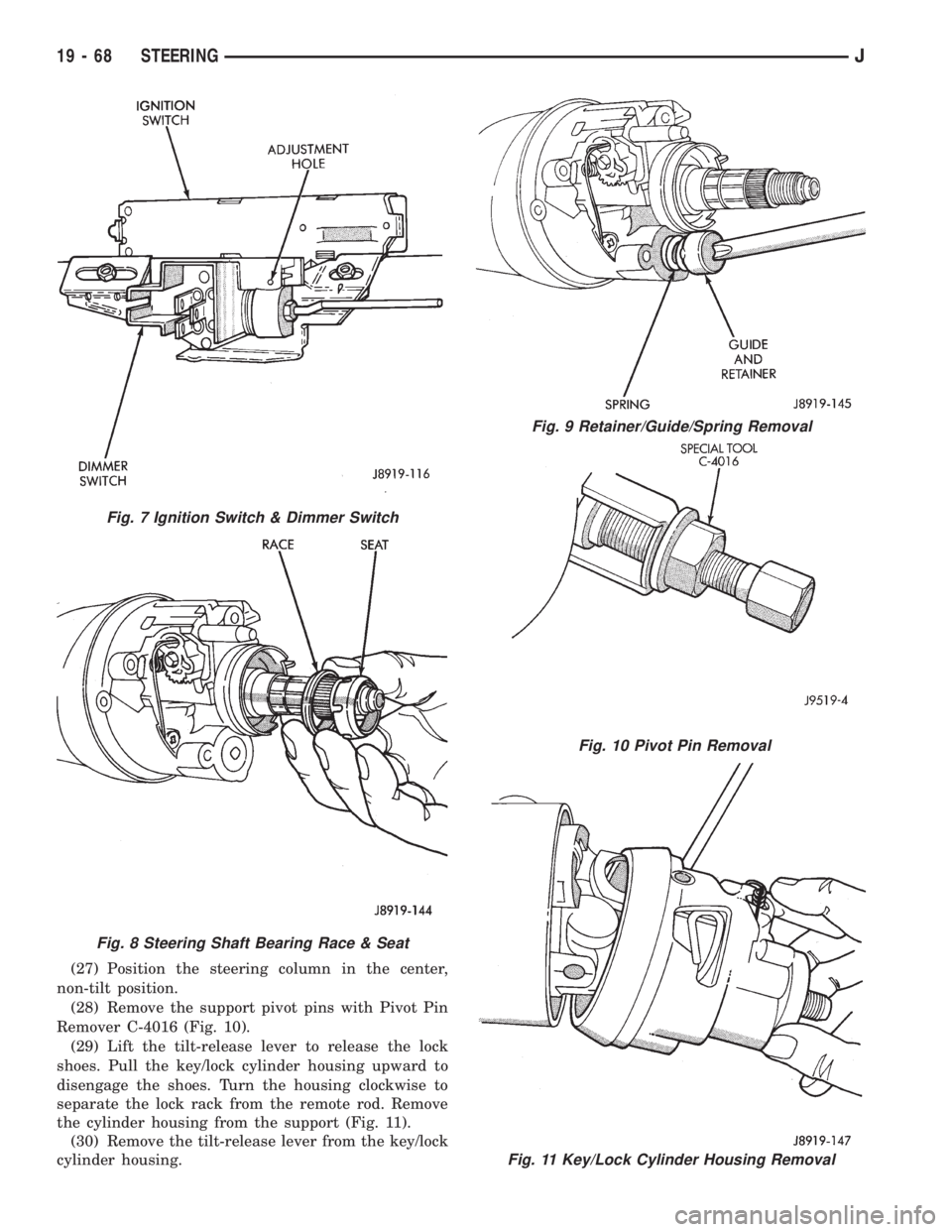

(28) Remove the support pivot pins with Pivot Pin

Remover C-4016 (Fig. 10).

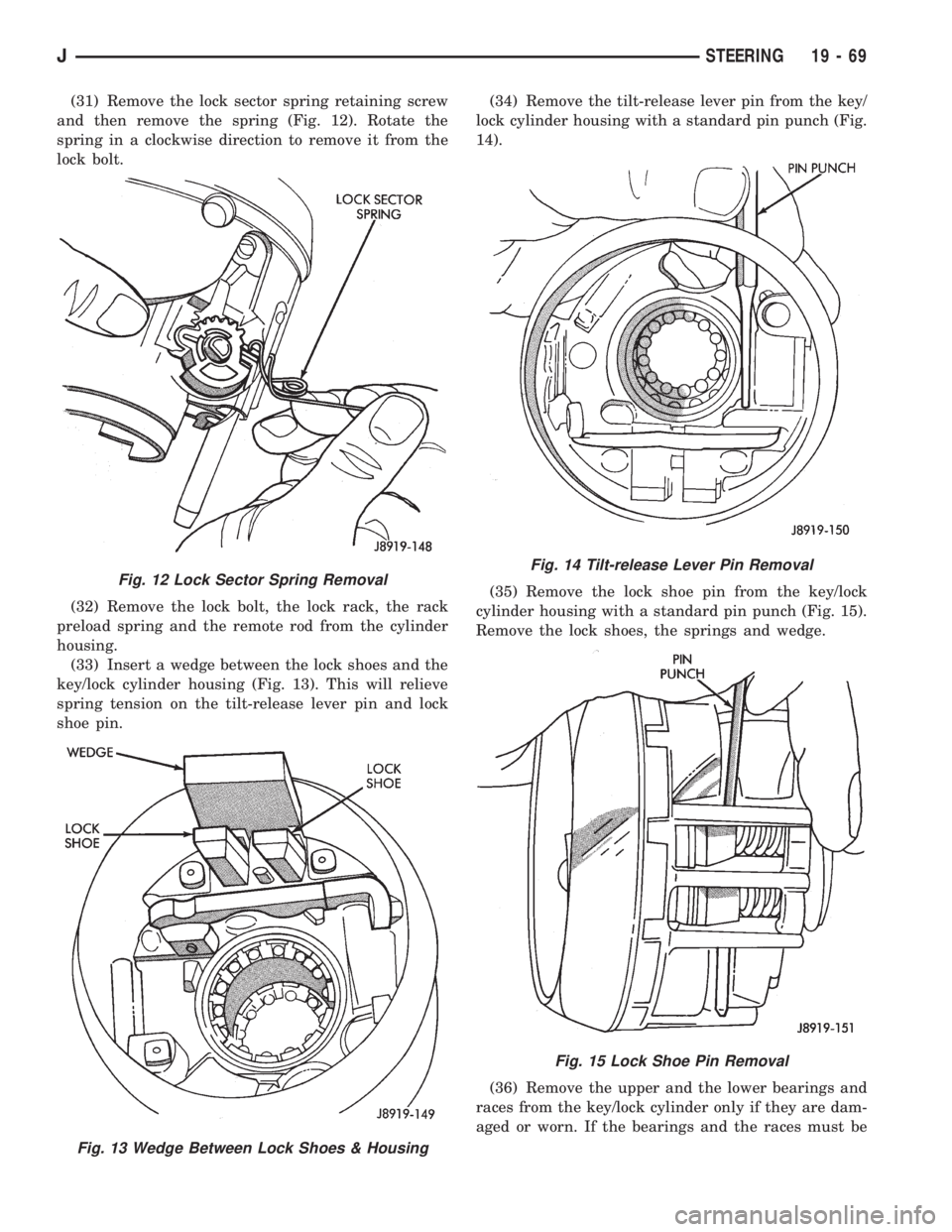

(29) Lift the tilt-release lever to release the lock

shoes. Pull the key/lock cylinder housing upward to

disengage the shoes. Turn the housing clockwise to

separate the lock rack from the remote rod. Remove

the cylinder housing from the support (Fig. 11).

(30) Remove the tilt-release lever from the key/lock

cylinder housing.

Fig. 10 Pivot Pin Removal

Fig. 11 Key/Lock Cylinder Housing Removal

Fig. 7 Ignition Switch & Dimmer Switch

Fig. 8 Steering Shaft Bearing Race & Seat

Fig. 9 Retainer/Guide/Spring Removal

19 - 68 STEERINGJ

Page 1368 of 2198

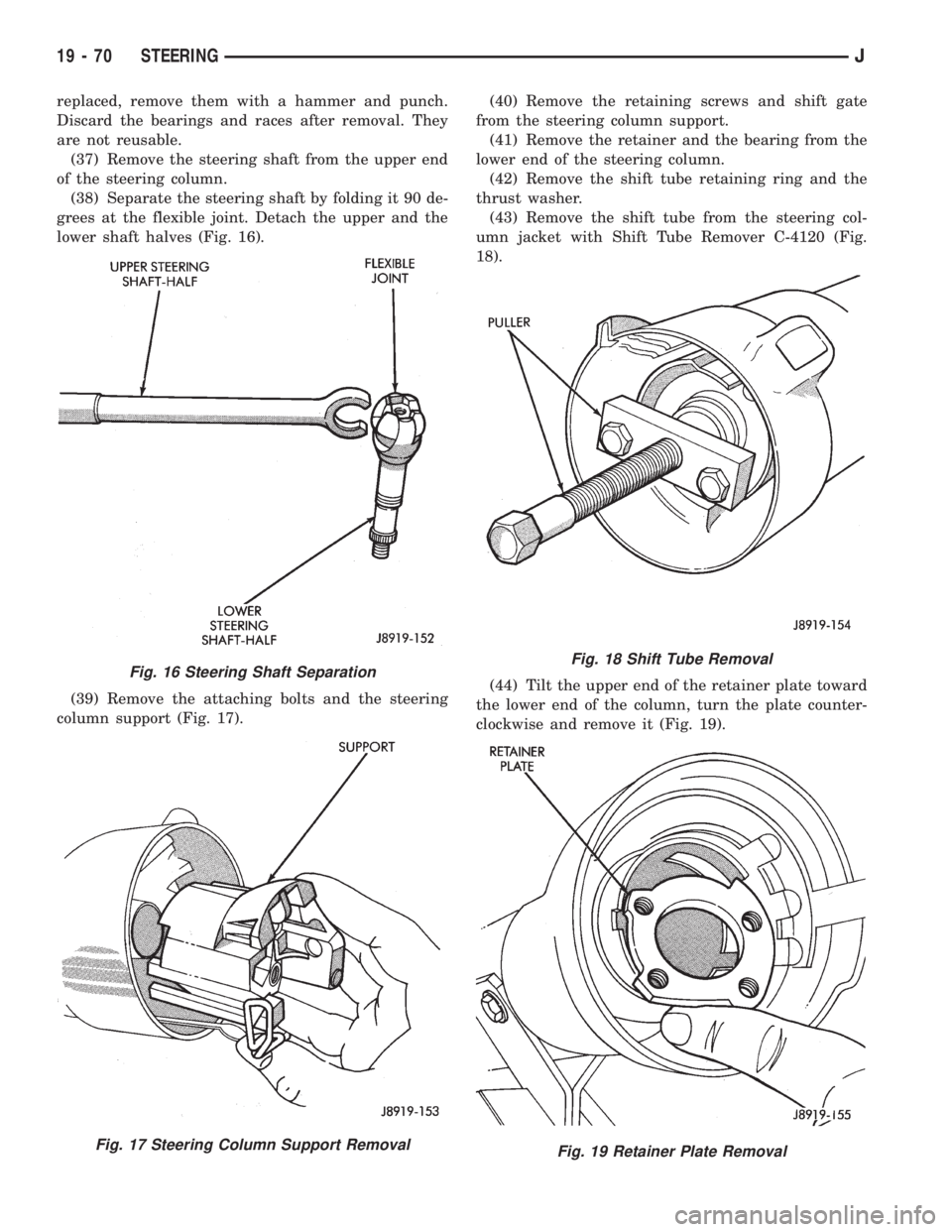

(31) Remove the lock sector spring retaining screw

and then remove the spring (Fig. 12). Rotate the

spring in a clockwise direction to remove it from the

lock bolt.

(32) Remove the lock bolt, the lock rack, the rack

preload spring and the remote rod from the cylinder

housing.

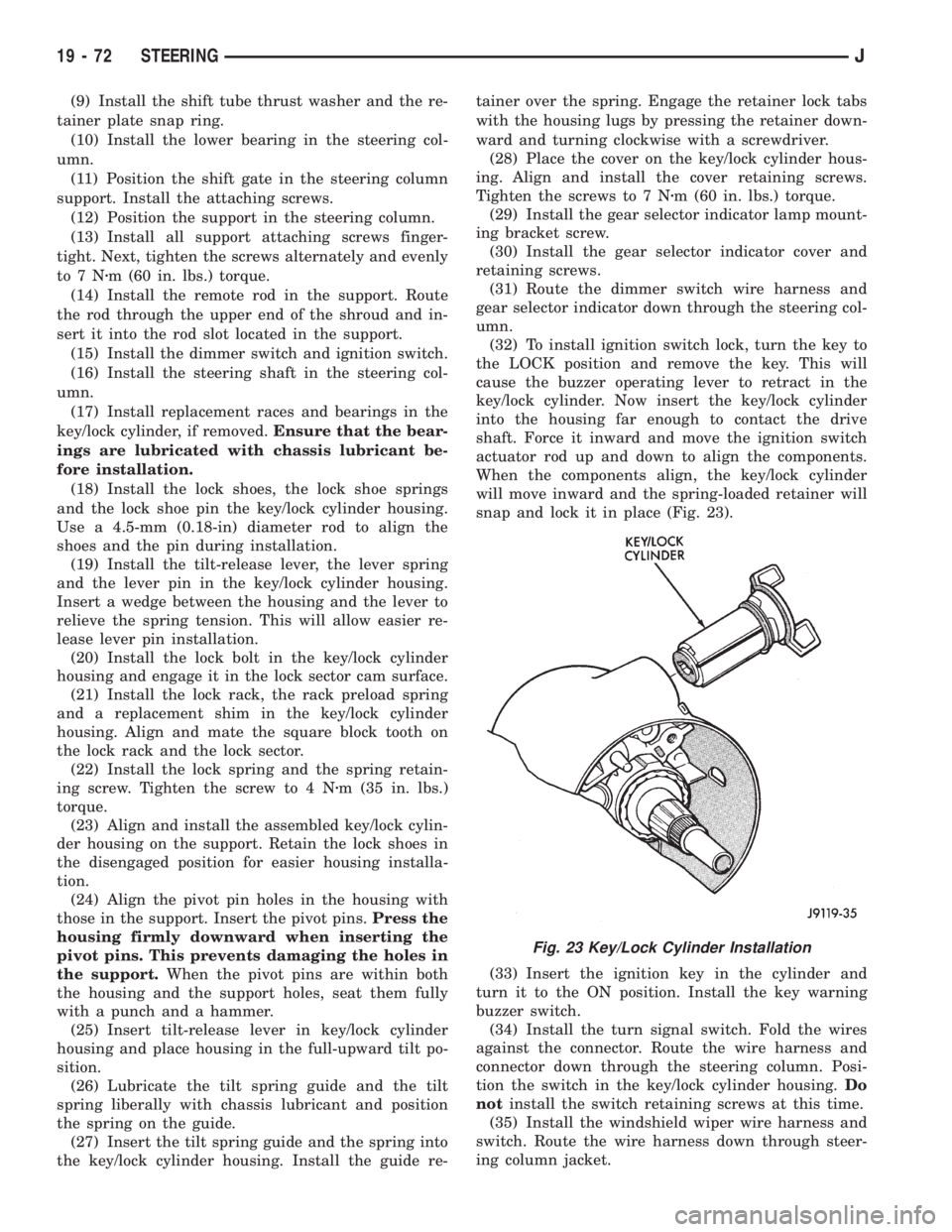

(33) Insert a wedge between the lock shoes and the

key/lock cylinder housing (Fig. 13). This will relieve

spring tension on the tilt-release lever pin and lock

shoe pin.(34) Remove the tilt-release lever pin from the key/

lock cylinder housing with a standard pin punch (Fig.

14).

(35) Remove the lock shoe pin from the key/lock

cylinder housing with a standard pin punch (Fig. 15).

Remove the lock shoes, the springs and wedge.

(36) Remove the upper and the lower bearings and

races from the key/lock cylinder only if they are dam-

aged or worn. If the bearings and the races must be

Fig. 12 Lock Sector Spring Removal

Fig. 13 Wedge Between Lock Shoes & Housing

Fig. 14 Tilt-release Lever Pin Removal

Fig. 15 Lock Shoe Pin Removal

JSTEERING 19 - 69

Page 1369 of 2198

replaced, remove them with a hammer and punch.

Discard the bearings and races after removal. They

are not reusable.

(37) Remove the steering shaft from the upper end

of the steering column.

(38) Separate the steering shaft by folding it 90 de-

grees at the flexible joint. Detach the upper and the

lower shaft halves (Fig. 16).

(39) Remove the attaching bolts and the steering

column support (Fig. 17).(40) Remove the retaining screws and shift gate

from the steering column support.

(41) Remove the retainer and the bearing from the

lower end of the steering column.

(42) Remove the shift tube retaining ring and the

thrust washer.

(43) Remove the shift tube from the steering col-

umn jacket with Shift Tube Remover C-4120 (Fig.

18).

(44) Tilt the upper end of the retainer plate toward

the lower end of the column, turn the plate counter-

clockwise and remove it (Fig. 19).

Fig. 16 Steering Shaft Separation

Fig. 17 Steering Column Support Removal

Fig. 18 Shift Tube Removal

Fig. 19 Retainer Plate Removal

19 - 70 STEERINGJ

Page 1371 of 2198

(9) Install the shift tube thrust washer and the re-

tainer plate snap ring.

(10) Install the lower bearing in the steering col-

umn.

(11) Position the shift gate in the steering column

support. Install the attaching screws.

(12) Position the support in the steering column.

(13) Install all support attaching screws finger-

tight. Next, tighten the screws alternately and evenly

to7Nzm (60 in. lbs.) torque.

(14) Install the remote rod in the support. Route

the rod through the upper end of the shroud and in-

sert it into the rod slot located in the support.

(15) Install the dimmer switch and ignition switch.

(16) Install the steering shaft in the steering col-

umn.

(17) Install replacement races and bearings in the

key/lock cylinder, if removed.Ensure that the bear-

ings are lubricated with chassis lubricant be-

fore installation.

(18) Install the lock shoes, the lock shoe springs

and the lock shoe pin the key/lock cylinder housing.

Use a 4.5-mm (0.18-in) diameter rod to align the

shoes and the pin during installation.

(19) Install the tilt-release lever, the lever spring

and the lever pin in the key/lock cylinder housing.

Insert a wedge between the housing and the lever to

relieve the spring tension. This will allow easier re-

lease lever pin installation.

(20) Install the lock bolt in the key/lock cylinder

housing and engage it in the lock sector cam surface.

(21) Install the lock rack, the rack preload spring

and a replacement shim in the key/lock cylinder

housing. Align and mate the square block tooth on

the lock rack and the lock sector.

(22) Install the lock spring and the spring retain-

ing screw. Tighten the screw to 4 Nzm (35 in. lbs.)

torque.

(23) Align and install the assembled key/lock cylin-

der housing on the support. Retain the lock shoes in

the disengaged position for easier housing installa-

tion.

(24) Align the pivot pin holes in the housing with

those in the support. Insert the pivot pins.Press the

housing firmly downward when inserting the

pivot pins. This prevents damaging the holes in

the support.When the pivot pins are within both

the housing and the support holes, seat them fully

with a punch and a hammer.

(25) Insert tilt-release lever in key/lock cylinder

housing and place housing in the full-upward tilt po-

sition.

(26) Lubricate the tilt spring guide and the tilt

spring liberally with chassis lubricant and position

the spring on the guide.

(27) Insert the tilt spring guide and the spring into

the key/lock cylinder housing. Install the guide re-tainer over the spring. Engage the retainer lock tabs

with the housing lugs by pressing the retainer down-

ward and turning clockwise with a screwdriver.

(28) Place the cover on the key/lock cylinder hous-

ing. Align and install the cover retaining screws.

Tighten the screws to 7 Nzm (60 in. lbs.) torque.

(29) Install the gear selector indicator lamp mount-

ing bracket screw.

(30) Install the gear selector indicator cover and

retaining screws.

(31) Route the dimmer switch wire harness and

gear selector indicator down through the steering col-

umn.

(32) To install ignition switch lock, turn the key to

the LOCK position and remove the key. This will

cause the buzzer operating lever to retract in the

key/lock cylinder. Now insert the key/lock cylinder

into the housing far enough to contact the drive

shaft. Force it inward and move the ignition switch

actuator rod up and down to align the components.

When the components align, the key/lock cylinder

will move inward and the spring-loaded retainer will

snap and lock it in place (Fig. 23).

(33) Insert the ignition key in the cylinder and

turn it to the ON position. Install the key warning

buzzer switch.

(34) Install the turn signal switch. Fold the wires

against the connector. Route the wire harness and

connector down through the steering column. Posi-

tion the switch in the key/lock cylinder housing.Do

notinstall the switch retaining screws at this time.

(35) Install the windshield wiper wire harness and

switch. Route the wire harness down through steer-

ing column jacket.

Fig. 23 Key/Lock Cylinder Installation

19 - 72 STEERINGJ

Page 1375 of 2198

(4) Tighten fittings at pump and gear to 28 Nzm

(21 ft. lbs.) torque.

(5) After installation, add power steering fluid, in-

spect and test for fluid leaks.

PUMP REPLACEMENT

REMOVAL

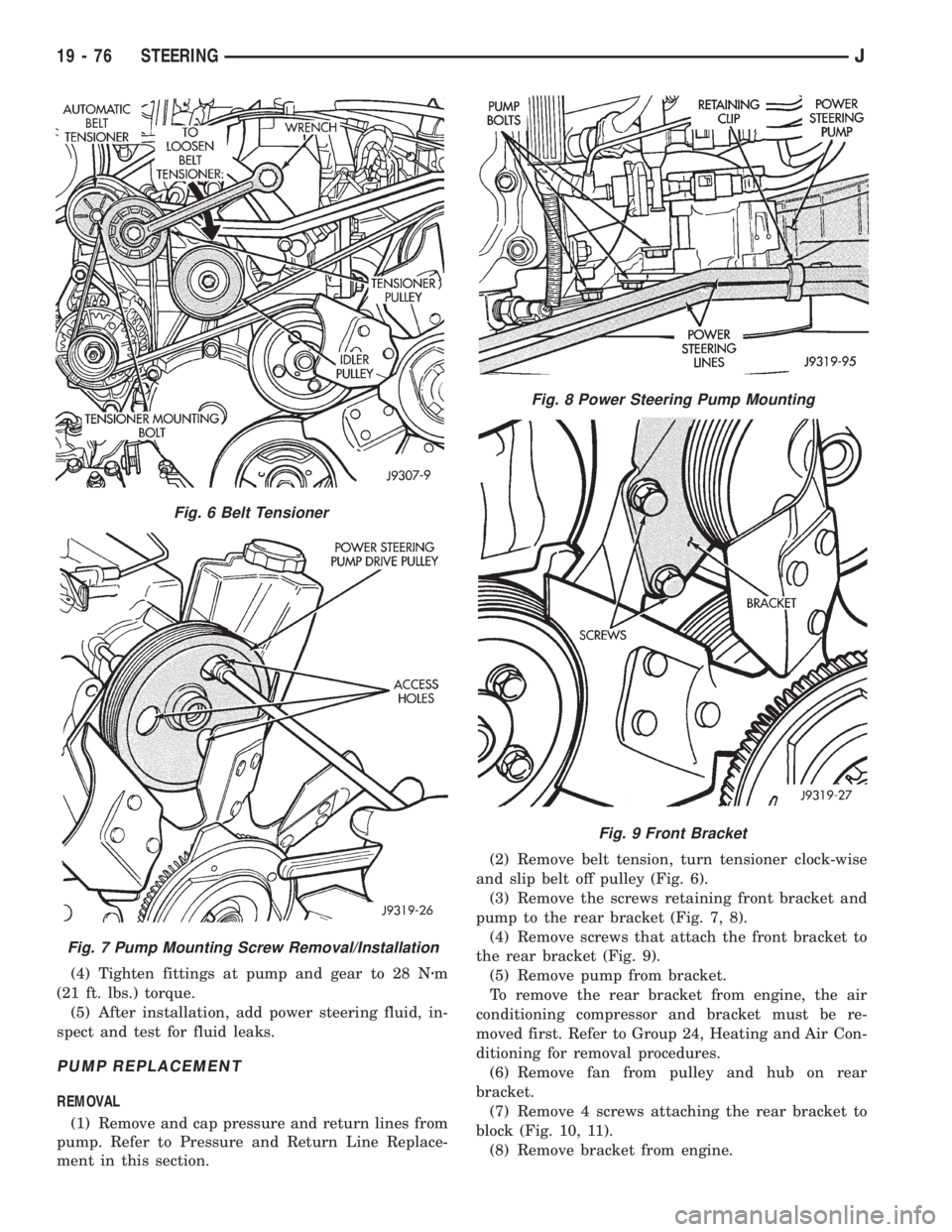

(1) Remove and cap pressure and return lines from

pump. Refer to Pressure and Return Line Replace-

ment in this section.(2) Remove belt tension, turn tensioner clock-wise

and slip belt off pulley (Fig. 6).

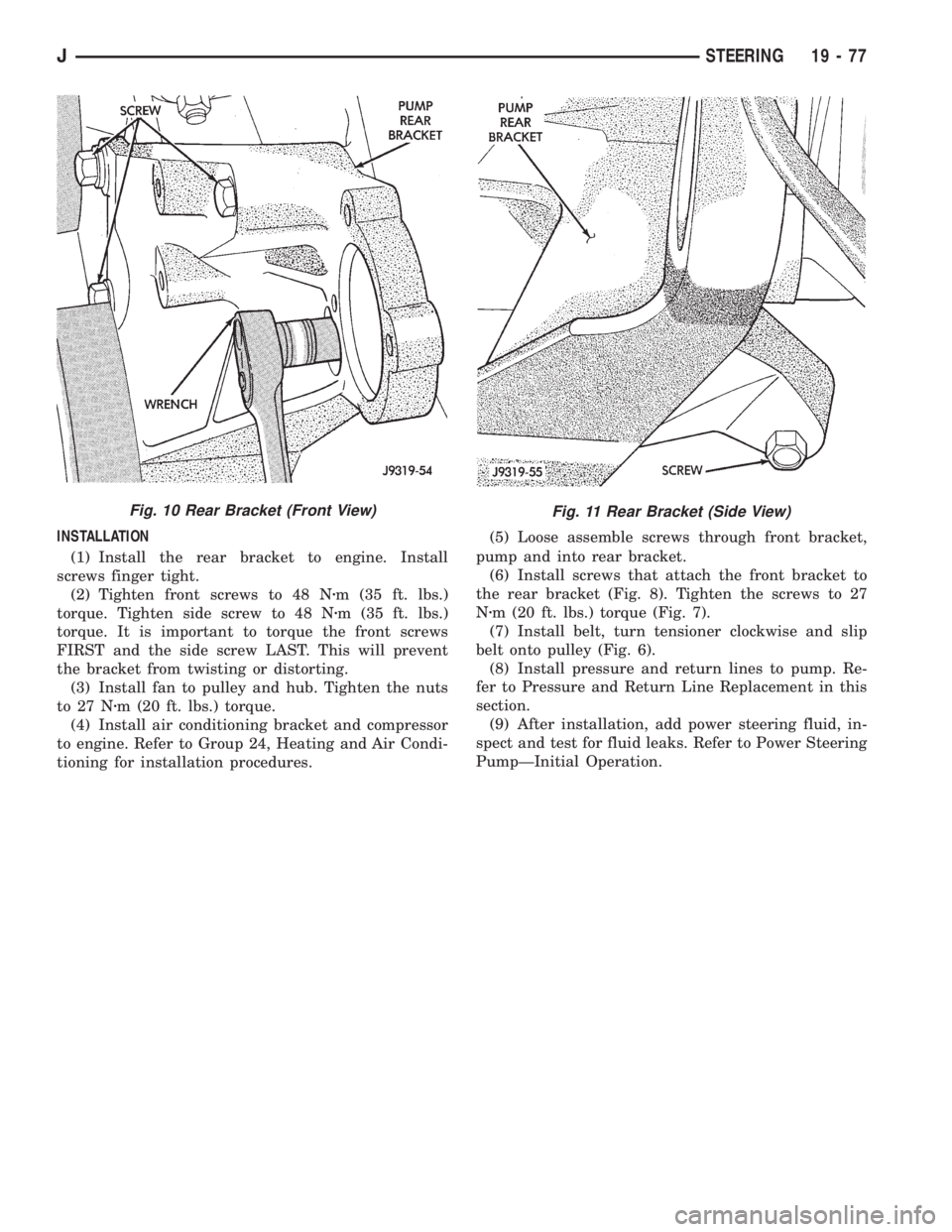

(3) Remove the screws retaining front bracket and

pump to the rear bracket (Fig. 7, 8).

(4) Remove screws that attach the front bracket to

the rear bracket (Fig. 9).

(5) Remove pump from bracket.

To remove the rear bracket from engine, the air

conditioning compressor and bracket must be re-

moved first. Refer to Group 24, Heating and Air Con-

ditioning for removal procedures.

(6) Remove fan from pulley and hub on rear

bracket.

(7) Remove 4 screws attaching the rear bracket to

block (Fig. 10, 11).

(8) Remove bracket from engine.

Fig. 6 Belt Tensioner

Fig. 7 Pump Mounting Screw Removal/Installation

Fig. 8 Power Steering Pump Mounting

Fig. 9 Front Bracket

19 - 76 STEERINGJ

Page 1376 of 2198

INSTALLATION

(1) Install the rear bracket to engine. Install

screws finger tight.

(2) Tighten front screws to 48 Nzm (35 ft. lbs.)

torque. Tighten side screw to 48 Nzm (35 ft. lbs.)

torque. It is important to torque the front screws

FIRST and the side screw LAST. This will prevent

the bracket from twisting or distorting.

(3) Install fan to pulley and hub. Tighten the nuts

to 27 Nzm (20 ft. lbs.) torque.

(4) Install air conditioning bracket and compressor

to engine. Refer to Group 24, Heating and Air Condi-

tioning for installation procedures.(5) Loose assemble screws through front bracket,

pump and into rear bracket.

(6) Install screws that attach the front bracket to

the rear bracket (Fig. 8). Tighten the screws to 27

Nzm (20 ft. lbs.) torque (Fig. 7).

(7) Install belt, turn tensioner clockwise and slip

belt onto pulley (Fig. 6).

(8) Install pressure and return lines to pump. Re-

fer to Pressure and Return Line Replacement in this

section.

(9) After installation, add power steering fluid, in-

spect and test for fluid leaks. Refer to Power Steering

PumpÐInitial Operation.

Fig. 11 Rear Bracket (Side View)Fig. 10 Rear Bracket (Front View)

JSTEERING 19 - 77

Page 1381 of 2198

(7) Disconnect transfer case shift linkage at trans-

fer case.

(8) Disconnect vehicle speed sensor wires and

transfer case vent hose.

(9) Remove slave cylinder from clutch housing.

(10) Disconnect transmission shift lever as follows:

(a) Lower transmission-transfer case assembly

approximately 7-8 cm (3 in.) for access to shift le-

ver.

(b) Reach up and around transmission case and

unseat shift lever dust boot from transmission shift

tower (Fig. 6). Move boot upward on shift lever for

access to retainer that secures lever in shift tower.

(c) Reach up and around transmission case and

press shift lever retainer downward with your fin-

gers. Turn retainer counterclockwise to release it.

(d) Lift lever and retainer out of shift tower (Fig.

6).Do not remove the shift lever from the

floorpan boots. Leave the lever in place for

later transmission installation.

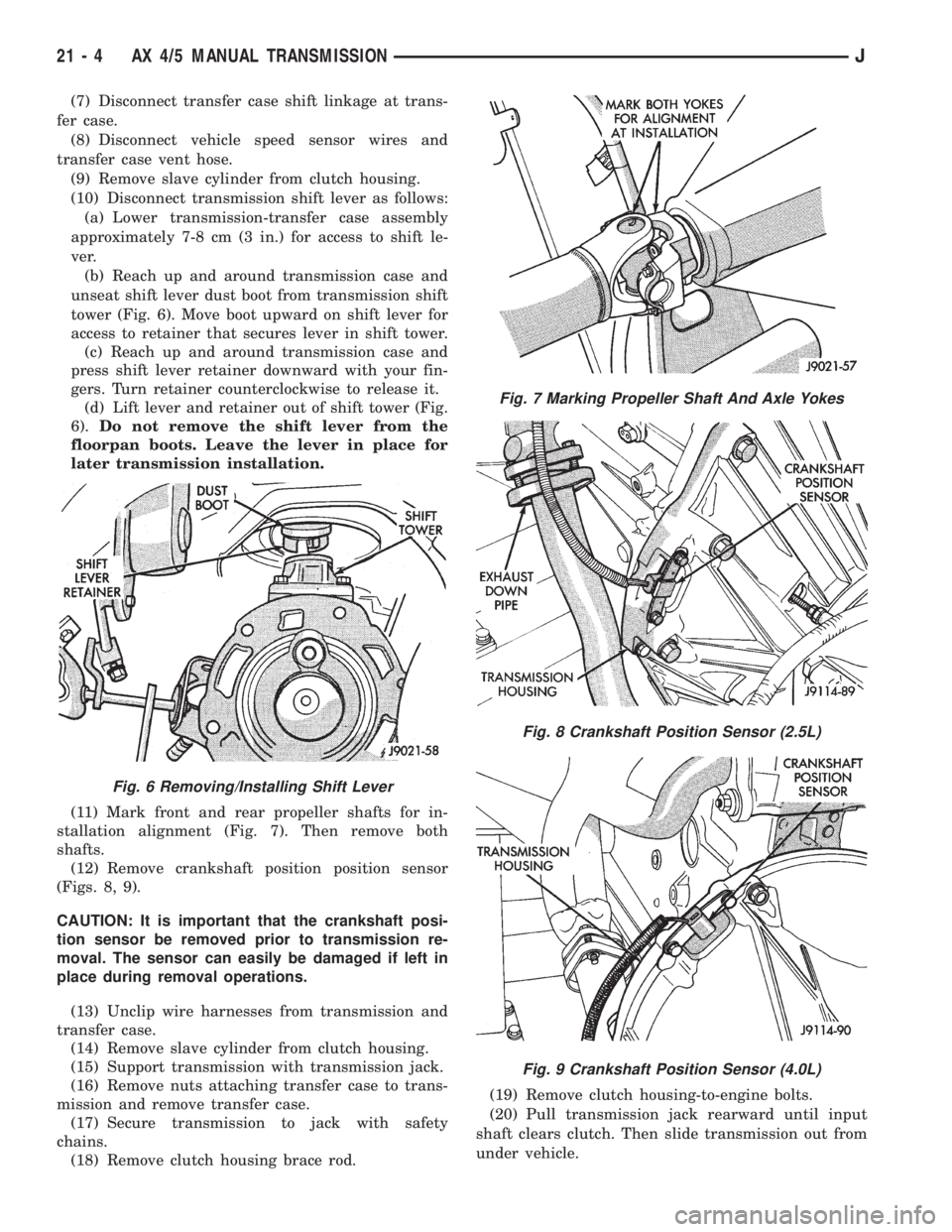

(11) Mark front and rear propeller shafts for in-

stallation alignment (Fig. 7). Then remove both

shafts.

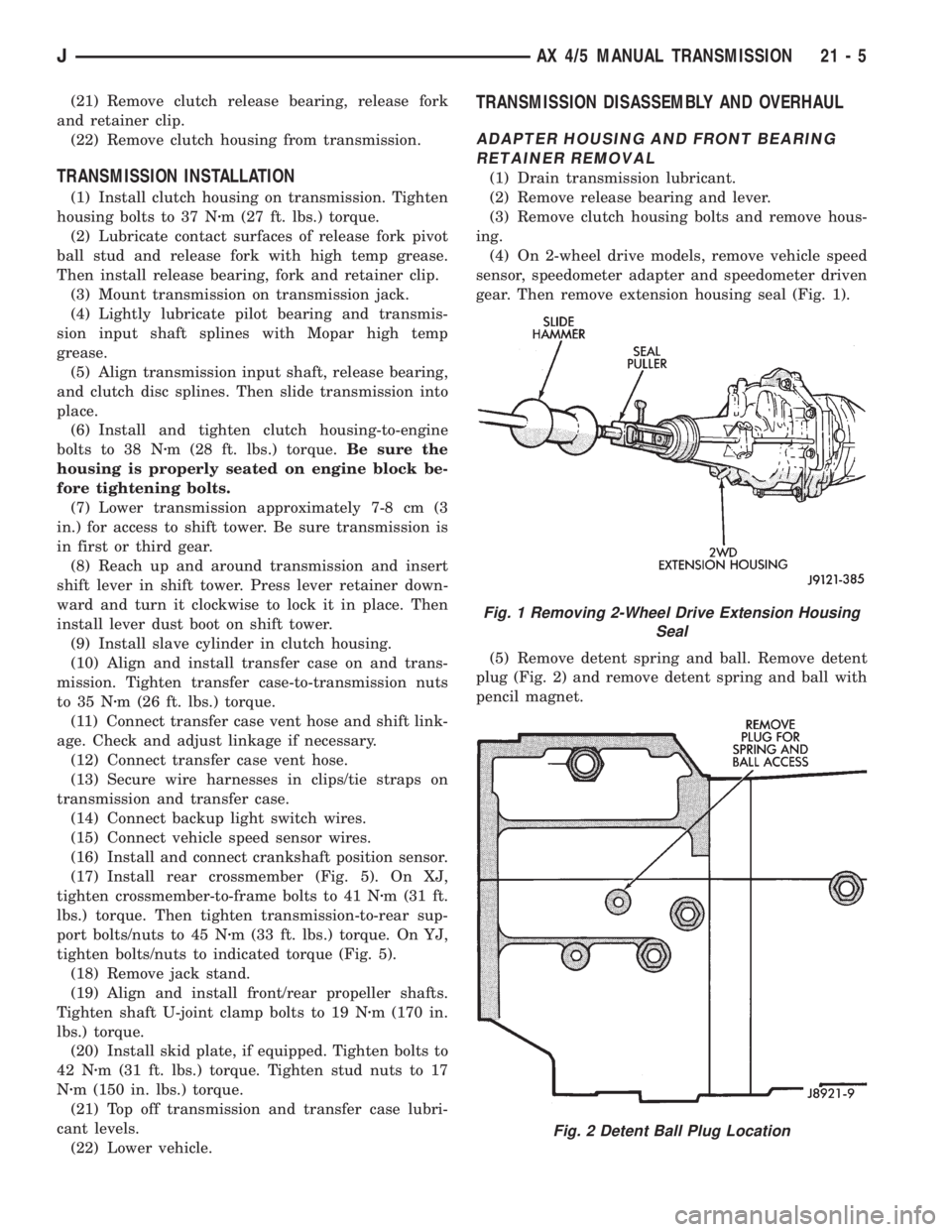

(12) Remove crankshaft position position sensor

(Figs. 8, 9).

CAUTION: It is important that the crankshaft posi-

tion sensor be removed prior to transmission re-

moval. The sensor can easily be damaged if left in

place during removal operations.

(13) Unclip wire harnesses from transmission and

transfer case.

(14) Remove slave cylinder from clutch housing.

(15) Support transmission with transmission jack.

(16) Remove nuts attaching transfer case to trans-

mission and remove transfer case.

(17) Secure transmission to jack with safety

chains.

(18) Remove clutch housing brace rod.(19) Remove clutch housing-to-engine bolts.

(20) Pull transmission jack rearward until input

shaft clears clutch. Then slide transmission out from

under vehicle.

Fig. 6 Removing/Installing Shift Lever

Fig. 7 Marking Propeller Shaft And Axle Yokes

Fig. 8 Crankshaft Position Sensor (2.5L)

Fig. 9 Crankshaft Position Sensor (4.0L)

21 - 4 AX 4/5 MANUAL TRANSMISSIONJ

Page 1382 of 2198

(21) Remove clutch release bearing, release fork

and retainer clip.

(22) Remove clutch housing from transmission.

TRANSMISSION INSTALLATION

(1) Install clutch housing on transmission. Tighten

housing bolts to 37 Nzm (27 ft. lbs.) torque.

(2) Lubricate contact surfaces of release fork pivot

ball stud and release fork with high temp grease.

Then install release bearing, fork and retainer clip.

(3) Mount transmission on transmission jack.

(4) Lightly lubricate pilot bearing and transmis-

sion input shaft splines with Mopar high temp

grease.

(5) Align transmission input shaft, release bearing,

and clutch disc splines. Then slide transmission into

place.

(6) Install and tighten clutch housing-to-engine

bolts to 38 Nzm (28 ft. lbs.) torque.Be sure the

housing is properly seated on engine block be-

fore tightening bolts.

(7) Lower transmission approximately 7-8 cm (3

in.) for access to shift tower. Be sure transmission is

in first or third gear.

(8) Reach up and around transmission and insert

shift lever in shift tower. Press lever retainer down-

ward and turn it clockwise to lock it in place. Then

install lever dust boot on shift tower.

(9) Install slave cylinder in clutch housing.

(10) Align and install transfer case on and trans-

mission. Tighten transfer case-to-transmission nuts

to 35 Nzm (26 ft. lbs.) torque.

(11) Connect transfer case vent hose and shift link-

age. Check and adjust linkage if necessary.

(12) Connect transfer case vent hose.

(13) Secure wire harnesses in clips/tie straps on

transmission and transfer case.

(14) Connect backup light switch wires.

(15) Connect vehicle speed sensor wires.

(16) Install and connect crankshaft position sensor.

(17) Install rear crossmember (Fig. 5). On XJ,

tighten crossmember-to-frame bolts to 41 Nzm (31 ft.

lbs.) torque. Then tighten transmission-to-rear sup-

port bolts/nuts to 45 Nzm (33 ft. lbs.) torque. On YJ,

tighten bolts/nuts to indicated torque (Fig. 5).

(18) Remove jack stand.

(19) Align and install front/rear propeller shafts.

Tighten shaft U-joint clamp bolts to 19 Nzm (170 in.

lbs.) torque.

(20) Install skid plate, if equipped. Tighten bolts to

42 Nzm (31 ft. lbs.) torque. Tighten stud nuts to 17

Nzm (150 in. lbs.) torque.

(21) Top off transmission and transfer case lubri-

cant levels.

(22) Lower vehicle.

TRANSMISSION DISASSEMBLY AND OVERHAUL

ADAPTER HOUSING AND FRONT BEARING

RETAINER REMOVAL

(1) Drain transmission lubricant.

(2) Remove release bearing and lever.

(3) Remove clutch housing bolts and remove hous-

ing.

(4) On 2-wheel drive models, remove vehicle speed

sensor, speedometer adapter and speedometer driven

gear. Then remove extension housing seal (Fig. 1).

(5) Remove detent spring and ball. Remove detent

plug (Fig. 2) and remove detent spring and ball with

pencil magnet.

Fig. 1 Removing 2-Wheel Drive Extension Housing

Seal

Fig. 2 Detent Ball Plug Location

JAX 4/5 MANUAL TRANSMISSION 21 - 5

Page 1413 of 2198

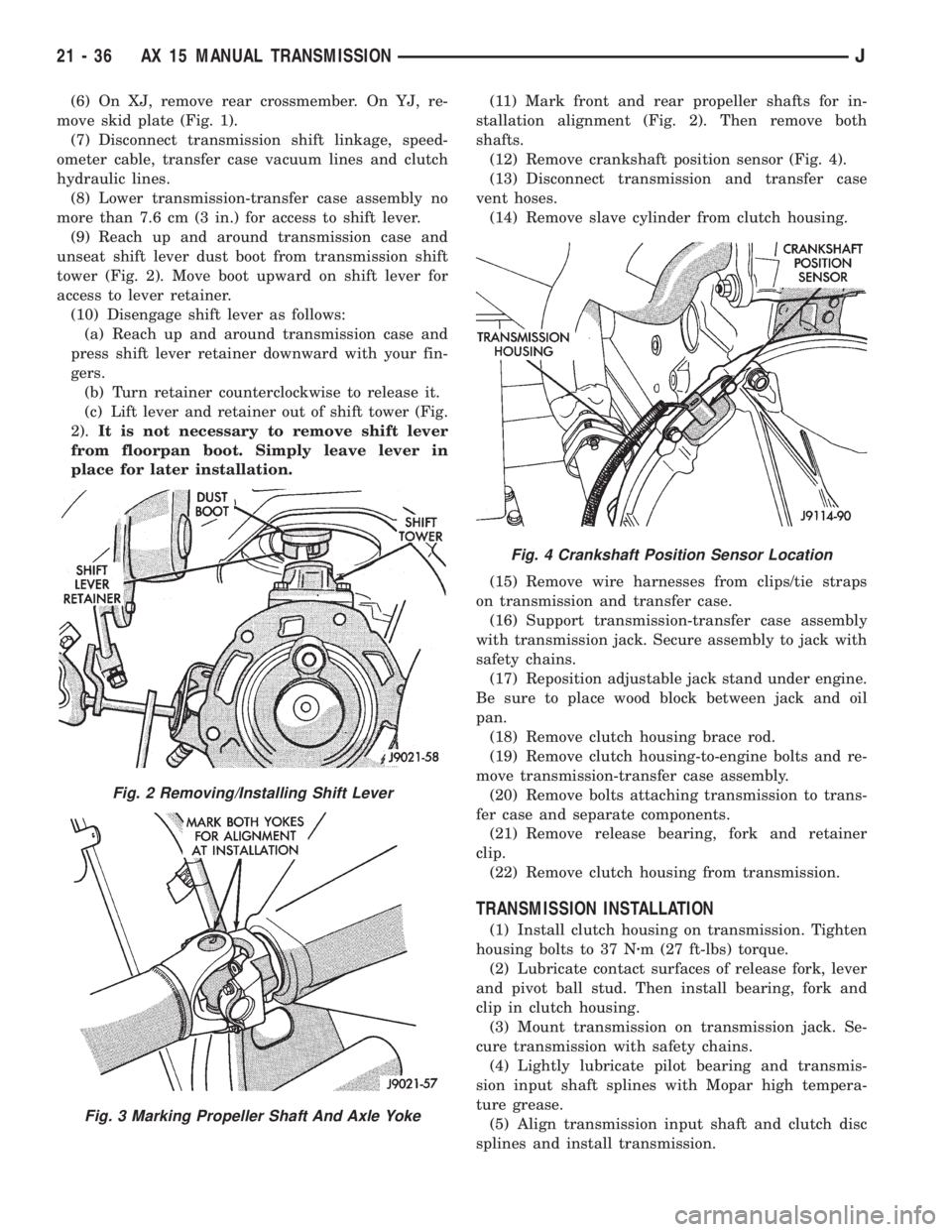

(6) On XJ, remove rear crossmember. On YJ, re-

move skid plate (Fig. 1).

(7) Disconnect transmission shift linkage, speed-

ometer cable, transfer case vacuum lines and clutch

hydraulic lines.

(8) Lower transmission-transfer case assembly no

more than 7.6 cm (3 in.) for access to shift lever.

(9) Reach up and around transmission case and

unseat shift lever dust boot from transmission shift

tower (Fig. 2). Move boot upward on shift lever for

access to lever retainer.

(10) Disengage shift lever as follows:

(a) Reach up and around transmission case and

press shift lever retainer downward with your fin-

gers.

(b) Turn retainer counterclockwise to release it.

(c) Lift lever and retainer out of shift tower (Fig.

2).It is not necessary to remove shift lever

from floorpan boot. Simply leave lever in

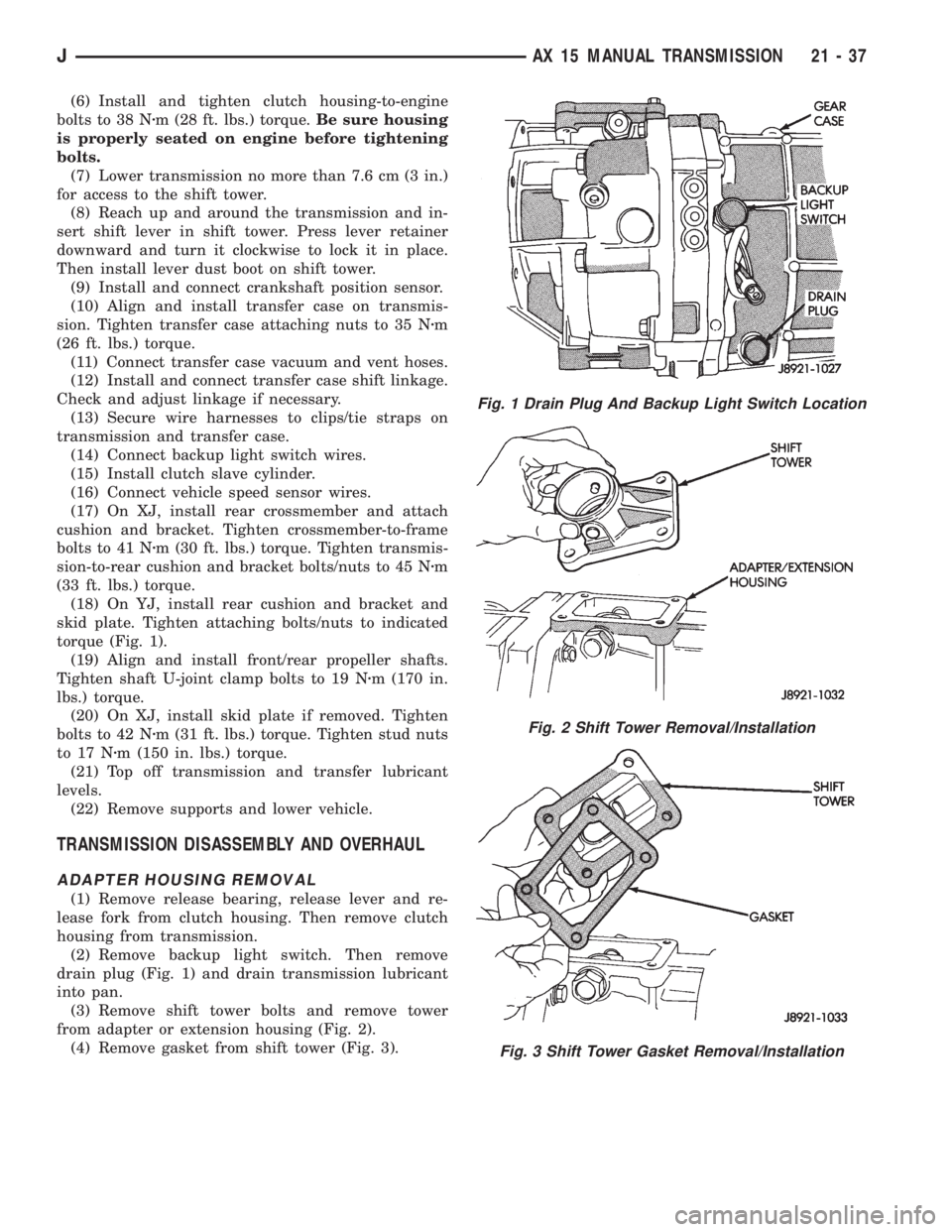

place for later installation.(11) Mark front and rear propeller shafts for in-

stallation alignment (Fig. 2). Then remove both

shafts.

(12) Remove crankshaft position sensor (Fig. 4).

(13) Disconnect transmission and transfer case

vent hoses.

(14) Remove slave cylinder from clutch housing.

(15) Remove wire harnesses from clips/tie straps

on transmission and transfer case.

(16) Support transmission-transfer case assembly

with transmission jack. Secure assembly to jack with

safety chains.

(17) Reposition adjustable jack stand under engine.

Be sure to place wood block between jack and oil

pan.

(18) Remove clutch housing brace rod.

(19) Remove clutch housing-to-engine bolts and re-

move transmission-transfer case assembly.

(20) Remove bolts attaching transmission to trans-

fer case and separate components.

(21) Remove release bearing, fork and retainer

clip.

(22) Remove clutch housing from transmission.

TRANSMISSION INSTALLATION

(1) Install clutch housing on transmission. Tighten

housing bolts to 37 Nzm (27 ft-lbs) torque.

(2) Lubricate contact surfaces of release fork, lever

and pivot ball stud. Then install bearing, fork and

clip in clutch housing.

(3) Mount transmission on transmission jack. Se-

cure transmission with safety chains.

(4) Lightly lubricate pilot bearing and transmis-

sion input shaft splines with Mopar high tempera-

ture grease.

(5) Align transmission input shaft and clutch disc

splines and install transmission.

Fig. 2 Removing/Installing Shift Lever

Fig. 3 Marking Propeller Shaft And Axle Yoke

Fig. 4 Crankshaft Position Sensor Location

21 - 36 AX 15 MANUAL TRANSMISSIONJ

Page 1414 of 2198

(6) Install and tighten clutch housing-to-engine

bolts to 38 Nzm (28 ft. lbs.) torque.Be sure housing

is properly seated on engine before tightening

bolts.

(7) Lower transmission no more than 7.6 cm (3 in.)

for access to the shift tower.

(8) Reach up and around the transmission and in-

sert shift lever in shift tower. Press lever retainer

downward and turn it clockwise to lock it in place.

Then install lever dust boot on shift tower.

(9) Install and connect crankshaft position sensor.

(10) Align and install transfer case on transmis-

sion. Tighten transfer case attaching nuts to 35 Nzm

(26 ft. lbs.) torque.

(11) Connect transfer case vacuum and vent hoses.

(12) Install and connect transfer case shift linkage.

Check and adjust linkage if necessary.

(13) Secure wire harnesses to clips/tie straps on

transmission and transfer case.

(14) Connect backup light switch wires.

(15) Install clutch slave cylinder.

(16) Connect vehicle speed sensor wires.

(17) On XJ, install rear crossmember and attach

cushion and bracket. Tighten crossmember-to-frame

bolts to 41 Nzm (30 ft. lbs.) torque. Tighten transmis-

sion-to-rear cushion and bracket bolts/nuts to 45 Nzm

(33 ft. lbs.) torque.

(18) On YJ, install rear cushion and bracket and

skid plate. Tighten attaching bolts/nuts to indicated

torque (Fig. 1).

(19) Align and install front/rear propeller shafts.

Tighten shaft U-joint clamp bolts to 19 Nzm (170 in.

lbs.) torque.

(20) On XJ, install skid plate if removed. Tighten

bolts to 42 Nzm (31 ft. lbs.) torque. Tighten stud nuts

to 17 Nzm (150 in. lbs.) torque.

(21) Top off transmission and transfer lubricant

levels.

(22) Remove supports and lower vehicle.

TRANSMISSION DISASSEMBLY AND OVERHAUL

ADAPTER HOUSING REMOVAL

(1) Remove release bearing, release lever and re-

lease fork from clutch housing. Then remove clutch

housing from transmission.

(2) Remove backup light switch. Then remove

drain plug (Fig. 1) and drain transmission lubricant

into pan.

(3) Remove shift tower bolts and remove tower

from adapter or extension housing (Fig. 2).

(4) Remove gasket from shift tower (Fig. 3).

Fig. 1 Drain Plug And Backup Light Switch Location

Fig. 2 Shift Tower Removal/Installation

Fig. 3 Shift Tower Gasket Removal/Installation

JAX 15 MANUAL TRANSMISSION 21 - 37