lock JEEP CHEROKEE 1995 Service Owner's Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 1995, Model line: CHEROKEE, Model: JEEP CHEROKEE 1995Pages: 2198, PDF Size: 82.83 MB

Page 118 of 2198

BEARING AND SEAL INSTALLATION

Do not install the original axle shaft seal. Al-

ways install a new seal.

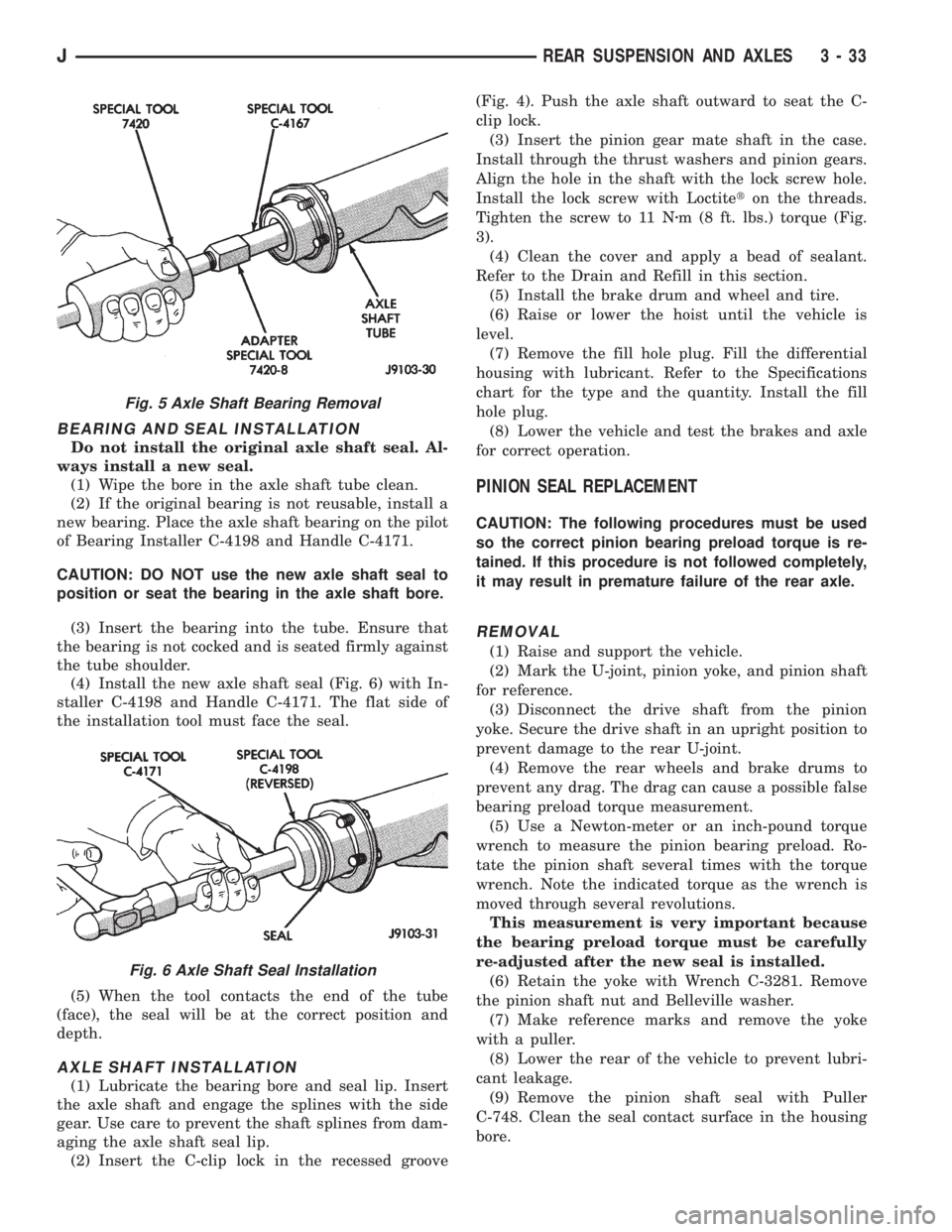

(1) Wipe the bore in the axle shaft tube clean.

(2) If the original bearing is not reusable, install a

new bearing. Place the axle shaft bearing on the pilot

of Bearing Installer C-4198 and Handle C-4171.

CAUTION: DO NOT use the new axle shaft seal to

position or seat the bearing in the axle shaft bore.

(3) Insert the bearing into the tube. Ensure that

the bearing is not cocked and is seated firmly against

the tube shoulder.

(4) Install the new axle shaft seal (Fig. 6) with In-

staller C-4198 and Handle C-4171. The flat side of

the installation tool must face the seal.

(5) When the tool contacts the end of the tube

(face), the seal will be at the correct position and

depth.

AXLE SHAFT INSTALLATION

(1) Lubricate the bearing bore and seal lip. Insert

the axle shaft and engage the splines with the side

gear. Use care to prevent the shaft splines from dam-

aging the axle shaft seal lip.

(2) Insert the C-clip lock in the recessed groove(Fig. 4). Push the axle shaft outward to seat the C-

clip lock.

(3) Insert the pinion gear mate shaft in the case.

Install through the thrust washers and pinion gears.

Align the hole in the shaft with the lock screw hole.

Install the lock screw with Loctiteton the threads.

Tighten the screw to 11 Nzm (8 ft. lbs.) torque (Fig.

3).

(4) Clean the cover and apply a bead of sealant.

Refer to the Drain and Refill in this section.

(5) Install the brake drum and wheel and tire.

(6) Raise or lower the hoist until the vehicle is

level.

(7) Remove the fill hole plug. Fill the differential

housing with lubricant. Refer to the Specifications

chart for the type and the quantity. Install the fill

hole plug.

(8) Lower the vehicle and test the brakes and axle

for correct operation.

PINION SEAL REPLACEMENT

CAUTION: The following procedures must be used

so the correct pinion bearing preload torque is re-

tained. If this procedure is not followed completely,

it may result in premature failure of the rear axle.

REMOVAL

(1) Raise and support the vehicle.

(2) Mark the U-joint, pinion yoke, and pinion shaft

for reference.

(3) Disconnect the drive shaft from the pinion

yoke. Secure the drive shaft in an upright position to

prevent damage to the rear U-joint.

(4) Remove the rear wheels and brake drums to

prevent any drag. The drag can cause a possible false

bearing preload torque measurement.

(5) Use a Newton-meter or an inch-pound torque

wrench to measure the pinion bearing preload. Ro-

tate the pinion shaft several times with the torque

wrench. Note the indicated torque as the wrench is

moved through several revolutions.

This measurement is very important because

the bearing preload torque must be carefully

re-adjusted after the new seal is installed.

(6) Retain the yoke with Wrench C-3281. Remove

the pinion shaft nut and Belleville washer.

(7) Make reference marks and remove the yoke

with a puller.

(8) Lower the rear of the vehicle to prevent lubri-

cant leakage.

(9) Remove the pinion shaft seal with Puller

C-748. Clean the seal contact surface in the housing

bore.

Fig. 5 Axle Shaft Bearing Removal

Fig. 6 Axle Shaft Seal Installation

JREAR SUSPENSION AND AXLES 3 - 33

Page 120 of 2198

CAUTION: Do not subject the bearings, cups, bores

or journals to heat from a torch or other abuse. Per-

manent damage could result. Special tools are

available and recommended when servicing axle.

DIFFERENTIAL CASE REMOVAL

(1) Remove the axle shafts, refer to Axle Shaft Re-

moval.

Side play and runout checks taken during

disassembly will be very useful in reassembly.

(2) Check differential side play. Position a screw-

driver or pinch bar between left side of axle housing

and case flange (Fig. 9). Use a prying motion to de-

termine if any side play exists. There should be no

side play.

Side play resulting from bearing races being

loose on case hubs require replacement of the

differential case. Otherwise, use threaded ad-

juster to remove the side play before measuring

the ring gear runout.

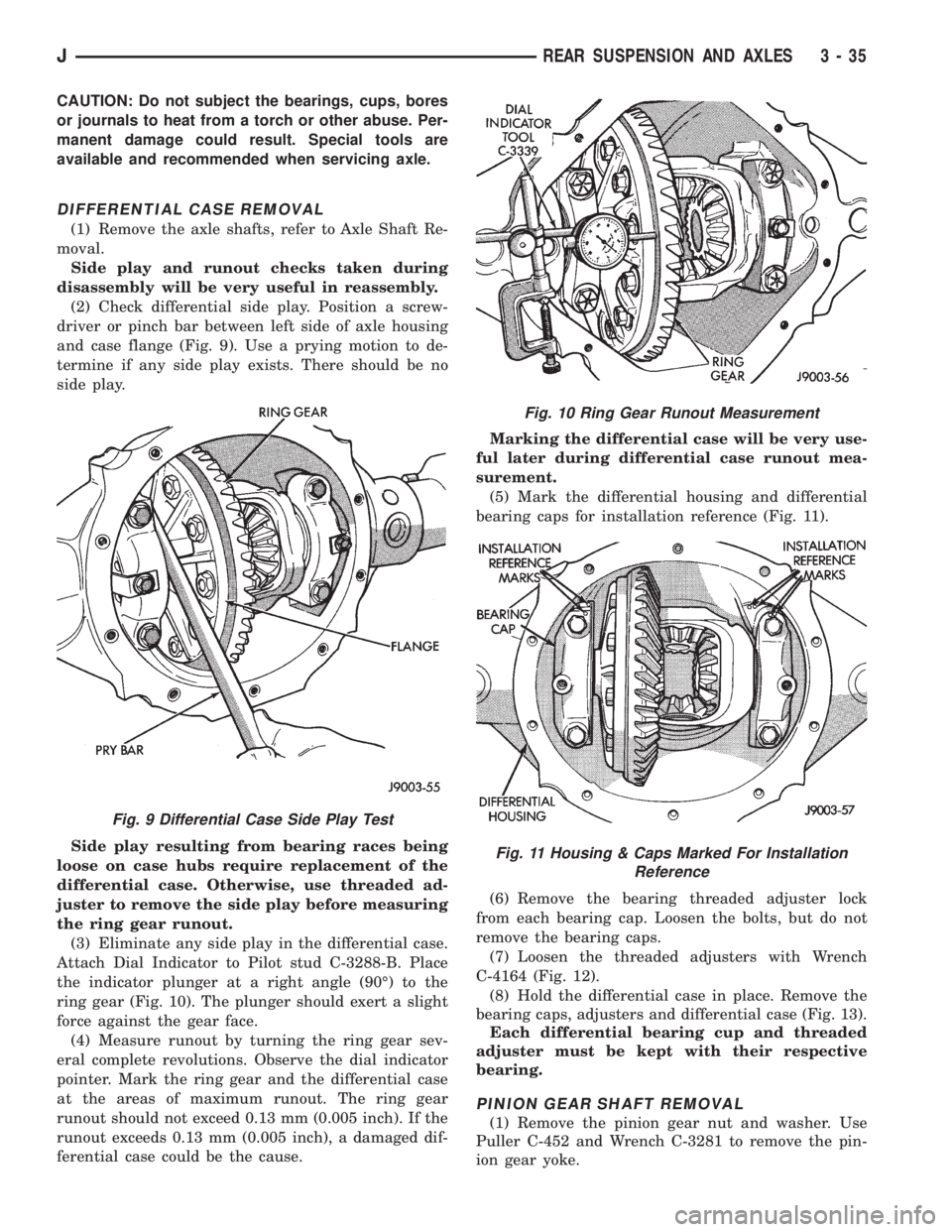

(3) Eliminate any side play in the differential case.

Attach Dial Indicator to Pilot stud C-3288-B. Place

the indicator plunger at a right angle (90É) to the

ring gear (Fig. 10). The plunger should exert a slight

force against the gear face.

(4) Measure runout by turning the ring gear sev-

eral complete revolutions. Observe the dial indicator

pointer. Mark the ring gear and the differential case

at the areas of maximum runout. The ring gear

runout should not exceed 0.13 mm (0.005 inch). If the

runout exceeds 0.13 mm (0.005 inch), a damaged dif-

ferential case could be the cause.Marking the differential case will be very use-

ful later during differential case runout mea-

surement.

(5) Mark the differential housing and differential

bearing caps for installation reference (Fig. 11).

(6) Remove the bearing threaded adjuster lock

from each bearing cap. Loosen the bolts, but do not

remove the bearing caps.

(7) Loosen the threaded adjusters with Wrench

C-4164 (Fig. 12).

(8) Hold the differential case in place. Remove the

bearing caps, adjusters and differential case (Fig. 13).

Each differential bearing cup and threaded

adjuster must be kept with their respective

bearing.

PINION GEAR SHAFT REMOVAL

(1) Remove the pinion gear nut and washer. Use

Puller C-452 and Wrench C-3281 to remove the pin-

ion gear yoke.

Fig. 9 Differential Case Side Play Test

Fig. 10 Ring Gear Runout Measurement

Fig. 11 Housing & Caps Marked For Installation

Reference

JREAR SUSPENSION AND AXLES 3 - 35

Page 122 of 2198

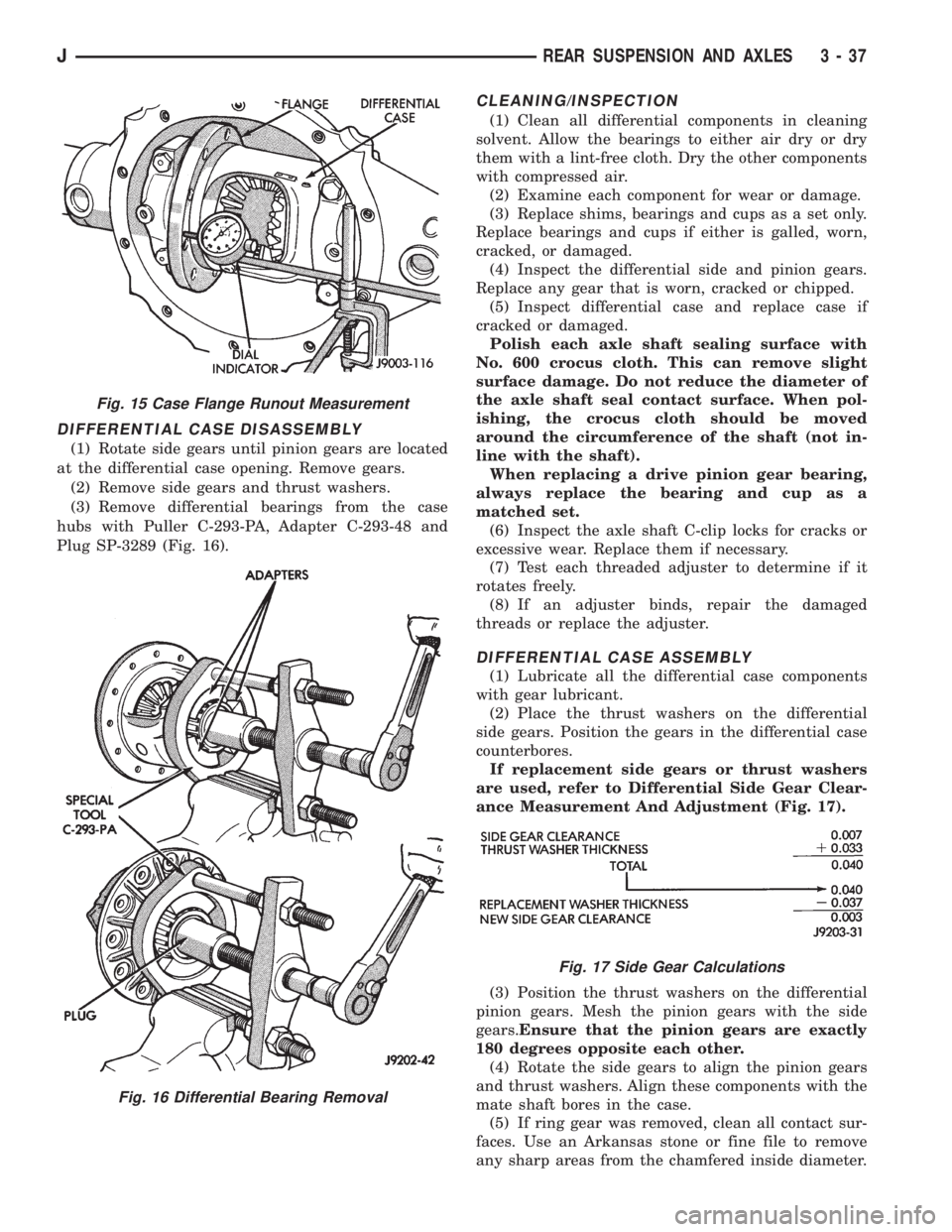

DIFFERENTIAL CASE DISASSEMBLY

(1) Rotate side gears until pinion gears are located

at the differential case opening. Remove gears.

(2) Remove side gears and thrust washers.

(3) Remove differential bearings from the case

hubs with Puller C-293-PA, Adapter C-293-48 and

Plug SP-3289 (Fig. 16).

CLEANING/INSPECTION

(1) Clean all differential components in cleaning

solvent. Allow the bearings to either air dry or dry

them with a lint-free cloth. Dry the other components

with compressed air.

(2) Examine each component for wear or damage.

(3) Replace shims, bearings and cups as a set only.

Replace bearings and cups if either is galled, worn,

cracked, or damaged.

(4) Inspect the differential side and pinion gears.

Replace any gear that is worn, cracked or chipped.

(5) Inspect differential case and replace case if

cracked or damaged.

Polish each axle shaft sealing surface with

No. 600 crocus cloth. This can remove slight

surface damage. Do not reduce the diameter of

the axle shaft seal contact surface. When pol-

ishing, the crocus cloth should be moved

around the circumference of the shaft (not in-

line with the shaft).

When replacing a drive pinion gear bearing,

always replace the bearing and cup as a

matched set.

(6) Inspect the axle shaft C-clip locks for cracks or

excessive wear. Replace them if necessary.

(7) Test each threaded adjuster to determine if it

rotates freely.

(8) If an adjuster binds, repair the damaged

threads or replace the adjuster.

DIFFERENTIAL CASE ASSEMBLY

(1) Lubricate all the differential case components

with gear lubricant.

(2) Place the thrust washers on the differential

side gears. Position the gears in the differential case

counterbores.

If replacement side gears or thrust washers

are used, refer to Differential Side Gear Clear-

ance Measurement And Adjustment (Fig. 17).

(3) Position the thrust washers on the differential

pinion gears. Mesh the pinion gears with the side

gears.Ensure that the pinion gears are exactly

180 degrees opposite each other.

(4) Rotate the side gears to align the pinion gears

and thrust washers. Align these components with the

mate shaft bores in the case.

(5) If ring gear was removed, clean all contact sur-

faces. Use an Arkansas stone or fine file to remove

any sharp areas from the chamfered inside diameter.

Fig. 15 Case Flange Runout Measurement

Fig. 16 Differential Bearing Removal

Fig. 17 Side Gear Calculations

JREAR SUSPENSION AND AXLES 3 - 37

Page 123 of 2198

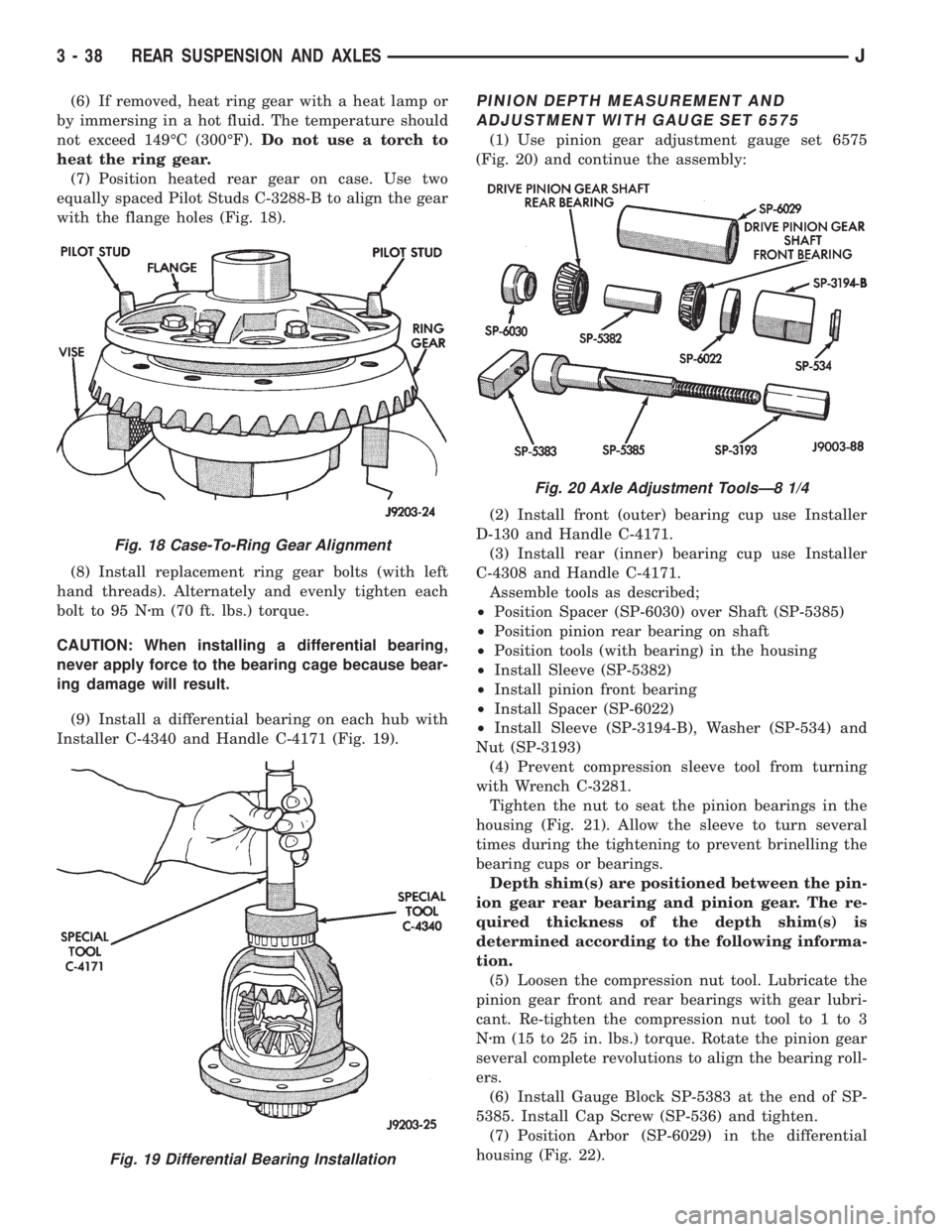

(6) If removed, heat ring gear with a heat lamp or

by immersing in a hot fluid. The temperature should

not exceed 149ÉC (300ÉF).Do not use a torch to

heat the ring gear.

(7) Position heated rear gear on case. Use two

equally spaced Pilot Studs C-3288-B to align the gear

with the flange holes (Fig. 18).

(8) Install replacement ring gear bolts (with left

hand threads). Alternately and evenly tighten each

bolt to 95 Nzm (70 ft. lbs.) torque.

CAUTION: When installing a differential bearing,

never apply force to the bearing cage because bear-

ing damage will result.

(9) Install a differential bearing on each hub with

Installer C-4340 and Handle C-4171 (Fig. 19).PINION DEPTH MEASUREMENT AND

ADJUSTMENT WITH GAUGE SET 6575

(1) Use pinion gear adjustment gauge set 6575

(Fig. 20) and continue the assembly:

(2) Install front (outer) bearing cup use Installer

D-130 and Handle C-4171.

(3) Install rear (inner) bearing cup use Installer

C-4308 and Handle C-4171.

Assemble tools as described;

²Position Spacer (SP-6030) over Shaft (SP-5385)

²Position pinion rear bearing on shaft

²Position tools (with bearing) in the housing

²Install Sleeve (SP-5382)

²Install pinion front bearing

²Install Spacer (SP-6022)

²Install Sleeve (SP-3194-B), Washer (SP-534) and

Nut (SP-3193)

(4) Prevent compression sleeve tool from turning

with Wrench C-3281.

Tighten the nut to seat the pinion bearings in the

housing (Fig. 21). Allow the sleeve to turn several

times during the tightening to prevent brinelling the

bearing cups or bearings.

Depth shim(s) are positioned between the pin-

ion gear rear bearing and pinion gear. The re-

quired thickness of the depth shim(s) is

determined according to the following informa-

tion.

(5) Loosen the compression nut tool. Lubricate the

pinion gear front and rear bearings with gear lubri-

cant. Re-tighten the compression nut tool to 1 to 3

Nzm (15 to 25 in. lbs.) torque. Rotate the pinion gear

several complete revolutions to align the bearing roll-

ers.

(6) Install Gauge Block SP-5383 at the end of SP-

5385. Install Cap Screw (SP-536) and tighten.

(7) Position Arbor (SP-6029) in the differential

housing (Fig. 22).

Fig. 18 Case-To-Ring Gear Alignment

Fig. 19 Differential Bearing Installation

Fig. 20 Axle Adjustment ToolsÐ8 1/4

3 - 38 REAR SUSPENSION AND AXLESJ

Page 124 of 2198

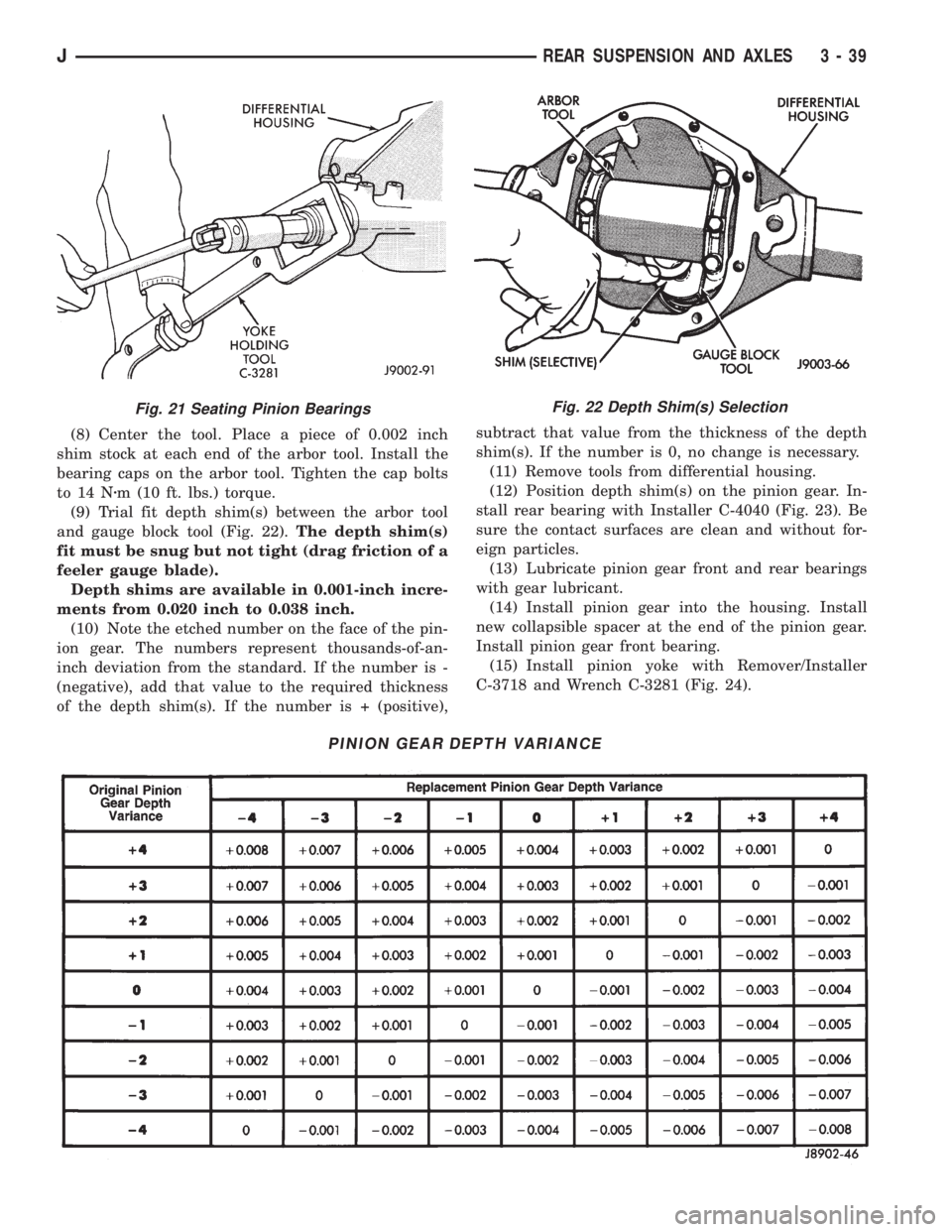

(8) Center the tool. Place a piece of 0.002 inch

shim stock at each end of the arbor tool. Install the

bearing caps on the arbor tool. Tighten the cap bolts

to 14 Nzm (10 ft. lbs.) torque.

(9) Trial fit depth shim(s) between the arbor tool

and gauge block tool (Fig. 22).The depth shim(s)

fit must be snug but not tight (drag friction of a

feeler gauge blade).

Depth shims are available in 0.001-inch incre-

ments from 0.020 inch to 0.038 inch.

(10) Note the etched number on the face of the pin-

ion gear. The numbers represent thousands-of-an-

inch deviation from the standard. If the number is -

(negative), add that value to the required thickness

of the depth shim(s). If the number is + (positive),subtract that value from the thickness of the depth

shim(s). If the number is 0, no change is necessary.

(11) Remove tools from differential housing.

(12) Position depth shim(s) on the pinion gear. In-

stall rear bearing with Installer C-4040 (Fig. 23). Be

sure the contact surfaces are clean and without for-

eign particles.

(13) Lubricate pinion gear front and rear bearings

with gear lubricant.

(14) Install pinion gear into the housing. Install

new collapsible spacer at the end of the pinion gear.

Install pinion gear front bearing.

(15) Install pinion yoke with Remover/Installer

C-3718 and Wrench C-3281 (Fig. 24).

Fig. 22 Depth Shim(s) Selection

PINION GEAR DEPTH VARIANCE

Fig. 21 Seating Pinion Bearings

JREAR SUSPENSION AND AXLES 3 - 39

Page 127 of 2198

ring and pinion gear. Seat the bearing cups with the

procedure described above.

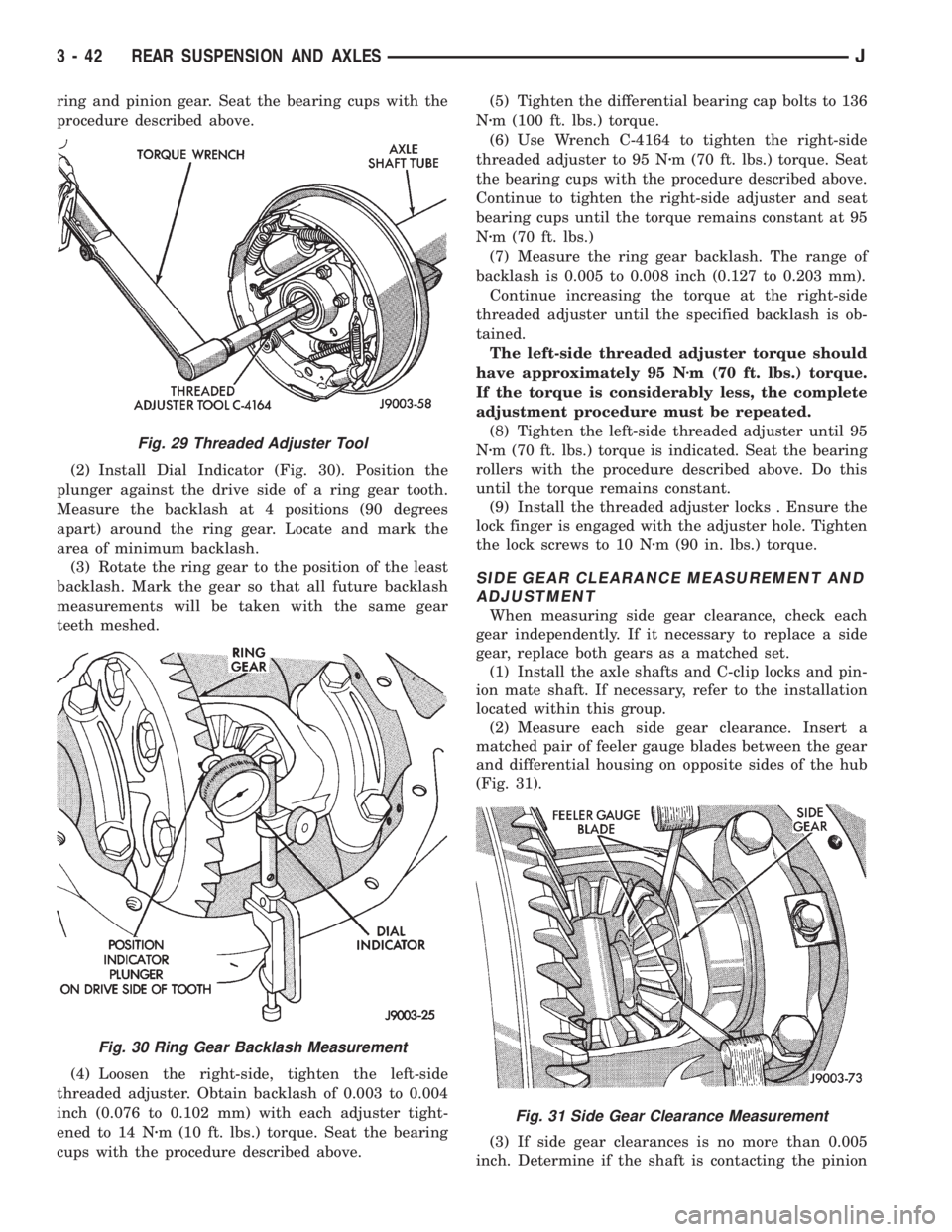

(2) Install Dial Indicator (Fig. 30). Position the

plunger against the drive side of a ring gear tooth.

Measure the backlash at 4 positions (90 degrees

apart) around the ring gear. Locate and mark the

area of minimum backlash.

(3) Rotate the ring gear to the position of the least

backlash. Mark the gear so that all future backlash

measurements will be taken with the same gear

teeth meshed.

(4) Loosen the right-side, tighten the left-side

threaded adjuster. Obtain backlash of 0.003 to 0.004

inch (0.076 to 0.102 mm) with each adjuster tight-

ened to 14 Nzm (10 ft. lbs.) torque. Seat the bearing

cups with the procedure described above.(5) Tighten the differential bearing cap bolts to 136

Nzm (100 ft. lbs.) torque.

(6) Use Wrench C-4164 to tighten the right-side

threaded adjuster to 95 Nzm (70 ft. lbs.) torque. Seat

the bearing cups with the procedure described above.

Continue to tighten the right-side adjuster and seat

bearing cups until the torque remains constant at 95

Nzm (70 ft. lbs.)

(7) Measure the ring gear backlash. The range of

backlash is 0.005 to 0.008 inch (0.127 to 0.203 mm).

Continue increasing the torque at the right-side

threaded adjuster until the specified backlash is ob-

tained.

The left-side threaded adjuster torque should

have approximately 95 Nzm (70 ft. lbs.) torque.

If the torque is considerably less, the complete

adjustment procedure must be repeated.

(8) Tighten the left-side threaded adjuster until 95

Nzm (70 ft. lbs.) torque is indicated. Seat the bearing

rollers with the procedure described above. Do this

until the torque remains constant.

(9) Install the threaded adjuster locks . Ensure the

lock finger is engaged with the adjuster hole. Tighten

the lock screws to 10 Nzm (90 in. lbs.) torque.

SIDE GEAR CLEARANCE MEASUREMENT AND

ADJUSTMENT

When measuring side gear clearance, check each

gear independently. If it necessary to replace a side

gear, replace both gears as a matched set.

(1) Install the axle shafts and C-clip locks and pin-

ion mate shaft. If necessary, refer to the installation

located within this group.

(2) Measure each side gear clearance. Insert a

matched pair of feeler gauge blades between the gear

and differential housing on opposite sides of the hub

(Fig. 31).

(3) If side gear clearances is no more than 0.005

inch. Determine if the shaft is contacting the pinion

Fig. 29 Threaded Adjuster Tool

Fig. 30 Ring Gear Backlash Measurement

Fig. 31 Side Gear Clearance Measurement

3 - 42 REAR SUSPENSION AND AXLESJ

Page 128 of 2198

gear mate shaft.Do not remove the feeler

gauges, inspect the axle shaft with the feeler

gauge inserted behind the side gear.If the end of

the axle shaft is not contacting the pinion gear mate

shaft, the side gear clearance is acceptable.

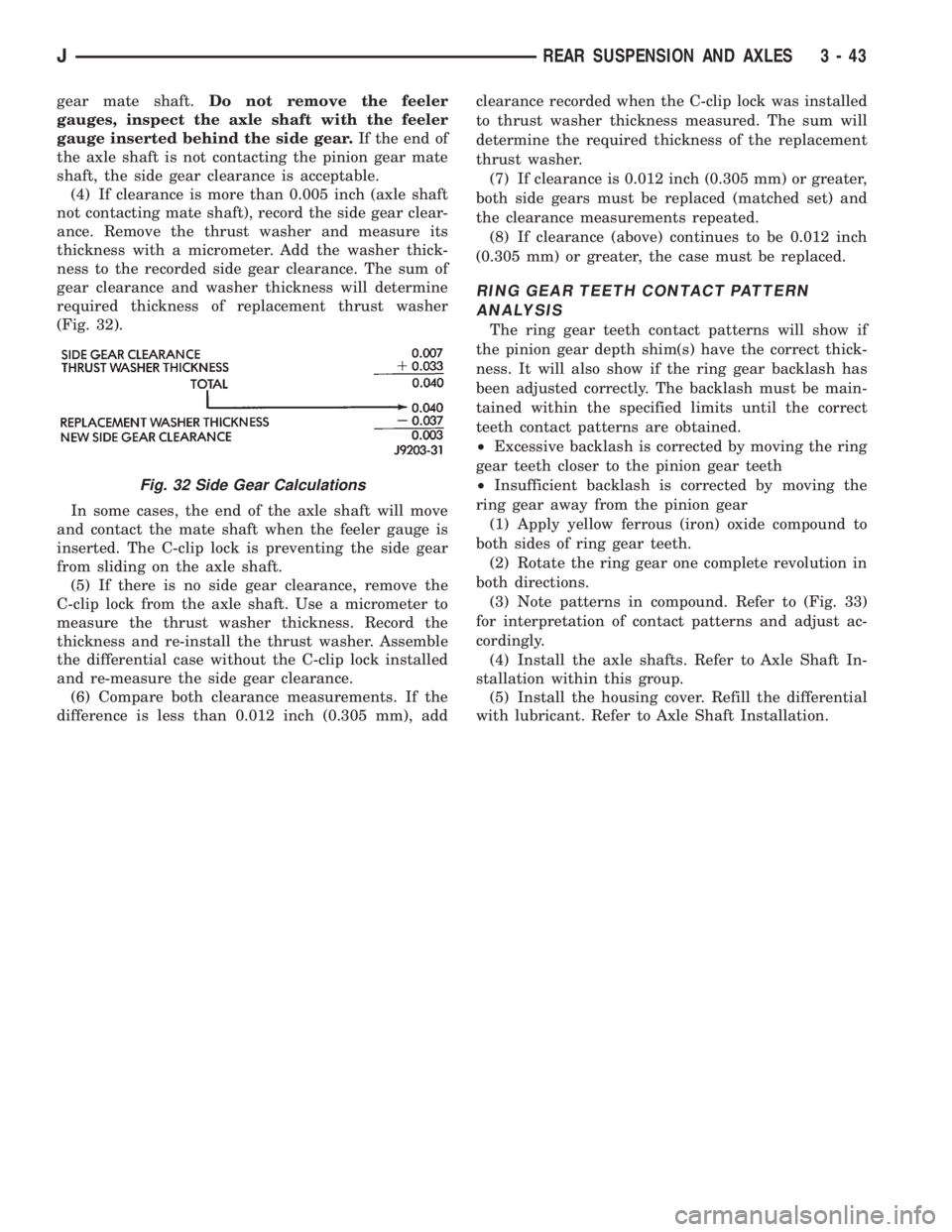

(4) If clearance is more than 0.005 inch (axle shaft

not contacting mate shaft), record the side gear clear-

ance. Remove the thrust washer and measure its

thickness with a micrometer. Add the washer thick-

ness to the recorded side gear clearance. The sum of

gear clearance and washer thickness will determine

required thickness of replacement thrust washer

(Fig. 32).

In some cases, the end of the axle shaft will move

and contact the mate shaft when the feeler gauge is

inserted. The C-clip lock is preventing the side gear

from sliding on the axle shaft.

(5) If there is no side gear clearance, remove the

C-clip lock from the axle shaft. Use a micrometer to

measure the thrust washer thickness. Record the

thickness and re-install the thrust washer. Assemble

the differential case without the C-clip lock installed

and re-measure the side gear clearance.

(6) Compare both clearance measurements. If the

difference is less than 0.012 inch (0.305 mm), addclearance recorded when the C-clip lock was installed

to thrust washer thickness measured. The sum will

determine the required thickness of the replacement

thrust washer.

(7) If clearance is 0.012 inch (0.305 mm) or greater,

both side gears must be replaced (matched set) and

the clearance measurements repeated.

(8) If clearance (above) continues to be 0.012 inch

(0.305 mm) or greater, the case must be replaced.

RING GEAR TEETH CONTACT PATTERN

ANALYSIS

The ring gear teeth contact patterns will show if

the pinion gear depth shim(s) have the correct thick-

ness. It will also show if the ring gear backlash has

been adjusted correctly. The backlash must be main-

tained within the specified limits until the correct

teeth contact patterns are obtained.

²Excessive backlash is corrected by moving the ring

gear teeth closer to the pinion gear teeth

²Insufficient backlash is corrected by moving the

ring gear away from the pinion gear

(1) Apply yellow ferrous (iron) oxide compound to

both sides of ring gear teeth.

(2) Rotate the ring gear one complete revolution in

both directions.

(3) Note patterns in compound. Refer to (Fig. 33)

for interpretation of contact patterns and adjust ac-

cordingly.

(4) Install the axle shafts. Refer to Axle Shaft In-

stallation within this group.

(5) Install the housing cover. Refill the differential

with lubricant. Refer to Axle Shaft Installation.

Fig. 32 Side Gear Calculations

JREAR SUSPENSION AND AXLES 3 - 43

Page 130 of 2198

TRAC-LOK DIFFERENTIAL

OPERATION

In a conventional differential, the torque applied to

the ring gear is transmitted to the axle shafts through

the differential gears. During normal operation, the

torque transmitted to each wheel is equal at all times.

However, if one wheel spins, the opposite wheel will

generate only as much torque as the spinning wheel.

In the Trac-Lok differential, part of the ring gear

torque is transmitted through clutch packs. The clutch

packs contain multiple disc. The clutch will have radial

grooves on the plates, and concentric grooves on the

discs or bonded fiber material which is smooth.

In operation, the Trac-Lok clutches are engaged by

two concurrent forces. The first being preload force ex-

erted through Belleville spring washers. The second is

from separating forces generated by the side gears (Fig.

1).

The Trac-Lok design provides the normal differential

action needed for turning corners. It also provides for

the transmission of equal torque to both wheels when

driving straight ahead. When one wheel loses traction,

the clutch packs transfer torque to the wheel having the

most traction. Trac-lok differentials resist wheel spin on

bumpy roads. It also provides more pulling power when

one wheel loses traction. Pulling power is continuous

until both wheels lose traction. If both wheels slip due

to unequal traction, Trac-Lok operation is normal. In ex-

treme cases of differences of traction, the wheel with

the least traction may spin. This occurs after the Trac-

Lok has transferred as much torque as possible to the

non-spinning wheel.

NOISE DIAGNOSIS

If chatter occurs when turning corners, the most

probable cause is incorrect or contaminated lubri-

cant. Before removing the Trac-Lok unit for repair,

drain, flush and refill the axle with the specified lu-

bricant. Refer to Lubricant change in this Group.

A container of Trac-Lok Lubricant (friction modi-

fier) should be added after.

Vehicles with a limited slip differential should be

road tested by making 10 to 12 slow figure-eight

turns. This maneuver will pump the lubricant

through the clutch discs.

Refer to Group 0, Lubrication and Maintenance for

additional information.

DIFFERENTIAL TEST

WARNING: WHEN SERVICING VEHICLES WITH A

LIMITED SLIP DIFFERENTIAL DO NOT USE THE EN-

GINE TO TURN THE AXLE AND WHEELS. BOTH

REAR WHEELS MUST BE RAISED AND THE VEHI-

CLE SUPPORTED. A LIMITED SLIP AXLE CAN EX-

ERT ENOUGH FORCE (IF ONE WHEEL IS IN

CONTACT WITH THE SURFACE) TO CAUSE THE

VEHICLE TO MOVE.

The differential can be tested without removing the

differential case by measuring rotating torque. Make

sure brakes are not dragging during this measure-

ment.

(1) Engine off, transmission in neutral, and park-

ing brake off.

(2) Place blocks in front and rear of both front

wheels.

(3) Jack up one rear wheel until it is completely off

the ground.

(4) Remove wheel and bolt special tool to studs.

Fig. 1 Limited Slip Differential OperationÐBoth

Wheels Driving

JREAR SUSPENSION AND AXLES 3 - 45

Page 132 of 2198

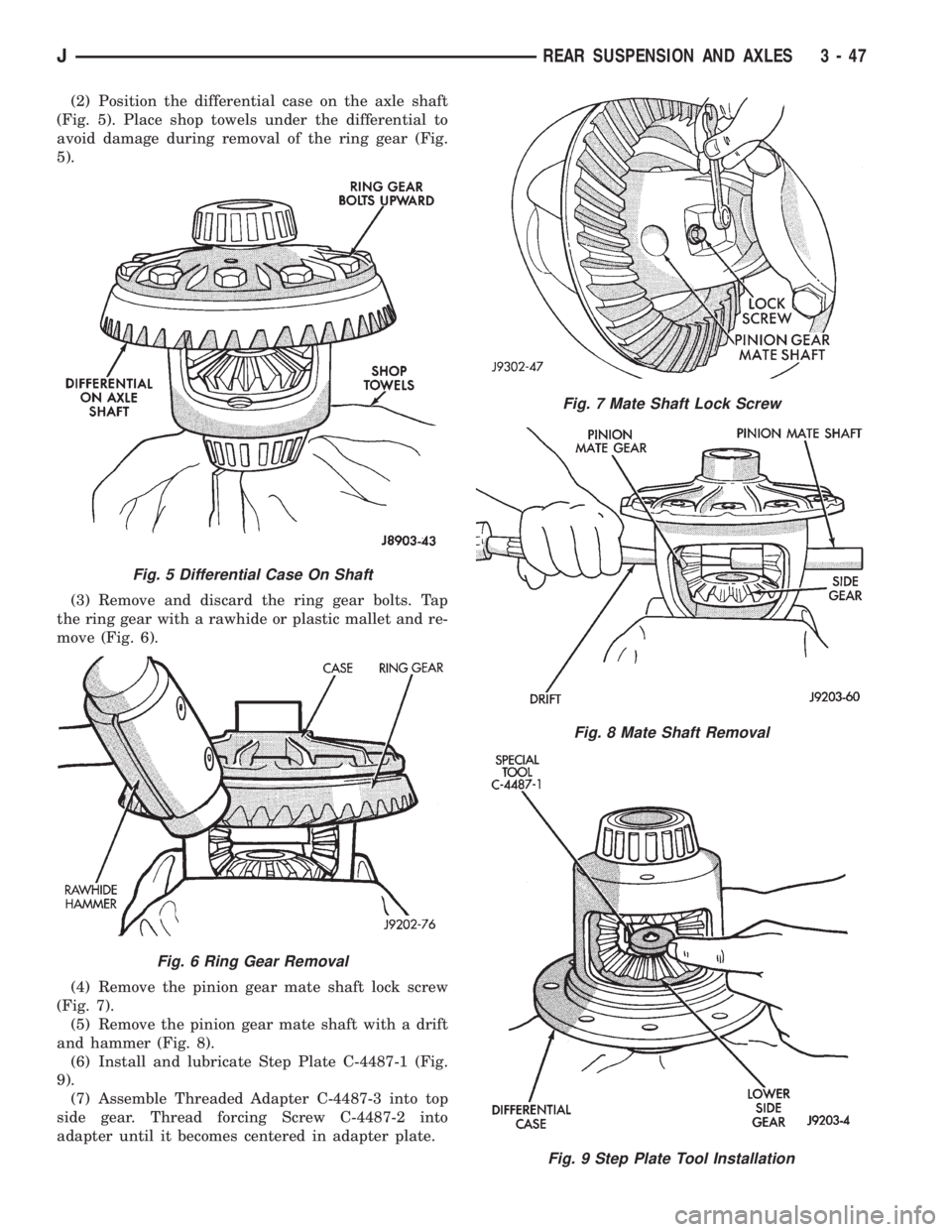

(2) Position the differential case on the axle shaft

(Fig. 5). Place shop towels under the differential to

avoid damage during removal of the ring gear (Fig.

5).

(3) Remove and discard the ring gear bolts. Tap

the ring gear with a rawhide or plastic mallet and re-

move (Fig. 6).

(4) Remove the pinion gear mate shaft lock screw

(Fig. 7).

(5) Remove the pinion gear mate shaft with a drift

and hammer (Fig. 8).

(6) Install and lubricate Step Plate C-4487-1 (Fig.

9).

(7) Assemble Threaded Adapter C-4487-3 into top

side gear. Thread forcing Screw C-4487-2 into

adapter until it becomes centered in adapter plate.

Fig. 7 Mate Shaft Lock Screw

Fig. 8 Mate Shaft Removal

Fig. 9 Step Plate Tool Installation

Fig. 5 Differential Case On Shaft

Fig. 6 Ring Gear Removal

JREAR SUSPENSION AND AXLES 3 - 47

Page 134 of 2198

(2) Inspect clutch pack plates for wear, scoring or

damage. Replace both clutch packs if any one compo-

nent in either pack is damaged.

(3) Inspect side and pinion gears. Replace any gear

that is worn, cracked, chipped or damaged.

(4) Inspect differential case and pinion shaft. Re-

place if worn or damaged.

PRESOAK PLATES AND DISC

Plates and dics with fiber coating (no groves or

lines) must be presoaked in Friction Modifier before

assembly. Soak plates and discs for a minimum of 20

minutes. Add remaining Friction Modifier to differen-

tial after assembly.

ASSEMBLY

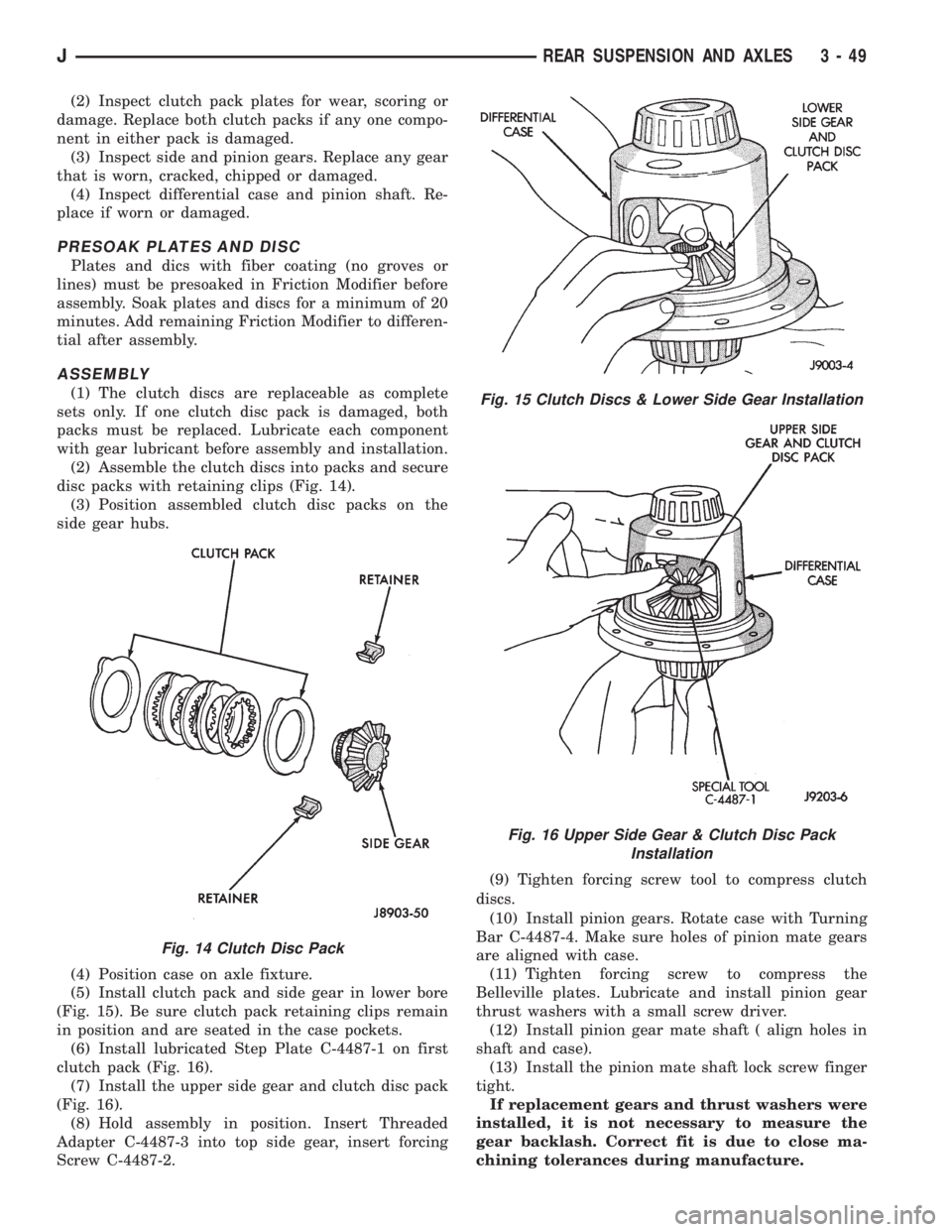

(1) The clutch discs are replaceable as complete

sets only. If one clutch disc pack is damaged, both

packs must be replaced. Lubricate each component

with gear lubricant before assembly and installation.

(2) Assemble the clutch discs into packs and secure

disc packs with retaining clips (Fig. 14).

(3) Position assembled clutch disc packs on the

side gear hubs.

(4) Position case on axle fixture.

(5) Install clutch pack and side gear in lower bore

(Fig. 15). Be sure clutch pack retaining clips remain

in position and are seated in the case pockets.

(6) Install lubricated Step Plate C-4487-1 on first

clutch pack (Fig. 16).

(7) Install the upper side gear and clutch disc pack

(Fig. 16).

(8) Hold assembly in position. Insert Threaded

Adapter C-4487-3 into top side gear, insert forcing

Screw C-4487-2.(9) Tighten forcing screw tool to compress clutch

discs.

(10) Install pinion gears. Rotate case with Turning

Bar C-4487-4. Make sure holes of pinion mate gears

are aligned with case.

(11) Tighten forcing screw to compress the

Belleville plates. Lubricate and install pinion gear

thrust washers with a small screw driver.

(12) Install pinion gear mate shaft ( align holes in

shaft and case).

(13) Install the pinion mate shaft lock screw finger

tight.

If replacement gears and thrust washers were

installed, it is not necessary to measure the

gear backlash. Correct fit is due to close ma-

chining tolerances during manufacture.

Fig. 14 Clutch Disc Pack

Fig. 15 Clutch Discs & Lower Side Gear Installation

Fig. 16 Upper Side Gear & Clutch Disc Pack

Installation

JREAR SUSPENSION AND AXLES 3 - 49