lock JEEP CHEROKEE 1995 Service Workshop Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 1995, Model line: CHEROKEE, Model: JEEP CHEROKEE 1995Pages: 2198, PDF Size: 82.83 MB

Page 223 of 2198

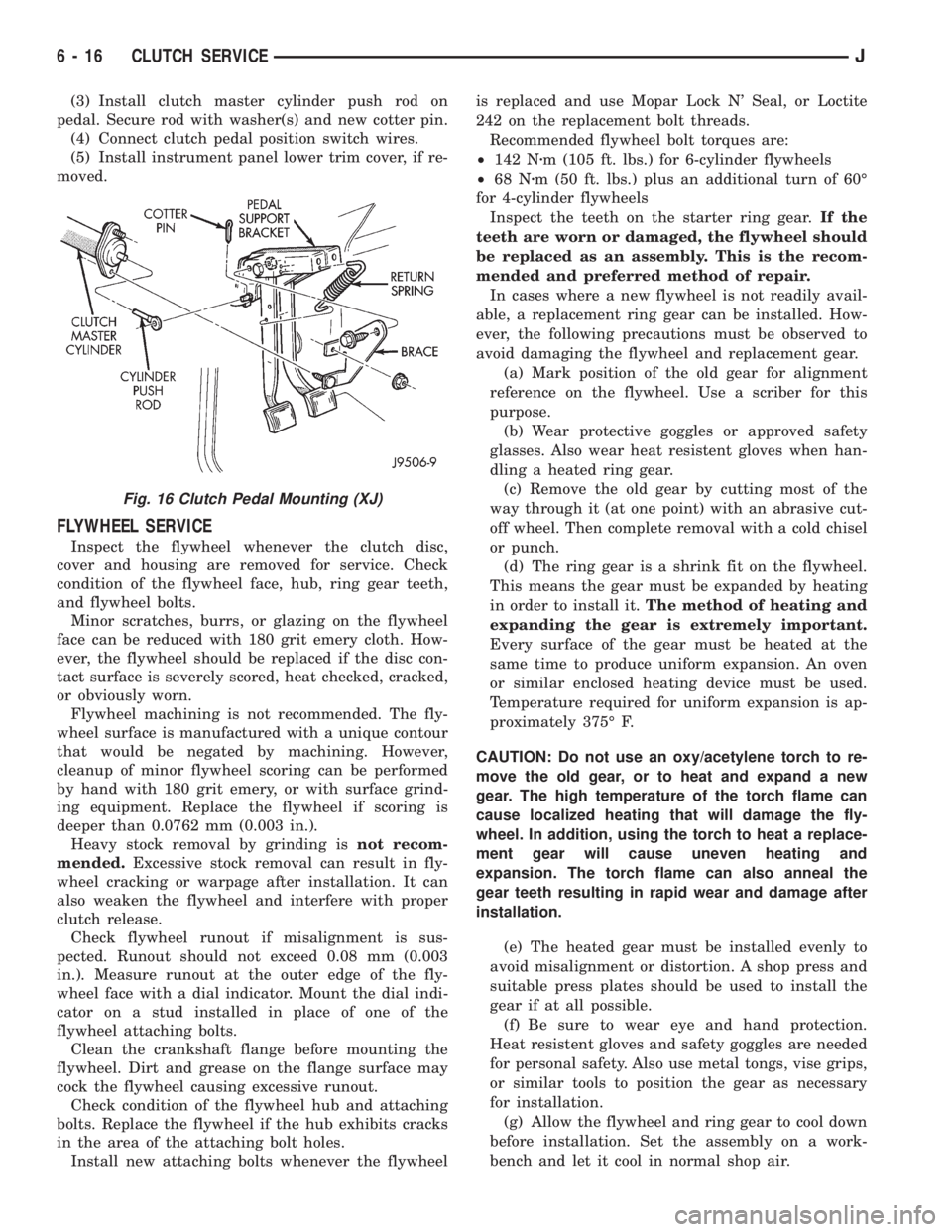

(3) Install clutch master cylinder push rod on

pedal. Secure rod with washer(s) and new cotter pin.

(4) Connect clutch pedal position switch wires.

(5) Install instrument panel lower trim cover, if re-

moved.

FLYWHEEL SERVICE

Inspect the flywheel whenever the clutch disc,

cover and housing are removed for service. Check

condition of the flywheel face, hub, ring gear teeth,

and flywheel bolts.

Minor scratches, burrs, or glazing on the flywheel

face can be reduced with 180 grit emery cloth. How-

ever, the flywheel should be replaced if the disc con-

tact surface is severely scored, heat checked, cracked,

or obviously worn.

Flywheel machining is not recommended. The fly-

wheel surface is manufactured with a unique contour

that would be negated by machining. However,

cleanup of minor flywheel scoring can be performed

by hand with 180 grit emery, or with surface grind-

ing equipment. Replace the flywheel if scoring is

deeper than 0.0762 mm (0.003 in.).

Heavy stock removal by grinding isnot recom-

mended.Excessive stock removal can result in fly-

wheel cracking or warpage after installation. It can

also weaken the flywheel and interfere with proper

clutch release.

Check flywheel runout if misalignment is sus-

pected. Runout should not exceed 0.08 mm (0.003

in.). Measure runout at the outer edge of the fly-

wheel face with a dial indicator. Mount the dial indi-

cator on a stud installed in place of one of the

flywheel attaching bolts.

Clean the crankshaft flange before mounting the

flywheel. Dirt and grease on the flange surface may

cock the flywheel causing excessive runout.

Check condition of the flywheel hub and attaching

bolts. Replace the flywheel if the hub exhibits cracks

in the area of the attaching bolt holes.

Install new attaching bolts whenever the flywheelis replaced and use Mopar Lock N' Seal, or Loctite

242 on the replacement bolt threads.

Recommended flywheel bolt torques are:

²142 Nzm (105 ft. lbs.) for 6-cylinder flywheels

²68 Nzm (50 ft. lbs.) plus an additional turn of 60É

for 4-cylinder flywheels

Inspect the teeth on the starter ring gear.If the

teeth are worn or damaged, the flywheel should

be replaced as an assembly. This is the recom-

mended and preferred method of repair.

In cases where a new flywheel is not readily avail-

able, a replacement ring gear can be installed. How-

ever, the following precautions must be observed to

avoid damaging the flywheel and replacement gear.

(a) Mark position of the old gear for alignment

reference on the flywheel. Use a scriber for this

purpose.

(b) Wear protective goggles or approved safety

glasses. Also wear heat resistent gloves when han-

dling a heated ring gear.

(c) Remove the old gear by cutting most of the

way through it (at one point) with an abrasive cut-

off wheel. Then complete removal with a cold chisel

or punch.

(d) The ring gear is a shrink fit on the flywheel.

This means the gear must be expanded by heating

in order to install it.The method of heating and

expanding the gear is extremely important.

Every surface of the gear must be heated at the

same time to produce uniform expansion. An oven

or similar enclosed heating device must be used.

Temperature required for uniform expansion is ap-

proximately 375É F.

CAUTION: Do not use an oxy/acetylene torch to re-

move the old gear, or to heat and expand a new

gear. The high temperature of the torch flame can

cause localized heating that will damage the fly-

wheel. In addition, using the torch to heat a replace-

ment gear will cause uneven heating and

expansion. The torch flame can also anneal the

gear teeth resulting in rapid wear and damage after

installation.

(e) The heated gear must be installed evenly to

avoid misalignment or distortion. A shop press and

suitable press plates should be used to install the

gear if at all possible.

(f) Be sure to wear eye and hand protection.

Heat resistent gloves and safety goggles are needed

for personal safety. Also use metal tongs, vise grips,

or similar tools to position the gear as necessary

for installation.

(g) Allow the flywheel and ring gear to cool down

before installation. Set the assembly on a work-

bench and let it cool in normal shop air.

Fig. 16 Clutch Pedal Mounting (XJ)

6 - 16 CLUTCH SERVICEJ

Page 226 of 2198

COOLING SYSTEM

CONTENTS

page page

DIAGNOSIS............................. 4

ENGINE ACCESSORY DRIVE BELTS......... 38

ENGINE BLOCK HEATER.................. 44GENERAL INFORMATION.................. 1

SERVICE PROCEDURES.................. 13

SPECIFICATIONS........................ 45

GENERAL INFORMATION

Throughout this group, references are made to par-

ticular vehicle models by alphabetical designation

(XJ or YJ) or by the particular vehicle nameplate. A

chart showing a breakdown of alphabetical designa-

tions is included in the Introduction section at the

beginning of this manual.

COOLING SYSTEM

The cooling system regulates engine operating tem-

perature. It allows the engine to reach normal oper-

ating temperature as quickly as possible, maintains

normal operating temperature and prevents over-

heating.

The cooling system also provides a means of heat-

ing the passenger compartment and cooling the auto-

matic transmission fluid (if equipped). The cooling

system is pressurized and uses a centrifugal water

pump to circulate coolant throughout the system.

An optional factory installed heavy duty cooling

package is available on most models. The package

consists of a radiator that has an increased number

of cooling fins. XJ models equipped with a 4.0L 6-cyl-inder engine and heavy duty cooling and/or air con-

ditioning also have an auxiliary electric cooling fan.

COOLING SYSTEM COMPONENTS

The cooling system consists of:

²A radiator

²Cooling fan (mechanical and/or electrical)

²Thermal viscous fan drive

²Fan shroud

²Radiator pressure cap

²Thermostat

²Coolant reserve/overflow system

²Transmission oil cooler (if equipped with an auto-

matic transmission)

²Coolant

²Water pump

²Hoses and hose clamps

SYSTEM COOLANT ROUTING

For cooling system flow routings, refer to Figs. 1, 2,

3or4.

JCOOLING SYSTEM 7 - 1

Page 238 of 2198

SERVICE PROCEDURES

INDEX

page page

Auxiliary Electric Cooling FanÐXJ Models with 4.0L

6-Cylinder Engine....................... 35

Coolant................................. 20

Coolant Reserve/Overflow System............. 24

Cooling System Cleaning/Reverse Flushing...... 22

Cooling System Fans...................... 32

Cooling System Hoses..................... 32

Draining Cooling System.................... 21

Radiator Pressure Cap..................... 25

Radiators............................... 26Refilling Cooling System.................... 21

Testing Cooling System for Leaks............. 22

Thermostat.............................. 17

Transmission Oil Coolers.................... 36

Viscous Fan Drive......................... 34

Water Pump Tests......................... 13

Water PumpsÐGeneral Information............ 13

Water PumpsÐRemoval/Installation........... 14

WATER PUMPSÐGENERAL INFORMATION

A centrifugal water pump circulates coolant

through the water jackets, passages, intake manifold,

radiator core, cooling system hoses and heater core.

The pump is driven from the engine crankshaft by a

drive belt on all engines.

The water pump impeller is pressed onto the rear

of a shaft that rotates in bearings pressed into the

housing. The housing has a small hole to allow seep-

age to escape. The water pump seals are lubricated

by the antifreeze in the coolant mixture. No addi-

tional lubrication is necessary.

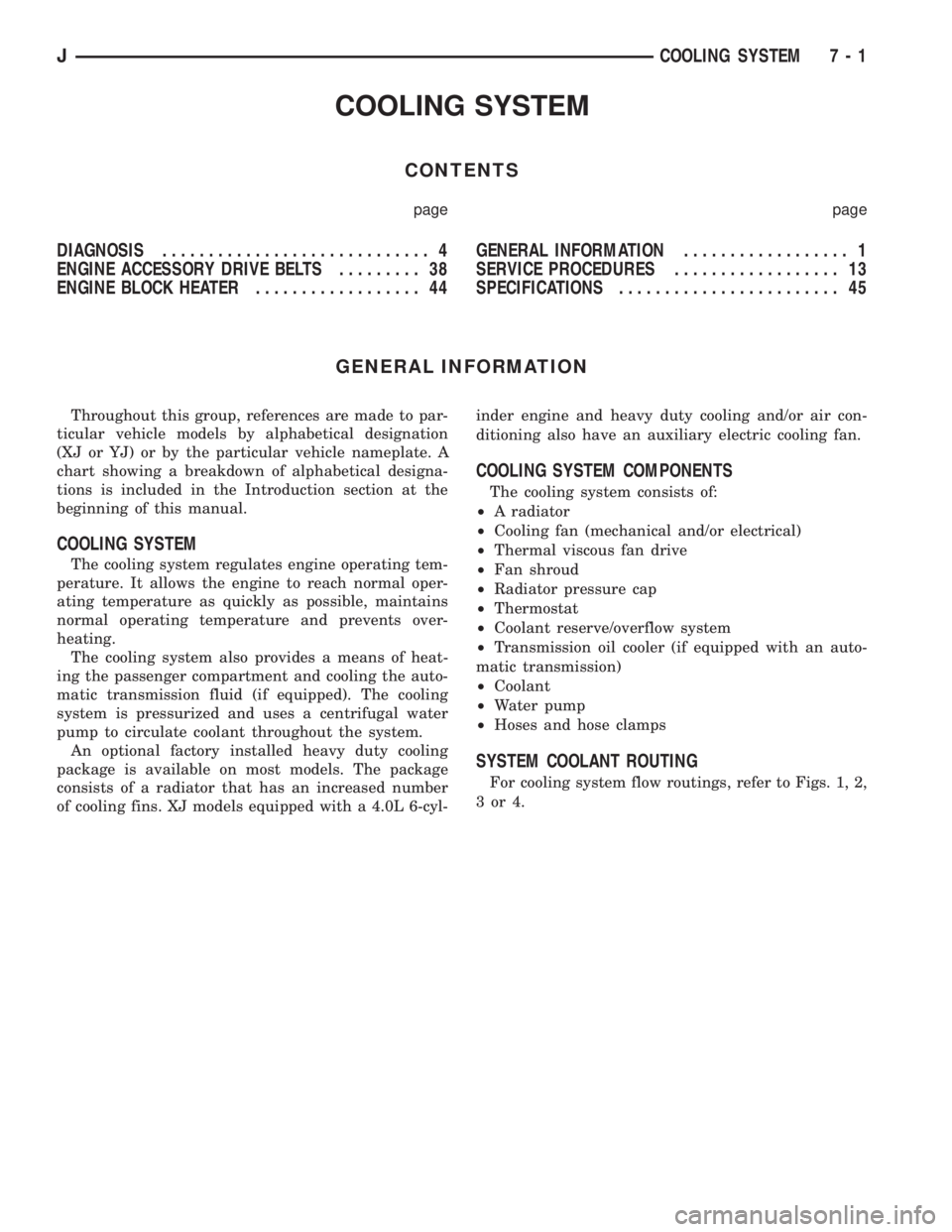

CAUTION: All engines are equipped with a reverse

(counter-clockwise) rotating water pump and vis-

cous fan drive assembly. REVERSE is stamped or

imprinted on the cover of the viscous fan drive and

inner side of the fan. The letter R is stamped into

the back of the water pump impeller (Fig. 1).

Engines from previous model years, depending

upon application, may have been equipped with a for-

ward (clockwise) rotating water pump. Installation of

the wrong water pump will cause engine overheating.

A quick test to determine if the pump is working is

to check if the heater warms properly. A defective wa-

ter pump will not be able to circulate heated coolant

through the long heater hose to the heater core.

WATER PUMP TESTS

LOOSE IMPELLER

DO NOT WASTE reusable coolant. If solution is

clean, drain coolant into a clean container for reuse.

WARNING: DO NOT REMOVE THE CYLINDER

BLOCK DRAIN PLUGS OR LOOSEN THE RADIATOR

DRAINCOCK WITH THE SYSTEM HOT AND UNDER

PRESSURE. SERIOUS BURNS FROM THE COOL-

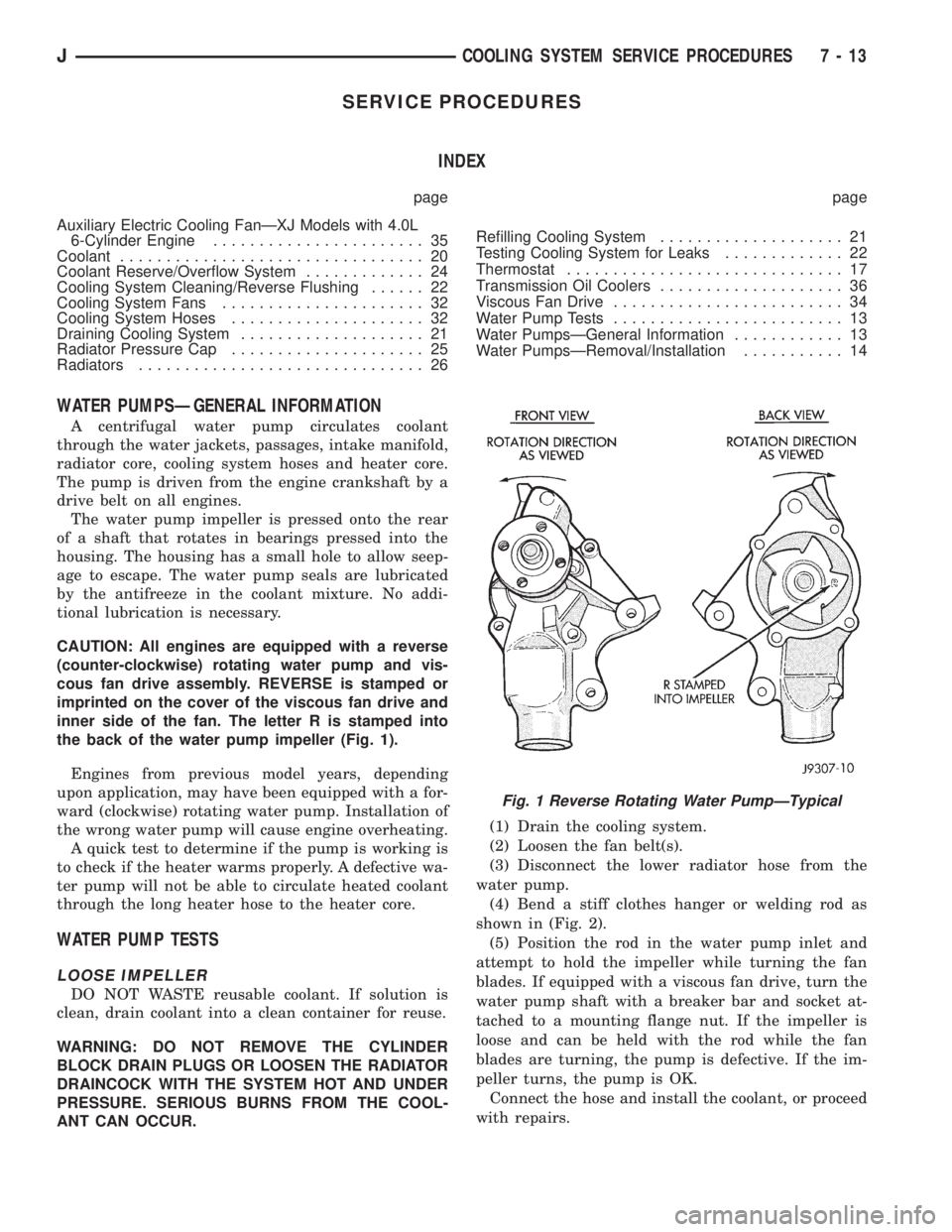

ANT CAN OCCUR.(1) Drain the cooling system.

(2) Loosen the fan belt(s).

(3) Disconnect the lower radiator hose from the

water pump.

(4) Bend a stiff clothes hanger or welding rod as

shown in (Fig. 2).

(5) Position the rod in the water pump inlet and

attempt to hold the impeller while turning the fan

blades. If equipped with a viscous fan drive, turn the

water pump shaft with a breaker bar and socket at-

tached to a mounting flange nut. If the impeller is

loose and can be held with the rod while the fan

blades are turning, the pump is defective. If the im-

peller turns, the pump is OK.

Connect the hose and install the coolant, or proceed

with repairs.

Fig. 1 Reverse Rotating Water PumpÐTypical

JCOOLING SYSTEM SERVICE PROCEDURES 7 - 13

Page 239 of 2198

INSPECTING FOR INLET RESTRICTIONS

Inadequate heater performance may be caused by a

metal casting restriction in the water pump heater

hose inlet.

DO NOT WASTE reusable coolant. If solution is

clean, drain coolant into a clean container for reuse.

WARNING: DO NOT REMOVE THE CYLINDER

BLOCK DRAIN PLUGS OR LOOSEN THE RADIATOR

DRAINCOCK WITH THE SYSTEM HOT AND UNDER

PRESSURE. SERIOUS BURNS FROM THE COOL-

ANT CAN OCCUR.

(1) Drain sufficient coolant from the radiator to de-

crease the level below the water pump heater hose

inlet.

(2) Remove the heater hose.

(3) Inspect the inlet for metal casting flash or

other restrictions.

Remove the pump from engine before remov-

ing restriction to prevent contamination of the

coolant with debris. Refer to Water Pump Re-

moval.

WATER PUMPSÐREMOVAL/INSTALLATION

REMOVALÐALL MODELS

CAUTION: If the water pump is replaced because of

mechanical damage, the fan blades and viscous fan

drive should also be inspected. These components

could have been damaged due to excessive vibra-

tion.The water pump on all models can be removed

without discharging the air conditioning system (if

equipped).

CAUTION: All engines have a reverse (counter-

clockwise) rotating water pump. The letter R is

stamped into the back of the water pump impeller

(Fig. 1) to identify. Engines from previous model

years, depending upon application, may be

equipped with a forward (clockwise) rotating water

pump. Installation of the wrong water pump will

cause engine over heating.

The water pump impeller is pressed on the rear of

the pump shaft and bearing assembly. The water

pump is serviced only as a complete assembly.

WARNING: DO NOT REMOVE THE BLOCK DRAIN

PLUG(S) OR LOOSEN RADIATOR DRAINCOCK

WITH THE SYSTEM HOT AND UNDER PRESSURE.

SERIOUS BURNS FROM COOLANT CAN OCCUR.

DO NOT WASTE reusable coolant. If the solution

is clean, drain coolant into a clean container for re-

use.

(1) Disconnect negative battery cable at battery.

(2) Drain the cooling system. Refer to Draining

Cooling System in this group.

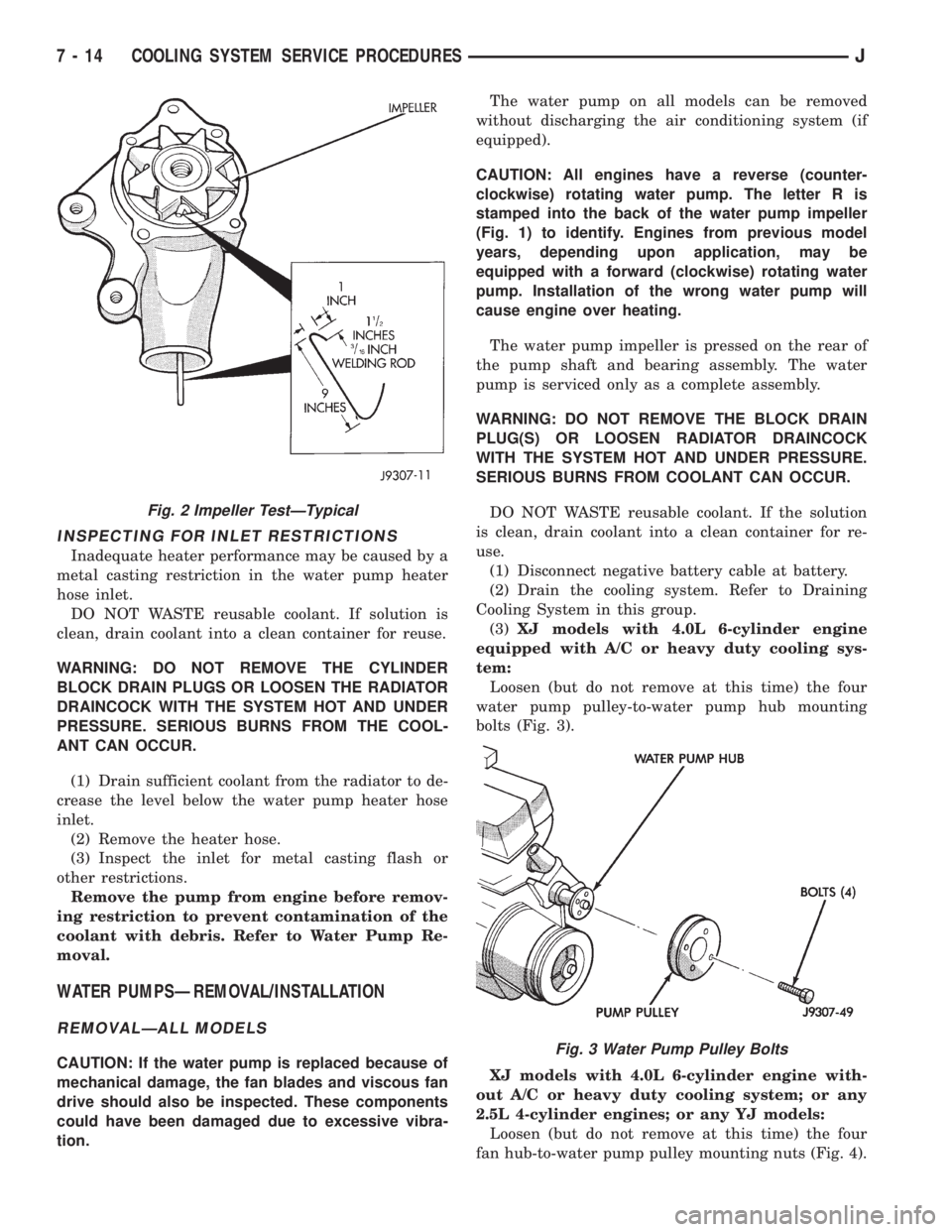

(3)XJ models with 4.0L 6-cylinder engine

equipped with A/C or heavy duty cooling sys-

tem:

Loosen (but do not remove at this time) the four

water pump pulley-to-water pump hub mounting

bolts (Fig. 3).

XJ models with 4.0L 6-cylinder engine with-

out A/C or heavy duty cooling system; or any

2.5L 4-cylinder engines; or any YJ models:

Loosen (but do not remove at this time) the four

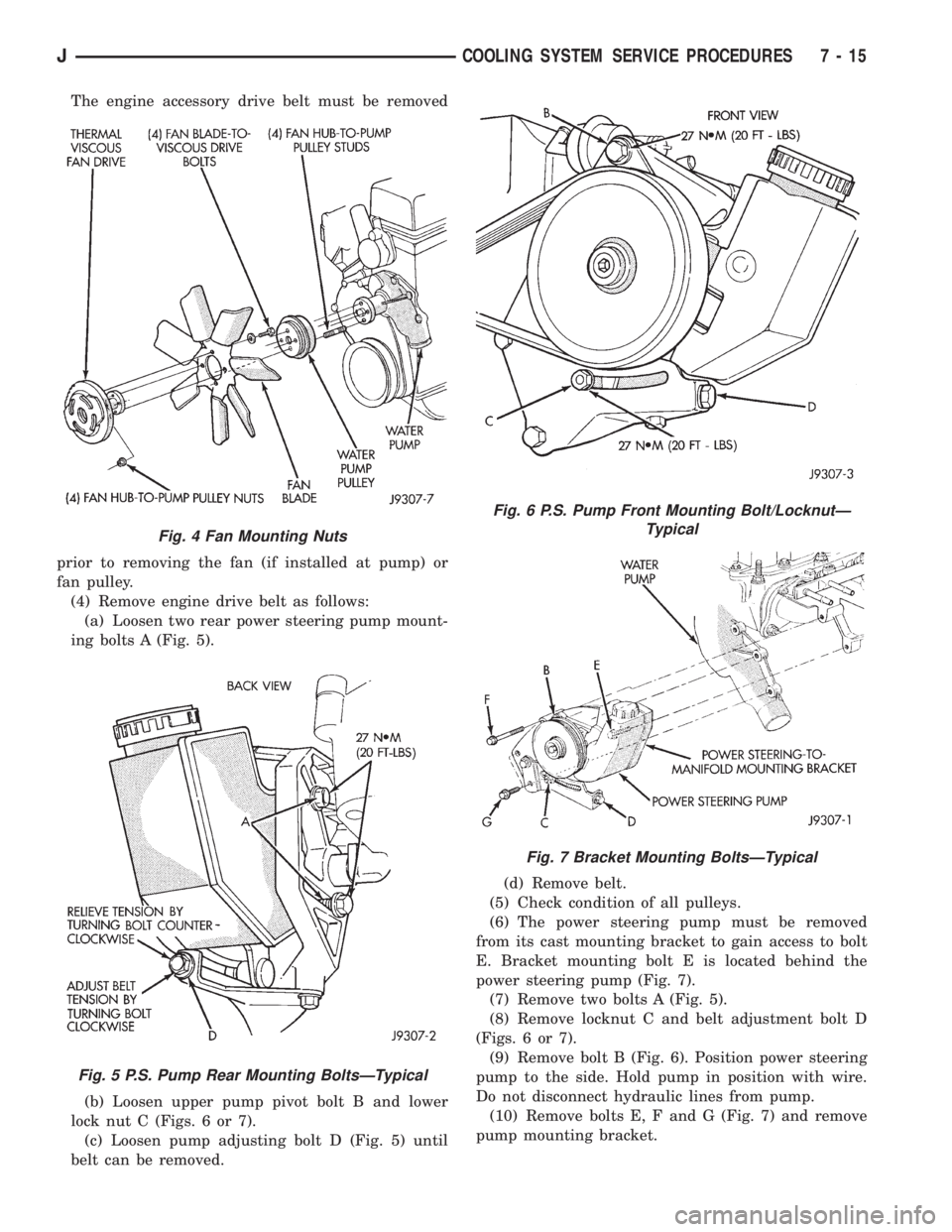

fan hub-to-water pump pulley mounting nuts (Fig. 4).

Fig. 2 Impeller TestÐTypical

Fig. 3 Water Pump Pulley Bolts

7 - 14 COOLING SYSTEM SERVICE PROCEDURESJ

Page 240 of 2198

The engine accessory drive belt must be removed

prior to removing the fan (if installed at pump) or

fan pulley.

(4) Remove engine drive belt as follows:

(a) Loosen two rear power steering pump mount-

ing bolts A (Fig. 5).

(b) Loosen upper pump pivot bolt B and lower

lock nut C (Figs. 6 or 7).

(c) Loosen pump adjusting bolt D (Fig. 5) until

belt can be removed.(d) Remove belt.

(5) Check condition of all pulleys.

(6) The power steering pump must be removed

from its cast mounting bracket to gain access to bolt

E. Bracket mounting bolt E is located behind the

power steering pump (Fig. 7).

(7) Remove two bolts A (Fig. 5).

(8) Remove locknut C and belt adjustment bolt D

(Figs. 6 or 7).

(9) Remove bolt B (Fig. 6). Position power steering

pump to the side. Hold pump in position with wire.

Do not disconnect hydraulic lines from pump.

(10) Remove bolts E, F and G (Fig. 7) and remove

pump mounting bracket.

Fig. 4 Fan Mounting Nuts

Fig. 5 P.S. Pump Rear Mounting BoltsÐTypical

Fig. 6 P.S. Pump Front Mounting Bolt/LocknutÐ

Typical

Fig. 7 Bracket Mounting BoltsÐTypical

JCOOLING SYSTEM SERVICE PROCEDURES 7 - 15

Page 242 of 2198

INSTALLATIONÐALL MODELS

(1) If pump is being replaced, install the heater

hose fitting to the pump. Use a sealant on the fitting

such as MoparŸ Thread Sealant With Teflon. Refer

to the directions on the package.

(2) Clean the gasket mating surfaces. If the origi-

nal pump is used, remove any deposits or other for-

eign material. Inspect the cylinder block and water

pump mating surfaces for erosion or damage from

cavitation.

(3) Install the gasket and water pump. The silicone

bead on the gasket should be facing the water pump.

Also, the gasket is installed dry. Tighten mounting

bolts to 30 Nzm (22 ft. lbs.) torque. Rotate the shaft

by hand to be sure it turns freely.

(4) Connect the radiator and heater hoses to the

water pump.

(5) Position water pump pulley to water pump hub.

(6) If equipped with a water pump mounted fan,

install fan and four nuts to water pump hub. If not

equipped with a water pump mounted fan, install

four pump hub bolts. Tighten bolts (or nuts) to 27

Nzm (20 ft. lbs.) torque.

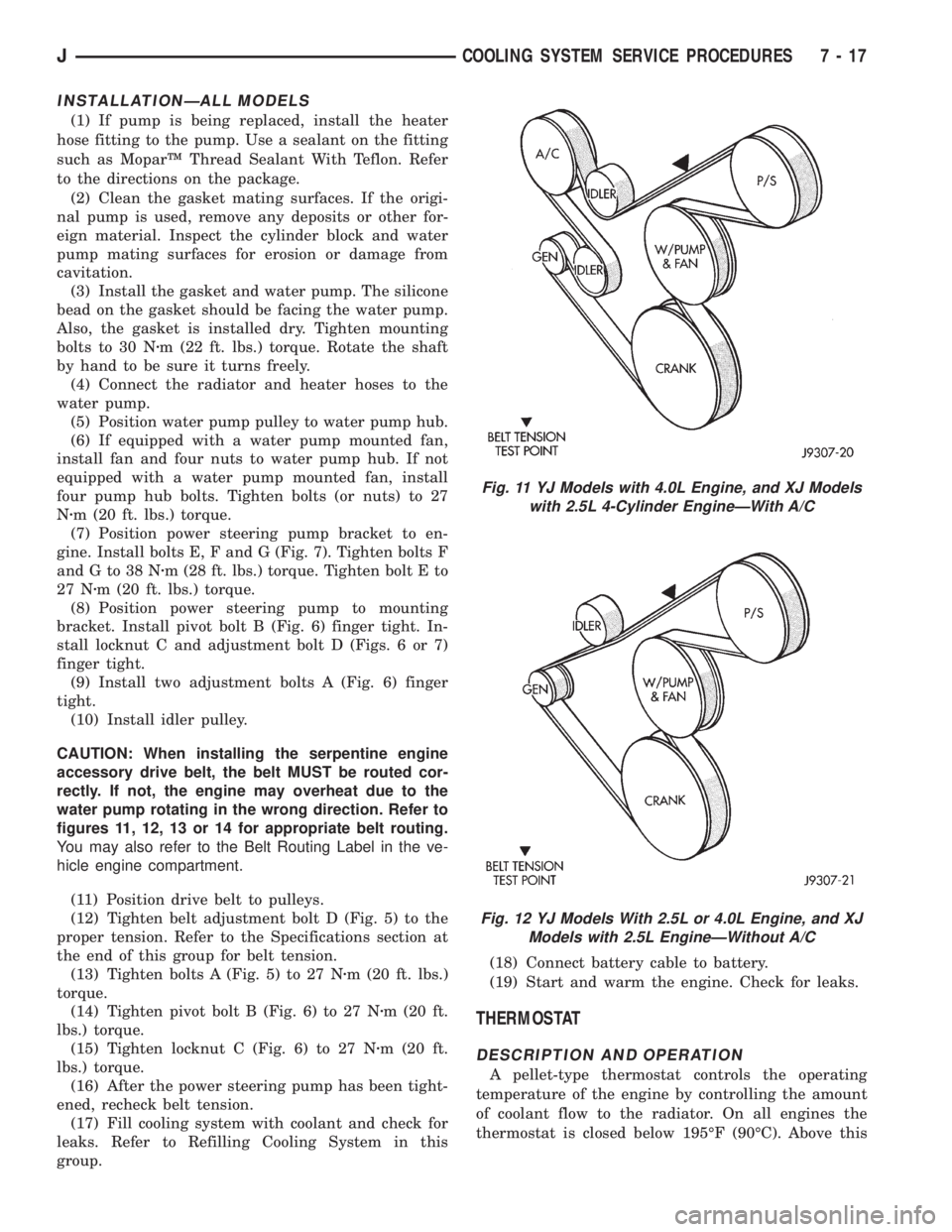

(7) Position power steering pump bracket to en-

gine. Install bolts E, F and G (Fig. 7). Tighten bolts F

andGto38Nzm (28 ft. lbs.) torque. Tighten bolt E to

27 Nzm (20 ft. lbs.) torque.

(8) Position power steering pump to mounting

bracket. Install pivot bolt B (Fig. 6) finger tight. In-

stall locknut C and adjustment bolt D (Figs. 6 or 7)

finger tight.

(9) Install two adjustment bolts A (Fig. 6) finger

tight.

(10) Install idler pulley.

CAUTION: When installing the serpentine engine

accessory drive belt, the belt MUST be routed cor-

rectly. If not, the engine may overheat due to the

water pump rotating in the wrong direction. Refer to

figures 11, 12, 13 or 14 for appropriate belt routing.

You may also refer to the Belt Routing Label in the ve-

hicle engine compartment.

(11) Position drive belt to pulleys.

(12) Tighten belt adjustment bolt D (Fig. 5) to the

proper tension. Refer to the Specifications section at

the end of this group for belt tension.

(13) Tighten bolts A (Fig. 5) to 27 Nzm (20 ft. lbs.)

torque.

(14) Tighten pivot bolt B (Fig. 6) to 27 Nzm (20 ft.

lbs.) torque.

(15) Tighten locknut C (Fig. 6) to 27 Nzm (20 ft.

lbs.) torque.

(16) After the power steering pump has been tight-

ened, recheck belt tension.

(17) Fill cooling system with coolant and check for

leaks. Refer to Refilling Cooling System in this

group.(18) Connect battery cable to battery.

(19) Start and warm the engine. Check for leaks.

THERMOSTAT

DESCRIPTION AND OPERATION

A pellet-type thermostat controls the operating

temperature of the engine by controlling the amount

of coolant flow to the radiator. On all engines the

thermostat is closed below 195ÉF (90ÉC). Above this

Fig. 11 YJ Models with 4.0L Engine, and XJ Models

with 2.5L 4-Cylinder EngineÐWith A/C

Fig. 12 YJ Models With 2.5L or 4.0L Engine, and XJ

Models with 2.5L EngineÐWithout A/C

JCOOLING SYSTEM SERVICE PROCEDURES 7 - 17

Page 246 of 2198

Low coolant level can cause thermostat pellet to be

suspended in air instead of coolant. This will cause

thermostat to open later, which in turn causes higher

coolant temperature. Air trapped in cooling system

also reduces amount of coolant circulating in heater

core resulting in low heat output.

DEAERATION

As the engine operates, any air trapped in cooling

system gathers under the radiator cap. The next time

the engine is operated, thermal expansion of coolant

will push any trapped air past radiator cap into the

coolant reserve/overflow tank. Here it escapes to the

atmosphere into the tank. When the engine cools

down the coolant, it will be drawn from the reserve/

overflow tank into the radiator to replace any re-

moved air.

DRAINING COOLING SYSTEM

ALL MODELSÐEXCEPT XJ WITH 4.0L

6-CYLINDER ENGINE

WARNING: DO NOT REMOVE THE CYLINDER

BLOCK DRAIN PLUGS OR LOOSEN THE RADIATOR

DRAINCOCK WITH SYSTEM HOT AND UNDER

PRESSURE. SERIOUS BURNS FROM COOLANT

CAN OCCUR.

DO NOT WASTE reusable coolant. If the solution

is clean, drain the coolant into a clean container for

reuse.

DO NOT remove the radiator cap when draining

the coolant from the reserve/overflow tank. Open the

radiator draincock and when the tank is empty, re-

move the radiator cap. The coolant does not have to

be removed from the tank unless the system is being

refilled with a fresh mixture.

(1) Drain the coolant from the radiator by loosen-

ing the draincock.

(2) Drain coolant from engine as follows:

(a) On 2.5L 4-cylinder engines (all models) by re-

moving drain plug at left rear side of block.

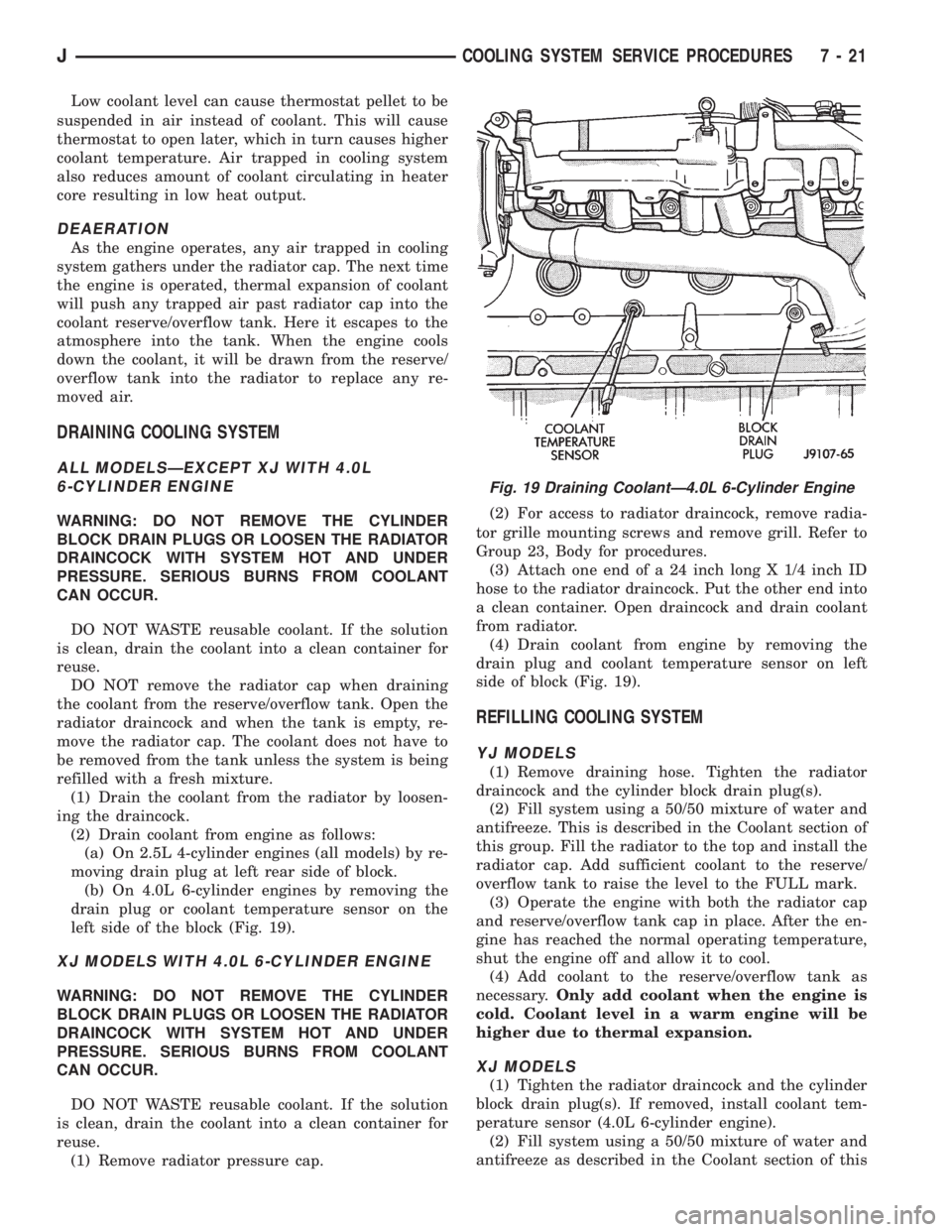

(b) On 4.0L 6-cylinder engines by removing the

drain plug or coolant temperature sensor on the

left side of the block (Fig. 19).

XJ MODELS WITH 4.0L 6-CYLINDER ENGINE

WARNING: DO NOT REMOVE THE CYLINDER

BLOCK DRAIN PLUGS OR LOOSEN THE RADIATOR

DRAINCOCK WITH SYSTEM HOT AND UNDER

PRESSURE. SERIOUS BURNS FROM COOLANT

CAN OCCUR.

DO NOT WASTE reusable coolant. If the solution

is clean, drain the coolant into a clean container for

reuse.

(1) Remove radiator pressure cap.(2) For access to radiator draincock, remove radia-

tor grille mounting screws and remove grill. Refer to

Group 23, Body for procedures.

(3) Attach one end of a 24 inch long X 1/4 inch ID

hose to the radiator draincock. Put the other end into

a clean container. Open draincock and drain coolant

from radiator.

(4) Drain coolant from engine by removing the

drain plug and coolant temperature sensor on left

side of block (Fig. 19).

REFILLING COOLING SYSTEM

YJ MODELS

(1) Remove draining hose. Tighten the radiator

draincock and the cylinder block drain plug(s).

(2) Fill system using a 50/50 mixture of water and

antifreeze. This is described in the Coolant section of

this group. Fill the radiator to the top and install the

radiator cap. Add sufficient coolant to the reserve/

overflow tank to raise the level to the FULL mark.

(3) Operate the engine with both the radiator cap

and reserve/overflow tank cap in place. After the en-

gine has reached the normal operating temperature,

shut the engine off and allow it to cool.

(4) Add coolant to the reserve/overflow tank as

necessary.Only add coolant when the engine is

cold. Coolant level in a warm engine will be

higher due to thermal expansion.

XJ MODELS

(1) Tighten the radiator draincock and the cylinder

block drain plug(s). If removed, install coolant tem-

perature sensor (4.0L 6-cylinder engine).

(2) Fill system using a 50/50 mixture of water and

antifreeze as described in the Coolant section of this

Fig. 19 Draining CoolantÐ4.0L 6-Cylinder Engine

JCOOLING SYSTEM SERVICE PROCEDURES 7 - 21

Page 249 of 2198

CAUTION: Do not operate the engine with a spark

plug shorted for more than a minute. The catalytic

converter may be damaged.

Isolate the compression leak by shorting each

spark plug to the cylinder block. The gauge pointer

should stop or decrease vibration when spark plug

for leaking cylinder is shorted. This happens because

of the absence of combustion pressure.

COMBUSTION LEAKAGE TEST (WITHOUT

PRESSURE TESTER)

DO NOT WASTE reusable coolant. If the solution

is clean, drain the coolant into a clean container for

reuse.

WARNING: DO NOT REMOVE THE CYLINDER

BLOCK DRAIN PLUGS OR LOOSEN THE RADIATOR

DRAINCOCK WITH THE SYSTEM HOT AND UNDER

PRESSURE. SERIOUS BURNS FROM COOLANT

CAN OCCUR.

Drain sufficient coolant to allow for thermostat re-

moval. Refer to Thermostat Replacement. Disconnect

the water pump drive belt.

Disconnect the upper radiator hose from the ther-

mostat housing. Remove the housing and thermostat.

Install the thermostat housing.

Add coolant to the radiator to bring the level to

within 6.3 mm (1/4 in) of the top of the thermostat

housing.

CAUTION: Avoid overheating. Do not operate the

engine for an excessive period of time. Open the

draincock immediately after the test to eliminate

boil over of coolant.

Start the engine and accelerate rapidly three times

(to approximately 3000 rpm) while observing the

coolant. If internal engine combustion gases are leak-

ing into the cooling system, bubbles will appear in

the coolant. If bubbles do not appear, there is no in-

ternal combustion gas leakage.

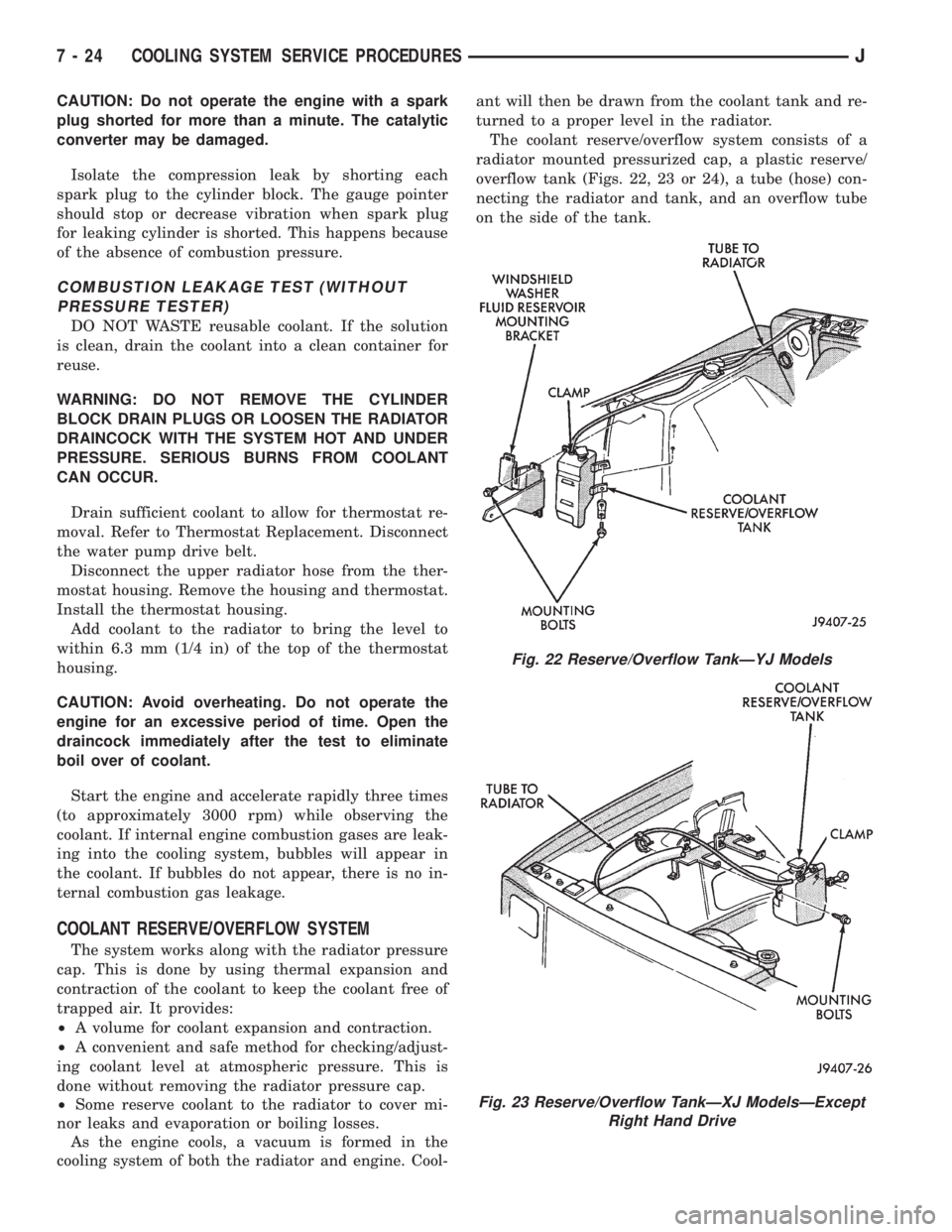

COOLANT RESERVE/OVERFLOW SYSTEM

The system works along with the radiator pressure

cap. This is done by using thermal expansion and

contraction of the coolant to keep the coolant free of

trapped air. It provides:

²A volume for coolant expansion and contraction.

²A convenient and safe method for checking/adjust-

ing coolant level at atmospheric pressure. This is

done without removing the radiator pressure cap.

²Some reserve coolant to the radiator to cover mi-

nor leaks and evaporation or boiling losses.

As the engine cools, a vacuum is formed in the

cooling system of both the radiator and engine. Cool-ant will then be drawn from the coolant tank and re-

turned to a proper level in the radiator.

The coolant reserve/overflow system consists of a

radiator mounted pressurized cap, a plastic reserve/

overflow tank (Figs. 22, 23 or 24), a tube (hose) con-

necting the radiator and tank, and an overflow tube

on the side of the tank.

Fig. 22 Reserve/Overflow TankÐYJ Models

Fig. 23 Reserve/Overflow TankÐXJ ModelsÐExcept

Right Hand Drive

7 - 24 COOLING SYSTEM SERVICE PROCEDURESJ

Page 251 of 2198

(4) When checking for vacuum leaks.

WARNING: IF VEHICLE HAS BEEN RUN RECENTLY,

WAIT AT LEAST 15 MINUTES BEFORE REMOVING

RADIATOR CAP. WITH A RAG, SQUEEZE RADIATOR

UPPER HOSE TO CHECK IF SYSTEM IS UNDER

PRESSURE. PLACE A RAG OVER THE CAP AND

WITHOUT PUSHING DOWN, ROTATE CAP

COUNTER-CLOCKWISE TO THE FIRST STOP. AL-

LOW FLUID TO ESCAPE THROUGH OVERFLOW

HOSE INTO COOLANT RESERVE/OVERFLOW

TANK. SQUEEZE RADIATOR UPPER HOSE TO DE-

TERMINE WHEN PRESSURE HAS BEEN RE-

LEASED. WHEN COOLANT AND STEAM STOP

BEING PUSHED INTO TANK AND SYSTEM PRES-

SURE DROPS, REMOVE RADIATOR CAP COM-

PLETELY.

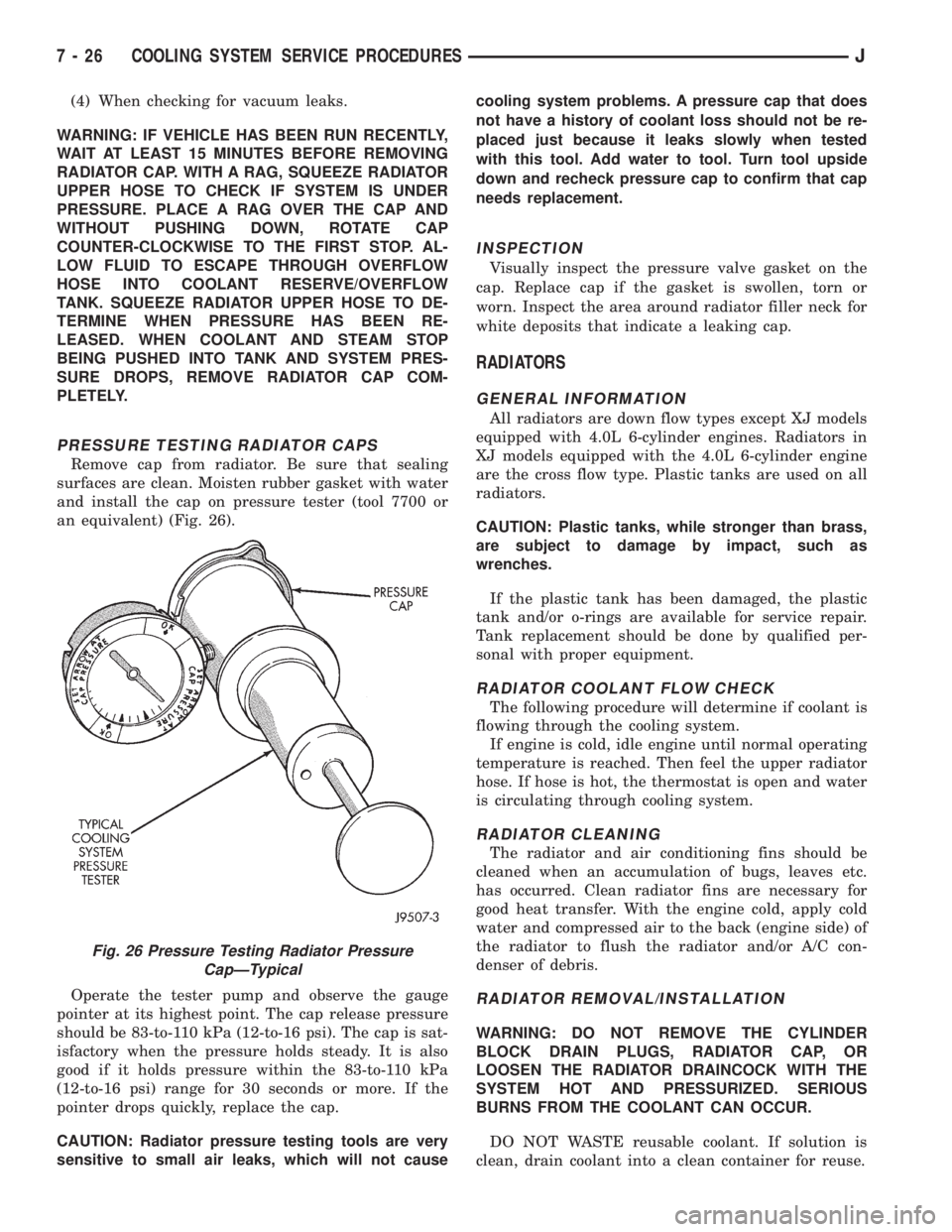

PRESSURE TESTING RADIATOR CAPS

Remove cap from radiator. Be sure that sealing

surfaces are clean. Moisten rubber gasket with water

and install the cap on pressure tester (tool 7700 or

an equivalent) (Fig. 26).

Operate the tester pump and observe the gauge

pointer at its highest point. The cap release pressure

should be 83-to-110 kPa (12-to-16 psi). The cap is sat-

isfactory when the pressure holds steady. It is also

good if it holds pressure within the 83-to-110 kPa

(12-to-16 psi) range for 30 seconds or more. If the

pointer drops quickly, replace the cap.

CAUTION: Radiator pressure testing tools are very

sensitive to small air leaks, which will not causecooling system problems. A pressure cap that does

not have a history of coolant loss should not be re-

placed just because it leaks slowly when tested

with this tool. Add water to tool. Turn tool upside

down and recheck pressure cap to confirm that cap

needs replacement.

INSPECTION

Visually inspect the pressure valve gasket on the

cap. Replace cap if the gasket is swollen, torn or

worn. Inspect the area around radiator filler neck for

white deposits that indicate a leaking cap.

RADIATORS

GENERAL INFORMATION

All radiators are down flow types except XJ models

equipped with 4.0L 6-cylinder engines. Radiators in

XJ models equipped with the 4.0L 6-cylinder engine

are the cross flow type. Plastic tanks are used on all

radiators.

CAUTION: Plastic tanks, while stronger than brass,

are subject to damage by impact, such as

wrenches.

If the plastic tank has been damaged, the plastic

tank and/or o-rings are available for service repair.

Tank replacement should be done by qualified per-

sonal with proper equipment.

RADIATOR COOLANT FLOW CHECK

The following procedure will determine if coolant is

flowing through the cooling system.

If engine is cold, idle engine until normal operating

temperature is reached. Then feel the upper radiator

hose. If hose is hot, the thermostat is open and water

is circulating through cooling system.

RADIATOR CLEANING

The radiator and air conditioning fins should be

cleaned when an accumulation of bugs, leaves etc.

has occurred. Clean radiator fins are necessary for

good heat transfer. With the engine cold, apply cold

water and compressed air to the back (engine side) of

the radiator to flush the radiator and/or A/C con-

denser of debris.

RADIATOR REMOVAL/INSTALLATION

WARNING: DO NOT REMOVE THE CYLINDER

BLOCK DRAIN PLUGS, RADIATOR CAP, OR

LOOSEN THE RADIATOR DRAINCOCK WITH THE

SYSTEM HOT AND PRESSURIZED. SERIOUS

BURNS FROM THE COOLANT CAN OCCUR.

DO NOT WASTE reusable coolant. If solution is

clean, drain coolant into a clean container for reuse.

Fig. 26 Pressure Testing Radiator Pressure

CapÐTypical

7 - 26 COOLING SYSTEM SERVICE PROCEDURESJ

Page 253 of 2198

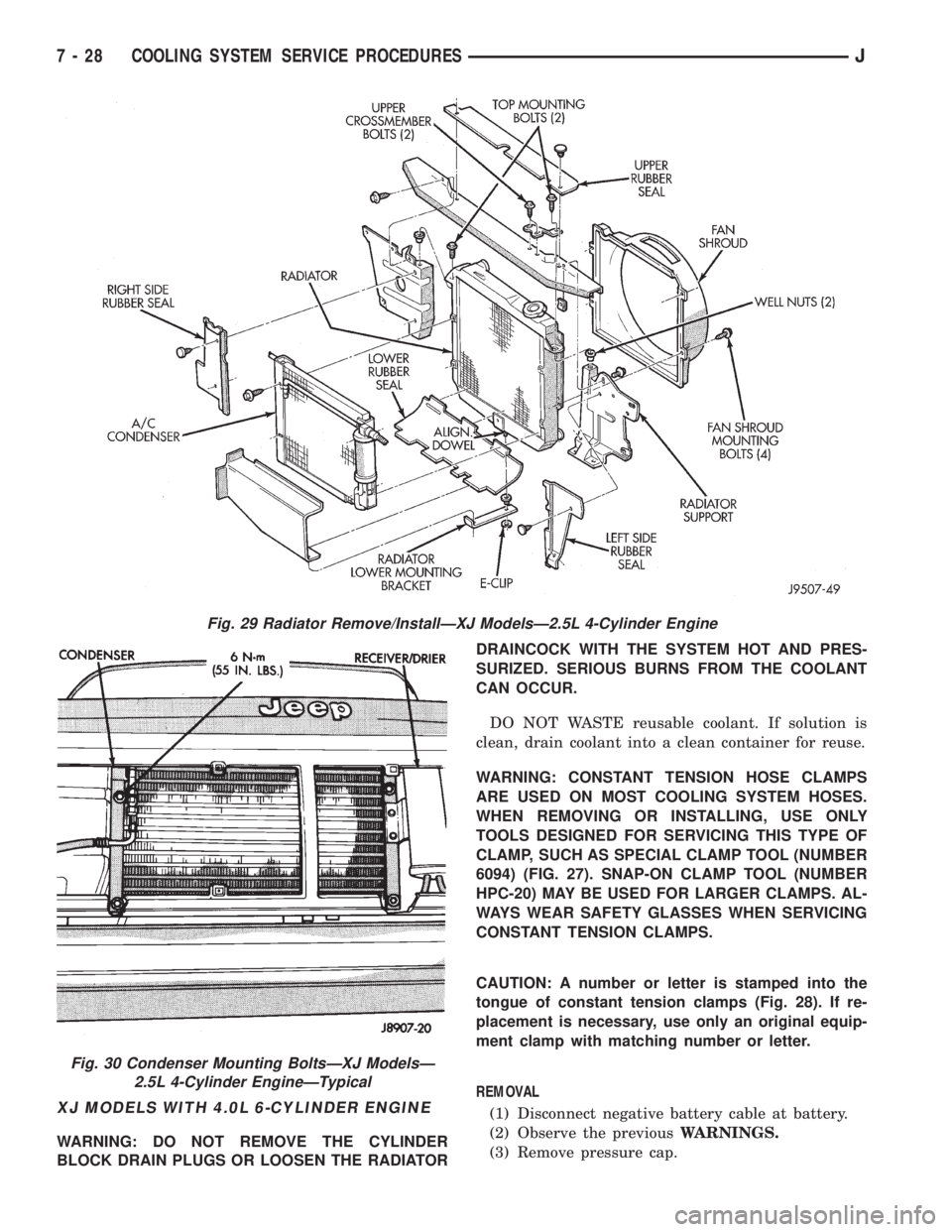

XJ MODELS WITH 4.0L 6-CYLINDER ENGINE

WARNING: DO NOT REMOVE THE CYLINDER

BLOCK DRAIN PLUGS OR LOOSEN THE RADIATORDRAINCOCK WITH THE SYSTEM HOT AND PRES-

SURIZED. SERIOUS BURNS FROM THE COOLANT

CAN OCCUR.

DO NOT WASTE reusable coolant. If solution is

clean, drain coolant into a clean container for reuse.

WARNING: CONSTANT TENSION HOSE CLAMPS

ARE USED ON MOST COOLING SYSTEM HOSES.

WHEN REMOVING OR INSTALLING, USE ONLY

TOOLS DESIGNED FOR SERVICING THIS TYPE OF

CLAMP, SUCH AS SPECIAL CLAMP TOOL (NUMBER

6094) (FIG. 27). SNAP-ON CLAMP TOOL (NUMBER

HPC-20) MAY BE USED FOR LARGER CLAMPS. AL-

WAYS WEAR SAFETY GLASSES WHEN SERVICING

CONSTANT TENSION CLAMPS.

CAUTION: A number or letter is stamped into the

tongue of constant tension clamps (Fig. 28). If re-

placement is necessary, use only an original equip-

ment clamp with matching number or letter.

REMOVAL

(1) Disconnect negative battery cable at battery.

(2) Observe the previousWARNINGS.

(3) Remove pressure cap.

Fig. 29 Radiator Remove/InstallÐXJ ModelsÐ2.5L 4-Cylinder Engine

Fig. 30 Condenser Mounting BoltsÐXJ ModelsÐ

2.5L 4-Cylinder EngineÐTypical

7 - 28 COOLING SYSTEM SERVICE PROCEDURESJ