JEEP CHEROKEE 1995 Service Workshop Manual

Manufacturer: JEEP, Model Year: 1995, Model line: CHEROKEE, Model: JEEP CHEROKEE 1995Pages: 2198, PDF Size: 82.83 MB

Page 51 of 2198

The shock absorber bushings do not require any

type of lubrication. Do not lubricate the bushings to

reduce bushing noise. Grease or mineral oil-base lu-

bricants will deteriorate the bushing rubber.

The shock absorbers are not refillable or adjustable.

If a malfunction occurs, the shock absorber must be

replaced. To test a shock absorber, hold it in an up-

right position and force the piston into and out of the

cylinder four or five times. The action throughout

each stroke should be smooth and even.

SHOCK ABSORBER

REMOVAL

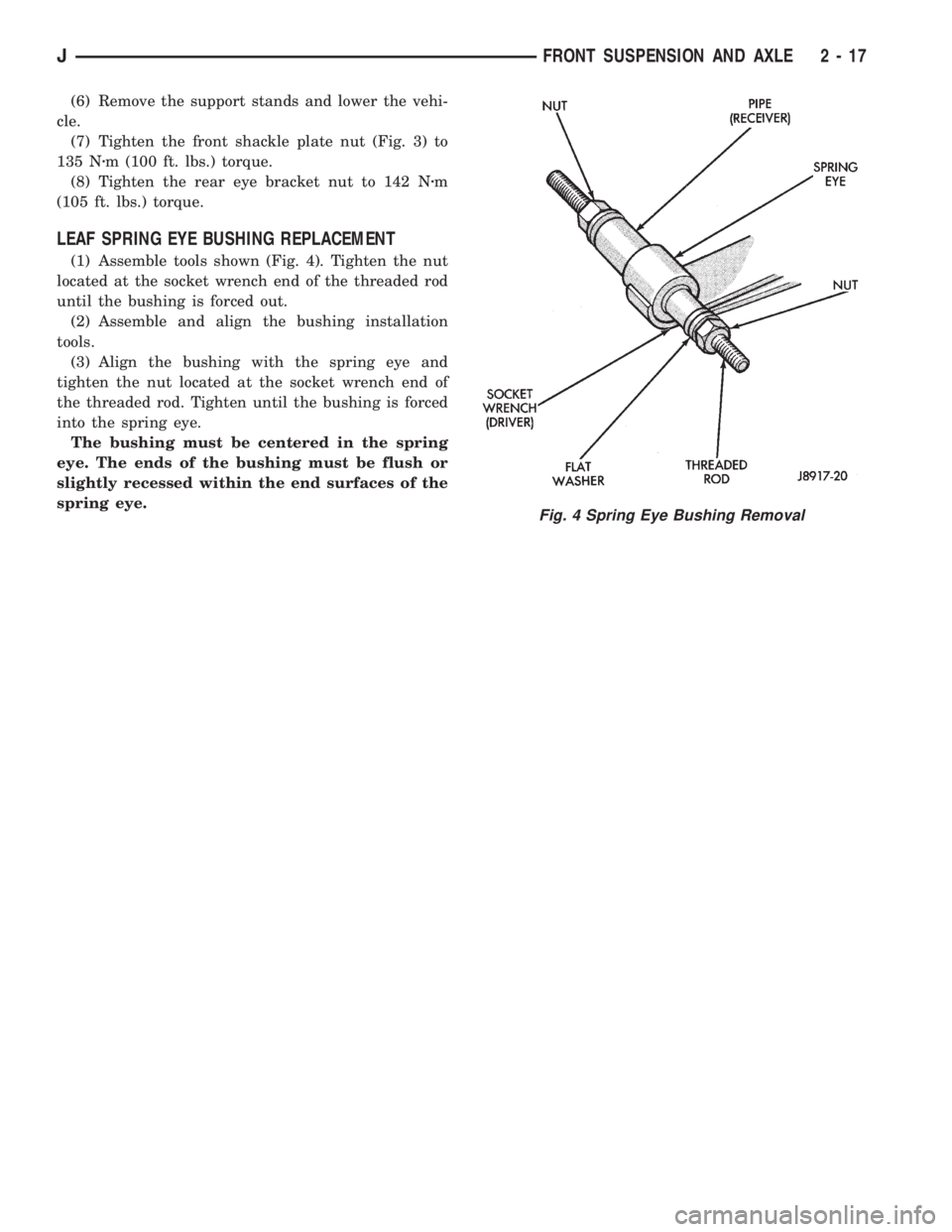

(1) Remove the nut, retainer and grommet from the

upper stud on the frame bracket (Fig. 3).

(2) Raise and support the vehicle.

(3) Remove the nut, washers and bolt from the

shock absorber lower eye (Fig.3).

(4) Remove the shock absorber.

(5) Remove the remaining grommet and retainer

from the shock absorber stud.

INSTALLATION

(1) Position the lower retainer and grommet on the

upper stud. Insert the shock absorber through the

shock tower hole.

(2) Install the lower bolts and nuts. Tighten the

nuts to 61 Nzm (45 ft. lbs.) torque.

(3) Install the upper grommet and retainer on the

stud on the frame bracket. Install the nut and tighten

to 12 Nzm (9 ft. lbs.) torque.

LEAF SPRING

REMOVAL

(1) Raise the vehicle.

(2) Support the vehicle with jack stands placed un-

der the frame.

(3) Position a hydraulic jack under the axle. Raise

the axle to relieve the axle weight from the springs.

(4) Remove the stabilizer bar links attaching nut.

(5) Remove the nuts, the U-bolts and spring

bracket from the axle.

(6) Remove the nut and bolt that attaches the

spring front eye to the shackle (Fig. 3).

(7) Remove the nut and bolt from the spring rear

eye.

(8) Remove the spring from the vehicle.

The spring can be disassembled by removing

the spring clips and the center bolt. If the

spring bushings require replacement, refer to

the bushing removal and installation proce-

dures.

INSTALLATION

(1) Position the spring front eye in the shackle.

Loosely install the attaching bolt and nut. Do not

tighten at this time.

(2) Position the rear eye in the hanger bracket.

Loosely install the attaching bolt and nut (Fig. 3). Do

not tighten at this time.

(3) Position the axle. Install the spring bracket,

U-bolts and nuts (Fig. 3). Tighten the U-bolt nuts to

122 Nzm (90 ft. lbs.) torque.

(4) Attach the stabilizer bar links.

(5) Remove the hydraulic jack.

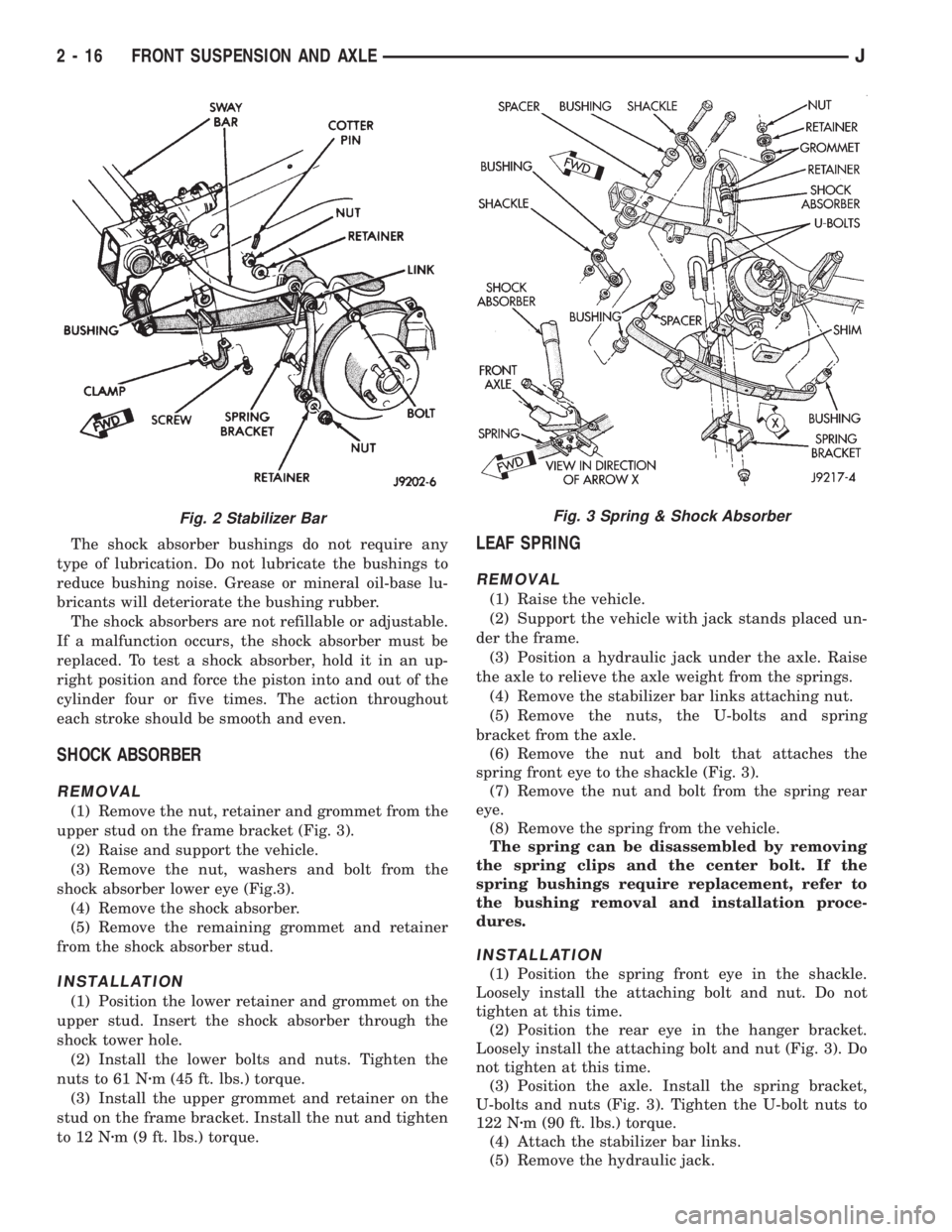

Fig. 2 Stabilizer BarFig. 3 Spring & Shock Absorber

2 - 16 FRONT SUSPENSION AND AXLEJ

Page 52 of 2198

(6) Remove the support stands and lower the vehi-

cle.

(7) Tighten the front shackle plate nut (Fig. 3) to

135 Nzm (100 ft. lbs.) torque.

(8) Tighten the rear eye bracket nut to 142 Nzm

(105 ft. lbs.) torque.

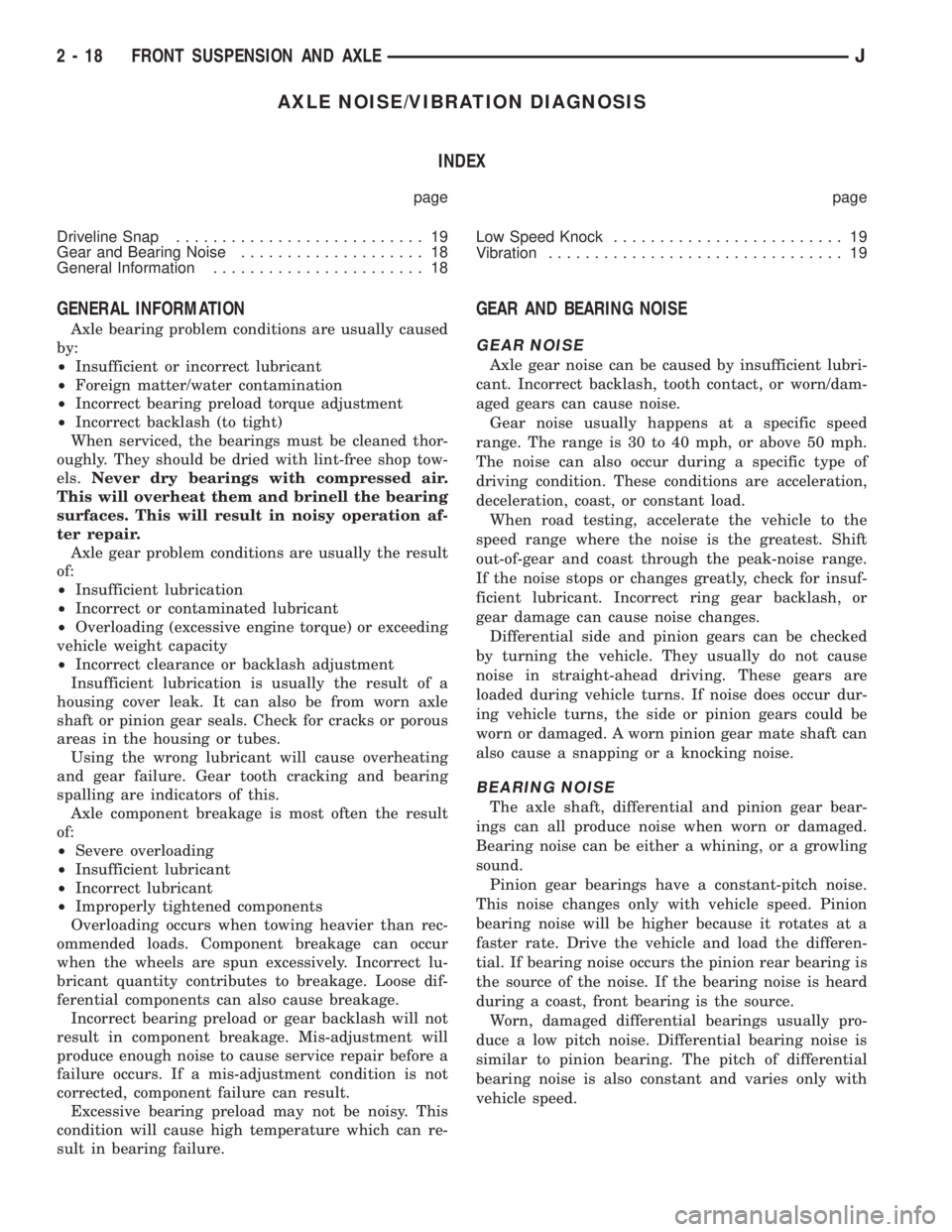

LEAF SPRING EYE BUSHING REPLACEMENT

(1) Assemble tools shown (Fig. 4). Tighten the nut

located at the socket wrench end of the threaded rod

until the bushing is forced out.

(2) Assemble and align the bushing installation

tools.

(3) Align the bushing with the spring eye and

tighten the nut located at the socket wrench end of

the threaded rod. Tighten until the bushing is forced

into the spring eye.

The bushing must be centered in the spring

eye. The ends of the bushing must be flush or

slightly recessed within the end surfaces of the

spring eye.

Fig. 4 Spring Eye Bushing Removal

JFRONT SUSPENSION AND AXLE 2 - 17

Page 53 of 2198

AXLE NOISE/VIBRATION DIAGNOSIS

INDEX

page page

Driveline Snap........................... 19

Gear and Bearing Noise.................... 18

General Information....................... 18Low Speed Knock......................... 19

Vibration................................ 19

GENERAL INFORMATION

Axle bearing problem conditions are usually caused

by:

²Insufficient or incorrect lubricant

²Foreign matter/water contamination

²Incorrect bearing preload torque adjustment

²Incorrect backlash (to tight)

When serviced, the bearings must be cleaned thor-

oughly. They should be dried with lint-free shop tow-

els.Never dry bearings with compressed air.

This will overheat them and brinell the bearing

surfaces. This will result in noisy operation af-

ter repair.

Axle gear problem conditions are usually the result

of:

²Insufficient lubrication

²Incorrect or contaminated lubricant

²Overloading (excessive engine torque) or exceeding

vehicle weight capacity

²Incorrect clearance or backlash adjustment

Insufficient lubrication is usually the result of a

housing cover leak. It can also be from worn axle

shaft or pinion gear seals. Check for cracks or porous

areas in the housing or tubes.

Using the wrong lubricant will cause overheating

and gear failure. Gear tooth cracking and bearing

spalling are indicators of this.

Axle component breakage is most often the result

of:

²Severe overloading

²Insufficient lubricant

²Incorrect lubricant

²Improperly tightened components

Overloading occurs when towing heavier than rec-

ommended loads. Component breakage can occur

when the wheels are spun excessively. Incorrect lu-

bricant quantity contributes to breakage. Loose dif-

ferential components can also cause breakage.

Incorrect bearing preload or gear backlash will not

result in component breakage. Mis-adjustment will

produce enough noise to cause service repair before a

failure occurs. If a mis-adjustment condition is not

corrected, component failure can result.

Excessive bearing preload may not be noisy. This

condition will cause high temperature which can re-

sult in bearing failure.

GEAR AND BEARING NOISE

GEAR NOISE

Axle gear noise can be caused by insufficient lubri-

cant. Incorrect backlash, tooth contact, or worn/dam-

aged gears can cause noise.

Gear noise usually happens at a specific speed

range. The range is 30 to 40 mph, or above 50 mph.

The noise can also occur during a specific type of

driving condition. These conditions are acceleration,

deceleration, coast, or constant load.

When road testing, accelerate the vehicle to the

speed range where the noise is the greatest. Shift

out-of-gear and coast through the peak-noise range.

If the noise stops or changes greatly, check for insuf-

ficient lubricant. Incorrect ring gear backlash, or

gear damage can cause noise changes.

Differential side and pinion gears can be checked

by turning the vehicle. They usually do not cause

noise in straight-ahead driving. These gears are

loaded during vehicle turns. If noise does occur dur-

ing vehicle turns, the side or pinion gears could be

worn or damaged. A worn pinion gear mate shaft can

also cause a snapping or a knocking noise.

BEARING NOISE

The axle shaft, differential and pinion gear bear-

ings can all produce noise when worn or damaged.

Bearing noise can be either a whining, or a growling

sound.

Pinion gear bearings have a constant-pitch noise.

This noise changes only with vehicle speed. Pinion

bearing noise will be higher because it rotates at a

faster rate. Drive the vehicle and load the differen-

tial. If bearing noise occurs the pinion rear bearing is

the source of the noise. If the bearing noise is heard

during a coast, front bearing is the source.

Worn, damaged differential bearings usually pro-

duce a low pitch noise. Differential bearing noise is

similar to pinion bearing. The pitch of differential

bearing noise is also constant and varies only with

vehicle speed.

2 - 18 FRONT SUSPENSION AND AXLEJ

Page 54 of 2198

Axle shaft bearings produce noise and vibration

when worn or damaged. The noise generally changes

when the bearings are loaded. Road test the vehicle.

Turn the vehicle sharply to the left and to the right.

This will load the bearings and change the noise

level. Where axle bearing damage is slight, the noise

is usually not noticeable at speeds above 30 mph.

LOW SPEED KNOCK

Low speed knock is generally caused by a worn U-

joint or by worn side-gear thrust washers. A worn

pinion gear shaft bore will also cause low speed

knock.

VIBRATION

Vibration at the rear of the vehicle is usually

caused by a:

²Damaged drive shaft

²Missing drive shaft balance weight

²Worn, out-of-balance wheels

²Loose wheel lug nuts

²Worn U-joint

²Loose spring U-bolts

²Loose/broken springs

²Damaged axle shaft bearings

²Loose pinion gear nut

²Excessive pinion yoke run out²Bent axle shaft

Check for loose or damaged front-end components

or engine/transmission mounts. These components

can contribute to what appears to be a rear-end vi-

bration. Do not overlook engine accessories, brackets

and drive belts.

All driveline components should be examined be-

fore starting any repair.

Refer to Group 22ÐTires And Wheels for addi-

tional information involving vibration diagnosis.

DRIVELINE SNAP

A snap or clunk noise when the vehicle is shifted

into gear (or the clutch engaged), can be caused by:

²High engine idle speed

²Loose engine/transmission/transfer case mounts

²Worn U-joints

²Loose spring mounts

²Loose pinion gear nut and yoke

²Excessive ring gear backlash

²Excessive differential side gear-to-case clearance

The source of a snap or a clunk noise can be deter-

mined with the assistance of a helper. Raise the ve-

hicle on a hoist with the wheels free to rotate.

Instruct the helper to shift the transmission into

gear. Listen for the noise, a mechanics stethoscope is

helpful in isolating the source of a noise.

JFRONT SUSPENSION AND AXLE 2 - 19

Page 55 of 2198

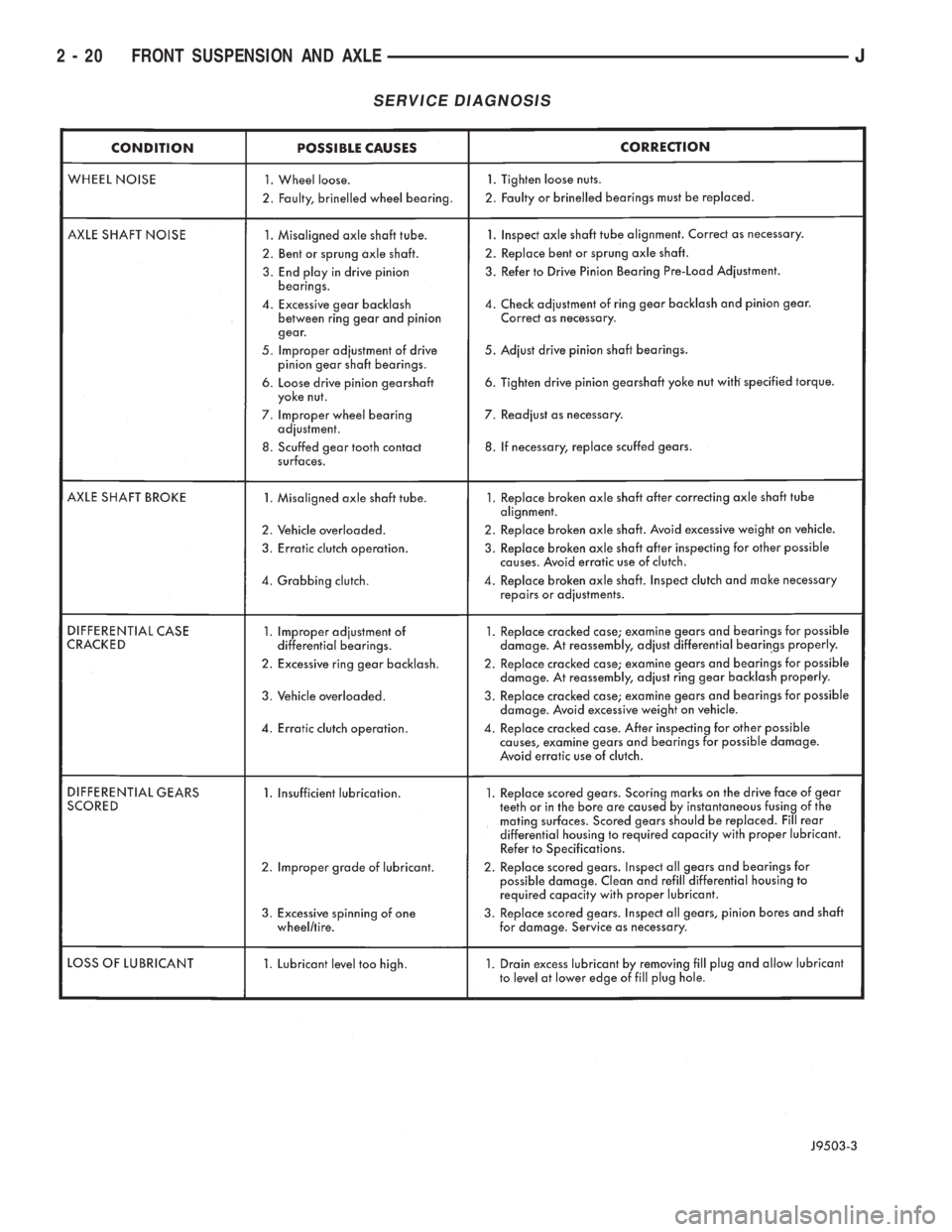

SERVICE DIAGNOSIS

2 - 20 FRONT SUSPENSION AND AXLEJ

Page 56 of 2198

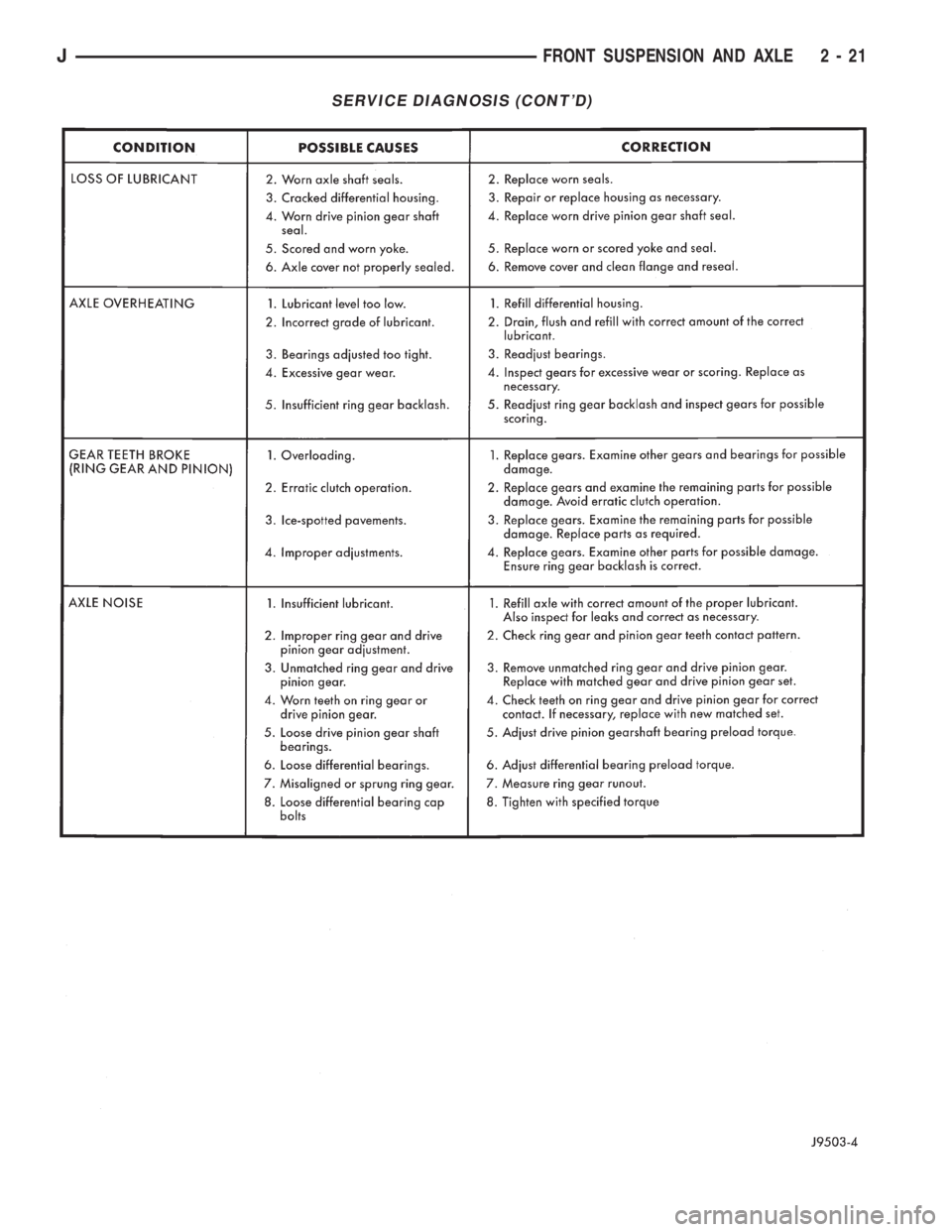

SERVICE DIAGNOSIS (CONT'D)

JFRONT SUSPENSION AND AXLE 2 - 21

Page 57 of 2198

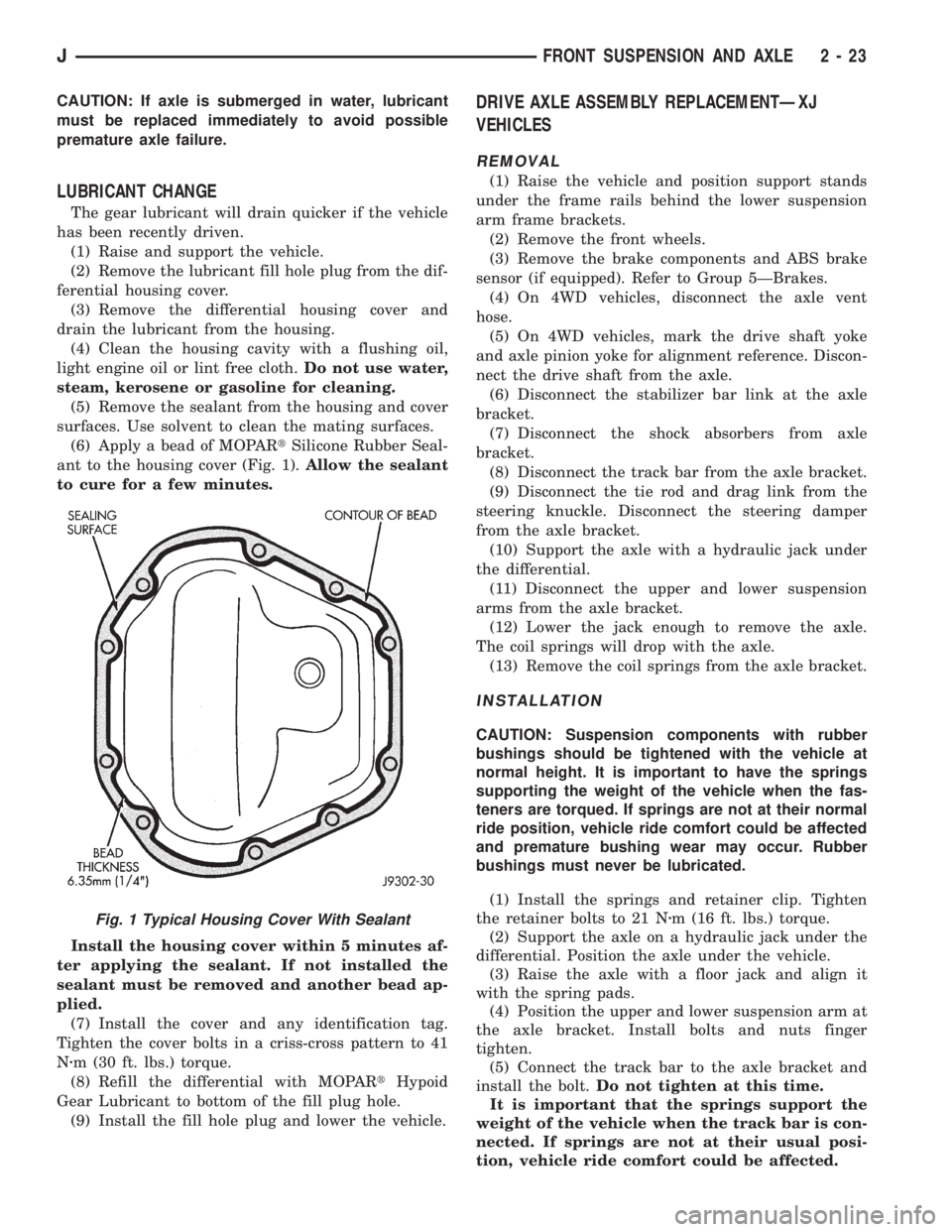

MODEL 30 AXLE AND TUBE AXLE (2WD)

INDEX

page page

Axle Bushing Replacement.................. 34

Axle ShaftÐCardan U-Joint.................. 26

Backlash and Contact Pattern Analysis......... 45

Cleaning/Inspection........................ 37

Differential and Pinion Measurement........... 40

Differential Assembly....................... 38

Differential Disassembly.................... 35

Differential Installation...................... 44

Differential Removal....................... 34

Differential Shim Pack Measurement and

Adjustment............................ 43

Drive Axle Assembly ReplacementÐXJ Vehicles . . 23

Drive Axle Assembly ReplacementÐYJ Vehicles . . 24Final Assembly........................... 46

Hub Bearing and Axle Shaft................. 25

Information.............................. 22

Inner Axle Shaft Oil Seal Replacement......... 35

Lubricant Change......................... 23

Lubricant Specifications..................... 22

Pinion Gear Assembly/Installation............. 42

Pinion Gear Depth Information............... 39

Pinion Removal/Disassembly................. 36

Pinion Seal Replacement................... 25

Steering Knuckle and Ball Studs.............. 32

Vacuum Disconnect AxleÐYJ Vehicles......... 27

INFORMATION

The Model 30 front axles consists of a cast iron dif-

ferential housing with axle shaft tubes extending

from either side. The tubes are pressed into the dif-

ferential housing and welded.

The integral type housing, hypoid gear design has

the centerline of the pinion set above the centerline

of the ring gear.

The axle has a fitting for a vent hose used to re-

lieve internal pressure caused by lubricant vaporiza-

tion and internal expansion.

The axles are equipped with semi-floating axle

shafts, meaning that loads are supported by the hub

bearings. The axle shafts are retained by nuts at the

hub bearings. The hub bearings are bolted to the

steering knuckle at the outboard end of the axle tube

yoke. The hub bearings are serviced as an assembly.

The axles are equipped with ABS brake sensors.

The sensors are attached to the knuckle assemblies

and tone rings are pressed on the axle shaft.Use

care when removing axle shafts as NOT to dam-

age the tone wheel or the sensor.

The stamped steel cover provides a means for in-

spection and servicing the differential.

The Model 30 axle has the assembly part number

and gear ratio listed on a tag. The tag is attached to

the housing cover. Build date identification codes are

stamped on the axle shaft tube cover side.

The differential case is a one-piece design. The dif-

ferential pinion mate shaft is retained with a roll

pin. Differential bearing preload and ring gear back-

lash is adjusted by the use of shims (select thick-

ness). The shims are located between the differential

bearing cones and case. Pinion bearing preload is set

and maintained by the use of collapsible spacer.

COMMAND-TRACÐYJ VEHICLES

The Command-Trac system is a vacuum disconnect

axle. The system has a two-piece axle shaft coupled

together by a shift collar. For two-wheel drive opera-

tion, the vacuum motor and shift fork disengages the

axle shaft splines. For four-wheel drive operation, the

vacuum motor and shift fork engages the axle

splines.

SELEC-TRACÐXJ VEHICLES

The Selec-Trac system is a non-disconnect axle.

Shifting from two-wheel to four-wheel drive is done

at the transfer case.

For XJ vehicles equipped withSelec-Tracand

ABS brake system, refer to Group 5ÐBrakes for ad-

ditional service information.

LUBRICANT SPECIFICATIONS

Multi-purpose, hypoid gear lubricant should be

used for Model 30 axles. The lubricant should have

MIL-L-2105C and API GL 5 quality specifications.

MOPARtHypoid Gear Lubricant conforms to both of

these specifications.

²The factory fill for the Model 30 axle is SAE Ther-

mally Stable 80W-90 gear lubricant.Do not use

heavier weight lubricant, this will cause axle

engagement difficulties.

²The factory installed lubricant quantity for the

NON-DISCONNECT TYPE AXLE is 1.48 L (3.13

pts.).

²The factory installed lubricant quantity for the

VACUUM-DISCONNECT TYPE AXLE is 1.65 L (3.76

pts.).

Refer to Group 0, Lubrication and Maintenance for

additional information regarding temperature range,

viscosity and fluid level.

2 - 22 FRONT SUSPENSION AND AXLEJ

Page 58 of 2198

CAUTION: If axle is submerged in water, lubricant

must be replaced immediately to avoid possible

premature axle failure.

LUBRICANT CHANGE

The gear lubricant will drain quicker if the vehicle

has been recently driven.

(1) Raise and support the vehicle.

(2) Remove the lubricant fill hole plug from the dif-

ferential housing cover.

(3) Remove the differential housing cover and

drain the lubricant from the housing.

(4) Clean the housing cavity with a flushing oil,

light engine oil or lint free cloth.Do not use water,

steam, kerosene or gasoline for cleaning.

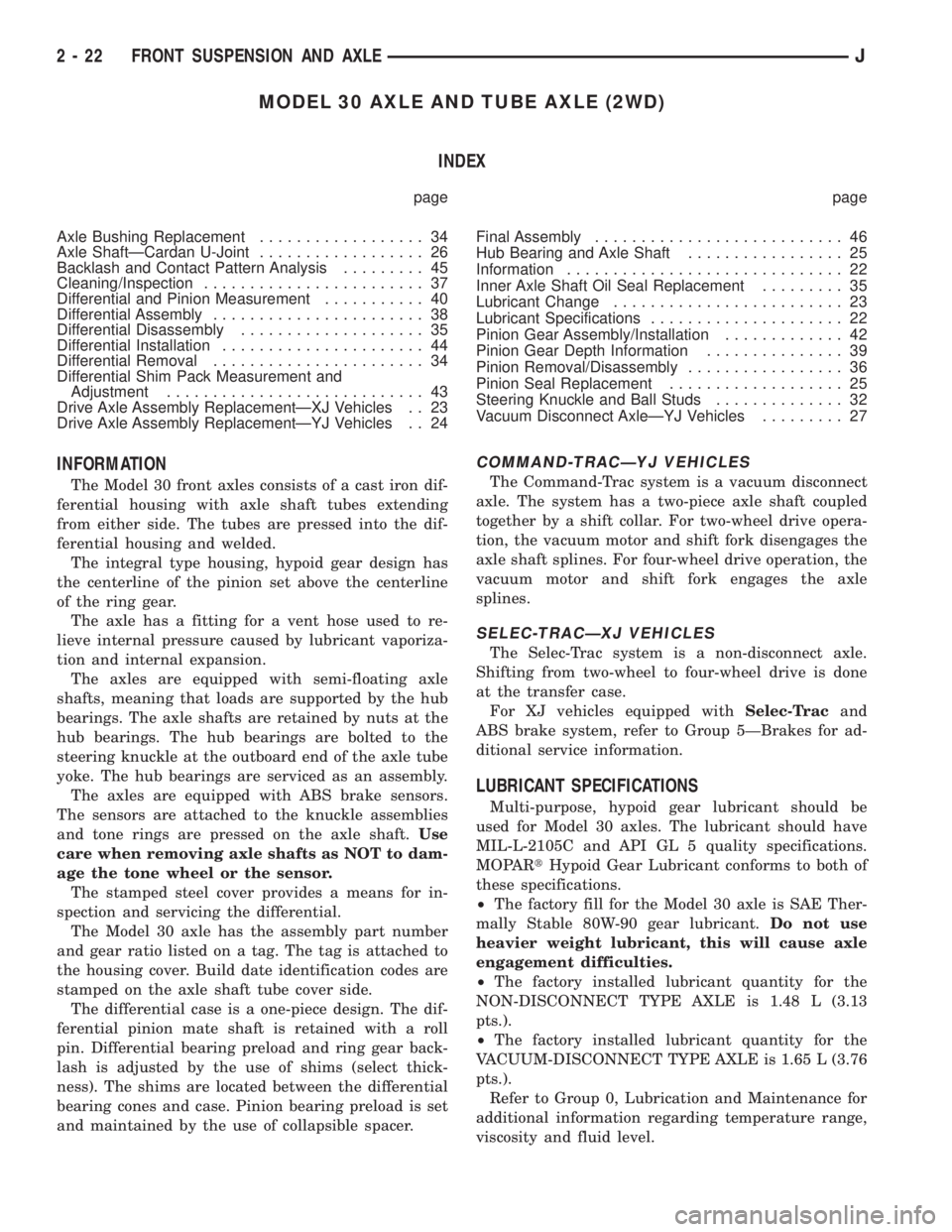

(5) Remove the sealant from the housing and cover

surfaces. Use solvent to clean the mating surfaces.

(6) Apply a bead of MOPARtSilicone Rubber Seal-

ant to the housing cover (Fig. 1).Allow the sealant

to cure for a few minutes.

Install the housing cover within 5 minutes af-

ter applying the sealant. If not installed the

sealant must be removed and another bead ap-

plied.

(7) Install the cover and any identification tag.

Tighten the cover bolts in a criss-cross pattern to 41

Nzm (30 ft. lbs.) torque.

(8) Refill the differential with MOPARtHypoid

Gear Lubricant to bottom of the fill plug hole.

(9) Install the fill hole plug and lower the vehicle.

DRIVE AXLE ASSEMBLY REPLACEMENTÐXJ

VEHICLES

REMOVAL

(1) Raise the vehicle and position support stands

under the frame rails behind the lower suspension

arm frame brackets.

(2) Remove the front wheels.

(3) Remove the brake components and ABS brake

sensor (if equipped). Refer to Group 5ÐBrakes.

(4) On 4WD vehicles, disconnect the axle vent

hose.

(5) On 4WD vehicles, mark the drive shaft yoke

and axle pinion yoke for alignment reference. Discon-

nect the drive shaft from the axle.

(6) Disconnect the stabilizer bar link at the axle

bracket.

(7) Disconnect the shock absorbers from axle

bracket.

(8) Disconnect the track bar from the axle bracket.

(9) Disconnect the tie rod and drag link from the

steering knuckle. Disconnect the steering damper

from the axle bracket.

(10) Support the axle with a hydraulic jack under

the differential.

(11) Disconnect the upper and lower suspension

arms from the axle bracket.

(12) Lower the jack enough to remove the axle.

The coil springs will drop with the axle.

(13) Remove the coil springs from the axle bracket.

INSTALLATION

CAUTION: Suspension components with rubber

bushings should be tightened with the vehicle at

normal height. It is important to have the springs

supporting the weight of the vehicle when the fas-

teners are torqued. If springs are not at their normal

ride position, vehicle ride comfort could be affected

and premature bushing wear may occur. Rubber

bushings must never be lubricated.

(1) Install the springs and retainer clip. Tighten

the retainer bolts to 21 Nzm (16 ft. lbs.) torque.

(2) Support the axle on a hydraulic jack under the

differential. Position the axle under the vehicle.

(3) Raise the axle with a floor jack and align it

with the spring pads.

(4) Position the upper and lower suspension arm at

the axle bracket. Install bolts and nuts finger

tighten.

(5) Connect the track bar to the axle bracket and

install the bolt.Do not tighten at this time.

It is important that the springs support the

weight of the vehicle when the track bar is con-

nected. If springs are not at their usual posi-

tion, vehicle ride comfort could be affected.

Fig. 1 Typical Housing Cover With Sealant

JFRONT SUSPENSION AND AXLE 2 - 23

Page 59 of 2198

(6) Install the shock absorber and tighten the bolt

to 23 Nzm (17 ft. lbs.) torque.

(7) Install the stabilizer bar link to the axle

bracket. Tighten the nut to 95 Nzm (70 ft. lbs.)

torque.

(8) Install the drag link and tie rod to the steering

knuckles and tighten the nuts to 47 Nzm (35 ft. lbs.)

torque. Install the steering damper to the axle

bracket and tighten the nut to 75 Nzm (55 ft. lbs.)

torque.

(9) Install the brake components and ABS brake

sensor (if equipped). Refer to Group 5ÐBrakes.

(10) On 4WD vehicles, connect the vent hose to the

tube fitting.

(11) On 4WD vehicles, align the reference marks

and connect the drive shaft to the axle yoke. Tighten

the U-joint clamp bolts to 19 Nzm (14 ft. lbs.) torque.

(12) Check differential lubricant and add if neces-

sary.

(13) Install the wheel and tire assemblies.

(14) Remove the supports and lower the vehicle.

(15) Tighten the upper suspension arm nuts to 75

Nzm (55 ft. lbs.) torque. Tighten the lower suspension

arm nuts to 115 Nzm (85 ft. lbs.) torque.

(16) Tighten the track bar bolt at the axle bracket

to 100 Nzm (74 ft. lbs.) torque.

(17) Check the front wheel alignment.

DRIVE AXLE ASSEMBLY REPLACEMENTÐYJ

VEHICLES

REMOVAL

(1) Raise the vehicle and position support stands

under the frame rails behind the spring frame brack-

ets.

(2) Remove the front wheels.

(3) Remove the brake components and ABS brake

sensor (if equipped). Refer to Group 5ÐBrakes.

(4) Disconnect the axle vent hose and axle shift

motor vacuum harness.

(5) Mark the drive shaft yoke and axle pinion yoke

for alignment reference. Disconnect the drive shaft

from the axle.

(6) Disconnect the stabilizer bar link at the axle

bracket.

(7) Disconnect the shock absorbers from axle

bracket.

(8) Disconnect the track bar from the axle bracket.

(9) Disconnect the tie rod from the steering

knuckle. Disconnect the steering damper from the

axle bracket.

(10) Support the axle with a hydraulic jack under

the differential. Raise the axle just enough to relieve

the axle weight from the springs.

(11) Remove the spring U-bolts from the plate

brackets.(12) Loosen BUT DO NOT REMOVE the bolts that

attach the spring rear pivot at the frame rail brack-

ets. This will allow the springs to pivot without bind-

ing on the bushings.

(13) Disconnect shackle from the springs and lower

the springs to the surface.

(14) Lower the jack enough to remove the axle.

INSTALLATION

CAUTION: Suspension components with rubber

bushings should be tightened with the vehicle at

normal height. It is important to have the springs

supporting the weight of the vehicle when the fas-

teners are torqued. If springs are not at their normal

ride position, vehicle ride comfort could be affected

and premature bushing wear may occur. Rubber

bushings must never be lubricated.

(1) Support the axle on a hydraulic jack under the

differential. Position the axle under the vehicle.

(2) Raise the springs and install the spring shackle

bolts.Do not tighten at this time.

(3) Lower the axle and align the spring center

bolts with the locating holes in the axle pads and

plate brackets.

(4) Install the spring U-bolts through the plate

brackets and tighten to 122 Nzm (90 ft. lbs.) torque.

(5) Connect the track bar to the axle bracket and

install the bolt.Do not tighten at this time.

It is important that the springs support the

weight of the vehicle when the track bar is con-

nected. If springs are not at their usual posi-

tion, the vehicle ride comfort could be affected.

(6) Install the shock absorber and tighten the nut

to 61 Nzm (45 ft. lbs.) torque.

(7) Install the stabilizer bar link to the axle

bracket. Tighten the nut to 61 Nzm (45 ft. lbs.)

torque.

(8) Install the tie rod to the steering knuckles and

tighten the nuts to 47 Nzm (35 ft. lbs.) torque. Install

the steering damper to the axle bracket and tighten

the bolt to 75 Nzm (55 ft. lbs.) torque.

(9) Install the brake components and ABS brake

sensor (if equipped). Refer to Group 5ÐBrakes.

(10) Connect the vent hose to the tube fitting and

axle shift motor vacuum harness.

(11) Align the reference marks and connect the

drive shaft to the axle yoke. Tighten the U-joint

clamp bolts to 19 Nzm (14 ft. lbs.) torque.

(12) Check differential lubricant and add if neces-

sary.

(13) Install the wheel and tire assemblies.

(15) Remove the supports and lower the vehicle.

(16) Tighten the spring rear pivot bolt/nut to 142

Nzm (105 ft. lbs.) torque. Tighten the spring shackle

bolt/nut to 135 Nzm (100 ft. lbs.) torque.

2 - 24 FRONT SUSPENSION AND AXLEJ

Page 60 of 2198

(17) Tighten the track bar nut at the axle bracket

to 100 Nzm (74 ft. lbs.) torque.

(18) Check the front wheel alignment.

PINION SEAL REPLACEMENT

REMOVAL

(1) Raise and support the vehicle.

(2) Remove wheel and tire assemblies.

(3) Mark the propeller shaft yoke and pinion yoke

for installation alignment reference.

(4) Remove the propeller shaft from the yoke.

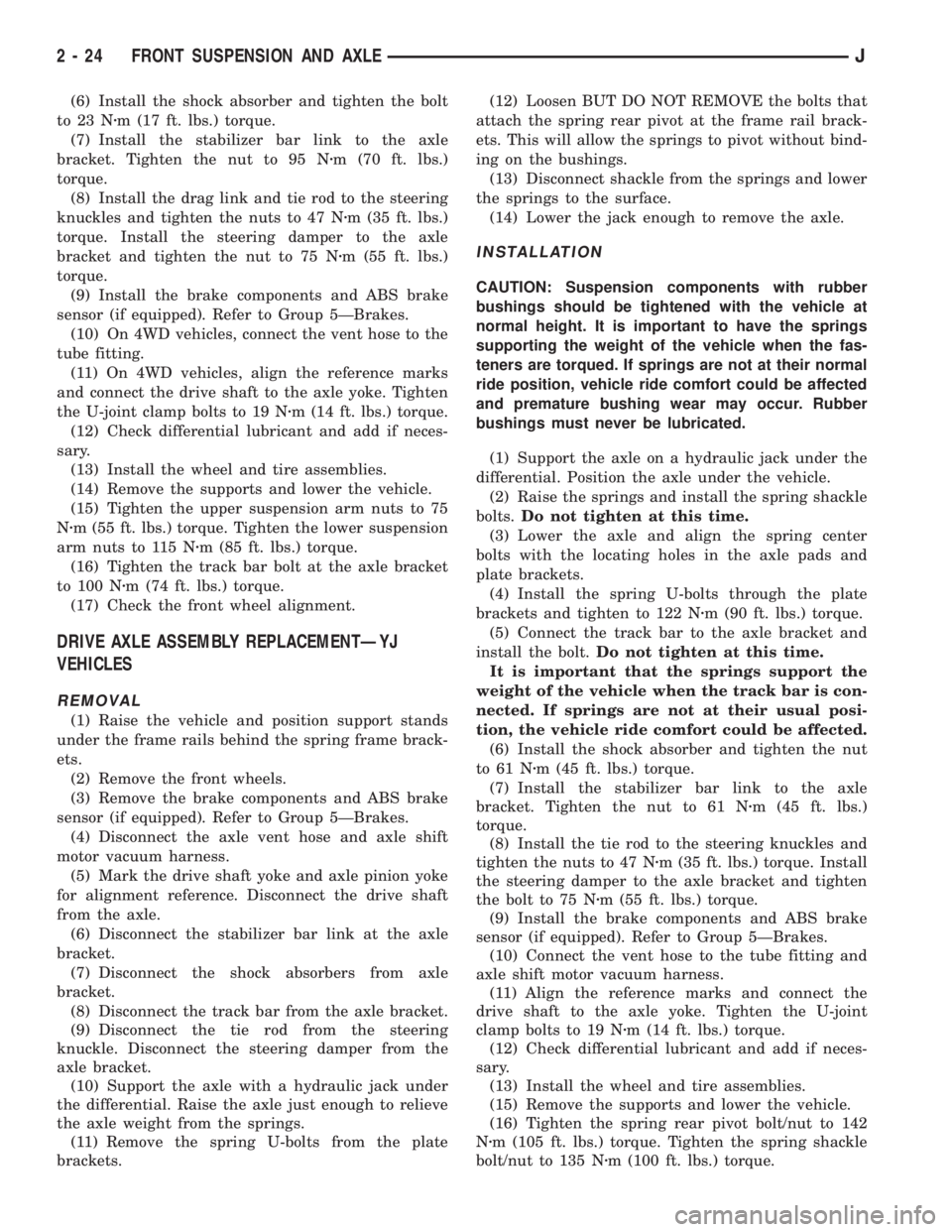

(5) Remove the pinion yoke nut and washer. Use

Remover C-452 and Wrench C-3281 to remove the

pinion yoke (Fig. 2).

(6) Mark the positions of the yoke and pinion gear

for installation alignment reference.

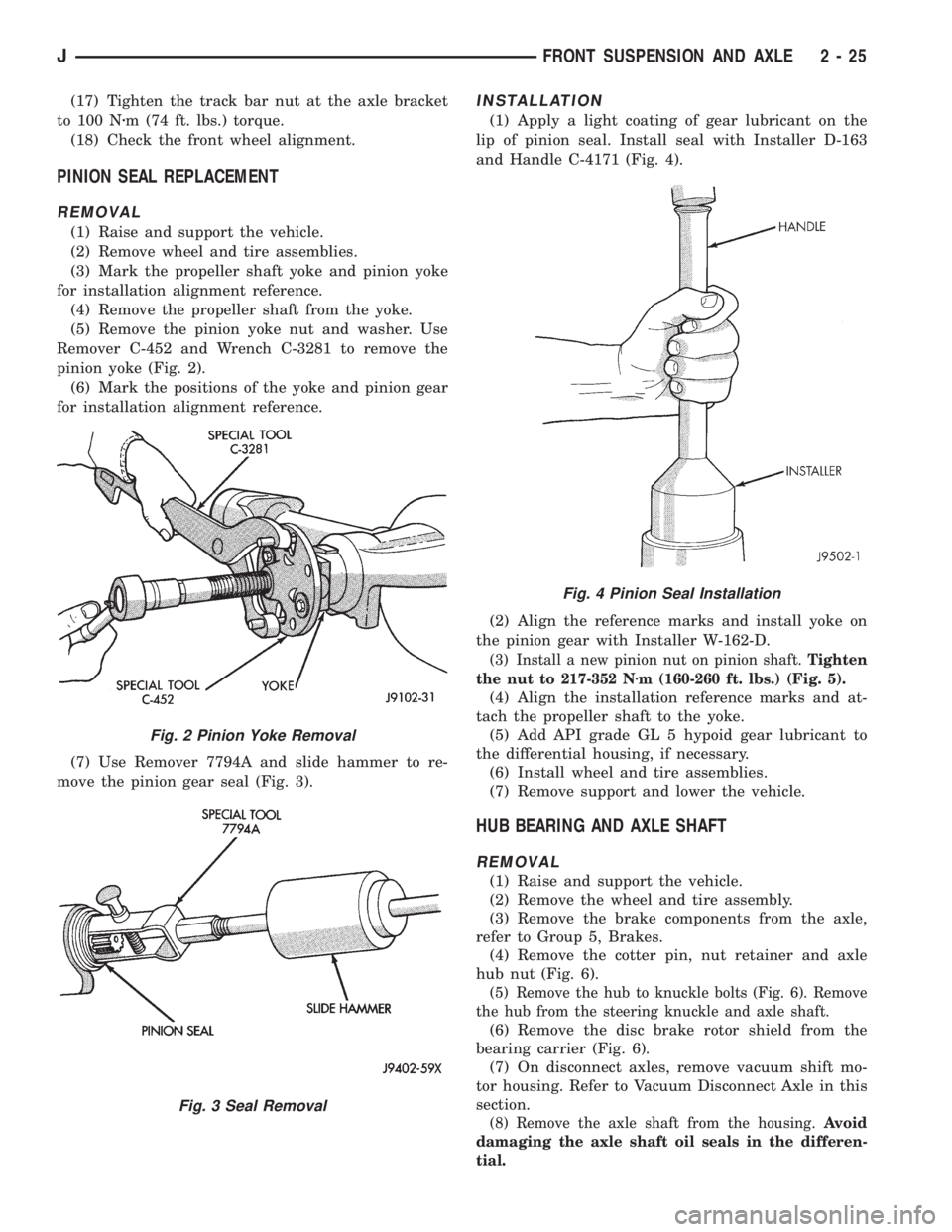

(7) Use Remover 7794A and slide hammer to re-

move the pinion gear seal (Fig. 3).

INSTALLATION

(1) Apply a light coating of gear lubricant on the

lip of pinion seal. Install seal with Installer D-163

and Handle C-4171 (Fig. 4).

(2) Align the reference marks and install yoke on

the pinion gear with Installer W-162-D.

(3) Install a new pinion nut on pinion shaft.Tighten

the nut to 217-352 Nzm (160-260 ft. lbs.) (Fig. 5).

(4) Align the installation reference marks and at-

tach the propeller shaft to the yoke.

(5) Add API grade GL 5 hypoid gear lubricant to

the differential housing, if necessary.

(6) Install wheel and tire assemblies.

(7) Remove support and lower the vehicle.

HUB BEARING AND AXLE SHAFT

REMOVAL

(1) Raise and support the vehicle.

(2) Remove the wheel and tire assembly.

(3) Remove the brake components from the axle,

refer to Group 5, Brakes.

(4) Remove the cotter pin, nut retainer and axle

hub nut (Fig. 6).

(5) Remove the hub to knuckle bolts (Fig. 6). Remove

the hub from the steering knuckle and axle shaft.

(6) Remove the disc brake rotor shield from the

bearing carrier (Fig. 6).

(7) On disconnect axles, remove vacuum shift mo-

tor housing. Refer to Vacuum Disconnect Axle in this

section.

(8) Remove the axle shaft from the housing.Avoid

damaging the axle shaft oil seals in the differen-

tial.

Fig. 2 Pinion Yoke Removal

Fig. 3 Seal Removal

Fig. 4 Pinion Seal Installation

JFRONT SUSPENSION AND AXLE 2 - 25