distributor JEEP CHEROKEE 1995 Service Workshop Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 1995, Model line: CHEROKEE, Model: JEEP CHEROKEE 1995Pages: 2198, PDF Size: 82.83 MB

Page 1166 of 2198

INSPECTION

Inspect the cam lobes for wear.

Inspect the bearing journals for uneven wear pat-

tern or finish.

Inspect the bearings for wear.

Inspect the distributor drive gear for wear.

If the camshaft appears to have been rubbing

against the timing case cover, examine the oil pres-

sure relief holes in the rear cam journal. The oil

pressure relief holes must be free of debris.

INSTALLATION

(1) Lubricate the camshaft with Mopar Engine Oil

Supplement, or equivalent.

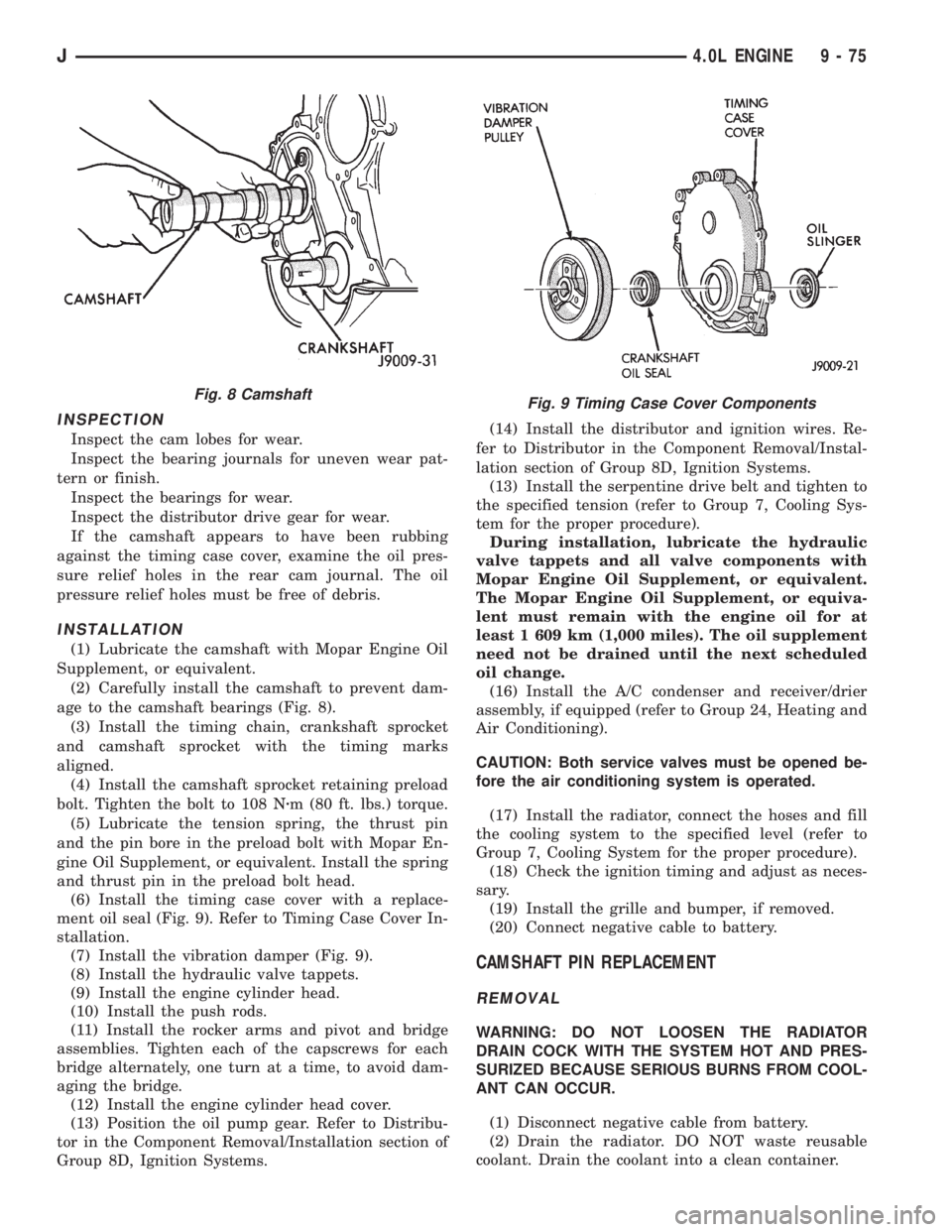

(2) Carefully install the camshaft to prevent dam-

age to the camshaft bearings (Fig. 8).

(3) Install the timing chain, crankshaft sprocket

and camshaft sprocket with the timing marks

aligned.

(4) Install the camshaft sprocket retaining preload

bolt. Tighten the bolt to 108 Nzm (80 ft. lbs.) torque.

(5) Lubricate the tension spring, the thrust pin

and the pin bore in the preload bolt with Mopar En-

gine Oil Supplement, or equivalent. Install the spring

and thrust pin in the preload bolt head.

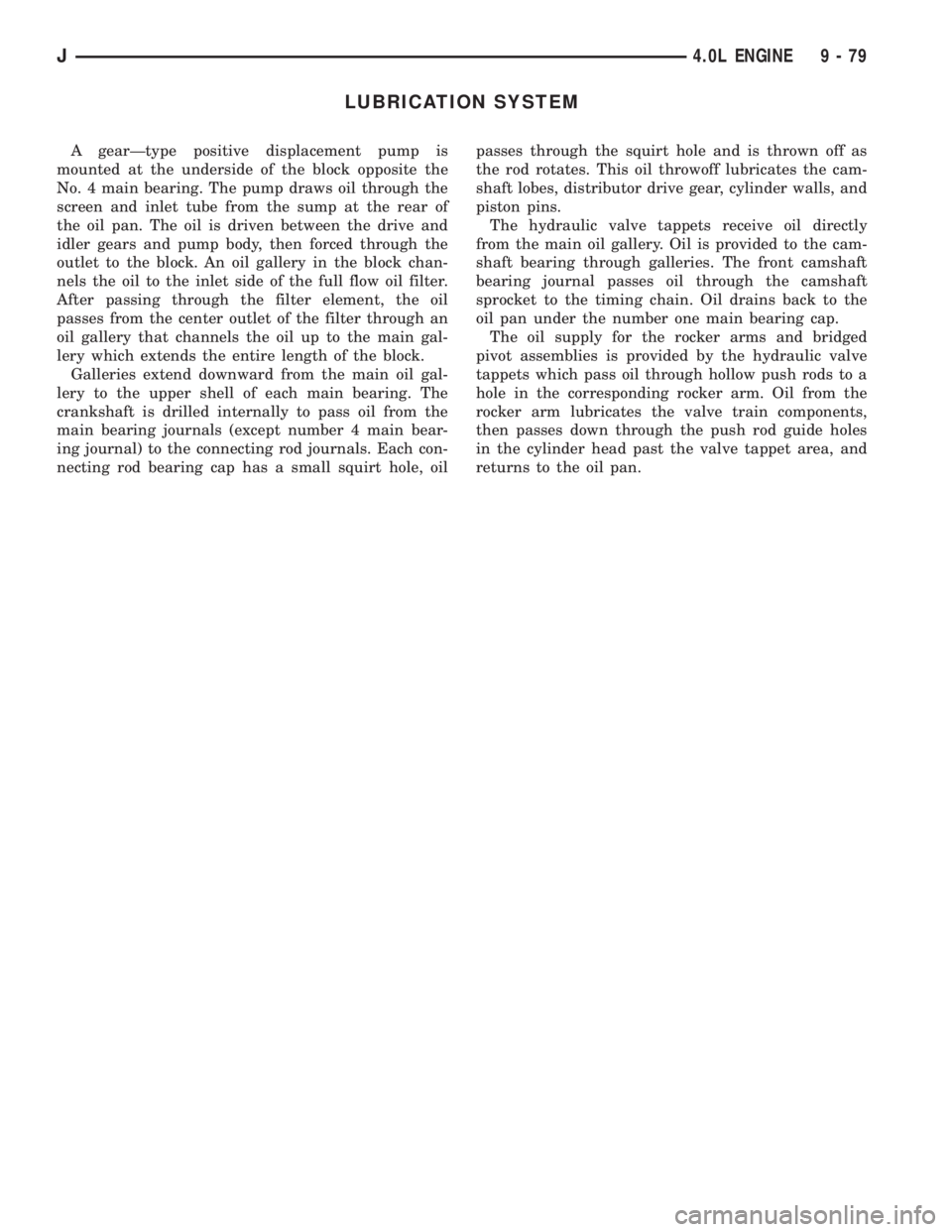

(6) Install the timing case cover with a replace-

ment oil seal (Fig. 9). Refer to Timing Case Cover In-

stallation.

(7) Install the vibration damper (Fig. 9).

(8) Install the hydraulic valve tappets.

(9) Install the engine cylinder head.

(10) Install the push rods.

(11) Install the rocker arms and pivot and bridge

assemblies. Tighten each of the capscrews for each

bridge alternately, one turn at a time, to avoid dam-

aging the bridge.

(12) Install the engine cylinder head cover.

(13) Position the oil pump gear. Refer to Distribu-

tor in the Component Removal/Installation section of

Group 8D, Ignition Systems.(14) Install the distributor and ignition wires. Re-

fer to Distributor in the Component Removal/Instal-

lation section of Group 8D, Ignition Systems.

(13) Install the serpentine drive belt and tighten to

the specified tension (refer to Group 7, Cooling Sys-

tem for the proper procedure).

During installation, lubricate the hydraulic

valve tappets and all valve components with

Mopar Engine Oil Supplement, or equivalent.

The Mopar Engine Oil Supplement, or equiva-

lent must remain with the engine oil for at

least 1 609 km (1,000 miles). The oil supplement

need not be drained until the next scheduled

oil change.

(16) Install the A/C condenser and receiver/drier

assembly, if equipped (refer to Group 24, Heating and

Air Conditioning).

CAUTION: Both service valves must be opened be-

fore the air conditioning system is operated.

(17) Install the radiator, connect the hoses and fill

the cooling system to the specified level (refer to

Group 7, Cooling System for the proper procedure).

(18) Check the ignition timing and adjust as neces-

sary.

(19) Install the grille and bumper, if removed.

(20) Connect negative cable to battery.

CAMSHAFT PIN REPLACEMENT

REMOVAL

WARNING: DO NOT LOOSEN THE RADIATOR

DRAIN COCK WITH THE SYSTEM HOT AND PRES-

SURIZED BECAUSE SERIOUS BURNS FROM COOL-

ANT CAN OCCUR.

(1) Disconnect negative cable from battery.

(2) Drain the radiator. DO NOT waste reusable

coolant. Drain the coolant into a clean container.

Fig. 9 Timing Case Cover ComponentsFig. 8 Camshaft

J4.0L ENGINE 9 - 75

Page 1170 of 2198

LUBRICATION SYSTEM

A gearÐtype positive displacement pump is

mounted at the underside of the block opposite the

No. 4 main bearing. The pump draws oil through the

screen and inlet tube from the sump at the rear of

the oil pan. The oil is driven between the drive and

idler gears and pump body, then forced through the

outlet to the block. An oil gallery in the block chan-

nels the oil to the inlet side of the full flow oil filter.

After passing through the filter element, the oil

passes from the center outlet of the filter through an

oil gallery that channels the oil up to the main gal-

lery which extends the entire length of the block.

Galleries extend downward from the main oil gal-

lery to the upper shell of each main bearing. The

crankshaft is drilled internally to pass oil from the

main bearing journals (except number 4 main bear-

ing journal) to the connecting rod journals. Each con-

necting rod bearing cap has a small squirt hole, oilpasses through the squirt hole and is thrown off as

the rod rotates. This oil throwoff lubricates the cam-

shaft lobes, distributor drive gear, cylinder walls, and

piston pins.

The hydraulic valve tappets receive oil directly

from the main oil gallery. Oil is provided to the cam-

shaft bearing through galleries. The front camshaft

bearing journal passes oil through the camshaft

sprocket to the timing chain. Oil drains back to the

oil pan under the number one main bearing cap.

The oil supply for the rocker arms and bridged

pivot assemblies is provided by the hydraulic valve

tappets which pass oil through hollow push rods to a

hole in the corresponding rocker arm. Oil from the

rocker arm lubricates the valve train components,

then passes down through the push rod guide holes

in the cylinder head past the valve tappet area, and

returns to the oil pan.

J4.0L ENGINE 9 - 79

Page 1172 of 2198

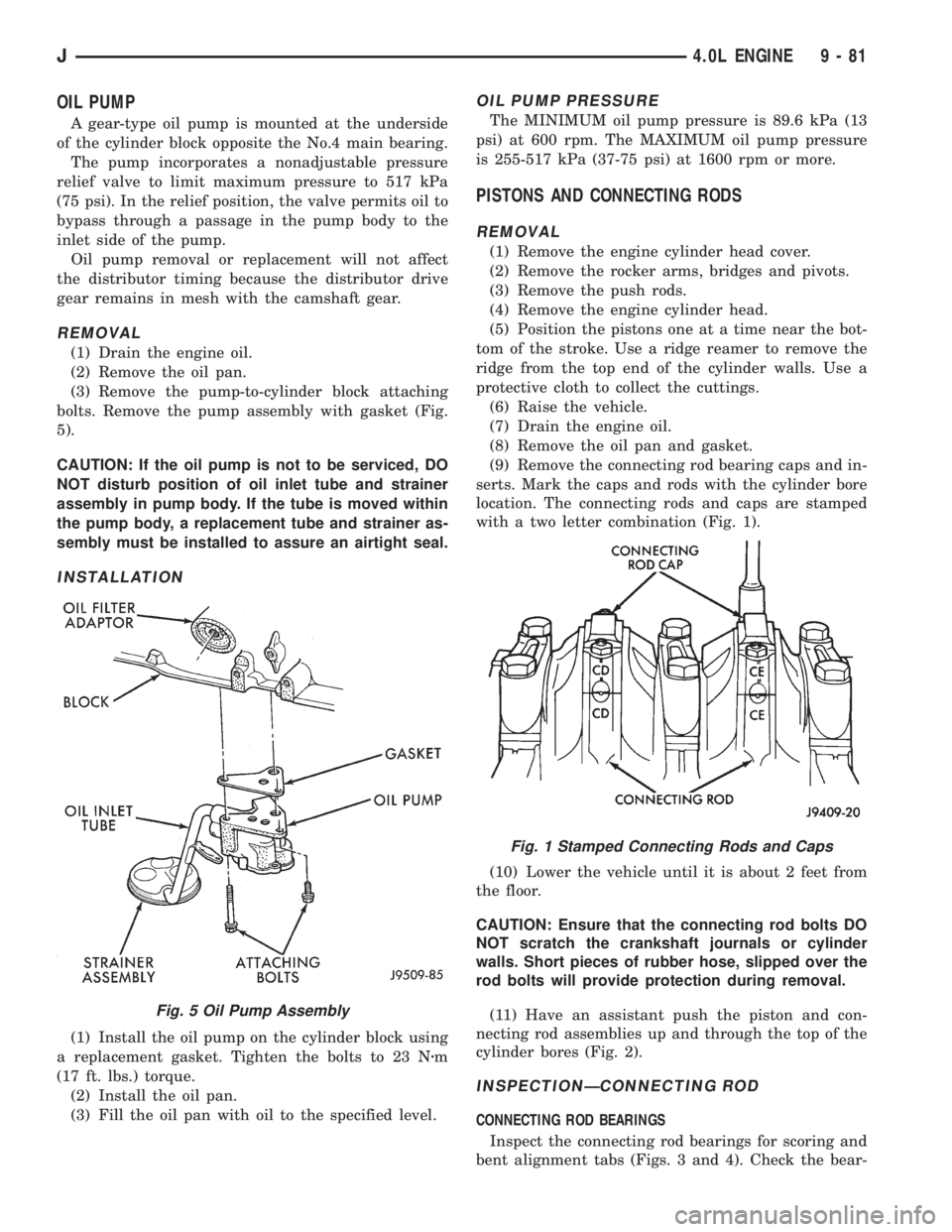

OIL PUMP

A gear-type oil pump is mounted at the underside

of the cylinder block opposite the No.4 main bearing.

The pump incorporates a nonadjustable pressure

relief valve to limit maximum pressure to 517 kPa

(75 psi). In the relief position, the valve permits oil to

bypass through a passage in the pump body to the

inlet side of the pump.

Oil pump removal or replacement will not affect

the distributor timing because the distributor drive

gear remains in mesh with the camshaft gear.

REMOVAL

(1) Drain the engine oil.

(2) Remove the oil pan.

(3) Remove the pump-to-cylinder block attaching

bolts. Remove the pump assembly with gasket (Fig.

5).

CAUTION: If the oil pump is not to be serviced, DO

NOT disturb position of oil inlet tube and strainer

assembly in pump body. If the tube is moved within

the pump body, a replacement tube and strainer as-

sembly must be installed to assure an airtight seal.

INSTALLATION

(1) Install the oil pump on the cylinder block using

a replacement gasket. Tighten the bolts to 23 Nzm

(17 ft. lbs.) torque.

(2) Install the oil pan.

(3) Fill the oil pan with oil to the specified level.

OIL PUMP PRESSURE

The MINIMUM oil pump pressure is 89.6 kPa (13

psi) at 600 rpm. The MAXIMUM oil pump pressure

is 255-517 kPa (37-75 psi) at 1600 rpm or more.

PISTONS AND CONNECTING RODS

REMOVAL

(1) Remove the engine cylinder head cover.

(2) Remove the rocker arms, bridges and pivots.

(3) Remove the push rods.

(4) Remove the engine cylinder head.

(5) Position the pistons one at a time near the bot-

tom of the stroke. Use a ridge reamer to remove the

ridge from the top end of the cylinder walls. Use a

protective cloth to collect the cuttings.

(6) Raise the vehicle.

(7) Drain the engine oil.

(8) Remove the oil pan and gasket.

(9) Remove the connecting rod bearing caps and in-

serts. Mark the caps and rods with the cylinder bore

location. The connecting rods and caps are stamped

with a two letter combination (Fig. 1).

(10) Lower the vehicle until it is about 2 feet from

the floor.

CAUTION: Ensure that the connecting rod bolts DO

NOT scratch the crankshaft journals or cylinder

walls. Short pieces of rubber hose, slipped over the

rod bolts will provide protection during removal.

(11) Have an assistant push the piston and con-

necting rod assemblies up and through the top of the

cylinder bores (Fig. 2).

INSPECTIONÐCONNECTING ROD

CONNECTING ROD BEARINGS

Inspect the connecting rod bearings for scoring and

bent alignment tabs (Figs. 3 and 4). Check the bear-

Fig. 5 Oil Pump Assembly

Fig. 1 Stamped Connecting Rods and Caps

J4.0L ENGINE 9 - 81

Page 1237 of 2198

energized). This is done to compensate for the re-

duced flow through injector caused by the lowered

voltage.

BRAKE SWITCHÐPCM INPUT

When the brake light switch is activated, the pow-

ertrain control module (PCM) receives an input indi-

cating that the brakes are being applied. After

receiving this input, the PCM maintains idle speed to

a scheduled rpm through control of the idle air con-

trol (IAC) motor. The brake switch input is also used

to operate the speed control system.

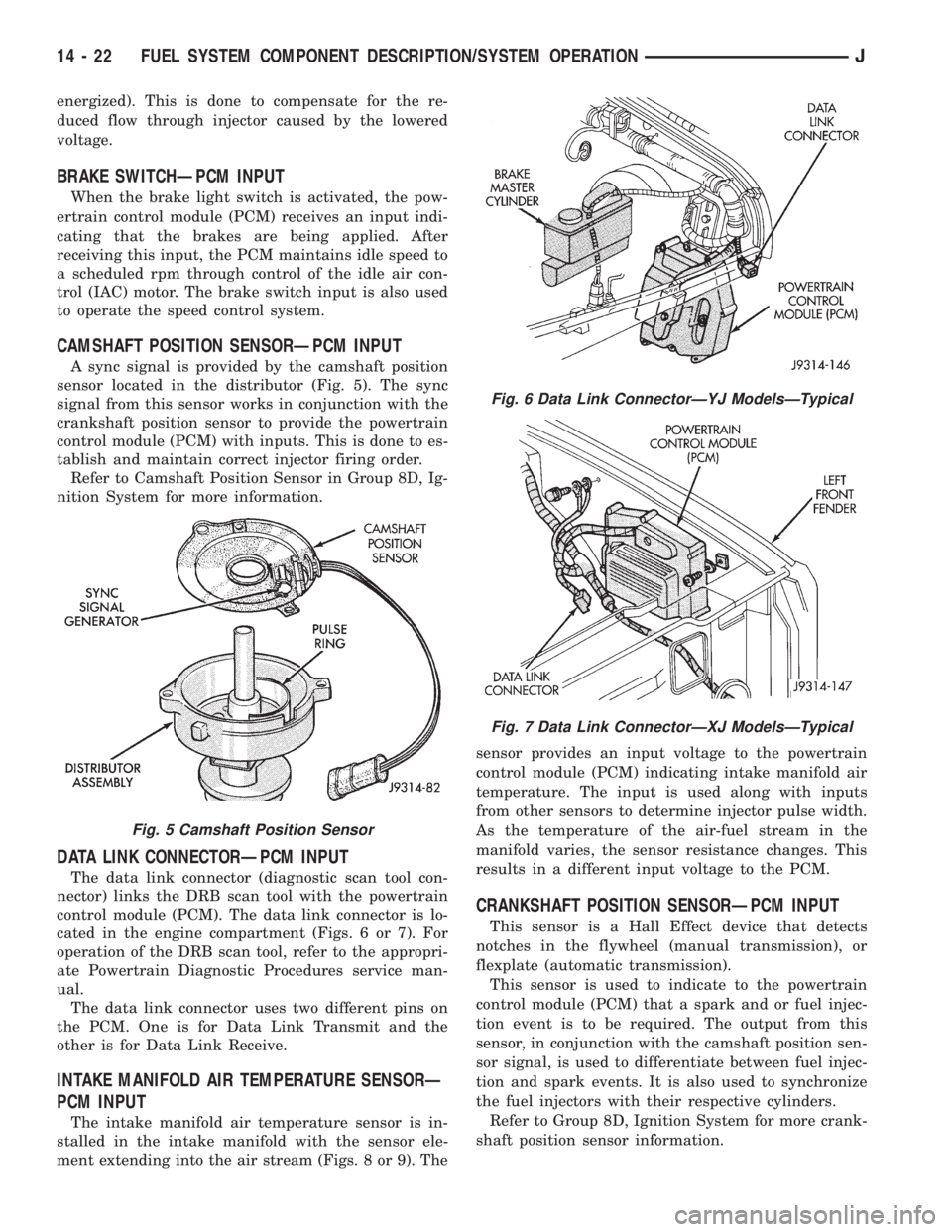

CAMSHAFT POSITION SENSORÐPCM INPUT

A sync signal is provided by the camshaft position

sensor located in the distributor (Fig. 5). The sync

signal from this sensor works in conjunction with the

crankshaft position sensor to provide the powertrain

control module (PCM) with inputs. This is done to es-

tablish and maintain correct injector firing order.

Refer to Camshaft Position Sensor in Group 8D, Ig-

nition System for more information.

DATA LINK CONNECTORÐPCM INPUT

The data link connector (diagnostic scan tool con-

nector) links the DRB scan tool with the powertrain

control module (PCM). The data link connector is lo-

cated in the engine compartment (Figs. 6 or 7). For

operation of the DRB scan tool, refer to the appropri-

ate Powertrain Diagnostic Procedures service man-

ual.

The data link connector uses two different pins on

the PCM. One is for Data Link Transmit and the

other is for Data Link Receive.

INTAKE MANIFOLD AIR TEMPERATURE SENSORÐ

PCM INPUT

The intake manifold air temperature sensor is in-

stalled in the intake manifold with the sensor ele-

ment extending into the air stream (Figs. 8 or 9). Thesensor provides an input voltage to the powertrain

control module (PCM) indicating intake manifold air

temperature. The input is used along with inputs

from other sensors to determine injector pulse width.

As the temperature of the air-fuel stream in the

manifold varies, the sensor resistance changes. This

results in a different input voltage to the PCM.

CRANKSHAFT POSITION SENSORÐPCM INPUT

This sensor is a Hall Effect device that detects

notches in the flywheel (manual transmission), or

flexplate (automatic transmission).

This sensor is used to indicate to the powertrain

control module (PCM) that a spark and or fuel injec-

tion event is to be required. The output from this

sensor, in conjunction with the camshaft position sen-

sor signal, is used to differentiate between fuel injec-

tion and spark events. It is also used to synchronize

the fuel injectors with their respective cylinders.

Refer to Group 8D, Ignition System for more crank-

shaft position sensor information.

Fig. 5 Camshaft Position Sensor

Fig. 6 Data Link ConnectorÐYJ ModelsÐTypical

Fig. 7 Data Link ConnectorÐXJ ModelsÐTypical

14 - 22 FUEL SYSTEM COMPONENT DESCRIPTION/SYSTEM OPERATIONJ

Page 1243 of 2198

The throttle body has an air control passage that

provides air for the engine at idle (the throttle plate

is closed). The IAC motor pintle protrudes into the

air control passage and regulates air flow through it.

Based on various sensor inputs, the powertrain con-

trol module (PCM) adjusts engine idle speed by mov-

ing the IAC motor pintle in and out of the air control

passage. The IAC motor is positioned when the igni-

tion key is turned to the On position.

A (factory adjusted) set screw is used to mechani-

cally limit the position of the throttle body throttle

plate.Never attempt to adjust the engine idle

speed using this screw.All idle speed functions are

controlled by the PCM.

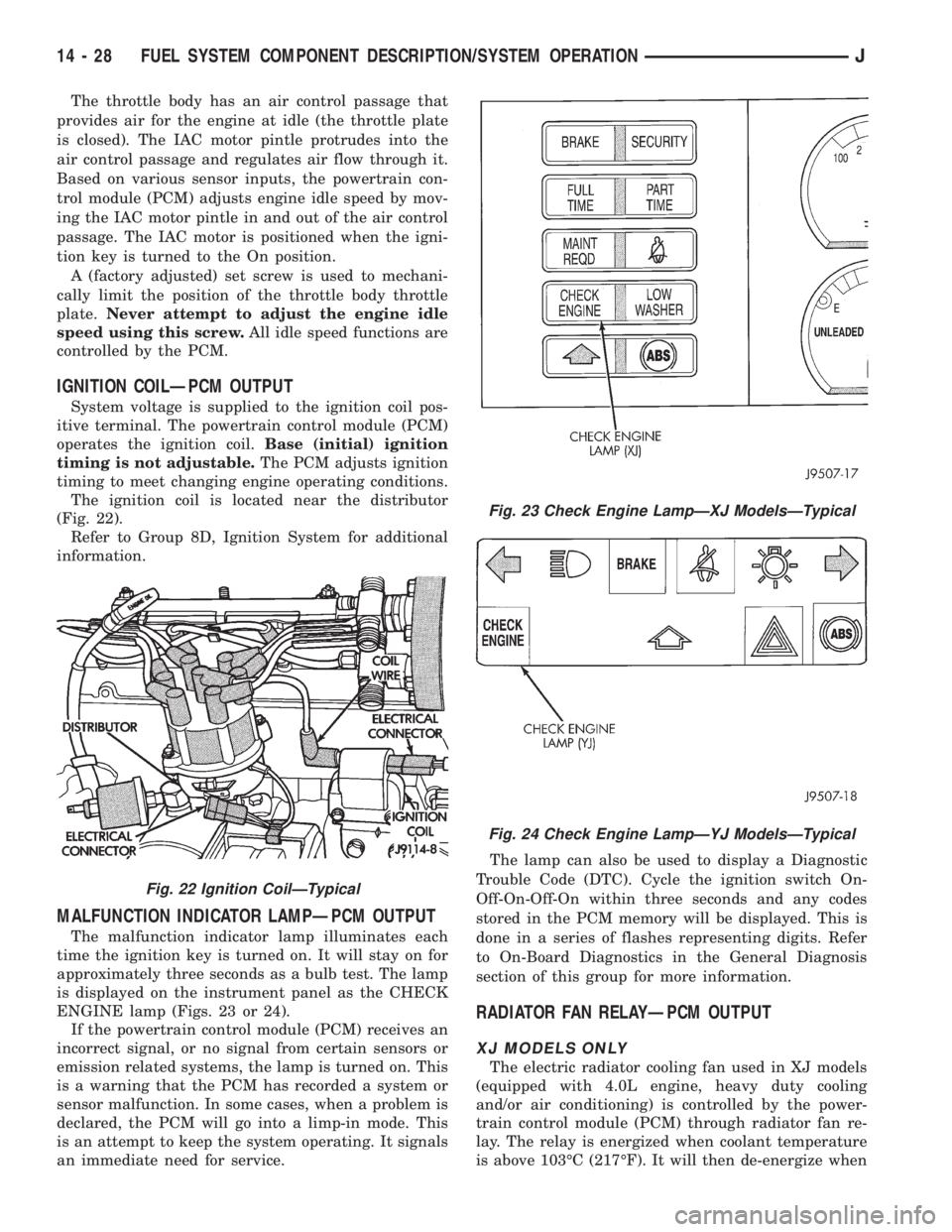

IGNITION COILÐPCM OUTPUT

System voltage is supplied to the ignition coil pos-

itive terminal. The powertrain control module (PCM)

operates the ignition coil.Base (initial) ignition

timing is not adjustable.The PCM adjusts ignition

timing to meet changing engine operating conditions.

The ignition coil is located near the distributor

(Fig. 22).

Refer to Group 8D, Ignition System for additional

information.

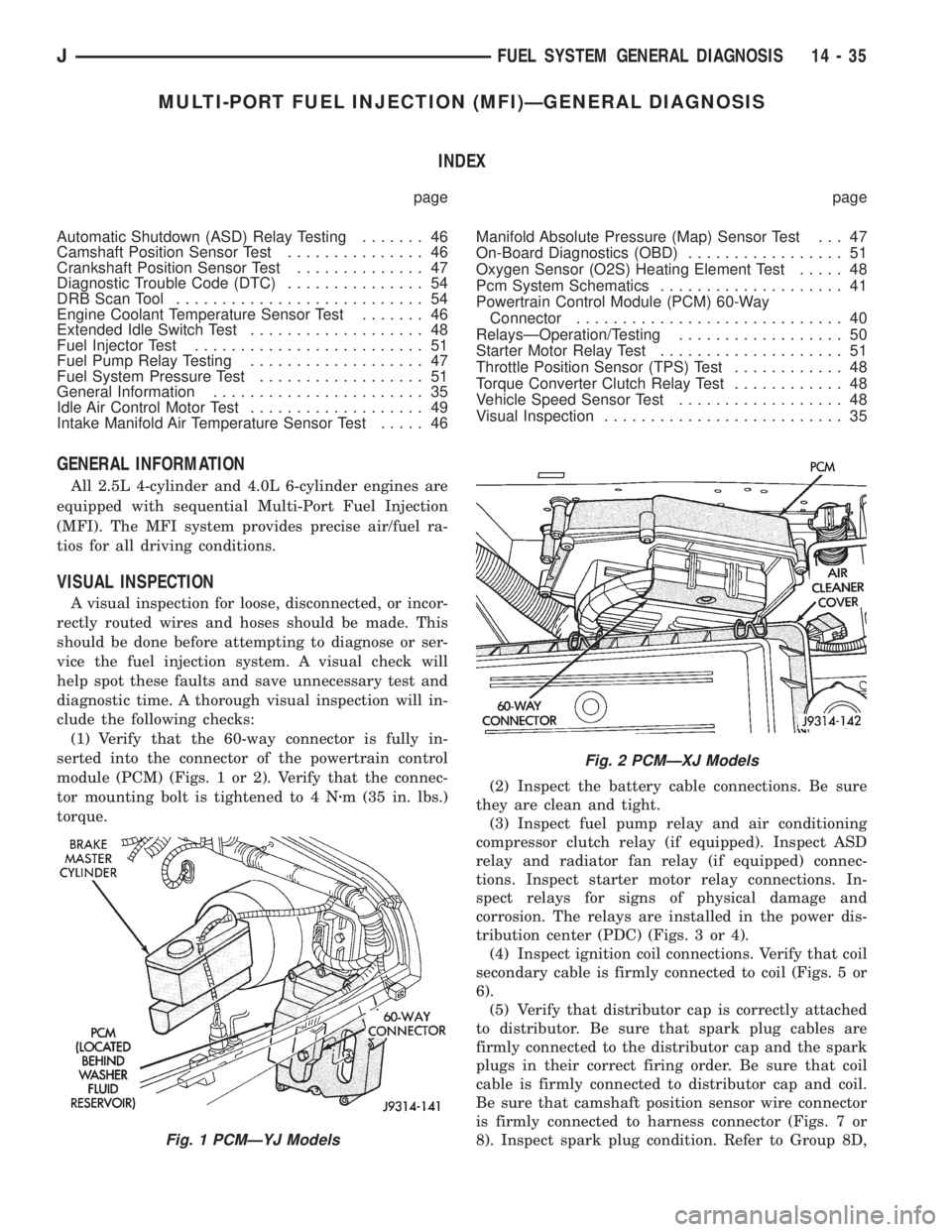

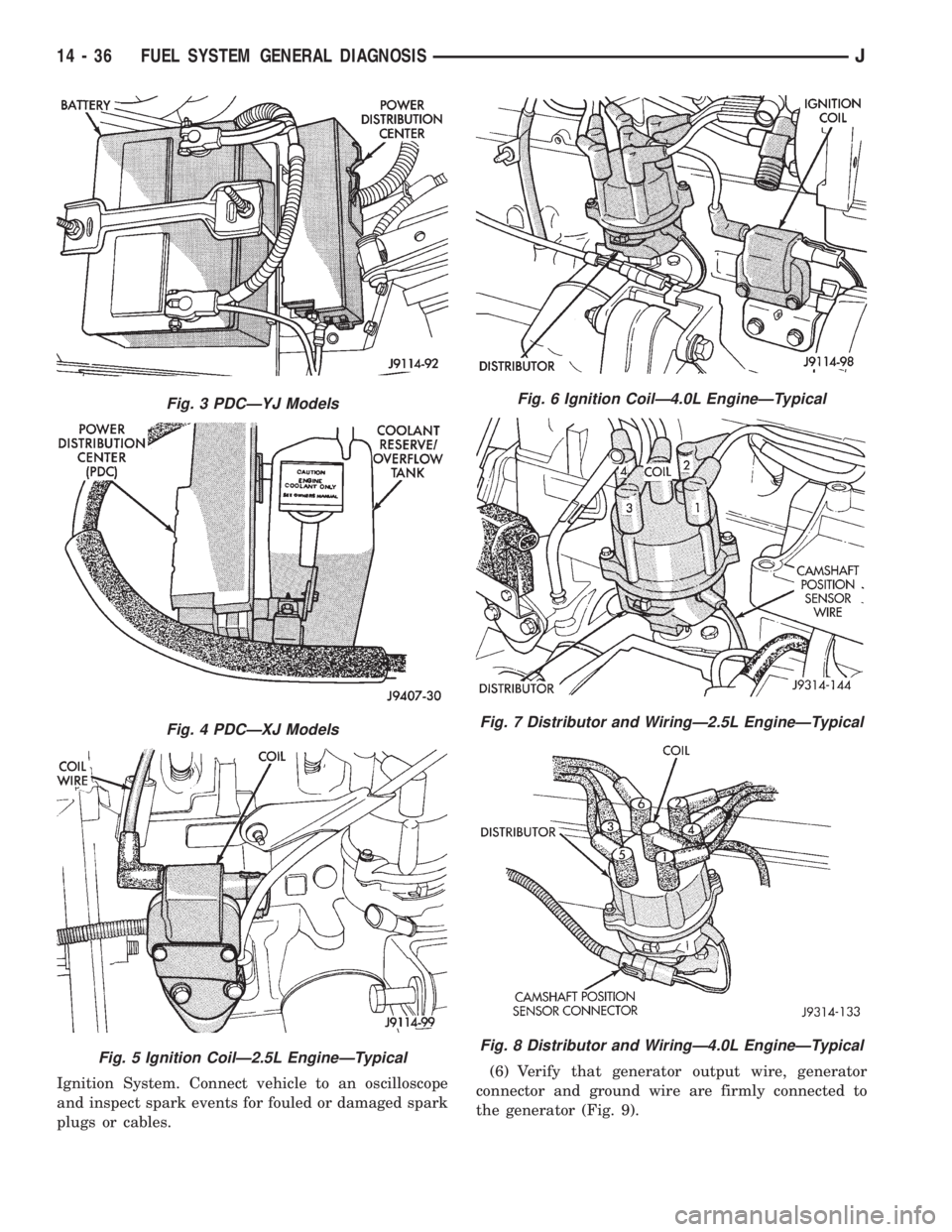

MALFUNCTION INDICATOR LAMPÐPCM OUTPUT

The malfunction indicator lamp illuminates each

time the ignition key is turned on. It will stay on for

approximately three seconds as a bulb test. The lamp

is displayed on the instrument panel as the CHECK

ENGINE lamp (Figs. 23 or 24).

If the powertrain control module (PCM) receives an

incorrect signal, or no signal from certain sensors or

emission related systems, the lamp is turned on. This

is a warning that the PCM has recorded a system or

sensor malfunction. In some cases, when a problem is

declared, the PCM will go into a limp-in mode. This

is an attempt to keep the system operating. It signals

an immediate need for service.The lamp can also be used to display a Diagnostic

Trouble Code (DTC). Cycle the ignition switch On-

Off-On-Off-On within three seconds and any codes

stored in the PCM memory will be displayed. This is

done in a series of flashes representing digits. Refer

to On-Board Diagnostics in the General Diagnosis

section of this group for more information.

RADIATOR FAN RELAYÐPCM OUTPUT

XJ MODELS ONLY

The electric radiator cooling fan used in XJ models

(equipped with 4.0L engine, heavy duty cooling

and/or air conditioning) is controlled by the power-

train control module (PCM) through radiator fan re-

lay. The relay is energized when coolant temperature

is above 103ÉC (217ÉF). It will then de-energize when

Fig. 22 Ignition CoilÐTypical

Fig. 23 Check Engine LampÐXJ ModelsÐTypical

Fig. 24 Check Engine LampÐYJ ModelsÐTypical

14 - 28 FUEL SYSTEM COMPONENT DESCRIPTION/SYSTEM OPERATIONJ

Page 1250 of 2198

MULTI-PORT FUEL INJECTION (MFI)ÐGENERAL DIAGNOSIS

INDEX

page page

Automatic Shutdown (ASD) Relay Testing....... 46

Camshaft Position Sensor Test............... 46

Crankshaft Position Sensor Test.............. 47

Diagnostic Trouble Code (DTC)............... 54

DRB Scan Tool........................... 54

Engine Coolant Temperature Sensor Test....... 46

Extended Idle Switch Test................... 48

Fuel Injector Test......................... 51

Fuel Pump Relay Testing................... 47

Fuel System Pressure Test.................. 51

General Information....................... 35

Idle Air Control Motor Test................... 49

Intake Manifold Air Temperature Sensor Test..... 46Manifold Absolute Pressure (Map) Sensor Test . . . 47

On-Board Diagnostics (OBD)................. 51

Oxygen Sensor (O2S) Heating Element Test..... 48

Pcm System Schematics.................... 41

Powertrain Control Module (PCM) 60-Way

Connector............................. 40

RelaysÐOperation/Testing.................. 50

Starter Motor Relay Test.................... 51

Throttle Position Sensor (TPS) Test............ 48

Torque Converter Clutch Relay Test............ 48

Vehicle Speed Sensor Test.................. 48

Visual Inspection.......................... 35

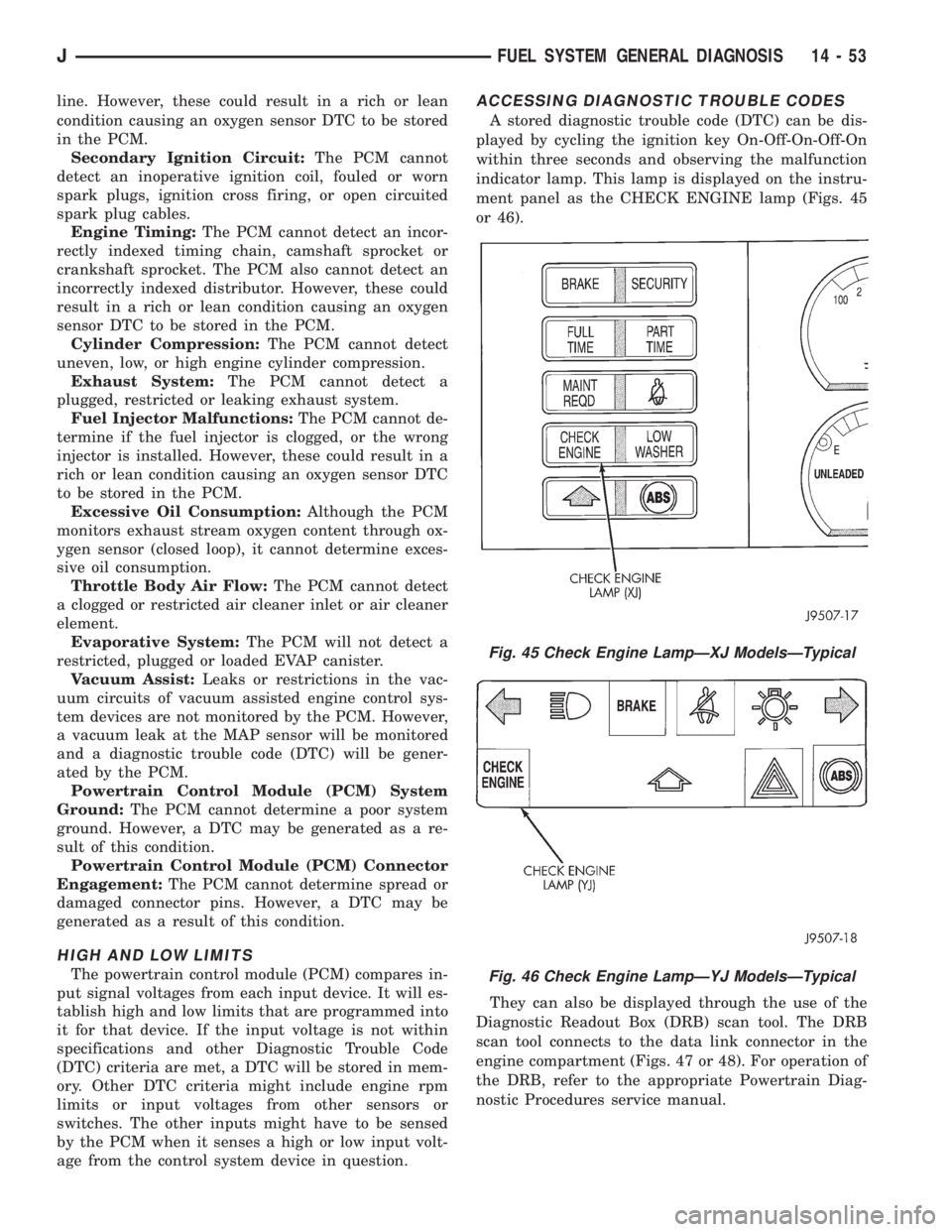

GENERAL INFORMATION

All 2.5L 4-cylinder and 4.0L 6-cylinder engines are

equipped with sequential Multi-Port Fuel Injection

(MFI). The MFI system provides precise air/fuel ra-

tios for all driving conditions.

VISUAL INSPECTION

A visual inspection for loose, disconnected, or incor-

rectly routed wires and hoses should be made. This

should be done before attempting to diagnose or ser-

vice the fuel injection system. A visual check will

help spot these faults and save unnecessary test and

diagnostic time. A thorough visual inspection will in-

clude the following checks:

(1) Verify that the 60-way connector is fully in-

serted into the connector of the powertrain control

module (PCM) (Figs. 1 or 2). Verify that the connec-

tor mounting bolt is tightened to 4 Nzm (35 in. lbs.)

torque.(2) Inspect the battery cable connections. Be sure

they are clean and tight.

(3) Inspect fuel pump relay and air conditioning

compressor clutch relay (if equipped). Inspect ASD

relay and radiator fan relay (if equipped) connec-

tions. Inspect starter motor relay connections. In-

spect relays for signs of physical damage and

corrosion. The relays are installed in the power dis-

tribution center (PDC) (Figs. 3 or 4).

(4) Inspect ignition coil connections. Verify that coil

secondary cable is firmly connected to coil (Figs. 5 or

6).

(5) Verify that distributor cap is correctly attached

to distributor. Be sure that spark plug cables are

firmly connected to the distributor cap and the spark

plugs in their correct firing order. Be sure that coil

cable is firmly connected to distributor cap and coil.

Be sure that camshaft position sensor wire connector

is firmly connected to harness connector (Figs. 7 or

8). Inspect spark plug condition. Refer to Group 8D,

Fig. 1 PCMÐYJ Models

Fig. 2 PCMÐXJ Models

JFUEL SYSTEM GENERAL DIAGNOSIS 14 - 35

Page 1251 of 2198

Ignition System. Connect vehicle to an oscilloscope

and inspect spark events for fouled or damaged spark

plugs or cables.(6) Verify that generator output wire, generator

connector and ground wire are firmly connected to

the generator (Fig. 9).

Fig. 3 PDCÐYJ Models

Fig. 4 PDCÐXJ Models

Fig. 5 Ignition CoilÐ2.5L EngineÐTypical

Fig. 6 Ignition CoilÐ4.0L EngineÐTypical

Fig. 7 Distributor and WiringÐ2.5L EngineÐTypical

Fig. 8 Distributor and WiringÐ4.0L EngineÐTypical

14 - 36 FUEL SYSTEM GENERAL DIAGNOSISJ

Page 1268 of 2198

line. However, these could result in a rich or lean

condition causing an oxygen sensor DTC to be stored

in the PCM.

Secondary Ignition Circuit:The PCM cannot

detect an inoperative ignition coil, fouled or worn

spark plugs, ignition cross firing, or open circuited

spark plug cables.

Engine Timing:The PCM cannot detect an incor-

rectly indexed timing chain, camshaft sprocket or

crankshaft sprocket. The PCM also cannot detect an

incorrectly indexed distributor. However, these could

result in a rich or lean condition causing an oxygen

sensor DTC to be stored in the PCM.

Cylinder Compression:The PCM cannot detect

uneven, low, or high engine cylinder compression.

Exhaust System:The PCM cannot detect a

plugged, restricted or leaking exhaust system.

Fuel Injector Malfunctions:The PCM cannot de-

termine if the fuel injector is clogged, or the wrong

injector is installed. However, these could result in a

rich or lean condition causing an oxygen sensor DTC

to be stored in the PCM.

Excessive Oil Consumption:Although the PCM

monitors exhaust stream oxygen content through ox-

ygen sensor (closed loop), it cannot determine exces-

sive oil consumption.

Throttle Body Air Flow:The PCM cannot detect

a clogged or restricted air cleaner inlet or air cleaner

element.

Evaporative System:The PCM will not detect a

restricted, plugged or loaded EVAP canister.

Vacuum Assist:Leaks or restrictions in the vac-

uum circuits of vacuum assisted engine control sys-

tem devices are not monitored by the PCM. However,

a vacuum leak at the MAP sensor will be monitored

and a diagnostic trouble code (DTC) will be gener-

ated by the PCM.

Powertrain Control Module (PCM) System

Ground:The PCM cannot determine a poor system

ground. However, a DTC may be generated as a re-

sult of this condition.

Powertrain Control Module (PCM) Connector

Engagement:The PCM cannot determine spread or

damaged connector pins. However, a DTC may be

generated as a result of this condition.

HIGH AND LOW LIMITS

The powertrain control module (PCM) compares in-

put signal voltages from each input device. It will es-

tablish high and low limits that are programmed into

it for that device. If the input voltage is not within

specifications and other Diagnostic Trouble Code

(DTC) criteria are met, a DTC will be stored in mem-

ory. Other DTC criteria might include engine rpm

limits or input voltages from other sensors or

switches. The other inputs might have to be sensed

by the PCM when it senses a high or low input volt-

age from the control system device in question.

ACCESSING DIAGNOSTIC TROUBLE CODES

A stored diagnostic trouble code (DTC) can be dis-

played by cycling the ignition key On-Off-On-Off-On

within three seconds and observing the malfunction

indicator lamp. This lamp is displayed on the instru-

ment panel as the CHECK ENGINE lamp (Figs. 45

or 46).

They can also be displayed through the use of the

Diagnostic Readout Box (DRB) scan tool. The DRB

scan tool connects to the data link connector in the

engine compartment (Figs. 47 or 48). For operation of

the DRB, refer to the appropriate Powertrain Diag-

nostic Procedures service manual.

Fig. 45 Check Engine LampÐXJ ModelsÐTypical

Fig. 46 Check Engine LampÐYJ ModelsÐTypical

JFUEL SYSTEM GENERAL DIAGNOSIS 14 - 53

Page 1965 of 2198

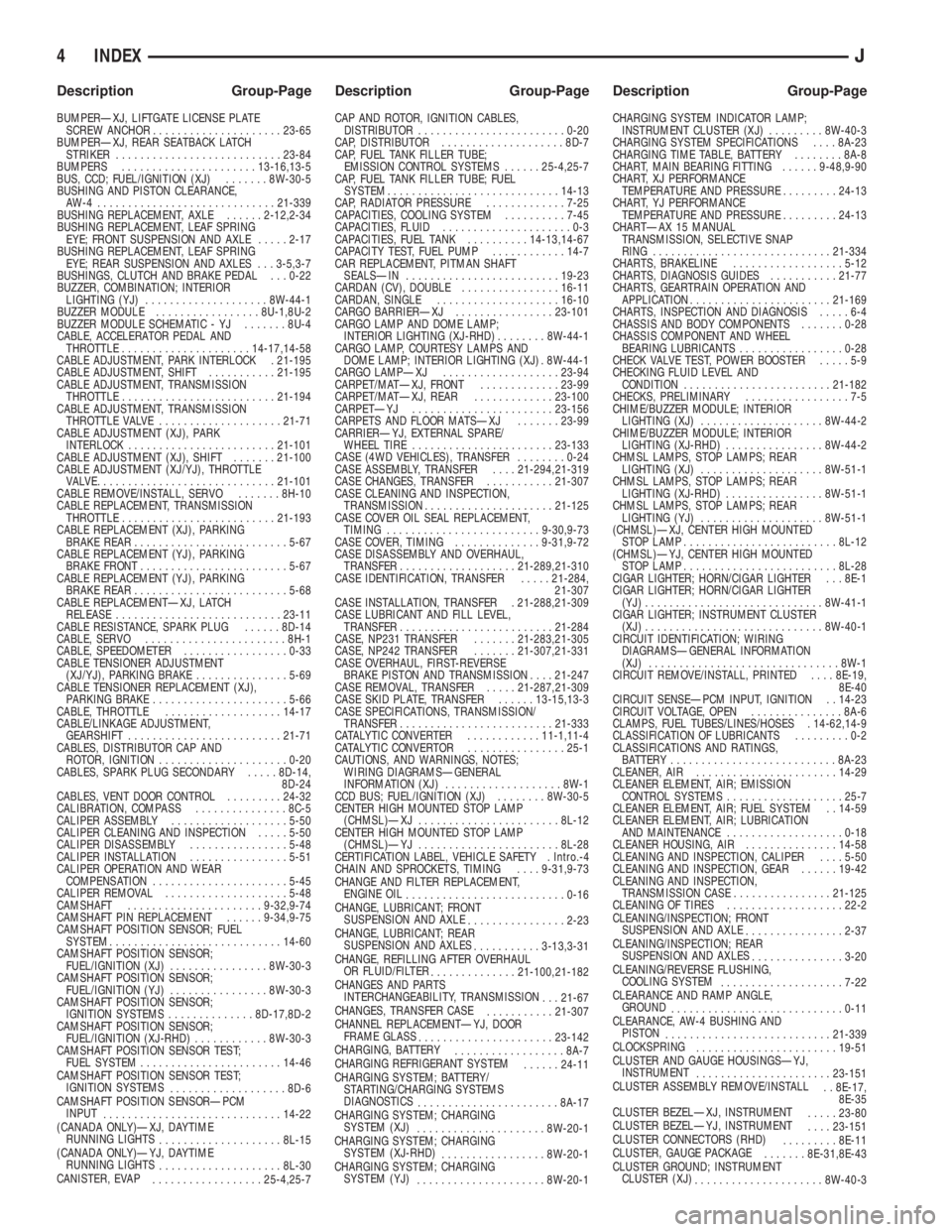

BUMPERÐXJ, LIFTGATE LICENSE PLATE

SCREW ANCHOR.....................23-65

BUMPERÐXJ, REAR SEATBACK LATCH

STRIKER...........................23-84

BUMPERS......................13-16,13-5

BUS, CCD; FUEL/IGNITION (XJ).......8W-30-5

BUSHING AND PISTON CLEARANCE,

AW-4 .............................21-339

BUSHING REPLACEMENT, AXLE......2-12,2-34

BUSHING REPLACEMENT, LEAF SPRING

EYE; FRONT SUSPENSION AND AXLE.....2-17

BUSHING REPLACEMENT, LEAF SPRING

EYE; REAR SUSPENSION AND AXLES . . . 3-5,3-7

BUSHINGS, CLUTCH AND BRAKE PEDAL . . . 0-22

BUZZER, COMBINATION; INTERIOR

LIGHTING (YJ)....................8W-44-1

BUZZER MODULE.................8U-1,8U-2

BUZZER MODULE SCHEMATIC - YJ.......8U-4

CABLE, ACCELERATOR PEDAL AND

THROTTLE.....................14-17,14-58

CABLE ADJUSTMENT, PARK INTERLOCK . 21-195

CABLE ADJUSTMENT, SHIFT...........21-195

CABLE ADJUSTMENT, TRANSMISSION

THROTTLE.........................21-194

CABLE ADJUSTMENT, TRANSMISSION

THROTTLE VALVE....................21-71

CABLE ADJUSTMENT (XJ), PARK

INTERLOCK........................21-101

CABLE ADJUSTMENT (XJ), SHIFT.......21-100

CABLE ADJUSTMENT (XJ/YJ), THROTTLE

VALVE..............................21-101

CABLE REMOVE/INSTALL, SERVO.......8H-10

CABLE REPLACEMENT, TRANSMISSION

THROTTLE.........................21-193

CABLE REPLACEMENT (XJ), PARKING

BRAKE REAR.........................5-67

CABLE REPLACEMENT (YJ), PARKING

BRAKE FRONT........................5-67

CABLE REPLACEMENT (YJ), PARKING

BRAKE REAR.........................5-68

CABLE REPLACEMENTÐXJ, LATCH

RELEASE...........................23-11

CABLE RESISTANCE, SPARK PLUG......8D-14

CABLE, SERVO.......................8H-1

CABLE, SPEEDOMETER.................0-33

CABLE TENSIONER ADJUSTMENT

(XJ/YJ), PARKING BRAKE...............5-69

CABLE TENSIONER REPLACEMENT (XJ),

PARKING BRAKE......................5-66

CABLE, THROTTLE...................14-17

CABLE/LINKAGE ADJUSTMENT,

GEARSHIFT.........................21-71

CABLES, DISTRIBUTOR CAP AND

ROTOR, IGNITION.....................0-20

CABLES, SPARK PLUG SECONDARY.....8D-14,

8D-24

CABLES, VENT DOOR CONTROL.........24-32

CALIBRATION, COMPASS...............8C-5

CALIPER ASSEMBLY...................5-50

CALIPER CLEANING AND INSPECTION.....5-50

CALIPER DISASSEMBLY................5-48

CALIPER INSTALLATION................5-51

CALIPER OPERATION AND WEAR

COMPENSATION......................5-45

CALIPER REMOVAL....................5-48

CAMSHAFT......................9-32,9-74

CAMSHAFT PIN REPLACEMENT......9-34,9-75

CAMSHAFT POSITION SENSOR; FUEL

SYSTEM............................14-60

CAMSHAFT POSITION SENSOR;

FUEL/IGNITION (XJ)................8W-30-3

CAMSHAFT POSITION SENSOR;

FUEL/IGNITION (YJ)................8W-30-3

CAMSHAFT POSITION SENSOR;

IGNITION SYSTEMS..............8D-17,8D-2

CAMSHAFT POSITION SENSOR;

FUEL/IGNITION (XJ-RHD)............8W-30-3

CAMSHAFT POSITION SENSOR TEST;

FUEL SYSTEM.......................14-46

CAMSHAFT POSITION SENSOR TEST;

IGNITION SYSTEMS

...................8D-6

CAMSHAFT POSITION SENSORÐPCM

INPUT

.............................14-22

(CANADA ONLY)ÐXJ, DAYTIME

RUNNING LIGHTS

....................8L-15

(CANADA ONLY)ÐYJ, DAYTIME

RUNNING LIGHTS

....................8L-30

CANISTER, EVAP

..................25-4,25-7CAP AND ROTOR, IGNITION CABLES,

DISTRIBUTOR........................0-20

CAP, DISTRIBUTOR....................8D-7

CAP, FUEL TANK FILLER TUBE;

EMISSION CONTROL SYSTEMS......25-4,25-7

CAP, FUEL TANK FILLER TUBE; FUEL

SYSTEM............................14-13

CAP, RADIATOR PRESSURE.............7-25

CAPACITIES, COOLING SYSTEM..........7-45

CAPACITIES, FLUID.....................0-3

CAPACITIES, FUEL TANK..........14-13,14-67

CAPACITY TEST, FUEL PUMP............14-7

CAR REPLACEMENT, PITMAN SHAFT

SEALSÐIN.........................19-23

CARDAN (CV), DOUBLE................16-11

CARDAN, SINGLE....................16-10

CARGO BARRIERÐXJ................23-101

CARGO LAMP AND DOME LAMP;

INTERIOR LIGHTING (XJ-RHD)........8W-44-1

CARGO LAMP, COURTESY LAMPS AND

DOME LAMP; INTERIOR LIGHTING (XJ) . 8W-44-1

CARGO LAMPÐXJ...................23-94

CARPET/MATÐXJ, FRONT.............23-99

CARPET/MATÐXJ, REAR.............23-100

CARPETÐYJ.......................23-156

CARPETS AND FLOOR MATSÐXJ.......23-99

CARRIERÐYJ, EXTERNAL SPARE/

WHEEL TIRE.......................23-133

CASE (4WD VEHICLES), TRANSFER........0-24

CASE ASSEMBLY, TRANSFER....21-294,21-319

CASE CHANGES, TRANSFER...........21-307

CASE CLEANING AND INSPECTION,

TRANSMISSION.....................21-125

CASE COVER OIL SEAL REPLACEMENT,

TIMING.........................9-30,9-73

CASE COVER, TIMING..............9-31,9-72

CASE DISASSEMBLY AND OVERHAUL,

TRANSFER...................21-289,21-310

CASE IDENTIFICATION, TRANSFER.....21-284,

21-307

CASE INSTALLATION, TRANSFER . 21-288,21-309

CASE LUBRICANT AND FILL LEVEL,

TRANSFER.........................21-284

CASE, NP231 TRANSFER.......21-283,21-305

CASE, NP242 TRANSFER.......21-307,21-331

CASE OVERHAUL, FIRST-REVERSE

BRAKE PISTON AND TRANSMISSION....21-247

CASE REMOVAL, TRANSFER.....21-287,21-309

CASE SKID PLATE, TRANSFER......13-15,13-3

CASE SPECIFICATIONS, TRANSMISSION/

TRANSFER.........................21-333

CATALYTIC CONVERTER............11-1,11-4

CATALYTIC CONVERTOR................25-1

CAUTIONS, AND WARNINGS, NOTES;

WIRING DIAGRAMSÐGENERAL

INFORMATION (XJ)...................8W-1

CCD BUS; FUEL/IGNITION (XJ)........8W-30-5

CENTER HIGH MOUNTED STOP LAMP

(CHMSL)ÐXJ.......................8L-12

CENTER HIGH MOUNTED STOP LAMP

(CHMSL)ÐYJ.......................8L-28

CERTIFICATION LABEL, VEHICLE SAFETY . Intro.-4

CHAIN AND SPROCKETS, TIMING....9-31,9-73

CHANGE AND FILTER REPLACEMENT,

ENGINE OIL

..........................0-16

CHANGE, LUBRICANT; FRONT

SUSPENSION AND AXLE

................2-23

CHANGE, LUBRICANT; REAR

SUSPENSION AND AXLES

...........3-13,3-31

CHANGE, REFILLING AFTER OVERHAUL

OR FLUID/FILTER

..............21-100,21-182

CHANGES AND PARTS

INTERCHANGEABILITY, TRANSMISSION

. . . 21-67

CHANGES, TRANSFER CASE

...........21-307

CHANNEL REPLACEMENTÐYJ, DOOR

FRAME GLASS

......................23-142

CHARGING, BATTERY

..................8A-7

CHARGING REFRIGERANT SYSTEM

......24-11

CHARGING SYSTEM; BATTERY/

STARTING/CHARGING SYSTEMS

DIAGNOSTICS

.......................8A-17

CHARGING SYSTEM; CHARGING

SYSTEM (XJ)

.....................8W-20-1

CHARGING SYSTEM; CHARGING

SYSTEM (XJ-RHD)

.................8W-20-1

CHARGING SYSTEM; CHARGING

SYSTEM (YJ)

.....................8W-20-1CHARGING SYSTEM INDICATOR LAMP;

INSTRUMENT CLUSTER (XJ).........8W-40-3

CHARGING SYSTEM SPECIFICATIONS....8A-23

CHARGING TIME TABLE, BATTERY........8A-8

CHART, MAIN BEARING FITTING......9-48,9-90

CHART, XJ PERFORMANCE

TEMPERATURE AND PRESSURE.........24-13

CHART, YJ PERFORMANCE

TEMPERATURE AND PRESSURE.........24-13

CHARTÐAX 15 MANUAL

TRANSMISSION, SELECTIVE SNAP

RING.............................21-334

CHARTS, BRAKELINE..................5-12

CHARTS, DIAGNOSIS GUIDES...........21-77

CHARTS, GEARTRAIN OPERATION AND

APPLICATION.......................21-169

CHARTS, INSPECTION AND DIAGNOSIS.....6-4

CHASSIS AND BODY COMPONENTS.......0-28

CHASSIS COMPONENT AND WHEEL

BEARING LUBRICANTS.................0-28

CHECK VALVE TEST, POWER BOOSTER.....5-9

CHECKING FLUID LEVEL AND

CONDITION........................21-182

CHECKS, PRELIMINARY.................7-5

CHIME/BUZZER MODULE; INTERIOR

LIGHTING (XJ)....................8W-44-2

CHIME/BUZZER MODULE; INTERIOR

LIGHTING (XJ-RHD)................8W-44-2

CHMSL LAMPS, STOP LAMPS; REAR

LIGHTING (XJ)....................8W-51-1

CHMSL LAMPS, STOP LAMPS; REAR

LIGHTING (XJ-RHD)................8W-51-1

CHMSL LAMPS, STOP LAMPS; REAR

LIGHTING (YJ)....................8W-51-1

(CHMSL)ÐXJ, CENTER HIGH MOUNTED

STOP LAMP.........................8L-12

(CHMSL)ÐYJ, CENTER HIGH MOUNTED

STOP LAMP.........................8L-28

CIGAR LIGHTER; HORN/CIGAR LIGHTER . . . 8E-1

CIGAR LIGHTER; HORN/CIGAR LIGHTER

(YJ).............................8W-41-1

CIGAR LIGHTER; INSTRUMENT CLUSTER

(XJ).............................8W-40-1

CIRCUIT IDENTIFICATION; WIRING

DIAGRAMSÐGENERAL INFORMATION

(XJ)...............................8W-1

CIRCUIT REMOVE/INSTALL, PRINTED....8E-19,

8E-40

CIRCUIT SENSEÐPCM INPUT, IGNITION . . 14-23

CIRCUIT VOLTAGE, OPEN...............8A-6

CLAMPS, FUEL TUBES/LINES/HOSES . 14-62,14-9

CLASSIFICATION OF LUBRICANTS.........0-2

CLASSIFICATIONS AND RATINGS,

BATTERY...........................8A-23

CLEANER, AIR.......................14-29

CLEANER ELEMENT, AIR; EMISSION

CONTROL SYSTEMS...................25-7

CLEANER ELEMENT, AIR; FUEL SYSTEM . . 14-59

CLEANER ELEMENT, AIR; LUBRICATION

AND MAINTENANCE...................0-18

CLEANER HOUSING, AIR...............14-58

CLEANING AND INSPECTION, CALIPER....5-50

CLEANING AND INSPECTION, GEAR......19-42

CLEANING AND INSPECTION,

TRANSMISSION CASE................21-125

CLEANING OF TIRES...................22-2

CLEANING/INSPECTION; FRONT

SUSPENSION AND AXLE

................2-37

CLEANING/INSPECTION; REAR

SUSPENSION AND AXLES

...............3-20

CLEANING/REVERSE FLUSHING,

COOLING SYSTEM

....................7-22

CLEARANCE AND RAMP ANGLE,

GROUND

............................0-11

CLEARANCE, AW-4 BUSHING AND

PISTON

...........................21-339

CLOCKSPRING

.......................19-51

CLUSTER AND GAUGE HOUSINGSÐYJ,

INSTRUMENT

......................23-151

CLUSTER ASSEMBLY REMOVE/INSTALL

. . 8E-17,

8E-35

CLUSTER BEZELÐXJ, INSTRUMENT

.....23-80

CLUSTER BEZELÐYJ, INSTRUMENT

....23-151

CLUSTER CONNECTORS (RHD)

.........8E-11

CLUSTER, GAUGE PACKAGE

.......8E-31,8E-43

CLUSTER GROUND; INSTRUMENT

CLUSTER (XJ)

.....................8W-40-3

4 INDEXJ

Description Group-Page Description Group-Page Description Group-Page

Page 1969 of 2198

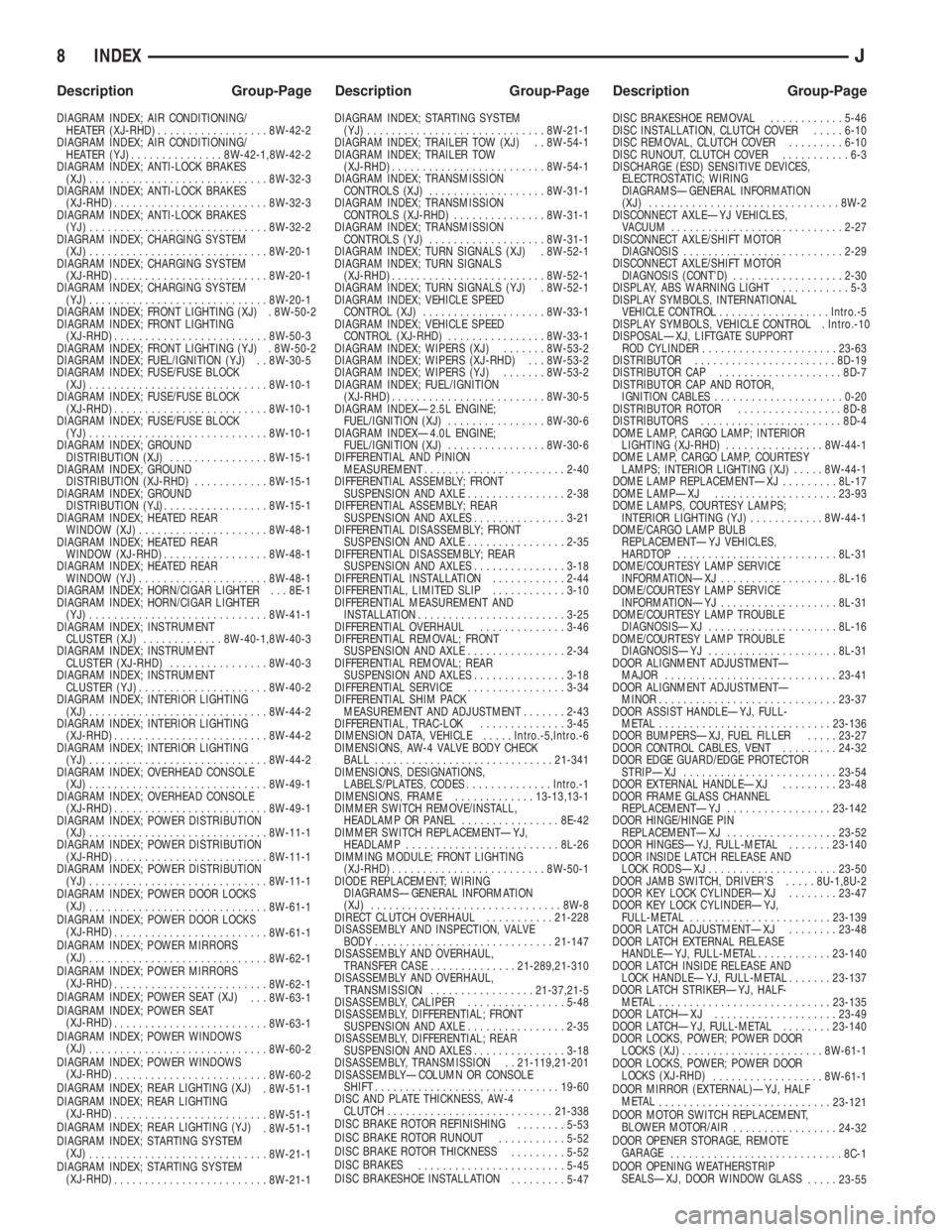

DIAGRAM INDEX; AIR CONDITIONING/

HEATER (XJ-RHD)..................8W-42-2

DIAGRAM INDEX; AIR CONDITIONING/

HEATER (YJ)...............8W-42-1,8W-42-2

DIAGRAM INDEX; ANTI-LOCK BRAKES

(XJ).............................8W-32-3

DIAGRAM INDEX; ANTI-LOCK BRAKES

(XJ-RHD).........................8W-32-3

DIAGRAM INDEX; ANTI-LOCK BRAKES

(YJ).............................8W-32-2

DIAGRAM INDEX; CHARGING SYSTEM

(XJ).............................8W-20-1

DIAGRAM INDEX; CHARGING SYSTEM

(XJ-RHD).........................8W-20-1

DIAGRAM INDEX; CHARGING SYSTEM

(YJ).............................8W-20-1

DIAGRAM INDEX; FRONT LIGHTING (XJ) . 8W-50-2

DIAGRAM INDEX; FRONT LIGHTING

(XJ-RHD).........................8W-50-3

DIAGRAM INDEX; FRONT LIGHTING (YJ) . 8W-50-2

DIAGRAM INDEX; FUEL/IGNITION (YJ) . . 8W-30-5

DIAGRAM INDEX; FUSE/FUSE BLOCK

(XJ).............................8W-10-1

DIAGRAM INDEX; FUSE/FUSE BLOCK

(XJ-RHD).........................8W-10-1

DIAGRAM INDEX; FUSE/FUSE BLOCK

(YJ).............................8W-10-1

DIAGRAM INDEX; GROUND

DISTRIBUTION (XJ)................8W-15-1

DIAGRAM INDEX; GROUND

DISTRIBUTION (XJ-RHD)............8W-15-1

DIAGRAM INDEX; GROUND

DISTRIBUTION (YJ)..................8W-15-1

DIAGRAM INDEX; HEATED REAR

WINDOW (XJ).....................8W-48-1

DIAGRAM INDEX; HEATED REAR

WINDOW (XJ-RHD).................8W-48-1

DIAGRAM INDEX; HEATED REAR

WINDOW (YJ).....................8W-48-1

DIAGRAM INDEX; HORN/CIGAR LIGHTER . . . 8E-1

DIAGRAM INDEX; HORN/CIGAR LIGHTER

(YJ).............................8W-41-1

DIAGRAM INDEX; INSTRUMENT

CLUSTER (XJ).............8W-40-1,8W-40-3

DIAGRAM INDEX; INSTRUMENT

CLUSTER (XJ-RHD)................8W-40-3

DIAGRAM INDEX; INSTRUMENT

CLUSTER (YJ).....................8W-40-2

DIAGRAM INDEX; INTERIOR LIGHTING

(XJ).............................8W-44-2

DIAGRAM INDEX; INTERIOR LIGHTING

(XJ-RHD).........................8W-44-2

DIAGRAM INDEX; INTERIOR LIGHTING

(YJ).............................8W-44-2

DIAGRAM INDEX; OVERHEAD CONSOLE

(XJ).............................8W-49-1

DIAGRAM INDEX; OVERHEAD CONSOLE

(XJ-RHD).........................8W-49-1

DIAGRAM INDEX; POWER DISTRIBUTION

(XJ).............................8W-11-1

DIAGRAM INDEX; POWER DISTRIBUTION

(XJ-RHD).........................8W-11-1

DIAGRAM INDEX; POWER DISTRIBUTION

(YJ).............................8W-11-1

DIAGRAM INDEX; POWER DOOR LOCKS

(XJ)

.............................8W-61-1

DIAGRAM INDEX; POWER DOOR LOCKS

(XJ-RHD)

.........................8W-61-1

DIAGRAM INDEX; POWER MIRRORS

(XJ)

.............................8W-62-1

DIAGRAM INDEX; POWER MIRRORS

(XJ-RHD)

.........................8W-62-1

DIAGRAM INDEX; POWER SEAT (XJ)

. . . 8W-63-1

DIAGRAM INDEX; POWER SEAT

(XJ-RHD)

.........................8W-63-1

DIAGRAM INDEX; POWER WINDOWS

(XJ)

.............................8W-60-2

DIAGRAM INDEX; POWER WINDOWS

(XJ-RHD)

.........................8W-60-2

DIAGRAM INDEX; REAR LIGHTING (XJ)

. 8W-51-1

DIAGRAM INDEX; REAR LIGHTING

(XJ-RHD)

.........................8W-51-1

DIAGRAM INDEX; REAR LIGHTING (YJ)

. 8W-51-1

DIAGRAM INDEX; STARTING SYSTEM

(XJ)

.............................8W-21-1

DIAGRAM INDEX; STARTING SYSTEM

(XJ-RHD)

.........................8W-21-1DIAGRAM INDEX; STARTING SYSTEM

(YJ).............................8W-21-1

DIAGRAM INDEX; TRAILER TOW (XJ) . . 8W-54-1

DIAGRAM INDEX; TRAILER TOW

(XJ-RHD).........................8W-54-1

DIAGRAM INDEX; TRANSMISSION

CONTROLS (XJ)...................8W-31-1

DIAGRAM INDEX; TRANSMISSION

CONTROLS (XJ-RHD)...............8W-31-1

DIAGRAM INDEX; TRANSMISSION

CONTROLS (YJ)...................8W-31-1

DIAGRAM INDEX; TURN SIGNALS (XJ) . 8W-52-1

DIAGRAM INDEX; TURN SIGNALS

(XJ-RHD).........................8W-52-1

DIAGRAM INDEX; TURN SIGNALS (YJ) . 8W-52-1

DIAGRAM INDEX; VEHICLE SPEED

CONTROL (XJ)....................8W-33-1

DIAGRAM INDEX; VEHICLE SPEED

CONTROL (XJ-RHD)................8W-33-1

DIAGRAM INDEX; WIPERS (XJ).......8W-53-2

DIAGRAM INDEX; WIPERS (XJ-RHD) . . . 8W-53-2

DIAGRAM INDEX; WIPERS (YJ).......8W-53-2

DIAGRAM INDEX; FUEL/IGNITION

(XJ-RHD).........................8W-30-5

DIAGRAM INDEXÐ2.5L ENGINE;

FUEL/IGNITION (XJ)................8W-30-6

DIAGRAM INDEXÐ4.0L ENGINE;

FUEL/IGNITION (XJ)................8W-30-6

DIFFERENTIAL AND PINION

MEASUREMENT.......................2-40

DIFFERENTIAL ASSEMBLY; FRONT

SUSPENSION AND AXLE.................2-38

DIFFERENTIAL ASSEMBLY; REAR

SUSPENSION AND AXLES...............3-21

DIFFERENTIAL DISASSEMBLY; FRONT

SUSPENSION AND AXLE................2-35

DIFFERENTIAL DISASSEMBLY; REAR

SUSPENSION AND AXLES...............3-18

DIFFERENTIAL INSTALLATION............2-44

DIFFERENTIAL, LIMITED SLIP............3-10

DIFFERENTIAL MEASUREMENT AND

INSTALLATION........................3-25

DIFFERENTIAL OVERHAUL..............3-46

DIFFERENTIAL REMOVAL; FRONT

SUSPENSION AND AXLE................2-34

DIFFERENTIAL REMOVAL; REAR

SUSPENSION AND AXLES...............3-18

DIFFERENTIAL SERVICE................3-34

DIFFERENTIAL SHIM PACK

MEASUREMENT AND ADJUSTMENT.......2-43

DIFFERENTIAL, TRAC-LOK..............3-45

DIMENSION DATA, VEHICLE.....Intro.-5,Intro.-6

DIMENSIONS, AW-4 VALVE BODY CHECK

BALL.............................21-341

DIMENSIONS, DESIGNATIONS,

LABELS/PLATES, CODES..............Intro.-1

DIMENSIONS, FRAME.............13-13,13-1

DIMMER SWITCH REMOVE/INSTALL,

HEADLAMP OR PANEL................8E-42

DIMMER SWITCH REPLACEMENTÐYJ,

HEADLAMP.........................8L-26

DIMMING MODULE; FRONT LIGHTING

(XJ-RHD).........................8W-50-1

DIODE REPLACEMENT; WIRING

DIAGRAMSÐGENERAL INFORMATION

(XJ)...............................8W-8

DIRECT CLUTCH OVERHAUL...........21-228

DISASSEMBLY AND INSPECTION, VALVE

BODY.............................21-147

DISASSEMBLY AND OVERHAUL,

TRANSFER CASE..............21-289,21-310

DISASSEMBLY AND OVERHAUL,

TRANSMISSION.................21-37,21-5

DISASSEMBLY, CALIPER................5-48

DISASSEMBLY, DIFFERENTIAL; FRONT

SUSPENSION AND AXLE................2-35

DISASSEMBLY, DIFFERENTIAL; REAR

SUSPENSION AND AXLES...............3-18

DISASSEMBLY, TRANSMISSION . . 21-119,21-201

DISASSEMBLYÐCOLUMN OR CONSOLE

SHIFT..............................19-60

DISC AND PLATE THICKNESS, AW-4

CLUTCH...........................21-338

DISC BRAKE ROTOR REFINISHING

........5-53

DISC BRAKE ROTOR RUNOUT

...........5-52

DISC BRAKE ROTOR THICKNESS

.........5-52

DISC BRAKES

........................5-45

DISC BRAKESHOE INSTALLATION

.........5-47DISC BRAKESHOE REMOVAL............5-46

DISC INSTALLATION, CLUTCH COVER.....6-10

DISC REMOVAL, CLUTCH COVER.........6-10

DISC RUNOUT, CLUTCH COVER...........6-3

DISCHARGE (ESD) SENSITIVE DEVICES,

ELECTROSTATIC; WIRING

DIAGRAMSÐGENERAL INFORMATION

(XJ)...............................8W-2

DISCONNECT AXLEÐYJ VEHICLES,

VACUUM............................2-27

DISCONNECT AXLE/SHIFT MOTOR

DIAGNOSIS..........................2-29

DISCONNECT AXLE/SHIFT MOTOR

DIAGNOSIS (CONT'D)..................2-30

DISPLAY, ABS WARNING LIGHT...........5-3

DISPLAY SYMBOLS, INTERNATIONAL

VEHICLE CONTROL..................Intro.-5

DISPLAY SYMBOLS, VEHICLE CONTROL . Intro.-10

DISPOSALÐXJ, LIFTGATE SUPPORT

ROD CYLINDER......................23-63

DISTRIBUTOR.......................8D-19

DISTRIBUTOR CAP....................8D-7

DISTRIBUTOR CAP AND ROTOR,

IGNITION CABLES.....................0-20

DISTRIBUTOR ROTOR.................8D-8

DISTRIBUTORS.......................8D-4

DOME LAMP, CARGO LAMP; INTERIOR

LIGHTING (XJ-RHD)................8W-44-1

DOME LAMP, CARGO LAMP, COURTESY

LAMPS; INTERIOR LIGHTING (XJ).....8W-44-1

DOME LAMP REPLACEMENTÐXJ.........8L-17

DOME LAMPÐXJ....................23-93

DOME LAMPS, COURTESY LAMPS;

INTERIOR LIGHTING (YJ)............8W-44-1

DOME/CARGO LAMP BULB

REPLACEMENTÐYJ VEHICLES,

HARDTOP..........................8L-31

DOME/COURTESY LAMP SERVICE

INFORMATIONÐXJ...................8L-16

DOME/COURTESY LAMP SERVICE

INFORMATIONÐYJ...................8L-31

DOME/COURTESY LAMP TROUBLE

DIAGNOSISÐXJ.....................8L-16

DOME/COURTESY LAMP TROUBLE

DIAGNOSISÐYJ.....................8L-31

DOOR ALIGNMENT ADJUSTMENTÐ

MAJOR............................23-41

DOOR ALIGNMENT ADJUSTMENTÐ

MINOR.............................23-37

DOOR ASSIST HANDLEÐYJ, FULL-

METAL............................23-136

DOOR BUMPERSÐXJ, FUEL FILLER.....23-27

DOOR CONTROL CABLES, VENT.........24-32

DOOR EDGE GUARD/EDGE PROTECTOR

STRIPÐXJ.........................23-54

DOOR EXTERNAL HANDLEÐXJ.........23-48

DOOR FRAME GLASS CHANNEL

REPLACEMENTÐYJ.................23-142

DOOR HINGE/HINGE PIN

REPLACEMENTÐXJ..................23-52

DOOR HINGESÐYJ, FULL-METAL.......23-140

DOOR INSIDE LATCH RELEASE AND

LOCK RODSÐXJ.....................23-50

DOOR JAMB SWITCH, DRIVER'S.....8U-1,8U-2

DOOR KEY LOCK CYLINDERÐXJ........23-47

DOOR KEY LOCK CYLINDERÐYJ,

FULL-METAL.......................23-139

DOOR LATCH ADJUSTMENTÐXJ........23-48

DOOR LATCH EXTERNAL RELEASE

HANDLEÐYJ, FULL-METAL............23-140

DOOR LATCH INSIDE RELEASE AND

LOCK HANDLEÐYJ, FULL-METAL.......23-137

DOOR LATCH STRIKERÐYJ, HALF-

METAL............................23-135

DOOR LATCHÐXJ....................23-49

DOOR LATCHÐYJ, FULL-METAL........23-140

DOOR LOCKS, POWER; POWER DOOR

LOCKS (XJ).......................8W-61-1

DOOR LOCKS, POWER; POWER DOOR

LOCKS (XJ-RHD)

..................8W-61-1

DOOR MIRROR (EXTERNAL)ÐYJ, HALF

METAL

............................23-121

DOOR MOTOR SWITCH REPLACEMENT,

BLOWER MOTOR/AIR

.................24-32

DOOR OPENER STORAGE, REMOTE

GARAGE

............................8C-1

DOOR OPENING WEATHERSTRIP

SEALSÐXJ, DOOR WINDOW GLASS

.....23-55

8 INDEXJ

Description Group-Page Description Group-Page Description Group-Page