distributor JEEP CHEROKEE 1995 Service Owner's Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 1995, Model line: CHEROKEE, Model: JEEP CHEROKEE 1995Pages: 2198, PDF Size: 82.83 MB

Page 332 of 2198

(2) Check the position of the slot on the oil pump

gear. On the 2.5L engine, it should be just slightly

before (counterclockwise of) the 10 o'clock position

(Fig. 10). On the 4.0L engine, it should be just

slightly before (counterclockwise of) the 11 o'clock po-

sition (Fig. 11). If not, place a flat blade screwdriver

into the oil pump gear and rotate it into the proper

position.

(3) Factory replacement distributors are equipped

with a plastic alignment pin already installed (Fig.

7). This pin is used to temporarily hold the rotor to

the cylinder number 1 firing position during distrib-

utor installation. If this pin is in place, proceed to

step number 8. If not, proceed to step number 4.

(4) If the original distributor is to be reinstalled,

such as during engine overhaul, the plastic pin will

not be available. A 3/16 inch drift pin punch tool may

be substituted for the plastic pin.

(5) Remove the camshaft position sensor from the

distributor housing. Lift straight up.

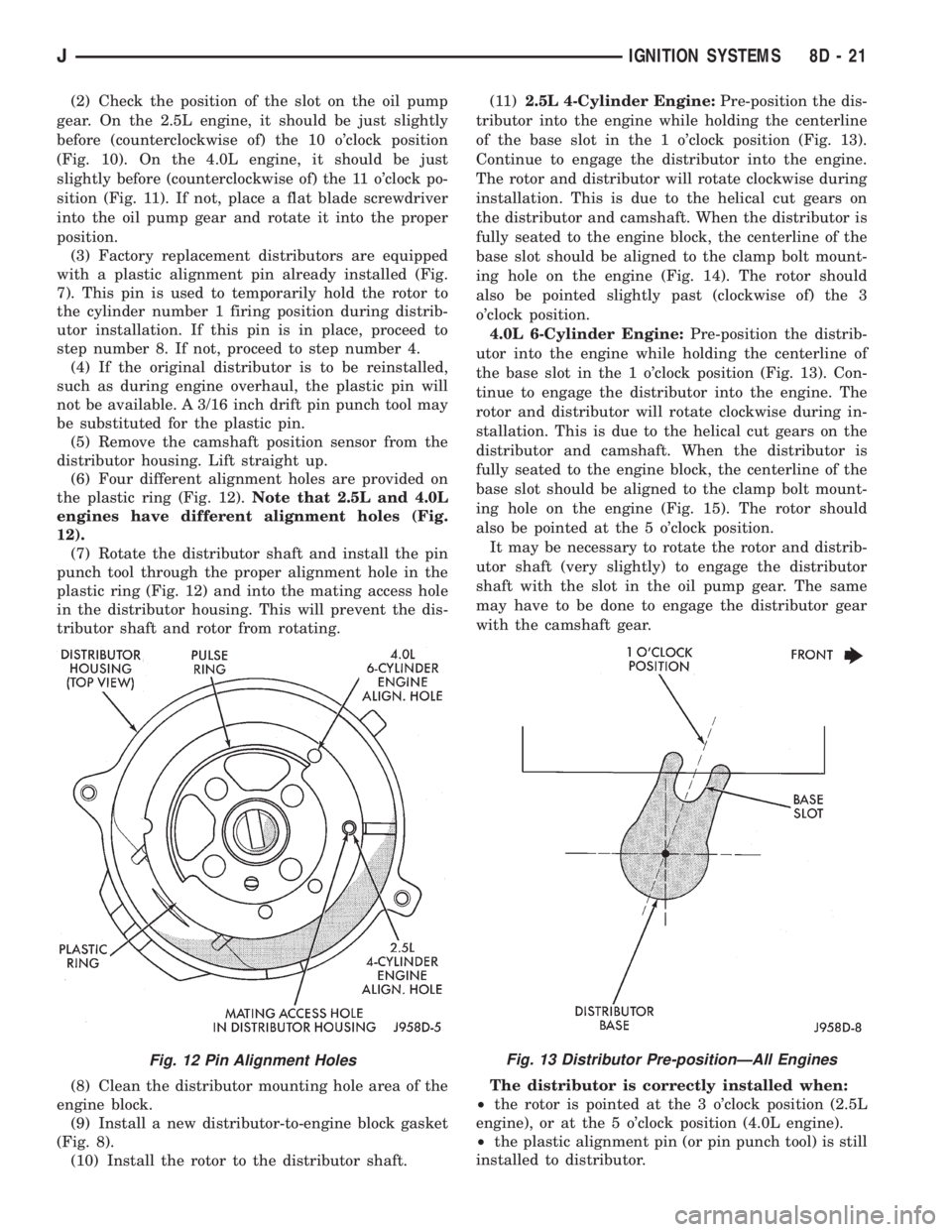

(6) Four different alignment holes are provided on

the plastic ring (Fig. 12).Note that 2.5L and 4.0L

engines have different alignment holes (Fig.

12).

(7) Rotate the distributor shaft and install the pin

punch tool through the proper alignment hole in the

plastic ring (Fig. 12) and into the mating access hole

in the distributor housing. This will prevent the dis-

tributor shaft and rotor from rotating.

(8) Clean the distributor mounting hole area of the

engine block.

(9) Install a new distributor-to-engine block gasket

(Fig. 8).

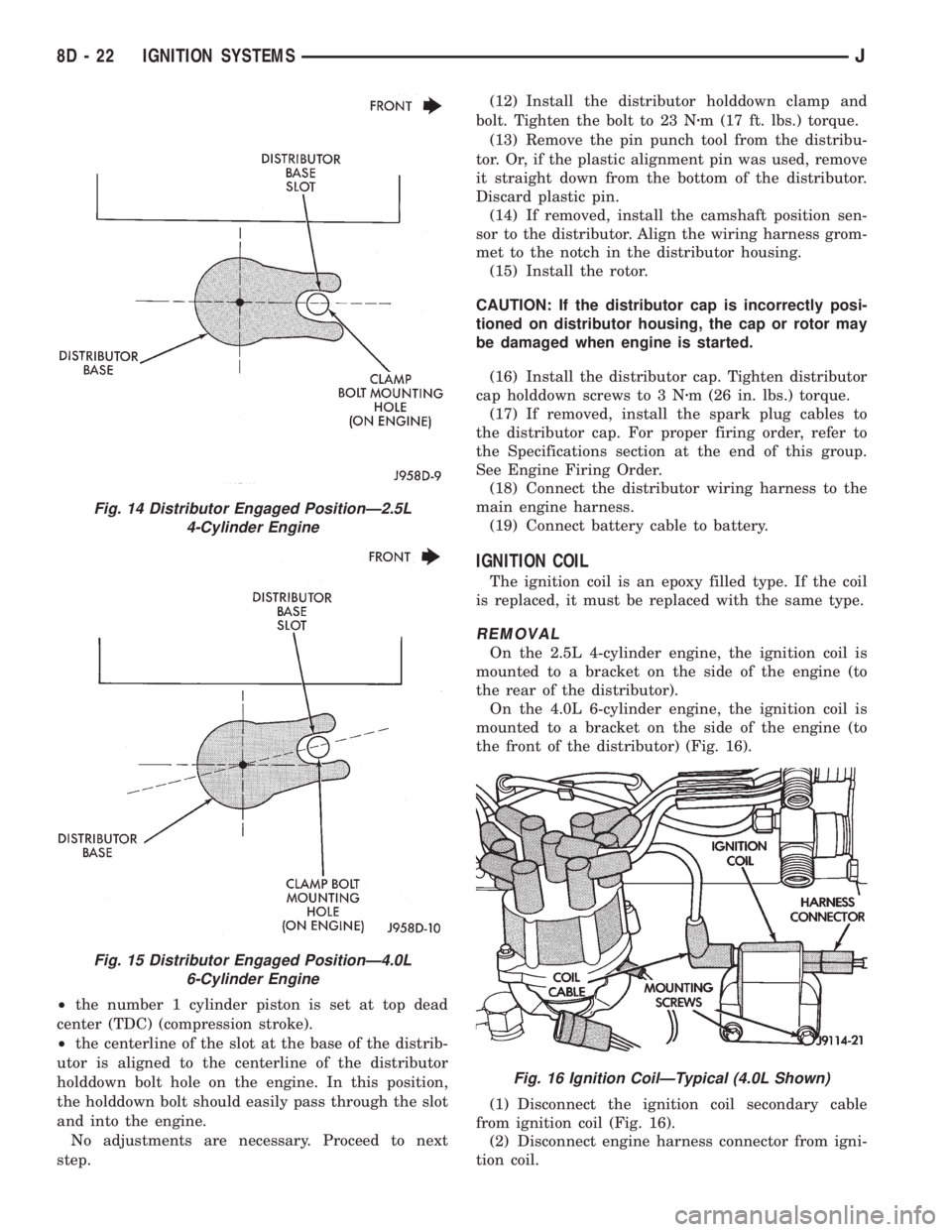

(10) Install the rotor to the distributor shaft.(11)2.5L 4-Cylinder Engine:Pre-position the dis-

tributor into the engine while holding the centerline

of the base slot in the 1 o'clock position (Fig. 13).

Continue to engage the distributor into the engine.

The rotor and distributor will rotate clockwise during

installation. This is due to the helical cut gears on

the distributor and camshaft. When the distributor is

fully seated to the engine block, the centerline of the

base slot should be aligned to the clamp bolt mount-

ing hole on the engine (Fig. 14). The rotor should

also be pointed slightly past (clockwise of) the 3

o'clock position.

4.0L 6-Cylinder Engine:Pre-position the distrib-

utor into the engine while holding the centerline of

the base slot in the 1 o'clock position (Fig. 13). Con-

tinue to engage the distributor into the engine. The

rotor and distributor will rotate clockwise during in-

stallation. This is due to the helical cut gears on the

distributor and camshaft. When the distributor is

fully seated to the engine block, the centerline of the

base slot should be aligned to the clamp bolt mount-

ing hole on the engine (Fig. 15). The rotor should

also be pointed at the 5 o'clock position.

It may be necessary to rotate the rotor and distrib-

utor shaft (very slightly) to engage the distributor

shaft with the slot in the oil pump gear. The same

may have to be done to engage the distributor gear

with the camshaft gear.

The distributor is correctly installed when:

²the rotor is pointed at the 3 o'clock position (2.5L

engine), or at the 5 o'clock position (4.0L engine).

²the plastic alignment pin (or pin punch tool) is still

installed to distributor.

Fig. 12 Pin Alignment HolesFig. 13 Distributor Pre-positionÐAll Engines

JIGNITION SYSTEMS 8D - 21

Page 333 of 2198

²the number 1 cylinder piston is set at top dead

center (TDC) (compression stroke).

²the centerline of the slot at the base of the distrib-

utor is aligned to the centerline of the distributor

holddown bolt hole on the engine. In this position,

the holddown bolt should easily pass through the slot

and into the engine.

No adjustments are necessary. Proceed to next

step.(12) Install the distributor holddown clamp and

bolt. Tighten the bolt to 23 Nzm (17 ft. lbs.) torque.

(13) Remove the pin punch tool from the distribu-

tor. Or, if the plastic alignment pin was used, remove

it straight down from the bottom of the distributor.

Discard plastic pin.

(14) If removed, install the camshaft position sen-

sor to the distributor. Align the wiring harness grom-

met to the notch in the distributor housing.

(15) Install the rotor.

CAUTION: If the distributor cap is incorrectly posi-

tioned on distributor housing, the cap or rotor may

be damaged when engine is started.

(16) Install the distributor cap. Tighten distributor

cap holddown screws to 3 Nzm (26 in. lbs.) torque.

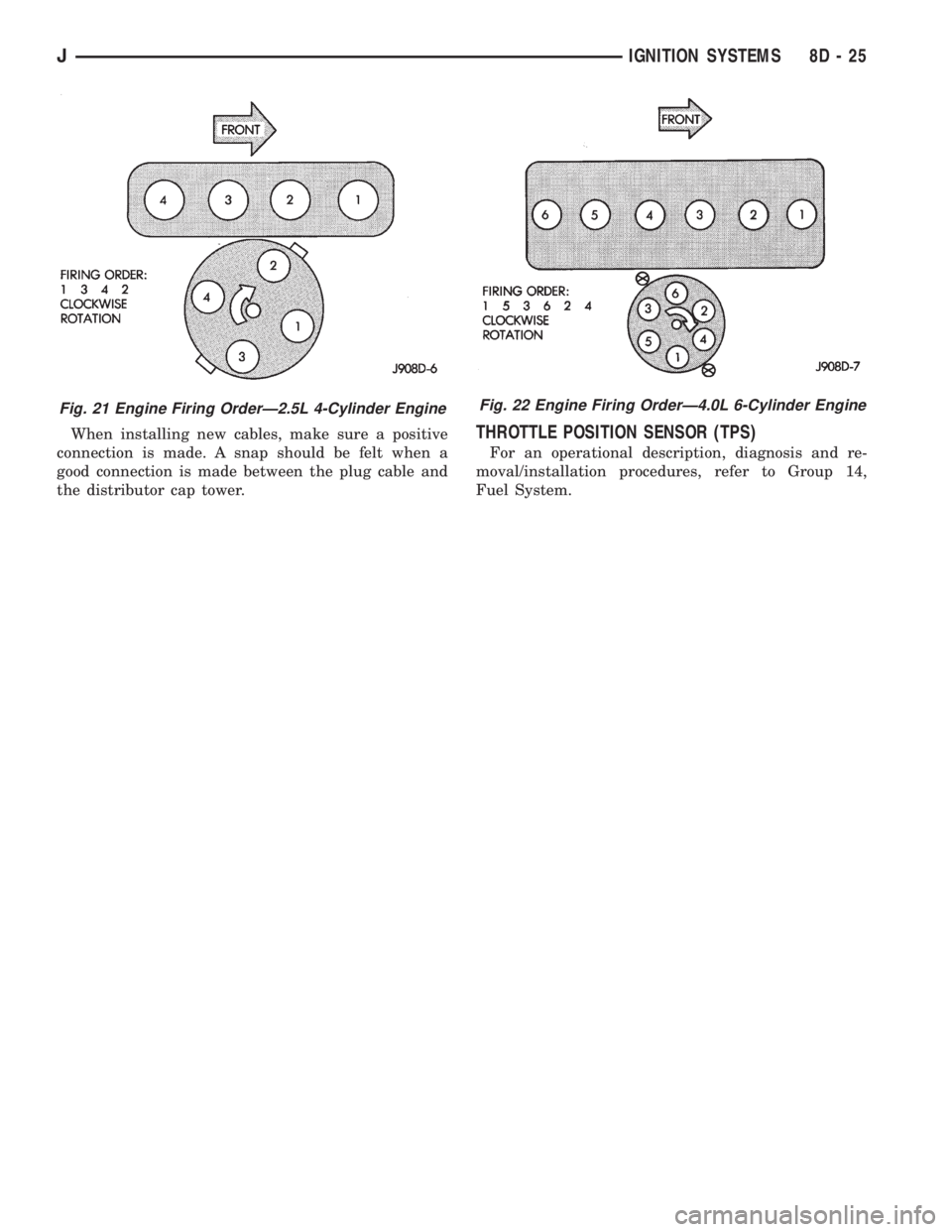

(17) If removed, install the spark plug cables to

the distributor cap. For proper firing order, refer to

the Specifications section at the end of this group.

See Engine Firing Order.

(18) Connect the distributor wiring harness to the

main engine harness.

(19) Connect battery cable to battery.

IGNITION COIL

The ignition coil is an epoxy filled type. If the coil

is replaced, it must be replaced with the same type.

REMOVAL

On the 2.5L 4-cylinder engine, the ignition coil is

mounted to a bracket on the side of the engine (to

the rear of the distributor).

On the 4.0L 6-cylinder engine, the ignition coil is

mounted to a bracket on the side of the engine (to

the front of the distributor) (Fig. 16).

(1) Disconnect the ignition coil secondary cable

from ignition coil (Fig. 16).

(2) Disconnect engine harness connector from igni-

tion coil.

Fig. 14 Distributor Engaged PositionÐ2.5L

4-Cylinder Engine

Fig. 15 Distributor Engaged PositionÐ4.0L

6-Cylinder Engine

Fig. 16 Ignition CoilÐTypical (4.0L Shown)

8D - 22 IGNITION SYSTEMSJ

Page 335 of 2198

motion. Never pull directly on the cable. Internal

damage to cable will result.

(2) Prior to removing the spark plug, spray com-

pressed air around the spark plug hole and the area

around the spark plug. This will help prevent foreign

material from entering the combustion chamber.

(3) Remove the spark plug using a quality socket

with a rubber or foam insert.

(4) Inspect the spark plug condition. Refer to

Spark Plugs in the Diagnostics/Service Procedures

section of this group.

PLUG CLEANING

The plugs may be cleaned using commercially

available spark plug cleaning equipment. After clean-

ing, file the center electrode flat with a small point

file or jewelers file before adjusting gap.

CAUTION: Never use a motorized wire wheel brush

to clean the spark plugs. Metallic deposits will re-

main on the spark plug insulator and will cause

plug misfire.

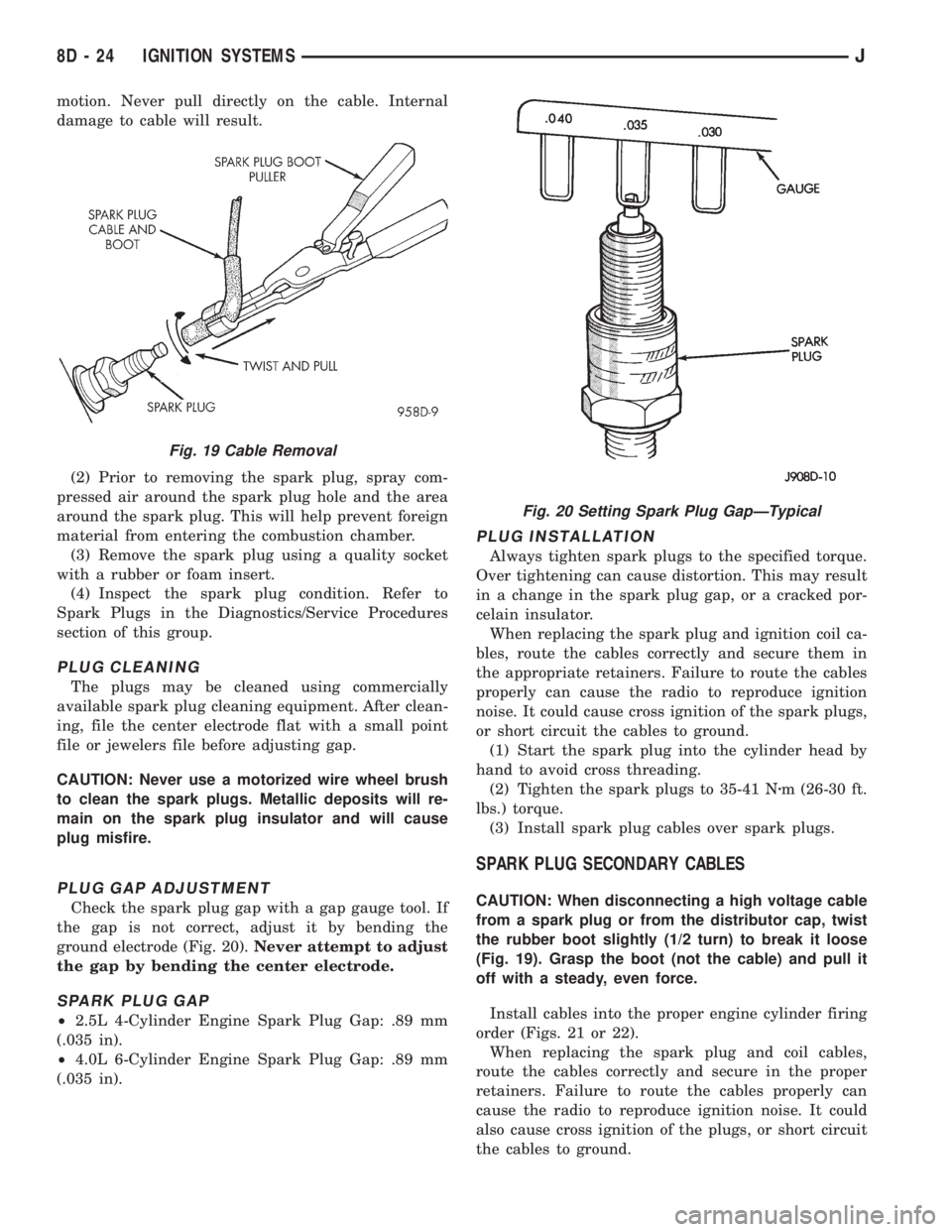

PLUG GAP ADJUSTMENT

Check the spark plug gap with a gap gauge tool. If

the gap is not correct, adjust it by bending the

ground electrode (Fig. 20).Never attempt to adjust

the gap by bending the center electrode.

SPARK PLUG GAP

²2.5L 4-Cylinder Engine Spark Plug Gap: .89 mm

(.035 in).

²4.0L 6-Cylinder Engine Spark Plug Gap: .89 mm

(.035 in).

PLUG INSTALLATION

Always tighten spark plugs to the specified torque.

Over tightening can cause distortion. This may result

in a change in the spark plug gap, or a cracked por-

celain insulator.

When replacing the spark plug and ignition coil ca-

bles, route the cables correctly and secure them in

the appropriate retainers. Failure to route the cables

properly can cause the radio to reproduce ignition

noise. It could cause cross ignition of the spark plugs,

or short circuit the cables to ground.

(1) Start the spark plug into the cylinder head by

hand to avoid cross threading.

(2) Tighten the spark plugs to 35-41 Nzm (26-30 ft.

lbs.) torque.

(3) Install spark plug cables over spark plugs.

SPARK PLUG SECONDARY CABLES

CAUTION: When disconnecting a high voltage cable

from a spark plug or from the distributor cap, twist

the rubber boot slightly (1/2 turn) to break it loose

(Fig. 19). Grasp the boot (not the cable) and pull it

off with a steady, even force.

Install cables into the proper engine cylinder firing

order (Figs. 21 or 22).

When replacing the spark plug and coil cables,

route the cables correctly and secure in the proper

retainers. Failure to route the cables properly can

cause the radio to reproduce ignition noise. It could

also cause cross ignition of the plugs, or short circuit

the cables to ground.

Fig. 19 Cable Removal

Fig. 20 Setting Spark Plug GapÐTypical

8D - 24 IGNITION SYSTEMSJ

Page 336 of 2198

When installing new cables, make sure a positive

connection is made. A snap should be felt when a

good connection is made between the plug cable and

the distributor cap tower.THROTTLE POSITION SENSOR (TPS)

For an operational description, diagnosis and re-

moval/installation procedures, refer to Group 14,

Fuel System.

Fig. 22 Engine Firing OrderÐ4.0L 6-Cylinder EngineFig. 21 Engine Firing OrderÐ2.5L 4-Cylinder Engine

JIGNITION SYSTEMS 8D - 25

Page 349 of 2198

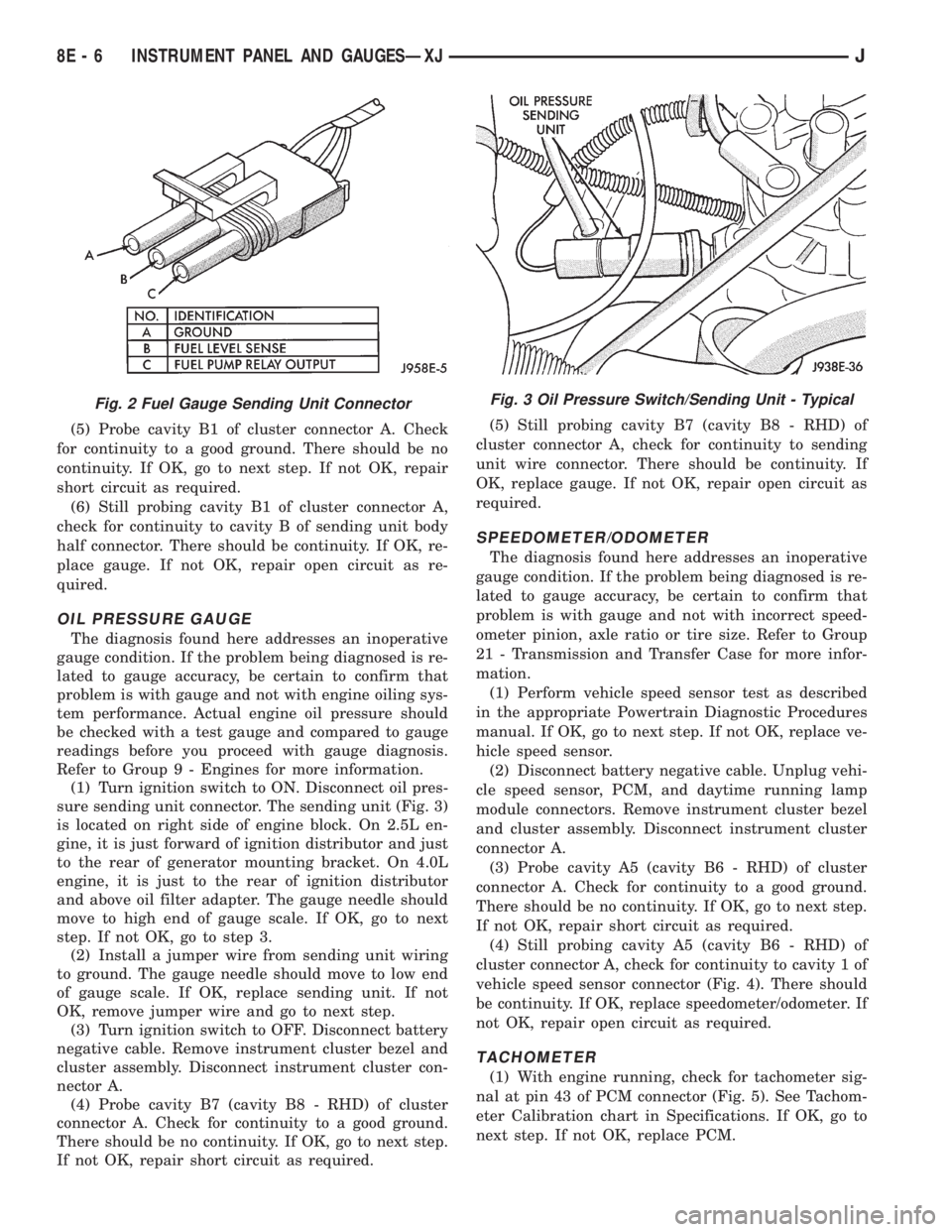

(5) Probe cavity B1 of cluster connector A. Check

for continuity to a good ground. There should be no

continuity. If OK, go to next step. If not OK, repair

short circuit as required.

(6) Still probing cavity B1 of cluster connector A,

check for continuity to cavity B of sending unit body

half connector. There should be continuity. If OK, re-

place gauge. If not OK, repair open circuit as re-

quired.

OIL PRESSURE GAUGE

The diagnosis found here addresses an inoperative

gauge condition. If the problem being diagnosed is re-

lated to gauge accuracy, be certain to confirm that

problem is with gauge and not with engine oiling sys-

tem performance. Actual engine oil pressure should

be checked with a test gauge and compared to gauge

readings before you proceed with gauge diagnosis.

Refer to Group 9 - Engines for more information.

(1) Turn ignition switch to ON. Disconnect oil pres-

sure sending unit connector. The sending unit (Fig. 3)

is located on right side of engine block. On 2.5L en-

gine, it is just forward of ignition distributor and just

to the rear of generator mounting bracket. On 4.0L

engine, it is just to the rear of ignition distributor

and above oil filter adapter. The gauge needle should

move to high end of gauge scale. If OK, go to next

step. If not OK, go to step 3.

(2) Install a jumper wire from sending unit wiring

to ground. The gauge needle should move to low end

of gauge scale. If OK, replace sending unit. If not

OK, remove jumper wire and go to next step.

(3) Turn ignition switch to OFF. Disconnect battery

negative cable. Remove instrument cluster bezel and

cluster assembly. Disconnect instrument cluster con-

nector A.

(4) Probe cavity B7 (cavity B8 - RHD) of cluster

connector A. Check for continuity to a good ground.

There should be no continuity. If OK, go to next step.

If not OK, repair short circuit as required.(5) Still probing cavity B7 (cavity B8 - RHD) of

cluster connector A, check for continuity to sending

unit wire connector. There should be continuity. If

OK, replace gauge. If not OK, repair open circuit as

required.

SPEEDOMETER/ODOMETER

The diagnosis found here addresses an inoperative

gauge condition. If the problem being diagnosed is re-

lated to gauge accuracy, be certain to confirm that

problem is with gauge and not with incorrect speed-

ometer pinion, axle ratio or tire size. Refer to Group

21 - Transmission and Transfer Case for more infor-

mation.

(1) Perform vehicle speed sensor test as described

in the appropriate Powertrain Diagnostic Procedures

manual. If OK, go to next step. If not OK, replace ve-

hicle speed sensor.

(2) Disconnect battery negative cable. Unplug vehi-

cle speed sensor, PCM, and daytime running lamp

module connectors. Remove instrument cluster bezel

and cluster assembly. Disconnect instrument cluster

connector A.

(3) Probe cavity A5 (cavity B6 - RHD) of cluster

connector A. Check for continuity to a good ground.

There should be no continuity. If OK, go to next step.

If not OK, repair short circuit as required.

(4) Still probing cavity A5 (cavity B6 - RHD) of

cluster connector A, check for continuity to cavity 1 of

vehicle speed sensor connector (Fig. 4). There should

be continuity. If OK, replace speedometer/odometer. If

not OK, repair open circuit as required.

TACHOMETER

(1) With engine running, check for tachometer sig-

nal at pin 43 of PCM connector (Fig. 5). See Tachom-

eter Calibration chart in Specifications. If OK, go to

next step. If not OK, replace PCM.

Fig. 2 Fuel Gauge Sending Unit ConnectorFig. 3 Oil Pressure Switch/Sending Unit - Typical

8E - 6 INSTRUMENT PANEL AND GAUGESÐXJJ

Page 357 of 2198

(2) Disconnect battery negative cable. Remove in-

strument cluster bezel and cluster assembly. Unplug

cluster connector A. Connect battery negative cable.

Turn headlamps on and select high beam. Check for

battery voltage at cavity A4 of cluster connector A. If

OK, replace indicator bulb. If not OK, repair circuit

to headlamp dimmer (multi-function) switch as re-

quired.

LOW FUEL WARNING LAMP

(1) Check that fuel gauge is operating as designed.

See Fuel Gauge Calibration chart in Specifications. If

OK, go to next step. If not OK, see Fuel Gauge in

this section for diagnosis.

(2) With at least 10 gallons of fuel in fuel tank, un-

plug fuel tank sending unit connector. Turn ignition

switch to ON and wait 10 seconds. Lamp (LED)

should light. Reconnect fuel tank sending unit and

wait 20 seconds. Lamp (LED) should go off. If not

OK, replace low fuel warning lamp module.

LOW OIL PRESSURE WARNING LAMP

The diagnosis found here addresses an inoperative

lamp condition. If the problem being diagnosed is re-

lated to lamp accuracy, be certain to confirm that

problem is with lamp and not with engine oiling sys-

tem. Actual engine oil pressure should be checked

with a test gauge before you proceed with lamp diag-

nosis. Refer to Group 9 - Engines for more informa-

tion.

(1) Turn ignition switch to ON. Lamp should light.

Start engine. Lamp should go off. If not OK, turn en-

gine off and go to next step.

(2) Unplug connector at oil pressure switch (Fig.

3). The switch is located on right side of engine block.

On 2.5L engine, it is just forward of ignition distrib-

utor and just to the rear of generator mounting

bracket. On 4.0L engine, it is just to the rear of igni-

tion distributor and above oil filter adapter. Install a

jumper wire from connector to a good ground. Turn

ignition switch to ON. Lamp should light. Unplug

jumper wire. Lamp should go out. If OK, replace oil

pressure switch. If not OK, go to next step.

(3) Turn ignition switch to OFF. Disconnect battery

negative cable. Remove instrument cluster bezel and

cluster assembly. Install a jumper wire from cavity

B7 (cavity B8 - RHD) of cluster connector A to a good

ground. Connect battery negative cable and turn ig-

nition switch to ON. Lamp should light. If OK, go to

next step. If not OK, replace lamp bulb.

(4) Turn ignition switch to OFF. Disconnect battery

negative cable. Unplug instrument cluster connector

A. Check continuity between cavity B7 (cavity B8 -

RHD) of cluster connector A and a good ground.

There should be no continuity. If OK, go to next step.

If not OK, repair short circuit as required.

(5) Check continuity between cavity B7 (cavity B8

- RHD) of cluster connector A and oil pressure switchconnector. There should be continuity. If not OK, re-

pair open circuit as required.

LOW WASHER FLUID WARNING LAMP

(1) Unplug washer fluid level switch connector.

Turn ignition switch to ON. Check for battery voltage

at connector cavity A. If OK, turn ignition switch to

OFF and go to next step. If not OK, repair open cir-

cuit to fuse F6 in PDC.

(2) Install a jumper wire from cavity A to cavity B

of washer fluid level switch connector. Turn ignition

switch to ON. Lamp should light. Unplug jumper and

lamp should go OFF. If OK, replace washer fluid

level switch. If not OK, go to next step.

(3) Turn ignition switch to OFF. Disconnect battery

negative cable. Remove instrument cluster bezel and

cluster assembly. Unplug instrument cluster (tell-

tale) connector B. Check continuity between cavity 16

(cavity 1 - RHD) of cluster connector B and a good

ground. There should be continuity. If OK, plug clus-

ter connector B back into cluster and go to next step.

If not OK, repair open circuit to ground as required.

(4) Connect battery negative cable. Install a

jumper wire from a 12-volt battery feed to cavity 1

(cavity 16 - RHD) of cluster connector B. Lamp

should light. If OK, go to next step. If not OK, re-

place bulb.

(5) Disconnect battery negative cable. Unplug clus-

ter connector B. Check continuity between cavity 1

(cavity 16 - RHD) of cluster connector B and a good

ground. There should be no continuity. If OK, go to

next step. If not OK, repair short circuit to switch as

required.

(6) Check continuity between cavity 1 (cavity 16 -

RHD) of cluster connector B and cavity B of washer

fluid level switch connector. There should be continu-

ity. If not OK, repair open circuit to switch as re-

quired.

MALFUNCTION INDICATOR LAMP

The diagnosis found here addresses an inoperative

lamp condition. If the lamp comes on and stays on

with engine running, refer to Group 14 - Fuel System

for diagnosis. If no fuel or emission system problem

is found, the following procedure will help locate a

short or open in the lamp circuit.

(1) Disconnect battery negative cable. Unplug PCM

connector. Install a jumper wire from cavity 32 of

PCM connector (Fig. 5) to a good ground. Connect

battery negative cable. Turn ignition switch to ON.

Lamp should light. Remove jumper wire and lamp

should go OFF. If OK, refer to Powertrain Diagnostic

Procedures to check PCM. If not OK, go to next step.

(2) Turn ignition switch to OFF. Disconnect battery

negative cable. Remove instrument cluster bezel and

cluster assembly. Install a jumper wire from cavity 2

(cavity 15 - RHD) of cluster (tell-tale) connector B to

a good ground. Connect battery negative cable. Turn

8E - 14 INSTRUMENT PANEL AND GAUGESÐXJJ

Page 371 of 2198

continuity. If OK, go to next step. If not OK, repair

circuit to ground as required.

(4) Remove center instrument cluster bezel and

gauge package cluster assembly. Disconnect cluster

connector.

(5) Probe cavity 6 of cluster connector. Check for

continuity to a good ground. There should be no con-

tinuity. If OK, go to next step. If not OK, repair short

circuit as required.

(6) Still probing cavity 6 of cluster connector, check

for continuity to cavity 2 of sending unit wiring body

half connector. There should be continuity. If OK, re-

place gauge. If not OK, repair open circuit as re-

quired.

OIL PRESSURE GAUGE

The diagnosis found here addresses an inoperative

gauge condition. If the problem being diagnosed is re-

lated to gauge accuracy, be certain to confirm that

problem is with gauge and not with engine oiling sys-

tem performance. Actual engine oil pressure should

be checked with a test gauge and compared to gauge

readings before you proceed with gauge diagnosis.

Refer to Group 9 - Engines for more information.

(1) Turn ignition switch to ON. Disconnect oil pres-

sure sending unit connector. The sending unit (Fig. 3)

is located on right side of engine block. On 2.5L en-

gine, it is just forward of ignition distributor and just

to the rear of generator mounting bracket. On 4.0L

engine, it is just to the rear of ignition distributor

and above oil filter adapter. The gauge needle should

move to high end of gauge scale. If OK, go to next

step. If not OK, go to step 3.

(2) Install a jumper wire from sending unit wiring

to ground. The gauge needle should move to low end

of gauge scale. If OK, replace sending unit. If not

OK, remove jumper wire and go to next step.(3) Turn ignition switch to OFF. Disconnect battery

negative cable. Remove center instrument cluster be-

zel and gauge package cluster assembly. Disconnect

cluster connector.

(4) Probe cavity 9 of cluster connector. Check for

continuity to a good ground. There should be no con-

tinuity. If OK, go to next step. If not OK, repair short

circuit as required.

(5) Still probing cavity 9 of cluster connector, check

for continuity to sending unit wire connector. There

should be continuity. If OK, replace gauge. If not OK,

repair open circuit as required.

SPEEDOMETER/ODOMETER

The diagnosis found here addresses an inoperative

gauge condition. If the problem being diagnosed is re-

lated to gauge accuracy, be certain to confirm that

problem is with gauge and not with incorrect speed-

ometer pinion, axle ratio or tire size. Refer to Group

21 - Transmission and Transfer Case for more infor-

mation.

(1) Perform vehicle speed sensor test as described

in the appropriate Powertrain Diagnostic Procedures

manual. If OK, go to next step. If not OK, replace ve-

hicle speed sensor.

(2) Disconnect battery negative cable. Unplug vehi-

cle speed sensor, PCM, and daytime running lamp

module connectors. Remove left instrument cluster

bezel and main cluster assembly. Disconnect cluster

connector.

(3) Probe cavity 13 of cluster connector. Check for

continuity to a good ground. There should be no con-

tinuity. If OK, go to next step. If not OK, repair short

circuit as required.

(4) Still probing cavity 13 of cluster connector,

check for continuity to cavity 1 of vehicle speed sen-

sor connector (Fig. 4). There should be continuity. If

OK, replace speedometer/odometer. If not OK, repair

open circuit as required.

Fig. 2 Fuel Gauge Sending Unit ConnectorFig. 3 Oil Pressure Sending Unit - Typical

8E - 28 INSTRUMENT PANEL AND GAUGESÐYJJ

Page 392 of 2198

(5) The coil ground terminal (85) is connected to

the electromagnet in the relay. Check as follows:

(a) On YJ models, it is grounded at all times.

There should be continuity to ground at cavity for

relay terminal 85 at all times. If not, repair circuit

to ground as required.

(b) On XJ models, it is energized when the head-

lamp switch is on. There should be battery voltage

at cavity for relay terminal 85 with the headlamp

switch on. If not, repair circuit to headlamp switch

as required.

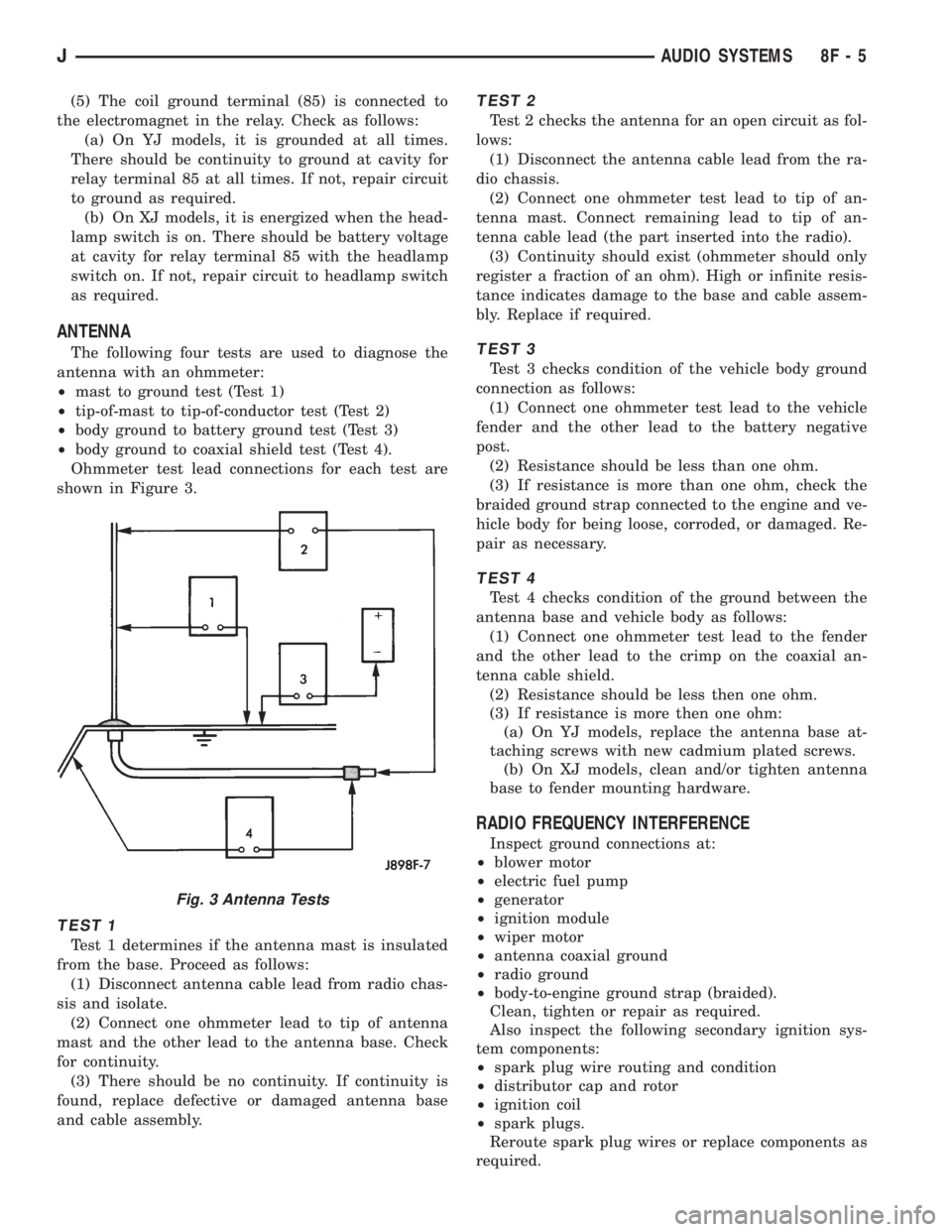

ANTENNA

The following four tests are used to diagnose the

antenna with an ohmmeter:

²mast to ground test (Test 1)

²tip-of-mast to tip-of-conductor test (Test 2)

²body ground to battery ground test (Test 3)

²body ground to coaxial shield test (Test 4).

Ohmmeter test lead connections for each test are

shown in Figure 3.

TEST 1

Test 1 determines if the antenna mast is insulated

from the base. Proceed as follows:

(1) Disconnect antenna cable lead from radio chas-

sis and isolate.

(2) Connect one ohmmeter lead to tip of antenna

mast and the other lead to the antenna base. Check

for continuity.

(3) There should be no continuity. If continuity is

found, replace defective or damaged antenna base

and cable assembly.

TEST 2

Test 2 checks the antenna for an open circuit as fol-

lows:

(1) Disconnect the antenna cable lead from the ra-

dio chassis.

(2) Connect one ohmmeter test lead to tip of an-

tenna mast. Connect remaining lead to tip of an-

tenna cable lead (the part inserted into the radio).

(3) Continuity should exist (ohmmeter should only

register a fraction of an ohm). High or infinite resis-

tance indicates damage to the base and cable assem-

bly. Replace if required.

TEST 3

Test 3 checks condition of the vehicle body ground

connection as follows:

(1) Connect one ohmmeter test lead to the vehicle

fender and the other lead to the battery negative

post.

(2) Resistance should be less than one ohm.

(3) If resistance is more than one ohm, check the

braided ground strap connected to the engine and ve-

hicle body for being loose, corroded, or damaged. Re-

pair as necessary.

TEST 4

Test 4 checks condition of the ground between the

antenna base and vehicle body as follows:

(1) Connect one ohmmeter test lead to the fender

and the other lead to the crimp on the coaxial an-

tenna cable shield.

(2) Resistance should be less then one ohm.

(3) If resistance is more then one ohm:

(a) On YJ models, replace the antenna base at-

taching screws with new cadmium plated screws.

(b) On XJ models, clean and/or tighten antenna

base to fender mounting hardware.

RADIO FREQUENCY INTERFERENCE

Inspect ground connections at:

²blower motor

²electric fuel pump

²generator

²ignition module

²wiper motor

²antenna coaxial ground

²radio ground

²body-to-engine ground strap (braided).

Clean, tighten or repair as required.

Also inspect the following secondary ignition sys-

tem components:

²spark plug wire routing and condition

²distributor cap and rotor

²ignition coil

²spark plugs.

Reroute spark plug wires or replace components as

required.

Fig. 3 Antenna Tests

JAUDIO SYSTEMS 8F - 5

Page 578 of 2198

Circuit G7 from the vehicle speed sensor provides

an input signal to the PCM. The G7 circuit connects

to cavity 47 of the PCM.

The PCM provides a ground for the vehicle speed

sensor signal (circuit G7) through circuit K4. Circuit

K4 connects to cavity 4 of the PCM.

HELPFUL INFORMATION

²Circuit G7 splices to the speedometer, and daytime

running lights module (DRL).

²Circuit K7 splices to supply 8 volts to the camshaft

position sensor and crankshaft position sensor.

Circuit K4 splices to supply ground for the signals

from the following:

²Heated oxygen sensor

²Camshaft position sensor

²Crankshaft position sensor

²Throttle position sensor

²Manifold absolute pressure sensor

²Engine coolant temperature sensor

²Intake air temperature sensor

HEATED OXYGEN SENSOR

When the fuel pump relay contacts close, they con-

nect circuits A14 and A141. Circuit A141 splices to

supply voltage to the heated oxygen sensor.

Circuit K41 delivers the signal from the heated ox-

ygen sensor to the PCM. Circuit K41 connects to cav-

ity 41 of the PCM.

The PCM provides a ground for the heated oxygen

sensor signal (circuit K41) through circuit K4. Circuit

K4 connects to cavity 4 of the PCM connector.

Circuit Z12 provides a ground for the heater circuit

in the sensor.

Circuit Z12 terminates at the right side of the en-

gine.

HELPFUL INFORMATION

²Circuit A141 also supplies battery voltage to the

fuel pump.

Circuit K4 splices to supply ground for the signals

from the following:

²Heated oxygen sensor

²Camshaft position sensor

²Crankshaft position sensor

²Intake air temperature sensor

²Throttle position sensor

²Manifold absolute pressure sensor

²Engine coolant temperature sensor

²Vehicle speed sensor

CAMSHAFT POSITION SENSOR

The Powertrain Control Module (PCM) supplies 8

volts to the camshaft position sensor (in distributor)

on circuit K7. Circuit K7 connects to cavity 7 of the

PCM.The PCM receives the camshaft position sensor sig-

nal on circuit K44. Circuit K44 connects to cavity 44

of the PCM.

The PCM provides a ground for the camshaft posi-

tion sensor signal (circuit K44) through circuit K4.

Circuit K4 connects to cavity 4 of the PCM.

HELPFUL INFORMATION

²Circuit K7 splices to supply 8 volts to the crank-

shaft position sensor and the vehicle speed sensor.

Circuit K4 splices to supply ground for the signals

from the following:

²Heated oxygen sensor

²Camshaft position sensor

²Crankshaft position sensor

²Intake air temperature sensor

²Throttle position sensor

²Manifold absolute pressure sensor

²Engine coolant temperature sensor

²Vehicle speed sensor

CRANKSHAFT POSITION SENSOR

The Powertrain Control Module (PCM) supplies 8

volts to the crankshaft position sensor on circuit K7.

Circuit K7 connects to cavity 7 of the PCM.

The PCM receives the crankshaft position sensor

signal on circuit K24. Circuit K24 connects to cavity

24 of the PCM.

The PCM provides a ground for the crankshaft po-

sition sensor (circuit K24) through circuit K4. Circuit

K4 connects to cavity 4 of the PCM.

HELPFUL INFORMATION

²Circuit K7 splices to supply 8 volts to the camshaft

position sensor and the vehicle speed sensor.

Circuit K4 splices to supply ground for the signals

from the following:

²Heated oxygen sensor

²Camshaft position sensor

²Crankshaft position sensor

²Intake air temperature sensor

²Throttle position sensor

²Manifold absolute pressure sensor

²Engine coolant temperature sensor

²Vehicle speed sensor

ENGINE COOLANT TEMPERATURE SENSOR

The engine coolant temperature sensor provides an

input to the Powertrain Control Module (PCM) on

circuit K2. From circuit K2, the engine coolant tem-

perature sensor draws up to 5 volts from the PCM.

The sensor is a variable resistor. As coolant temper-

ature changes, the resistance in the sensor changes,

causing a change in current draw. The K2 circuit

connects to cavity 2 of the PCM.

J8W-30 FUEL/IGNITIONÐXJ VEHICLES 8W - 30 - 3

Page 581 of 2198

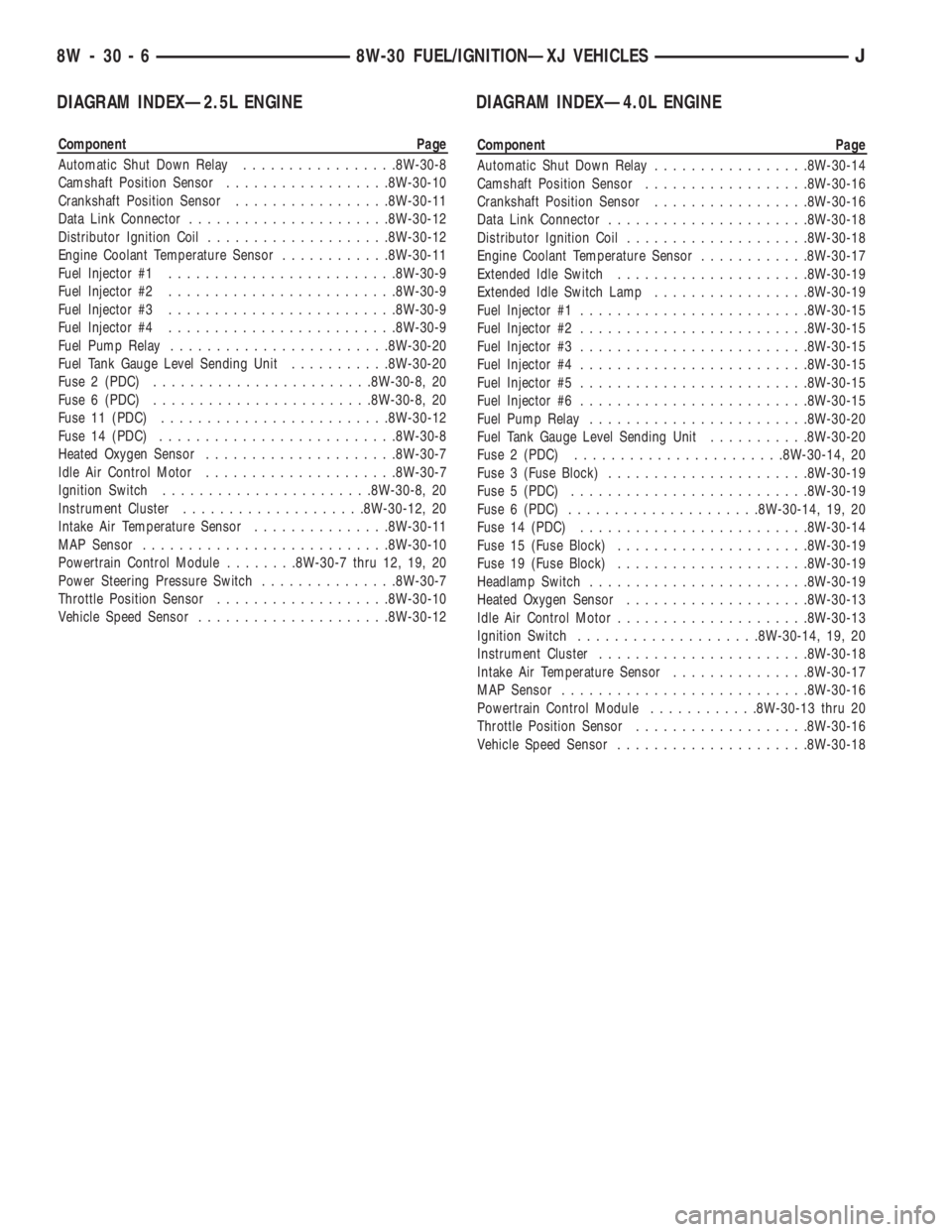

DIAGRAM INDEXÐ2.5L ENGINE

Component Page

Automatic Shut Down Relay.................8W-30-8

Camshaft Position Sensor..................8W-30-10

Crankshaft Position Sensor.................8W-30-11

Data Link Connector......................8W-30-12

Distributor Ignition Coil....................8W-30-12

Engine Coolant Temperature Sensor............8W-30-11

Fuel Injector #1.........................8W-30-9

Fuel Injector #2.........................8W-30-9

Fuel Injector #3.........................8W-30-9

Fuel Injector #4.........................8W-30-9

Fuel Pump Relay........................8W-30-20

Fuel Tank Gauge Level Sending Unit...........8W-30-20

Fuse 2 (PDC)........................8W-30-8, 20

Fuse 6 (PDC)........................8W-30-8, 20

Fuse 11 (PDC).........................8W-30-12

Fuse 14 (PDC)..........................8W-30-8

Heated Oxygen Sensor.....................8W-30-7

Idle Air Control Motor.....................8W-30-7

Ignition Switch.......................8W-30-8, 20

Instrument Cluster....................8W-30-12, 20

Intake Air Temperature Sensor...............8W-30-11

MAP Sensor...........................8W-30-10

Powertrain Control Module........8W-30-7 thru 12, 19, 20

Power Steering Pressure Switch...............8W-30-7

Throttle Position Sensor...................8W-30-10

Vehicle Speed Sensor.....................8W-30-12

DIAGRAM INDEXÐ4.0L ENGINE

Component Page

Automatic Shut Down Relay.................8W-30-14

Camshaft Position Sensor..................8W-30-16

Crankshaft Position Sensor.................8W-30-16

Data Link Connector......................8W-30-18

Distributor Ignition Coil....................8W-30-18

Engine Coolant Temperature Sensor............8W-30-17

Extended Idle Switch.....................8W-30-19

Extended Idle Switch Lamp.................8W-30-19

Fuel Injector #1.........................8W-30-15

Fuel Injector #2.........................8W-30-15

Fuel Injector #3.........................8W-30-15

Fuel Injector #4.........................8W-30-15

Fuel Injector #5.........................8W-30-15

Fuel Injector #6.........................8W-30-15

Fuel Pump Relay........................8W-30-20

Fuel Tank Gauge Level Sending Unit...........8W-30-20

Fuse 2 (PDC).......................8W-30-14, 20

Fuse 3 (Fuse Block)......................8W-30-19

Fuse 5 (PDC)..........................8W-30-19

Fuse 6 (PDC).....................8W-30-14, 19, 20

Fuse 14 (PDC).........................8W-30-14

Fuse 15 (Fuse Block).....................8W-30-19

Fuse 19 (Fuse Block).....................8W-30-19

Headlamp Switch........................8W-30-19

Heated Oxygen Sensor....................8W-30-13

Idle Air Control Motor.....................8W-30-13

Ignition Switch....................8W-30-14, 19, 20

Instrument Cluster.......................8W-30-18

Intake Air Temperature Sensor...............8W-30-17

MAP Sensor...........................8W-30-16

Powertrain Control Module............8W-30-13 thru 20

Throttle Position Sensor...................8W-30-16

Vehicle Speed Sensor.....................8W-30-18

8W - 30 - 6 8W-30 FUEL/IGNITIONÐXJ VEHICLESJ