distributor JEEP CHEROKEE 1995 Service Owner's Guide

[x] Cancel search | Manufacturer: JEEP, Model Year: 1995, Model line: CHEROKEE, Model: JEEP CHEROKEE 1995Pages: 2198, PDF Size: 82.83 MB

Page 780 of 2198

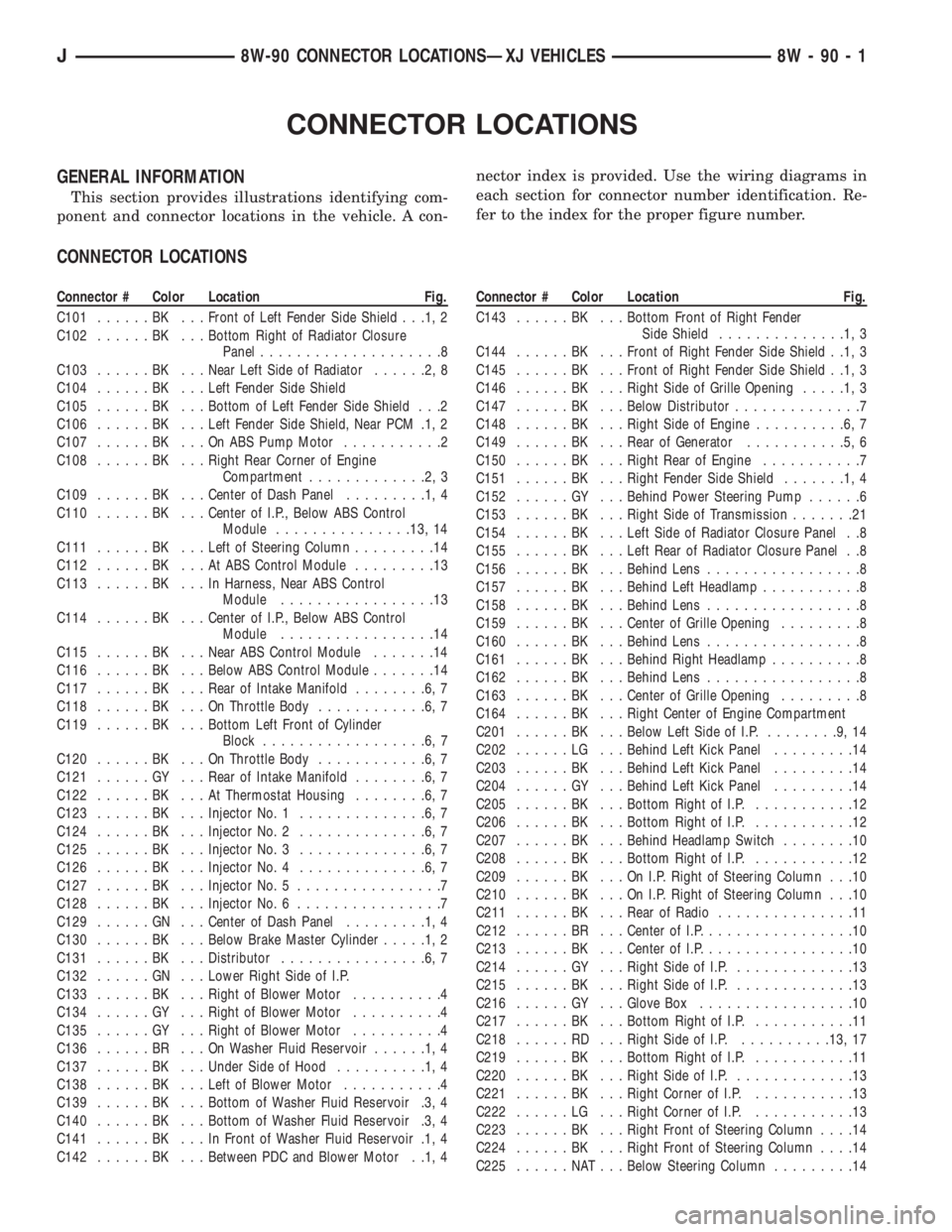

CONNECTOR LOCATIONS

GENERAL INFORMATION

This section provides illustrations identifying com-

ponent and connector locations in the vehicle. A con-nector index is provided. Use the wiring diagrams in

each section for connector number identification. Re-

fer to the index for the proper figure number.

CONNECTOR LOCATIONS

Connector # Color Location Fig.

C101......BK ...Front of Left Fender Side Shield . . .1, 2

C102......BK ...Bottom Right of Radiator Closure

Panel....................8

C103......BK ...Near Left Side of Radiator......2,8

C104......BK ...Left Fender Side Shield

C105......BK ...Bottom of Left Fender Side Shield . . .2

C106......BK ...Left Fender Side Shield, Near PCM .1, 2

C107......BK ...OnABSPump Motor...........2

C108......BK ...Right Rear Corner of Engine

Compartment.............2,3

C109......BK ...Center of Dash Panel.........1,4

C110......BK ...Center of I.P., Below ABS Control

Module...............13, 14

C111......BK ...Left of Steering Column.........14

C112......BK ...AtABSControl Module.........13

C113......BK ...InHarness, Near ABS Control

Module.................13

C114......BK ...Center of I.P., Below ABS Control

Module.................14

C115......BK ...Near ABS Control Module.......14

C116......BK ...Below ABS Control Module.......14

C117......BK ...Rear of Intake Manifold........6,7

C118......BK ...OnThrottle Body............6,7

C119......BK ...Bottom Left Front of Cylinder

Block..................6,7

C120......BK ...OnThrottle Body............6,7

C121......GY ...Rear of Intake Manifold........6,7

C122......BK ...AtThermostat Housing........6,7

C123......BK ...Injector No. 1..............6,7

C124......BK ...Injector No. 2..............6,7

C125......BK ...Injector No. 3..............6,7

C126......BK ...Injector No. 4..............6,7

C127......BK ...Injector No. 5................7

C128......BK ...Injector No. 6................7

C129......GN ...Center of Dash Panel.........1,4

C130......BK ...Below Brake Master Cylinder.....1,2

C131......BK ...Distributor................6,7

C132......GN ...Lower Right Side of I.P.

C133......BK ...Right of Blower Motor..........4

C134......GY ...Right of Blower Motor..........4

C135......GY ...Right of Blower Motor..........4

C136......BR ...OnWasher Fluid Reservoir......1,4

C137......BK ...Under Side of Hood..........1,4

C138......BK ...Left of Blower Motor...........4

C139......BK ...Bottom of Washer Fluid Reservoir .3, 4

C140......BK ...Bottom of Washer Fluid Reservoir .3, 4

C141......BK ...InFront of Washer Fluid Reservoir .1, 4

C142......BK ...Between PDC and Blower Motor . .1, 4Connector # Color Location Fig.

C143......BK ...Bottom Front of Right Fender

Side Shield..............1,3

C144......BK ...Front of Right Fender Side Shield . .1, 3

C145......BK ...Front of Right Fender Side Shield . .1, 3

C146......BK ...Right Side of Grille Opening.....1,3

C147......BK ...Below Distributor..............7

C148......BK ...Right Side of Engine..........6,7

C149......BK ...Rear of Generator...........5,6

C150......BK ...Right Rear of Engine...........7

C151......BK ...Right Fender Side Shield.......1,4

C152......GY ...Behind Power Steering Pump......6

C153......BK ...Right Side of Transmission.......21

C154......BK ...Left Side of Radiator Closure Panel . .8

C155......BK ...Left Rear of Radiator Closure Panel . .8

C156......BK ...Behind Lens.................8

C157......BK ...Behind Left Headlamp...........8

C158......BK ...Behind Lens.................8

C159......BK ...Center of Grille Opening.........8

C160......BK ...Behind Lens.................8

C161......BK ...Behind Right Headlamp..........8

C162......BK ...Behind Lens.................8

C163......BK ...Center of Grille Opening.........8

C164......BK ...Right Center of Engine Compartment

C201......BK ...Below Left Side of I.P.........9,14

C202......LG ...Behind Left Kick Panel.........14

C203......BK ...Behind Left Kick Panel.........14

C204......GY ...Behind Left Kick Panel.........14

C205......BK ...Bottom Right of I.P............12

C206......BK ...Bottom Right of I.P............12

C207......BK ...Behind Headlamp Switch........10

C208......BK ...Bottom Right of I.P............12

C209......BK ...OnI.P.Right of Steering Column . . .10

C210......BK ...OnI.P.Right of Steering Column . . .10

C211......BK ...Rear of Radio...............11

C212......BR ...Center of I.P.................10

C213......BK ...Center of I.P.................10

C214......GY ...Right Side of I.P..............13

C215......BK ...Right Side of I.P..............13

C216......GY ...Glove Box.................10

C217......BK ...Bottom Right of I.P............11

C218......RD ...Right Side of I.P...........13, 17

C219......BK ...Bottom Right of I.P............11

C220......BK ...Right Side of I.P..............13

C221......BK ...Right Corner of I.P............13

C222......LG ...Right Corner of I.P............13

C223......BK ...Right Front of Steering Column....14

C224......BK ...Right Front of Steering Column....14

C225......NAT...Below Steering Column.........14

J8W-90 CONNECTOR LOCATIONSÐXJ VEHICLES 8W - 90 - 1

Page 804 of 2198

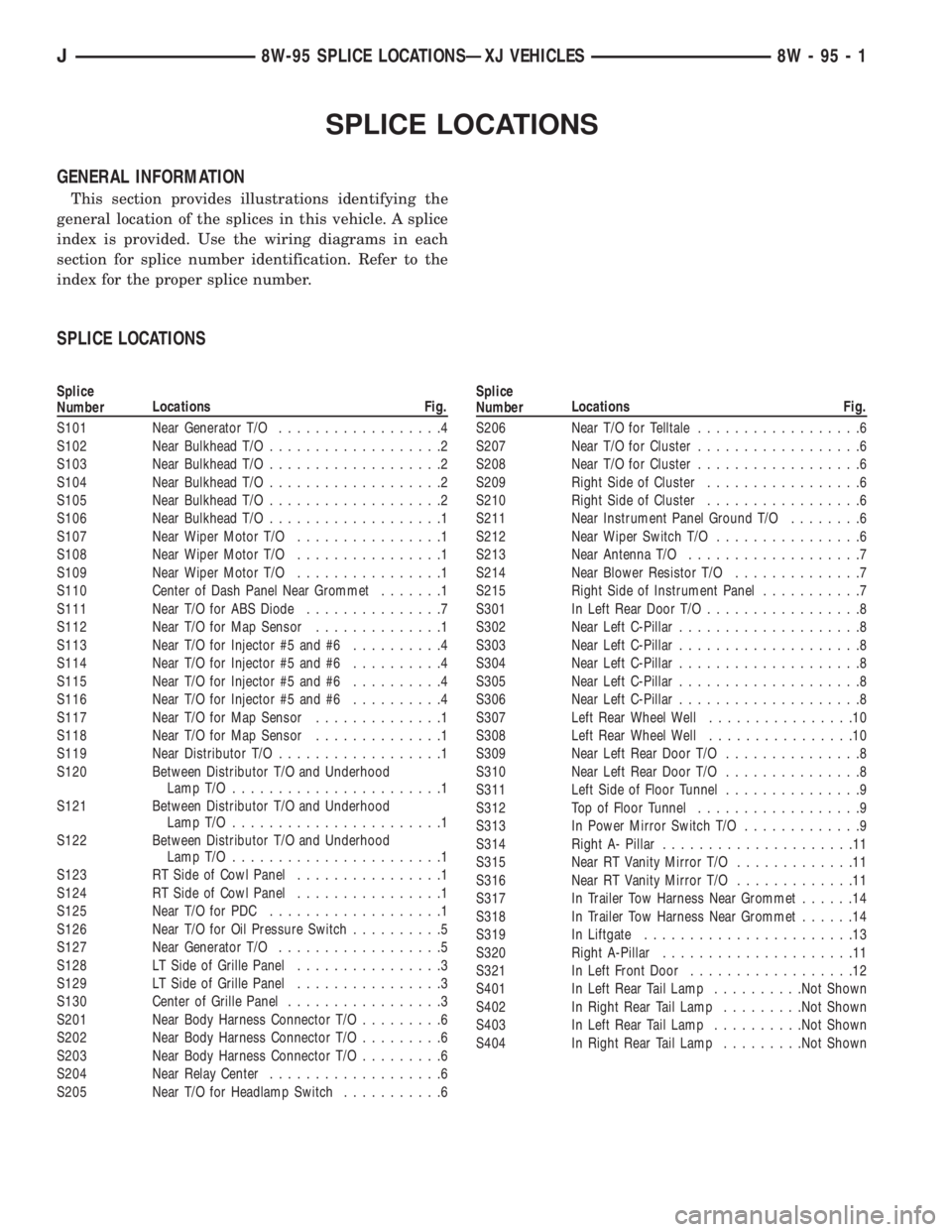

SPLICE LOCATIONS

GENERAL INFORMATION

This section provides illustrations identifying the

general location of the splices in this vehicle. A splice

index is provided. Use the wiring diagrams in each

section for splice number identification. Refer to the

index for the proper splice number.

SPLICE LOCATIONS

Splice

NumberLocations Fig.

S101 Near Generator T/O..................4

S102 Near Bulkhead T/O...................2

S103 Near Bulkhead T/O...................2

S104 Near Bulkhead T/O...................2

S105 Near Bulkhead T/O...................2

S106 Near Bulkhead T/O...................1

S107 Near Wiper Motor T/O................1

S108 Near Wiper Motor T/O................1

S109 Near Wiper Motor T/O................1

S110 Center of Dash Panel Near Grommet.......1

S111 Near T/O for ABS Diode...............7

S112 Near T/O for Map Sensor..............1

S113 Near T/O for Injector #5 and #6..........4

S114 Near T/O for Injector #5 and #6..........4

S115 Near T/O for Injector #5 and #6..........4

S116 Near T/O for Injector #5 and #6..........4

S117 Near T/O for Map Sensor..............1

S118 Near T/O for Map Sensor..............1

S119 Near Distributor T/O..................1

S120 Between Distributor T/O and Underhood

Lamp T/O.......................1

S121 Between Distributor T/O and Underhood

Lamp T/O.......................1

S122 Between Distributor T/O and Underhood

Lamp T/O.......................1

S123 RT Side of Cowl Panel................1

S124 RT Side of Cowl Panel................1

S125 Near T/O for PDC...................1

S126 Near T/O for Oil Pressure Switch..........5

S127 Near Generator T/O..................5

S128 LT Side of Grille Panel................3

S129 LT Side of Grille Panel................3

S130 Center of Grille Panel.................3

S201 Near Body Harness Connector T/O.........6

S202 Near Body Harness Connector T/O.........6

S203 Near Body Harness Connector T/O.........6

S204 Near Relay Center...................6

S205 Near T/O for Headlamp Switch...........6Splice

NumberLocations Fig.

S206 Near T/O for Telltale..................6

S207 Near T/O for Cluster..................6

S208 Near T/O for Cluster..................6

S209 Right Side of Cluster.................6

S210 Right Side of Cluster.................6

S211 Near Instrument Panel Ground T/O........6

S212 Near Wiper Switch T/O................6

S213 Near Antenna T/O...................7

S214 Near Blower Resistor T/O..............7

S215 Right Side of Instrument Panel...........7

S301 In Left Rear Door T/O.................8

S302 Near Left C-Pillar....................8

S303 Near Left C-Pillar....................8

S304 Near Left C-Pillar....................8

S305 Near Left C-Pillar....................8

S306 Near Left C-Pillar....................8

S307 Left Rear Wheel Well................10

S308 Left Rear Wheel Well................10

S309 Near Left Rear Door T/O...............8

S310 Near Left Rear Door T/O...............8

S311 Left Side of Floor Tunnel...............9

S312 Top of Floor Tunnel..................9

S313 In Power Mirror Switch T/O.............9

S314 Right A- Pillar.....................11

S315 Near RT Vanity Mirror T/O.............11

S316 Near RT Vanity Mirror T/O.............11

S317 In Trailer Tow Harness Near Grommet......14

S318 In Trailer Tow Harness Near Grommet......14

S319 In Liftgate.......................13

S320 Right A-Pillar.....................11

S321 In Left Front Door..................12

S401 In Left Rear Tail Lamp..........Not Shown

S402 In Right Rear Tail Lamp.........Not Shown

S403 In Left Rear Tail Lamp..........Not Shown

S404 In Right Rear Tail Lamp.........Not Shown

J8W-95 SPLICE LOCATIONSÐXJ VEHICLES 8W - 95 - 1

Page 858 of 2198

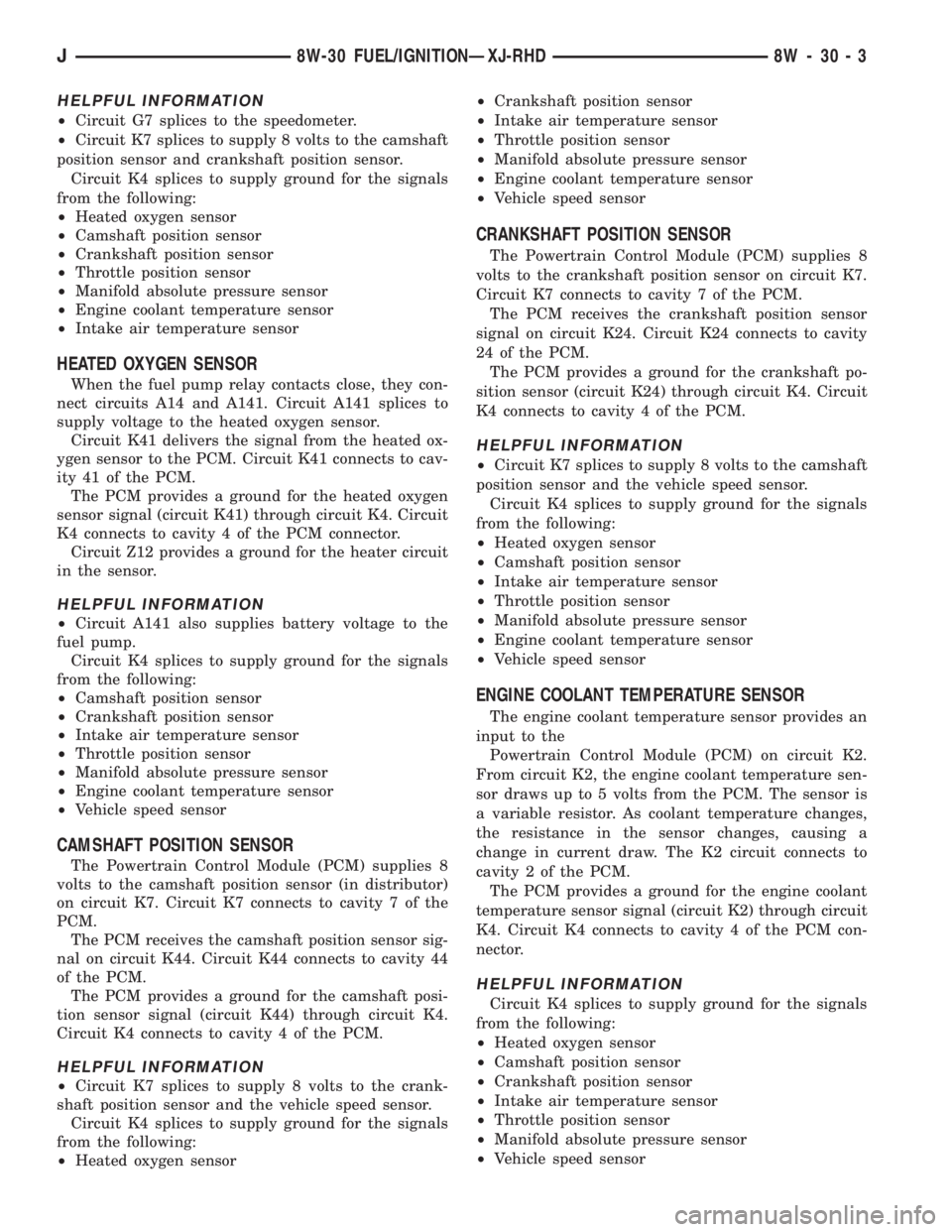

HELPFUL INFORMATION

²Circuit G7 splices to the speedometer.

²Circuit K7 splices to supply 8 volts to the camshaft

position sensor and crankshaft position sensor.

Circuit K4 splices to supply ground for the signals

from the following:

²Heated oxygen sensor

²Camshaft position sensor

²Crankshaft position sensor

²Throttle position sensor

²Manifold absolute pressure sensor

²Engine coolant temperature sensor

²Intake air temperature sensor

HEATED OXYGEN SENSOR

When the fuel pump relay contacts close, they con-

nect circuits A14 and A141. Circuit A141 splices to

supply voltage to the heated oxygen sensor.

Circuit K41 delivers the signal from the heated ox-

ygen sensor to the PCM. Circuit K41 connects to cav-

ity 41 of the PCM.

The PCM provides a ground for the heated oxygen

sensor signal (circuit K41) through circuit K4. Circuit

K4 connects to cavity 4 of the PCM connector.

Circuit Z12 provides a ground for the heater circuit

in the sensor.

HELPFUL INFORMATION

²Circuit A141 also supplies battery voltage to the

fuel pump.

Circuit K4 splices to supply ground for the signals

from the following:

²Camshaft position sensor

²Crankshaft position sensor

²Intake air temperature sensor

²Throttle position sensor

²Manifold absolute pressure sensor

²Engine coolant temperature sensor

²Vehicle speed sensor

CAMSHAFT POSITION SENSOR

The Powertrain Control Module (PCM) supplies 8

volts to the camshaft position sensor (in distributor)

on circuit K7. Circuit K7 connects to cavity 7 of the

PCM.

The PCM receives the camshaft position sensor sig-

nal on circuit K44. Circuit K44 connects to cavity 44

of the PCM.

The PCM provides a ground for the camshaft posi-

tion sensor signal (circuit K44) through circuit K4.

Circuit K4 connects to cavity 4 of the PCM.

HELPFUL INFORMATION

²Circuit K7 splices to supply 8 volts to the crank-

shaft position sensor and the vehicle speed sensor.

Circuit K4 splices to supply ground for the signals

from the following:

²Heated oxygen sensor²Crankshaft position sensor

²Intake air temperature sensor

²Throttle position sensor

²Manifold absolute pressure sensor

²Engine coolant temperature sensor

²Vehicle speed sensor

CRANKSHAFT POSITION SENSOR

The Powertrain Control Module (PCM) supplies 8

volts to the crankshaft position sensor on circuit K7.

Circuit K7 connects to cavity 7 of the PCM.

The PCM receives the crankshaft position sensor

signal on circuit K24. Circuit K24 connects to cavity

24 of the PCM.

The PCM provides a ground for the crankshaft po-

sition sensor (circuit K24) through circuit K4. Circuit

K4 connects to cavity 4 of the PCM.

HELPFUL INFORMATION

²Circuit K7 splices to supply 8 volts to the camshaft

position sensor and the vehicle speed sensor.

Circuit K4 splices to supply ground for the signals

from the following:

²Heated oxygen sensor

²Camshaft position sensor

²Intake air temperature sensor

²Throttle position sensor

²Manifold absolute pressure sensor

²Engine coolant temperature sensor

²Vehicle speed sensor

ENGINE COOLANT TEMPERATURE SENSOR

The engine coolant temperature sensor provides an

input to the

Powertrain Control Module (PCM) on circuit K2.

From circuit K2, the engine coolant temperature sen-

sor draws up to 5 volts from the PCM. The sensor is

a variable resistor. As coolant temperature changes,

the resistance in the sensor changes, causing a

change in current draw. The K2 circuit connects to

cavity 2 of the PCM.

The PCM provides a ground for the engine coolant

temperature sensor signal (circuit K2) through circuit

K4. Circuit K4 connects to cavity 4 of the PCM con-

nector.

HELPFUL INFORMATION

Circuit K4 splices to supply ground for the signals

from the following:

²Heated oxygen sensor

²Camshaft position sensor

²Crankshaft position sensor

²Intake air temperature sensor

²Throttle position sensor

²Manifold absolute pressure sensor

²Vehicle speed sensor

J8W-30 FUEL/IGNITIONÐXJ-RHD 8W - 30 - 3

Page 860 of 2198

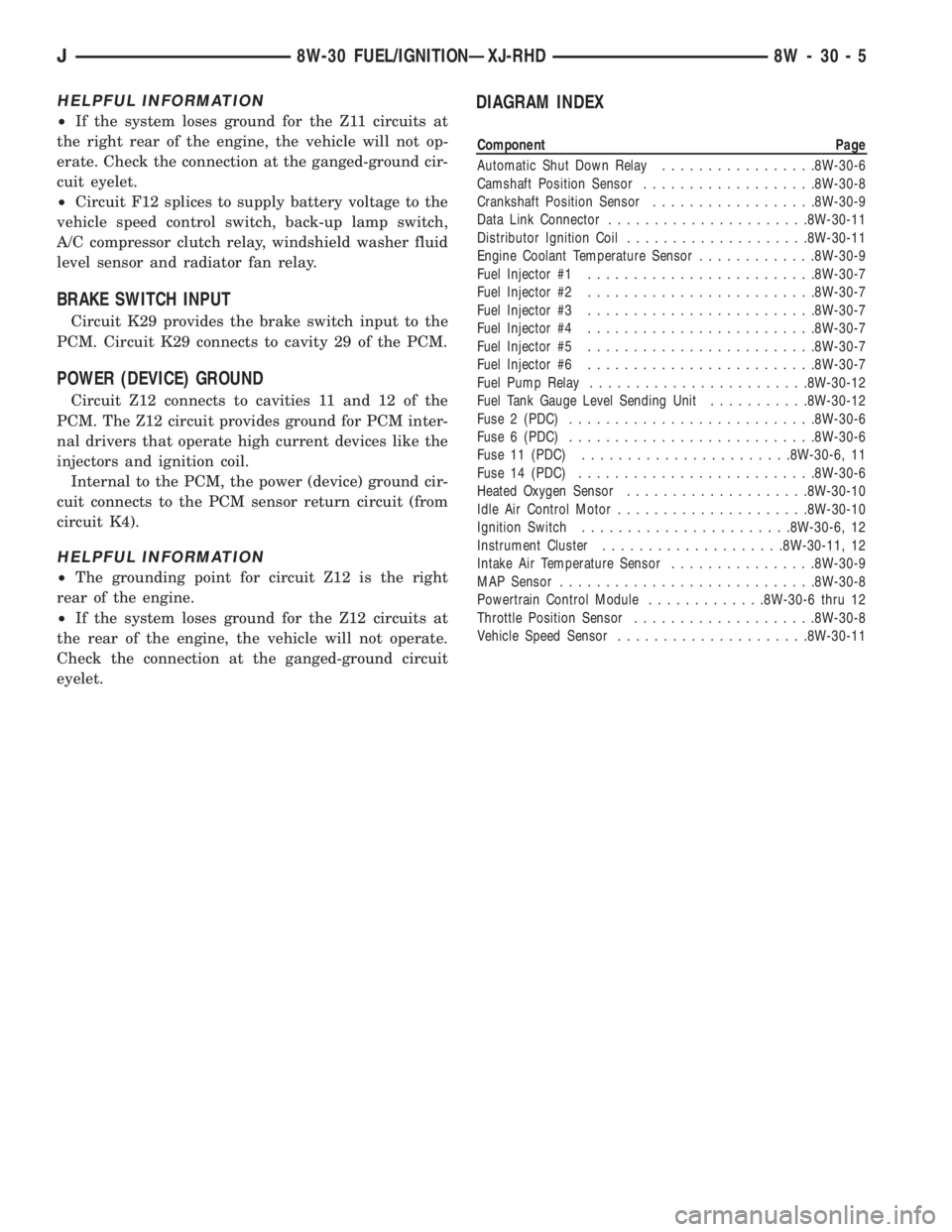

HELPFUL INFORMATION

²If the system loses ground for the Z11 circuits at

the right rear of the engine, the vehicle will not op-

erate. Check the connection at the ganged-ground cir-

cuit eyelet.

²Circuit F12 splices to supply battery voltage to the

vehicle speed control switch, back-up lamp switch,

A/C compressor clutch relay, windshield washer fluid

level sensor and radiator fan relay.

BRAKE SWITCH INPUT

Circuit K29 provides the brake switch input to the

PCM. Circuit K29 connects to cavity 29 of the PCM.

POWER (DEVICE) GROUND

Circuit Z12 connects to cavities 11 and 12 of the

PCM. The Z12 circuit provides ground for PCM inter-

nal drivers that operate high current devices like the

injectors and ignition coil.

Internal to the PCM, the power (device) ground cir-

cuit connects to the PCM sensor return circuit (from

circuit K4).

HELPFUL INFORMATION

²The grounding point for circuit Z12 is the right

rear of the engine.

²If the system loses ground for the Z12 circuits at

the rear of the engine, the vehicle will not operate.

Check the connection at the ganged-ground circuit

eyelet.

DIAGRAM INDEX

Component Page

Automatic Shut Down Relay.................8W-30-6

Camshaft Position Sensor...................8W-30-8

Crankshaft Position Sensor..................8W-30-9

Data Link Connector......................8W-30-11

Distributor Ignition Coil....................8W-30-11

Engine Coolant Temperature Sensor.............8W-30-9

Fuel Injector #1.........................8W-30-7

Fuel Injector #2.........................8W-30-7

Fuel Injector #3.........................8W-30-7

Fuel Injector #4.........................8W-30-7

Fuel Injector #5.........................8W-30-7

Fuel Injector #6.........................8W-30-7

Fuel Pump Relay........................8W-30-12

Fuel Tank Gauge Level Sending Unit...........8W-30-12

Fuse 2 (PDC)...........................8W-30-6

Fuse 6 (PDC)...........................8W-30-6

Fuse 11 (PDC).......................8W-30-6, 11

Fuse 14 (PDC)..........................8W-30-6

Heated Oxygen Sensor....................8W-30-10

Idle Air Control Motor.....................8W-30-10

Ignition Switch.......................8W-30-6, 12

Instrument Cluster....................8W-30-11, 12

Intake Air Temperature Sensor................8W-30-9

MAP Sensor............................8W-30-8

Powertrain Control Module.............8W-30-6 thru 12

Throttle Position Sensor....................8W-30-8

Vehicle Speed Sensor.....................8W-30-11

J8W-30 FUEL/IGNITIONÐXJ-RHD 8W - 30 - 5

Page 1064 of 2198

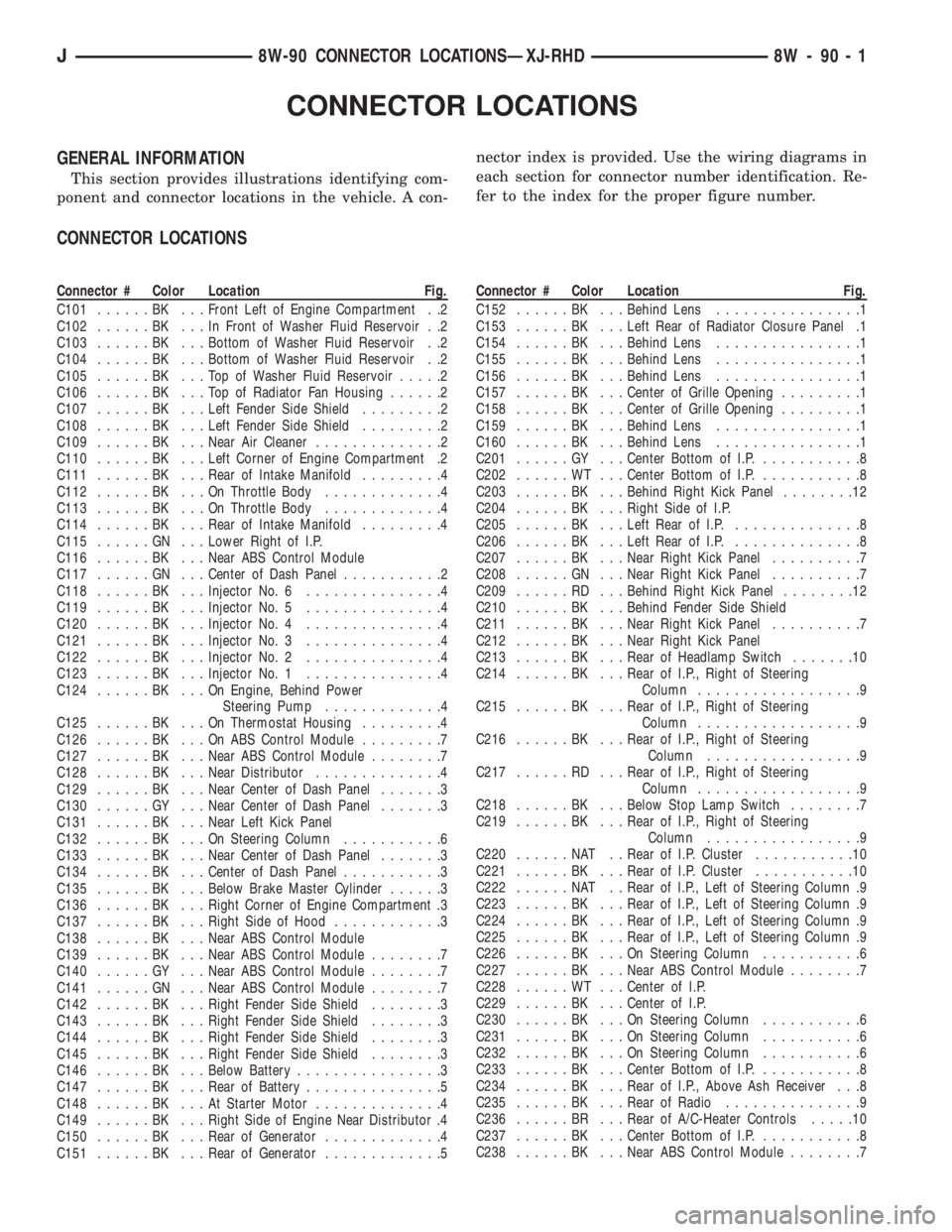

CONNECTOR LOCATIONS

GENERAL INFORMATION

This section provides illustrations identifying com-

ponent and connector locations in the vehicle. A con-nector index is provided. Use the wiring diagrams in

each section for connector number identification. Re-

fer to the index for the proper figure number.

CONNECTOR LOCATIONS

Connector # Color Location Fig.

C101......BK ...Front Left of Engine Compartment . .2

C102......BK ...InFront of Washer Fluid Reservoir . .2

C103......BK ...Bottom of Washer Fluid Reservoir . .2

C104......BK ...Bottom of Washer Fluid Reservoir . .2

C105......BK ...TopofWasher Fluid Reservoir.....2

C106......BK ...TopofRadiator Fan Housing......2

C107......BK ...Left Fender Side Shield.........2

C108......BK ...Left Fender Side Shield.........2

C109......BK ...Near Air Cleaner..............2

C110......BK ...Left Corner of Engine Compartment .2

C111......BK ...Rear of Intake Manifold.........4

C112......BK ...OnThrottle Body.............4

C113......BK ...OnThrottle Body.............4

C114......BK ...Rear of Intake Manifold.........4

C115......GN ...Lower Right of I.P.

C116......BK ...Near ABS Control Module

C117......GN ...Center of Dash Panel...........2

C118......BK ...Injector No. 6...............4

C119......BK ...Injector No. 5...............4

C120......BK ...Injector No. 4...............4

C121......BK ...Injector No. 3...............4

C122......BK ...Injector No. 2...............4

C123......BK ...Injector No. 1...............4

C124......BK ...OnEngine, Behind Power

Steering Pump.............4

C125......BK ...OnThermostat Housing.........4

C126......BK ...OnABSControl Module.........7

C127......BK ...Near ABS Control Module........7

C128......BK ...Near Distributor..............4

C129......BK ...Near Center of Dash Panel.......3

C130......GY ...Near Center of Dash Panel.......3

C131......BK ...Near Left Kick Panel

C132......BK ...OnSteering Column...........6

C133......BK ...Near Center of Dash Panel.......3

C134......BK ...Center of Dash Panel...........3

C135......BK ...Below Brake Master Cylinder......3

C136......BK ...Right Corner of Engine Compartment .3

C137......BK ...Right Side of Hood............3

C138......BK ...Near ABS Control Module

C139......BK ...Near ABS Control Module........7

C140......GY ...Near ABS Control Module........7

C141......GN ...Near ABS Control Module........7

C142......BK ...Right Fender Side Shield........3

C143......BK ...Right Fender Side Shield........3

C144......BK ...Right Fender Side Shield........3

C145......BK ...Right Fender Side Shield........3

C146......BK ...Below Battery................3

C147......BK ...Rear of Battery...............5

C148......BK ...AtStarter Motor..............4

C149......BK ...Right Side of Engine Near Distributor .4

C150......BK ...Rear of Generator.............4

C151......BK ...Rear of Generator.............5Connector # Color Location Fig.

C152......BK ...Behind Lens................1

C153......BK ...Left Rear of Radiator Closure Panel .1

C154......BK ...Behind Lens................1

C155......BK ...Behind Lens................1

C156......BK ...Behind Lens................1

C157......BK ...Center of Grille Opening.........1

C158......BK ...Center of Grille Opening.........1

C159......BK ...Behind Lens................1

C160......BK ...Behind Lens................1

C201......GY ...Center Bottom of I.P............8

C202......WT ...Center Bottom of I.P............8

C203......BK ...Behind Right Kick Panel........12

C204......BK ...Right Side of I.P.

C205......BK ...Left Rear of I.P...............8

C206......BK ...Left Rear of I.P...............8

C207......BK ...Near Right Kick Panel..........7

C208......GN ...Near Right Kick Panel..........7

C209......RD ...Behind Right Kick Panel........12

C210......BK ...Behind Fender Side Shield

C211......BK ...Near Right Kick Panel..........7

C212......BK ...Near Right Kick Panel

C213......BK ...Rear of Headlamp Switch.......10

C214......BK ...Rear of I.P., Right of Steering

Column..................9

C215......BK ...Rear of I.P., Right of Steering

Column..................9

C216......BK ...Rear of I.P., Right of Steering

Column.................9

C217......RD ...Rear of I.P., Right of Steering

Column..................9

C218......BK ...Below Stop Lamp Switch........7

C219......BK ...Rear of I.P., Right of Steering

Column.................9

C220......NAT ..Rear of I.P. Cluster...........10

C221......BK ...Rear of I.P. Cluster...........10

C222......NAT ..Rear of I.P., Left of Steering Column .9

C223......BK ...Rear of I.P., Left of Steering Column .9

C224......BK ...Rear of I.P., Left of Steering Column .9

C225......BK ...Rear of I.P., Left of Steering Column .9

C226......BK ...OnSteering Column...........6

C227......BK ...Near ABS Control Module........7

C228......WT ...Center of I.P.

C229......BK ...Center of I.P.

C230......BK ...OnSteering Column...........6

C231......BK ...OnSteering Column...........6

C232......BK ...OnSteering Column...........6

C233......BK ...Center Bottom of I.P............8

C234......BK ...Rear of I.P., Above Ash Receiver . . .8

C235......BK ...Rear of Radio...............9

C236......BR ...Rear of A/C-Heater Controls.....10

C237......BK ...Center Bottom of I.P............8

C238......BK ...Near ABS Control Module........7

J8W-90 CONNECTOR LOCATIONSÐXJ-RHD 8W - 90 - 1

Page 1093 of 2198

minutes). The use of a locating dowel is recom-

mended during assembly to prevent smearing the

material off location.

Mopar Gasket Maker should be applied sparingly

to one gasket surface. The sealant diameter should

be 1.00 mm (0.04 inch) or less. Be certain the mate-

rial surrounds each mounting hole. Excess material

can easily be wiped off. Components should be

torqued in place within 15 minutes. The use of a lo-

cating dowel is recommended during assembly to pre-

vent smearing the material off location.

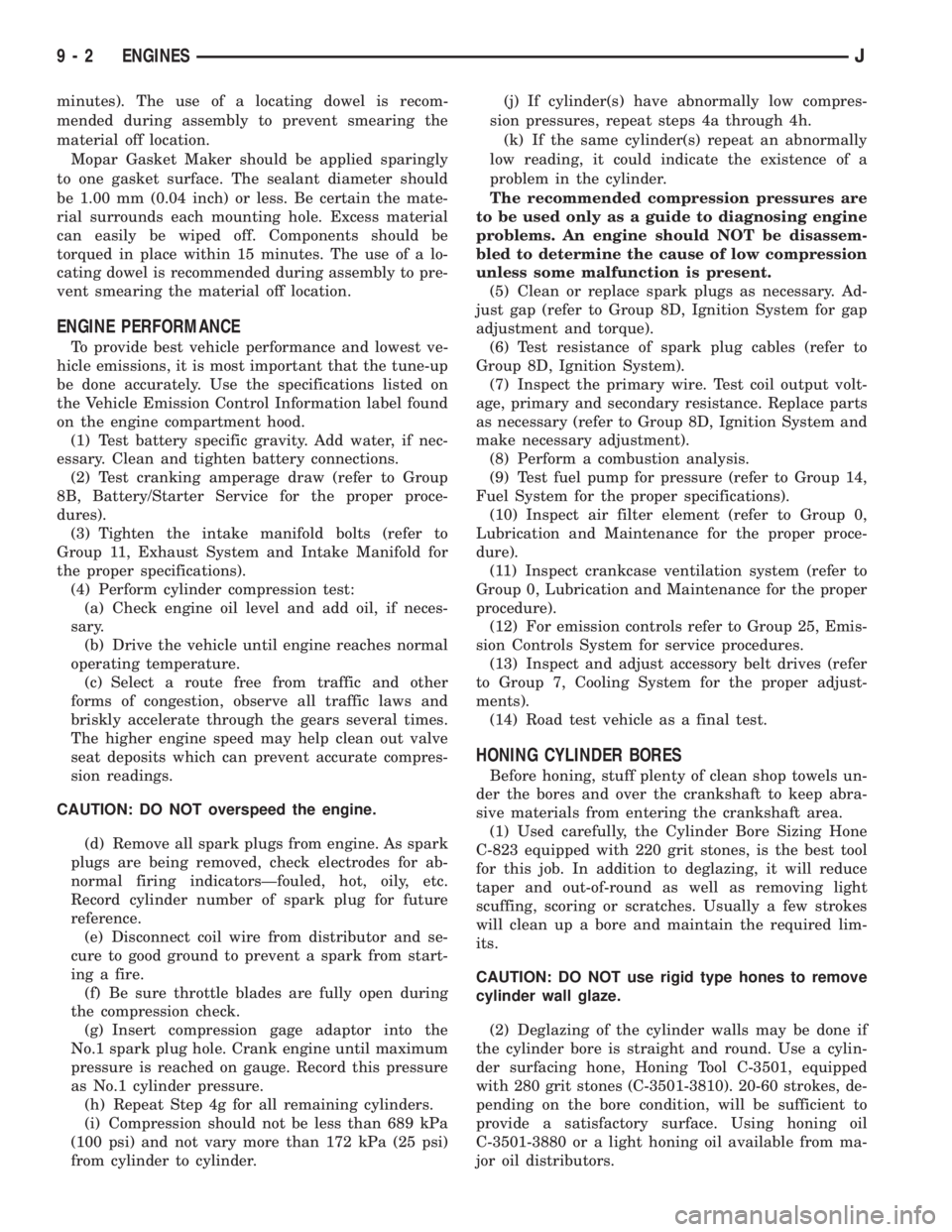

ENGINE PERFORMANCE

To provide best vehicle performance and lowest ve-

hicle emissions, it is most important that the tune-up

be done accurately. Use the specifications listed on

the Vehicle Emission Control Information label found

on the engine compartment hood.

(1) Test battery specific gravity. Add water, if nec-

essary. Clean and tighten battery connections.

(2) Test cranking amperage draw (refer to Group

8B, Battery/Starter Service for the proper proce-

dures).

(3) Tighten the intake manifold bolts (refer to

Group 11, Exhaust System and Intake Manifold for

the proper specifications).

(4) Perform cylinder compression test:

(a) Check engine oil level and add oil, if neces-

sary.

(b) Drive the vehicle until engine reaches normal

operating temperature.

(c) Select a route free from traffic and other

forms of congestion, observe all traffic laws and

briskly accelerate through the gears several times.

The higher engine speed may help clean out valve

seat deposits which can prevent accurate compres-

sion readings.

CAUTION: DO NOT overspeed the engine.

(d) Remove all spark plugs from engine. As spark

plugs are being removed, check electrodes for ab-

normal firing indicatorsÐfouled, hot, oily, etc.

Record cylinder number of spark plug for future

reference.

(e) Disconnect coil wire from distributor and se-

cure to good ground to prevent a spark from start-

ing a fire.

(f) Be sure throttle blades are fully open during

the compression check.

(g) Insert compression gage adaptor into the

No.1 spark plug hole. Crank engine until maximum

pressure is reached on gauge. Record this pressure

as No.1 cylinder pressure.

(h) Repeat Step 4g for all remaining cylinders.

(i) Compression should not be less than 689 kPa

(100 psi) and not vary more than 172 kPa (25 psi)

from cylinder to cylinder.(j) If cylinder(s) have abnormally low compres-

sion pressures, repeat steps 4a through 4h.

(k) If the same cylinder(s) repeat an abnormally

low reading, it could indicate the existence of a

problem in the cylinder.

The recommended compression pressures are

to be used only as a guide to diagnosing engine

problems. An engine should NOT be disassem-

bled to determine the cause of low compression

unless some malfunction is present.

(5) Clean or replace spark plugs as necessary. Ad-

just gap (refer to Group 8D, Ignition System for gap

adjustment and torque).

(6) Test resistance of spark plug cables (refer to

Group 8D, Ignition System).

(7) Inspect the primary wire. Test coil output volt-

age, primary and secondary resistance. Replace parts

as necessary (refer to Group 8D, Ignition System and

make necessary adjustment).

(8) Perform a combustion analysis.

(9) Test fuel pump for pressure (refer to Group 14,

Fuel System for the proper specifications).

(10) Inspect air filter element (refer to Group 0,

Lubrication and Maintenance for the proper proce-

dure).

(11) Inspect crankcase ventilation system (refer to

Group 0, Lubrication and Maintenance for the proper

procedure).

(12) For emission controls refer to Group 25, Emis-

sion Controls System for service procedures.

(13) Inspect and adjust accessory belt drives (refer

to Group 7, Cooling System for the proper adjust-

ments).

(14) Road test vehicle as a final test.

HONING CYLINDER BORES

Before honing, stuff plenty of clean shop towels un-

der the bores and over the crankshaft to keep abra-

sive materials from entering the crankshaft area.

(1) Used carefully, the Cylinder Bore Sizing Hone

C-823 equipped with 220 grit stones, is the best tool

for this job. In addition to deglazing, it will reduce

taper and out-of-round as well as removing light

scuffing, scoring or scratches. Usually a few strokes

will clean up a bore and maintain the required lim-

its.

CAUTION: DO NOT use rigid type hones to remove

cylinder wall glaze.

(2) Deglazing of the cylinder walls may be done if

the cylinder bore is straight and round. Use a cylin-

der surfacing hone, Honing Tool C-3501, equipped

with 280 grit stones (C-3501-3810). 20-60 strokes, de-

pending on the bore condition, will be sufficient to

provide a satisfactory surface. Using honing oil

C-3501-3880 or a light honing oil available from ma-

jor oil distributors.

9 - 2 ENGINESJ

Page 1097 of 2198

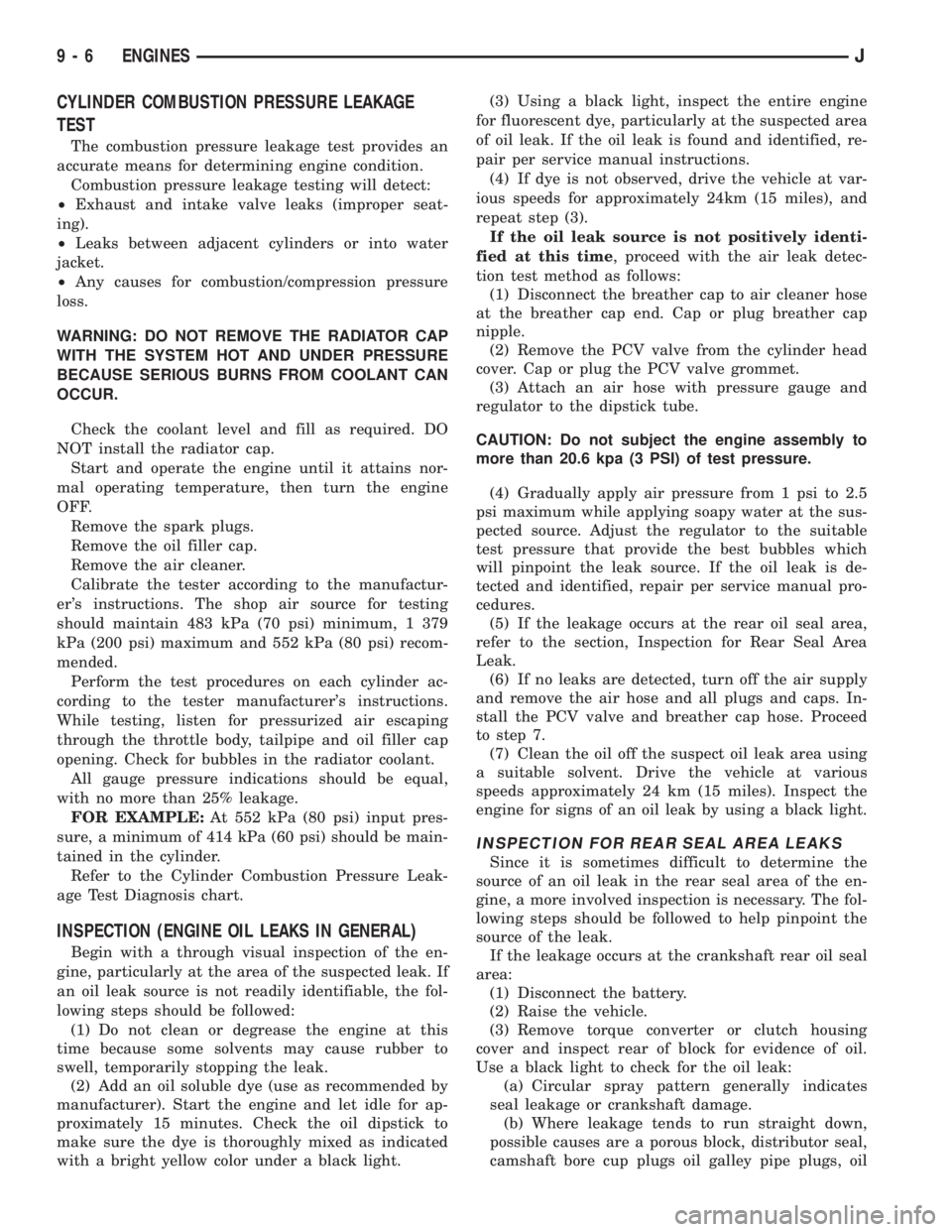

CYLINDER COMBUSTION PRESSURE LEAKAGE

TEST

The combustion pressure leakage test provides an

accurate means for determining engine condition.

Combustion pressure leakage testing will detect:

²Exhaust and intake valve leaks (improper seat-

ing).

²Leaks between adjacent cylinders or into water

jacket.

²Any causes for combustion/compression pressure

loss.

WARNING: DO NOT REMOVE THE RADIATOR CAP

WITH THE SYSTEM HOT AND UNDER PRESSURE

BECAUSE SERIOUS BURNS FROM COOLANT CAN

OCCUR.

Check the coolant level and fill as required. DO

NOT install the radiator cap.

Start and operate the engine until it attains nor-

mal operating temperature, then turn the engine

OFF.

Remove the spark plugs.

Remove the oil filler cap.

Remove the air cleaner.

Calibrate the tester according to the manufactur-

er's instructions. The shop air source for testing

should maintain 483 kPa (70 psi) minimum, 1 379

kPa (200 psi) maximum and 552 kPa (80 psi) recom-

mended.

Perform the test procedures on each cylinder ac-

cording to the tester manufacturer's instructions.

While testing, listen for pressurized air escaping

through the throttle body, tailpipe and oil filler cap

opening. Check for bubbles in the radiator coolant.

All gauge pressure indications should be equal,

with no more than 25% leakage.

FOR EXAMPLE:At 552 kPa (80 psi) input pres-

sure, a minimum of 414 kPa (60 psi) should be main-

tained in the cylinder.

Refer to the Cylinder Combustion Pressure Leak-

age Test Diagnosis chart.

INSPECTION (ENGINE OIL LEAKS IN GENERAL)

Begin with a through visual inspection of the en-

gine, particularly at the area of the suspected leak. If

an oil leak source is not readily identifiable, the fol-

lowing steps should be followed:

(1) Do not clean or degrease the engine at this

time because some solvents may cause rubber to

swell, temporarily stopping the leak.

(2) Add an oil soluble dye (use as recommended by

manufacturer). Start the engine and let idle for ap-

proximately 15 minutes. Check the oil dipstick to

make sure the dye is thoroughly mixed as indicated

with a bright yellow color under a black light.(3) Using a black light, inspect the entire engine

for fluorescent dye, particularly at the suspected area

of oil leak. If the oil leak is found and identified, re-

pair per service manual instructions.

(4) If dye is not observed, drive the vehicle at var-

ious speeds for approximately 24km (15 miles), and

repeat step (3).

If the oil leak source is not positively identi-

fied at this time, proceed with the air leak detec-

tion test method as follows:

(1) Disconnect the breather cap to air cleaner hose

at the breather cap end. Cap or plug breather cap

nipple.

(2) Remove the PCV valve from the cylinder head

cover. Cap or plug the PCV valve grommet.

(3) Attach an air hose with pressure gauge and

regulator to the dipstick tube.

CAUTION: Do not subject the engine assembly to

more than 20.6 kpa (3 PSI) of test pressure.

(4) Gradually apply air pressure from 1 psi to 2.5

psi maximum while applying soapy water at the sus-

pected source. Adjust the regulator to the suitable

test pressure that provide the best bubbles which

will pinpoint the leak source. If the oil leak is de-

tected and identified, repair per service manual pro-

cedures.

(5) If the leakage occurs at the rear oil seal area,

refer to the section, Inspection for Rear Seal Area

Leak.

(6) If no leaks are detected, turn off the air supply

and remove the air hose and all plugs and caps. In-

stall the PCV valve and breather cap hose. Proceed

to step 7.

(7) Clean the oil off the suspect oil leak area using

a suitable solvent. Drive the vehicle at various

speeds approximately 24 km (15 miles). Inspect the

engine for signs of an oil leak by using a black light.

INSPECTION FOR REAR SEAL AREA LEAKS

Since it is sometimes difficult to determine the

source of an oil leak in the rear seal area of the en-

gine, a more involved inspection is necessary. The fol-

lowing steps should be followed to help pinpoint the

source of the leak.

If the leakage occurs at the crankshaft rear oil seal

area:

(1) Disconnect the battery.

(2) Raise the vehicle.

(3) Remove torque converter or clutch housing

cover and inspect rear of block for evidence of oil.

Use a black light to check for the oil leak:

(a) Circular spray pattern generally indicates

seal leakage or crankshaft damage.

(b) Where leakage tends to run straight down,

possible causes are a porous block, distributor seal,

camshaft bore cup plugs oil galley pipe plugs, oil

9 - 6 ENGINESJ

Page 1105 of 2198

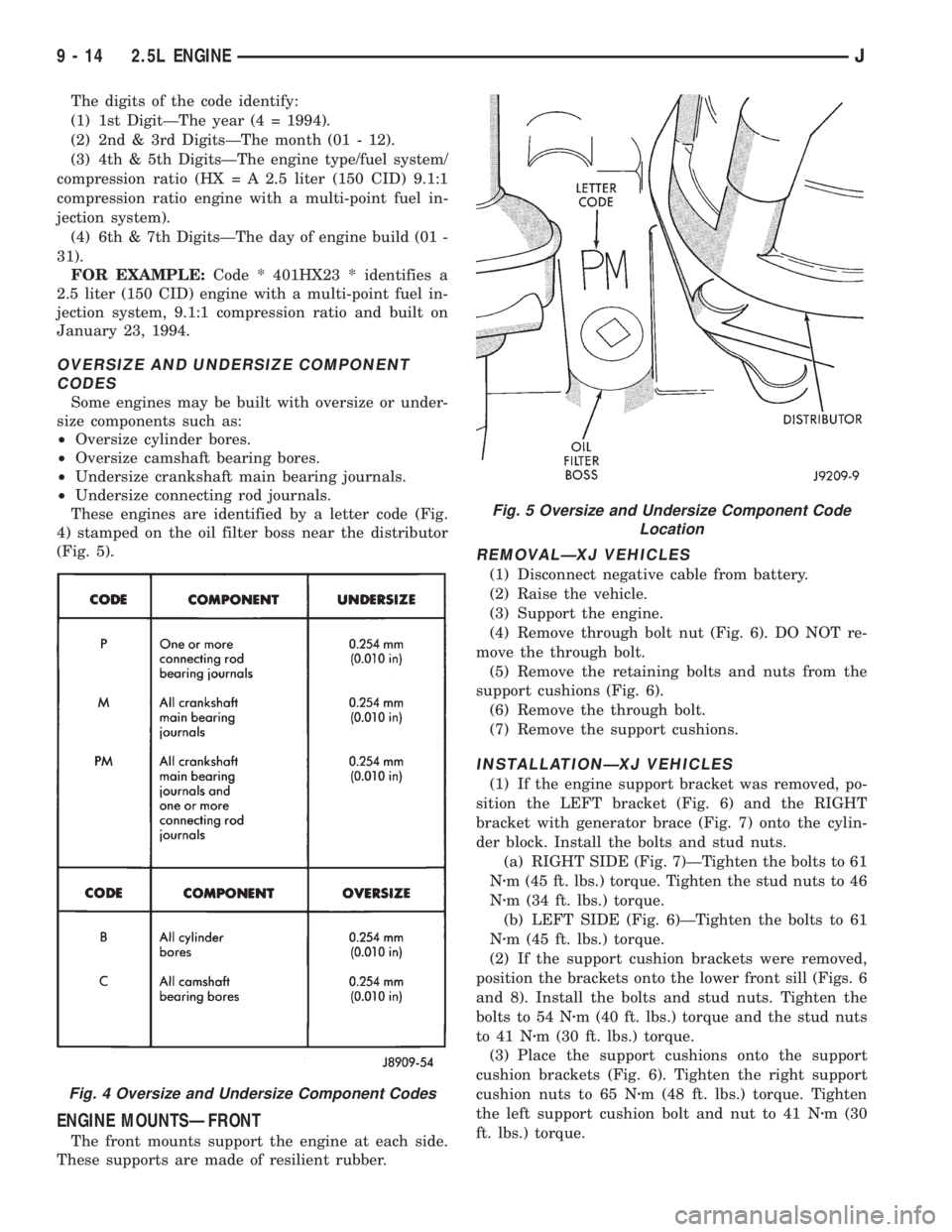

The digits of the code identify:

(1) 1st DigitÐThe year (4 = 1994).

(2) 2nd & 3rd DigitsÐThe month (01 - 12).

(3) 4th & 5th DigitsÐThe engine type/fuel system/

compression ratio (HX = A 2.5 liter (150 CID) 9.1:1

compression ratio engine with a multi-point fuel in-

jection system).

(4) 6th & 7th DigitsÐThe day of engine build (01 -

31).

FOR EXAMPLE:Code * 401HX23 * identifies a

2.5 liter (150 CID) engine with a multi-point fuel in-

jection system, 9.1:1 compression ratio and built on

January 23, 1994.

OVERSIZE AND UNDERSIZE COMPONENT

CODES

Some engines may be built with oversize or under-

size components such as:

²Oversize cylinder bores.

²Oversize camshaft bearing bores.

²Undersize crankshaft main bearing journals.

²Undersize connecting rod journals.

These engines are identified by a letter code (Fig.

4) stamped on the oil filter boss near the distributor

(Fig. 5).

ENGINE MOUNTSÐFRONT

The front mounts support the engine at each side.

These supports are made of resilient rubber.

REMOVALÐXJ VEHICLES

(1) Disconnect negative cable from battery.

(2) Raise the vehicle.

(3) Support the engine.

(4) Remove through bolt nut (Fig. 6). DO NOT re-

move the through bolt.

(5) Remove the retaining bolts and nuts from the

support cushions (Fig. 6).

(6) Remove the through bolt.

(7) Remove the support cushions.

INSTALLATIONÐXJ VEHICLES

(1) If the engine support bracket was removed, po-

sition the LEFT bracket (Fig. 6) and the RIGHT

bracket with generator brace (Fig. 7) onto the cylin-

der block. Install the bolts and stud nuts.

(a) RIGHT SIDE (Fig. 7)ÐTighten the bolts to 61

Nzm (45 ft. lbs.) torque. Tighten the stud nuts to 46

Nzm (34 ft. lbs.) torque.

(b) LEFT SIDE (Fig. 6)ÐTighten the bolts to 61

Nzm (45 ft. lbs.) torque.

(2) If the support cushion brackets were removed,

position the brackets onto the lower front sill (Figs. 6

and 8). Install the bolts and stud nuts. Tighten the

bolts to 54 Nzm (40 ft. lbs.) torque and the stud nuts

to 41 Nzm (30 ft. lbs.) torque.

(3) Place the support cushions onto the support

cushion brackets (Fig. 6). Tighten the right support

cushion nuts to 65 Nzm (48 ft. lbs.) torque. Tighten

the left support cushion bolt and nut to 41 Nzm (30

ft. lbs.) torque.

Fig. 4 Oversize and Undersize Component Codes

Fig. 5 Oversize and Undersize Component Code

Location

9 - 14 2.5L ENGINEJ

Page 1111 of 2198

(a) Align the transmission torque converter hous-

ing with the engine.

(b) Loosely install the converter housing lower

bolts and install the next higher bolt and nut on

each side.

(c) Tighten all 4 bolts finger-tight.

(5) Install the engine support cushions (if re-

moved).

(6) Lower the engine and engine support cushions

onto the engine compartment brackets.

(7) Remove the engine lifting device.

(8) Raise the vehicle.

(9) If equipped with an automatic transmission:

(a) Install the converter-to-drive plate bolts. En-

sure the installation reference marks are aligned.

Tighten the bolts to 54 Nzm (40 ft. lbs.) torque.

(b) Install the converter-housing access cover.

(c) Install the exhaust pipe support.

(10) Install the remaining converter or flywheel

housing bolts.

(11) Install the starter motor and connect the ca-

ble. Tighten the bolts to 45 Nzm (33 ft. lbs.) torque.

(12) Tighten the engine support cushing through-

bolt nuts.

(13) Install the remaining flywheel and converter

housing bolts. Tighten the bolts to 38 Nzm (28 ft. lbs.)

torque.

(14) Connect the exhaust pipe to the manifold.

(15) Install the oil filter.

(16) Lower the vehicle.

(17) Connect the coolant hoses and tighten the

clamps.

(18) If equipped with power steering:

(a) Remove the protective caps

(b) Connect the hoses to the fittings at the steer-

ing gear. Tighten the nut to 52 Nzm (38 ft. lbs.)

torque.

(c) Fill the pump reservoir with fluid.

(19) Remove the pulley-to-water pump flange

alignment capscrew and install the fan and spacer or

Tempatrol fan assembly.

(20) Install the fan shroud and radiator and con-

denser (if equipped with air conditioning).

(21) Connect the radiator hoses.

(22) Connect the automatic transmission fluid

cooler pipes, if equipped.

(23) Connect the oxygen sensor wire connector.

(24) Connect the throttle valve rod and retainer.

Connect the throttle cable and install the rod. Install

the throttle valve rod spring.

(25) Connect the speed control cable, if equipped.

(26) Connect the fuel supply and return lines to

the throttle body.

(27) Connect all the vacuum hoses and wire con-

nectors.

(28) Connect the service valves to the A/C compres-

sor ports, if equipped with air conditioning.(29) Fill the power steering reservoir.

(30) Connect the battery cables.

(31) Install the hood.

(32) Install the air cleaner.

(33) Start the engine and inspect for leaks.

(34) Fill the cooling system.

(35) Stop the engine and check the fluid levels.

Add fluid, as required.

ENGINE ASSEMBLYÐYJ VEHICLES

REMOVAL

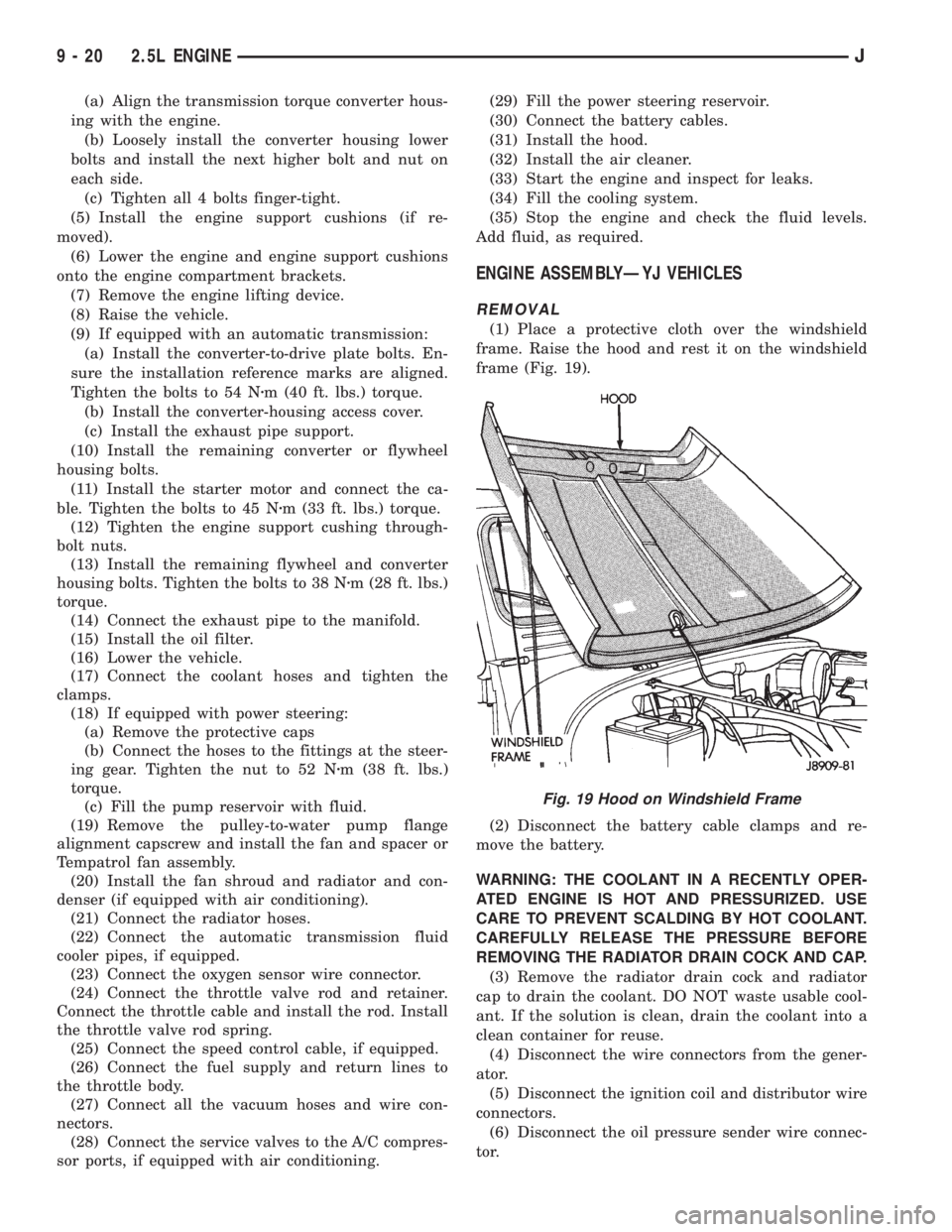

(1) Place a protective cloth over the windshield

frame. Raise the hood and rest it on the windshield

frame (Fig. 19).

(2) Disconnect the battery cable clamps and re-

move the battery.

WARNING: THE COOLANT IN A RECENTLY OPER-

ATED ENGINE IS HOT AND PRESSURIZED. USE

CARE TO PREVENT SCALDING BY HOT COOLANT.

CAREFULLY RELEASE THE PRESSURE BEFORE

REMOVING THE RADIATOR DRAIN COCK AND CAP.

(3) Remove the radiator drain cock and radiator

cap to drain the coolant. DO NOT waste usable cool-

ant. If the solution is clean, drain the coolant into a

clean container for reuse.

(4) Disconnect the wire connectors from the gener-

ator.

(5) Disconnect the ignition coil and distributor wire

connectors.

(6) Disconnect the oil pressure sender wire connec-

tor.

Fig. 19 Hood on Windshield Frame

9 - 20 2.5L ENGINEJ

Page 1124 of 2198

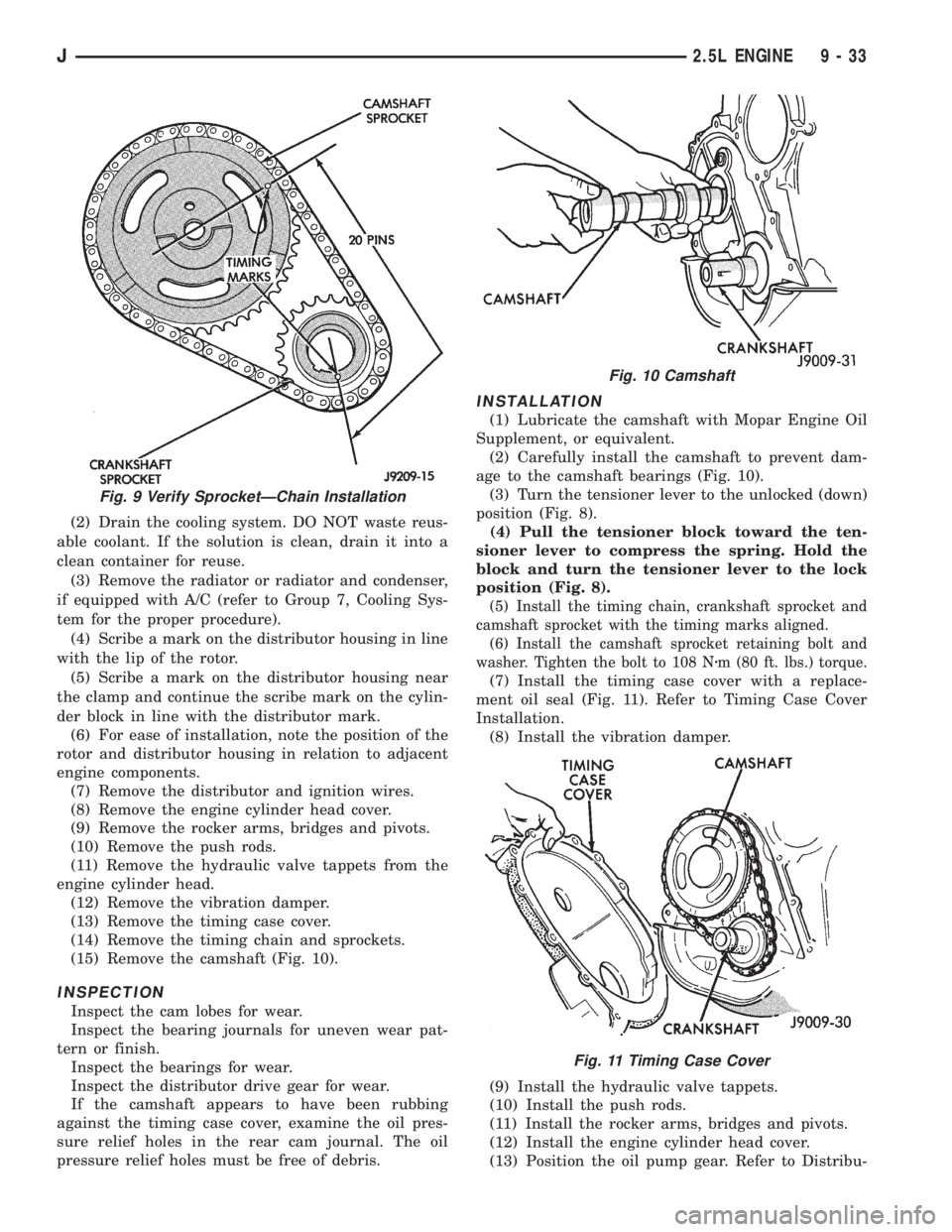

(2) Drain the cooling system. DO NOT waste reus-

able coolant. If the solution is clean, drain it into a

clean container for reuse.

(3) Remove the radiator or radiator and condenser,

if equipped with A/C (refer to Group 7, Cooling Sys-

tem for the proper procedure).

(4) Scribe a mark on the distributor housing in line

with the lip of the rotor.

(5) Scribe a mark on the distributor housing near

the clamp and continue the scribe mark on the cylin-

der block in line with the distributor mark.

(6) For ease of installation, note the position of the

rotor and distributor housing in relation to adjacent

engine components.

(7) Remove the distributor and ignition wires.

(8) Remove the engine cylinder head cover.

(9) Remove the rocker arms, bridges and pivots.

(10) Remove the push rods.

(11) Remove the hydraulic valve tappets from the

engine cylinder head.

(12) Remove the vibration damper.

(13) Remove the timing case cover.

(14) Remove the timing chain and sprockets.

(15) Remove the camshaft (Fig. 10).

INSPECTION

Inspect the cam lobes for wear.

Inspect the bearing journals for uneven wear pat-

tern or finish.

Inspect the bearings for wear.

Inspect the distributor drive gear for wear.

If the camshaft appears to have been rubbing

against the timing case cover, examine the oil pres-

sure relief holes in the rear cam journal. The oil

pressure relief holes must be free of debris.

INSTALLATION

(1) Lubricate the camshaft with Mopar Engine Oil

Supplement, or equivalent.

(2) Carefully install the camshaft to prevent dam-

age to the camshaft bearings (Fig. 10).

(3) Turn the tensioner lever to the unlocked (down)

position (Fig. 8).

(4) Pull the tensioner block toward the ten-

sioner lever to compress the spring. Hold the

block and turn the tensioner lever to the lock

position (Fig. 8).

(5) Install the timing chain, crankshaft sprocket and

camshaft sprocket with the timing marks aligned.

(6) Install the camshaft sprocket retaining bolt and

washer. Tighten the bolt to 108 Nzm (80 ft. lbs.) torque.

(7) Install the timing case cover with a replace-

ment oil seal (Fig. 11). Refer to Timing Case Cover

Installation.

(8) Install the vibration damper.

(9) Install the hydraulic valve tappets.

(10) Install the push rods.

(11) Install the rocker arms, bridges and pivots.

(12) Install the engine cylinder head cover.

(13) Position the oil pump gear. Refer to Distribu-

Fig. 9 Verify SprocketÐChain Installation

Fig. 10 Camshaft

Fig. 11 Timing Case Cover

J2.5L ENGINE 9 - 33