ECO mode JEEP CHEROKEE 1995 Service Manual PDF

[x] Cancel search | Manufacturer: JEEP, Model Year: 1995, Model line: CHEROKEE, Model: JEEP CHEROKEE 1995Pages: 2198, PDF Size: 82.83 MB

Page 1661 of 2198

OPERATING RANGES

NP231 operating ranges are: 2-wheel drive high;

4-wheel drive high and 4-wheel drive low.

2-wheel drive range is for use on all road surfaces.

The 4-wheel drive high and low ranges are undiffer-

entiated and should only be used on unpaved, low

traction surfaces only. The only exception being when

hard surface roads are snow and ice covered.

SHIFT MECHANISM

Operating ranges are selected with a floor mounted

shift lever. The shift lever is connected to the trans-

fer case range lever by an adjustable linkage rod. A

straight line shift pattern is used. Range positions

are marked on the shifter bezel cover plate, or on the

shift knob.

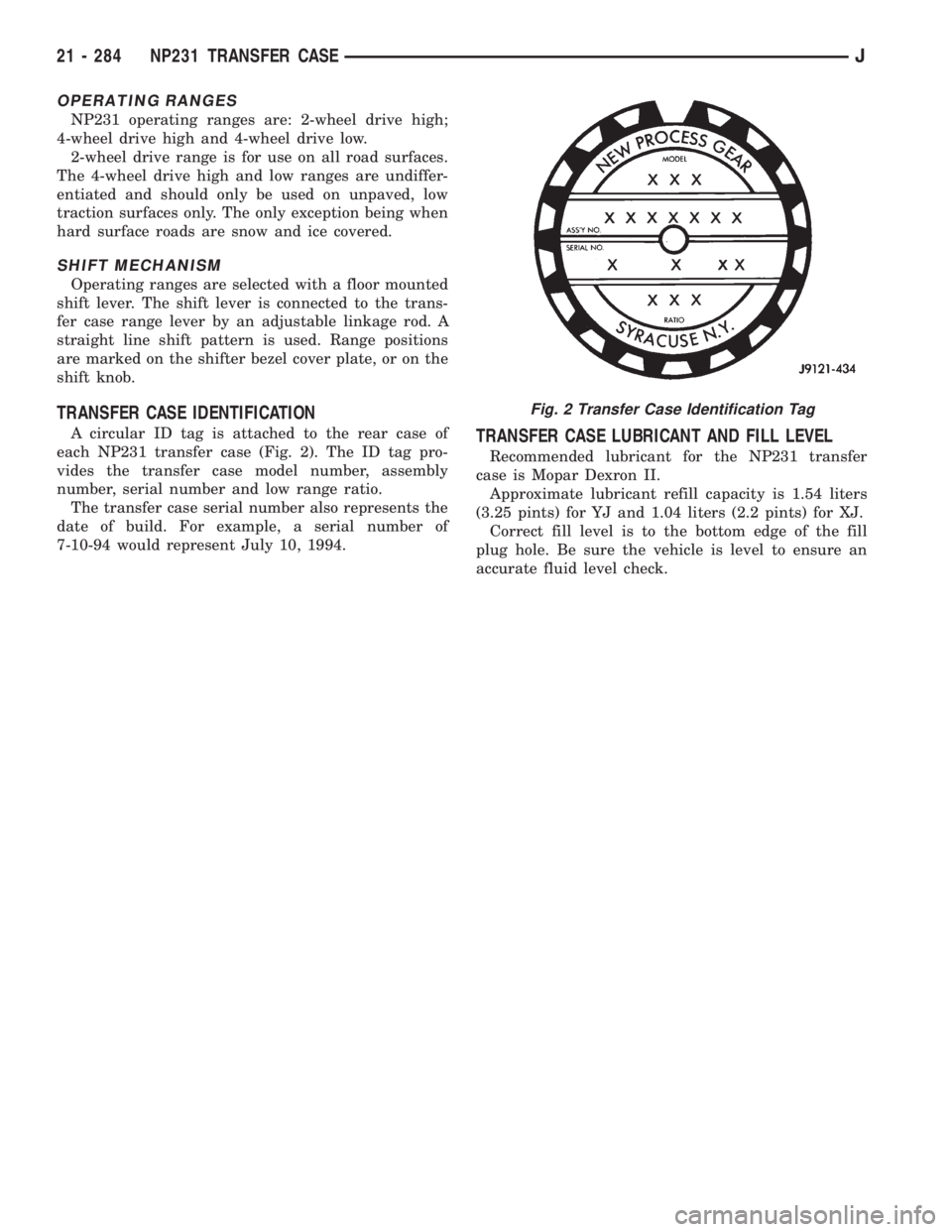

TRANSFER CASE IDENTIFICATION

A circular ID tag is attached to the rear case of

each NP231 transfer case (Fig. 2). The ID tag pro-

vides the transfer case model number, assembly

number, serial number and low range ratio.

The transfer case serial number also represents the

date of build. For example, a serial number of

7-10-94 would represent July 10, 1994.TRANSFER CASE LUBRICANT AND FILL LEVEL

Recommended lubricant for the NP231 transfer

case is Mopar Dexron II.

Approximate lubricant refill capacity is 1.54 liters

(3.25 pints) for YJ and 1.04 liters (2.2 pints) for XJ.

Correct fill level is to the bottom edge of the fill

plug hole. Be sure the vehicle is level to ensure an

accurate fluid level check.

Fig. 2 Transfer Case Identification Tag

21 - 284 NP231 TRANSFER CASEJ

Page 1671 of 2198

OVERHAUL CLEANING AND INSPECTION

Clean the transfer case components thoroughly

with solvent. Remove all traces of sealer from the

case and retainer seal surfaces.

Clean the oil pickup screen with solvent. Shake ex-

cess solvent from screen and allow it air dry. Use

compressed air to remove solvent residue from all oil

feed passages and channels in the case halves.

Inspect the splines and bearing surfaces on the

both shafts. Replace either shaft as necessary if wear,

or damage is evident.

Check condition of the shift forks, fork pads and

shift rail. Minor scratches/nicks on the rail can be

smoothed with 320/400 grit emery cloth. Replace the

mode fork pads if worn. Replace the range fork if the

pads are worn, missing, or damaged.

On synchro equipped models, inspect the synchro

sleeve, hub, struts, springs, and the stop ring. Re-

place worn, or damaged parts as necessary.

Do not attempt to salvage and reuse snap rings

that were bent, or distorted. It is recommended that

all snap rings be replaced during overhaul.Replace the front yoke nut as it should not be re-

used. Also replace the rubber seal if worn, cut, or

torn.

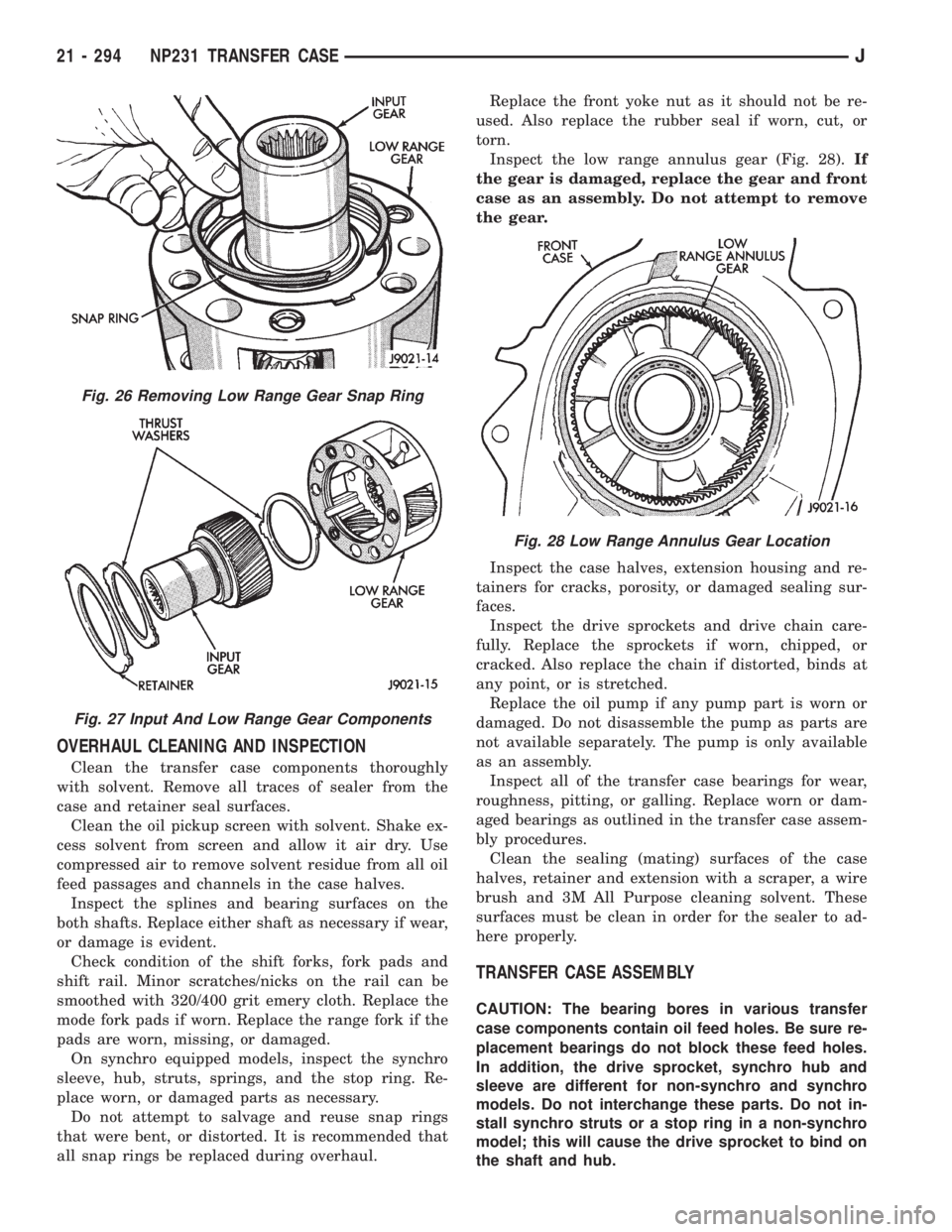

Inspect the low range annulus gear (Fig. 28).If

the gear is damaged, replace the gear and front

case as an assembly. Do not attempt to remove

the gear.

Inspect the case halves, extension housing and re-

tainers for cracks, porosity, or damaged sealing sur-

faces.

Inspect the drive sprockets and drive chain care-

fully. Replace the sprockets if worn, chipped, or

cracked. Also replace the chain if distorted, binds at

any point, or is stretched.

Replace the oil pump if any pump part is worn or

damaged. Do not disassemble the pump as parts are

not available separately. The pump is only available

as an assembly.

Inspect all of the transfer case bearings for wear,

roughness, pitting, or galling. Replace worn or dam-

aged bearings as outlined in the transfer case assem-

bly procedures.

Clean the sealing (mating) surfaces of the case

halves, retainer and extension with a scraper, a wire

brush and 3M All Purpose cleaning solvent. These

surfaces must be clean in order for the sealer to ad-

here properly.

TRANSFER CASE ASSEMBLY

CAUTION: The bearing bores in various transfer

case components contain oil feed holes. Be sure re-

placement bearings do not block these feed holes.

In addition, the drive sprocket, synchro hub and

sleeve are different for non-synchro and synchro

models. Do not interchange these parts. Do not in-

stall synchro struts or a stop ring in a non-synchro

model; this will cause the drive sprocket to bind on

the shaft and hub.

Fig. 26 Removing Low Range Gear Snap Ring

Fig. 27 Input And Low Range Gear Components

Fig. 28 Low Range Annulus Gear Location

21 - 294 NP231 TRANSFER CASEJ

Page 1684 of 2198

NP242 TRANSFER CASE

INDEX

page page

General Information....................... 307

Operating Ranges........................ 307

Overhaul Cleaning and Inspection............ 318

Recommended Lubricant/Capacity/Fill Level..... 307

Shift Lever Installation (XJ)................. 309

Shift Lever Removal (XJ)................... 309

Shift Linkage Adjustment................... 309

Shift Mechanism......................... 307Speedometer Service..................... 309

Transfer Case Assembly................... 319

Transfer Case Changes.................... 307

Transfer Case Disassembly and Overhaul...... 310

Transfer Case Identification................. 307

Transfer Case Installation.................. 309

Transfer Case Removal.................... 309

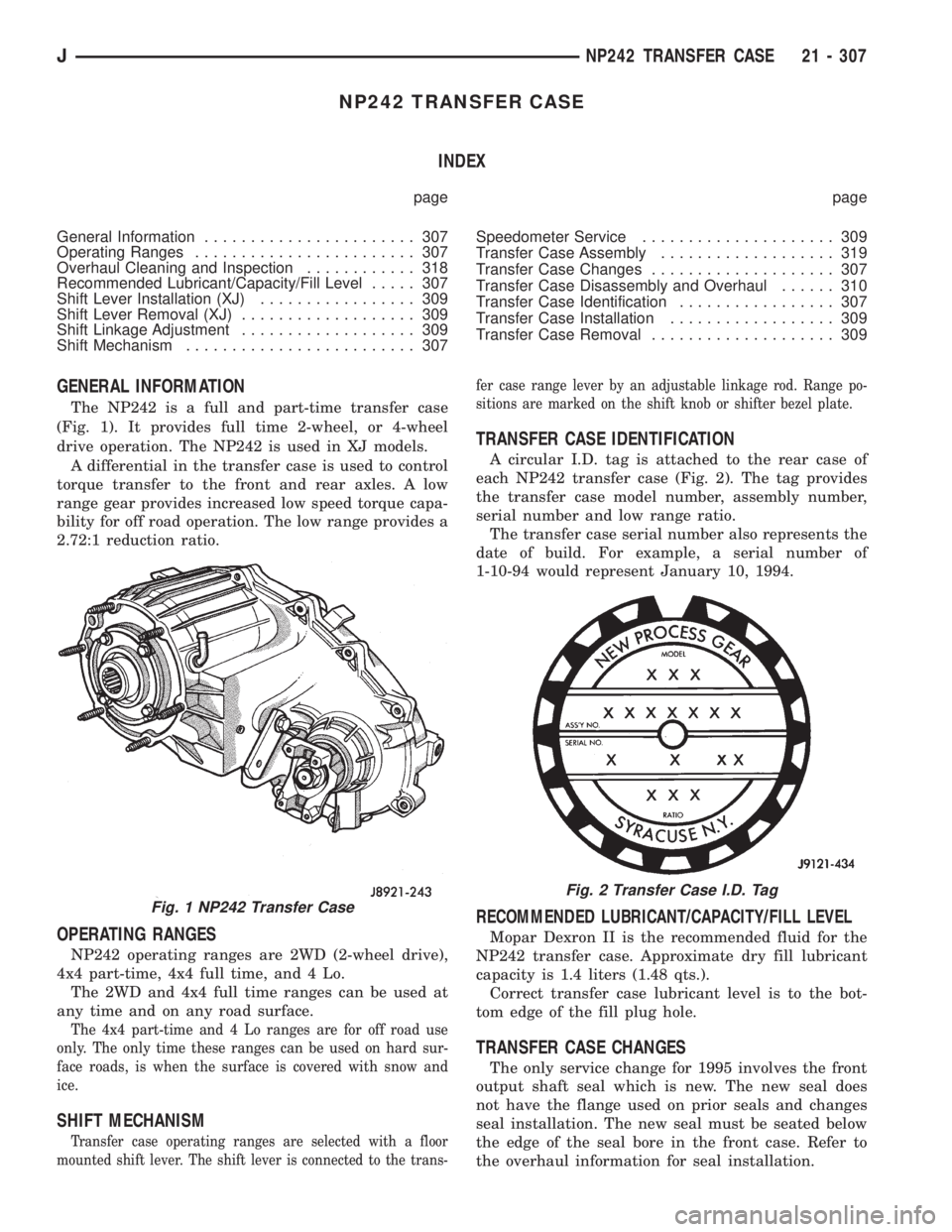

GENERAL INFORMATION

The NP242 is a full and part-time transfer case

(Fig. 1). It provides full time 2-wheel, or 4-wheel

drive operation. The NP242 is used in XJ models.

A differential in the transfer case is used to control

torque transfer to the front and rear axles. A low

range gear provides increased low speed torque capa-

bility for off road operation. The low range provides a

2.72:1 reduction ratio.

OPERATING RANGES

NP242 operating ranges are 2WD (2-wheel drive),

4x4 part-time, 4x4 full time, and 4 Lo.

The 2WD and 4x4 full time ranges can be used at

any time and on any road surface.

The 4x4 part-time and 4 Lo ranges are for off road use

only. The only time these ranges can be used on hard sur-

face roads, is when the surface is covered with snow and

ice.

SHIFT MECHANISM

Transfer case operating ranges are selected with a floor

mounted shift lever. The shift lever is connected to the trans-fer case range lever by an adjustable linkage rod. Range po-

sitions are marked on the shift knob or shifter bezel plate.

TRANSFER CASE IDENTIFICATION

A circular I.D. tag is attached to the rear case of

each NP242 transfer case (Fig. 2). The tag provides

the transfer case model number, assembly number,

serial number and low range ratio.

The transfer case serial number also represents the

date of build. For example, a serial number of

1-10-94 would represent January 10, 1994.

RECOMMENDED LUBRICANT/CAPACITY/FILL LEVEL

Mopar Dexron II is the recommended fluid for the

NP242 transfer case. Approximate dry fill lubricant

capacity is 1.4 liters (1.48 qts.).

Correct transfer case lubricant level is to the bot-

tom edge of the fill plug hole.

TRANSFER CASE CHANGES

The only service change for 1995 involves the front

output shaft seal which is new. The new seal does

not have the flange used on prior seals and changes

seal installation. The new seal must be seated below

the edge of the seal bore in the front case. Refer to

the overhaul information for seal installation.

Fig. 1 NP242 Transfer Case

Fig. 2 Transfer Case I.D. Tag

JNP242 TRANSFER CASE 21 - 307

Page 1723 of 2198

TIRE CHAINS

Tire snow chains may be used on certain models.

Refer to Owner's Manual for more information.

CLEANING OF TIRES

Steam cleaning may be used for cleaning.

DO NOT use gasoline or wire brush for cleaning.

DO NOT use mineral oil or an oil-based solvent.

PRESSURE GAUGES

High-quality, dial-type, air-pressure gauges are rec-

ommended. After checking with the gauge, replace

valve cap and finger tight.

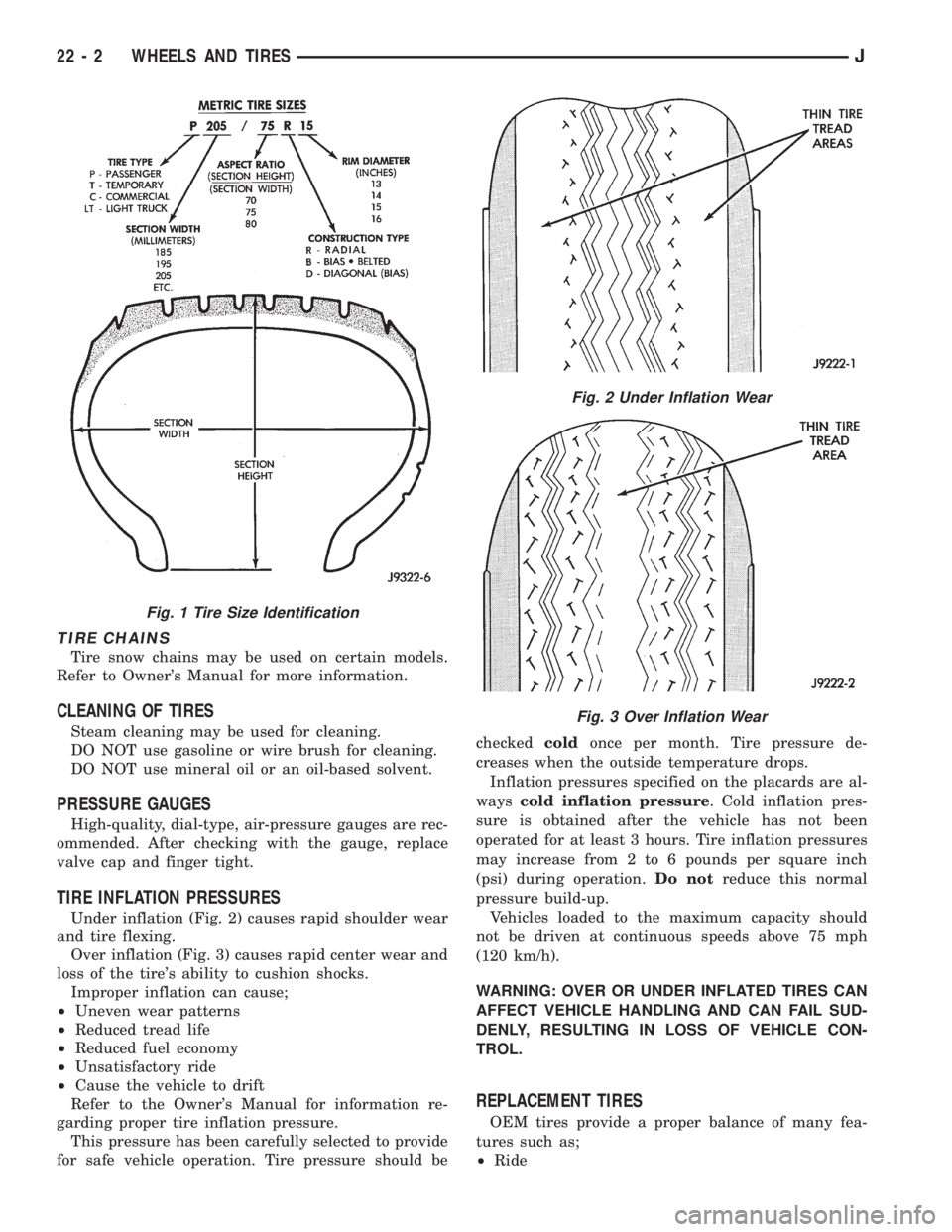

TIRE INFLATION PRESSURES

Under inflation (Fig. 2) causes rapid shoulder wear

and tire flexing.

Over inflation (Fig. 3) causes rapid center wear and

loss of the tire's ability to cushion shocks.

Improper inflation can cause;

²Uneven wear patterns

²Reduced tread life

²Reduced fuel economy

²Unsatisfactory ride

²Cause the vehicle to drift

Refer to the Owner's Manual for information re-

garding proper tire inflation pressure.

This pressure has been carefully selected to provide

for safe vehicle operation. Tire pressure should becheckedcoldonce per month. Tire pressure de-

creases when the outside temperature drops.

Inflation pressures specified on the placards are al-

wayscold inflation pressure. Cold inflation pres-

sure is obtained after the vehicle has not been

operated for at least 3 hours. Tire inflation pressures

may increase from 2 to 6 pounds per square inch

(psi) during operation.Do notreduce this normal

pressure build-up.

Vehicles loaded to the maximum capacity should

not be driven at continuous speeds above 75 mph

(120 km/h).

WARNING: OVER OR UNDER INFLATED TIRES CAN

AFFECT VEHICLE HANDLING AND CAN FAIL SUD-

DENLY, RESULTING IN LOSS OF VEHICLE CON-

TROL.

REPLACEMENT TIRES

OEM tires provide a proper balance of many fea-

tures such as;

²Ride

Fig. 1 Tire Size Identification

Fig. 2 Under Inflation Wear

Fig. 3 Over Inflation Wear

22 - 2 WHEELS AND TIRESJ

Page 1727 of 2198

WHEELS

GENERAL INFORMATION

Original equipment wheels are designed for the

specified Maximum Vehicle Capacity.

All models use steel or cast aluminum drop center

wheels. The safety rim wheel (Fig. 1) has raised sec-

tions between the rim flanges and the rim well.

Initial inflation of the tire forces the bead over

these raised sections. In case of tire failure, the

raised sections hold the tire in position on the wheel

until the vehicle can be brought to a safe stop.

Cast aluminum wheels require special balance

weights and alignment equipment.

WHEEL INSTALLATION

The wheel studs and nuts are designed for specific

applications. They must be replaced with equivalent

parts. Do not use replacement parts of lesser quality

or a substitute design. All aluminum and some steel

wheels have wheel stud nuts which feature an en-

larged nose. This enlarged nose is necessary to en-

sure proper retention of the aluminum wheels.

Before installing the wheel, be sure to remove any

build up of corrosion on the wheel mounting surfaces.

Ensure wheels are installed with good metal-to-metal

contact. Improper installation could cause loosening

of wheel nuts. This could affect the safety and han-

dling of your vehicle.

To install the wheel, first position it properly on

the mounting surface. All wheel nuts should then be

tightened just snug. Gradually tighten them in se-

quence to 129 Nzm (95 ft. lbs.) torque (Fig. 2).Never

use oil or grease on studs or nuts.

WHEEL REPLACEMENT

Wheels must be replaced if they have:²Excessive runout

²Bent or dented

²Leak air through welds

²Have damaged bolt holes

Wheel repairs employing hammering, heating, or

welding are not allowed.

Original equipment wheels are available through

your dealer. Replacement wheels from any other

source should be equivalent in:

²Load carrying capacity

²Diameter

²Width

²Offset

²Mounting configuration

Failure to use equivalent replacement wheels may

affect the safety and handling of your vehicle. Re-

placement withusedwheels is not recommended.

Their service history may have included severe treat-

ment.

Refer to the Specifications Chart for informa-

tion regarding above requirements.

WHEEL ORNAMENTATION

WARNING: HANDLE ALL WHEEL ORNAMENTATION

WITH EXTREME CARE DURING REMOVAL AND IN-

STALLATION. SHARP EDGES ON THE COVERS OR

CAPS CAN CAUSE PERSONAL INJURY.

TIRE AND WHEEL BALANCE

It is recommended that a two plane dynamic bal-

ancer be used when a wheel and tire assembly re-

quire balancing. Static should be used only when a

two plane balancer is not available.

For static imbalance, find location of heavy spot

causing imbalance. Counter balance wheel directly

Fig. 1 Wheel Safety Rim

Fig. 2 Lug Nut Tightening Pattern

22 - 6 WHEELS AND TIRESJ

Page 1906 of 2198

REFRIGERANT SERVICE AND PERFORMANCE TEST

INDEX

page page

Air Conditioning Performance Tests............ 12

Charging Refrigerant System................. 11

Evacuating Refrigerant System............... 11Leak Testing Refrigerant.................... 11

Recovering Refrigerant System............... 11

Refrigerant Oil........................... 12

LEAK TESTING REFRIGERANT

REVIEW WARNINGS AND CAUTIONS IN

THIS GROUP BEFORE LEAK TESTING.

If A/C system is not cooling properly, determine if

system is fully charged. Refer to Refrigerant System

Diagnosis Chart. If the system is empty evacuate the

A/C system and charge system with 0.283 kPa (0.6

lbs. or 10 oz.) R-134a refrigerant. Refer to Charging

Refrigerant System for instructions. To detect a leak

in the system, perform the following procedures.

(1) Position the vehicle in a wind free work area.

This will aid in detecting small leaks.

(2) Bring A/C system up to operating temperature

and pressure. This is done by allowing the engine to

run with the A/C on for 5 to 7 minutes.

(3) Open hood 5 minutes prior to leak test. This

will dissipate any accumulated refrigerant in the en-

gine compartment.

(4) With the engine not running, use an R-134a

Electronic Leak Detector and search for leaks. Move

probe slowly along the bottom side of lines and fit-

tings, because R-134a is heavier than air. Fittings,

lines, or components that appear to be oily usually

indicates a refrigerant leak.

(5) To inspect the evaporator core for leaks. Set the

blower at low speed and the selector in PANEL and

RECIRC mode check for leaks at CENTER panel out-

lets.

RECOVERING REFRIGERANT SYSTEM

REVIEW WARNINGS AND CAUTIONS IN

GENERAL INFORMATION SECTION OF THIS

GROUP BEFORE DISCHARGING SYSTEM.

R-134a refrigerant is a hydrofluorocarbon (HFC)

that does not contain chlorine. R-134a refrigerant Re-

covery/Recycling Station that meets SAE standard

J2210 must be used to recover the refrigerant. Refer

to the operating instructions provided with the equip-

ment for proper operation.

EVACUATING REFRIGERANT SYSTEM

REVIEW WARNINGS AND CAUTIONS IN

GENERAL INFORMATION SECTION OF THIS

GROUP BEFORE EVACUATING SYSTEM.

If the A/C system has been open to the atmosphere,

it must be evacuated before the system can be

charged. Moisture and air mixed with refrigerant will

raise the compressor head pressure above acceptable

operating levels. This will reduce the performance of

the air conditioner and damage the compressor. Mois-

ture will boil at near room temperature when ex-

posed to vacuum. To evacuate the refrigerant system

use following procedure:

(1) Connect a suitable charging station and mani-

fold gauge set to the vehicle.

(2) Open the low and high side valves and start

vacuum pump. When suction gauge reads 88 kPa (26

in. Hg) vacuum or greater, close all valves and turn

off vacuum pump. If system fails to reach specified

vacuum, the system has a leak that must be cor-

rected. If system maintains the specified vacuum for

30 minutes, start the vacuum pump. Then open the

suction and discharge valves and evacuate an addi-

tional 10 minutes.

(3) Close all valves. Turn off and disconnect the

vacuum pump.

The system is now ready to be charged with refrig-

erant.

CHARGING REFRIGERANT SYSTEM

REVIEW WARNINGS AND CAUTIONS IN

GENERAL INFORMATION SECTION OF THIS

GROUP BEFORE CHARGING SYSTEM.

After the system has been tested for leaks and

evacuated, a refrigerant charge can be injected into

the system. Refer to refrigerant capacities for proper

amount of refrigerant charge. Charge the system us-

ing a Recovery/Recycling/Charging Station approved

for R-134a refrigerant. Refer to the instructions pro-

vided with the equipment for proper operation.

REFRIGERANT CHARGE CAPACITY

The R-134a system charge capacity is 0.9 kPa (32

oz.) for XJ and YJ vehicles.

JHEATING AND AIR CONDITIONING 24 - 11

Page 1937 of 2198

EMISSION CONTROLS

INDEX

page page

Crankcase Ventilation System................. 5

EVAP (Evaporation) Control System............ 4

EVAP Canister............................ 4Fuel Tank Filler Tube Cap.................... 4

Oxygen (O2S) Sensor....................... 6

Pressure Relief/Rollover Valve................. 6

EVAP (EVAPORATION) CONTROL SYSTEM

GENERAL INFORMATION

The function of the EVAP control system is to pre-

vent the emissions of gasoline vapors from the fuel

tank into the atmosphere. When fuel evaporates in

the fuel tank, the vapors pass through vent hoses or

tubes to a carbon filled EVAP canister. They are tem-

porarily held in the canister until they can be drawn

into the intake manifold when the engine is running.

The EVAP canister is a feature on all models for

the storage of fuel vapors from the fuel tank.

The hoses used in this system are specially

manufactured. If replacement becomes neces-

sary, it is important to use only fuel resistant

hose.

EVAP CANISTER

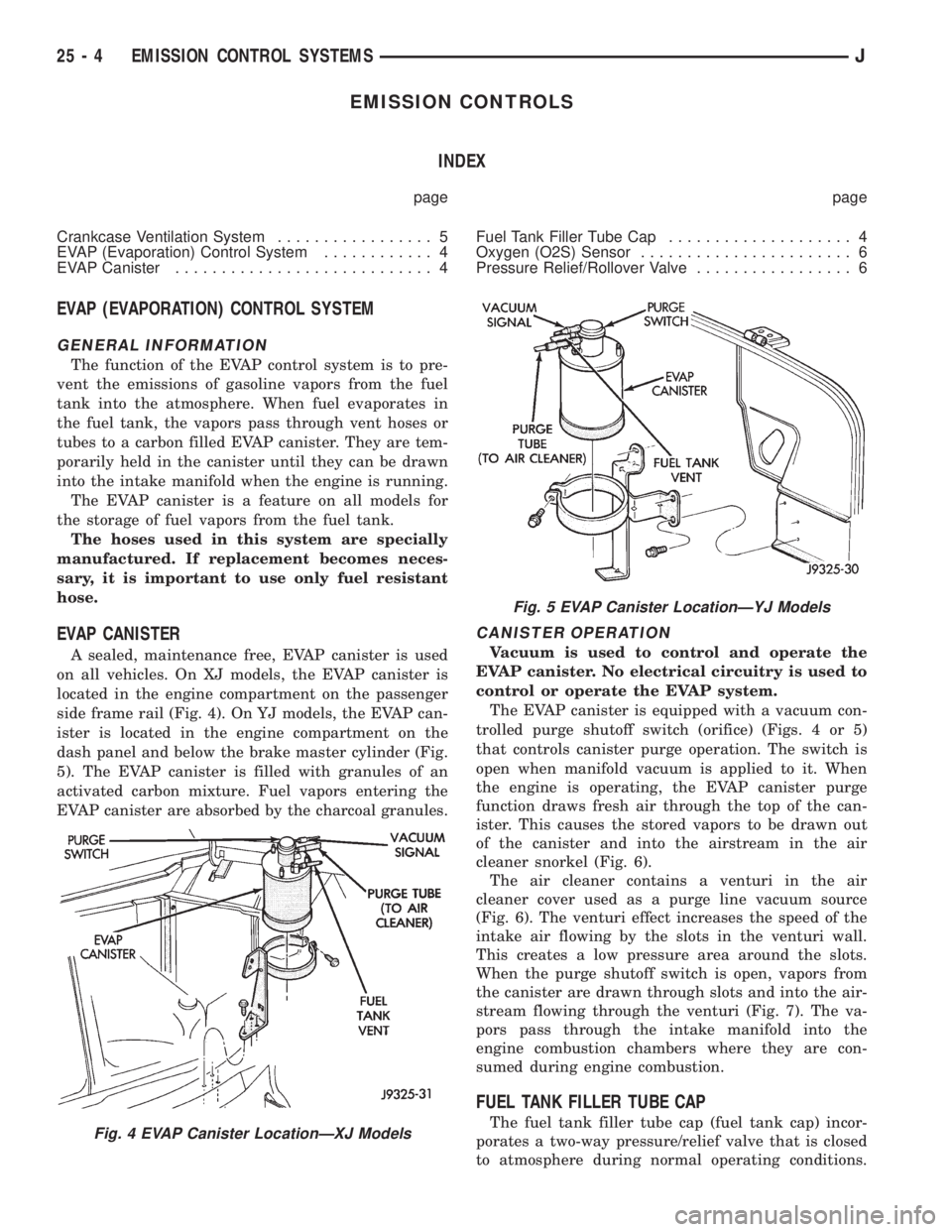

A sealed, maintenance free, EVAP canister is used

on all vehicles. On XJ models, the EVAP canister is

located in the engine compartment on the passenger

side frame rail (Fig. 4). On YJ models, the EVAP can-

ister is located in the engine compartment on the

dash panel and below the brake master cylinder (Fig.

5). The EVAP canister is filled with granules of an

activated carbon mixture. Fuel vapors entering the

EVAP canister are absorbed by the charcoal granules.

CANISTER OPERATION

Vacuum is used to control and operate the

EVAP canister. No electrical circuitry is used to

control or operate the EVAP system.

The EVAP canister is equipped with a vacuum con-

trolled purge shutoff switch (orifice) (Figs. 4 or 5)

that controls canister purge operation. The switch is

open when manifold vacuum is applied to it. When

the engine is operating, the EVAP canister purge

function draws fresh air through the top of the can-

ister. This causes the stored vapors to be drawn out

of the canister and into the airstream in the air

cleaner snorkel (Fig. 6).

The air cleaner contains a venturi in the air

cleaner cover used as a purge line vacuum source

(Fig. 6). The venturi effect increases the speed of the

intake air flowing by the slots in the venturi wall.

This creates a low pressure area around the slots.

When the purge shutoff switch is open, vapors from

the canister are drawn through slots and into the air-

stream flowing through the venturi (Fig. 7). The va-

pors pass through the intake manifold into the

engine combustion chambers where they are con-

sumed during engine combustion.

FUEL TANK FILLER TUBE CAP

The fuel tank filler tube cap (fuel tank cap) incor-

porates a two-way pressure/relief valve that is closed

to atmosphere during normal operating conditions.Fig. 4 EVAP Canister LocationÐXJ Models

Fig. 5 EVAP Canister LocationÐYJ Models

25 - 4 EMISSION CONTROL SYSTEMSJ

Page 1964 of 2198

BELT TENSIONERÐXJ MODELS WITH

RIGHT HAND DRIVE, AUTOMATIC........7-42

BELT TENSIONÐEXCEPT RIGHT HAND

DRIVE (RHD).........................7-38

BELT TENSIONÐEXCEPT RIGHT HAND

DRIVE (RHD) MODELS.................7-45

BELT TENSIONÐRIGHT HAND DRIVE

(RHD)..............................7-38

BELT/BUCKLEÐXJ, FRONT SHOULDER . . . 23-90

BELT/BUCKLEÐXJ, REAR SHOULDER/

LAP ...............................23-91

BELTLINE SEALÐYJ.................23-142

BELTS, ENGINE ACCESSORY DRIVE.......7-38

BELTSÐYJ, FRONT SHOULDER........23-154

BELTSÐYJ, REAR SHOULDER.........23-154

BENCH BLEEDING, MASTER CYLINDER....5-21

BENCH, GEAR ADJUSTMENTS ON.......19-44

BENCH SEATÐYJ, REAR..............23-153

BEZELÐXJ, INSTRUMENT CLUSTER.....23-80

BEZELÐYJ, INSTRUMENT CLUSTER....23-151

BIN REMOVE/INSTALL, SUNGLASSES

STORAGE...........................8C-7

BLADE REMOVE/INSTALL, WINDSHIELD

WIPER.............................8K-17

BLEEDING, MASTER CYLINDER BENCH....5-21

BLEEDING RECOMMENDATIONS, BRAKE . . . 5-10

BLEEDING (WITH ABS BRAKES), BRAKE . . . 5-11

BLEEDING (WITH STANDARD BRAKES),

BRAKE..............................5-11

BLEEDINGÐBRAKELINES AND HOSES,

BRAKE FLUIDÐBRAKE.................5-10

BLOCK, CYLINDER................9-49,9-91

BLOCK HEATER, ENGINE................7-44

BLOCKSÐTWO-DOOR VEHICLES, FRONT

DOOR SPACER......................23-53

BLOWER MOTOR; AIR CONDITIONING/

HEATER (XJ)......................8W-42-1

BLOWER MOTOR; AIR CONDITIONING/

HEATER (XJ-RHD)..................8W-42-1

BLOWER MOTOR; HEATING AND AIR

CONDITIONING......................24-17

BLOWER MOTOR, A/C.................24-35

BLOWER MOTOR, A/C-HEATER; AIR

CONDITIONING/HEATER (YJ).........8W-42-2

BLOWER MOTOR (HEATING)...........24-33

BLOWER MOTOR RESISTORS

REPLACEMENT......................24-31

BLOWER MOTOR SWITCH.............24-16

BLOWER MOTOR/AIR DOOR MOTOR

SWITCH REPLACEMENT...............24-32

BLOWER MOTOR/FAN REPLACEMENT....24-24

BODY ASSEMBLY AND ADJUSTMENT,

VALVE ............................21-153

BODY CHECK BALL DIMENSIONS, AW-4

VALVE ............................21-341

BODY CODE LETTERS, JEEP..............5-2

BODY LUBRICANT SPECIFICATIONS.......0-33

BODY OVERHAUL, TRANSMISSION

VALVE ............................21-250

BODY REMOVAL, TRANSMISSION VALVE . 21-186

BODY REMOVAL, VALVE..............21-104

BODY SERVICE INFORMATION, GENERAL . . 23-1

BODY SERVICE, VALVE...............21-104

BODY SIDE MOLDING/CLADDINGÐXJ....23-20

BODY SIDE STEP MOLDINGÐYJ.......23-115

BODY SOLENOIDS, TRANSMISSION

VALVE ............................21-184

BODY STRIPES/DECALSÐXJ...........23-21

BODY STRIPES/DECALSÐYJ..........23-116

BODY, THROTTLE...............14-33,14-64

BOLT IDENTIFICATION..............Intro.-14

BOLT STRENGTH..................Intro.-15

BOOSTER CHECK VALVE TEST, POWER.....5-9

BOOSTER INSTALLATION (XJ WITH

ABS), POWER BRAKE..................5-27

BOOSTER INSTALLATION (XJ WITHOUT

ABS), POWER BRAKE..................5-30

BOOSTER INSTALLATION (YJ), POWER

BRAKE..............................5-30

BOOSTER, MASTER CYLINDER/POWER

BRAKE

..............................5-34

BOOSTER OPERATION, POWER BRAKE

....5-23

BOOSTER REMOVAL (XJ WITH ABS),

POWER BRAKE

.......................5-24

BOOSTER REMOVAL (XJ WITHOUT ABS),

POWER BRAKE

.......................5-29

BOOSTER REMOVAL (YJ), POWER

BRAKE

..............................5-30BOOSTER TEST, MASTER CYLINDER/

POWER..............................5-8

BOOSTER VACUUM TEST, POWER.........5-9

BOOSTERÐBRAKE PEDALÐ

BRAKELIGHT SWITCH, POWER BRAKE....5-22

BORES, HONING CYLINDER..............9-2

BOX LAMP, GLOVE; INTERIOR LIGHTING

(XJ).............................8W-44-1

BOX LAMP, GLOVE; INTERIOR LIGHTING

(XJ-RHD).........................8W-44-1

BOXÐYJ, GLOVE...................23-152

BRACKET REPLACEMENTÐXJ, INTERIOR

REARVIEW MIRROR SUPPORT..........23-68

BRACKETÐYJ, REARVIEW MIRROR

RETAINING........................23-144

BRACKETSÐXJ, SPARE TIRE/WHEEL

HOLDDOWN AND FLOOR..............23-98

BRAKE ADJUSTMENT, DRUM............5-57

BRAKE BLEEDING RECOMMENDATIONS....5-10

BRAKE BLEEDING (WITH ABS BRAKES)....5-11

BRAKE BLEEDING (WITH STANDARD

BRAKES)............................5-11

BRAKE BOOSTER INSTALLATION (XJ

WITH ABS), POWER...................5-27

BRAKE BOOSTER INSTALLATION (XJ

WITHOUT ABS), POWER................5-30

BRAKE BOOSTER INSTALLATION (YJ),

POWER.............................5-30

BRAKE BOOSTER, MASTER CYLINDER/

POWER.............................5-34

BRAKE BOOSTER OPERATION, POWER....5-23

BRAKE BOOSTER REMOVAL (XJ WITH

ABS), POWER........................5-24

BRAKE BOOSTER REMOVAL (XJ

WITHOUT ABS), POWER................5-29

BRAKE BOOSTER REMOVAL (YJ),

POWER.............................5-30

BRAKE BOOSTERÐBRAKE PEDALÐ

BRAKELIGHT SWITCH, POWER...........5-22

BRAKE CABLE TENSIONER ADJUSTMENT

(XJ/YJ), PARKING.....................5-69

BRAKE CABLE TENSIONER

REPLACEMENT (XJ), PARKING...........5-66

BRAKE CHECK, PRELIMINARY............5-4

BRAKE COMPONENTS...................5-1

BRAKE DIAGNOSIS, ABS.................5-3

BRAKE DIAGNOSIS, SERVICE.............5-4

BRAKE DRUM REFINISHING.............5-58

BRAKE FLUID CONTAMINATION.......5-10,5-7

BRAKE FLUID LEVEL...................5-10

BRAKE FLUID, RECOMMENDED..........5-10

BRAKE FLUID/LUBRICANTS/CLEANING

SOLVENTS............................5-2

BRAKE FLUIDÐBRAKE BLEEDINGÐ

BRAKELINES AND HOSES...............5-10

BRAKE FRONT CABLE REPLACEMENT

(YJ), PARKING........................5-67

BRAKE HANDLE COVERÐXJ, PARKING . . . 23-94

BRAKE LEVER INSTALLATION (XJ WITH

FULL CONSOLE), PARKING..............5-64

BRAKE LEVER INSTALLATION (XJ WITH

MINI CONSOLE), PARKING..............5-63

BRAKE LEVER INSTALLATION (XJ

WITHOUT CONSOLE), PARKING..........5-65

BRAKE LEVER REMOVAL (XJ WITH FULL

CONSOLE), PARKING..................5-63

BRAKE LEVER REMOVAL (XJ WITH MINI

CONSOLE), PARKING..................5-62

BRAKE LEVER REMOVAL (XJ WITHOUT

CONSOLE), PARKING

..................5-64

BRAKE MALFUNCTIONS, DIAGNOSING

PARKING

.............................5-8

BRAKE NOISE

.........................5-7

BRAKE OPERATION, PARKING

...........5-60

BRAKE OVERHAUL, SECOND

..........21-241

BRAKE PACK REQUIREMENTS, AW-4

CLUTCH

...........................21-341

BRAKE PEDAL BUSHINGS, CLUTCH

.......0-22

BRAKE PEDAL INSTALLATION

............5-31

BRAKE PEDAL INSTALLATION (YJ),

PARKING

............................5-66

BRAKE PEDAL REMOVAL

...............5-31

BRAKE PEDAL REMOVAL (YJ), PARKING

. . . 5-66

BRAKE PEDAL TRAVEL SENSOR;

ANTI-LOCK BRAKES (YJ)

............8W-32-1

BRAKE PISTON AND TRANSMISSION

CASE OVERHAUL, FIRST-REVERSE

......21-247BRAKE REAR CABLE REPLACEMENT

(XJ), PARKING........................5-67

BRAKE REAR CABLE REPLACEMENT

(YJ), PARKING........................5-68

BRAKE ROTOR REFINISHING, DISC.......5-53

BRAKE ROTOR RUNOUT, DISC...........5-52

BRAKE ROTOR THICKNESS, DISC........5-52

BRAKE SAFETY PRECAUTIONS............5-2

BRAKE SWITCH......................14-59

BRAKE SWITCH INPUT; ANTI-LOCK

BRAKES (XJ)......................8W-32-2

BRAKE SWITCH INPUT; ANTI-LOCK

BRAKES (XJ-RHD).................8W-32-2

BRAKE SWITCH INPUT; ANTI-LOCK

BRAKES (YJ)......................8W-32-2

BRAKE SWITCH INPUT; FUEL/IGNITION

(XJ).............................8W-30-5

BRAKE SWITCH INPUT; FUEL/IGNITION

(YJ).............................8W-30-5

BRAKE SWITCH INPUT; FUEL/IGNITION

(XJ-RHD).........................8W-30-5

BRAKE SWITCH, PARKING..............5-68

BRAKE SWITCHÐPCM INPUT..........14-22

BRAKE SYSTEM, POWER...............0-30

BRAKE TORQUE SPECIFICATIONS.........5-70

BRAKE WARNING LAMP; INSTRUMENT

CLUSTER (XJ).....................8W-40-2

BRAKE WARNING LAMP; INSTRUMENT

CLUSTER (XJ-RHD)................8W-40-2

BRAKE WARNING LAMP; INSTRUMENT

CLUSTER (YJ)......................8W-40-2

BRAKE WARNING LIGHTS................5-1

BRAKELIGHT SWITCH ADJUSTMENT......5-32

BRAKELIGHT SWITCH INSTALLATION......5-32

BRAKELIGHT SWITCH REMOVAL.........5-32

BRAKELINE CHARTS...................5-12

BRAKELINES AND HOSES...............5-12

BRAKELINING, CONTAMINATED...........5-7

BRAKELINING MATERIAL................5-1

BRAKES (ABS), ANTILOCK...............5-1

BRAKES, DISC........................5-45

BRAKES DO NOT HOLD AFTER DRIVING

THROUGH DEEP WATER PUDDLES........5-7

BRAKES, DRUM......................5-55

BRAKES, PARKING....................5-60

BRAKESHOE INSTALLATION, DISC........5-47

BRAKESHOE INSTALLATION, DRUM.......5-55

BRAKESHOE REMOVAL, DISC............5-46

BRAKESHOE REMOVAL, DRUM...........5-55

BRAKING MODE, ABS OPERATION IN

ANTILOCK...........................5-36

BRAKING MODE, ABS OPERATION IN

NORMAL............................5-35

BREAK-IN, ENGINE....................0-15

BRUSH GUARDÐXJ...................23-3

BUCKET SEAT CUSHION AND COVERÐ

XJ ................................23-81

BUCKET SEAT PLATFORMÐXJ..........23-82

BUCKET SEATBACK COVER AND

FRAMEÐXJ.........................23-81

BUCKET SEATSÐXJ, FRONT............23-81

BUCKET SEATSÐYJ.................23-153

BULB APPLICATIONÐXJ VEHICLES......8L-18

BULB APPLICATIONÐYJ VEHICLES......8L-32

BULB REMOVE/INSTALL, READING/

COURTESY LAMP.....................8C-8

BULB REPLACEMENTÐXJ, BACK-UP/

REAR TURN SIGNAL/TAIL LAMP.........8L-12

BULB REPLACEMENTÐXJ, FRONT

PARK/TURN SIGNAL LAMP..............8L-9

BULB REPLACEMENTÐXJ, HEADLAMP....8L-7

BULB REPLACEMENTÐXJ, SIDE

MARKER LAMP......................8L-10

BULB REPLACEMENTÐXJ, UNDERHOOD

LAMP..............................8L-13

BULB REPLACEMENTÐYJ, BACK-UP/

REAR TURN SIGNAL/TAIL LAMP.........8L-28

BULB REPLACEMENTÐYJ, FRONT

PARK/TURN SIGNAL LAMP.............8L-25

BULB REPLACEMENTÐYJ, HEADLAMP . . . 8L-23

BULB REPLACEMENTÐYJ, SIDE

MARKER LAMP

......................8L-25

BULB REPLACEMENTÐYJ, UNDERHOOD

LAMP

..............................8L-29

BULB REPLACEMENTÐYJ VEHICLES,

HARDTOP DOME/CARGO LAMP

.........8L-31

BUMPER, FRONT

.................13-16,13-5

BUMPER, REAR

..................13-16,13-8

JINDEX 3

Description Group-Page Description Group-Page Description Group-Page

Page 1968 of 2198

CYLINDER COMBUSTION PRESSURE

LEAKAGE TEST DIAGNOSIS..............9-7

CYLINDER COMPRESSION PRESSURE

TEST................................9-5

CYLINDER DISPOSALÐXJ, LIFTGATE

SUPPORT ROD......................23-63

CYLINDER ENGINE, VACUUM ROUTING

SCHEMATICÐ2.5L 4...................25-3

CYLINDER ENGINE, VACUUM ROUTING

SCHEMATICÐ4.0L 6...................25-3

CYLINDER HEAD COVER, ENGINE....9-22,9-64

CYLINDER HEAD, ENGINE...........9-25,9-67

CYLINDER HEAD GASKET FAILURE

DIAGNOSIS, ENGINE....................9-5

CYLINDER INSTALLATION (NON-ABS),

MASTER............................5-16

CYLINDER INSTALLATION, WHEEL........5-58

CYLINDER OVERHAUL (4-CYLINDER

MODELS), MASTER....................5-16

CYLINDER OVERHAUL, WHEEL...........5-57

CYLINDER REMOVAL (NON-ABS),

MASTER............................5-15

CYLINDER REMOVAL, WHEEL...........5-57

CYLINDER SERVICE, IGNITION SWITCH

AND KEY...........................8D-26

CYLINDERÐCOMBINATION VALVE,

MASTER............................5-15

CYLINDERÐXJ, DOOR KEY LOCK.......23-47

CYLINDERÐXJ, LIFTGATE SUPPORT

ROD...............................23-62

CYLINDERÐYJ, FULL-METAL DOOR KEY

LOCK..............................23-139

CYLINDERÐYJ, TAILGATE LOCK.......23-122

CYLINDER/POWER BOOSTER TEST,

MASTER.............................5-8

CYLINDER/POWER BRAKE BOOSTER,

MASTER............................5-34

CYLINDER/STRIKERÐXJ, LIFTGATE

LATCH/KEY LOCK....................23-61

DAMAGED OR WORN THREADS, REPAIR....9-4

DAMPER, ENGINE.....................9-17

DAMPER, STEERING.............19-17,19-20

DAMPER, VIBRATION..............9-30,9-72

DASH PANEL INSULATOR PANELÐXJ....23-12

DATA LINK CONNECTOR; ANTI-LOCK

BRAKES (XJ)......................8W-32-2

DATA LINK CONNECTOR; ANTI-LOCK

BRAKES (XJ-RHD).................8W-32-2

DATA LINK CONNECTOR; ANTI-LOCK

BRAKES (YJ)......................8W-32-2

DATA LINK CONNECTOR; FUEL/IGNITION

(XJ).............................8W-30-5

DATA LINK CONNECTOR; FUEL/IGNITION

(YJ).............................8W-30-5

DATA LINK CONNECTOR;

TRANSMISSION CONTROLS (XJ-RHD) . . 8W-31-1

DATA LINK CONNECTOR; FUEL/IGNITION

(XJ-RHD).........................8W-30-4

DATA LINK CONNECTORÐPCM INPUT....14-22

DATA LINK CONNECTORÐPCM OUTPUT . . 14-27

DATA, VEHICLE DIMENSION.....Intro.-5,Intro.-6

DATA, VEHICLE LOAD................Intro.-5

DATAÐXJ, VEHICLE LOAD............Intro.-7

DATAÐYJ, VEHICLE LOAD............Intro.-8

DAYTIME RUNNING LAMP (DRL)

MODULE; FRONT LIGHTING (XJ)......8W-50-2

DAYTIME RUNNING LAMP (DRL)

MODULEÐCANADIAN VEHICLES ONLY;

FRONT LIGHTING (YJ)

..............8W-50-2

DAYTIME RUNNING LIGHTS (CANADA

ONLY)ÐXJ

.........................8L-15

DAYTIME RUNNING LIGHTS (CANADA

ONLY)ÐYJ

.........................8L-30

DECODING, VEHICLE CODE

...........Intro.-5

DECODING, VEHICLE IDENTIFICATION

NUMBER (VIN)

.....................Intro.-4

DEFLECTORÐXJ, COWL WEATHERSTRIP

SEAL/CROSSMEMBER AIR

.............23-11

DEFOGGER RELAY

....................8N-3

DEFOGGER RELAY/TIMER

...............8N-1

DEFOGGER RELAY/TIMER REMOVE/

INSTALL

............................8N-4

DEFOGGER SWITCH

...............8N-1,8N-3

DEFOGGER SWITCH REMOVE/INSTALL

....8N-4

DEFROSTER NOZZLE AND DUCT

........24-33

DELAY FUNCTION TROUBLE

DIAGNOSISÐXJ, HEADLAMP

...........8L-14DELAY MODULE, HEADLAMP; FRONT

LIGHTING (XJ)....................8W-50-2

DELAY MODULE, HEADLAMP; FRONT

LIGHTING (XJ-RHD)................8W-50-1

DELAY MODULE REPLACEMENTÐXJ,

HEADLAMP.........................8L-14

DELAY MODULEÐXJ, SENTINEL

HEADLAMP.........................8L-14

DELIVERY SYSTEM, FUEL...............14-3

DEMAGNETIZING, COMPASS............8C-5

DEPTH INFORMATION, PINION GEAR;

FRONT SUSPENSION AND AXLE..........2-39

DEPTH INFORMATION, PINION GEAR;

REAR SUSPENSION AND AXLES..........3-21

DEPTH VARIANCE, PINION GEAR; FRONT

SUSPENSION AND AXLE................2-40

DEPTH VARIANCE, PINION GEAR; REAR

SUSPENSION AND AXLES...........3-22,3-39

DESCRIPTION; HEATING AND AIR

CONDITIONING............24-19,24-23,24-32

DESCRIPTION; TRANSMISSION AND

TRANSFER CASE....................21-165

DESCRIPTION/SYSTEM OPERATION,

MULTI-PORT FUEL INJECTION

(MFI)ÐCOMPONENT..................14-19

DESIGNATIONS, LABELS/PLATES, CODES

AND DIMENSIONS..................Intro.-1

DESIGNATIONS, VEHICLE.............Intro.-1

DESIGNATIONS, VEHICLE CODE........Intro.-1

DETECTION AND REPAIRÐXJ,

STATIONARY GLASS WATER LEAK.......23-76

DETECTION AND REPAIRÐYJ,

STATIONARY GLASS WATER LEAK.......23-150

DEVICES, ELECTROSTATIC DISCHARGE

(ESD) SENSITIVE; WIRING

DIAGRAMSÐGENERAL INFORMATION

(XJ)...............................8W-2

DIAGNOSING PARKING BRAKE

MALFUNCTIONS.......................5-8

DIAGNOSIS; AUDIO SYSTEMS...........8F-2

DIAGNOSIS; BATTERY/STARTING/

CHARGING SYSTEMS DIAGNOSTICS.....8A-10,

8A-11,8A-17,8A-3

DIAGNOSIS; CHIME/BUZZER WARNING

SYSTEMS...........................8U-2

DIAGNOSIS; COOLING SYSTEM...........7-4

DIAGNOSIS; HORNS...................8G-2

DIAGNOSIS; INSTRUMENT PANEL AND

GAUGESÐXJ....................8E-27,8E-5

DIAGNOSIS; OVERHEAD CONSOLE........8C-2

DIAGNOSIS; POWER LOCKS.............8P-2

DIAGNOSIS; POWER MIRRORS..........8T-1

DIAGNOSIS; POWER SEATS.............8R-2

DIAGNOSIS; POWER WINDOWS..........8S-1

DIAGNOSIS; REAR WINDOW DEFOGGER . . . 8N-1

DIAGNOSIS; RESTRAINT SYSTEMS.......8M-2

DIAGNOSIS; STEERING................19-37

DIAGNOSIS; TURN SIGNAL AND HAZARD

WARNING SYSTEMS...................8J-3

DIAGNOSIS; VEHICLE SPEED CONTROL

SYSTEM............................8H-2

DIAGNOSIS, 2.5L STARTER NOISE.......8A-16

DIAGNOSIS, 30RH/32RH TRANSMISSION . 21-70

DIAGNOSIS, ABS BRAKE.................5-3

DIAGNOSIS, ANTILOCK ECU AND HCU......5-3

DIAGNOSIS, AW-4 TRANSMISSION.....21-176

DIAGNOSIS, AXLE NOISE/VIBRATION;

FRONT SUSPENSION AND AXLE..........2-18

DIAGNOSIS, AXLE NOISE/VIBRATION;

REAR SUSPENSION AND AXLES..........3-9

DIAGNOSIS, BATTERY..................8A-4

DIAGNOSIS, BELT.....................7-38

DIAGNOSIS, CHARGING SYSTEM........8A-19

DIAGNOSIS, CLUTCH...................6-3

DIAGNOSIS, COMPASS/THERMOMETER....8C-4

DIAGNOSIS (CONT.), COOLING SYSTEM . . . 7-10,

7-11,7-12,7-7,7-8,7-9

DIAGNOSIS (CONT.), SERPENTINE DRIVE

BELT ...............................7-40

DIAGNOSIS (CONT'D), DISCONNECT

AXLE/SHIFT MOTOR

...................2-30

DIAGNOSIS (CONT'D), SERVICE; FRONT

SUSPENSION AND AXLE

................2-21

DIAGNOSIS (CONT'D), SERVICE; REAR

SUSPENSION AND AXLES

...............3-12

DIAGNOSIS, CONVERTER HOUSING

LEAK

..............................21-75

DIAGNOSIS, COOLING SYSTEM

...........7-6DIAGNOSIS, CYLINDER COMBUSTION

PRESSURE LEAKAGE TEST...............9-7

DIAGNOSIS, DISCONNECT AXLE/SHIFT

MOTOR.............................2-29

DIAGNOSIS, ENGINE....................9-5

DIAGNOSIS, ENGINE CYLINDER HEAD

GASKET FAILURE......................9-5

DIAGNOSIS, EXHAUST SYSTEM..........11-2

DIAGNOSIS, FOG LAMP...........8L-21,8L-3

DIAGNOSIS, GEAR LEAKAGE............19-10

DIAGNOSIS, HEADLAMP...........8L-20,8L-2

DIAGNOSIS, HEATER..................24-17

DIAGNOSIS, HEATING SYSTEM..........24-18

DIAGNOSIS, IGNITION SECONDARY

CIRCUIT...........................8D-10

DIAGNOSIS INFORMATION, GENERAL;

CLUTCH..............................6-3

DIAGNOSIS INFORMATION, GENERAL;

TRANSMISSION AND TRANSFER CASE . . 21-176

DIAGNOSIS, INTAKE MANIFOLD

LEAKAGE.............................9-5

DIAGNOSIS, MANUAL STEERING

SYSTEM............................19-38

DIAGNOSIS, MULTI-PORT FUEL

INJECTION (MFI)ÐGENERAL...........14-35

DIAGNOSIS, NP231 SERVICE..........21-285

DIAGNOSIS, NP242 SERVICE..........21-308

DIAGNOSIS, PERFORMANCE............24-14

DIAGNOSIS, POWER STEERING SYSTEM . . 19-3,

19-4,19-5,19-6,19-7,19-8,19-9

DIAGNOSIS, PUMP LEAKAGE...........19-10

DIAGNOSIS, RADIO....................8F-3

DIAGNOSIS, SERPENTINE DRIVE BELT.....7-39

DIAGNOSIS, SERVICE; FRONT

SUSPENSION AND AXLE................2-20

DIAGNOSIS, SERVICE; PROPELLER

SHAFTS.............................16-3

DIAGNOSIS, SERVICE; REAR

SUSPENSION AND AXLES...............3-11

DIAGNOSIS, SERVICE; TRANSMISSION

AND TRANSFER CASE . 21-180,21-181,21-34,21-2

DIAGNOSIS, SERVICE BRAKE.............5-4

DIAGNOSIS, SPRING AND SHOCK;

FRONT SUSPENSION AND AXLE......2-13,2-15

DIAGNOSIS, SPRING AND SHOCK; REAR

SUSPENSION AND AXLES.............3-3,3-6

DIAGNOSIS, SPRING AND SHOCK

ABSORBER........................3-3,3-6

DIAGNOSIS, STARTER NOISE...........8A-16

DIAGNOSIS, STARTING SYSTEM........8A-12

DIAGNOSIS, SUSPENSION AND

STEERING SYSTEM.....................2-7

DIAGNOSIS, THERMOMETER............8C-2

DIAGNOSIS, TORQUE CONVERTER . 21-86,21-87,

21-88

DIAGNOSIS, TRANSMISSION . 21-78,21-79,21-80,

21-81,21-82,21-83,21-84,21-85

DIAGNOSIS, VIBRATION..........22-10,22-11

DIAGNOSISÐLUBRICATION SERVICE......9-12

DIAGNOSISÐXJ, DOME/COURTESY

LAMP TROUBLE.....................8L-16

DIAGNOSISÐXJ, HEADLAMP DELAY

FUNCTION TROUBLE..................8L-14

DIAGNOSISÐXJ, LIGHTED VANITY

MIRROR TROUBLE...................8L-16

DIAGNOSISÐYJ, DOME/COURTESY

LAMP TROUBLE.....................8L-31

DIAGNOSTIC CONNECTOR, ABS.......5-35,5-3

DIAGNOSTIC PROCEDURESÐXJ.........8L-1

DIAGNOSTIC PROCEDURESÐYJ........8L-19

DIAGNOSTIC SYSTEM, USING

ON-BOARD; BATTERY/STARTING/

CHARGING SYSTEMS DIAGNOSTICS.....8A-22

DIAGNOSTIC SYSTEM, USING

ON-BOARD; VEHICLE SPEED CONTROL

SYSTEM............................8H-5

DIAGNOSTIC TROUBLE CODE (DTC)......14-54

DIAGNOSTIC TROUBLE CODE,

GENERATOR........................8A-22

DIAGNOSTIC TROUBLE CODE, SPEED

CONTROL

...........................8H-5

DIAGNOSTICS (OBD), ON-BOARD;

COOLING SYSTEM

.....................7-4

DIAGNOSTICS (OBD), ON-BOARD; FUEL

SYSTEM

............................14-51

DIAGNOSTICS, ON-BOARD

.............8D-15

DIAGRAM INDEX; AIR CONDITIONING/

HEATER (XJ)

......................8W-42-2

JINDEX 7

Description Group-Page Description Group-Page Description Group-Page

Page 1971 of 2198

ENTRY MODULE REMOVE/INSTALL,

KEYLESS...........................8P-10

ENTRY RECEIVER, KEYLESS.............8C-1

ENTRY RECEIVERÐXJ, KEYLESS........23-93

ENTRY TRANSMITTER, KEYLESS . 8P-1,8P-7,8P-8

EQUIPMENT, REFRIGERANT.............24-7

EQUIVALENT VALUES, CONVERSION

FORMULAS.......................Intro.-11

EVACUATING REFRIGERANT SYSTEM.....24-11

EVAP CANISTER..................25-4,25-7

EVAP (EVAPORATION) CONTROL

SYSTEM............................25-4

EVAPORATIVE HOUSING

COMPONENTSÐYJ....................24-6

EVAPORATOR AND HOUSING...........24-35

EVAPORATOR COIL...................24-30

EVAPORATOR/BLOWER HOUSING........24-29

EXHAUST GAS RECIRCULATION (EGR)

SYSTEM............................25-1

EXHAUST GRILLEÐXJ, AIR............23-25

EXHAUST HEAT SHIELDS...............11-1

EXHAUST MANIFOLDÐ2.5L ENGINE,

ENGINE.............................11-7

EXHAUST MANIFOLDÐ4.0L ENGINE,

ENGINE.............................11-7

EXHAUST PIPEÐXJ VEHICLES...........11-3

EXHAUST PIPEÐYJ VEHICLES...........11-4

EXHAUST SYSTEM; EXHAUST SYSTEM

AND INTAKE MANIFOLD................11-1

EXHAUST SYSTEM; LUBRICATION AND

MAINTENANCE.......................0-21

EXHAUST SYSTEM DIAGNOSIS..........11-2

EXHAUST TAILPIPEÐXJ VEHICLES,

MUFFLER............................11-5

EXHAUST TAILPIPEÐYJ VEHICLES,

MUFFLER............................11-6

EXPANSION VALVE..............24-31,24-35

EXTENDED IDLE SWITCH; FUEL/

IGNITION (XJ).....................8W-30-5

EXTENDED IDLE SWITCH TEST..........14-48

EXTENDED IDLE SWITCHÐPCM INPUT . . . 14-23

EXTENSIONÐXJ, QUARTER TRIM PANEL . 23-87

EXTERIOR COMPONENTS.........23-104,23-3

EXTERIOR LAMPSÐXJ................8L-18

EXTERIOR LAMPSÐYJ................8L-32

EXTERIOR MOLDINGSÐXJ, DOOR

WINDOW...........................23-54

EXTERIOR NAMEPLATES (ADHESIVE-

BACKED)ÐYJ......................23-120

EXTERIOR NAMEPLATESÐXJ...........23-26

EXTERNAL HANDLEÐXJ, DOOR.........23-48

EXTERNAL MIRRORSÐXJ.............23-27

EXTERNAL RELEASE HANDLEÐYJ,

FULL-METAL DOOR LATCH............23-140

EXTERNAL SPARE/WHEEL TIRE

CARRIERÐYJ......................23-133

(EXTERNAL)ÐYJ, HALF METAL DOOR

MIRROR..........................23-121

EYE BUSHING REPLACEMENT, LEAF

SPRING; FRONT SUSPENSION AND

AXLE...............................2-17

EYE BUSHING REPLACEMENT, LEAF

SPRING; REAR SUSPENSION AND

AXLES............................3-5,3-7

FAN RELAY AND MOTOR, RADIATOR;

AIR CONDITIONING/HEATER (XJ)......8W-42-2

FAN RELAY AND MOTOR, RADIATOR;

AIR CONDITIONING/HEATER (XJ-RHD) . . 8W-42-2

FAN RELAYÐPCM OUTPUT, RADIATOR . . . 14-28

FANÐXJ MODELS WITH 4.0L

6-CYLINDER ENGINE, AUXILIARY

ELECTRIC COOLING...................7-35

FANS, COOLING SYSTEM...............7-32

FEED, BATTERY; FUEL/IGNITION (XJ) . . . 8W-30-1

FEED, BATTERY; FUEL/IGNITION (YJ) . . . 8W-30-2

FEED, BATTERY; FUEL/IGNITION

(XJ-RHD).........................8W-30-1

FEED, IGNITION; FUEL/IGNITION

(XJ-RHD).........................8W-30-1

FENDER FLAREÐYJ.................23-114

FENDER INNER SPLASH SHIELDSÐYJ . . 23-116

FENDER SPLASH APRONSÐYJ........23-115

FENDERÐXJ, FRONT

.................23-14

FENDERSÐYJ

......................23-110

FIELDÐPCM OUTPUT, GENERATOR

......14-27

FILL LEVEL, TRANSFER CASE

LUBRICANT

........................21-284

FILLER DOOR BUMPERSÐXJ, FUEL

.....23-27FILLER HOSE SPLASH SHIELDÐXJ

VEHICLES, FUEL......................13-4

FILLER NOZZLE/TUBEÐXJ, FUEL........23-26

FILLER PROTECTOR/NOZZLEÐYJ, FUEL . 23-121

FILLER TUBE CAP, FUEL TANK;

EMISSION CONTROL SYSTEMS......25-4,25-7

FILLER TUBE CAP, FUEL TANK; FUEL

SYSTEM............................14-13

FILLER TUBE, NO-LEAD FUEL TANK......14-13

FILTER DRIERÐ2.5L ENGINES,

CONDENSER........................24-27

FILTER DRIERÐ4.0L ENGINES..........24-28

FILTER, ENGINE OIL...................0-17

FILTER, FUEL; FUEL SYSTEM.......14-60,14-9

FILTER, FUEL; LUBRICATION AND

MAINTENANCE.......................0-19

FILTER REPLACEMENT, ENGINE OIL

CHANGE............................0-16

FILTER REPLACEMENT, FLUID..........21-99

FILTER REPLACEMENT, OIL............21-103

FIN SENSING CYCLING CLUTCH SWITCH . 24-15,

24-31

FINAL ASSEMBLY; FRONT SUSPENSION

AND AXLE...........................2-46

FINAL ASSEMBLY; REAR SUSPENSION

AND AXLES..........................3-29

FIRING ORDERÐ2.5L 4-CYLINDER

ENGINE, ENGINE.....................8D-32

FIRING ORDERÐ4.0L 6-CYLINDER

ENGINE, ENGINE.....................8D-32

FIRST-REVERSE BRAKE PISTON AND

TRANSMISSION CASE OVERHAUL......21-247

FIRST/SECOND/THIRD/REVERSE

COMPONENTS......................21-168

FITTING CHART, CONNECTING ROD

BEARING........................9-41,9-83

FITTING CHART, MAIN BEARING......9-48,9-90

FITTING O-RING SEAL, FLOW CONTROL

VALVE .............................19-14

FITTING SERVICE, TRANSMISSION

COOLER LINE......................21-111

FITTINGS, TRANSMISSION COOLER LINE . 21-197

FLAREÐYJ, FENDER.................23-114

FLARES AND LINERSÐXJ, REAR

WHEELHOUSE.......................23-19

FLASHER, COMBINATION; TURN

SIGNALS (XJ).....................8W-52-1

FLASHERS, HAZARD; TURN SIGNALS

(XJ).............................8W-52-1

FLASHERS, HAZARD; TURN SIGNALS

(XJ-RHD).........................8W-52-1

FLASHERS, HAZARD; TURN SIGNALS

(YJ).............................8W-52-1

FLOOR BRACKETSÐXJ, SPARE

TIRE/WHEEL HOLDDOWN..............23-98

FLOOR CONSOLEÐXJ, FULL...........23-95

FLOOR CONSOLESÐYJ...............23-155

FLOOR MATSÐXJ, CARPETS...........23-99

FLOOR SHIFTÐXJ, MINI-CONSOLE WITH . 23-94

FLOW CONTROL VALVE FITTING O-RING

SEAL..............................19-14

FLOW TESTING, TRANSMISSION

COOLER...........................21-113

FLUID AND FILTER REPLACEMENT.......21-99

FLUID CAPACITIES.....................0-3

FLUID, CLUTCH LINKAGE................6-1

FLUID CONTAMINATION, BRAKE.......5-10,5-7

FLUID LEVEL AND CONDITION,

CHECKING.........................21-182

FLUID LEVEL, BRAKE..................5-10

FLUID LEVEL CHECK.............21-70,21-99

FLUID LEVEL, CLUTCH.................6-14

FLUID, RECOMMENDED BRAKE..........5-10

FLUID WARNING LAMP, LOW WASHER;

INSTRUMENT CLUSTER (XJ).........8W-40-2

FLUID WARNING LAMP, LOW WASHER;

INSTRUMENT CLUSTER (XJ-RHD).....8W-40-2

FLUID/FILTER CHANGE, REFILLING

AFTER OVERHAUL OR..........21-100,21-182

FLUID/LUBRICANTS/CLEANING

SOLVENTS, BRAKE

.....................5-2

FLUIDÐBRAKE BLEEDINGÐ

BRAKELINES AND HOSES, BRAKE

........5-10

FLUSHING, COOLING SYSTEM

CLEANING/REVERSE

...................7-22

FLUSHING, TRANSMISSION COOLER

REVERSE

..........................21-114

FLYWHEEL RUNOUT

....................6-3FLYWHEEL SERVICE...................6-16

FOG LAMP DIAGNOSIS............8L-21,8L-3

FOG LAMP REPLACEMENTÐXJ..........8L-9

FOG LAMP REPLACEMENTÐYJ.........8L-25

FOG LAMP SWITCH REPLACEMENTÐXJ . . 8L-10

FOG LAMP SWITCH REPLACEMENTÐYJ . . 8L-26

FOG LAMPS; FRONT LIGHTING (XJ) . . . 8W-50-1

FOG LAMPS; FRONT LIGHTING (XJ-RHD) . 8W-50-2

FOG LAMPS; FRONT LIGHTING (YJ) . . . 8W-50-1

FOG LAMPSÐXJ......................8L-7

FOG LAMPSÐYJ.....................8L-23

FORM-IN-PLACE GASKETS...............9-1

FORMULAS AND EQUIVALENT VALUES,

CONVERSION.....................Intro.-11

FORWARD CLUTCH OVERHAUL........21-232

FOURTH GEAR OVERDRIVE

COMPONENTS......................21-167

FOUR-WHEEL DRIVE (4WD) SWITCH;

INSTRUMENT CLUSTER (XJ-RHD).....8W-40-2

FOUR-WHEEL DRIVE (4WD) SWITCH;

TRANSMISSION CONTROLS (XJ-RHD) . . 8W-31-1

FOUR-WHEEL-DRIVE VEHICLE TOWING....0-12

FRAME.........................13-10,13-1

FRAME CROSSMEMBER COVER.........13-16

FRAME DIMENSIONS.............13-13,13-1

FRAME GLASS CHANNEL

REPLACEMENTÐYJ, DOOR...........23-142

FRAME REPAIRS......................13-13

FRAME STRAIGHTENING...............13-13

FRAME WEATHERSTRIP SEALÐYJ,

WINDSHIELD.......................23-146

FRAMEÐXJ, BUCKET SEATBACK COVER . . 23-81

FRAMEÐYJ, WINDSHIELD............23-145

FREQUENCY INTERFERENCE, RADIO......8F-5

FRESH AIR DOOR VACUUM MOTOR......24-34

FRESH AIR INTAKE DUCT..............24-34

FRONT AND REAR AXLES...............0-24

FRONT AXLE, MODEL 30...............2-49

FRONT BUCKET SEATSÐXJ............23-81

FRONT BUMPER.................13-16,13-5

FRONT CABLE REPLACEMENT (YJ),

PARKING BRAKE......................5-67

FRONT CARPET/MATÐXJ..............23-99

FRONT CLUTCH OVERHAUL...........21-134

FRONT DOOR SPACER BLOCKSÐTWO-

DOOR VEHICLES.....................23-53

FRONT DOOR WINDOW GLASS

REGULATORÐXJ....................23-42

FRONT DOOR WINDOW GLASSÐXJ.....23-43

FRONT DRIVE AXLE....................2-3

FRONT FENDERÐXJ..................23-14

FRONT INNER SCUFF PLATE/COWL SIDE

TRIM PANELÐXJ....................23-86

FRONT PARK/TURN SIGNAL LAMP BULB

REPLACEMENTÐXJ...................8L-9

FRONT PARK/TURN SIGNAL LAMP BULB

REPLACEMENTÐYJ..................8L-25

FRONT PLANETARY GEAR OVERHAUL . . . 21-237

FRONT SERVO AND BAND OVERHAUL . . . 21-146

FRONT SHOULDER BELT/BUCKLEÐXJ....23-90

FRONT SHOULDER BELTSÐYJ.........23-154

FRONT SKID PLATE

....................13-1

FRONT SUSPENSION

...................2-1

FRONT SUSPENSION COMPONENTS, XJ

. . . 2-49

FRONT SUSPENSION COMPONENTS, YJ

. . . 2-49

FRONT SUSPENSION, XJ

...............2-11

FRONT SUSPENSION, YJ

...............2-15

FRONT TOW HOOKS

...................13-7

FRONT WHEEL ALIGNMENT

..............2-5

FRONT WHEEL BEARINGS

..............0-28

FRONT WHEEL SENSOR INSTALLATION

....5-38

FRONT WHEEL SENSOR REMOVAL

.......5-38

FUEL DELIVERY SYSTEM

...............14-3

FUEL FILLER DOOR BUMPERSÐXJ

......23-27

FUEL FILLER HOSE SPLASH SHIELDÐXJ

VEHICLES

...........................13-4

FUEL FILLER NOZZLE/TUBEÐXJ

........23-26

FUEL FILLER PROTECTOR/NOZZLEÐYJ

. . 23-121

FUEL FILTER; FUEL SYSTEM

........14-60,14-9

FUEL FILTER; LUBRICATION AND

MAINTENANCE

.......................0-19

FUEL GAUGE; INSTRUMENT CLUSTER

(XJ)

.............................8W-40-1

FUEL GAUGE; INSTRUMENT CLUSTER

(XJ-RHD)

.........................8W-40-1

FUEL GAUGE SENDING UNIT

...........14-16

10 INDEXJ

Description Group-Page Description Group-Page Description Group-Page