clock JEEP CHEROKEE 1995 Service Manual PDF

[x] Cancel search | Manufacturer: JEEP, Model Year: 1995, Model line: CHEROKEE, Model: JEEP CHEROKEE 1995Pages: 2198, PDF Size: 82.83 MB

Page 1617 of 2198

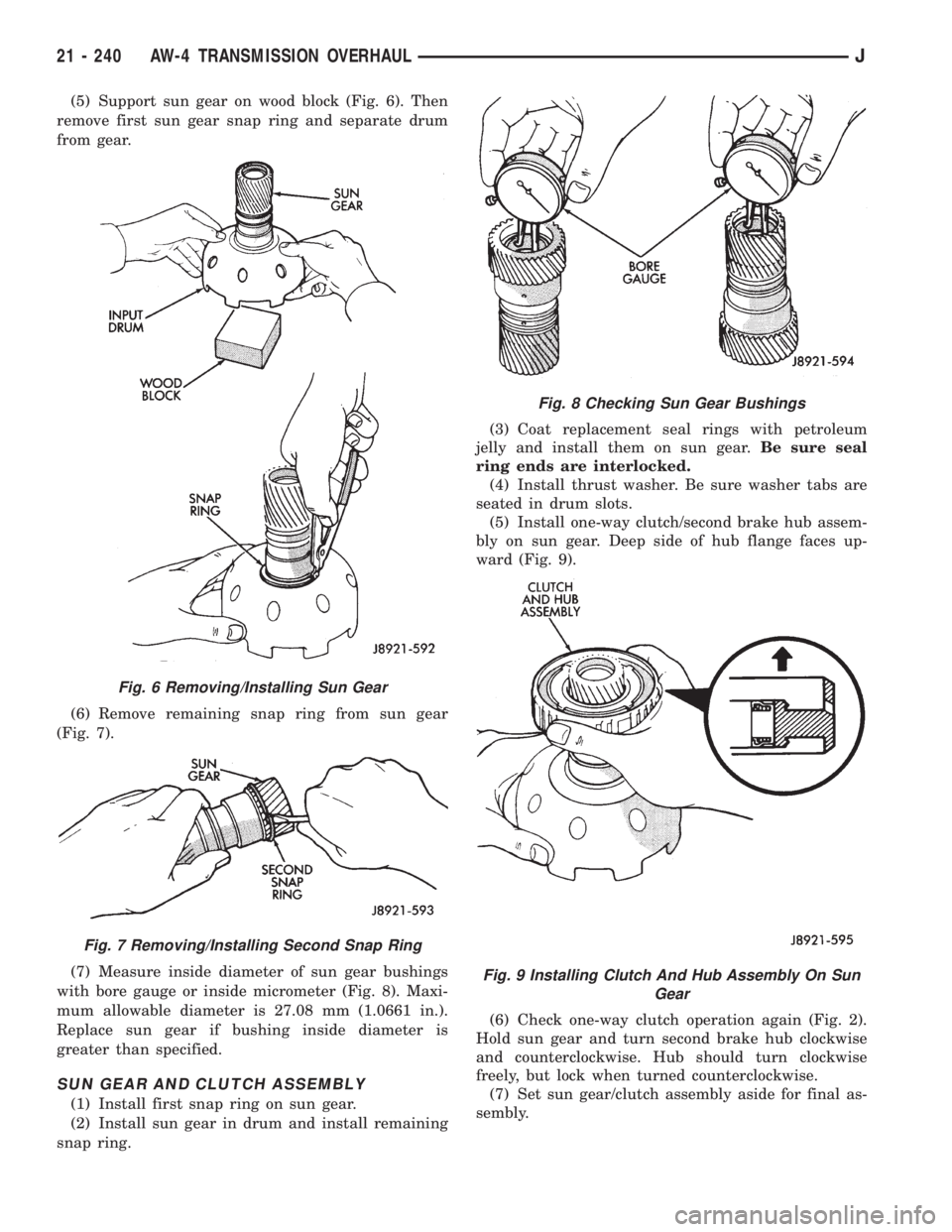

(5) Support sun gear on wood block (Fig. 6). Then

remove first sun gear snap ring and separate drum

from gear.

(6) Remove remaining snap ring from sun gear

(Fig. 7).

(7) Measure inside diameter of sun gear bushings

with bore gauge or inside micrometer (Fig. 8). Maxi-

mum allowable diameter is 27.08 mm (1.0661 in.).

Replace sun gear if bushing inside diameter is

greater than specified.

SUN GEAR AND CLUTCH ASSEMBLY

(1) Install first snap ring on sun gear.

(2) Install sun gear in drum and install remaining

snap ring.(3) Coat replacement seal rings with petroleum

jelly and install them on sun gear.Be sure seal

ring ends are interlocked.

(4) Install thrust washer. Be sure washer tabs are

seated in drum slots.

(5) Install one-way clutch/second brake hub assem-

bly on sun gear. Deep side of hub flange faces up-

ward (Fig. 9).

(6) Check one-way clutch operation again (Fig. 2).

Hold sun gear and turn second brake hub clockwise

and counterclockwise. Hub should turn clockwise

freely, but lock when turned counterclockwise.

(7) Set sun gear/clutch assembly aside for final as-

sembly.

Fig. 6 Removing/Installing Sun Gear

Fig. 7 Removing/Installing Second Snap Ring

Fig. 8 Checking Sun Gear Bushings

Fig. 9 Installing Clutch And Hub Assembly On Sun

Gear

21 - 240 AW-4 TRANSMISSION OVERHAULJ

Page 1622 of 2198

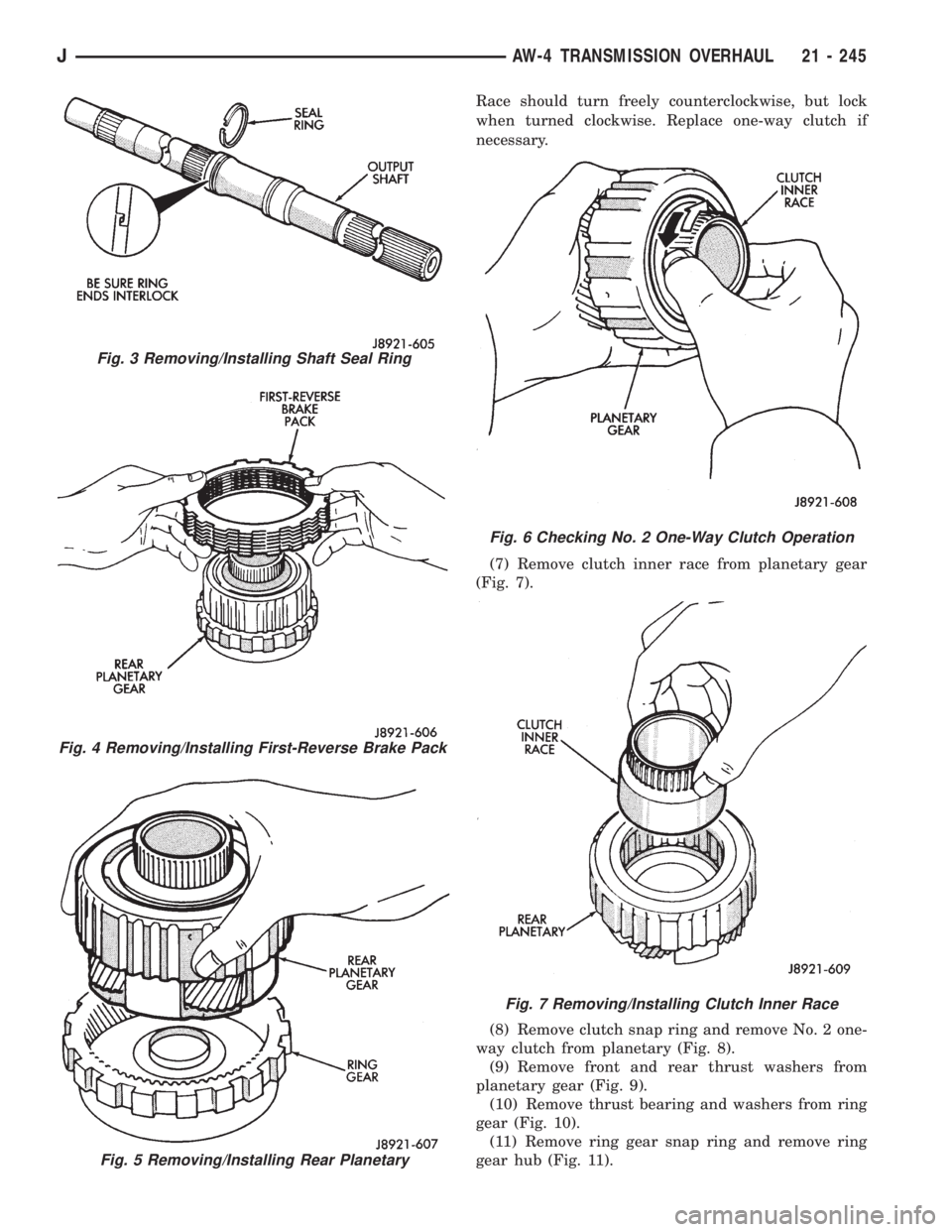

Race should turn freely counterclockwise, but lock

when turned clockwise. Replace one-way clutch if

necessary.

(7) Remove clutch inner race from planetary gear

(Fig. 7).

(8) Remove clutch snap ring and remove No. 2 one-

way clutch from planetary (Fig. 8).

(9) Remove front and rear thrust washers from

planetary gear (Fig. 9).

(10) Remove thrust bearing and washers from ring

gear (Fig. 10).

(11) Remove ring gear snap ring and remove ring

gear hub (Fig. 11).

Fig. 3 Removing/Installing Shaft Seal Ring

Fig. 4 Removing/Installing First-Reverse Brake Pack

Fig. 5 Removing/Installing Rear Planetary

Fig. 6 Checking No. 2 One-Way Clutch Operation

Fig. 7 Removing/Installing Clutch Inner Race

JAW-4 TRANSMISSION OVERHAUL 21 - 245

Page 1623 of 2198

(12) Inspect and replace any worn or damaged

planetary gear components.

ASSEMBLING REAR PLANETARY, BRAKE

PACK, CLUTCH AND SHAFT

(1) Install hub and snap ring in ring gear (Fig. 11)

(2) Identify ring gear thrust bearing and races by

following dimensions (Fig. 10):

²Outer diameter of bottom race is 44.8 mm (1.764

in.) and inner diameter is 27.6 mm (1.087 in.).

²Outer diameter of bearing is 44.7 mm (1.760 in.)

and inner diameter is 30.1 mm (1.185 in.).

²Outer diameter of upper race is 44.8 mm (1.764

in.) and inner diameter is 28.8 mm (1.134 in.).

(3) Lubricate ring gear thrust bearing and races

with petroleum jelly and install them in ring gear

(Fig. 10).

(4) Coat planetary thrust washers with petroleum

jelly and install them in gear (Fig. 9).(5) Install No. 2 one-way clutch in planetary gear.

Be sure flanged side of clutch faces upward (Fig. 12).

(6) Install clutch retaining snap ring and install

clutch inner race (Fig. 7). Turn race counterclockwise

to ease installation.

(7) Verify one-way clutch operation. Hold gear and

turn inner race in both directions. Race should turn

freely counterclockwise, but lock when turned clock-

wise.

(8) Install planetary gear in ring gear.

Fig. 8 Removing.Installing One-Way Clutch

Fig. 9 Removing/Installing Rear Planetary Thrust

Washers

Fig. 10 Removing/Installing Ring Gear Thrust

Bearing And Races

21 - 246 AW-4 TRANSMISSION OVERHAULJ

Page 1666 of 2198

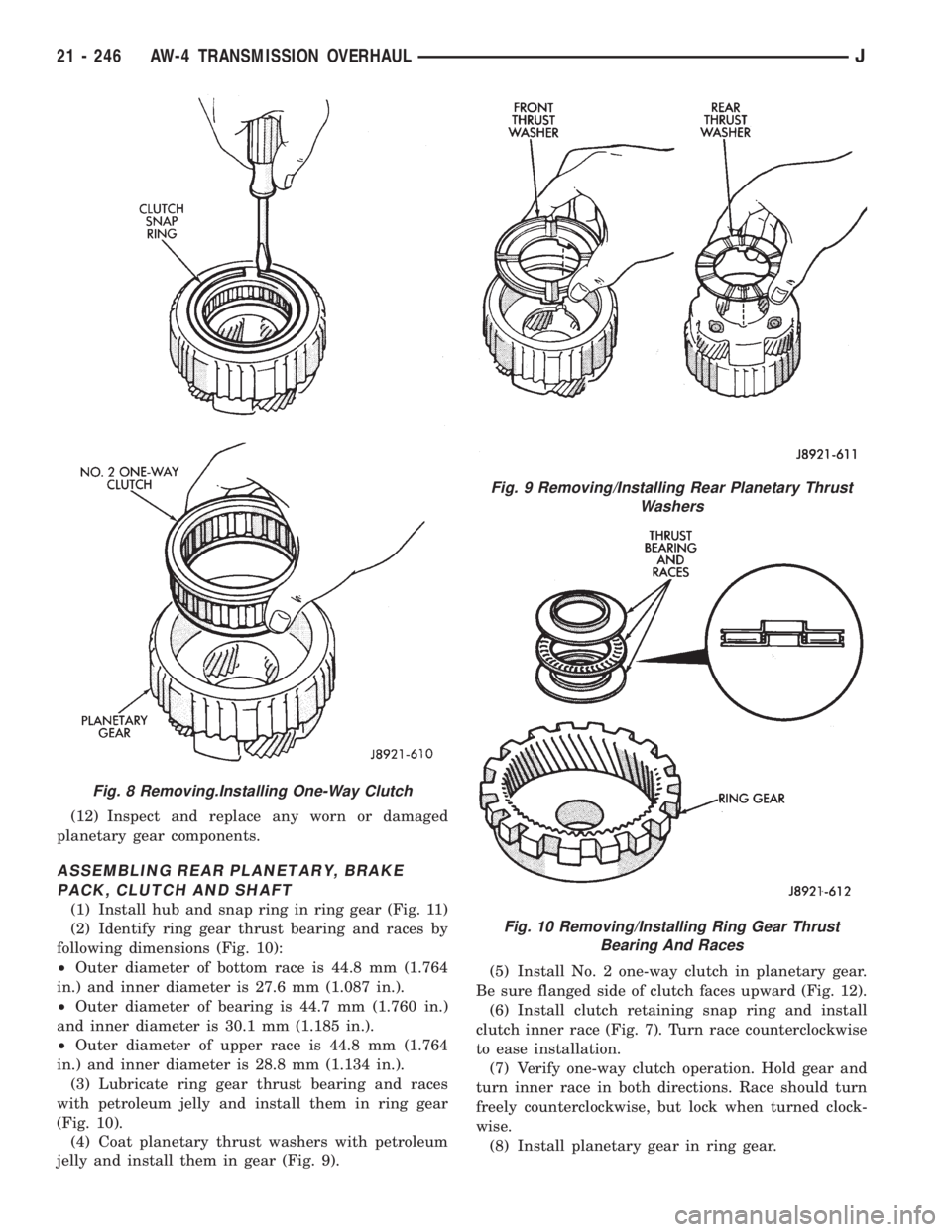

TRANSFER CASE DISASSEMBLY AND OVERHAUL

Two versions of the NP231 are used in current

models. One version retains the synchronizer

components used in previous years. A newly intro-

duced version does not have synchro components.

The non-synchro version is not equipped with a

synchro gear, struts, springs, or stop ring. During

overhaul, note which version is being serviced

and order needed parts accordingly.

(1) Remove fill and drain plugs. Also remove speed-

ometer adapter and pinion if not previously removed.

(2) Remove front yoke. Discard yoke seal washer

and nut. They should not be reused.

(3) Move transfer case range lever rearward to 4L

position.

(4) Remove extension housing attaching bolts.

(5) Tap extension housing in clockwise direction to

break sealer bead and remove housing (Fig. 1).

CAUTION: To avoid damaging the sealing surfaces

of the extension housing and rear retainer, do not

pry or wedge the housing off the retainer.

(6) Remove rear bearing snap ring (Fig. 2).

(7) Remove rear retainer attaching bolts.

(8) Remove rear retainer. Position screwdriver un-

der each tab on retainer housing (Fig. 3). Then care-

fully pry retainer upward and off rear case.

CAUTION: Do not pry against the sealing surfaces

of the retainer or rear case. The surfaces could be

damaged.

(9) Remove bolts attaching rear case to front case.

Retain bolts and washers.

(10) Separate rear case from front case (Fig. 4) Insert

screwdrivers into slots cast in case ends. Then gently

pry upward to break sealer bead and loosen rear case.

CAUTION: Do not pry against the sealing surfaces of

the retainer or rear case. The surfaces could be dam-

aged.

Fig. 1 Extension Housing Removal

Fig. 2 Rear Bearing Snap Ring Removal

Fig. 3 Rear Retainer Removal

Fig. 4 Loosening Rear Case

JNP231 TRANSFER CASE 21 - 289

Page 1673 of 2198

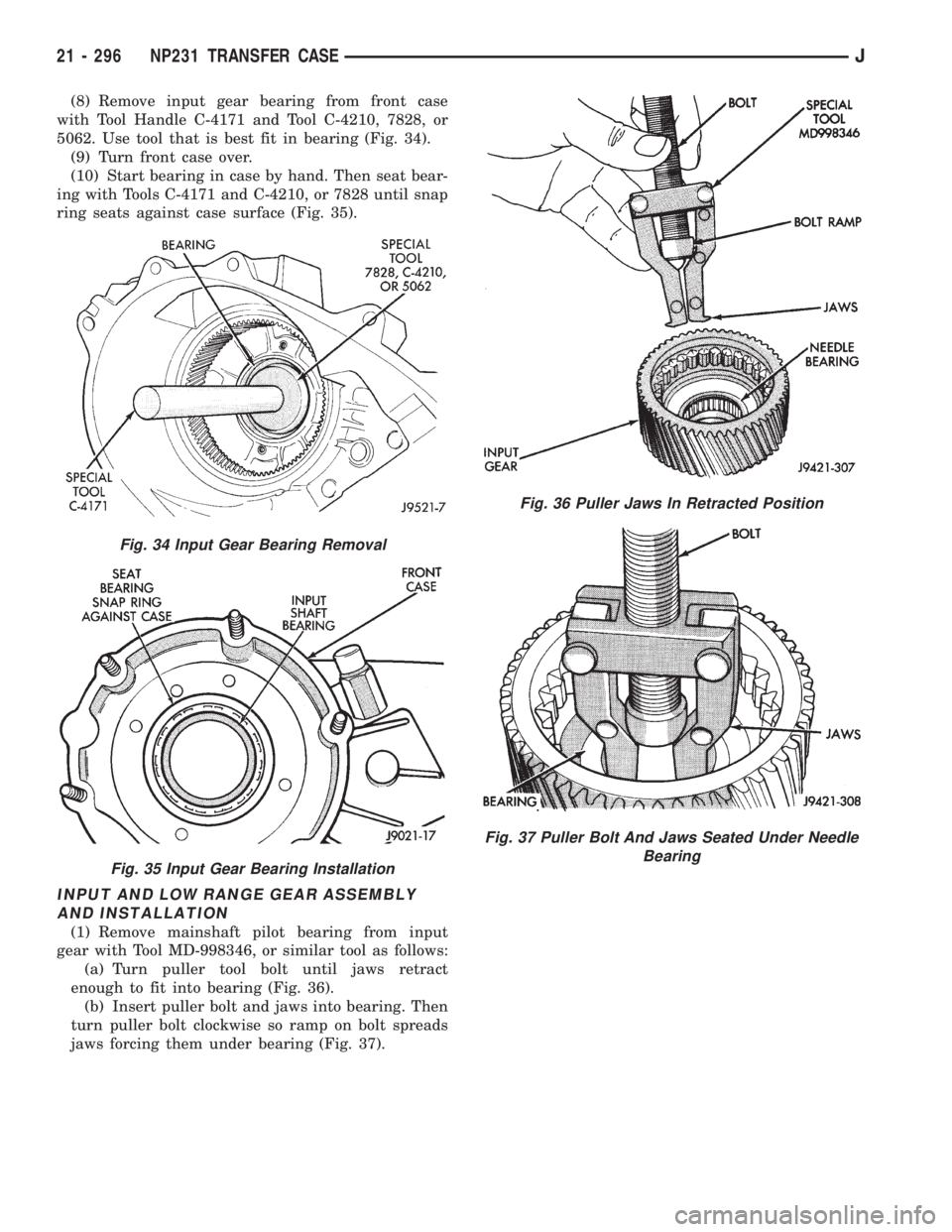

(8) Remove input gear bearing from front case

with Tool Handle C-4171 and Tool C-4210, 7828, or

5062. Use tool that is best fit in bearing (Fig. 34).

(9) Turn front case over.

(10) Start bearing in case by hand. Then seat bear-

ing with Tools C-4171 and C-4210, or 7828 until snap

ring seats against case surface (Fig. 35).

INPUT AND LOW RANGE GEAR ASSEMBLY

AND INSTALLATION

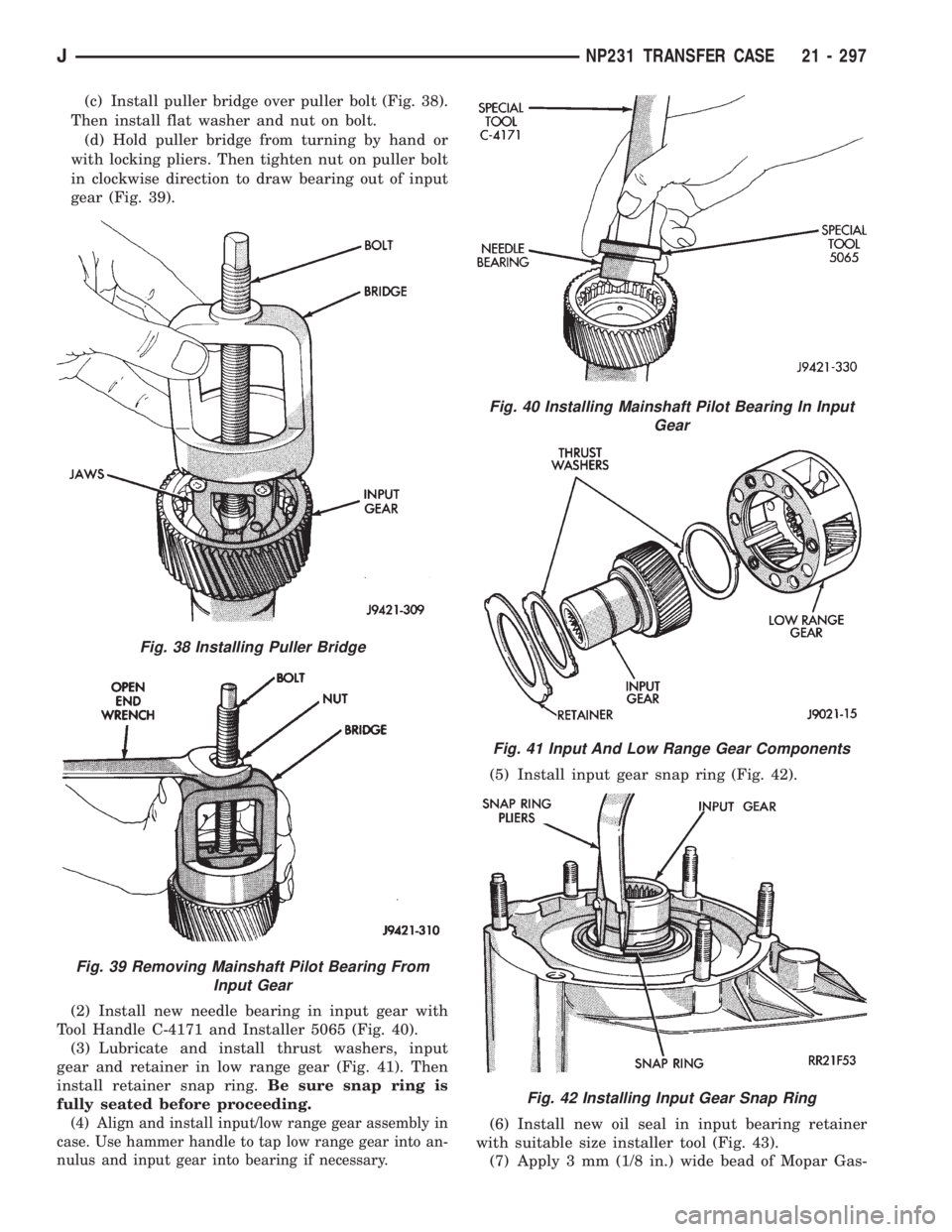

(1) Remove mainshaft pilot bearing from input

gear with Tool MD-998346, or similar tool as follows:

(a) Turn puller tool bolt until jaws retract

enough to fit into bearing (Fig. 36).

(b) Insert puller bolt and jaws into bearing. Then

turn puller bolt clockwise so ramp on bolt spreads

jaws forcing them under bearing (Fig. 37).

Fig. 34 Input Gear Bearing Removal

Fig. 35 Input Gear Bearing Installation

Fig. 36 Puller Jaws In Retracted Position

Fig. 37 Puller Bolt And Jaws Seated Under Needle

Bearing

21 - 296 NP231 TRANSFER CASEJ

Page 1674 of 2198

(c) Install puller bridge over puller bolt (Fig. 38).

Then install flat washer and nut on bolt.

(d) Hold puller bridge from turning by hand or

with locking pliers. Then tighten nut on puller bolt

in clockwise direction to draw bearing out of input

gear (Fig. 39).

(2) Install new needle bearing in input gear with

Tool Handle C-4171 and Installer 5065 (Fig. 40).

(3) Lubricate and install thrust washers, input

gear and retainer in low range gear (Fig. 41). Then

install retainer snap ring.Be sure snap ring is

fully seated before proceeding.

(4) Align and install input/low range gear assembly in

case. Use hammer handle to tap low range gear into an-

nulus and input gear into bearing if necessary.

(5) Install input gear snap ring (Fig. 42).

(6) Install new oil seal in input bearing retainer

with suitable size installer tool (Fig. 43).

(7) Apply 3 mm (1/8 in.) wide bead of Mopar Gas-

Fig. 38 Installing Puller Bridge

Fig. 39 Removing Mainshaft Pilot Bearing From

Input Gear

Fig. 40 Installing Mainshaft Pilot Bearing In Input

Gear

Fig. 41 Input And Low Range Gear Components

Fig. 42 Installing Input Gear Snap Ring

JNP231 TRANSFER CASE 21 - 297

Page 1687 of 2198

(6) Install vehicle speed sensor and adapter, if re-

moved. Then connect vehicle speed sensor wires, vent

hoses and electrical switch connector.

(7) Align and connect propeller shafts. Tighten

shaft U-joint clamp bolts to 19 Nzm (14 ft. lbs.)

torque.

(8) Fill transfer case with Mopar Dexron II. Cor-

rect fill level is to bottom edge of fill plug hole.

(9) Install rear crossmember. Tighten crossmember

bolts to 41 Nzm (30 ft. lbs.) torque.

(10) Remove transmission jack and transmission

support stand.

(11) Move transfer case range lever to 4L position.

(12) Connect shift rod to transfer case range lever.

(13) Adjust transfer case shift linkage as described

in this section.

(14) Lower vehicle.

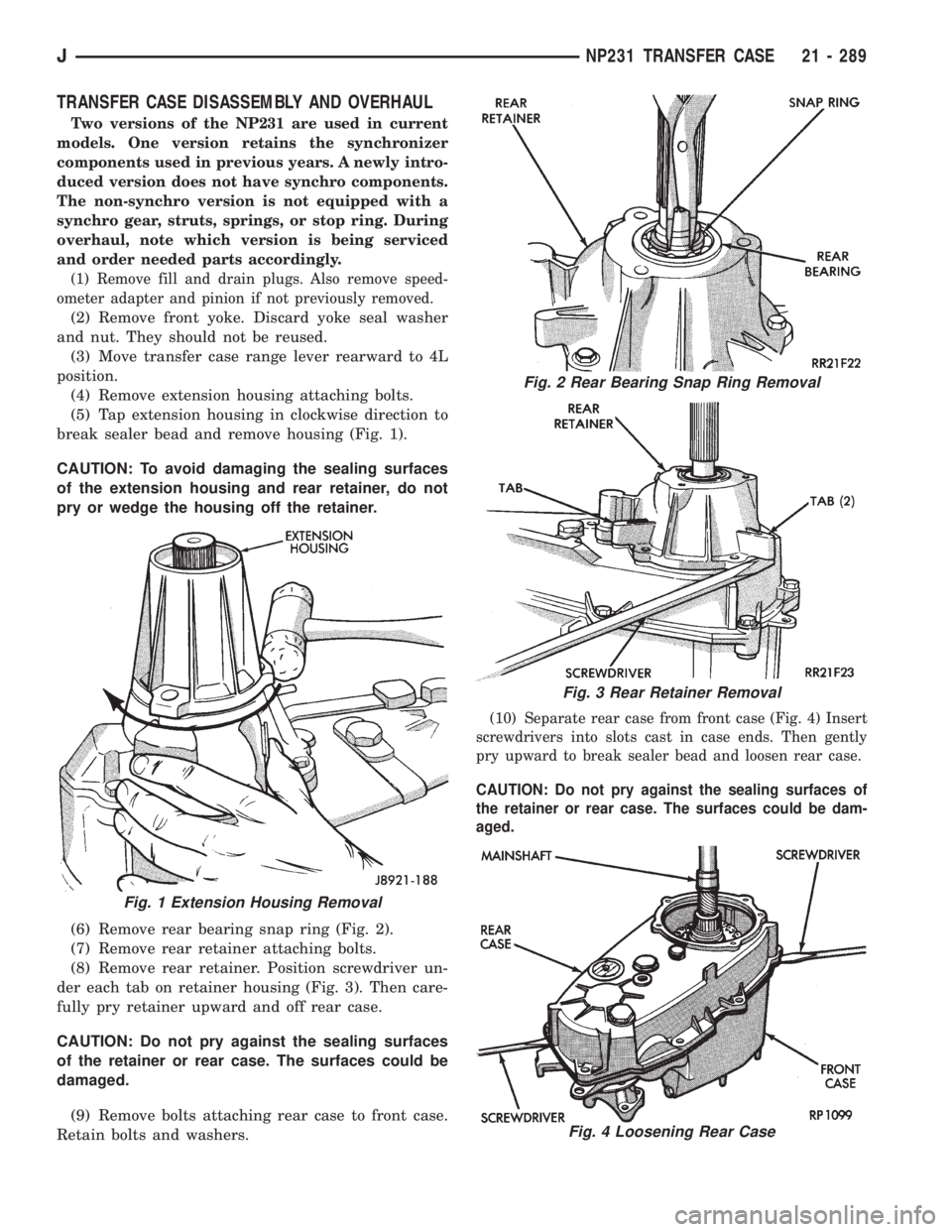

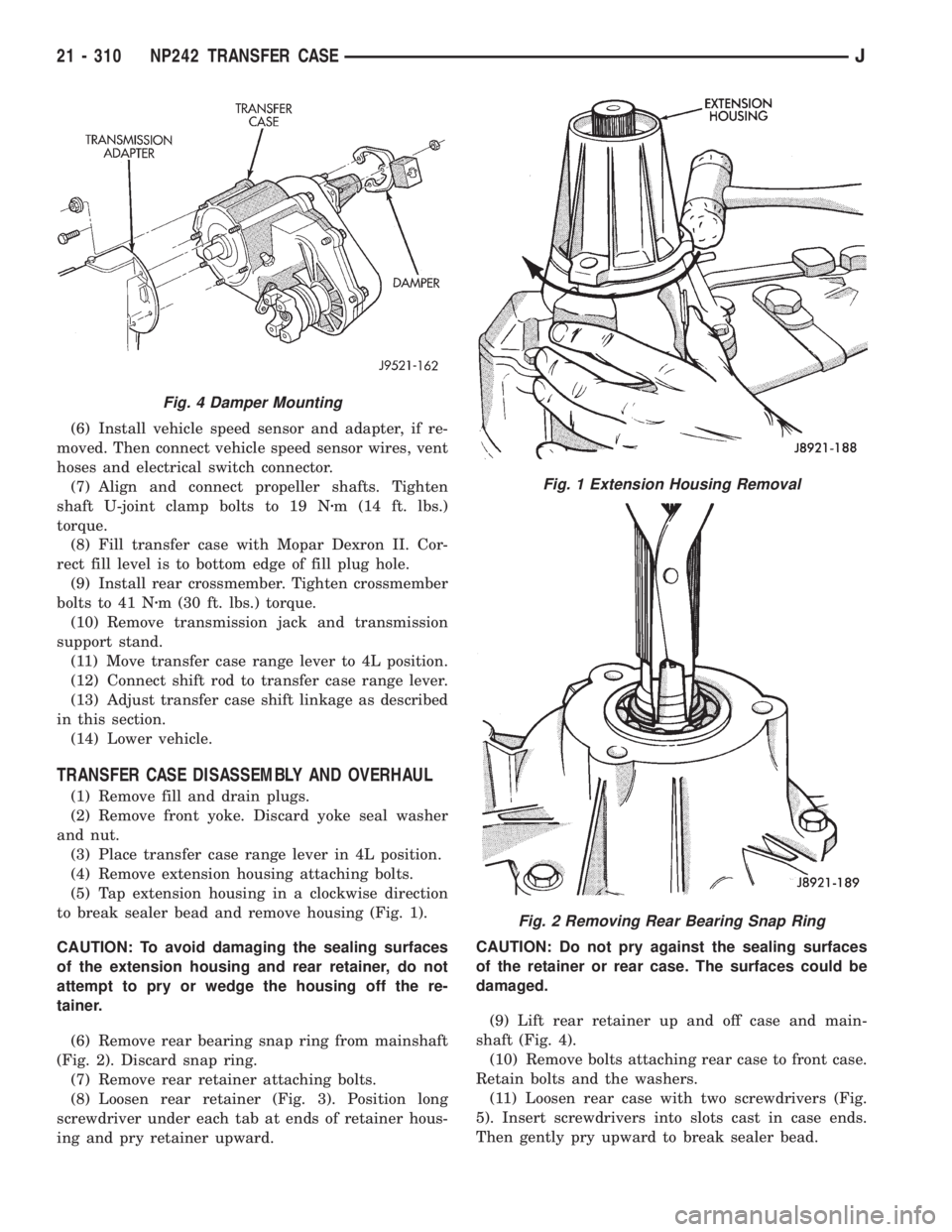

TRANSFER CASE DISASSEMBLY AND OVERHAUL

(1) Remove fill and drain plugs.

(2) Remove front yoke. Discard yoke seal washer

and nut.

(3) Place transfer case range lever in 4L position.

(4) Remove extension housing attaching bolts.

(5) Tap extension housing in a clockwise direction

to break sealer bead and remove housing (Fig. 1).

CAUTION: To avoid damaging the sealing surfaces

of the extension housing and rear retainer, do not

attempt to pry or wedge the housing off the re-

tainer.

(6) Remove rear bearing snap ring from mainshaft

(Fig. 2). Discard snap ring.

(7) Remove rear retainer attaching bolts.

(8) Loosen rear retainer (Fig. 3). Position long

screwdriver under each tab at ends of retainer hous-

ing and pry retainer upward.CAUTION: Do not pry against the sealing surfaces

of the retainer or rear case. The surfaces could be

damaged.

(9) Lift rear retainer up and off case and main-

shaft (Fig. 4).

(10) Remove bolts attaching rear case to front case.

Retain bolts and the washers.

(11) Loosen rear case with two screwdrivers (Fig.

5). Insert screwdrivers into slots cast in case ends.

Then gently pry upward to break sealer bead.

Fig. 4 Damper Mounting

Fig. 1 Extension Housing Removal

Fig. 2 Removing Rear Bearing Snap Ring

21 - 310 NP242 TRANSFER CASEJ

Page 1690 of 2198

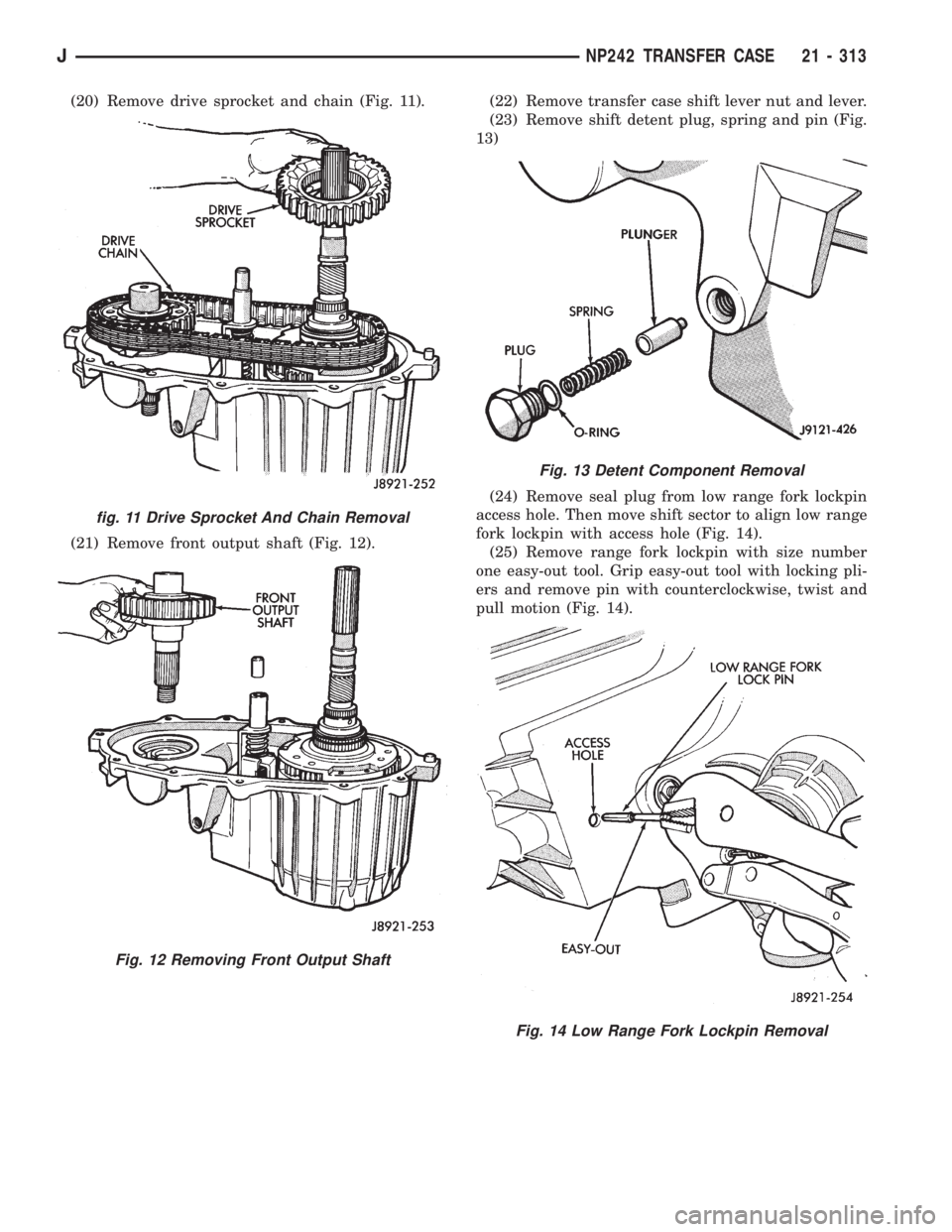

(20) Remove drive sprocket and chain (Fig. 11).

(21) Remove front output shaft (Fig. 12).(22) Remove transfer case shift lever nut and lever.

(23) Remove shift detent plug, spring and pin (Fig.

13)

(24) Remove seal plug from low range fork lockpin

access hole. Then move shift sector to align low range

fork lockpin with access hole (Fig. 14).

(25) Remove range fork lockpin with size number

one easy-out tool. Grip easy-out tool with locking pli-

ers and remove pin with counterclockwise, twist and

pull motion (Fig. 14).

fig. 11 Drive Sprocket And Chain Removal

Fig. 12 Removing Front Output Shaft

Fig. 13 Detent Component Removal

Fig. 14 Low Range Fork Lockpin Removal

JNP242 TRANSFER CASE 21 - 313

Page 1797 of 2198

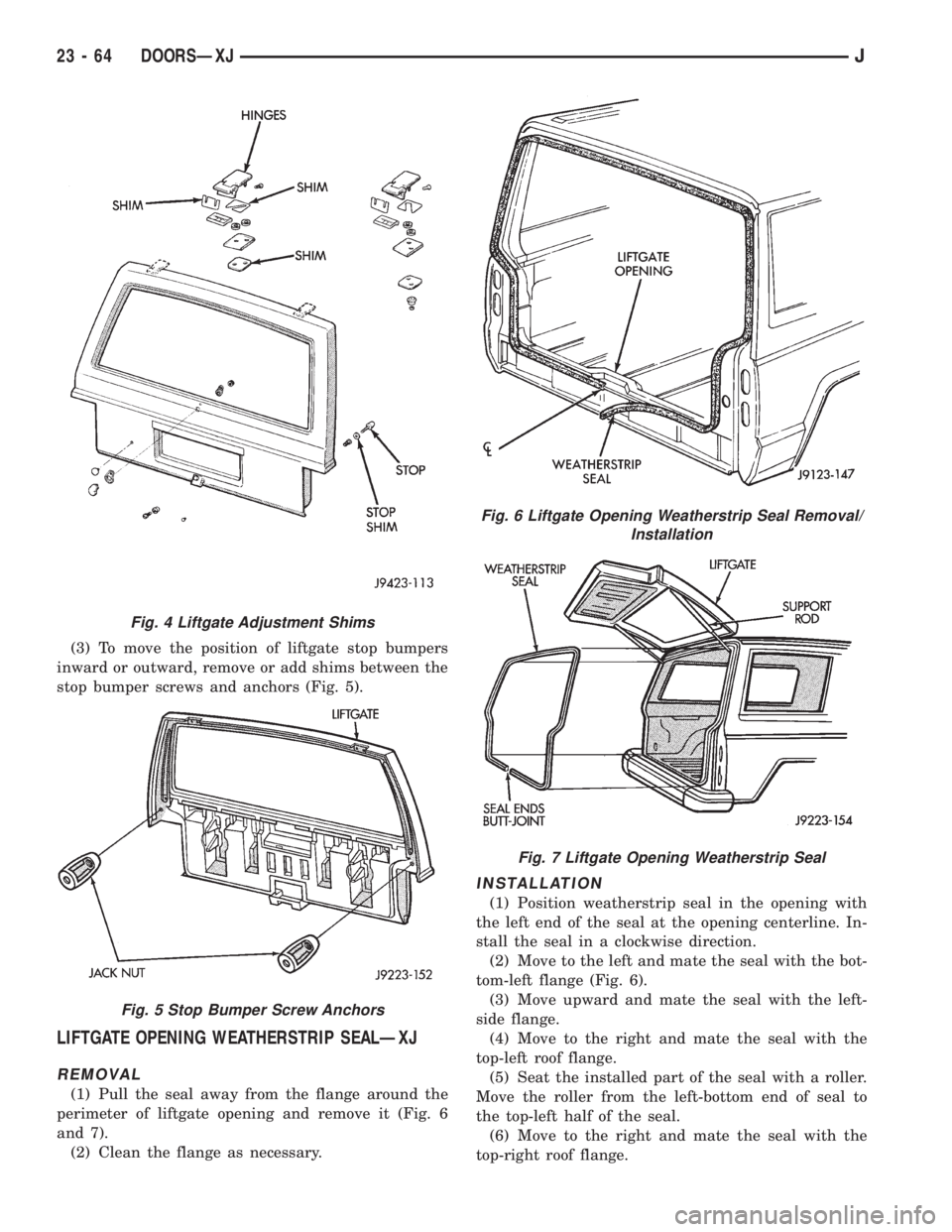

(3) To move the position of liftgate stop bumpers

inward or outward, remove or add shims between the

stop bumper screws and anchors (Fig. 5).

LIFTGATE OPENING WEATHERSTRIP SEALÐXJ

REMOVAL

(1) Pull the seal away from the flange around the

perimeter of liftgate opening and remove it (Fig. 6

and 7).

(2) Clean the flange as necessary.

INSTALLATION

(1) Position weatherstrip seal in the opening with

the left end of the seal at the opening centerline. In-

stall the seal in a clockwise direction.

(2) Move to the left and mate the seal with the bot-

tom-left flange (Fig. 6).

(3) Move upward and mate the seal with the left-

side flange.

(4) Move to the right and mate the seal with the

top-left roof flange.

(5) Seat the installed part of the seal with a roller.

Move the roller from the left-bottom end of seal to

the top-left half of the seal.

(6) Move to the right and mate the seal with the

top-right roof flange.

Fig. 4 Liftgate Adjustment Shims

Fig. 5 Stop Bumper Screw Anchors

Fig. 6 Liftgate Opening Weatherstrip Seal Removal/

Installation

Fig. 7 Liftgate Opening Weatherstrip Seal

23 - 64 DOORSÐXJJ

Page 1888 of 2198

(4) Install the shoulder belt buckle at the floor

panel with the anchor bolt. Tighten the bolt to 41

Nzm (30 ft-lbs) torque.

SUNVISORSÐYJ

REMOVAL

(1) Remove the screws that attach the sunvisor

arm support brackets to the windshield frame (Fig.

6).

(2) Remove the sunvisor from the windshield

frame.

(3) Remove the sunvisor from the vehicle.

INSTALLATION

(1) If applicable, replace the labels (Fig. 6).

(2) Position the sunvisor on the windshield frame

and align the arm support bracket holes with the

frame.

(3) Install the screws that attach the sunvisor arm

support brackets to the frame. Tighten the screws se-

curely.

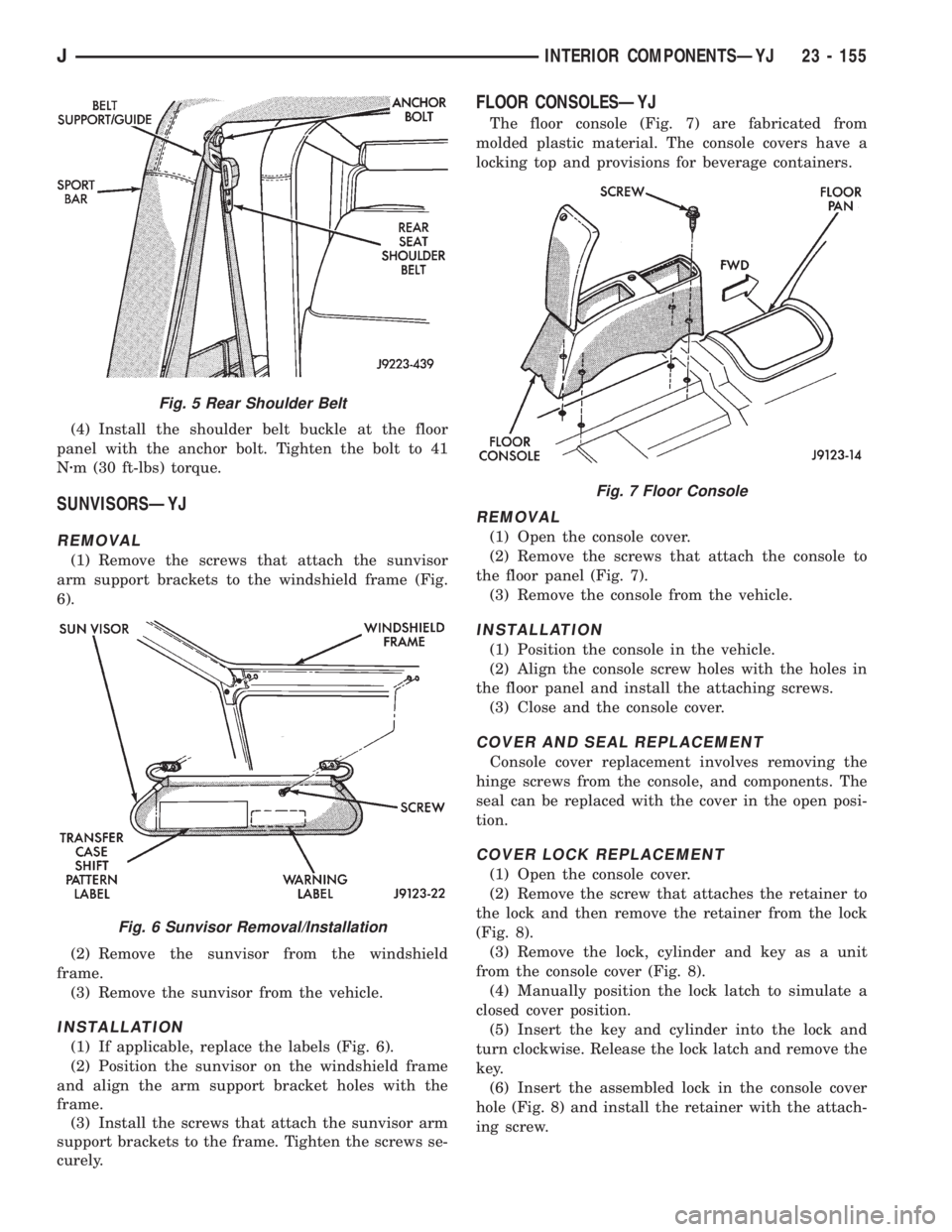

FLOOR CONSOLESÐYJ

The floor console (Fig. 7) are fabricated from

molded plastic material. The console covers have a

locking top and provisions for beverage containers.

REMOVAL

(1) Open the console cover.

(2) Remove the screws that attach the console to

the floor panel (Fig. 7).

(3) Remove the console from the vehicle.

INSTALLATION

(1) Position the console in the vehicle.

(2) Align the console screw holes with the holes in

the floor panel and install the attaching screws.

(3) Close and the console cover.

COVER AND SEAL REPLACEMENT

Console cover replacement involves removing the

hinge screws from the console, and components. The

seal can be replaced with the cover in the open posi-

tion.

COVER LOCK REPLACEMENT

(1) Open the console cover.

(2) Remove the screw that attaches the retainer to

the lock and then remove the retainer from the lock

(Fig. 8).

(3) Remove the lock, cylinder and key as a unit

from the console cover (Fig. 8).

(4) Manually position the lock latch to simulate a

closed cover position.

(5) Insert the key and cylinder into the lock and

turn clockwise. Release the lock latch and remove the

key.

(6) Insert the assembled lock in the console cover

hole (Fig. 8) and install the retainer with the attach-

ing screw.

Fig. 5 Rear Shoulder Belt

Fig. 6 Sunvisor Removal/Installation

Fig. 7 Floor Console

JINTERIOR COMPONENTSÐYJ 23 - 155