check engine JEEP CHEROKEE 1995 Service Manual Online

[x] Cancel search | Manufacturer: JEEP, Model Year: 1995, Model line: CHEROKEE, Model: JEEP CHEROKEE 1995Pages: 2198, PDF Size: 82.83 MB

Page 580 of 2198

Circuit T17 from fuse 3 in the power distribution

center supplies voltage to the coil and contact sides

of the TCC relay. When the PCM provides a ground

path on circuit K54 for the coil side of the relay, the

relay contacts close.

When the relay contacts close, they connect circuit

T17 with circuit T22. Circuit T22 supplies battery

voltage to the case grounded TCC solenoid. Circuit

K54 connects to PCM cavity 54.

HELPFUL INFORMATION

²In the RUN or START position, the ignition switch

connects circuit A1 from fuse 4 in the PDC to circuit

A21.

UPSHIFT LAMP

On vehicles equipped with a manual transmission,

the PCM grounds the up-shift lamp on circuit K54.

Circuit K54 connects to cavity 54 of the PCM.

POWER STEERING PRESSURE SWITCH

The PCM supplies voltage to the power steering

pressure switch on circuit K10. Circuit Z12 provides

ground for the switch. When the switch closes, volt-

age flows through the switch to ground on circuit

Z12. The switch closes during periods of high power

steering pump load and low engine speed; such as

parking maneuvers.

Circuit K10 connects to cavity 10 of the PCM. Cir-

cuit Z12 terminates at the right rear of the engine.

TACHOMETER SIGNAL

The PCM supplies the signal for the tachometer on

circuit G21. Circuit G21 connects to cavity 43 of the

PCM.

MALFUNCTION INDICATOR LAMP (MIL)

The PCM provides ground for the instrument clus-

ter malfunction indicator lamp on circuit G3. The

MIL displays the message CHECK ENGINE when il-

luminated. Circuit F87 provides voltage for the lamp.

DATA LINK CONNECTOR

Circuit F12 supplies battery voltage to the data

link connector. Circuit F12 originates at fuse 11 in

the Power Distribution Center.

Circuit D20 connects to cavity 45 of the PCM. Cir-

cuit D20 is the SCI receive circuit for the PCM.

Circuit D21 connects to cavity 25 of the PCM. Cir-

cuit D21 is the SCI transmit circuit for the PCM.

Circuit Z11 provides ground for the data link con-

nector. Circuit Z11 terminates at the right rear of the

engine. Circuit Z11 also connects to cavity 5 of the

PCM.

HELPFUL INFORMATION

²Circuit Z1 also supplies a ground for the PCM

high current drivers.

²If the system loses ground for the Z11 circuits at

the right rear of the engine, the vehicle will not op-

erate. Check the connection at the ganged-ground cir-

cuit eyelet.

²Circuit F12 splices to supply battery voltage to the

vehicle speed control switch, back-up lamp switch,

A/C compressor clutch relay, windshield washer fluid

level sensor and radiator fan relay (4.0L engines).

BRAKE SWITCH INPUT

Circuit K29 provides the brake switch input to the

PCM. Circuit V40 connects to cavity 29 of the PCM.

POWER (DEVICE) GROUND

Circuit Z12 connects to cavities 11 and 12 of the

PCM. The Z12 circuit provides ground for PCM inter-

nal drivers that operate high current devices like the

injectors and ignition coil.

Internal to the PCM, the power (device) ground cir-

cuit connects to the PCM sensor return circuit (from

circuit K4).

HELPFUL INFORMATION

²The grounding point for circuit Z12 is the right

rear of the engine.

²If the system loses ground for the Z12 circuits at

the rear of the engine, the vehicle will not operate.

Check the connection at the ganged-ground circuit

eyelet.

²On vehicles equipped with the 4.0L engine and au-

tomatic transmission, circuit Z12 splices to provide

ground for the transmission control module.

EXTENDED IDLE SWITCH

On Police Package vehicles, an optional extended

idle switch provides an input to the Powertrain Con-

trol Module (PCM) on circuit K10. Circuit K10 con-

nects to cavity 10 of the PCM. Circuit F60 supplies

battery voltage to the extended idle switch. Circuit

Z1 grounds the switch.

CCD BUS

On vehicles equipped with the 4.0L engine, circuits

D1 and D2 connect the Powertrain Control Module

(PCM) to the CCD Bus. Circuit D1 connects to cavity

26 of the PCM. Circuit D2 connects to cavity 46 of

the PCM. Circuits D1 and D2 are a twisted pair of

wires.

J8W-30 FUEL/IGNITIONÐXJ VEHICLES 8W - 30 - 5

Page 613 of 2198

OIL PRESSURE GAUGE

The case grounded oil pressure sensor is a variable

resistor that connects to circuit G6. Circuit G6 con-

nects to the oil pressure gauge.

Circuit F87 connects to the instrument cluster con-

nector and supplies battery voltage to oil pressure

gauge. The gauge uses two coils. Current passing

through the coils creates a magnetic field. Position of

the gauge needle is controlled by the amount of cur-

rent passing through the coils to ground at the sen-

sor.

OIL PRESSURE WARNING LAMP

The case grounded oil pressure switch connects to

circuit G6. Circuit G6 connects to the oil pressure

warning lamp. Circuit F87 connects to the instru-

ment cluster connector and supplies battery voltage

to oil pressure lamp.

When the oil pressure switch close, battery voltage

flows through the warning lamp to ground through

the switch, illuminating the lamp.

TACHOMETER

The tachometer module in the instrument cluster

operates the tachometer. The Powertrain Control

Module (PCM) supplies the signal for the tachometer

on circuit G21. Circuit G21 connects to cavity 43 of

the PCM.

SPEEDOMETER

The speedometer and odometer receive a signal

from the vehicle speed sensor on circuit G7. Circuit

G7 also connects to the Powertrain Control Module

(PCM) at cavity 47.

ABS WARNING LAMP

Circuit F87 provides power for the ABS warning

lamp at the instrument cluster. Ground for the ABS

warning lamp is provided by either the ABS control

module or by the ABS power relay when the relay is

not energized. The ABS control module illuminates

the lamp by providing ground on circuit B205.

Circuit B205 splices to connect to circuit B235

through a diode. When the ABS power relay is not

energized, it connects circuit B235 to circuit Z12. The

ground path for the warning lamp is through the di-

ode to circuit B235, through the ABS power relay to

ground on circuit Z12.

The diode between circuit B205 and B235 prevents

voltage from flowing to the ABS control module when

the ABS power relay switches to supply power on cir-

cuit B235.

MALFUNCTION INDICATOR LAMP (MIL)

The PCM provides ground for the instrument clus-

ter malfunction indicator lamp on circuit G3. Circuit

G3 connects to cavity 32 of the PCM. Circuit F87provides voltage for the lamp. The MIL displays the

message CHECK ENGINE when illuminated.

For information regarding diagnostic trouble code

access using the MIL lamp, refer to Group 14, Fuel

Systems.

LOW WASHER FLUID WARNING LAMP

Circuit G29 connects the low washer fluid switch to

the warning lamp in the instrument cluster. Circuit

F12 supplies battery voltage to the switch.

When the low washer fluid switch closes, it con-

nects circuits G29 and F12. Battery voltage from cir-

cuit F12 powers the low washer fluid lamp. Circuit

Z1 at the instrument cluster provides ground to illu-

minate the warning lamp.

SEAT BELT INDICATOR WARNING LAMP

The seat belt indicator warning lamp is activated

by the chime/buzzer on circuit G11. Circuit G11 sup-

plies power to instrument cluster for the lamp. Cir-

cuit Z1 provides ground for the lamp at the cluster.

The chime/buzzer module powers circuit G11 after

it receives an input on circuit G10 indicating the seat

belt switch is open.

HIGH-BEAM INDICATOR LAMP

Circuit L3 supplies power for the high-beam indi-

cator lamp. The ground path for the lamp is through

circuit Z1. If the vehicle has Daytime Running

Lamps (DRL), the DRL module powers circuit L3

through circuit G465. On vehicles not equipped with

DRL, the headlamp switch powers circuit L3.

Circuit Z1 provides ground for the indicator lamp

at the cluster.

TURN SIGNAL INDICATOR LAMPS

Circuits L61 and L60 power for the turn signal in-

dicator lamps. Circuit L61 powers the left indicator

lamp. Circuit L60 powers the right indicator lamp.

Circuit Z1 provides ground for the lamps.

BRAKE WARNING LAMP

Circuit F87 supplies power to the park brake lamp.

Ground for the park brake lamp is supplied through

the case grounded park brake switch or brake warn-

ing switch on circuit G9. Circuit G9 Connects to cir-

cuit B203. Circuit B203 connects to the brake

warning lamp at the instrument cluster.

MANUAL TRANSMISSION UP-SHIFT LAMP

Circuit F87 supplies power for the manual trans-

mission up-shift lamp. The lamp illuminates when

the Powertrain Control Module (PCM) provides

ground for the lamp on circuit K54. Circuit K54 con-

nects to cavity 54 of the PCM.

8W - 40 - 2 8W-40 INSTRUMENT CLUSTERÐXJ VEHICLESJ

Page 614 of 2198

CHARGING SYSTEM INDICATOR LAMP

The Powertrain Control Module (PCM) illuminates

the charging system indicator lamp by providing

ground for the lamp on circuit G12. Circuit G12 con-

nects to cavity 36 of the PCM. Circuit F87 supplies

battery voltage to the lamp.

FOUR-WHEEL DRIVE (4WD) SWITCH

When the 4WD switch closes, circuit Z1 provides

ground for the 4WD indicator lamp in the instrument

cluster. Circuit F87 connects to the instrument clus-

ter and supplies battery voltage to the 4WD indicator

lamp. Circuit 107 connects the indicator lamp to the

4WD switch. Circuit 106 connects the lamp to the in-

strument cluster and circuit F87.

CLUSTER GROUND

Circuit Z1 from the instrument cluster left connec-

tor provides ground for the illumination lamps and

indicator lamps.

HELPFUL INFORMATION

²If the warning lamps don't operate, check fuse 14

in the fuse block.

²If the indicator lamps and illumination lamps

don't operate, check fuse 13 in the fuse block.

²Inspect the ground at the instrument panel lower

right reinforcement support.

DIAGRAM INDEX

Component Page

4WD Switch............................8W-40-9

4WD Indicator Lamp......................8W-40-9

ABS Control Module......................8W-40-9

Brake Warning Switch.....................8W-40-10

Chime/Buzzer Module......................8W-40-8

Daytime Running Lamps Module.............8W-40-5, 6

Engine Coolant Temperature Sending Unit.........8W-40-6

Engine Oil Pressure Sending Unit..............8W-40-6

Fuse 3 (PDC)...........................8W-40-8

Fuse 5 (PDC)...........................8W-40-4

Fuse 6 (PDC).........................8W-40-4, 8

Fuse 11 (PDC)..........................8W-40-8

Fuse 16 (PDC)..........................8W-40-8

Fuse 9 (Fuse Block).......................8W-40-8

Fuse 15 (Fuse Block)......................8W-40-4

Fuse 17 (Fuse Block)....................8W-40-4, 8

Fuse 19 (Fuse Block)......................8W-40-4

Headlamp Switch.......................8W-40-4, 5

Headlamp Delay Module....................8W-40-8

Headlamp Dimmer Switch...................8W-40-5

Ignition Switch......................8W-40-4, 8, 10

Instrument Cluster......................8W-40-4, 5

Low Washer Fluid Lamp Switch...............8W-40-8

Park Brake Switch.......................8W-40-10

Powertrain Control Module..................8W-40-6

Remote Keyless Entry Module................8W-40-8

Telltale Connector (Instrument Cluster).....8W-40-7 thru 10

J8W-40 INSTRUMENT CLUSTERÐXJ VEHICLES 8W - 40 - 3

Page 859 of 2198

THROTTLE POSITION SENSOR

From the Powertrain Control Module (PCM), cir-

cuit K6 supplies 5 volts to the throttle position sen-

sor (TPS). Circuit K6 connects to cavity 6 of the

PCM.

Circuit K22 delivers the TPS signal to the PCM.

Circuit K22 connects to cavity 22 of the PCM.

The PCM provides a ground for the throttle posi-

tion sensor signal (circuit K22) through circuit K4.

Circuit K4 connects to cavity 4 of the PCM.

HELPFUL INFORMATION

Refer to Group 14 for throttle position sensor oper-

ation.

Circuit K6 splices to supply 5 volts to the manifold

absolute pressure sensor.

Circuit K22 splices to the transmission control

module.

Circuit K4 splices to supply ground for the signals

from the following:

²Heated oxygen sensor

²Camshaft position sensor

²Crankshaft position sensor

²Intake air temperature sensor

²Manifold absolute pressure sensor

²Engine coolant temperature sensor

²Vehicle speed sensor

MANIFOLD ABSOLUTE PRESSURE SENSOR

From the Powertrain Control Module (PCM), cir-

cuit K6 supplies 5 volts to the manifold absolute

pressure (MAP) sensor. Circuit K6 connects to cavity

6 of the PCM.

Circuit K1 delivers the MAP signal to the PCM.

Circuit K1 connects to cavity 1 of the PCM.

The PCM provides a ground for the MAP sensor

signal (circuit K1) through circuit K4. Circuit K4 con-

nects to cavity 4 of the PCM.

HELPFUL INFORMATION

Refer to Group 14 for MAP sensor operation.

Circuit K6 splices to supply 5 volts to the throttle

position sensor.

Circuit K4 splices to supply ground for the signals

from the following:

²Heated oxygen sensor

²Camshaft position sensor

²Crankshaft position sensor

²Intake air temperature sensor

²Throttle position sensor

²Engine coolant temperature sensor

²Vehicle speed sensor

INTAKE AIR TEMPERATURE SENSOR

The intake air temperature sensor provides an in-

put to the Powertrain Control Module (PCM) on cir-

cuit K21. Circuit K21 connects to cavity 21 of the

PCM.From circuit K21, the intake air temperature sen-

sor draws voltage from the PCM. The sensor is a

variable resistor. As intake air temperature changes,

the resistance in the sensor changes, causing a

change in current draw.

The PCM provides a ground for the intake air tem-

perature sensor signal (circuit K21) through circuit

K4. Circuit K4 connects to cavity 4 of the PCM.

HELPFUL INFORMATION

Circuit K4 splices to supply ground for the signals

from the following:

²Heated oxygen sensor

²Camshaft position sensor

²Crankshaft position sensor

²Throttle position sensor

²Manifold absolute pressure sensor

²Engine coolant temperature sensor

²Vehicle speed sensor

PARK/NEUTRAL POSITION SWITCH

When closed, the case-grounded park/neutral posi-

tion switch provides a ground path on circuit T41 for

the coil side of the starter motor relay. Circuit A41

from the ignition switch provides battery voltage to

the coil side of the relay.

Circuit T41 splices to cavity 30 of the PCM. The

park/neutral position switch provides an input to the

Powertrain Control Module (PCM).

TACHOMETER SIGNAL

The PCM supplies the signal for the tachometer on

circuit G21. Circuit G21 connects to cavity 43 of the

PCM.

MALFUNCTION INDICATOR LAMP (MIL)

The Powertrain Control Module (PCM) provides

ground for the instrument cluster malfunction indica-

tor lamp on circuit G3. The MIL displays the mes-

sage CHECK ENGINE when illuminated. Circuit

F87 provides voltage for the lamp. Circuit G3 con-

nects to cavity 32 of the PCM.

DATA LINK CONNECTOR

Circuit F12 supplies battery voltage to the data

link connector. Circuit F12 originates at fuse 11 in

the Power Distribution Center.

Circuit D20 connects to cavity 45 of the PCM. Cir-

cuit D20 is the SCI receive circuit for the PCM.

Circuit D21 connects to cavity 25 of the PCM. Cir-

cuit D21 is the SCI transmit circuit for the PCM.

Circuit Z11 provides ground for the data link con-

nector. Circuit Z11 also connects to cavity 5 of the

PCM.

8W - 30 - 4 8W-30 FUEL/IGNITIONÐXJ-RHDJ

Page 860 of 2198

HELPFUL INFORMATION

²If the system loses ground for the Z11 circuits at

the right rear of the engine, the vehicle will not op-

erate. Check the connection at the ganged-ground cir-

cuit eyelet.

²Circuit F12 splices to supply battery voltage to the

vehicle speed control switch, back-up lamp switch,

A/C compressor clutch relay, windshield washer fluid

level sensor and radiator fan relay.

BRAKE SWITCH INPUT

Circuit K29 provides the brake switch input to the

PCM. Circuit K29 connects to cavity 29 of the PCM.

POWER (DEVICE) GROUND

Circuit Z12 connects to cavities 11 and 12 of the

PCM. The Z12 circuit provides ground for PCM inter-

nal drivers that operate high current devices like the

injectors and ignition coil.

Internal to the PCM, the power (device) ground cir-

cuit connects to the PCM sensor return circuit (from

circuit K4).

HELPFUL INFORMATION

²The grounding point for circuit Z12 is the right

rear of the engine.

²If the system loses ground for the Z12 circuits at

the rear of the engine, the vehicle will not operate.

Check the connection at the ganged-ground circuit

eyelet.

DIAGRAM INDEX

Component Page

Automatic Shut Down Relay.................8W-30-6

Camshaft Position Sensor...................8W-30-8

Crankshaft Position Sensor..................8W-30-9

Data Link Connector......................8W-30-11

Distributor Ignition Coil....................8W-30-11

Engine Coolant Temperature Sensor.............8W-30-9

Fuel Injector #1.........................8W-30-7

Fuel Injector #2.........................8W-30-7

Fuel Injector #3.........................8W-30-7

Fuel Injector #4.........................8W-30-7

Fuel Injector #5.........................8W-30-7

Fuel Injector #6.........................8W-30-7

Fuel Pump Relay........................8W-30-12

Fuel Tank Gauge Level Sending Unit...........8W-30-12

Fuse 2 (PDC)...........................8W-30-6

Fuse 6 (PDC)...........................8W-30-6

Fuse 11 (PDC).......................8W-30-6, 11

Fuse 14 (PDC)..........................8W-30-6

Heated Oxygen Sensor....................8W-30-10

Idle Air Control Motor.....................8W-30-10

Ignition Switch.......................8W-30-6, 12

Instrument Cluster....................8W-30-11, 12

Intake Air Temperature Sensor................8W-30-9

MAP Sensor............................8W-30-8

Powertrain Control Module.............8W-30-6 thru 12

Throttle Position Sensor....................8W-30-8

Vehicle Speed Sensor.....................8W-30-11

J8W-30 FUEL/IGNITIONÐXJ-RHD 8W - 30 - 5

Page 873 of 2198

ABS pump motor relay. The ABS control module pro-

vides ground for the relay on circuit B116. Circuit

B116 connects to cavity 15 of the ABS control mod-

ule.

When the ABS pump motor energizes, it connects

circuit A10 from PDC fuse 8 to circuit B233. Circuit

B233 supplies battery voltage to the pump motor.

Circuit Z12 provides ground for the pump motor.

PUMP MOTOR SPEED SENSOR

The input from the pump motor speed sensor tells

the ABS control module that the pump is operating.

Circuits B219 and B220 from the control module con-

nect to the speed sensor.

BRAKE SWITCH INPUT

Circuit L50 from the stop lamp provides the brake

switch input to the ABS control module. When the

brake pedal is depressed, the stop lamp switch closes

to supply battery voltage from circuit L9 to circuit

L50. Circuit L50 connects to cavity 32 of the ABS

control module. Circuit L9 originates at fuse 4 in the

Power Distribution Center (PDC).

HYDRAULIC CONTROL UNIT

When the ABS power relay energizes, two branches

of circuit B235 splice to supply voltage to the isola-

tion and decay solenoids in the hydraulic control

unit. The hydraulic control unit contains three sepa-

rate isolation solenoids and three separate dump so-

lenoids. The ABS control module activates the decay

and isolation solenoids by providing separate ground

paths for each.

The ABS module provides a ground path for the

rear isolation solenoid on circuit B251. Circuit B251

connects to cavity 54 of the ABS control module.

For the right front isolation solenoid, the ABS mod-

ule provides a ground path on circuit B249. Circuit

B249 connects to cavity 38 of the ABS control mod-

ule.

On circuit B245, the ABS control module provides

ground for the left front isolation solenoid. Circuit

B245 connects to cavity 20 of the ABS control mod-

ule.

The ABS control module provides a ground path for

the rear dump solenoid on circuit B254. Circuit B254

connects to cavity 36 of the ABS control module.For the right front dump solenoid, the ABS module

provides a ground path on circuit B248. Circuit B248

connects to cavity 21 of the ABS control module.

On circuit B243, the ABS module provides ground

for the left dump solenoid. Circuit B243 connects to

cavity 2 of the ABS control module.

ABS WARNING LAMP

Circuit F87 provides power for the ABS warning

lamp at the instrument cluster. Ground for the ABS

warning lamp is provided by either the ABS control

module or by the ABS power relay when the relay is

not energized. The ABS control module illuminates

the lamp by providing ground on circuit B205.

Circuit B205 splices to connect to circuit B235

through a diode. When the ABS power relay is not

energized, it connects circuit B235 to circuit Z12. The

ground path for the warning lamp is through the di-

ode to circuit B235, through the ABS power relay to

ground on circuit Z12.

The diode between circuit B205 and B235 prevents

voltage from flowing to the ABS control module when

the ABS power relay switches to supply power on cir-

cuit B235.

DATA LINK CONNECTOR

Circuit D1 from cavity 23 of the ABS control mod-

ule receives data from the DRB scan tool through the

data link connector. The ABS control module trans-

mits data to the scan tool through the connector on

circuit D2. Circuit D2 originates at cavity 42 of the

ABS control module.

Through the data link connector, circuit Z12 pro-

vides ground for the DRB scan tool. Circuit Z12 ter-

minates at the right rear of the engine.

Circuit A4 from fuse 7 in the Power Distribution

Center (PDC) supplies power to fuse 13 in the PDC.

Fuse 13 powers circuit F39 which supplies battery

voltage to the scan tool through the diagnostic con-

nector.

HELPFUL INFORMATION

²Check fuses 7 and 13 in the PDC.

²If the vehicle is equipped with an automatic trans-

mission, circuits D1 and D2 are double crimped at

the data link connector and connect to the Power-

train Control Module (PCM).

8W - 32 - 2 8W-32 ANTI-LOCK BRAKESÐXJ-RHDJ

Page 1093 of 2198

minutes). The use of a locating dowel is recom-

mended during assembly to prevent smearing the

material off location.

Mopar Gasket Maker should be applied sparingly

to one gasket surface. The sealant diameter should

be 1.00 mm (0.04 inch) or less. Be certain the mate-

rial surrounds each mounting hole. Excess material

can easily be wiped off. Components should be

torqued in place within 15 minutes. The use of a lo-

cating dowel is recommended during assembly to pre-

vent smearing the material off location.

ENGINE PERFORMANCE

To provide best vehicle performance and lowest ve-

hicle emissions, it is most important that the tune-up

be done accurately. Use the specifications listed on

the Vehicle Emission Control Information label found

on the engine compartment hood.

(1) Test battery specific gravity. Add water, if nec-

essary. Clean and tighten battery connections.

(2) Test cranking amperage draw (refer to Group

8B, Battery/Starter Service for the proper proce-

dures).

(3) Tighten the intake manifold bolts (refer to

Group 11, Exhaust System and Intake Manifold for

the proper specifications).

(4) Perform cylinder compression test:

(a) Check engine oil level and add oil, if neces-

sary.

(b) Drive the vehicle until engine reaches normal

operating temperature.

(c) Select a route free from traffic and other

forms of congestion, observe all traffic laws and

briskly accelerate through the gears several times.

The higher engine speed may help clean out valve

seat deposits which can prevent accurate compres-

sion readings.

CAUTION: DO NOT overspeed the engine.

(d) Remove all spark plugs from engine. As spark

plugs are being removed, check electrodes for ab-

normal firing indicatorsÐfouled, hot, oily, etc.

Record cylinder number of spark plug for future

reference.

(e) Disconnect coil wire from distributor and se-

cure to good ground to prevent a spark from start-

ing a fire.

(f) Be sure throttle blades are fully open during

the compression check.

(g) Insert compression gage adaptor into the

No.1 spark plug hole. Crank engine until maximum

pressure is reached on gauge. Record this pressure

as No.1 cylinder pressure.

(h) Repeat Step 4g for all remaining cylinders.

(i) Compression should not be less than 689 kPa

(100 psi) and not vary more than 172 kPa (25 psi)

from cylinder to cylinder.(j) If cylinder(s) have abnormally low compres-

sion pressures, repeat steps 4a through 4h.

(k) If the same cylinder(s) repeat an abnormally

low reading, it could indicate the existence of a

problem in the cylinder.

The recommended compression pressures are

to be used only as a guide to diagnosing engine

problems. An engine should NOT be disassem-

bled to determine the cause of low compression

unless some malfunction is present.

(5) Clean or replace spark plugs as necessary. Ad-

just gap (refer to Group 8D, Ignition System for gap

adjustment and torque).

(6) Test resistance of spark plug cables (refer to

Group 8D, Ignition System).

(7) Inspect the primary wire. Test coil output volt-

age, primary and secondary resistance. Replace parts

as necessary (refer to Group 8D, Ignition System and

make necessary adjustment).

(8) Perform a combustion analysis.

(9) Test fuel pump for pressure (refer to Group 14,

Fuel System for the proper specifications).

(10) Inspect air filter element (refer to Group 0,

Lubrication and Maintenance for the proper proce-

dure).

(11) Inspect crankcase ventilation system (refer to

Group 0, Lubrication and Maintenance for the proper

procedure).

(12) For emission controls refer to Group 25, Emis-

sion Controls System for service procedures.

(13) Inspect and adjust accessory belt drives (refer

to Group 7, Cooling System for the proper adjust-

ments).

(14) Road test vehicle as a final test.

HONING CYLINDER BORES

Before honing, stuff plenty of clean shop towels un-

der the bores and over the crankshaft to keep abra-

sive materials from entering the crankshaft area.

(1) Used carefully, the Cylinder Bore Sizing Hone

C-823 equipped with 220 grit stones, is the best tool

for this job. In addition to deglazing, it will reduce

taper and out-of-round as well as removing light

scuffing, scoring or scratches. Usually a few strokes

will clean up a bore and maintain the required lim-

its.

CAUTION: DO NOT use rigid type hones to remove

cylinder wall glaze.

(2) Deglazing of the cylinder walls may be done if

the cylinder bore is straight and round. Use a cylin-

der surfacing hone, Honing Tool C-3501, equipped

with 280 grit stones (C-3501-3810). 20-60 strokes, de-

pending on the bore condition, will be sufficient to

provide a satisfactory surface. Using honing oil

C-3501-3880 or a light honing oil available from ma-

jor oil distributors.

9 - 2 ENGINESJ

Page 1094 of 2198

CAUTION: DO NOT use engine or transmission oil,

mineral spirits or kerosene.

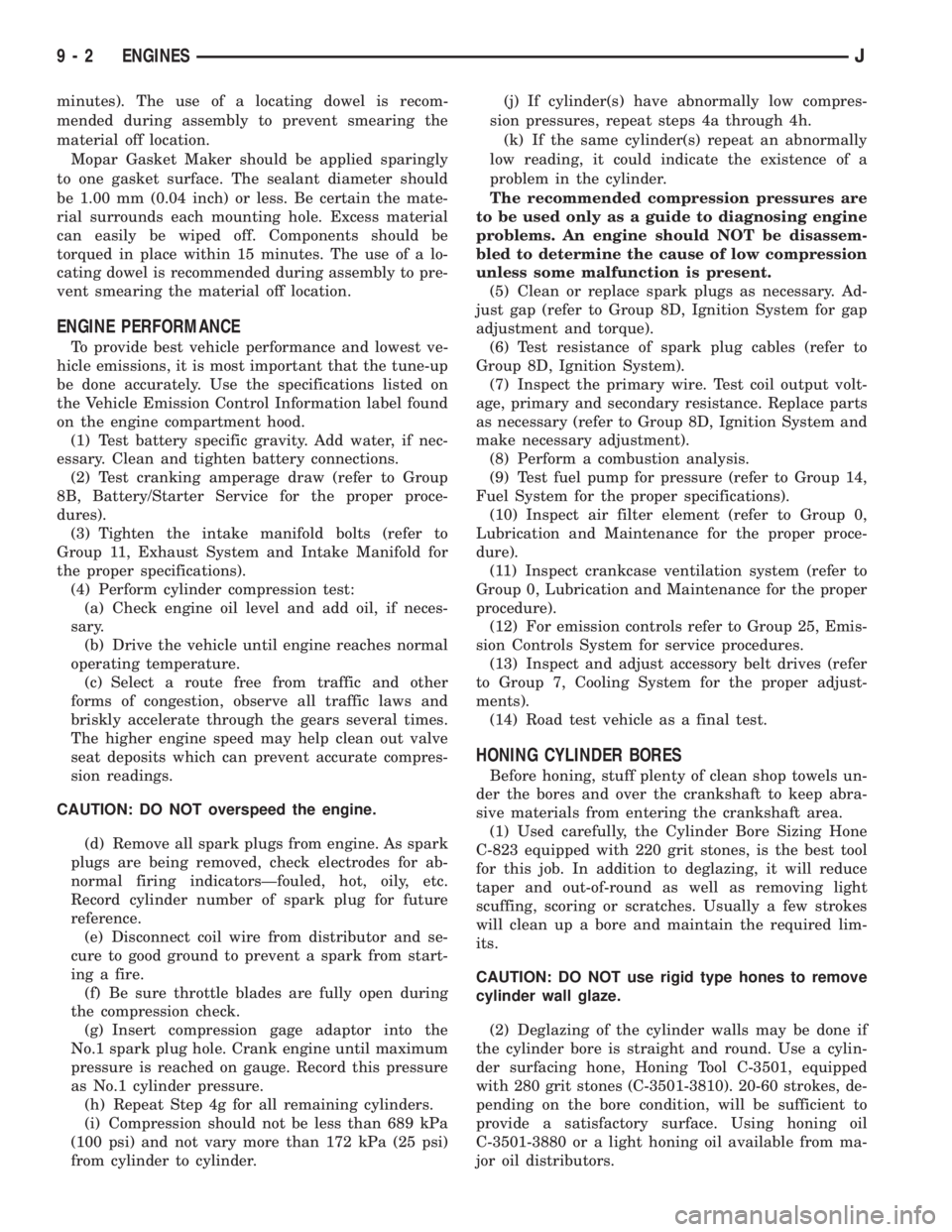

(3) Honing should be done by moving the hone up

and down fast enough to get a crosshatch pattern.

The hone marks should INTERSECT at 50É to 60É

for proper seating of rings (Fig. 1).

(4) A controlled hone motor speed between 200 and

300 RPM is necessary to obtain the proper cross-

hatch angle. The number of up and down strokes per

minute can be regulated to get the desired 50É to 60É

angle. Faster up and down strokes increase the cross-

hatch angle.

(5) After honing, it is necessary that the block be

cleaned to remove all traces of abrasive. Use a brush

to wash parts with a solution of hot water and deter-

gent. Dry parts thoroughly. Use a clean, white, lint-

free cloth to check that the bore is clean. Oil the

bores after cleaning to prevent rusting.

MEASURING WITH PLASTIGAGE

CRANKSHAFT MAIN BEARING CLEARANCE

Engine crankshaft bearing clearances can be deter-

mined by use of Plastigage, or equivalent. The follow-

ing is the recommended procedures for the use of

Plastigage:

(1) Remove oil film from surface to be checked.

Plastigage is soluble in oil.

(2) The total clearance of the main bearings can

only be determined by removing the weight of the

crankshaft. This can be accomplished by either of two

methods:

METHOD - 1 (PREFERRED)ÐShim the bear-

ings adjacent to the bearing to be checked. This will

remove the clearance between upper bearing shell

and the crankshaft. Place a minimum of 0.254 mm

(0.010 inch) shim between the bearing shell and the

adjacent bearing cap. Tighten the bolts to 18 Nzm (13

ft. lbs.) torque.²ALL ENGINESÐWhen checking No.1 main bear-

ing; shim No.2 main bearing.

²ALL ENGINESÐWhen checking No.2 main bear-

ing; shim No.1 and No.3 main bearing.

²ALL ENGINESÐWhen checking No.3 main bear-

ing; shim No.2 and No.4 main bearing.

²ALL ENGINESÐWhen checking No.4 main bear-

ing; shim No.3 and No.5 main bearing.

²2.5L ENGINEÐWhen checking No.5 main bear-

ing; shim No.4 main bearing.

²4.0L ENGINEÐWhen checking No.5 main bear-

ing; shim No.4 and No.6 main bearing.

²4.0L ENGINEÐWhen checking No.6 main bear-

ing; shim No.5 and No.7 main bearing.

²4.0L ENGINEÐWhen checking No.7 main bear-

ing; shim No.6 main bearing.

Remove all shims before assembling engine.

METHOD - 2 (ALTERNATIVE)ÐThe weight of

the crankshaft is supported by a jack under the coun-

terweight adjacent to the bearing being checked.

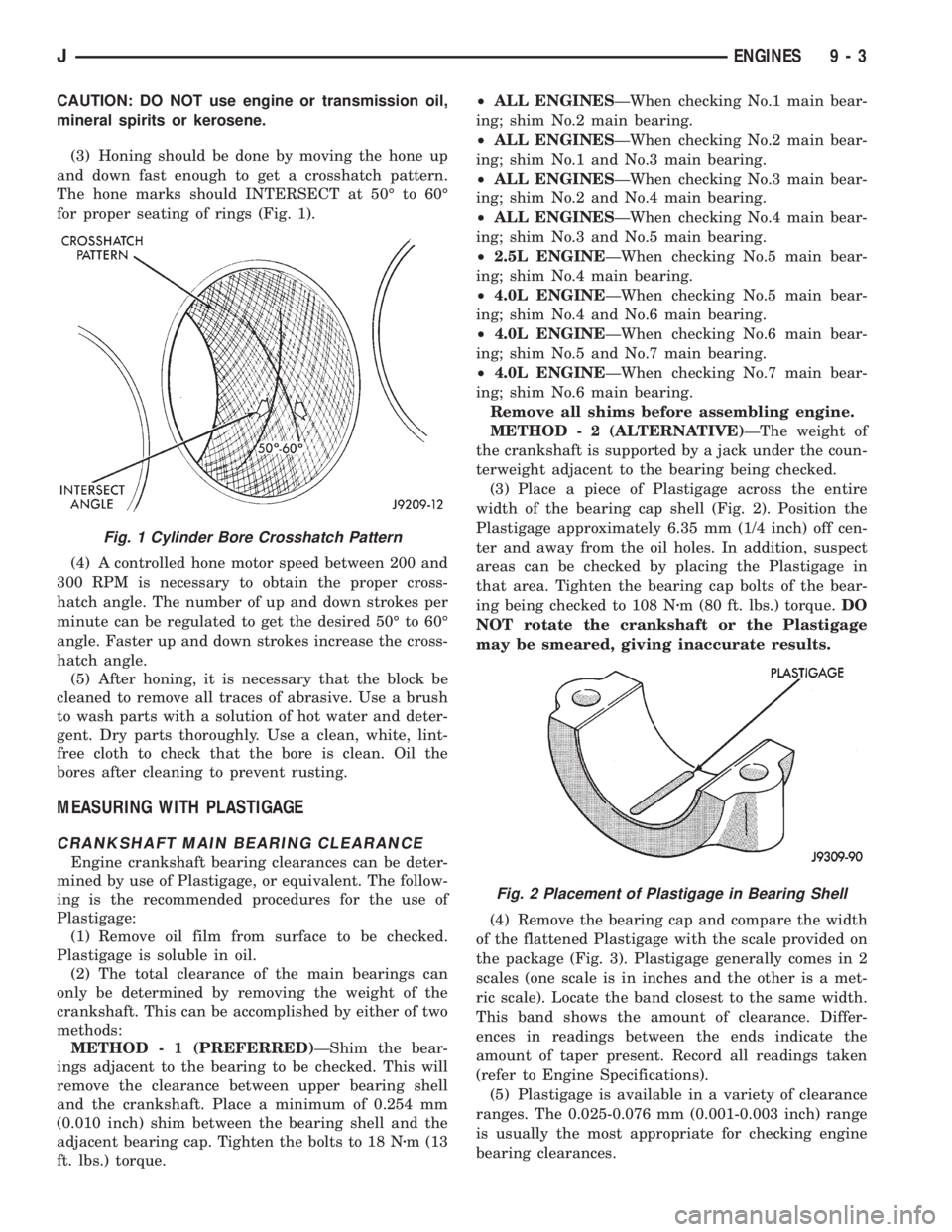

(3) Place a piece of Plastigage across the entire

width of the bearing cap shell (Fig. 2). Position the

Plastigage approximately 6.35 mm (1/4 inch) off cen-

ter and away from the oil holes. In addition, suspect

areas can be checked by placing the Plastigage in

that area. Tighten the bearing cap bolts of the bear-

ing being checked to 108 Nzm (80 ft. lbs.) torque.DO

NOT rotate the crankshaft or the Plastigage

may be smeared, giving inaccurate results.

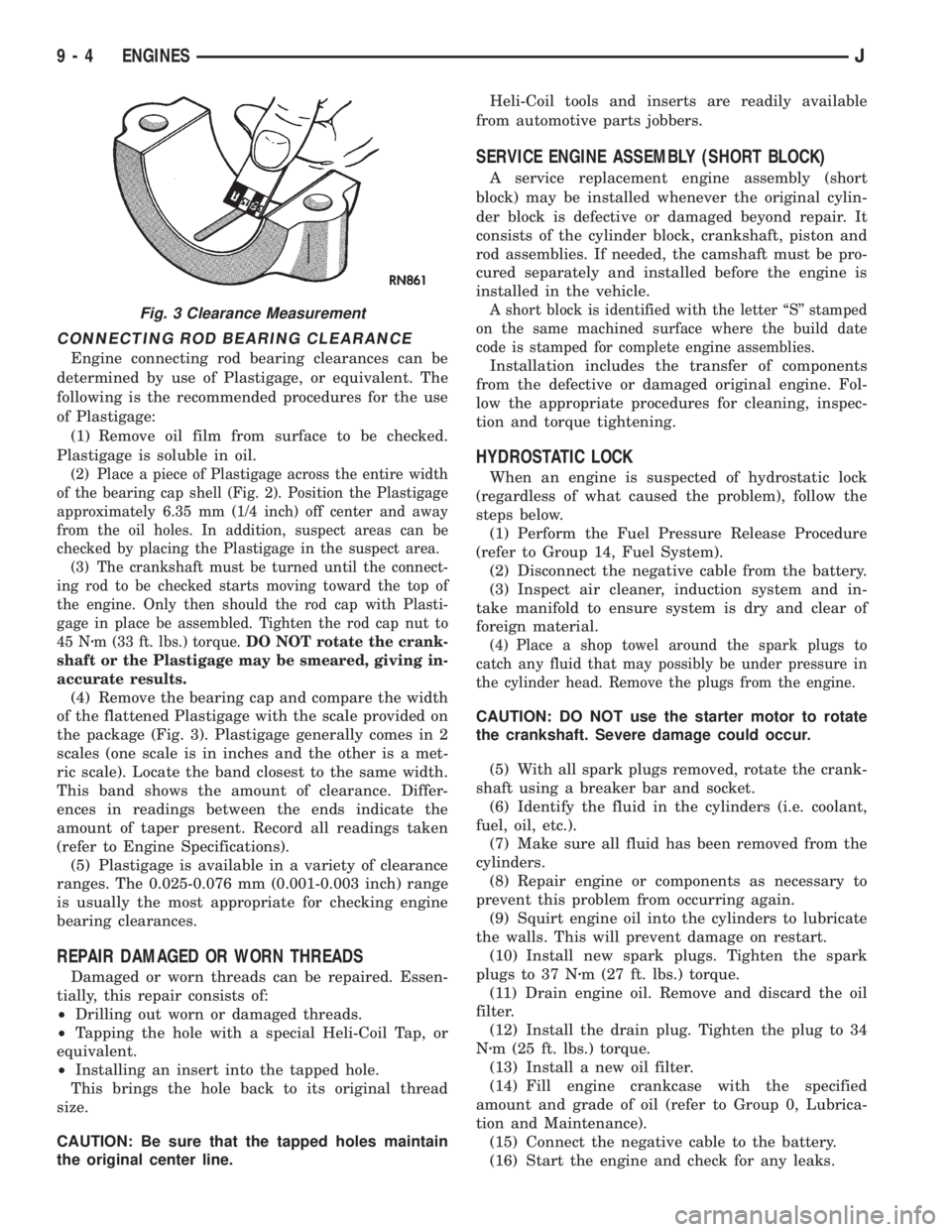

(4) Remove the bearing cap and compare the width

of the flattened Plastigage with the scale provided on

the package (Fig. 3). Plastigage generally comes in 2

scales (one scale is in inches and the other is a met-

ric scale). Locate the band closest to the same width.

This band shows the amount of clearance. Differ-

ences in readings between the ends indicate the

amount of taper present. Record all readings taken

(refer to Engine Specifications).

(5) Plastigage is available in a variety of clearance

ranges. The 0.025-0.076 mm (0.001-0.003 inch) range

is usually the most appropriate for checking engine

bearing clearances.

Fig. 1 Cylinder Bore Crosshatch Pattern

Fig. 2 Placement of Plastigage in Bearing Shell

JENGINES 9 - 3

Page 1095 of 2198

CONNECTING ROD BEARING CLEARANCE

Engine connecting rod bearing clearances can be

determined by use of Plastigage, or equivalent. The

following is the recommended procedures for the use

of Plastigage:

(1) Remove oil film from surface to be checked.

Plastigage is soluble in oil.

(2) Place a piece of Plastigage across the entire width

of the bearing cap shell (Fig. 2). Position the Plastigage

approximately 6.35 mm (1/4 inch) off center and away

from the oil holes. In addition, suspect areas can be

checked by placing the Plastigage in the suspect area.

(3) The crankshaft must be turned until the connect-

ing rod to be checked starts moving toward the top of

the engine. Only then should the rod cap with Plasti-

gage in place be assembled. Tighten the rod cap nut to

45 Nzm (33 ft. lbs.) torque.DO NOT rotate the crank-

shaft or the Plastigage may be smeared, giving in-

accurate results.

(4) Remove the bearing cap and compare the width

of the flattened Plastigage with the scale provided on

the package (Fig. 3). Plastigage generally comes in 2

scales (one scale is in inches and the other is a met-

ric scale). Locate the band closest to the same width.

This band shows the amount of clearance. Differ-

ences in readings between the ends indicate the

amount of taper present. Record all readings taken

(refer to Engine Specifications).

(5) Plastigage is available in a variety of clearance

ranges. The 0.025-0.076 mm (0.001-0.003 inch) range

is usually the most appropriate for checking engine

bearing clearances.

REPAIR DAMAGED OR WORN THREADS

Damaged or worn threads can be repaired. Essen-

tially, this repair consists of:

²Drilling out worn or damaged threads.

²Tapping the hole with a special Heli-Coil Tap, or

equivalent.

²Installing an insert into the tapped hole.

This brings the hole back to its original thread

size.

CAUTION: Be sure that the tapped holes maintain

the original center line.Heli-Coil tools and inserts are readily available

from automotive parts jobbers.

SERVICE ENGINE ASSEMBLY (SHORT BLOCK)

A service replacement engine assembly (short

block) may be installed whenever the original cylin-

der block is defective or damaged beyond repair. It

consists of the cylinder block, crankshaft, piston and

rod assemblies. If needed, the camshaft must be pro-

cured separately and installed before the engine is

installed in the vehicle.

A short block is identified with the letter ``S'' stamped

on the same machined surface where the build date

code is stamped for complete engine assemblies.

Installation includes the transfer of components

from the defective or damaged original engine. Fol-

low the appropriate procedures for cleaning, inspec-

tion and torque tightening.

HYDROSTATIC LOCK

When an engine is suspected of hydrostatic lock

(regardless of what caused the problem), follow the

steps below.

(1) Perform the Fuel Pressure Release Procedure

(refer to Group 14, Fuel System).

(2) Disconnect the negative cable from the battery.

(3) Inspect air cleaner, induction system and in-

take manifold to ensure system is dry and clear of

foreign material.

(4) Place a shop towel around the spark plugs to

catch any fluid that may possibly be under pressure in

the cylinder head. Remove the plugs from the engine.

CAUTION: DO NOT use the starter motor to rotate

the crankshaft. Severe damage could occur.

(5) With all spark plugs removed, rotate the crank-

shaft using a breaker bar and socket.

(6) Identify the fluid in the cylinders (i.e. coolant,

fuel, oil, etc.).

(7) Make sure all fluid has been removed from the

cylinders.

(8) Repair engine or components as necessary to

prevent this problem from occurring again.

(9) Squirt engine oil into the cylinders to lubricate

the walls. This will prevent damage on restart.

(10) Install new spark plugs. Tighten the spark

plugs to 37 Nzm (27 ft. lbs.) torque.

(11) Drain engine oil. Remove and discard the oil

filter.

(12) Install the drain plug. Tighten the plug to 34

Nzm (25 ft. lbs.) torque.

(13) Install a new oil filter.

(14) Fill engine crankcase with the specified

amount and grade of oil (refer to Group 0, Lubrica-

tion and Maintenance).

(15) Connect the negative cable to the battery.

(16) Start the engine and check for any leaks.

Fig. 3 Clearance Measurement

9 - 4 ENGINESJ

Page 1097 of 2198

CYLINDER COMBUSTION PRESSURE LEAKAGE

TEST

The combustion pressure leakage test provides an

accurate means for determining engine condition.

Combustion pressure leakage testing will detect:

²Exhaust and intake valve leaks (improper seat-

ing).

²Leaks between adjacent cylinders or into water

jacket.

²Any causes for combustion/compression pressure

loss.

WARNING: DO NOT REMOVE THE RADIATOR CAP

WITH THE SYSTEM HOT AND UNDER PRESSURE

BECAUSE SERIOUS BURNS FROM COOLANT CAN

OCCUR.

Check the coolant level and fill as required. DO

NOT install the radiator cap.

Start and operate the engine until it attains nor-

mal operating temperature, then turn the engine

OFF.

Remove the spark plugs.

Remove the oil filler cap.

Remove the air cleaner.

Calibrate the tester according to the manufactur-

er's instructions. The shop air source for testing

should maintain 483 kPa (70 psi) minimum, 1 379

kPa (200 psi) maximum and 552 kPa (80 psi) recom-

mended.

Perform the test procedures on each cylinder ac-

cording to the tester manufacturer's instructions.

While testing, listen for pressurized air escaping

through the throttle body, tailpipe and oil filler cap

opening. Check for bubbles in the radiator coolant.

All gauge pressure indications should be equal,

with no more than 25% leakage.

FOR EXAMPLE:At 552 kPa (80 psi) input pres-

sure, a minimum of 414 kPa (60 psi) should be main-

tained in the cylinder.

Refer to the Cylinder Combustion Pressure Leak-

age Test Diagnosis chart.

INSPECTION (ENGINE OIL LEAKS IN GENERAL)

Begin with a through visual inspection of the en-

gine, particularly at the area of the suspected leak. If

an oil leak source is not readily identifiable, the fol-

lowing steps should be followed:

(1) Do not clean or degrease the engine at this

time because some solvents may cause rubber to

swell, temporarily stopping the leak.

(2) Add an oil soluble dye (use as recommended by

manufacturer). Start the engine and let idle for ap-

proximately 15 minutes. Check the oil dipstick to

make sure the dye is thoroughly mixed as indicated

with a bright yellow color under a black light.(3) Using a black light, inspect the entire engine

for fluorescent dye, particularly at the suspected area

of oil leak. If the oil leak is found and identified, re-

pair per service manual instructions.

(4) If dye is not observed, drive the vehicle at var-

ious speeds for approximately 24km (15 miles), and

repeat step (3).

If the oil leak source is not positively identi-

fied at this time, proceed with the air leak detec-

tion test method as follows:

(1) Disconnect the breather cap to air cleaner hose

at the breather cap end. Cap or plug breather cap

nipple.

(2) Remove the PCV valve from the cylinder head

cover. Cap or plug the PCV valve grommet.

(3) Attach an air hose with pressure gauge and

regulator to the dipstick tube.

CAUTION: Do not subject the engine assembly to

more than 20.6 kpa (3 PSI) of test pressure.

(4) Gradually apply air pressure from 1 psi to 2.5

psi maximum while applying soapy water at the sus-

pected source. Adjust the regulator to the suitable

test pressure that provide the best bubbles which

will pinpoint the leak source. If the oil leak is de-

tected and identified, repair per service manual pro-

cedures.

(5) If the leakage occurs at the rear oil seal area,

refer to the section, Inspection for Rear Seal Area

Leak.

(6) If no leaks are detected, turn off the air supply

and remove the air hose and all plugs and caps. In-

stall the PCV valve and breather cap hose. Proceed

to step 7.

(7) Clean the oil off the suspect oil leak area using

a suitable solvent. Drive the vehicle at various

speeds approximately 24 km (15 miles). Inspect the

engine for signs of an oil leak by using a black light.

INSPECTION FOR REAR SEAL AREA LEAKS

Since it is sometimes difficult to determine the

source of an oil leak in the rear seal area of the en-

gine, a more involved inspection is necessary. The fol-

lowing steps should be followed to help pinpoint the

source of the leak.

If the leakage occurs at the crankshaft rear oil seal

area:

(1) Disconnect the battery.

(2) Raise the vehicle.

(3) Remove torque converter or clutch housing

cover and inspect rear of block for evidence of oil.

Use a black light to check for the oil leak:

(a) Circular spray pattern generally indicates

seal leakage or crankshaft damage.

(b) Where leakage tends to run straight down,

possible causes are a porous block, distributor seal,

camshaft bore cup plugs oil galley pipe plugs, oil

9 - 6 ENGINESJ