check engine JEEP CHEROKEE 1995 Service Repair Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 1995, Model line: CHEROKEE, Model: JEEP CHEROKEE 1995Pages: 2198, PDF Size: 82.83 MB

Page 1167 of 2198

(3) Remove the fan and shroud.

(4) Disconnect the radiator overflow tube, radiator

hoses, automatic transmission fluid cooler pipes (if

equipped).

(5) Remove the radiator.

(6) If equipped with air conditioning:

CAUTION: DO NOT loosen or disconnect any air

conditioner system fittings. Move the condenser

and receiver/drier aside as a complete assembly.

(a) Remove the A/C compressor serpentine drive

belt idler pulley.

(b) Disconnect and remove the generator.

(c) Remove the A/C condenser attaching bolts

and move the condenser and receiver/drier assem-

bly up and out of the way.

(7) Remove the serpentine drive belt.

(8) Remove the crankshaft vibration damper.

(9) Remove the timing case cover. Clean the gasket

material from the cover.

(10) Remove the thrust pin and tension spring

from the preload bolt head.

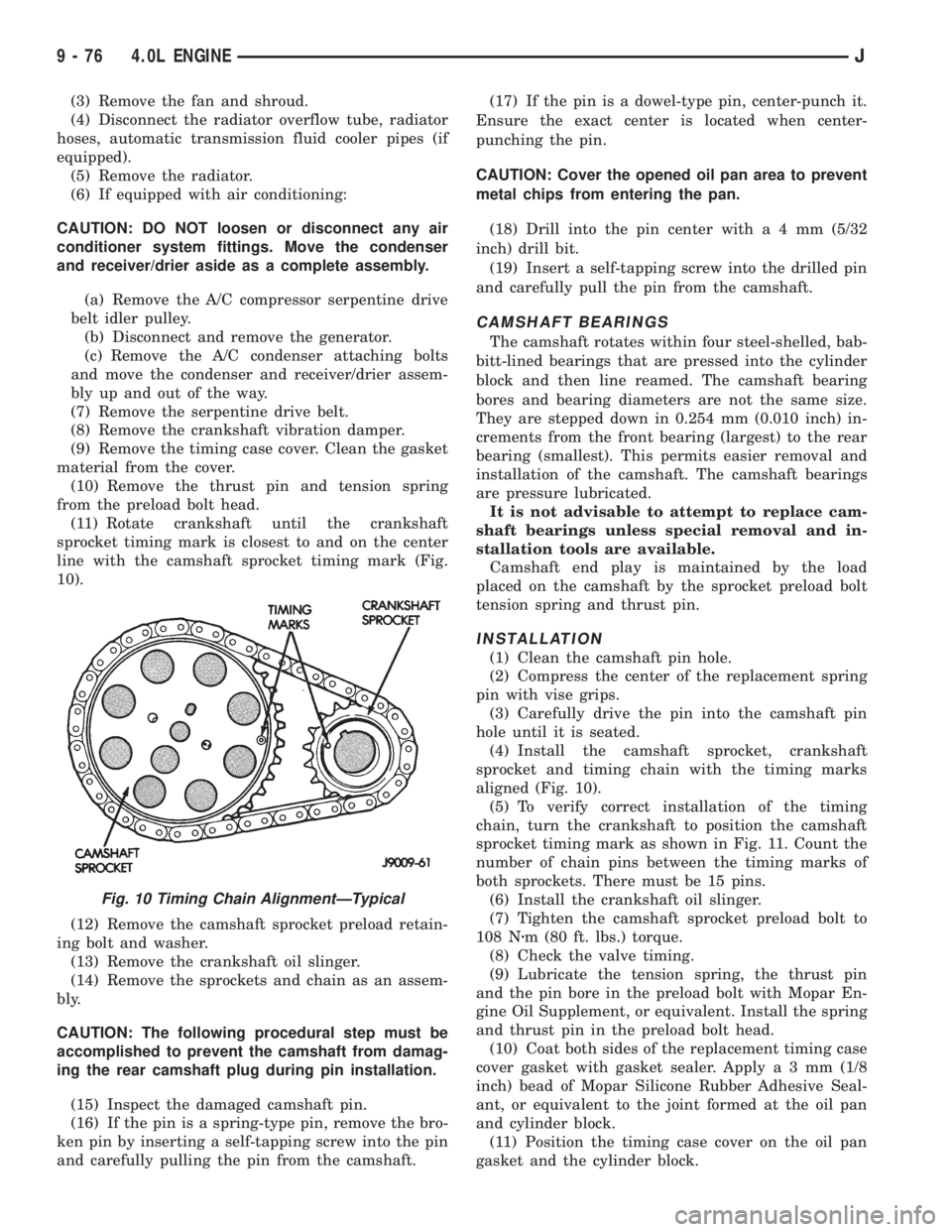

(11) Rotate crankshaft until the crankshaft

sprocket timing mark is closest to and on the center

line with the camshaft sprocket timing mark (Fig.

10).

(12) Remove the camshaft sprocket preload retain-

ing bolt and washer.

(13) Remove the crankshaft oil slinger.

(14) Remove the sprockets and chain as an assem-

bly.

CAUTION: The following procedural step must be

accomplished to prevent the camshaft from damag-

ing the rear camshaft plug during pin installation.

(15) Inspect the damaged camshaft pin.

(16) If the pin is a spring-type pin, remove the bro-

ken pin by inserting a self-tapping screw into the pin

and carefully pulling the pin from the camshaft.(17) If the pin is a dowel-type pin, center-punch it.

Ensure the exact center is located when center-

punching the pin.

CAUTION: Cover the opened oil pan area to prevent

metal chips from entering the pan.

(18) Drill into the pin center witha4mm(5/32

inch) drill bit.

(19) Insert a self-tapping screw into the drilled pin

and carefully pull the pin from the camshaft.

CAMSHAFT BEARINGS

The camshaft rotates within four steel-shelled, bab-

bitt-lined bearings that are pressed into the cylinder

block and then line reamed. The camshaft bearing

bores and bearing diameters are not the same size.

They are stepped down in 0.254 mm (0.010 inch) in-

crements from the front bearing (largest) to the rear

bearing (smallest). This permits easier removal and

installation of the camshaft. The camshaft bearings

are pressure lubricated.

It is not advisable to attempt to replace cam-

shaft bearings unless special removal and in-

stallation tools are available.

Camshaft end play is maintained by the load

placed on the camshaft by the sprocket preload bolt

tension spring and thrust pin.

INSTALLATION

(1) Clean the camshaft pin hole.

(2) Compress the center of the replacement spring

pin with vise grips.

(3) Carefully drive the pin into the camshaft pin

hole until it is seated.

(4) Install the camshaft sprocket, crankshaft

sprocket and timing chain with the timing marks

aligned (Fig. 10).

(5) To verify correct installation of the timing

chain, turn the crankshaft to position the camshaft

sprocket timing mark as shown in Fig. 11. Count the

number of chain pins between the timing marks of

both sprockets. There must be 15 pins.

(6) Install the crankshaft oil slinger.

(7) Tighten the camshaft sprocket preload bolt to

108 Nzm (80 ft. lbs.) torque.

(8) Check the valve timing.

(9) Lubricate the tension spring, the thrust pin

and the pin bore in the preload bolt with Mopar En-

gine Oil Supplement, or equivalent. Install the spring

and thrust pin in the preload bolt head.

(10) Coat both sides of the replacement timing case

cover gasket with gasket sealer. Applya3mm(1/8

inch) bead of Mopar Silicone Rubber Adhesive Seal-

ant, or equivalent to the joint formed at the oil pan

and cylinder block.

(11) Position the timing case cover on the oil pan

gasket and the cylinder block.

Fig. 10 Timing Chain AlignmentÐTypical

9 - 76 4.0L ENGINEJ

Page 1172 of 2198

OIL PUMP

A gear-type oil pump is mounted at the underside

of the cylinder block opposite the No.4 main bearing.

The pump incorporates a nonadjustable pressure

relief valve to limit maximum pressure to 517 kPa

(75 psi). In the relief position, the valve permits oil to

bypass through a passage in the pump body to the

inlet side of the pump.

Oil pump removal or replacement will not affect

the distributor timing because the distributor drive

gear remains in mesh with the camshaft gear.

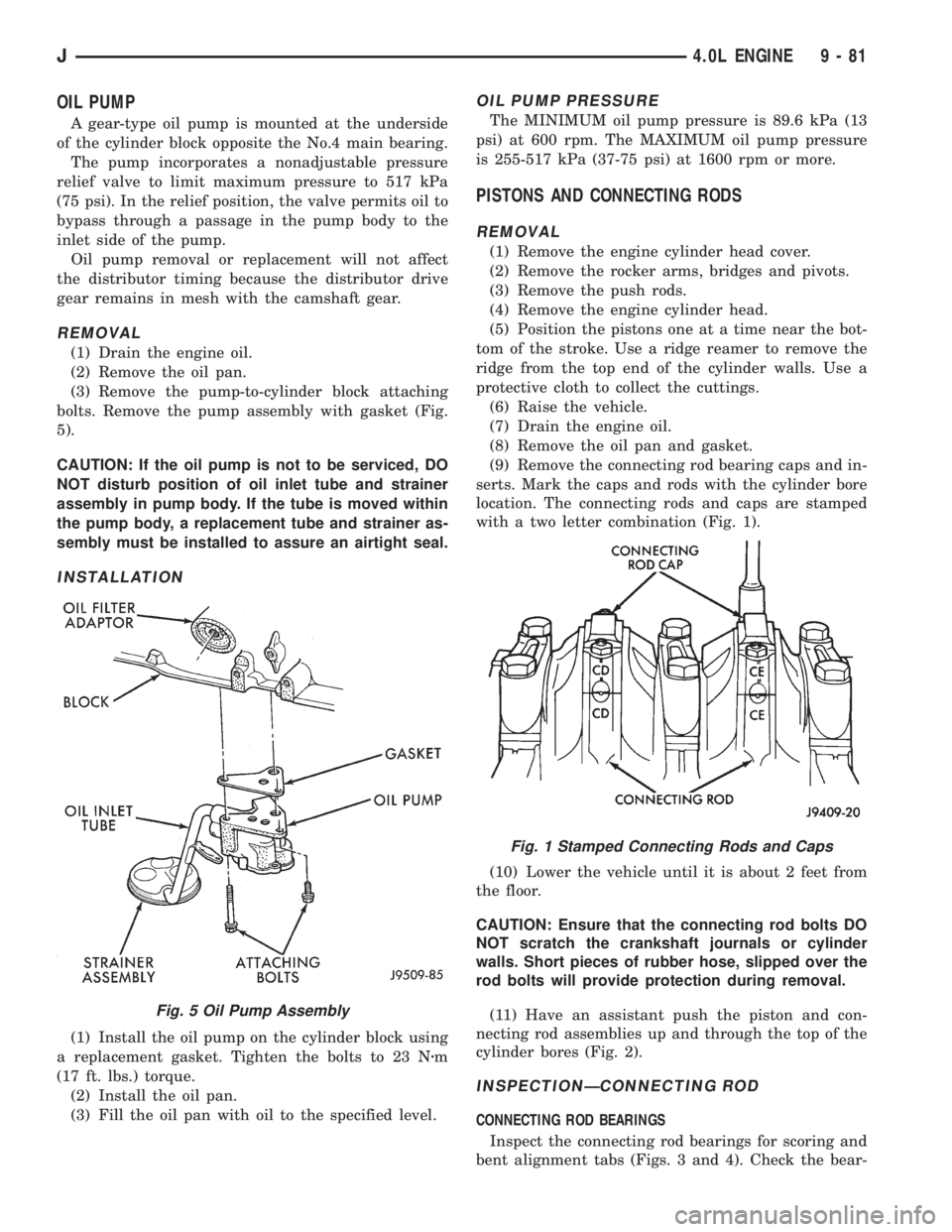

REMOVAL

(1) Drain the engine oil.

(2) Remove the oil pan.

(3) Remove the pump-to-cylinder block attaching

bolts. Remove the pump assembly with gasket (Fig.

5).

CAUTION: If the oil pump is not to be serviced, DO

NOT disturb position of oil inlet tube and strainer

assembly in pump body. If the tube is moved within

the pump body, a replacement tube and strainer as-

sembly must be installed to assure an airtight seal.

INSTALLATION

(1) Install the oil pump on the cylinder block using

a replacement gasket. Tighten the bolts to 23 Nzm

(17 ft. lbs.) torque.

(2) Install the oil pan.

(3) Fill the oil pan with oil to the specified level.

OIL PUMP PRESSURE

The MINIMUM oil pump pressure is 89.6 kPa (13

psi) at 600 rpm. The MAXIMUM oil pump pressure

is 255-517 kPa (37-75 psi) at 1600 rpm or more.

PISTONS AND CONNECTING RODS

REMOVAL

(1) Remove the engine cylinder head cover.

(2) Remove the rocker arms, bridges and pivots.

(3) Remove the push rods.

(4) Remove the engine cylinder head.

(5) Position the pistons one at a time near the bot-

tom of the stroke. Use a ridge reamer to remove the

ridge from the top end of the cylinder walls. Use a

protective cloth to collect the cuttings.

(6) Raise the vehicle.

(7) Drain the engine oil.

(8) Remove the oil pan and gasket.

(9) Remove the connecting rod bearing caps and in-

serts. Mark the caps and rods with the cylinder bore

location. The connecting rods and caps are stamped

with a two letter combination (Fig. 1).

(10) Lower the vehicle until it is about 2 feet from

the floor.

CAUTION: Ensure that the connecting rod bolts DO

NOT scratch the crankshaft journals or cylinder

walls. Short pieces of rubber hose, slipped over the

rod bolts will provide protection during removal.

(11) Have an assistant push the piston and con-

necting rod assemblies up and through the top of the

cylinder bores (Fig. 2).

INSPECTIONÐCONNECTING ROD

CONNECTING ROD BEARINGS

Inspect the connecting rod bearings for scoring and

bent alignment tabs (Figs. 3 and 4). Check the bear-

Fig. 5 Oil Pump Assembly

Fig. 1 Stamped Connecting Rods and Caps

J4.0L ENGINE 9 - 81

Page 1175 of 2198

SIDE CLEARANCE MEASUREMENT

Slide snug-fitting feeler gauge between the connect-

ing rod and crankshaft journal flange. Refer to En-

gine Specifications for the proper clearance. Replace

the connecting rod if the side clearance is not within

specification.

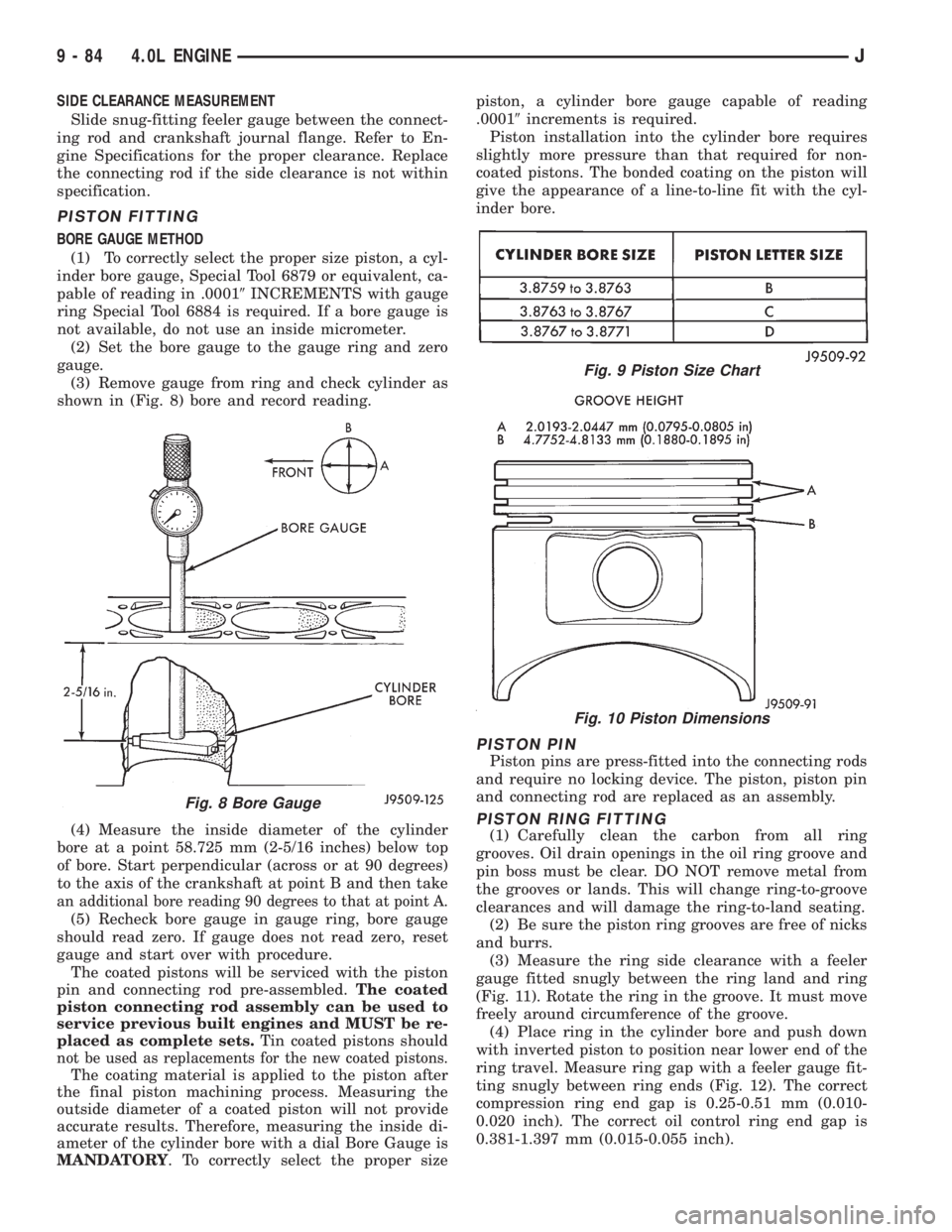

PISTON FITTING

BORE GAUGE METHOD

(1) To correctly select the proper size piston, a cyl-

inder bore gauge, Special Tool 6879 or equivalent, ca-

pable of reading in .00019INCREMENTS with gauge

ring Special Tool 6884 is required. If a bore gauge is

not available, do not use an inside micrometer.

(2) Set the bore gauge to the gauge ring and zero

gauge.

(3) Remove gauge from ring and check cylinder as

shown in (Fig. 8) bore and record reading.

(4) Measure the inside diameter of the cylinder

bore at a point 58.725 mm (2-5/16 inches) below top

of bore. Start perpendicular (across or at 90 degrees)

to the axis of the crankshaft at point B and then take

an additional bore reading 90 degrees to that at point A.

(5) Recheck bore gauge in gauge ring, bore gauge

should read zero. If gauge does not read zero, reset

gauge and start over with procedure.

The coated pistons will be serviced with the piston

pin and connecting rod pre-assembled.The coated

piston connecting rod assembly can be used to

service previous built engines and MUST be re-

placed as complete sets.Tin coated pistons should

not be used as replacements for the new coated pistons.

The coating material is applied to the piston after

the final piston machining process. Measuring the

outside diameter of a coated piston will not provide

accurate results. Therefore, measuring the inside di-

ameter of the cylinder bore with a dial Bore Gauge is

MANDATORY. To correctly select the proper sizepiston, a cylinder bore gauge capable of reading

.00019increments is required.

Piston installation into the cylinder bore requires

slightly more pressure than that required for non-

coated pistons. The bonded coating on the piston will

give the appearance of a line-to-line fit with the cyl-

inder bore.

PISTON PIN

Piston pins are press-fitted into the connecting rods

and require no locking device. The piston, piston pin

and connecting rod are replaced as an assembly.

PISTON RING FITTING

(1) Carefully clean the carbon from all ring

grooves. Oil drain openings in the oil ring groove and

pin boss must be clear. DO NOT remove metal from

the grooves or lands. This will change ring-to-groove

clearances and will damage the ring-to-land seating.

(2) Be sure the piston ring grooves are free of nicks

and burrs.

(3) Measure the ring side clearance with a feeler

gauge fitted snugly between the ring land and ring

(Fig. 11). Rotate the ring in the groove. It must move

freely around circumference of the groove.

(4) Place ring in the cylinder bore and push down

with inverted piston to position near lower end of the

ring travel. Measure ring gap with a feeler gauge fit-

ting snugly between ring ends (Fig. 12). The correct

compression ring end gap is 0.25-0.51 mm (0.010-

0.020 inch). The correct oil control ring end gap is

0.381-1.397 mm (0.015-0.055 inch).

Fig. 8 Bore Gauge

Fig. 9 Piston Size Chart

Fig. 10 Piston Dimensions

9 - 84 4.0L ENGINEJ

Page 1179 of 2198

ward position. The upper main bearing inserts are

grooved to provide oil channels while the lower in-

serts are smooth.

Each bearing insert pair is selectively fitted to its

respective journal to obtain the specified operating

clearance. In production, the select fit is obtained by

using various-sized color-coded bearing insert pairs

as listed in the Main Bearing Fitting Chart. The

bearing color code appears on the edge of the insert.

The size is not stamped on bearing inserts used

for engine production.

The main bearing journal size (diameter) is identi-

fied by a color-coded paint mark on the adjacent

cheek. The rear main journal, is identified by a color-

coded paint mark on the crankshaft rear flange.

When required, upper and lower bearing inserts of

different sizes may be used as a pair. A standard size

insert is sometimes used in combination with a 0.025

mm (0.001 inch) undersize insert to reduce the clear-

ance by 0.013 mm (0.0005 inch).Never use a pair

of bearing inserts with greater than a 0.025 mm

(0.001 inch) difference in size (Fig. 4).

When replacing inserts, the odd size inserts

must be either all on the top (in cylinder block)

or all on the bottom (in main bearing cap).

Once the bearings have been properly fitted, pro-

ceed to Crankshaft Main BearingÐInstallation.

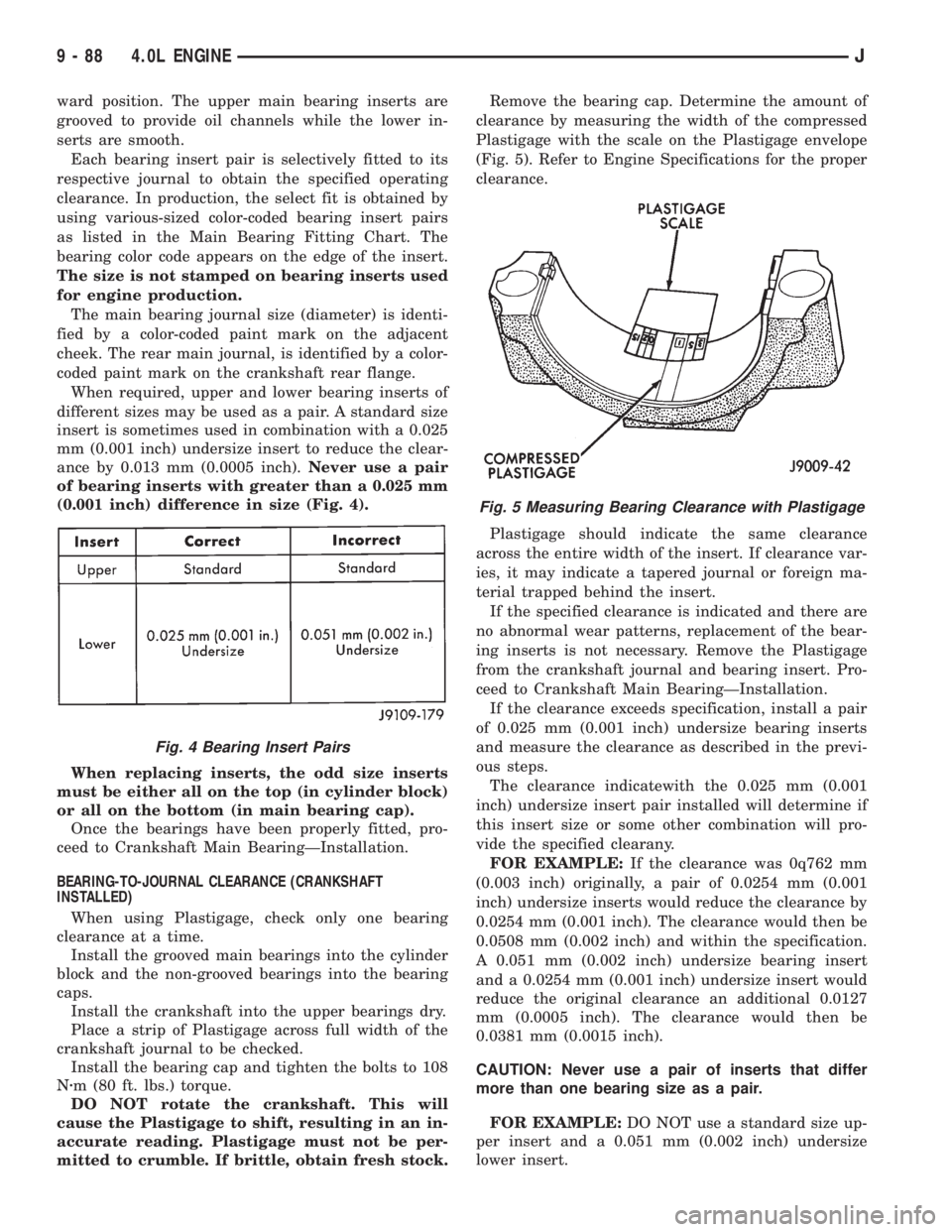

BEARING-TO-JOURNAL CLEARANCE (CRANKSHAFT

INSTALLED)

When using Plastigage, check only one bearing

clearance at a time.

Install the grooved main bearings into the cylinder

block and the non-grooved bearings into the bearing

caps.

Install the crankshaft into the upper bearings dry.

Place a strip of Plastigage across full width of the

crankshaft journal to be checked.

Install the bearing cap and tighten the bolts to 108

Nzm (80 ft. lbs.) torque.

DO NOT rotate the crankshaft. This will

cause the Plastigage to shift, resulting in an in-

accurate reading. Plastigage must not be per-

mitted to crumble. If brittle, obtain fresh stock.Remove the bearing cap. Determine the amount of

clearance by measuring the width of the compressed

Plastigage with the scale on the Plastigage envelope

(Fig. 5). Refer to Engine Specifications for the proper

clearance.

Plastigage should indicate the same clearance

across the entire width of the insert. If clearance var-

ies, it may indicate a tapered journal or foreign ma-

terial trapped behind the insert.

If the specified clearance is indicated and there are

no abnormal wear patterns, replacement of the bear-

ing inserts is not necessary. Remove the Plastigage

from the crankshaft journal and bearing insert. Pro-

ceed to Crankshaft Main BearingÐInstallation.

If the clearance exceeds specification, install a pair

of 0.025 mm (0.001 inch) undersize bearing inserts

and measure the clearance as described in the previ-

ous steps.

The clearance indicatewith the 0.025 mm (0.001

inch) undersize insert pair installed will determine if

this insert size or some other combination will pro-

vide the specified clearany.

FOR EXAMPLE:If the clearance was 0q762 mm

(0.003 inch) originally, a pair of 0.0254 mm (0.001

inch) undersize inserts would reduce the clearance by

0.0254 mm (0.001 inch). The clearance would then be

0.0508 mm (0.002 inch) and within the specification.

A 0.051 mm (0.002 inch) undersize bearing insert

and a 0.0254 mm (0.001 inch) undersize insert would

reduce the original clearance an additional 0.0127

mm (0.0005 inch). The clearance would then be

0.0381 mm (0.0015 inch).

CAUTION: Never use a pair of inserts that differ

more than one bearing size as a pair.

FOR EXAMPLE:DO NOT use a standard size up-

per insert and a 0.051 mm (0.002 inch) undersize

lower insert.

Fig. 4 Bearing Insert Pairs

Fig. 5 Measuring Bearing Clearance with Plastigage

9 - 88 4.0L ENGINEJ

Page 1180 of 2198

If the clearance exceeds specification using a pair

of 0.051 mm (0.002 inch) undersize bearing inserts,

measure crankshaft journal diameter with a mi-

crometer. If the journal diameter is correct, the

crankshaft bore in the cylinder block may be mis-

aligned, which requires cylinder block replacement or

machining to true bore.

Replace the crankshaft or grind to accept the ap-

propriate undersize bearing inserts if:

²Journal diameters 1 through 6 are less than

63.4517 mm (2.4981 inches)

²Journal 7 diameter is less than 63.4365 mm

(2.4975 inches).

Once the proper clearances have been obtained,

proceed to Crankshaft Main BearingÐInstallation.

MAIN BEARING JOURNAL DIAMETER (CRANKSHAFT

REMOVED)

Remove the crankshaft from the cylinder block (re-

fer to Cylinder Block - Disassemble).

Clean the oil off the main bearing journal.

Determine the maximum diameter of the journal

with a micrometer. Measure at two locations 90É

apart at each end of the journal.

The maximum allowable taper and out of round is

0.013 mm (0.0005 inch). Compare the measured di-

ameter with the journal diameter specification (Main

Bearing Fitting Chart). Select inserts required to ob-

tain the specified bearing-to-journal clearance.

Install the crankshaft into the cylinder block (refer

to Cylinder Block - Assemble and Crankshaft Main

Bearings - Installation).

INSTALLATION

(1) Lubricate the bearing surface of each insert

with engine oil.

(2) Loosen all the main bearing caps. Install the

main bearing upper inserts.

(3) Install the lower bearing inserts into the main

bearing caps.

(4) Install the main bearing cap(s) and lower in-

sert(s).

(5) Tighten the bolts of caps 1, 2, 4, 5, 6, and 7 to

54 Nzm (40 ft. lbs.) torque. Now tighten these bolts to

95 Nzm (70 ft. lbs.) torque. Finally, tighten these

bolts to 108 Nzm (80 ft. lbs.) torque.

(6) Push the crankshaft forward and backward.

Load the crankshaft front or rear and tighten cap

bolt No.3 to 54 Nzm (40 ft. lbs.) torque. Then tighten

to 95 Nzm (70 ft. lbs.) torque and finally tighten to

108 Nzm (80 ft. lbs.) torque.

(7) Rotate the crankshaft after tightening each

main bearing cap to ensure the crankshaft rotates

freely.

(8) Check crankshaft end play. Crankshaft end

play is controlled by the thrust bearing which is

flange and installed at the No.2 main bearing posi-

tion.(a) Attach a magnetic base dial indicator to the

cylinder block at either the front or rear of the en-

gine.

(b) Position the dial indicator rod so that it is

parallel to the center line of the crankshaft.

(c) Pry the crankshaft forward, position the dial

indicator to zero.

(d) Pry the crankshaft forward and backward.

Note the dial indicator readings. End play is the

difference between the high and low measurements

(Fig. 6). Correct end play is 0.038-0.165 mm

(0.0015-0.0065 inch). The desired specifications are

0.051-0.064 mm (0.002-0.0025 inch).

(e) If end play is not within specification, inspect

crankshaft thrust faces for wear. If no wear is ap-

parent, replace the thrust bearing and measure

end play. If end play is still not within specifica-

tion, replace the crankshaft.

If the crankshaft was removed, install the crank-

shaft into the cylinder block (refer to Cylinder Block -

Assemble).

(9) Install the oil pan.

(10) Install the drain plug. Tighten the plug to 34

Nzm (25 ft. lbs.) torque.

(11) Lower the vehicle.

(12) Install the spark plugs. Tighten the plugs to

37 Nzm (27 ft. lbs.) torque.

(13) Fill the oil pan with engine oil to the full

mark on the dipstick level.

(14) Connect negative cable to battery.

REAR MAIN OIL SEALS

The crankshaft rear main bearing oil seal consists

of two half pieces of viton with a single lip that ef-

fectively seals the rear of the crankshaft. Replace the

upper and lower seal halves as a unit to ensure leak-

free operation.

Fig. 6 Crankshaft End Play Measurement

J4.0L ENGINE 9 - 89

Page 1194 of 2198

INSTALLATION

(1) Install the muffler onto the catalytic converter

outlet. Ensure that the locator on the converter

aligns with the notch on the muffler, if so equipped.

Install the clamp and tighten the nuts finger tight.

(2) Install the exhaust tailpipe into the muffler

outlet. Ensure that the locator on the exhaust

tailpipe aligns with the notch on the muffler, if so

equipped. Install the clamp and tighten the nuts fin-

ger tight.

(3) Install the front exhaust tailpipe supports and

the rear exhaust tailpipe hanger. Ensure that the ex-

haust tailpipe has sufficient clearance from the floor

pan and shields.

(4) Tighten the nuts on the muffler-to-catalytic

converter and the muffler-to-exhaust tailpipe clamps

to 61 Nzm (45 ft. lbs.) torque.

(5) Lower the vehicle.

(6) Start the engine and inspect for exhaust leaks

and contact with the body panels and shields.

ENGINE EXHAUST MANIFOLDÐ2.5L ENGINE

REMOVAL

(1) Disconnect the battery negative cable.

(2) Remove all components attached to the intake

manifold.

(3) Raise the vehicle.

(4) Disconnect the exhaust pipe from the engine

exhaust manifold.

(5) Lower the vehicle.

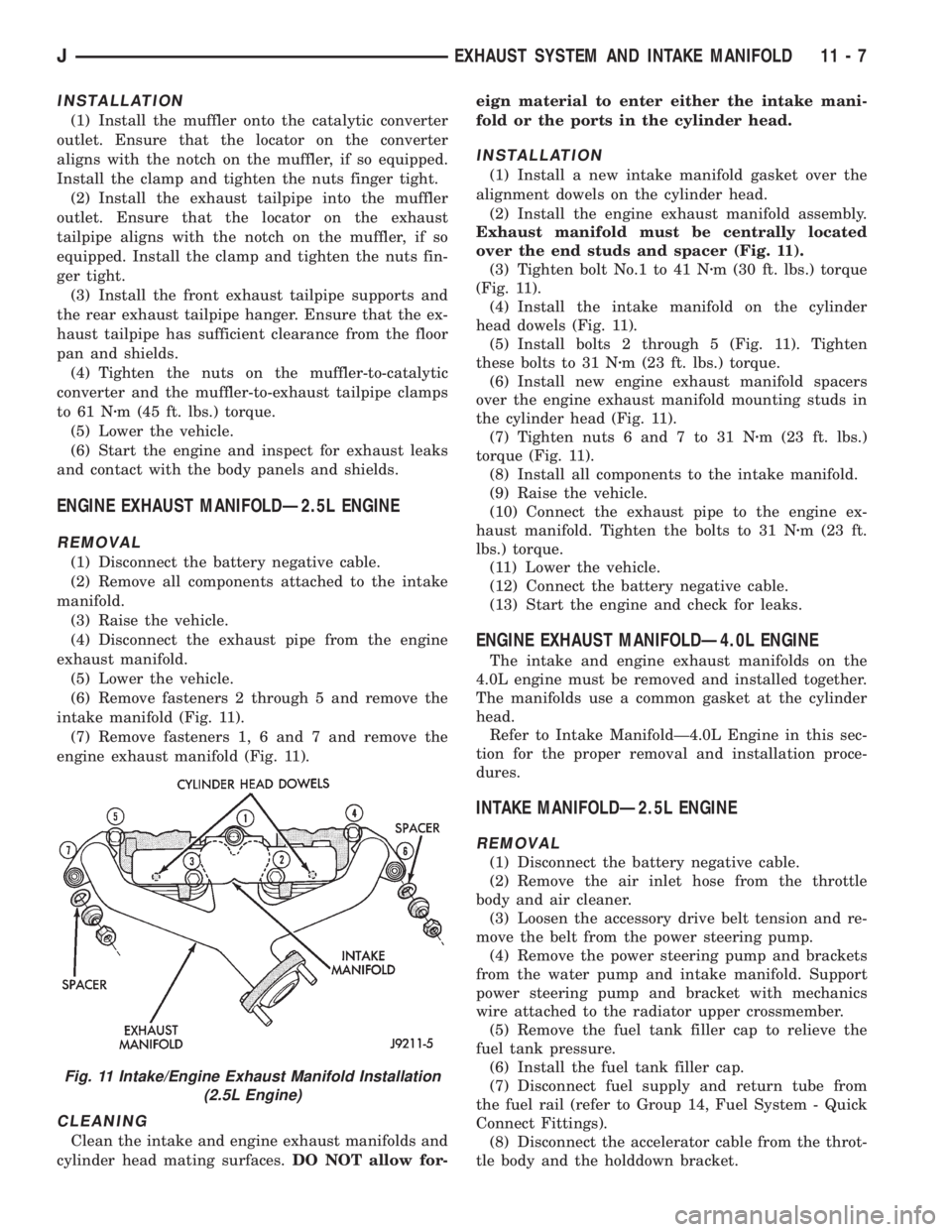

(6) Remove fasteners 2 through 5 and remove the

intake manifold (Fig. 11).

(7) Remove fasteners 1, 6 and 7 and remove the

engine exhaust manifold (Fig. 11).

CLEANING

Clean the intake and engine exhaust manifolds and

cylinder head mating surfaces.DO NOT allow for-eign material to enter either the intake mani-

fold or the ports in the cylinder head.

INSTALLATION

(1) Install a new intake manifold gasket over the

alignment dowels on the cylinder head.

(2) Install the engine exhaust manifold assembly.

Exhaust manifold must be centrally located

over the end studs and spacer (Fig. 11).

(3) Tighten bolt No.1 to 41 Nzm (30 ft. lbs.) torque

(Fig. 11).

(4) Install the intake manifold on the cylinder

head dowels (Fig. 11).

(5) Install bolts 2 through 5 (Fig. 11). Tighten

these bolts to 31 Nzm (23 ft. lbs.) torque.

(6) Install new engine exhaust manifold spacers

over the engine exhaust manifold mounting studs in

the cylinder head (Fig. 11).

(7) Tighten nuts 6 and 7 to 31 Nzm (23 ft. lbs.)

torque (Fig. 11).

(8) Install all components to the intake manifold.

(9) Raise the vehicle.

(10) Connect the exhaust pipe to the engine ex-

haust manifold. Tighten the bolts to 31 Nzm (23 ft.

lbs.) torque.

(11) Lower the vehicle.

(12) Connect the battery negative cable.

(13) Start the engine and check for leaks.

ENGINE EXHAUST MANIFOLDÐ4.0L ENGINE

The intake and engine exhaust manifolds on the

4.0L engine must be removed and installed together.

The manifolds use a common gasket at the cylinder

head.

Refer to Intake ManifoldÐ4.0L Engine in this sec-

tion for the proper removal and installation proce-

dures.

INTAKE MANIFOLDÐ2.5L ENGINE

REMOVAL

(1) Disconnect the battery negative cable.

(2) Remove the air inlet hose from the throttle

body and air cleaner.

(3) Loosen the accessory drive belt tension and re-

move the belt from the power steering pump.

(4) Remove the power steering pump and brackets

from the water pump and intake manifold. Support

power steering pump and bracket with mechanics

wire attached to the radiator upper crossmember.

(5) Remove the fuel tank filler cap to relieve the

fuel tank pressure.

(6) Install the fuel tank filler cap.

(7) Disconnect fuel supply and return tube from

the fuel rail (refer to Group 14, Fuel System - Quick

Connect Fittings).

(8) Disconnect the accelerator cable from the throt-

tle body and the holddown bracket.

Fig. 11 Intake/Engine Exhaust Manifold Installation

(2.5L Engine)

JEXHAUST SYSTEM AND INTAKE MANIFOLD 11 - 7

Page 1195 of 2198

CAUTION: When disconnecting the cruise control

connector at the throttle body, DO NOT pry the con-

nector off with pliers or screwdriver. Use finger

pressure only. Prying the connector off could break

it.

(9) Disconnect the electrical connectors. Pull the

harnesses away from the manifold.

²The throttle position sensor.

²The idle speed control motor.

²The coolant temperature sensor at the thermostat.

²The manifold air temperature sensor at the intake

manifold.

²The fuel injectors.

²The oxygen sensor.

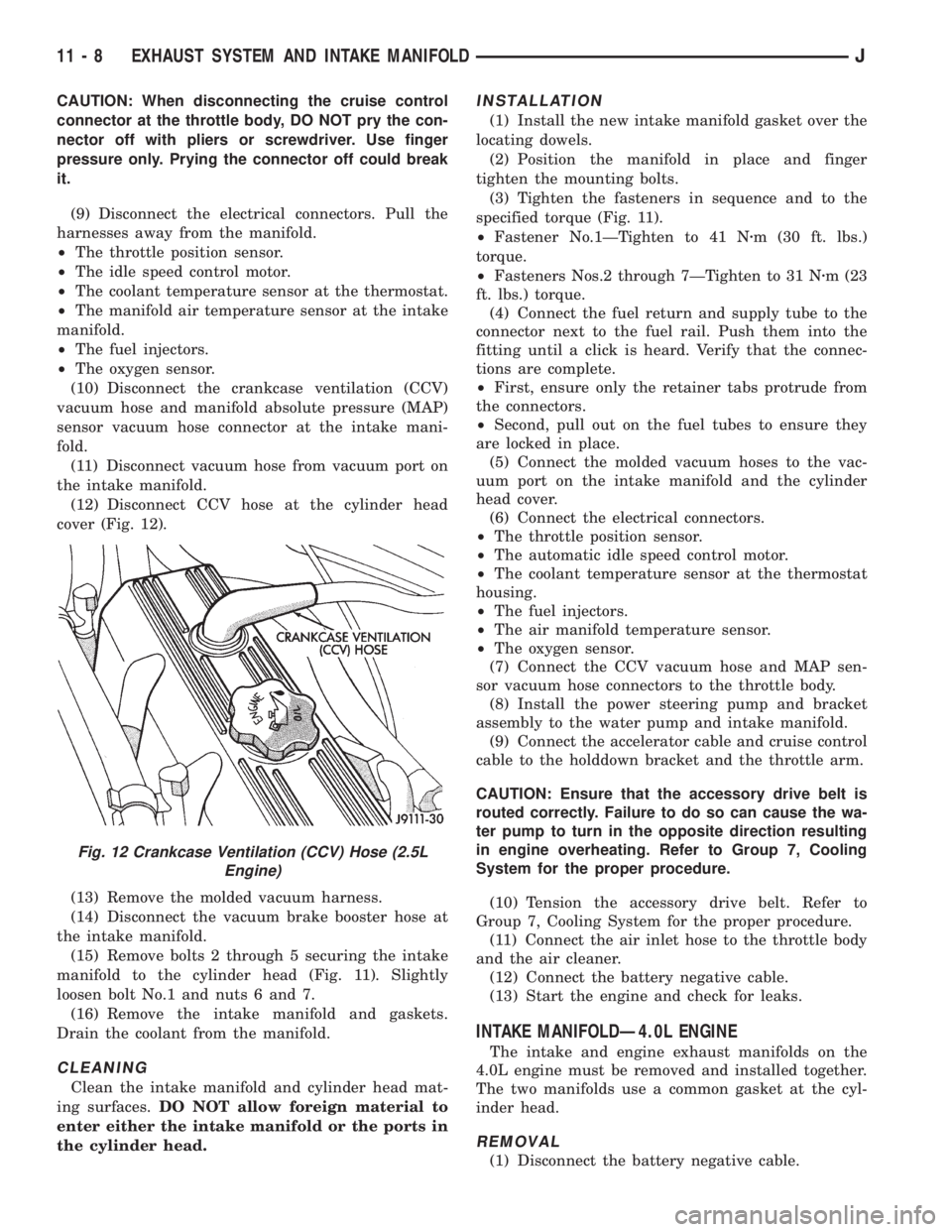

(10) Disconnect the crankcase ventilation (CCV)

vacuum hose and manifold absolute pressure (MAP)

sensor vacuum hose connector at the intake mani-

fold.

(11) Disconnect vacuum hose from vacuum port on

the intake manifold.

(12) Disconnect CCV hose at the cylinder head

cover (Fig. 12).

(13) Remove the molded vacuum harness.

(14) Disconnect the vacuum brake booster hose at

the intake manifold.

(15) Remove bolts 2 through 5 securing the intake

manifold to the cylinder head (Fig. 11). Slightly

loosen bolt No.1 and nuts 6 and 7.

(16) Remove the intake manifold and gaskets.

Drain the coolant from the manifold.

CLEANING

Clean the intake manifold and cylinder head mat-

ing surfaces.DO NOT allow foreign material to

enter either the intake manifold or the ports in

the cylinder head.

INSTALLATION

(1) Install the new intake manifold gasket over the

locating dowels.

(2) Position the manifold in place and finger

tighten the mounting bolts.

(3) Tighten the fasteners in sequence and to the

specified torque (Fig. 11).

²Fastener No.1ÐTighten to 41 Nzm (30 ft. lbs.)

torque.

²Fasteners Nos.2 through 7ÐTighten to 31 Nzm (23

ft. lbs.) torque.

(4) Connect the fuel return and supply tube to the

connector next to the fuel rail. Push them into the

fitting until a click is heard. Verify that the connec-

tions are complete.

²First, ensure only the retainer tabs protrude from

the connectors.

²Second, pull out on the fuel tubes to ensure they

are locked in place.

(5) Connect the molded vacuum hoses to the vac-

uum port on the intake manifold and the cylinder

head cover.

(6) Connect the electrical connectors.

²The throttle position sensor.

²The automatic idle speed control motor.

²The coolant temperature sensor at the thermostat

housing.

²The fuel injectors.

²The air manifold temperature sensor.

²The oxygen sensor.

(7) Connect the CCV vacuum hose and MAP sen-

sor vacuum hose connectors to the throttle body.

(8) Install the power steering pump and bracket

assembly to the water pump and intake manifold.

(9) Connect the accelerator cable and cruise control

cable to the holddown bracket and the throttle arm.

CAUTION: Ensure that the accessory drive belt is

routed correctly. Failure to do so can cause the wa-

ter pump to turn in the opposite direction resulting

in engine overheating. Refer to Group 7, Cooling

System for the proper procedure.

(10) Tension the accessory drive belt. Refer to

Group 7, Cooling System for the proper procedure.

(11) Connect the air inlet hose to the throttle body

and the air cleaner.

(12) Connect the battery negative cable.

(13) Start the engine and check for leaks.

INTAKE MANIFOLDÐ4.0L ENGINE

The intake and engine exhaust manifolds on the

4.0L engine must be removed and installed together.

The two manifolds use a common gasket at the cyl-

inder head.

REMOVAL

(1) Disconnect the battery negative cable.

Fig. 12 Crankcase Ventilation (CCV) Hose (2.5L

Engine)

11 - 8 EXHAUST SYSTEM AND INTAKE MANIFOLDJ

Page 1196 of 2198

(2) Remove air cleaner inlet hose from throttle

plate assembly.

(3) Remove the air cleaner assembly.

(4) Remove the throttle cable, cruise control cable

(if equipped) and the transmission line pressure ca-

ble.

(5) Disconnect all electrical connectors on the in-

take manifold.

(6) Disconnect and remove the fuel supply and re-

turn lines from the fuel rail assembly (refer to Group

14, Fuel System).

(7) Loosen the accessory drive belt (refer to Group

7, Cooling System). Loosen the tensioner.

(8) Remove the power steering pump and bracket

from the intake manifold and set aside.

(9) Remove the fuel rail and injectors (refer to

Group 14, Fuel System).

(10) Raise the vehicle.

(11) Disconnect the exhaust pipe from the engine

exhaust manifold. Discard the seal.

(12) Lower the vehicle.

(13) Remove the intake manifold and engine ex-

haust manifold.

CLEANING

Clean the mating surfaces of the cylinder head and

the manifold if the original manifold is to be in-

stalled.

If the manifold is being replaced, ensure all the fit-

ting, etc. are transferred to the replacement mani-

fold.

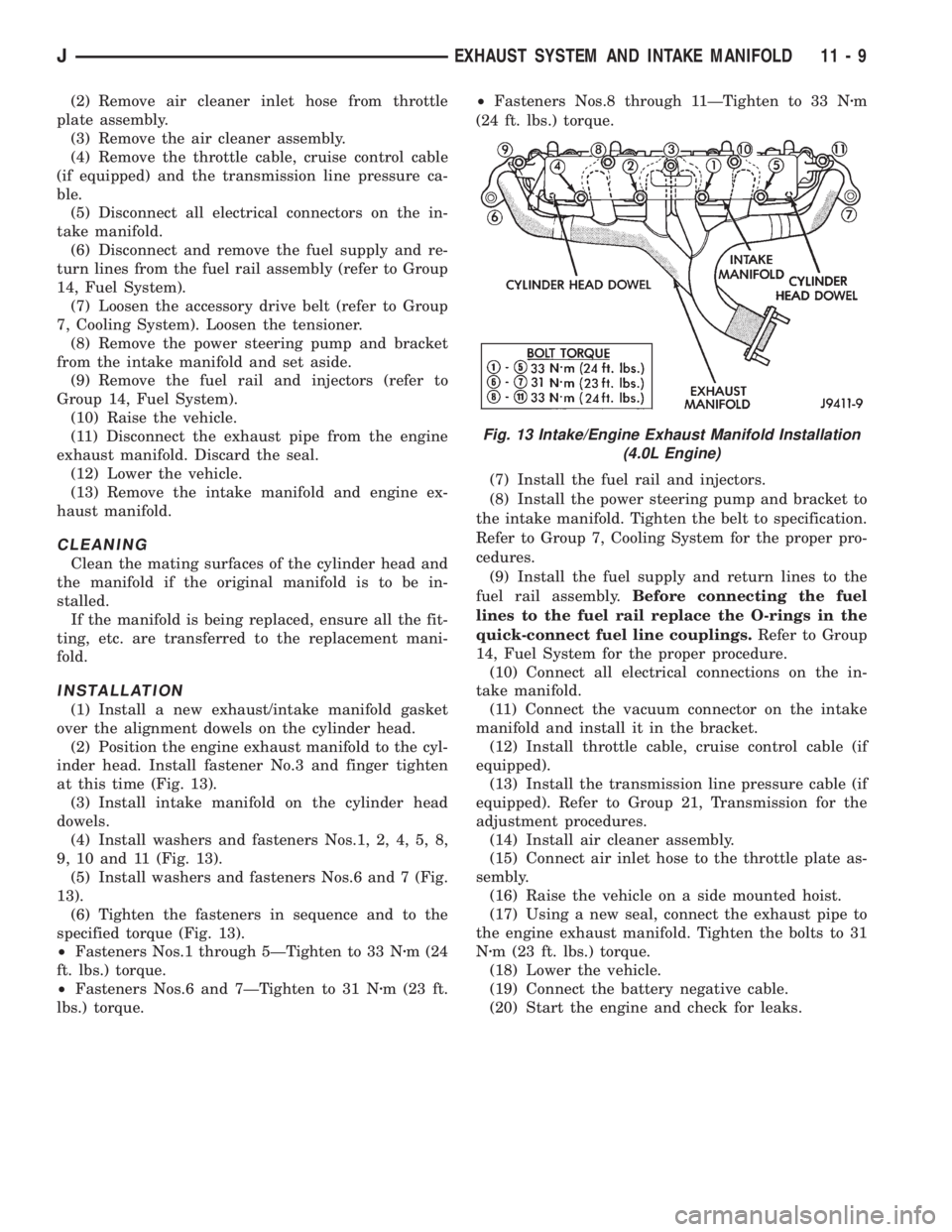

INSTALLATION

(1) Install a new exhaust/intake manifold gasket

over the alignment dowels on the cylinder head.

(2) Position the engine exhaust manifold to the cyl-

inder head. Install fastener No.3 and finger tighten

at this time (Fig. 13).

(3) Install intake manifold on the cylinder head

dowels.

(4) Install washers and fasteners Nos.1, 2, 4, 5, 8,

9, 10 and 11 (Fig. 13).

(5) Install washers and fasteners Nos.6 and 7 (Fig.

13).

(6) Tighten the fasteners in sequence and to the

specified torque (Fig. 13).

²Fasteners Nos.1 through 5ÐTighten to 33 Nzm (24

ft. lbs.) torque.

²Fasteners Nos.6 and 7ÐTighten to 31 Nzm (23 ft.

lbs.) torque.²Fasteners Nos.8 through 11ÐTighten to 33 Nzm

(24 ft. lbs.) torque.

(7) Install the fuel rail and injectors.

(8) Install the power steering pump and bracket to

the intake manifold. Tighten the belt to specification.

Refer to Group 7, Cooling System for the proper pro-

cedures.

(9) Install the fuel supply and return lines to the

fuel rail assembly.Before connecting the fuel

lines to the fuel rail replace the O-rings in the

quick-connect fuel line couplings.Refer to Group

14, Fuel System for the proper procedure.

(10) Connect all electrical connections on the in-

take manifold.

(11) Connect the vacuum connector on the intake

manifold and install it in the bracket.

(12) Install throttle cable, cruise control cable (if

equipped).

(13) Install the transmission line pressure cable (if

equipped). Refer to Group 21, Transmission for the

adjustment procedures.

(14) Install air cleaner assembly.

(15) Connect air inlet hose to the throttle plate as-

sembly.

(16) Raise the vehicle on a side mounted hoist.

(17) Using a new seal, connect the exhaust pipe to

the engine exhaust manifold. Tighten the bolts to 31

Nzm (23 ft. lbs.) torque.

(18) Lower the vehicle.

(19) Connect the battery negative cable.

(20) Start the engine and check for leaks.

Fig. 13 Intake/Engine Exhaust Manifold Installation

(4.0L Engine)

JEXHAUST SYSTEM AND INTAKE MANIFOLD 11 - 9

Page 1218 of 2198

FUEL DELIVERY SYSTEM

INDEX

page page

Fuel Filter................................ 9

Fuel Pressure Leak Down Test................ 8

Fuel Pressure Release Procedure.............. 6

Fuel Pump Capacity Test.................... 7

Fuel Pump Electrical Control.................. 5Fuel Pump Module......................... 3

Fuel System Pressure Test................... 6

Fuel Tubes/Lines/Hoses and Clamps............ 9

Quick-Connect Fittings..................... 10

FUEL PUMP MODULE

The fuel pump module is installed in the top of the

fuel tank. The fuel pump module contains the follow-

ing components:

²Electric fuel pump

²Fuel pump reservoir

²In-tank fuel filter

²Fuel gauge sending unit

²Fuel supply and return tube connections

The fuel pump used on all vehicles is a turbine

type pump. It is driven by a permanent magnet 12

volt electric motor that is immersed in the fuel tank.

The electrical pump is integral with the fuel sender

unit. The pump/sender assembly is installed inside

the fuel tank.

The fuel pump has a check valve at the outlet end

that consists of a ball held against a seat by force ap-

plied from a spring. When the pump is operating,

fuel pressure overcomes spring pressure and forces

the ball off its seat, allowing fuel to flow. When the

pump is not operating, spring pressure forces the ball

back against the seat preventing fuel backflow

through the pump.

Fuel system pressure is maintained at approxi-

mately 214 kPa (31 psi). This is when the pump is

operating and vacuum is supplied to the fuel pres-

sure regulator. If vacuum is not supplied to the pres-

sure regulator, fuel pressure will be approximately

55-69 kPa (8-10 psi) higher. This may be due to a

broken or clogged vacuum line. When the fuel pump

is not operating, fuel system pressure of 131-269 kPa

(19-39 psi) is maintained for approximately 2 to 6

hours. This is done by the fuel pump outlet check

valve and the vacuum assisted fuel pressure regula-

tor.

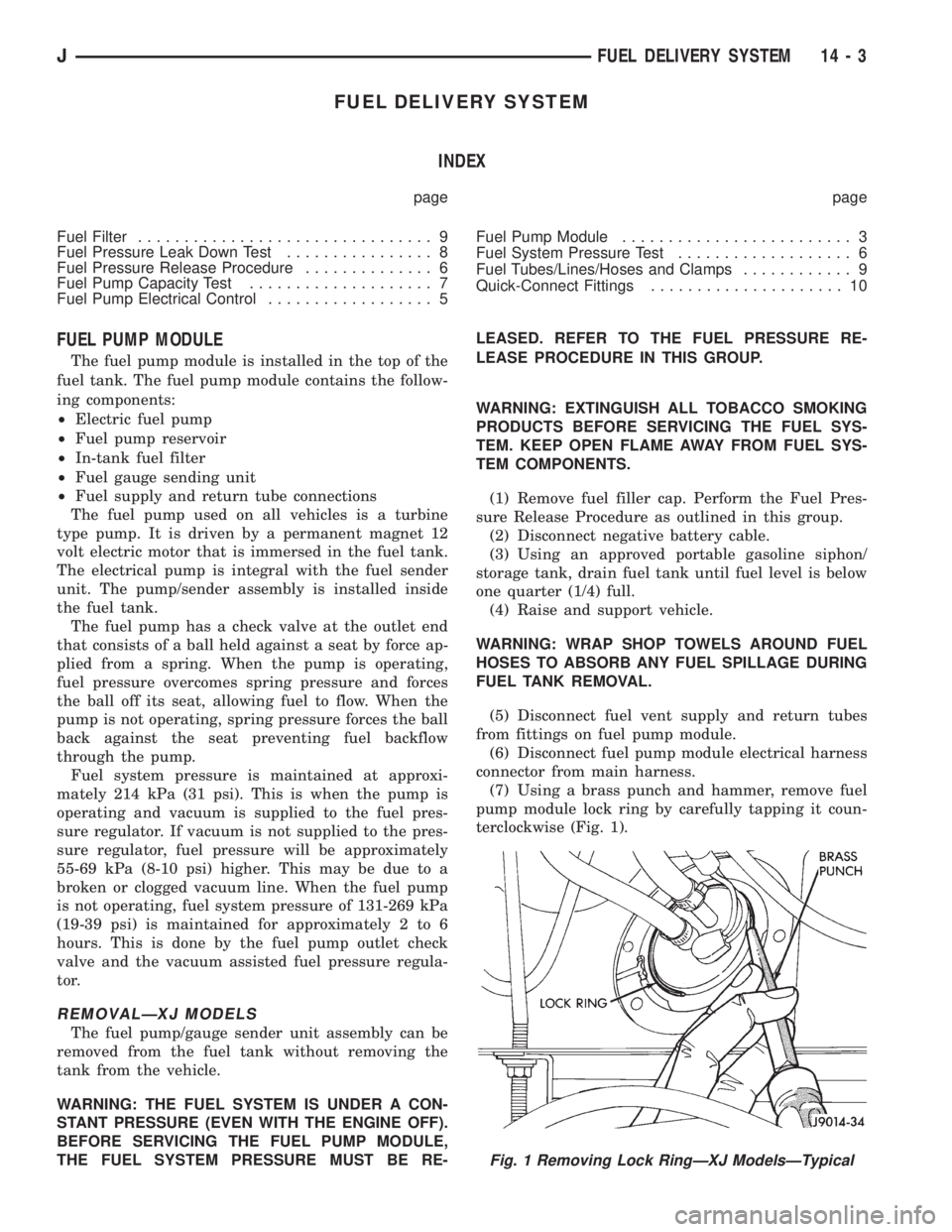

REMOVALÐXJ MODELS

The fuel pump/gauge sender unit assembly can be

removed from the fuel tank without removing the

tank from the vehicle.

WARNING: THE FUEL SYSTEM IS UNDER A CON-

STANT PRESSURE (EVEN WITH THE ENGINE OFF).

BEFORE SERVICING THE FUEL PUMP MODULE,

THE FUEL SYSTEM PRESSURE MUST BE RE-LEASED. REFER TO THE FUEL PRESSURE RE-

LEASE PROCEDURE IN THIS GROUP.

WARNING: EXTINGUISH ALL TOBACCO SMOKING

PRODUCTS BEFORE SERVICING THE FUEL SYS-

TEM. KEEP OPEN FLAME AWAY FROM FUEL SYS-

TEM COMPONENTS.

(1) Remove fuel filler cap. Perform the Fuel Pres-

sure Release Procedure as outlined in this group.

(2) Disconnect negative battery cable.

(3) Using an approved portable gasoline siphon/

storage tank, drain fuel tank until fuel level is below

one quarter (1/4) full.

(4) Raise and support vehicle.

WARNING: WRAP SHOP TOWELS AROUND FUEL

HOSES TO ABSORB ANY FUEL SPILLAGE DURING

FUEL TANK REMOVAL.

(5) Disconnect fuel vent supply and return tubes

from fittings on fuel pump module.

(6) Disconnect fuel pump module electrical harness

connector from main harness.

(7) Using a brass punch and hammer, remove fuel

pump module lock ring by carefully tapping it coun-

terclockwise (Fig. 1).

Fig. 1 Removing Lock RingÐXJ ModelsÐTypical

JFUEL DELIVERY SYSTEM 14 - 3

Page 1221 of 2198

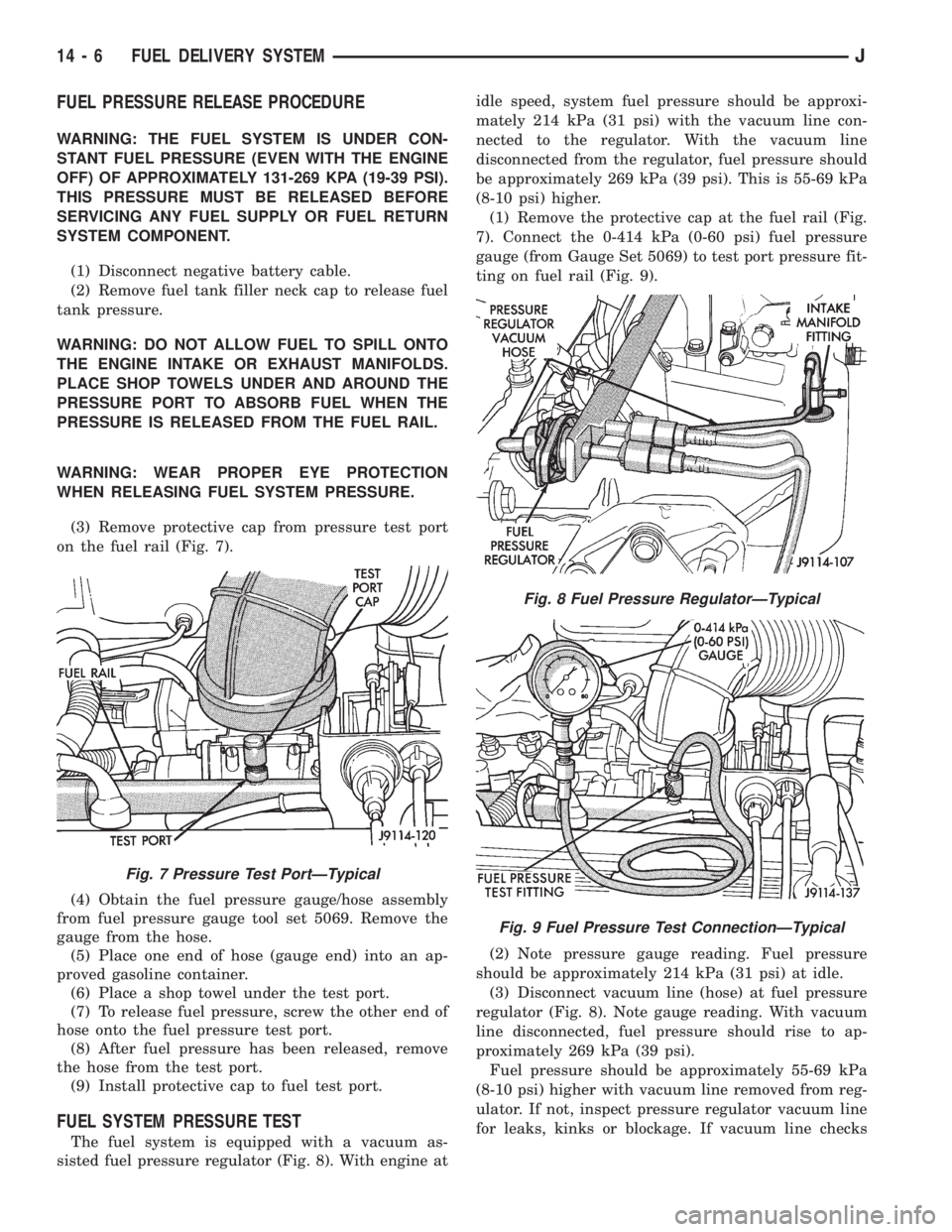

FUEL PRESSURE RELEASE PROCEDURE

WARNING: THE FUEL SYSTEM IS UNDER CON-

STANT FUEL PRESSURE (EVEN WITH THE ENGINE

OFF) OF APPROXIMATELY 131-269 KPA (19-39 PSI).

THIS PRESSURE MUST BE RELEASED BEFORE

SERVICING ANY FUEL SUPPLY OR FUEL RETURN

SYSTEM COMPONENT.

(1) Disconnect negative battery cable.

(2) Remove fuel tank filler neck cap to release fuel

tank pressure.

WARNING: DO NOT ALLOW FUEL TO SPILL ONTO

THE ENGINE INTAKE OR EXHAUST MANIFOLDS.

PLACE SHOP TOWELS UNDER AND AROUND THE

PRESSURE PORT TO ABSORB FUEL WHEN THE

PRESSURE IS RELEASED FROM THE FUEL RAIL.

WARNING: WEAR PROPER EYE PROTECTION

WHEN RELEASING FUEL SYSTEM PRESSURE.

(3) Remove protective cap from pressure test port

on the fuel rail (Fig. 7).

(4) Obtain the fuel pressure gauge/hose assembly

from fuel pressure gauge tool set 5069. Remove the

gauge from the hose.

(5) Place one end of hose (gauge end) into an ap-

proved gasoline container.

(6) Place a shop towel under the test port.

(7) To release fuel pressure, screw the other end of

hose onto the fuel pressure test port.

(8) After fuel pressure has been released, remove

the hose from the test port.

(9) Install protective cap to fuel test port.

FUEL SYSTEM PRESSURE TEST

The fuel system is equipped with a vacuum as-

sisted fuel pressure regulator (Fig. 8). With engine atidle speed, system fuel pressure should be approxi-

mately 214 kPa (31 psi) with the vacuum line con-

nected to the regulator. With the vacuum line

disconnected from the regulator, fuel pressure should

be approximately 269 kPa (39 psi). This is 55-69 kPa

(8-10 psi) higher.

(1) Remove the protective cap at the fuel rail (Fig.

7). Connect the 0-414 kPa (0-60 psi) fuel pressure

gauge (from Gauge Set 5069) to test port pressure fit-

ting on fuel rail (Fig. 9).

(2) Note pressure gauge reading. Fuel pressure

should be approximately 214 kPa (31 psi) at idle.

(3) Disconnect vacuum line (hose) at fuel pressure

regulator (Fig. 8). Note gauge reading. With vacuum

line disconnected, fuel pressure should rise to ap-

proximately 269 kPa (39 psi).

Fuel pressure should be approximately 55-69 kPa

(8-10 psi) higher with vacuum line removed from reg-

ulator. If not, inspect pressure regulator vacuum line

for leaks, kinks or blockage. If vacuum line checks

Fig. 7 Pressure Test PortÐTypical

Fig. 8 Fuel Pressure RegulatorÐTypical

Fig. 9 Fuel Pressure Test ConnectionÐTypical

14 - 6 FUEL DELIVERY SYSTEMJ