interior JEEP CHEROKEE 1995 Service Manual Online

[x] Cancel search | Manufacturer: JEEP, Model Year: 1995, Model line: CHEROKEE, Model: JEEP CHEROKEE 1995Pages: 2198, PDF Size: 82.83 MB

Page 1882 of 2198

HARD TOP QUARTER WINDOW GLASSÐYJ

REMOVAL

(1) Cover surface areas with protective covering to

avoid paint damage and extra clean-up time.

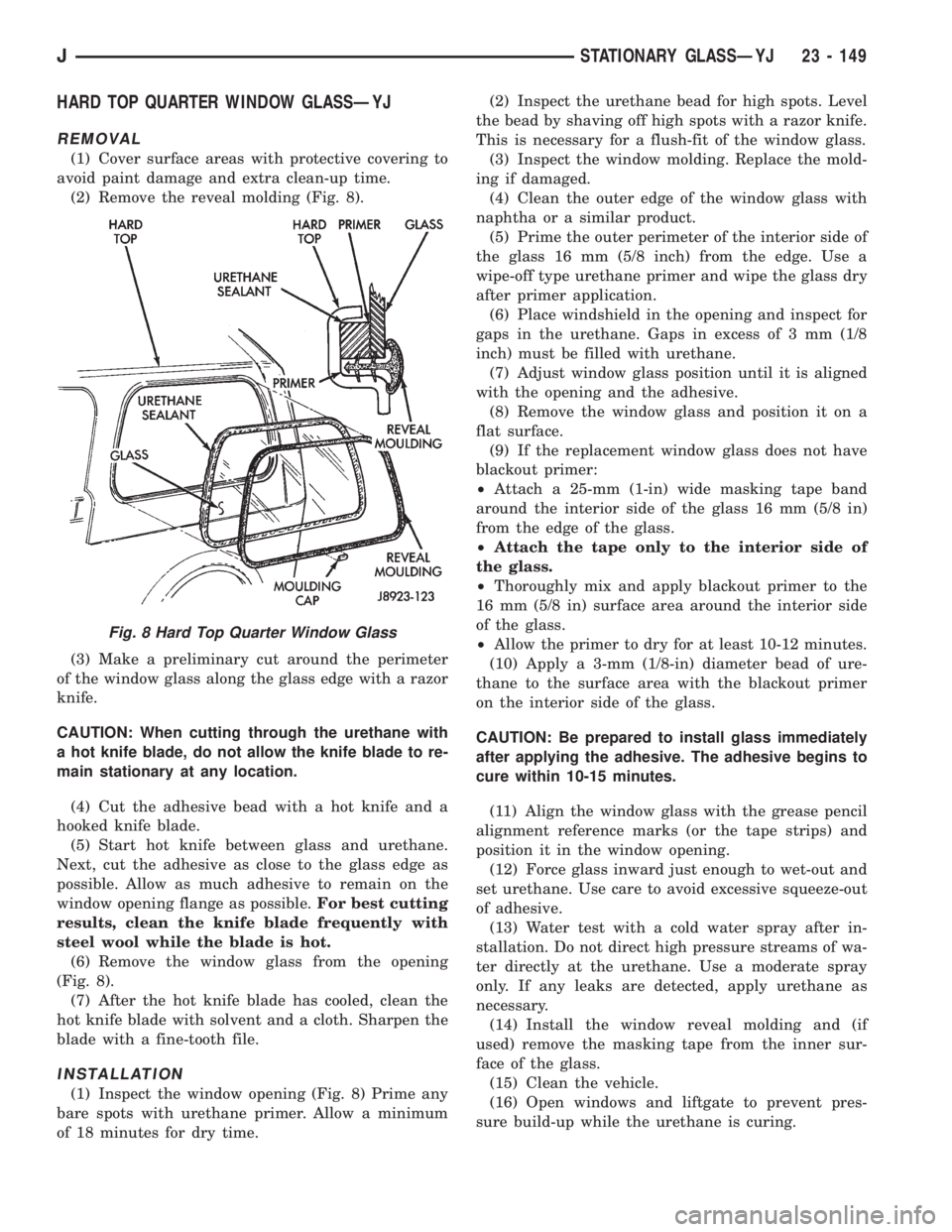

(2) Remove the reveal molding (Fig. 8).

(3) Make a preliminary cut around the perimeter

of the window glass along the glass edge with a razor

knife.

CAUTION: When cutting through the urethane with

a hot knife blade, do not allow the knife blade to re-

main stationary at any location.

(4) Cut the adhesive bead with a hot knife and a

hooked knife blade.

(5) Start hot knife between glass and urethane.

Next, cut the adhesive as close to the glass edge as

possible. Allow as much adhesive to remain on the

window opening flange as possible.For best cutting

results, clean the knife blade frequently with

steel wool while the blade is hot.

(6) Remove the window glass from the opening

(Fig. 8).

(7) After the hot knife blade has cooled, clean the

hot knife blade with solvent and a cloth. Sharpen the

blade with a fine-tooth file.

INSTALLATION

(1) Inspect the window opening (Fig. 8) Prime any

bare spots with urethane primer. Allow a minimum

of 18 minutes for dry time.(2) Inspect the urethane bead for high spots. Level

the bead by shaving off high spots with a razor knife.

This is necessary for a flush-fit of the window glass.

(3) Inspect the window molding. Replace the mold-

ing if damaged.

(4) Clean the outer edge of the window glass with

naphtha or a similar product.

(5) Prime the outer perimeter of the interior side of

the glass 16 mm (5/8 inch) from the edge. Use a

wipe-off type urethane primer and wipe the glass dry

after primer application.

(6) Place windshield in the opening and inspect for

gaps in the urethane. Gaps in excess of 3 mm (1/8

inch) must be filled with urethane.

(7) Adjust window glass position until it is aligned

with the opening and the adhesive.

(8) Remove the window glass and position it on a

flat surface.

(9) If the replacement window glass does not have

blackout primer:

²Attach a 25-mm (1-in) wide masking tape band

around the interior side of the glass 16 mm (5/8 in)

from the edge of the glass.

²Attach the tape only to the interior side of

the glass.

²Thoroughly mix and apply blackout primer to the

16 mm (5/8 in) surface area around the interior side

of the glass.

²Allow the primer to dry for at least 10-12 minutes.

(10) Apply a 3-mm (1/8-in) diameter bead of ure-

thane to the surface area with the blackout primer

on the interior side of the glass.

CAUTION: Be prepared to install glass immediately

after applying the adhesive. The adhesive begins to

cure within 10-15 minutes.

(11) Align the window glass with the grease pencil

alignment reference marks (or the tape strips) and

position it in the window opening.

(12) Force glass inward just enough to wet-out and

set urethane. Use care to avoid excessive squeeze-out

of adhesive.

(13) Water test with a cold water spray after in-

stallation. Do not direct high pressure streams of wa-

ter directly at the urethane. Use a moderate spray

only. If any leaks are detected, apply urethane as

necessary.

(14) Install the window reveal molding and (if

used) remove the masking tape from the inner sur-

face of the glass.

(15) Clean the vehicle.

(16) Open windows and liftgate to prevent pres-

sure build-up while the urethane is curing.

Fig. 8 Hard Top Quarter Window Glass

JSTATIONARY GLASSÐYJ 23 - 149

Page 1884 of 2198

INTERIOR COMPONENTS

INDEX

page page

Add-A-TrunkÐYJ........................ 157

Bucket SeatsÐYJ........................ 153

CarpetÐYJ............................. 156

Floor ConsolesÐYJ...................... 155

Front Shoulder BeltsÐYJ.................. 154

Glove BoxÐYJ.......................... 152

Instrument Cluster and Gauge HousingsÐYJ.... 151Instrument Cluster BezelÐYJ............... 151

Instrument Panel ComponentsÐYJ........... 152

Instrument PanelÐYJ..................... 151

Rear Bench SeatÐYJ..................... 153

Rear Shoulder BeltsÐYJ................... 154

SeatsÐYJ............................. 153

SunvisorsÐYJ.......................... 155

INSTRUMENT PANELÐYJ

The instrument panel is constructed of sheet metal

and is attached to cowl panel with screws. The in-

strument panel and defroster grille pad is attached

to the instrument panel with screws.

INSTRUMENT CLUSTER AND GAUGE HOUSINGSÐ

YJ

REMOVAL

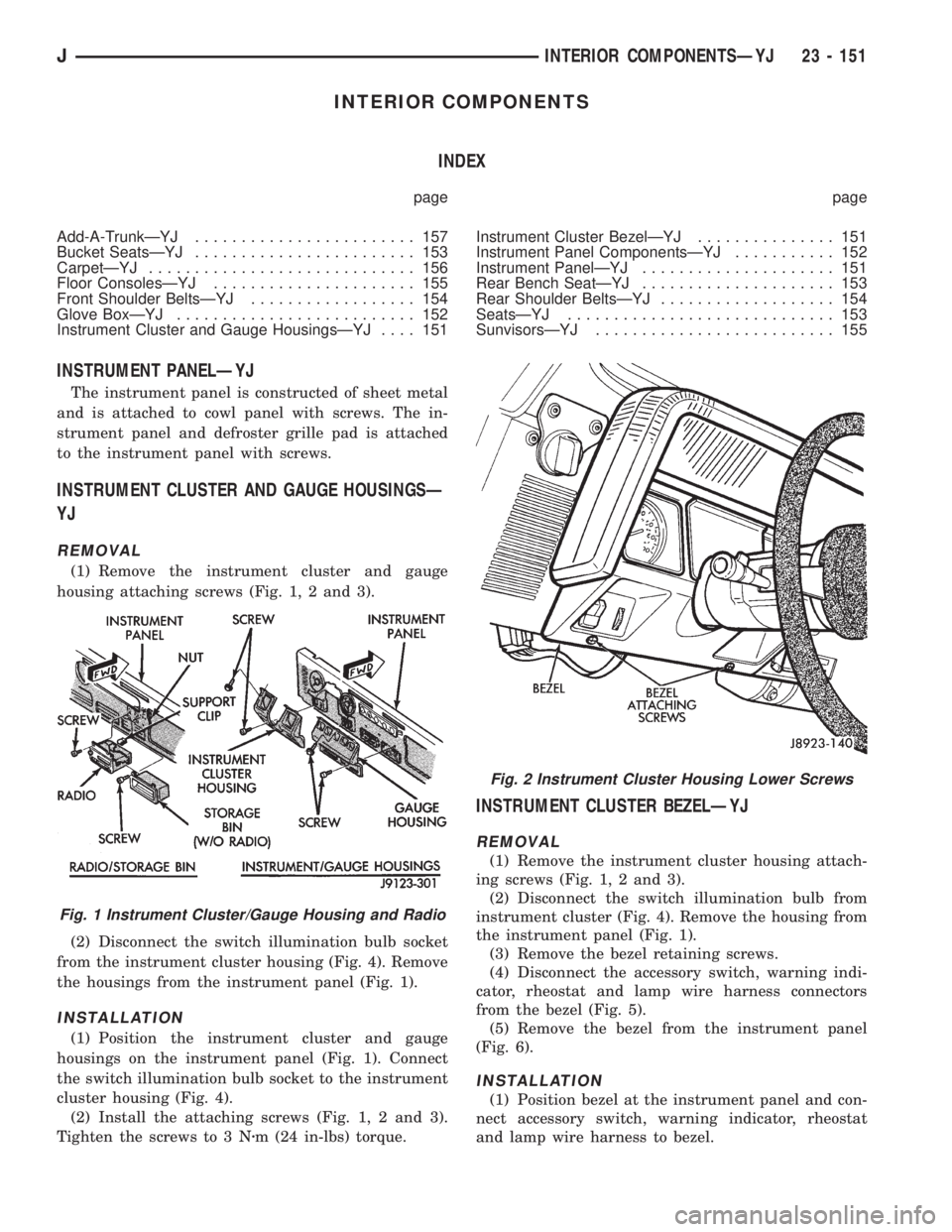

(1) Remove the instrument cluster and gauge

housing attaching screws (Fig. 1, 2 and 3).

(2) Disconnect the switch illumination bulb socket

from the instrument cluster housing (Fig. 4). Remove

the housings from the instrument panel (Fig. 1).

INSTALLATION

(1) Position the instrument cluster and gauge

housings on the instrument panel (Fig. 1). Connect

the switch illumination bulb socket to the instrument

cluster housing (Fig. 4).

(2) Install the attaching screws (Fig. 1, 2 and 3).

Tighten the screws to 3 Nzm (24 in-lbs) torque.

INSTRUMENT CLUSTER BEZELÐYJ

REMOVAL

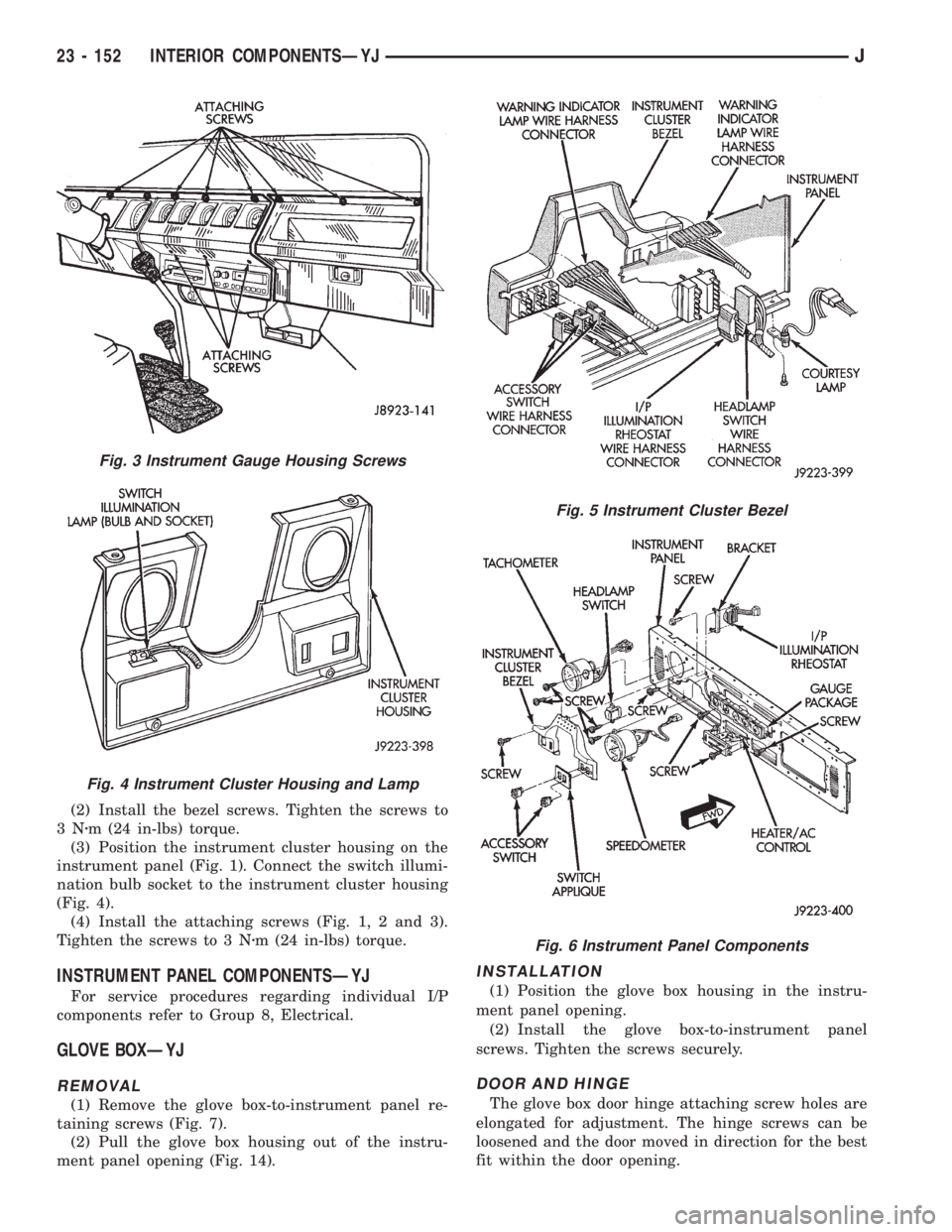

(1) Remove the instrument cluster housing attach-

ing screws (Fig. 1, 2 and 3).

(2) Disconnect the switch illumination bulb from

instrument cluster (Fig. 4). Remove the housing from

the instrument panel (Fig. 1).

(3) Remove the bezel retaining screws.

(4) Disconnect the accessory switch, warning indi-

cator, rheostat and lamp wire harness connectors

from the bezel (Fig. 5).

(5) Remove the bezel from the instrument panel

(Fig. 6).

INSTALLATION

(1) Position bezel at the instrument panel and con-

nect accessory switch, warning indicator, rheostat

and lamp wire harness to bezel.

Fig. 1 Instrument Cluster/Gauge Housing and Radio

Fig. 2 Instrument Cluster Housing Lower Screws

JINTERIOR COMPONENTSÐYJ 23 - 151

Page 1885 of 2198

(2) Install the bezel screws. Tighten the screws to

3Nzm (24 in-lbs) torque.

(3) Position the instrument cluster housing on the

instrument panel (Fig. 1). Connect the switch illumi-

nation bulb socket to the instrument cluster housing

(Fig. 4).

(4) Install the attaching screws (Fig. 1, 2 and 3).

Tighten the screws to 3 Nzm (24 in-lbs) torque.

INSTRUMENT PANEL COMPONENTSÐYJ

For service procedures regarding individual I/P

components refer to Group 8, Electrical.

GLOVE BOXÐYJ

REMOVAL

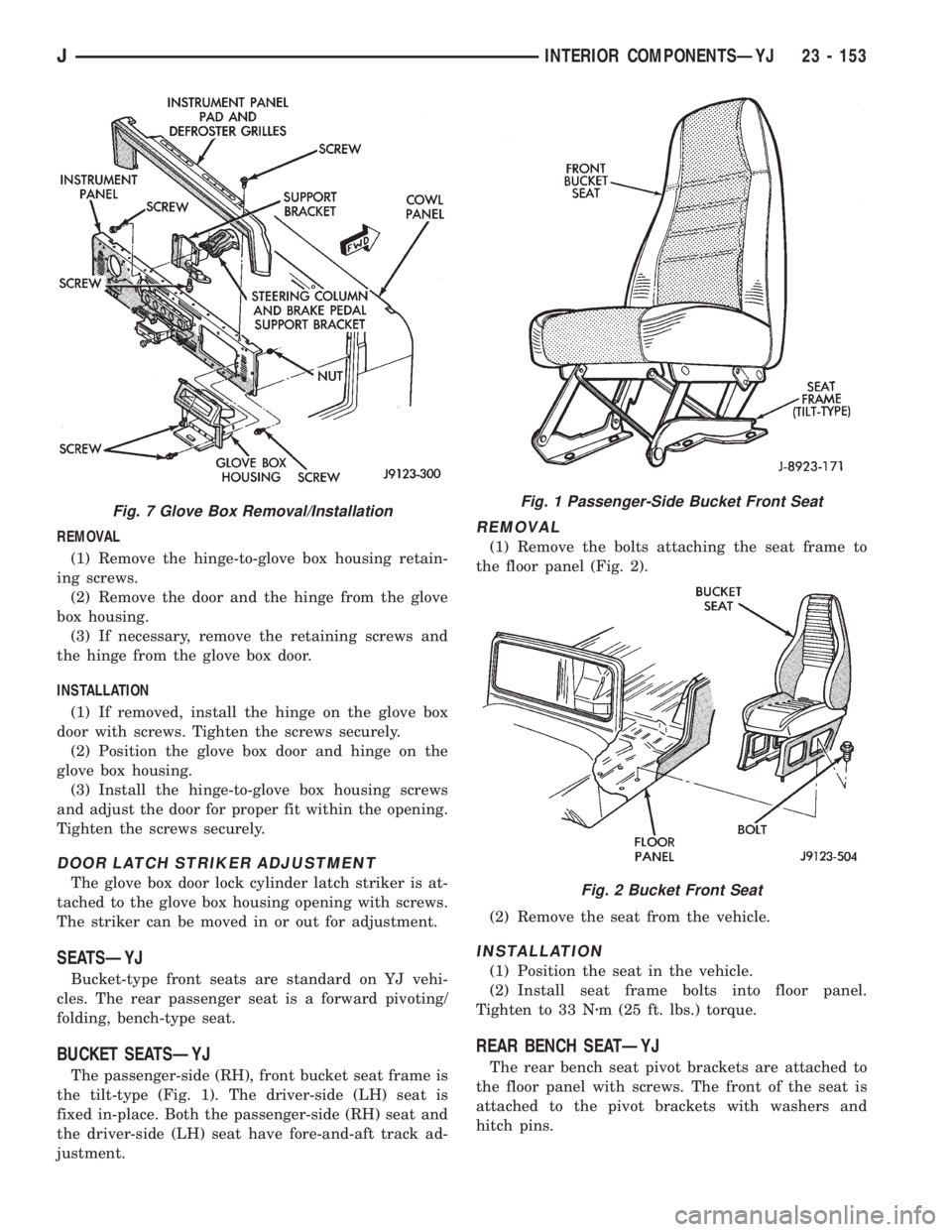

(1) Remove the glove box-to-instrument panel re-

taining screws (Fig. 7).

(2) Pull the glove box housing out of the instru-

ment panel opening (Fig. 14).

INSTALLATION

(1) Position the glove box housing in the instru-

ment panel opening.

(2) Install the glove box-to-instrument panel

screws. Tighten the screws securely.

DOOR AND HINGE

The glove box door hinge attaching screw holes are

elongated for adjustment. The hinge screws can be

loosened and the door moved in direction for the best

fit within the door opening.

Fig. 3 Instrument Gauge Housing Screws

Fig. 4 Instrument Cluster Housing and Lamp

Fig. 5 Instrument Cluster Bezel

Fig. 6 Instrument Panel Components

23 - 152 INTERIOR COMPONENTSÐYJJ

Page 1886 of 2198

REMOVAL

(1) Remove the hinge-to-glove box housing retain-

ing screws.

(2) Remove the door and the hinge from the glove

box housing.

(3) If necessary, remove the retaining screws and

the hinge from the glove box door.

INSTALLATION

(1) If removed, install the hinge on the glove box

door with screws. Tighten the screws securely.

(2) Position the glove box door and hinge on the

glove box housing.

(3) Install the hinge-to-glove box housing screws

and adjust the door for proper fit within the opening.

Tighten the screws securely.

DOOR LATCH STRIKER ADJUSTMENT

The glove box door lock cylinder latch striker is at-

tached to the glove box housing opening with screws.

The striker can be moved in or out for adjustment.

SEATSÐYJ

Bucket-type front seats are standard on YJ vehi-

cles. The rear passenger seat is a forward pivoting/

folding, bench-type seat.

BUCKET SEATSÐYJ

The passenger-side (RH), front bucket seat frame is

the tilt-type (Fig. 1). The driver-side (LH) seat is

fixed in-place. Both the passenger-side (RH) seat and

the driver-side (LH) seat have fore-and-aft track ad-

justment.

REMOVAL

(1) Remove the bolts attaching the seat frame to

the floor panel (Fig. 2).

(2) Remove the seat from the vehicle.

INSTALLATION

(1) Position the seat in the vehicle.

(2) Install seat frame bolts into floor panel.

Tighten to 33 Nzm (25 ft. lbs.) torque.

REAR BENCH SEATÐYJ

The rear bench seat pivot brackets are attached to

the floor panel with screws. The front of the seat is

attached to the pivot brackets with washers and

hitch pins.

Fig. 7 Glove Box Removal/InstallationFig. 1 Passenger-Side Bucket Front Seat

Fig. 2 Bucket Front Seat

JINTERIOR COMPONENTSÐYJ 23 - 153

Page 1887 of 2198

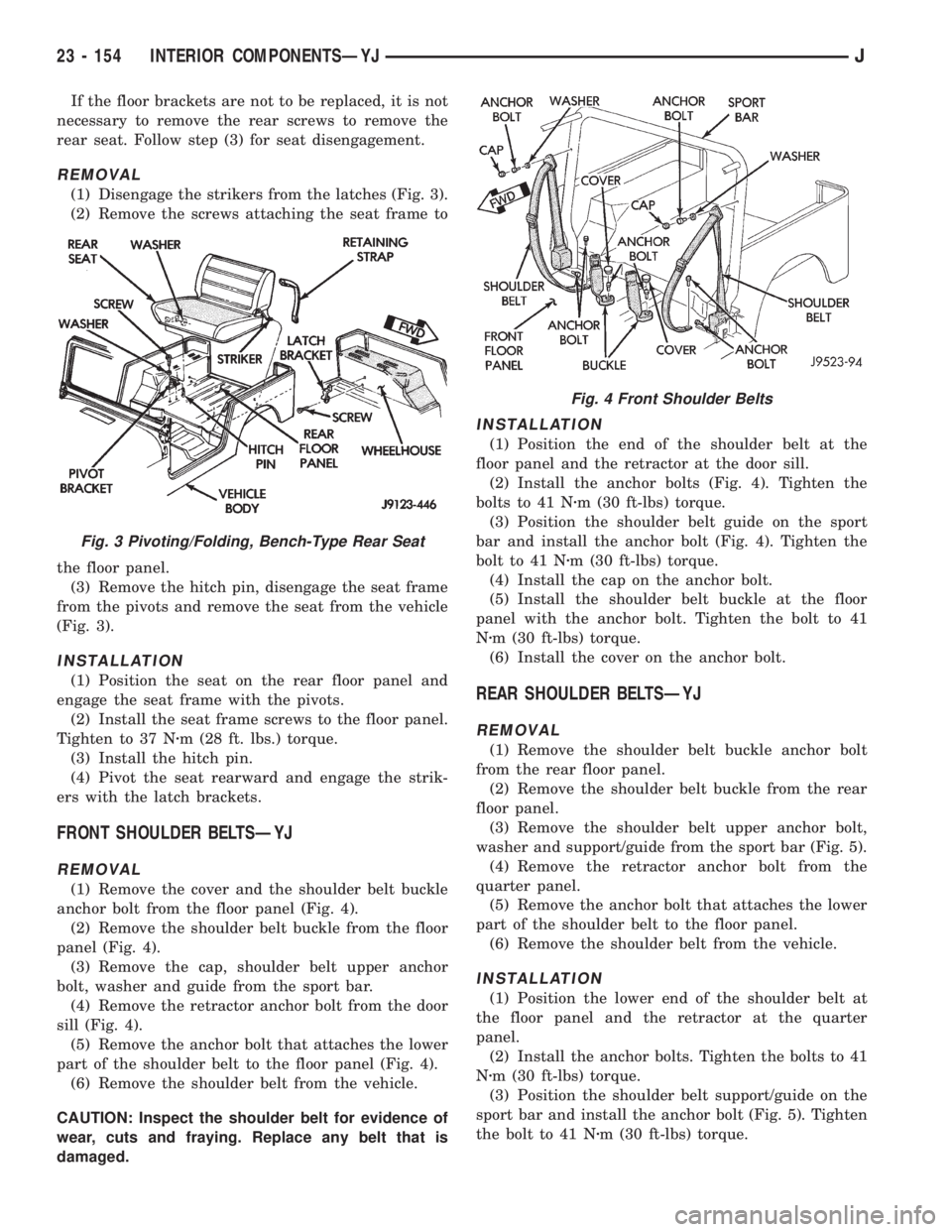

If the floor brackets are not to be replaced, it is not

necessary to remove the rear screws to remove the

rear seat. Follow step (3) for seat disengagement.

REMOVAL

(1) Disengage the strikers from the latches (Fig. 3).

(2) Remove the screws attaching the seat frame to

the floor panel.

(3) Remove the hitch pin, disengage the seat frame

from the pivots and remove the seat from the vehicle

(Fig. 3).

INSTALLATION

(1) Position the seat on the rear floor panel and

engage the seat frame with the pivots.

(2) Install the seat frame screws to the floor panel.

Tighten to 37 Nzm (28 ft. lbs.) torque.

(3) Install the hitch pin.

(4) Pivot the seat rearward and engage the strik-

ers with the latch brackets.

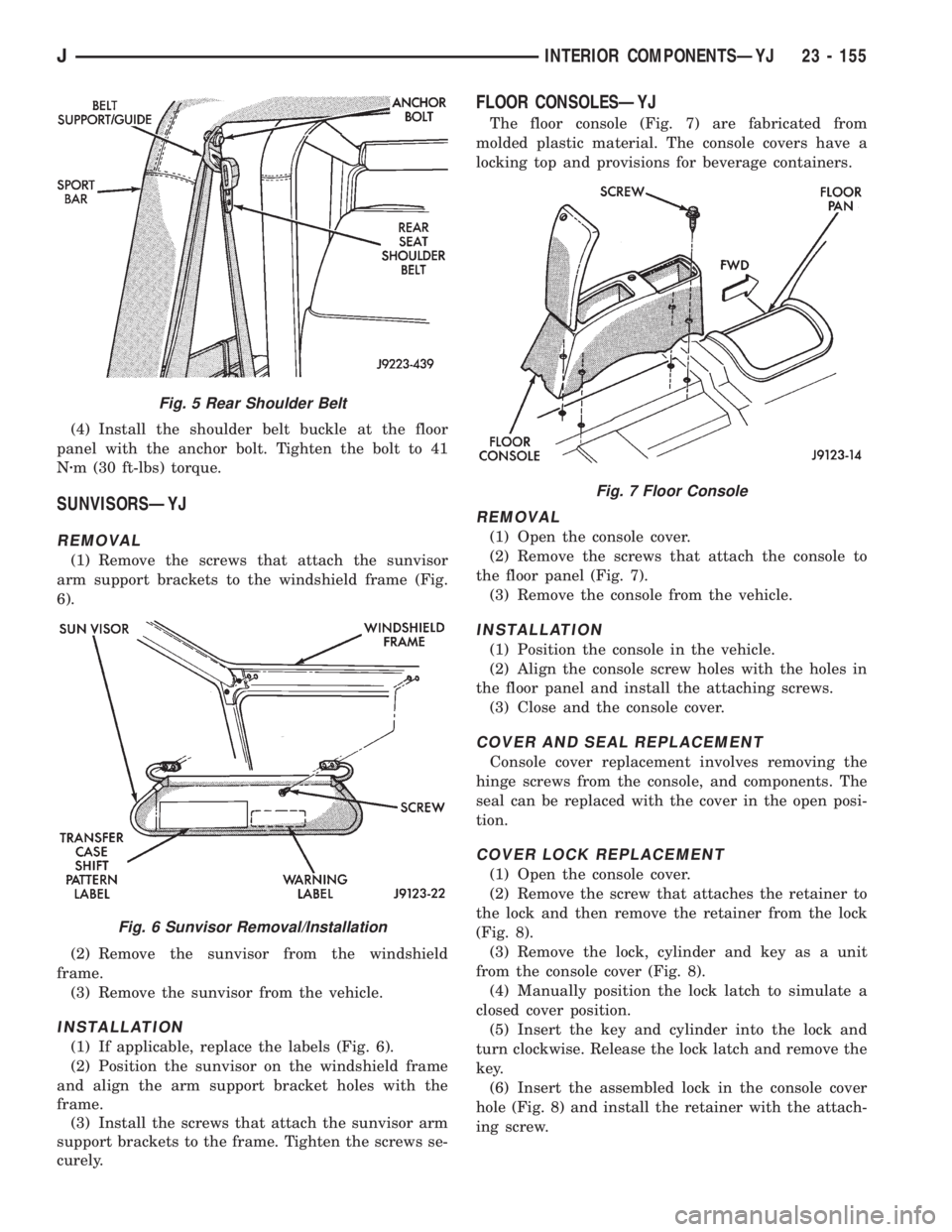

FRONT SHOULDER BELTSÐYJ

REMOVAL

(1) Remove the cover and the shoulder belt buckle

anchor bolt from the floor panel (Fig. 4).

(2) Remove the shoulder belt buckle from the floor

panel (Fig. 4).

(3) Remove the cap, shoulder belt upper anchor

bolt, washer and guide from the sport bar.

(4) Remove the retractor anchor bolt from the door

sill (Fig. 4).

(5) Remove the anchor bolt that attaches the lower

part of the shoulder belt to the floor panel (Fig. 4).

(6) Remove the shoulder belt from the vehicle.

CAUTION: Inspect the shoulder belt for evidence of

wear, cuts and fraying. Replace any belt that is

damaged.

INSTALLATION

(1) Position the end of the shoulder belt at the

floor panel and the retractor at the door sill.

(2) Install the anchor bolts (Fig. 4). Tighten the

bolts to 41 Nzm (30 ft-lbs) torque.

(3) Position the shoulder belt guide on the sport

bar and install the anchor bolt (Fig. 4). Tighten the

bolt to 41 Nzm (30 ft-lbs) torque.

(4) Install the cap on the anchor bolt.

(5) Install the shoulder belt buckle at the floor

panel with the anchor bolt. Tighten the bolt to 41

Nzm (30 ft-lbs) torque.

(6) Install the cover on the anchor bolt.

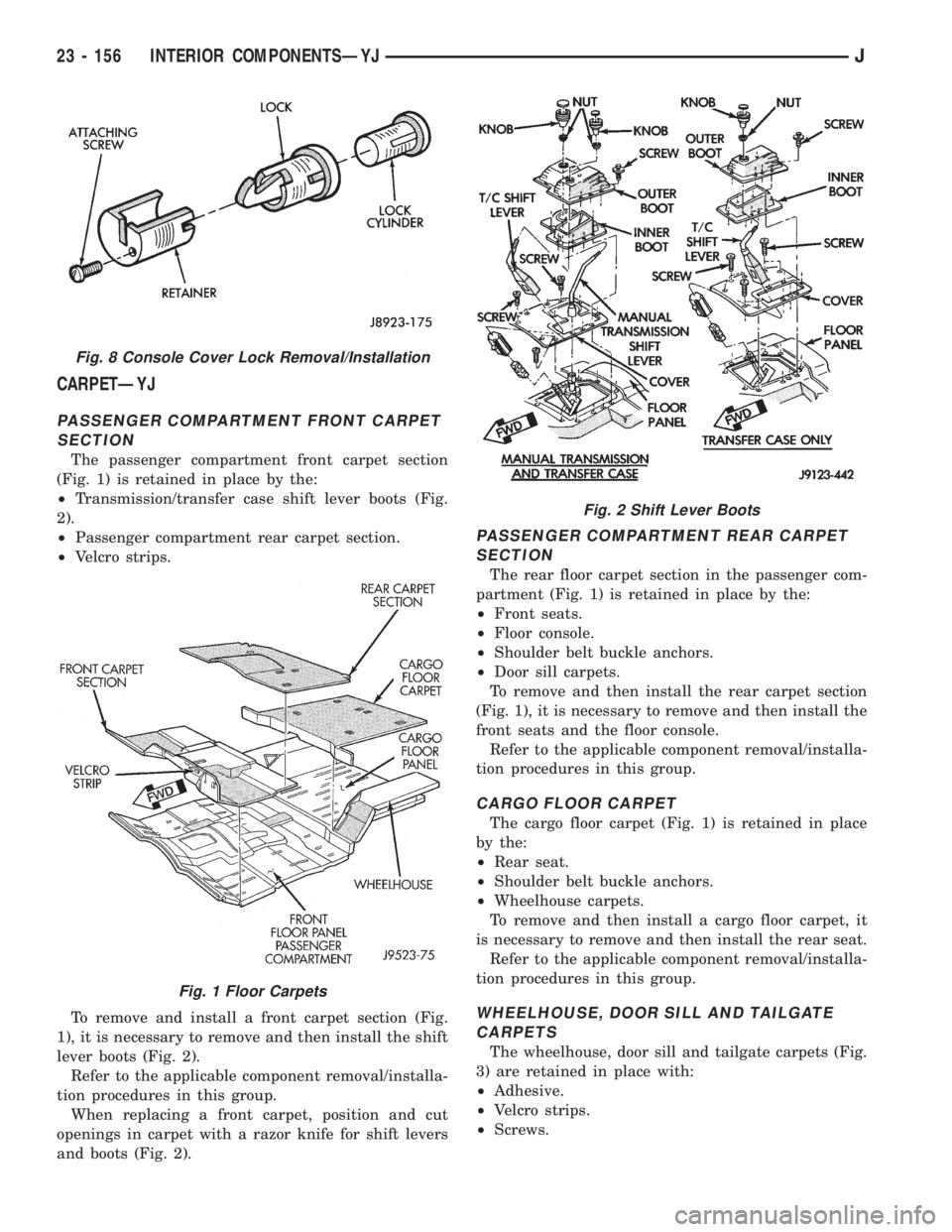

REAR SHOULDER BELTSÐYJ

REMOVAL

(1) Remove the shoulder belt buckle anchor bolt

from the rear floor panel.

(2) Remove the shoulder belt buckle from the rear

floor panel.

(3) Remove the shoulder belt upper anchor bolt,

washer and support/guide from the sport bar (Fig. 5).

(4) Remove the retractor anchor bolt from the

quarter panel.

(5) Remove the anchor bolt that attaches the lower

part of the shoulder belt to the floor panel.

(6) Remove the shoulder belt from the vehicle.

INSTALLATION

(1) Position the lower end of the shoulder belt at

the floor panel and the retractor at the quarter

panel.

(2) Install the anchor bolts. Tighten the bolts to 41

Nzm (30 ft-lbs) torque.

(3) Position the shoulder belt support/guide on the

sport bar and install the anchor bolt (Fig. 5). Tighten

the bolt to 41 Nzm (30 ft-lbs) torque.

Fig. 3 Pivoting/Folding, Bench-Type Rear Seat

Fig. 4 Front Shoulder Belts

23 - 154 INTERIOR COMPONENTSÐYJJ

Page 1888 of 2198

(4) Install the shoulder belt buckle at the floor

panel with the anchor bolt. Tighten the bolt to 41

Nzm (30 ft-lbs) torque.

SUNVISORSÐYJ

REMOVAL

(1) Remove the screws that attach the sunvisor

arm support brackets to the windshield frame (Fig.

6).

(2) Remove the sunvisor from the windshield

frame.

(3) Remove the sunvisor from the vehicle.

INSTALLATION

(1) If applicable, replace the labels (Fig. 6).

(2) Position the sunvisor on the windshield frame

and align the arm support bracket holes with the

frame.

(3) Install the screws that attach the sunvisor arm

support brackets to the frame. Tighten the screws se-

curely.

FLOOR CONSOLESÐYJ

The floor console (Fig. 7) are fabricated from

molded plastic material. The console covers have a

locking top and provisions for beverage containers.

REMOVAL

(1) Open the console cover.

(2) Remove the screws that attach the console to

the floor panel (Fig. 7).

(3) Remove the console from the vehicle.

INSTALLATION

(1) Position the console in the vehicle.

(2) Align the console screw holes with the holes in

the floor panel and install the attaching screws.

(3) Close and the console cover.

COVER AND SEAL REPLACEMENT

Console cover replacement involves removing the

hinge screws from the console, and components. The

seal can be replaced with the cover in the open posi-

tion.

COVER LOCK REPLACEMENT

(1) Open the console cover.

(2) Remove the screw that attaches the retainer to

the lock and then remove the retainer from the lock

(Fig. 8).

(3) Remove the lock, cylinder and key as a unit

from the console cover (Fig. 8).

(4) Manually position the lock latch to simulate a

closed cover position.

(5) Insert the key and cylinder into the lock and

turn clockwise. Release the lock latch and remove the

key.

(6) Insert the assembled lock in the console cover

hole (Fig. 8) and install the retainer with the attach-

ing screw.

Fig. 5 Rear Shoulder Belt

Fig. 6 Sunvisor Removal/Installation

Fig. 7 Floor Console

JINTERIOR COMPONENTSÐYJ 23 - 155

Page 1889 of 2198

CARPETÐYJ

PASSENGER COMPARTMENT FRONT CARPET

SECTION

The passenger compartment front carpet section

(Fig. 1) is retained in place by the:

²Transmission/transfer case shift lever boots (Fig.

2).

²Passenger compartment rear carpet section.

²Velcro strips.

To remove and install a front carpet section (Fig.

1), it is necessary to remove and then install the shift

lever boots (Fig. 2).

Refer to the applicable component removal/installa-

tion procedures in this group.

When replacing a front carpet, position and cut

openings in carpet with a razor knife for shift levers

and boots (Fig. 2).

PASSENGER COMPARTMENT REAR CARPET

SECTION

The rear floor carpet section in the passenger com-

partment (Fig. 1) is retained in place by the:

²Front seats.

²Floor console.

²Shoulder belt buckle anchors.

²Door sill carpets.

To remove and then install the rear carpet section

(Fig. 1), it is necessary to remove and then install the

front seats and the floor console.

Refer to the applicable component removal/installa-

tion procedures in this group.

CARGO FLOOR CARPET

The cargo floor carpet (Fig. 1) is retained in place

by the:

²Rear seat.

²Shoulder belt buckle anchors.

²Wheelhouse carpets.

To remove and then install a cargo floor carpet, it

is necessary to remove and then install the rear seat.

Refer to the applicable component removal/installa-

tion procedures in this group.

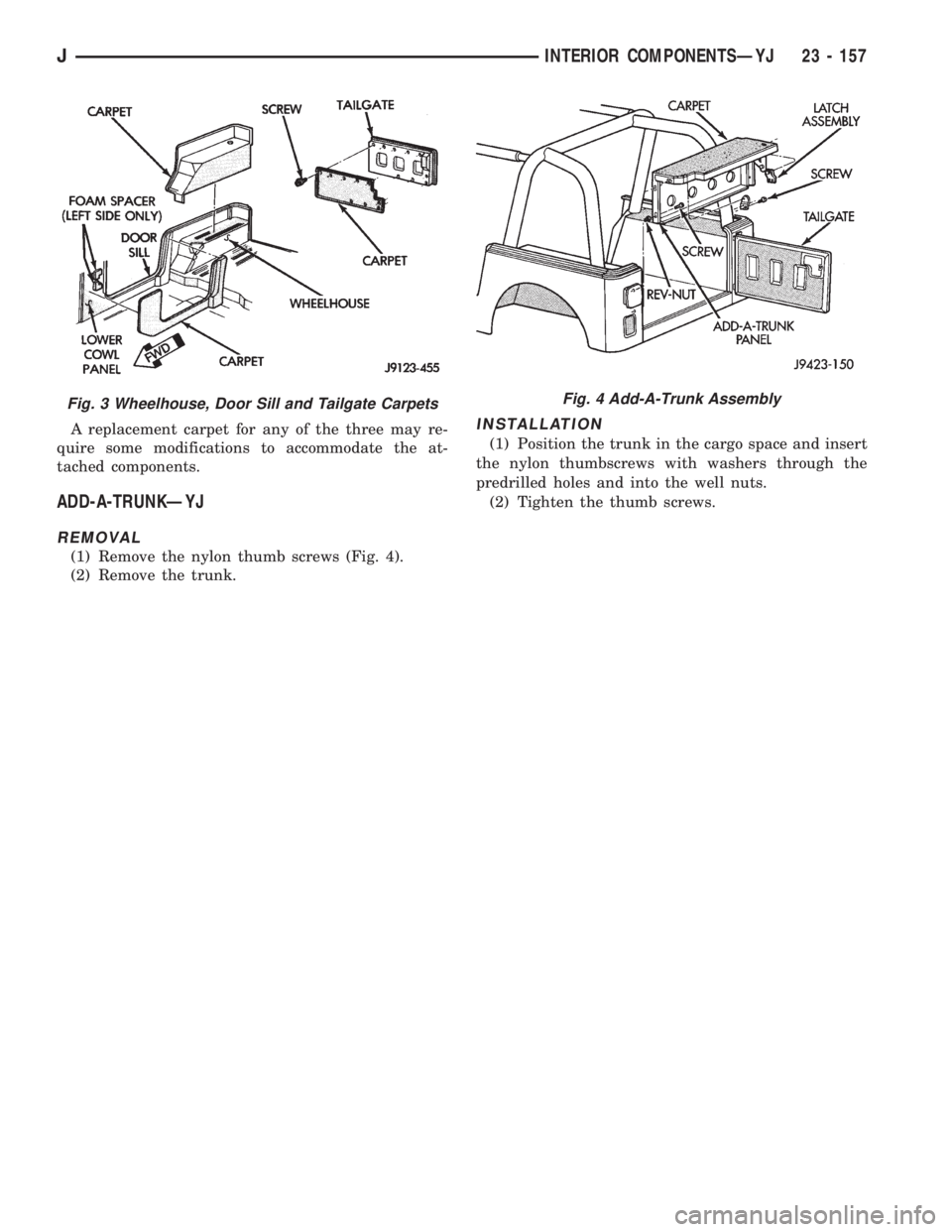

WHEELHOUSE, DOOR SILL AND TAILGATE

CARPETS

The wheelhouse, door sill and tailgate carpets (Fig.

3) are retained in place with:

²Adhesive.

²Velcro strips.

²Screws.

Fig. 8 Console Cover Lock Removal/Installation

Fig. 1 Floor Carpets

Fig. 2 Shift Lever Boots

23 - 156 INTERIOR COMPONENTSÐYJJ

Page 1890 of 2198

A replacement carpet for any of the three may re-

quire some modifications to accommodate the at-

tached components.

ADD-A-TRUNKÐYJ

REMOVAL

(1) Remove the nylon thumb screws (Fig. 4).

(2) Remove the trunk.

INSTALLATION

(1) Position the trunk in the cargo space and insert

the nylon thumbscrews with washers through the

predrilled holes and into the well nuts.

(2) Tighten the thumb screws.

Fig. 3 Wheelhouse, Door Sill and Tailgate CarpetsFig. 4 Add-A-Trunk Assembly

JINTERIOR COMPONENTSÐYJ 23 - 157

Page 1898 of 2198

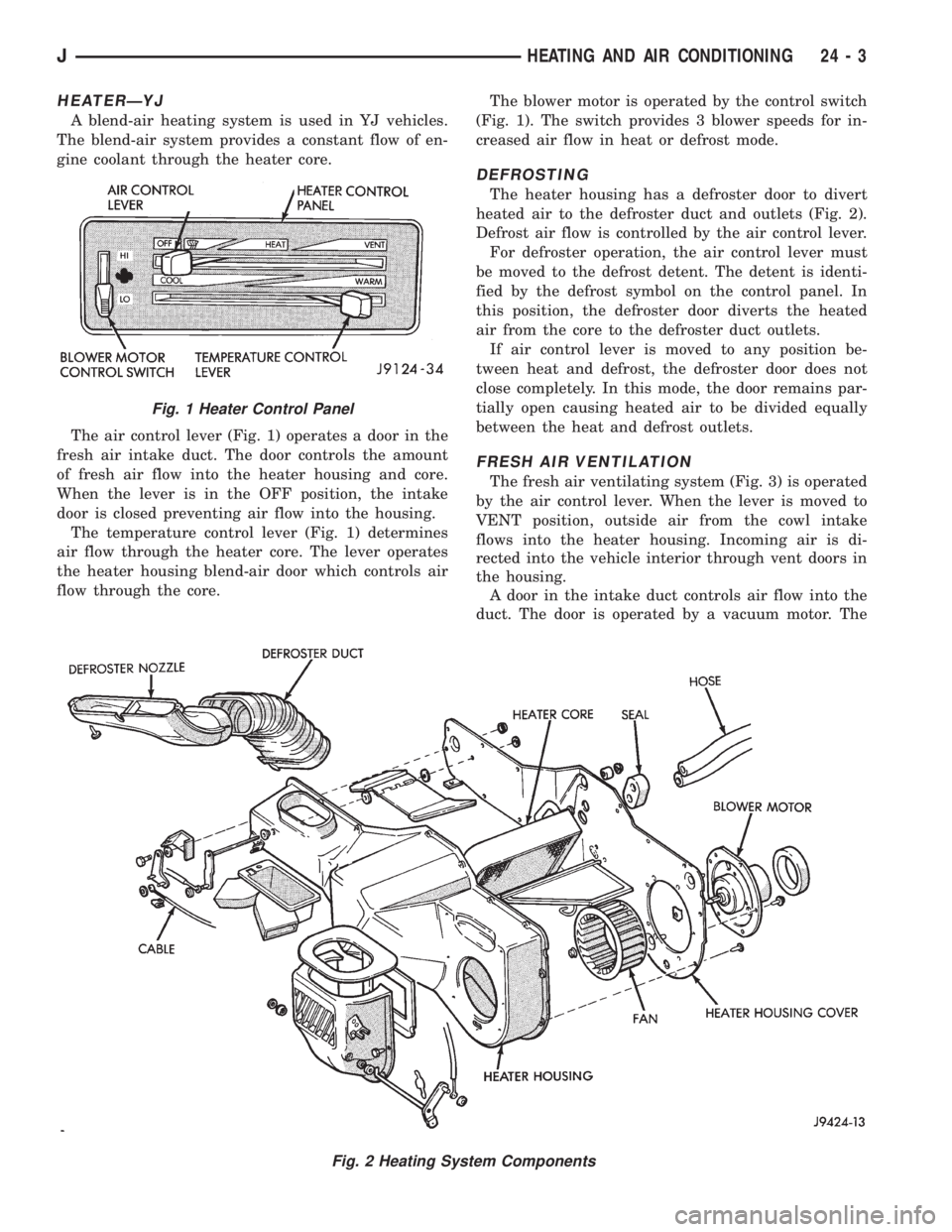

HEATERÐYJ

A blend-air heating system is used in YJ vehicles.

The blend-air system provides a constant flow of en-

gine coolant through the heater core.

The air control lever (Fig. 1) operates a door in the

fresh air intake duct. The door controls the amount

of fresh air flow into the heater housing and core.

When the lever is in the OFF position, the intake

door is closed preventing air flow into the housing.

The temperature control lever (Fig. 1) determines

air flow through the heater core. The lever operates

the heater housing blend-air door which controls air

flow through the core.The blower motor is operated by the control switch

(Fig. 1). The switch provides 3 blower speeds for in-

creased air flow in heat or defrost mode.

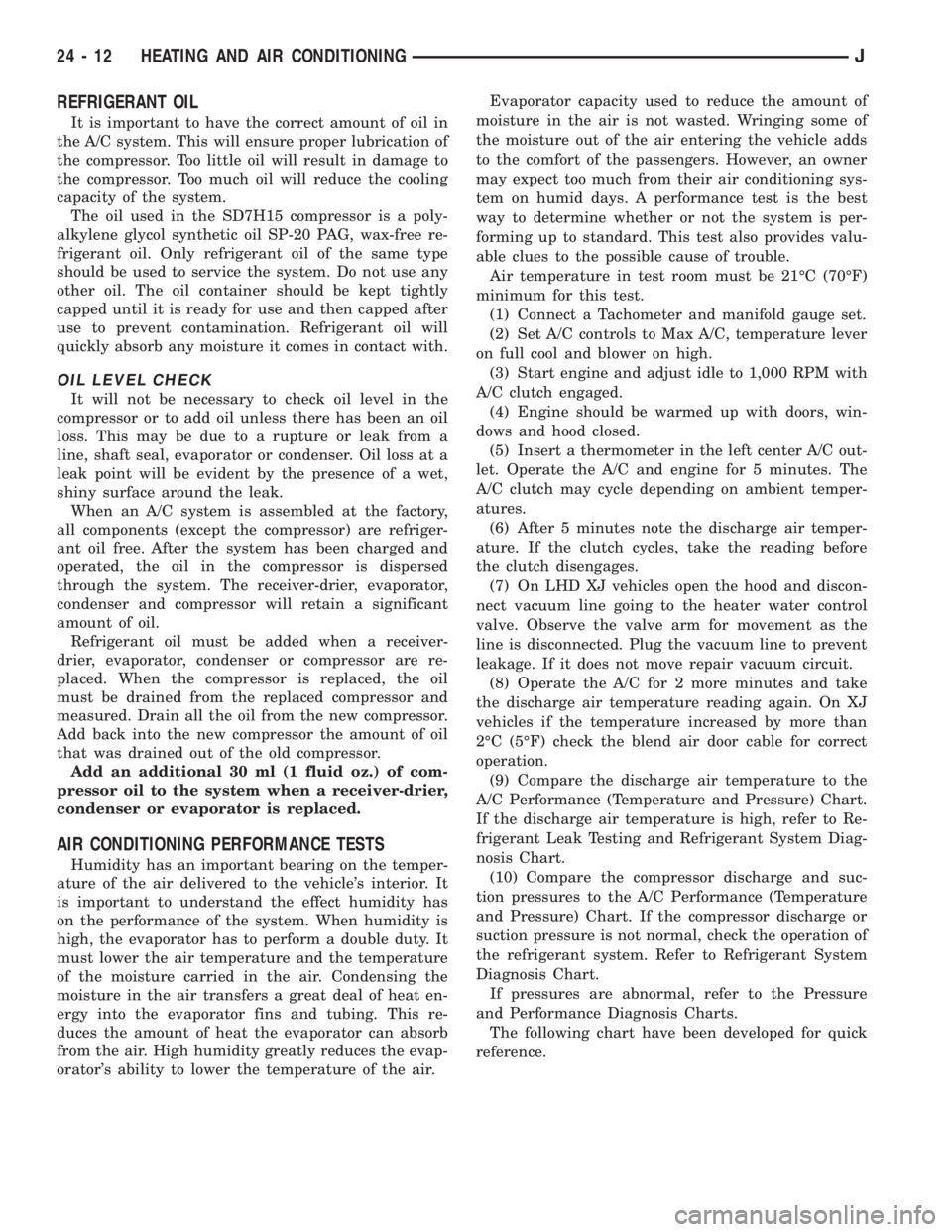

DEFROSTING

The heater housing has a defroster door to divert

heated air to the defroster duct and outlets (Fig. 2).

Defrost air flow is controlled by the air control lever.

For defroster operation, the air control lever must

be moved to the defrost detent. The detent is identi-

fied by the defrost symbol on the control panel. In

this position, the defroster door diverts the heated

air from the core to the defroster duct outlets.

If air control lever is moved to any position be-

tween heat and defrost, the defroster door does not

close completely. In this mode, the door remains par-

tially open causing heated air to be divided equally

between the heat and defrost outlets.

FRESH AIR VENTILATION

The fresh air ventilating system (Fig. 3) is operated

by the air control lever. When the lever is moved to

VENT position, outside air from the cowl intake

flows into the heater housing. Incoming air is di-

rected into the vehicle interior through vent doors in

the housing.

A door in the intake duct controls air flow into the

duct. The door is operated by a vacuum motor. The

Fig. 2 Heating System Components

Fig. 1 Heater Control Panel

JHEATING AND AIR CONDITIONING 24 - 3

Page 1907 of 2198

REFRIGERANT OIL

It is important to have the correct amount of oil in

the A/C system. This will ensure proper lubrication of

the compressor. Too little oil will result in damage to

the compressor. Too much oil will reduce the cooling

capacity of the system.

The oil used in the SD7H15 compressor is a poly-

alkylene glycol synthetic oil SP-20 PAG, wax-free re-

frigerant oil. Only refrigerant oil of the same type

should be used to service the system. Do not use any

other oil. The oil container should be kept tightly

capped until it is ready for use and then capped after

use to prevent contamination. Refrigerant oil will

quickly absorb any moisture it comes in contact with.

OIL LEVEL CHECK

It will not be necessary to check oil level in the

compressor or to add oil unless there has been an oil

loss. This may be due to a rupture or leak from a

line, shaft seal, evaporator or condenser. Oil loss at a

leak point will be evident by the presence of a wet,

shiny surface around the leak.

When an A/C system is assembled at the factory,

all components (except the compressor) are refriger-

ant oil free. After the system has been charged and

operated, the oil in the compressor is dispersed

through the system. The receiver-drier, evaporator,

condenser and compressor will retain a significant

amount of oil.

Refrigerant oil must be added when a receiver-

drier, evaporator, condenser or compressor are re-

placed. When the compressor is replaced, the oil

must be drained from the replaced compressor and

measured. Drain all the oil from the new compressor.

Add back into the new compressor the amount of oil

that was drained out of the old compressor.

Add an additional 30 ml (1 fluid oz.) of com-

pressor oil to the system when a receiver-drier,

condenser or evaporator is replaced.

AIR CONDITIONING PERFORMANCE TESTS

Humidity has an important bearing on the temper-

ature of the air delivered to the vehicle's interior. It

is important to understand the effect humidity has

on the performance of the system. When humidity is

high, the evaporator has to perform a double duty. It

must lower the air temperature and the temperature

of the moisture carried in the air. Condensing the

moisture in the air transfers a great deal of heat en-

ergy into the evaporator fins and tubing. This re-

duces the amount of heat the evaporator can absorb

from the air. High humidity greatly reduces the evap-

orator's ability to lower the temperature of the air.Evaporator capacity used to reduce the amount of

moisture in the air is not wasted. Wringing some of

the moisture out of the air entering the vehicle adds

to the comfort of the passengers. However, an owner

may expect too much from their air conditioning sys-

tem on humid days. A performance test is the best

way to determine whether or not the system is per-

forming up to standard. This test also provides valu-

able clues to the possible cause of trouble.

Air temperature in test room must be 21ÉC (70ÉF)

minimum for this test.

(1) Connect a Tachometer and manifold gauge set.

(2) Set A/C controls to Max A/C, temperature lever

on full cool and blower on high.

(3) Start engine and adjust idle to 1,000 RPM with

A/C clutch engaged.

(4) Engine should be warmed up with doors, win-

dows and hood closed.

(5) Insert a thermometer in the left center A/C out-

let. Operate the A/C and engine for 5 minutes. The

A/C clutch may cycle depending on ambient temper-

atures.

(6) After 5 minutes note the discharge air temper-

ature. If the clutch cycles, take the reading before

the clutch disengages.

(7) On LHD XJ vehicles open the hood and discon-

nect vacuum line going to the heater water control

valve. Observe the valve arm for movement as the

line is disconnected. Plug the vacuum line to prevent

leakage. If it does not move repair vacuum circuit.

(8) Operate the A/C for 2 more minutes and take

the discharge air temperature reading again. On XJ

vehicles if the temperature increased by more than

2ÉC (5ÉF) check the blend air door cable for correct

operation.

(9) Compare the discharge air temperature to the

A/C Performance (Temperature and Pressure) Chart.

If the discharge air temperature is high, refer to Re-

frigerant Leak Testing and Refrigerant System Diag-

nosis Chart.

(10) Compare the compressor discharge and suc-

tion pressures to the A/C Performance (Temperature

and Pressure) Chart. If the compressor discharge or

suction pressure is not normal, check the operation of

the refrigerant system. Refer to Refrigerant System

Diagnosis Chart.

If pressures are abnormal, refer to the Pressure

and Performance Diagnosis Charts.

The following chart have been developed for quick

reference.

24 - 12 HEATING AND AIR CONDITIONINGJ