interior JEEP CHEROKEE 1995 Service Manual PDF

[x] Cancel search | Manufacturer: JEEP, Model Year: 1995, Model line: CHEROKEE, Model: JEEP CHEROKEE 1995Pages: 2198, PDF Size: 82.83 MB

Page 1835 of 2198

BODY COMPONENTSÐYJ VEHICLES

CONTENTS

page page

DOORS............................... 134

EXTERIOR COMPONENTS................ 104

GENERAL SERVICE INFORMATION......... 102INTERIOR COMPONENTS................ 151

PAINT................................ 158

STATIONARY GLASS.................... 144

GENERAL SERVICE INFORMATION

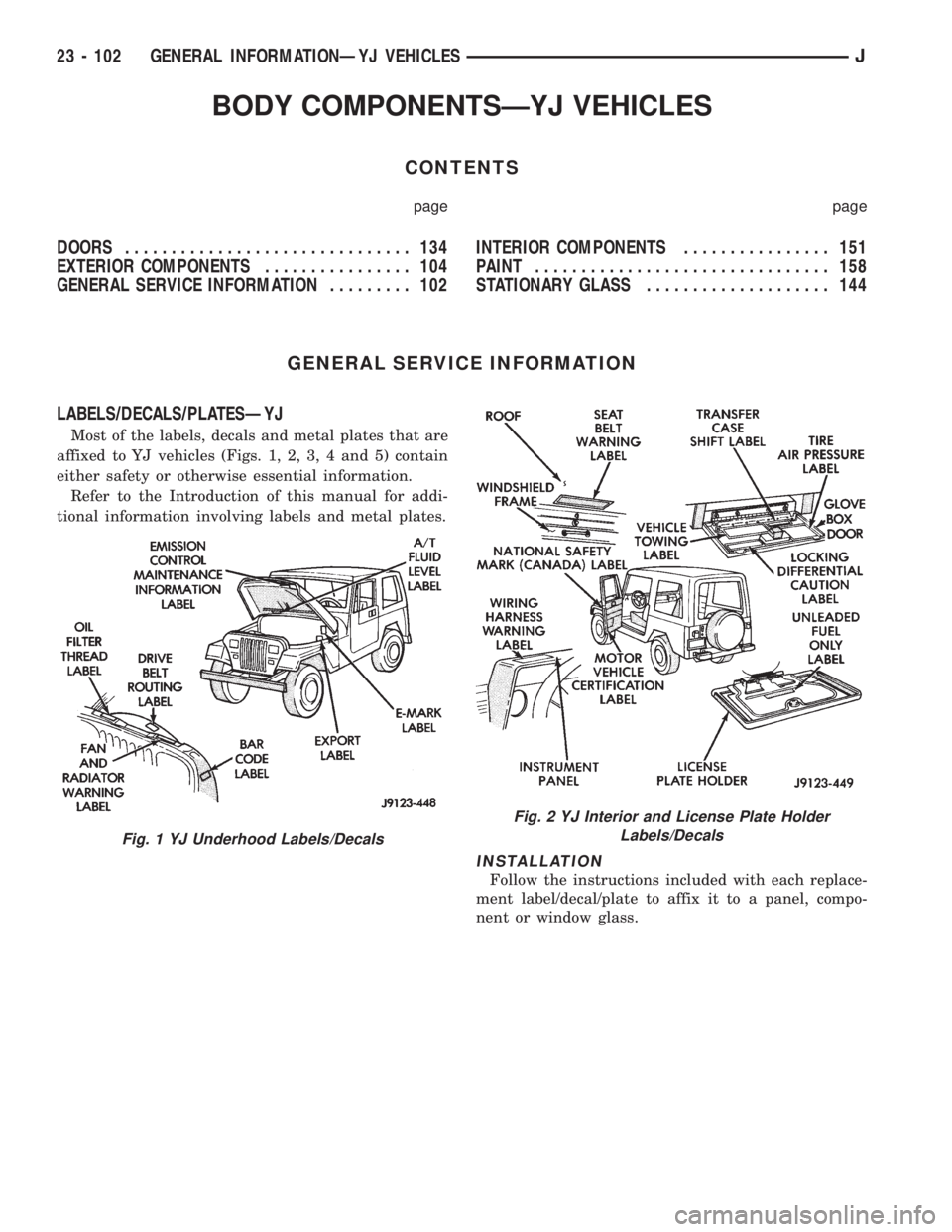

LABELS/DECALS/PLATESÐYJ

Most of the labels, decals and metal plates that are

affixed to YJ vehicles (Figs. 1, 2, 3, 4 and 5) contain

either safety or otherwise essential information.

Refer to the Introduction of this manual for addi-

tional information involving labels and metal plates.

INSTALLATION

Follow the instructions included with each replace-

ment label/decal/plate to affix it to a panel, compo-

nent or window glass.

Fig. 1 YJ Underhood Labels/Decals

Fig. 2 YJ Interior and License Plate Holder

Labels/Decals

23 - 102 GENERAL INFORMATIONÐYJ VEHICLESJ

Page 1838 of 2198

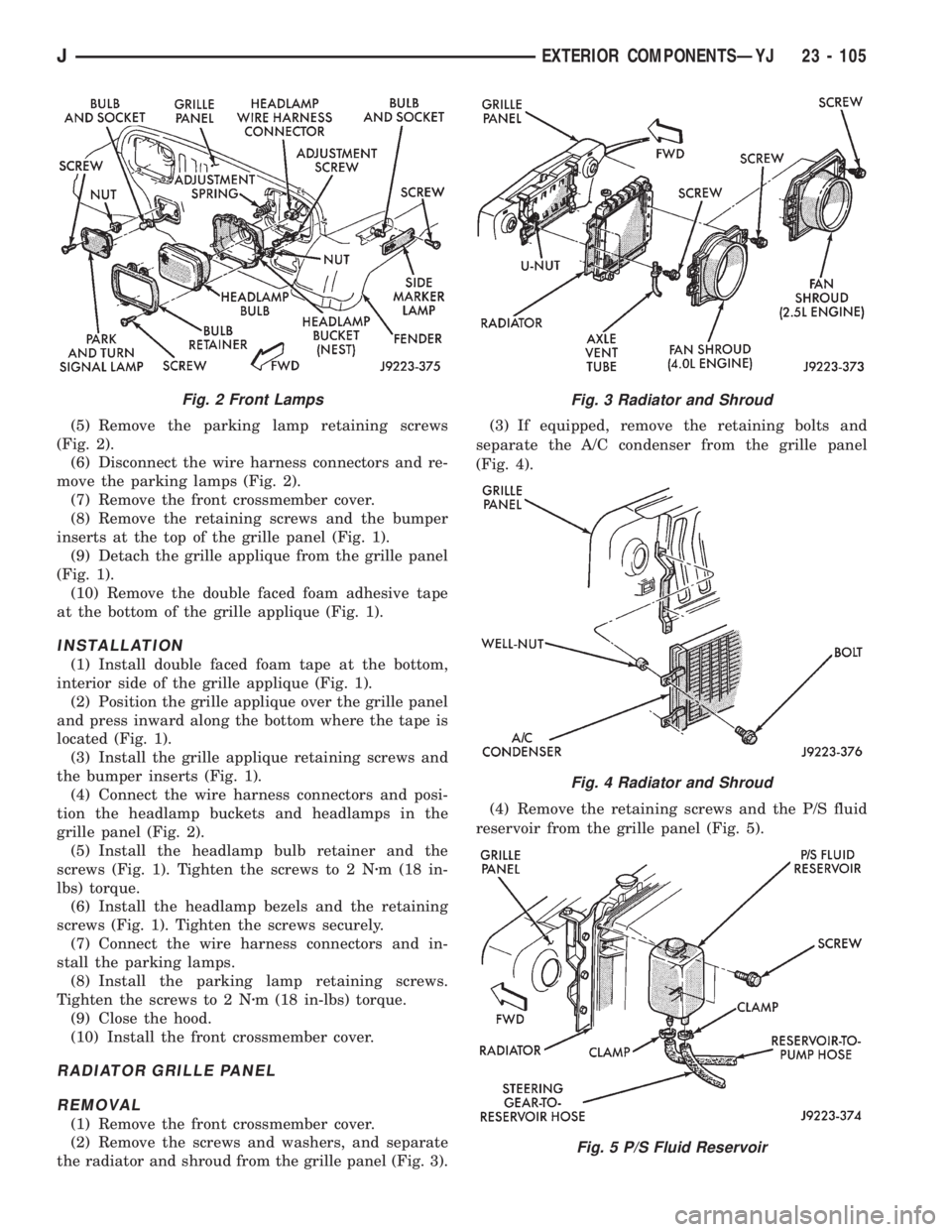

(5) Remove the parking lamp retaining screws

(Fig. 2).

(6) Disconnect the wire harness connectors and re-

move the parking lamps (Fig. 2).

(7) Remove the front crossmember cover.

(8) Remove the retaining screws and the bumper

inserts at the top of the grille panel (Fig. 1).

(9) Detach the grille applique from the grille panel

(Fig. 1).

(10) Remove the double faced foam adhesive tape

at the bottom of the grille applique (Fig. 1).

INSTALLATION

(1) Install double faced foam tape at the bottom,

interior side of the grille applique (Fig. 1).

(2) Position the grille applique over the grille panel

and press inward along the bottom where the tape is

located (Fig. 1).

(3) Install the grille applique retaining screws and

the bumper inserts (Fig. 1).

(4) Connect the wire harness connectors and posi-

tion the headlamp buckets and headlamps in the

grille panel (Fig. 2).

(5) Install the headlamp bulb retainer and the

screws (Fig. 1). Tighten the screws to 2 Nzm (18 in-

lbs) torque.

(6) Install the headlamp bezels and the retaining

screws (Fig. 1). Tighten the screws securely.

(7) Connect the wire harness connectors and in-

stall the parking lamps.

(8) Install the parking lamp retaining screws.

Tighten the screws to 2 Nzm (18 in-lbs) torque.

(9) Close the hood.

(10) Install the front crossmember cover.

RADIATOR GRILLE PANEL

REMOVAL

(1) Remove the front crossmember cover.

(2) Remove the screws and washers, and separate

the radiator and shroud from the grille panel (Fig. 3).(3) If equipped, remove the retaining bolts and

separate the A/C condenser from the grille panel

(Fig. 4).

(4) Remove the retaining screws and the P/S fluid

reservoir from the grille panel (Fig. 5).

Fig. 2 Front LampsFig. 3 Radiator and Shroud

Fig. 4 Radiator and Shroud

Fig. 5 P/S Fluid Reservoir

JEXTERIOR COMPONENTSÐYJ 23 - 105

Page 1862 of 2198

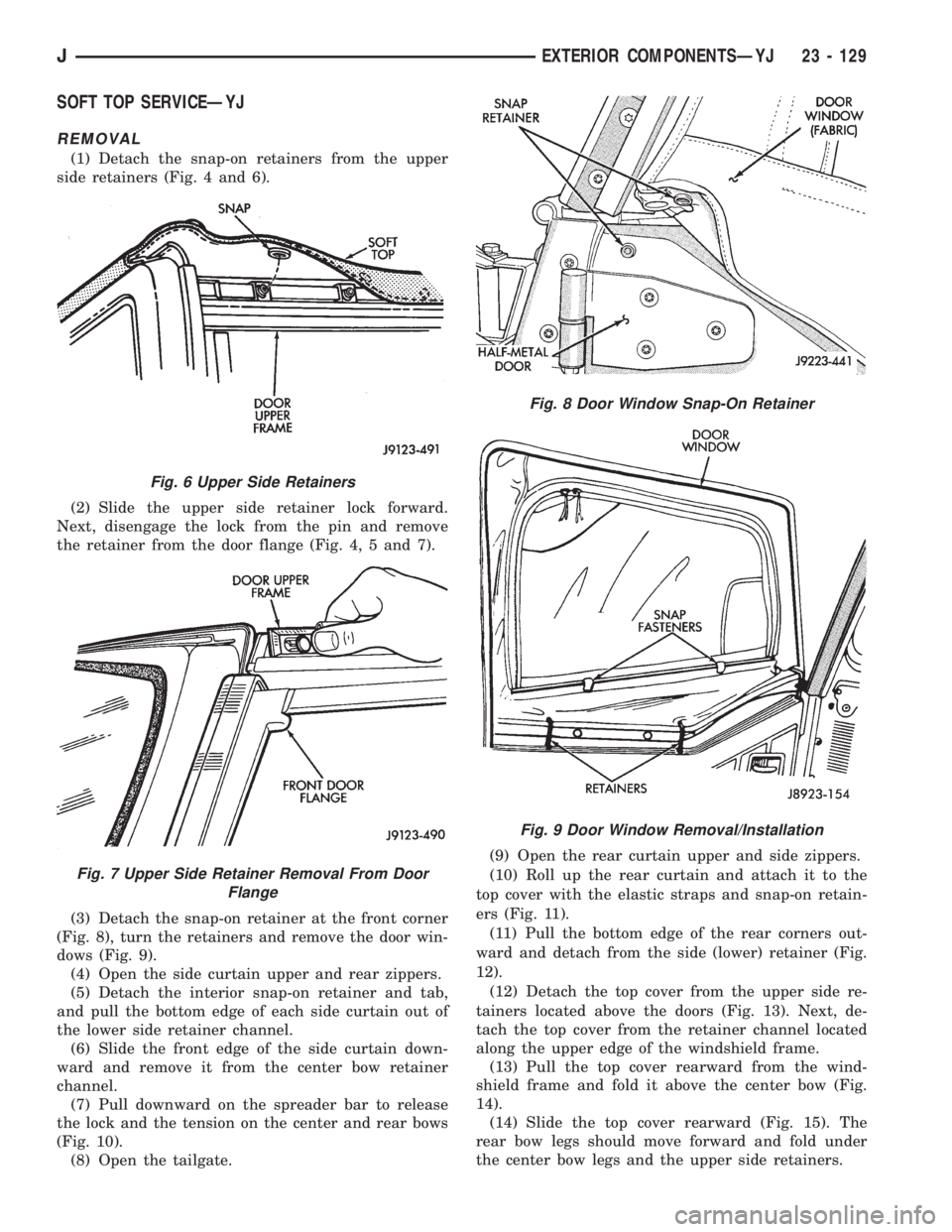

SOFT TOP SERVICEÐYJ

REMOVAL

(1) Detach the snap-on retainers from the upper

side retainers (Fig. 4 and 6).

(2) Slide the upper side retainer lock forward.

Next, disengage the lock from the pin and remove

the retainer from the door flange (Fig. 4, 5 and 7).

(3) Detach the snap-on retainer at the front corner

(Fig. 8), turn the retainers and remove the door win-

dows (Fig. 9).

(4) Open the side curtain upper and rear zippers.

(5) Detach the interior snap-on retainer and tab,

and pull the bottom edge of each side curtain out of

the lower side retainer channel.

(6) Slide the front edge of the side curtain down-

ward and remove it from the center bow retainer

channel.

(7) Pull downward on the spreader bar to release

the lock and the tension on the center and rear bows

(Fig. 10).

(8) Open the tailgate.(9) Open the rear curtain upper and side zippers.

(10) Roll up the rear curtain and attach it to the

top cover with the elastic straps and snap-on retain-

ers (Fig. 11).

(11) Pull the bottom edge of the rear corners out-

ward and detach from the side (lower) retainer (Fig.

12).

(12) Detach the top cover from the upper side re-

tainers located above the doors (Fig. 13). Next, de-

tach the top cover from the retainer channel located

along the upper edge of the windshield frame.

(13) Pull the top cover rearward from the wind-

shield frame and fold it above the center bow (Fig.

14).

(14) Slide the top cover rearward (Fig. 15). The

rear bow legs should move forward and fold under

the center bow legs and the upper side retainers.

Fig. 6 Upper Side Retainers

Fig. 7 Upper Side Retainer Removal From Door

Flange

Fig. 8 Door Window Snap-On Retainer

Fig. 9 Door Window Removal/Installation

JEXTERIOR COMPONENTSÐYJ 23 - 129

Page 1867 of 2198

DOORS

INDEX

page page

Beltline SealÐYJ........................ 142

Door Frame Glass Channel ReplacementÐYJ . . . 142

Door Weatherstrip Seal ReplacementÐYJ...... 142

Full-Metal Door Assist HandleÐYJ........... 136

Full-Metal Door HingesÐYJ................ 140

Full-Metal Door Key Lock CylinderÐYJ........ 139

Full-Metal Door Latch External Release

HandleÐYJ........................... 140

Full-Metal Door Latch Inside Release and Lock

HandleÐYJ........................... 137

Full-Metal Door LatchÐYJ.................. 140Full-Metal Door ServiceÐYJ................ 142

Full-Metal Door Trim PanelÐYJ.............. 137

Full-Metal Door Vent Window GlassÐYJ....... 137

Full-Metal Door WaterdamÐYJ.............. 137

Full-Metal Door Weatherstrip SealsÐYJ........ 141

Full-Metal Door Window Glass Regulator

HandleÐYJ........................... 136

Full-Metal Door Window Glass RegulatorÐYJ . . . 138

Full-Metal Door Window GlassÐYJ........... 139

Half-Metal Door Latch StrikerÐYJ............ 135

Half-Metal Soft Top DoorÐYJ............... 134

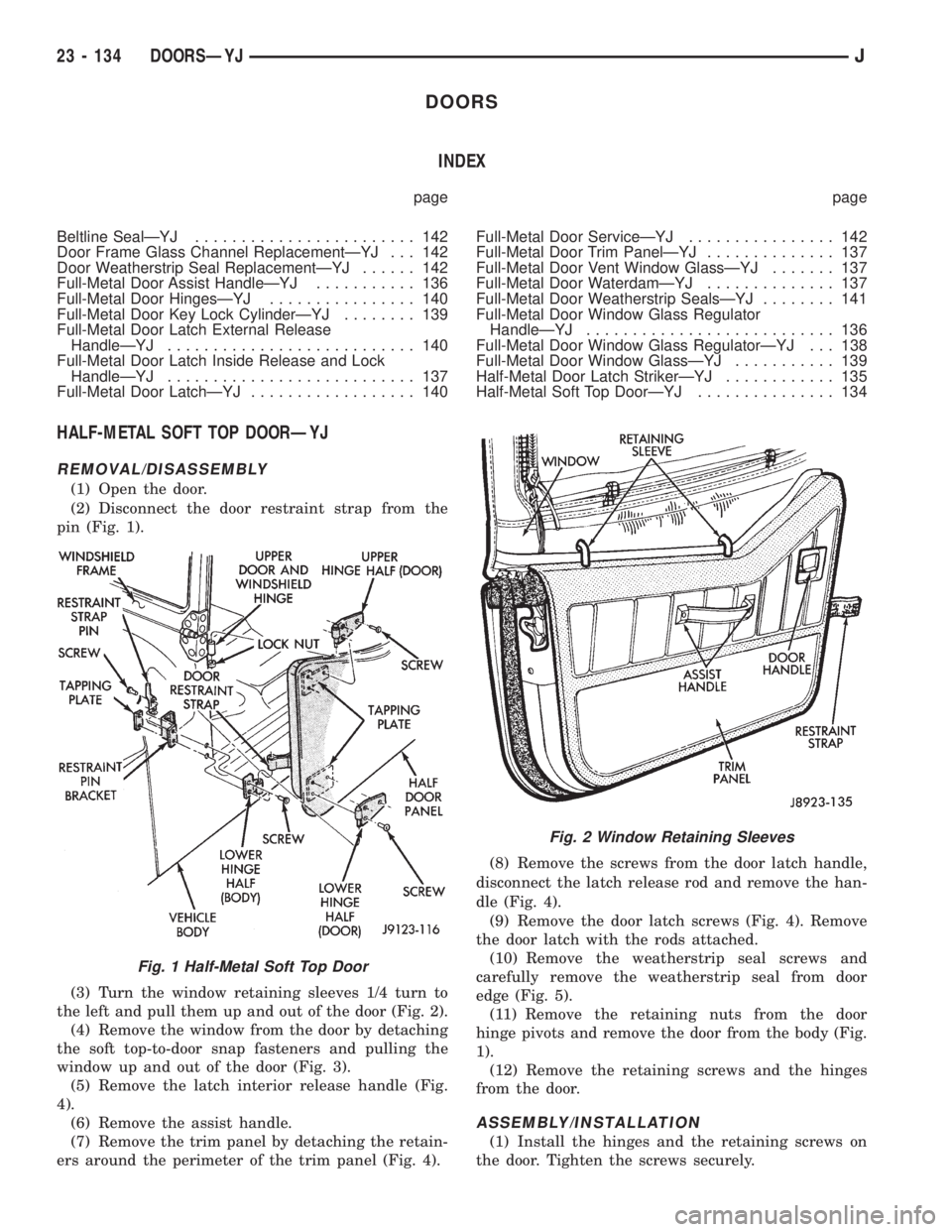

HALF-METAL SOFT TOP DOORÐYJ

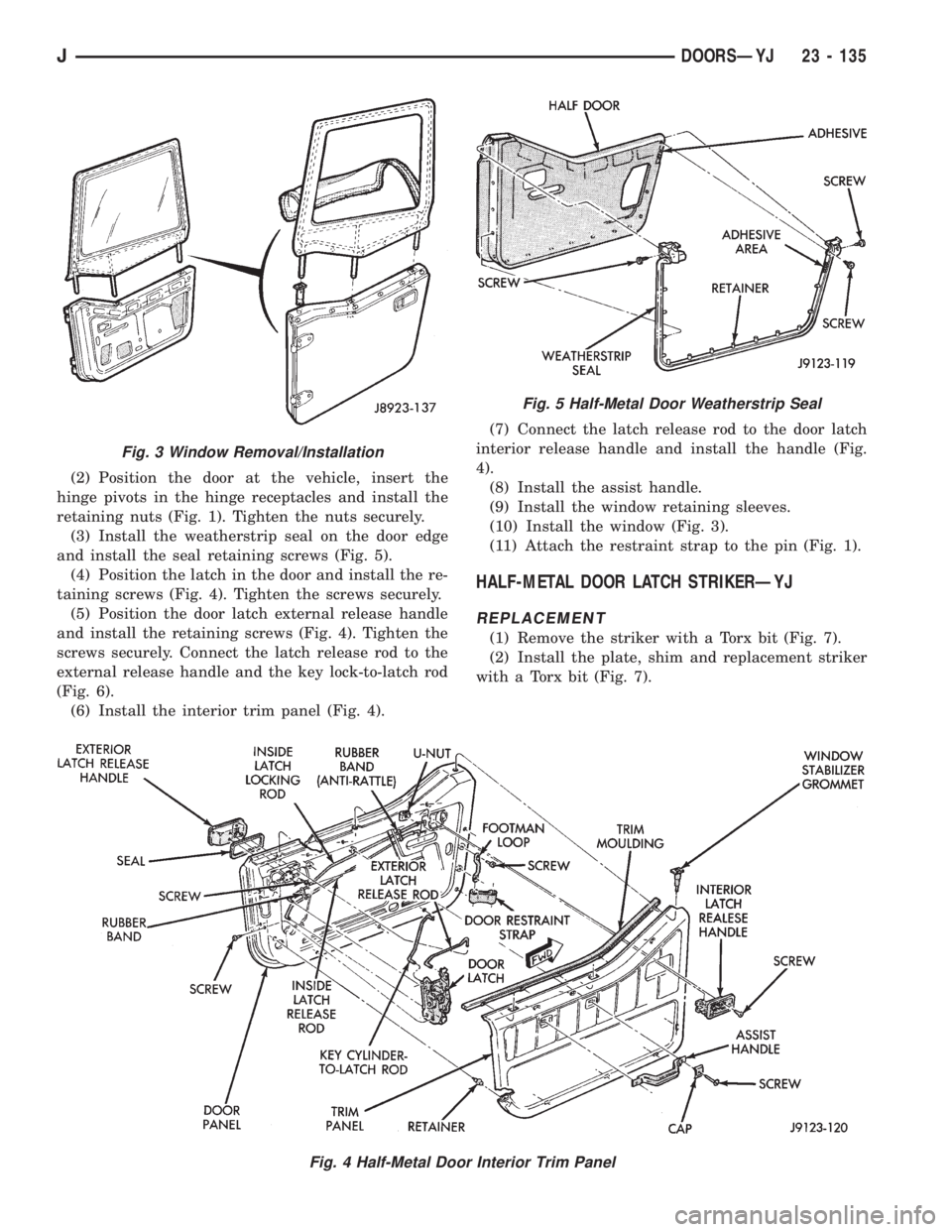

REMOVAL/DISASSEMBLY

(1) Open the door.

(2) Disconnect the door restraint strap from the

pin (Fig. 1).

(3) Turn the window retaining sleeves 1/4 turn to

the left and pull them up and out of the door (Fig. 2).

(4) Remove the window from the door by detaching

the soft top-to-door snap fasteners and pulling the

window up and out of the door (Fig. 3).

(5) Remove the latch interior release handle (Fig.

4).

(6) Remove the assist handle.

(7) Remove the trim panel by detaching the retain-

ers around the perimeter of the trim panel (Fig. 4).(8) Remove the screws from the door latch handle,

disconnect the latch release rod and remove the han-

dle (Fig. 4).

(9) Remove the door latch screws (Fig. 4). Remove

the door latch with the rods attached.

(10) Remove the weatherstrip seal screws and

carefully remove the weatherstrip seal from door

edge (Fig. 5).

(11) Remove the retaining nuts from the door

hinge pivots and remove the door from the body (Fig.

1).

(12) Remove the retaining screws and the hinges

from the door.

ASSEMBLY/INSTALLATION

(1) Install the hinges and the retaining screws on

the door. Tighten the screws securely.

Fig. 1 Half-Metal Soft Top Door

Fig. 2 Window Retaining Sleeves

23 - 134 DOORSÐYJJ

Page 1868 of 2198

(2) Position the door at the vehicle, insert the

hinge pivots in the hinge receptacles and install the

retaining nuts (Fig. 1). Tighten the nuts securely.

(3) Install the weatherstrip seal on the door edge

and install the seal retaining screws (Fig. 5).

(4) Position the latch in the door and install the re-

taining screws (Fig. 4). Tighten the screws securely.

(5) Position the door latch external release handle

and install the retaining screws (Fig. 4). Tighten the

screws securely. Connect the latch release rod to the

external release handle and the key lock-to-latch rod

(Fig. 6).

(6) Install the interior trim panel (Fig. 4).(7) Connect the latch release rod to the door latch

interior release handle and install the handle (Fig.

4).

(8) Install the assist handle.

(9) Install the window retaining sleeves.

(10) Install the window (Fig. 3).

(11) Attach the restraint strap to the pin (Fig. 1).

HALF-METAL DOOR LATCH STRIKERÐYJ

REPLACEMENT

(1) Remove the striker with a Torx bit (Fig. 7).

(2) Install the plate, shim and replacement striker

with a Torx bit (Fig. 7).

Fig. 4 Half-Metal Door Interior Trim Panel

Fig. 3 Window Removal/Installation

Fig. 5 Half-Metal Door Weatherstrip Seal

JDOORSÐYJ 23 - 135

Page 1870 of 2198

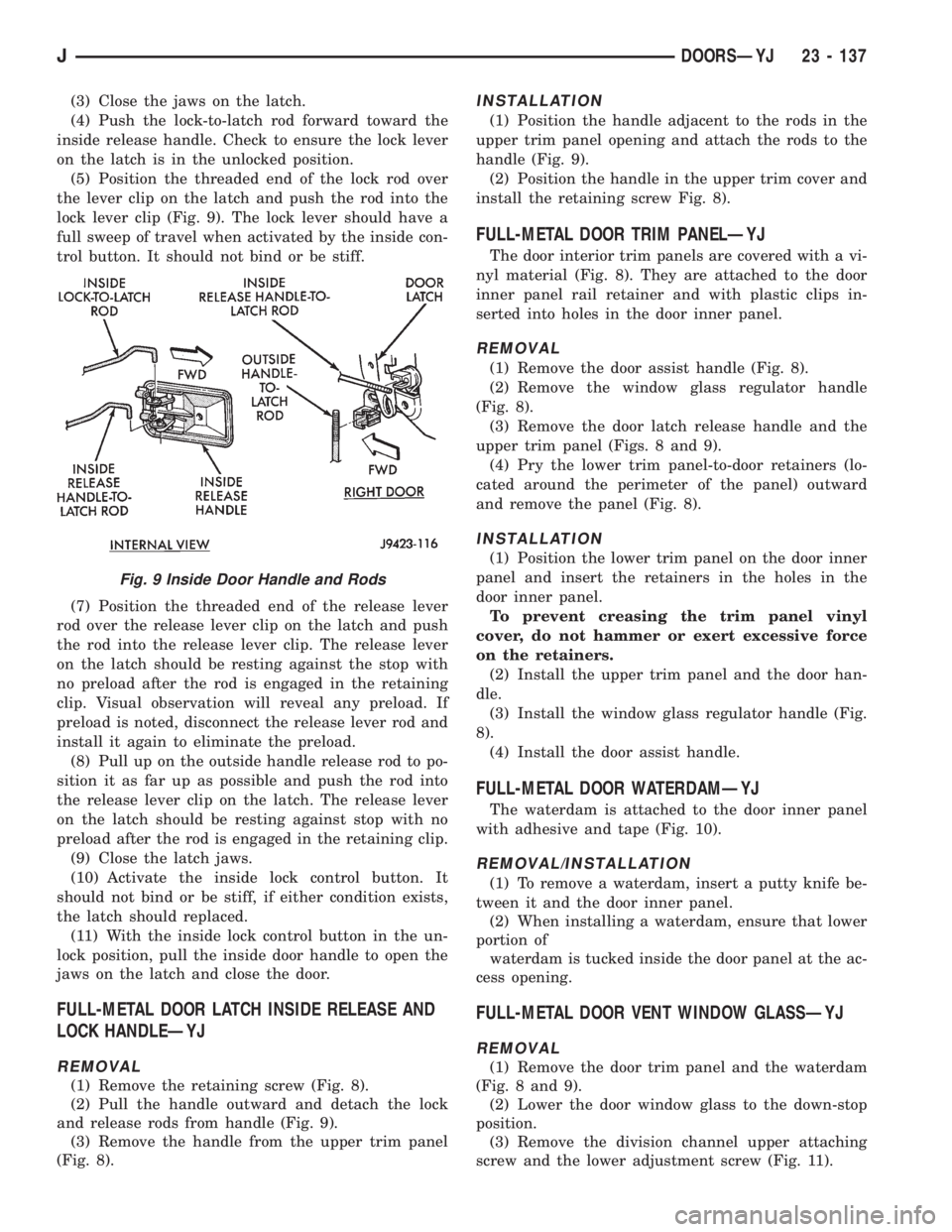

(3) Close the jaws on the latch.

(4) Push the lock-to-latch rod forward toward the

inside release handle. Check to ensure the lock lever

on the latch is in the unlocked position.

(5) Position the threaded end of the lock rod over

the lever clip on the latch and push the rod into the

lock lever clip (Fig. 9). The lock lever should have a

full sweep of travel when activated by the inside con-

trol button. It should not bind or be stiff.

(7) Position the threaded end of the release lever

rod over the release lever clip on the latch and push

the rod into the release lever clip. The release lever

on the latch should be resting against the stop with

no preload after the rod is engaged in the retaining

clip. Visual observation will reveal any preload. If

preload is noted, disconnect the release lever rod and

install it again to eliminate the preload.

(8) Pull up on the outside handle release rod to po-

sition it as far up as possible and push the rod into

the release lever clip on the latch. The release lever

on the latch should be resting against stop with no

preload after the rod is engaged in the retaining clip.

(9) Close the latch jaws.

(10) Activate the inside lock control button. It

should not bind or be stiff, if either condition exists,

the latch should replaced.

(11) With the inside lock control button in the un-

lock position, pull the inside door handle to open the

jaws on the latch and close the door.

FULL-METAL DOOR LATCH INSIDE RELEASE AND

LOCK HANDLEÐYJ

REMOVAL

(1) Remove the retaining screw (Fig. 8).

(2) Pull the handle outward and detach the lock

and release rods from handle (Fig. 9).

(3) Remove the handle from the upper trim panel

(Fig. 8).

INSTALLATION

(1) Position the handle adjacent to the rods in the

upper trim panel opening and attach the rods to the

handle (Fig. 9).

(2) Position the handle in the upper trim cover and

install the retaining screw Fig. 8).

FULL-METAL DOOR TRIM PANELÐYJ

The door interior trim panels are covered with a vi-

nyl material (Fig. 8). They are attached to the door

inner panel rail retainer and with plastic clips in-

serted into holes in the door inner panel.

REMOVAL

(1) Remove the door assist handle (Fig. 8).

(2) Remove the window glass regulator handle

(Fig. 8).

(3) Remove the door latch release handle and the

upper trim panel (Figs. 8 and 9).

(4) Pry the lower trim panel-to-door retainers (lo-

cated around the perimeter of the panel) outward

and remove the panel (Fig. 8).

INSTALLATION

(1) Position the lower trim panel on the door inner

panel and insert the retainers in the holes in the

door inner panel.

To prevent creasing the trim panel vinyl

cover, do not hammer or exert excessive force

on the retainers.

(2) Install the upper trim panel and the door han-

dle.

(3) Install the window glass regulator handle (Fig.

8).

(4) Install the door assist handle.

FULL-METAL DOOR WATERDAMÐYJ

The waterdam is attached to the door inner panel

with adhesive and tape (Fig. 10).

REMOVAL/INSTALLATION

(1) To remove a waterdam, insert a putty knife be-

tween it and the door inner panel.

(2) When installing a waterdam, ensure that lower

portion of

waterdam is tucked inside the door panel at the ac-

cess opening.

FULL-METAL DOOR VENT WINDOW GLASSÐYJ

REMOVAL

(1) Remove the door trim panel and the waterdam

(Fig. 8 and 9).

(2) Lower the door window glass to the down-stop

position.

(3) Remove the division channel upper attaching

screw and the lower adjustment screw (Fig. 11).

Fig. 9 Inside Door Handle and Rods

JDOORSÐYJ 23 - 137

Page 1876 of 2198

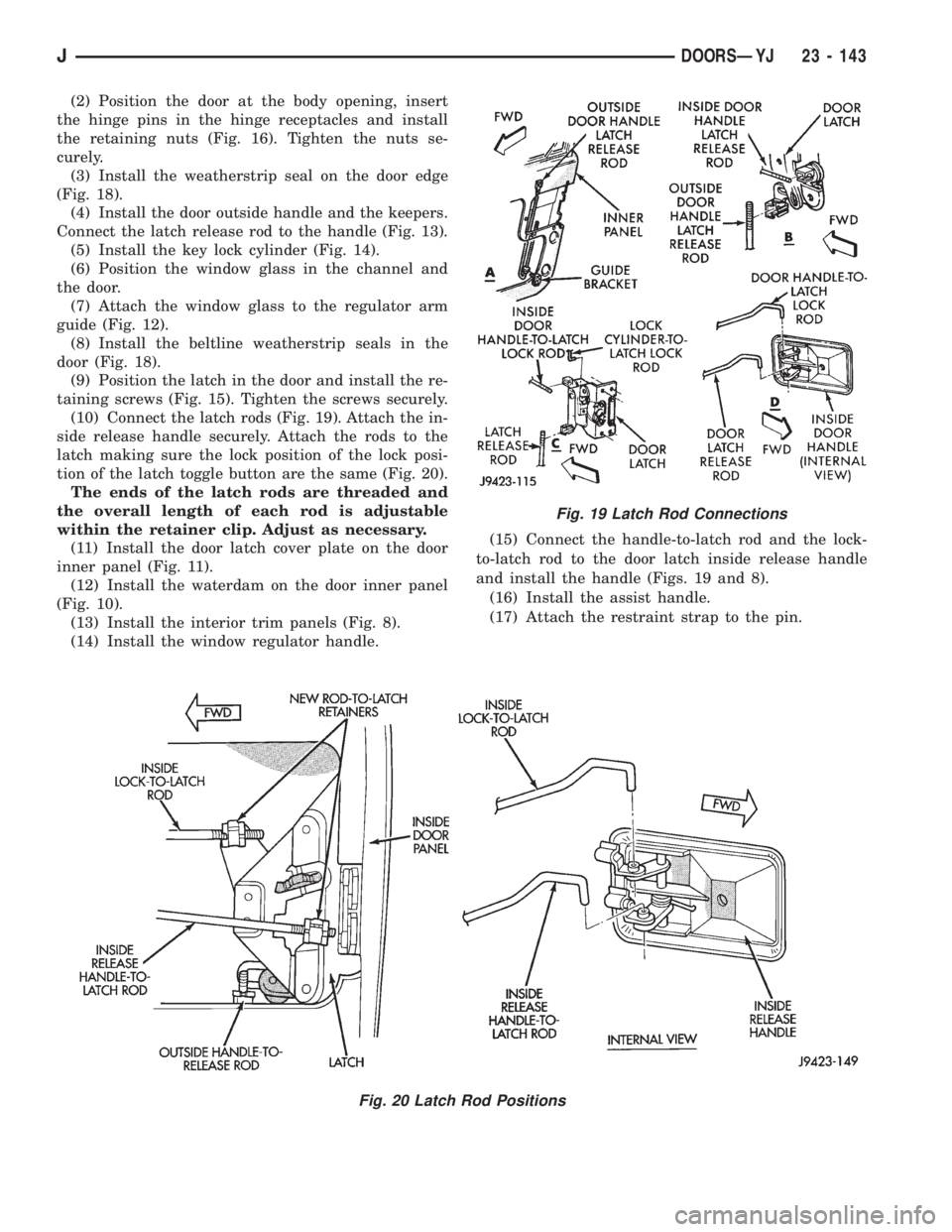

(2) Position the door at the body opening, insert

the hinge pins in the hinge receptacles and install

the retaining nuts (Fig. 16). Tighten the nuts se-

curely.

(3) Install the weatherstrip seal on the door edge

(Fig. 18).

(4) Install the door outside handle and the keepers.

Connect the latch release rod to the handle (Fig. 13).

(5) Install the key lock cylinder (Fig. 14).

(6) Position the window glass in the channel and

the door.

(7) Attach the window glass to the regulator arm

guide (Fig. 12).

(8) Install the beltline weatherstrip seals in the

door (Fig. 18).

(9) Position the latch in the door and install the re-

taining screws (Fig. 15). Tighten the screws securely.

(10) Connect the latch rods (Fig. 19). Attach the in-

side release handle securely. Attach the rods to the

latch making sure the lock position of the lock posi-

tion of the latch toggle button are the same (Fig. 20).

The ends of the latch rods are threaded and

the overall length of each rod is adjustable

within the retainer clip. Adjust as necessary.

(11) Install the door latch cover plate on the door

inner panel (Fig. 11).

(12) Install the waterdam on the door inner panel

(Fig. 10).

(13) Install the interior trim panels (Fig. 8).

(14) Install the window regulator handle.(15) Connect the handle-to-latch rod and the lock-

to-latch rod to the door latch inside release handle

and install the handle (Figs. 19 and 8).

(16) Install the assist handle.

(17) Attach the restraint strap to the pin.

Fig. 19 Latch Rod Connections

Fig. 20 Latch Rod Positions

JDOORSÐYJ 23 - 143

Page 1879 of 2198

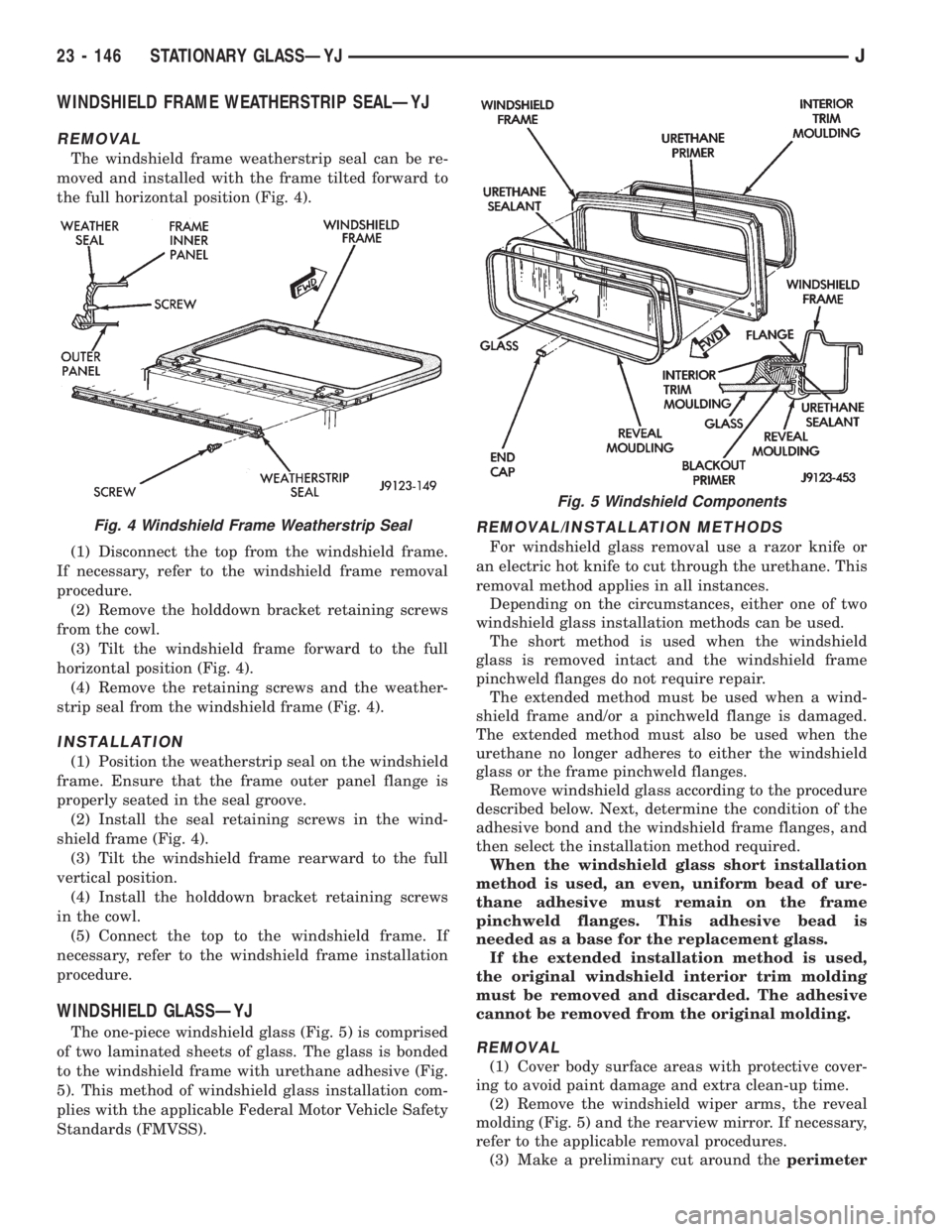

WINDSHIELD FRAME WEATHERSTRIP SEALÐYJ

REMOVAL

The windshield frame weatherstrip seal can be re-

moved and installed with the frame tilted forward to

the full horizontal position (Fig. 4).

(1) Disconnect the top from the windshield frame.

If necessary, refer to the windshield frame removal

procedure.

(2) Remove the holddown bracket retaining screws

from the cowl.

(3) Tilt the windshield frame forward to the full

horizontal position (Fig. 4).

(4) Remove the retaining screws and the weather-

strip seal from the windshield frame (Fig. 4).

INSTALLATION

(1) Position the weatherstrip seal on the windshield

frame. Ensure that the frame outer panel flange is

properly seated in the seal groove.

(2) Install the seal retaining screws in the wind-

shield frame (Fig. 4).

(3) Tilt the windshield frame rearward to the full

vertical position.

(4) Install the holddown bracket retaining screws

in the cowl.

(5) Connect the top to the windshield frame. If

necessary, refer to the windshield frame installation

procedure.

WINDSHIELD GLASSÐYJ

The one-piece windshield glass (Fig. 5) is comprised

of two laminated sheets of glass. The glass is bonded

to the windshield frame with urethane adhesive (Fig.

5). This method of windshield glass installation com-

plies with the applicable Federal Motor Vehicle Safety

Standards (FMVSS).

REMOVAL/INSTALLATION METHODS

For windshield glass removal use a razor knife or

an electric hot knife to cut through the urethane. This

removal method applies in all instances.

Depending on the circumstances, either one of two

windshield glass installation methods can be used.

The short method is used when the windshield

glass is removed intact and the windshield frame

pinchweld flanges do not require repair.

The extended method must be used when a wind-

shield frame and/or a pinchweld flange is damaged.

The extended method must also be used when the

urethane no longer adheres to either the windshield

glass or the frame pinchweld flanges.

Remove windshield glass according to the procedure

described below. Next, determine the condition of the

adhesive bond and the windshield frame flanges, and

then select the installation method required.

When the windshield glass short installation

method is used, an even, uniform bead of ure-

thane adhesive must remain on the frame

pinchweld flanges. This adhesive bead is

needed as a base for the replacement glass.

If the extended installation method is used,

the original windshield interior trim molding

must be removed and discarded. The adhesive

cannot be removed from the original molding.

REMOVAL

(1) Cover body surface areas with protective cover-

ing to avoid paint damage and extra clean-up time.

(2) Remove the windshield wiper arms, the reveal

molding (Fig. 5) and the rearview mirror. If necessary,

refer to the applicable removal procedures.

(3) Make a preliminary cut around theperimeter

Fig. 4 Windshield Frame Weatherstrip Seal

Fig. 5 Windshield Components

23 - 146 STATIONARY GLASSÐYJJ

Page 1880 of 2198

of the windshield glass along the glass edge with a

razor knife.

CAUTION: When cutting through the urethane with

a hot knife blade, do not allow the knife blade to re-

main stationary at any location.

(4) Cut the adhesive bead with a hot knife and a

straight or hooked knife blade.

(5) Start the hot knife blade between the glass and

the urethane. Next, cut the adhesive as close to the

glass edge as possible. Allow as much adhesive to re-

main on the frame flange as possible.For best cut-

ting results, clean the knife blade frequently

with steel wool while the blade is hot.

(6) Remove the windshield glass from the frame

(Fig. 5).

(7) After the hot knife blade has cooled, clean the

hot knife blade with solvent and a cloth. Sharpen the

blade with a fine-tooth file.

(8) If the extended windshield glass installation

method will be used, remove and discard the interior

trim molding (Fig. 5).

INSTALLATIONÐSHORT METHOD

Normally, after a windshield is installed, the rear-

view mirror bracket also requires installation. If so,

refer to the rearview mirror bracket replacement pro-

cedure.Do not install bracket until after wind-

shield installation is completed.

(1) Inspect the windshield frame pinchweld flanges

(Fig. 5) Prime any bare spots with urethane primer.

Allow a minimum of 18 minutes for dry time.

(2) Inspect the urethane bead for high spots. Level

the bead by shaving off high spots with a razor knife.

This is necessary for a flush-fit of the windshield

glass.

(3) Inspect the windshield molding. Replace the

molding if it has broken, distorted or ineffective re-

tainers.

(4) Clean the outer edge of the windshield glass

with naphtha or a similar product.

(5) Prime the outer perimeter of the interior side of

the glass 16 mm (5/8 inch) from the edge. Use a

wipe-off type urethane primer and wipe the glass dry

after primer application.

(6) Place the windshield glass in the frame on the

pinchweld flanges and inspect for gaps in the ure-

thane adhesive. Gaps in excess of 3 mm (1/8 inch)

must be filled with additional urethane adhesive.

(7) Adjust windshield glass position until it is

aligned with the flanges and the adhesive. Next,

make alignment marks on glass and body with a

grease pencil.

(8) Remove the windshield glass and position it on

a flat surface.

(9) If the replacement windshield glass does not

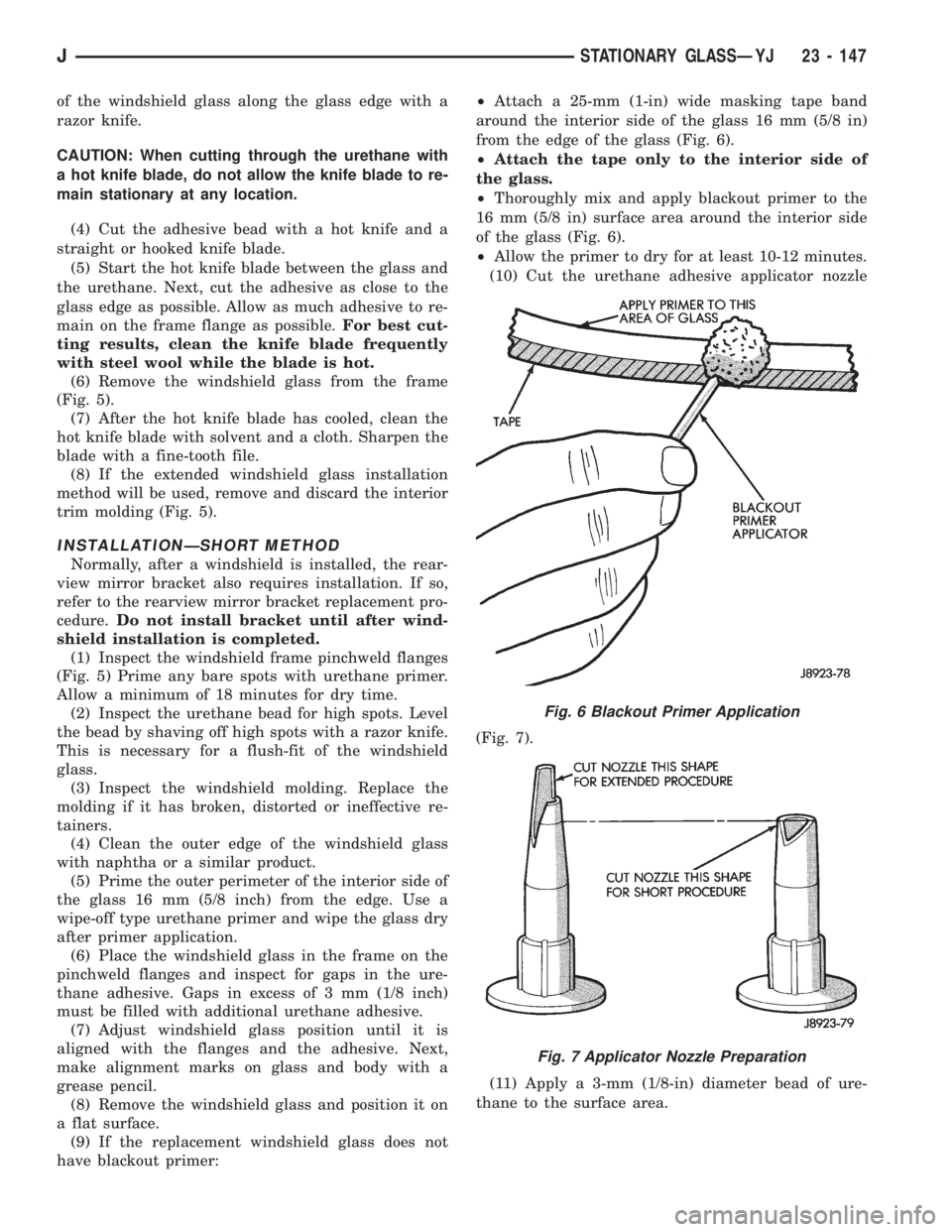

have blackout primer:²Attach a 25-mm (1-in) wide masking tape band

around the interior side of the glass 16 mm (5/8 in)

from the edge of the glass (Fig. 6).

²Attach the tape only to the interior side of

the glass.

²Thoroughly mix and apply blackout primer to the

16 mm (5/8 in) surface area around the interior side

of the glass (Fig. 6).

²Allow the primer to dry for at least 10-12 minutes.

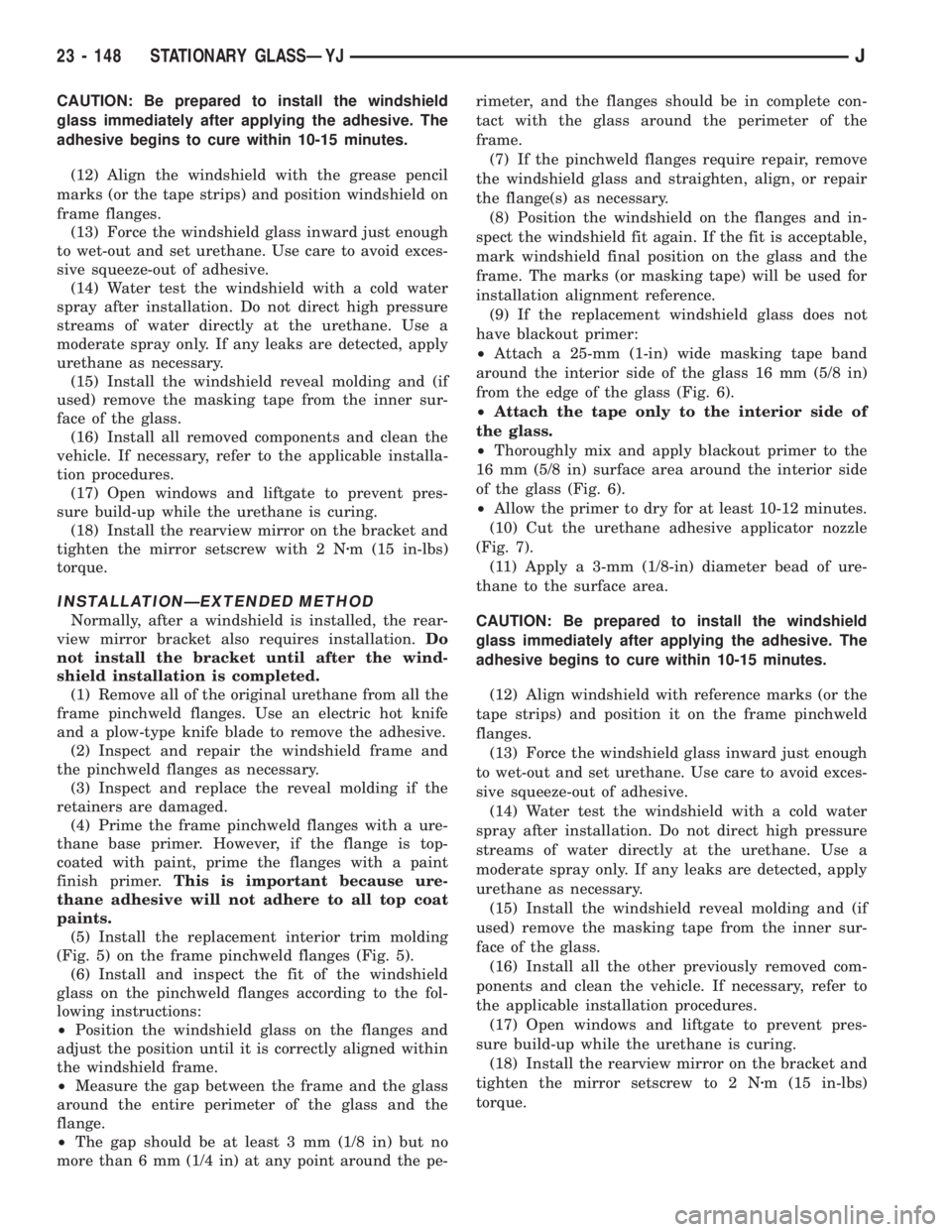

(10) Cut the urethane adhesive applicator nozzle

(Fig. 7).

(11) Apply a 3-mm (1/8-in) diameter bead of ure-

thane to the surface area.

Fig. 6 Blackout Primer Application

Fig. 7 Applicator Nozzle Preparation

JSTATIONARY GLASSÐYJ 23 - 147

Page 1881 of 2198

CAUTION: Be prepared to install the windshield

glass immediately after applying the adhesive. The

adhesive begins to cure within 10-15 minutes.

(12) Align the windshield with the grease pencil

marks (or the tape strips) and position windshield on

frame flanges.

(13) Force the windshield glass inward just enough

to wet-out and set urethane. Use care to avoid exces-

sive squeeze-out of adhesive.

(14) Water test the windshield with a cold water

spray after installation. Do not direct high pressure

streams of water directly at the urethane. Use a

moderate spray only. If any leaks are detected, apply

urethane as necessary.

(15) Install the windshield reveal molding and (if

used) remove the masking tape from the inner sur-

face of the glass.

(16) Install all removed components and clean the

vehicle. If necessary, refer to the applicable installa-

tion procedures.

(17) Open windows and liftgate to prevent pres-

sure build-up while the urethane is curing.

(18) Install the rearview mirror on the bracket and

tighten the mirror setscrew with 2 Nzm (15 in-lbs)

torque.

INSTALLATIONÐEXTENDED METHOD

Normally, after a windshield is installed, the rear-

view mirror bracket also requires installation.Do

not install the bracket until after the wind-

shield installation is completed.

(1) Remove all of the original urethane from all the

frame pinchweld flanges. Use an electric hot knife

and a plow-type knife blade to remove the adhesive.

(2) Inspect and repair the windshield frame and

the pinchweld flanges as necessary.

(3) Inspect and replace the reveal molding if the

retainers are damaged.

(4) Prime the frame pinchweld flanges with a ure-

thane base primer. However, if the flange is top-

coated with paint, prime the flanges with a paint

finish primer.This is important because ure-

thane adhesive will not adhere to all top coat

paints.

(5) Install the replacement interior trim molding

(Fig. 5) on the frame pinchweld flanges (Fig. 5).

(6) Install and inspect the fit of the windshield

glass on the pinchweld flanges according to the fol-

lowing instructions:

²Position the windshield glass on the flanges and

adjust the position until it is correctly aligned within

the windshield frame.

²Measure the gap between the frame and the glass

around the entire perimeter of the glass and the

flange.

²The gap should be at least 3 mm (1/8 in) but no

more than 6 mm (1/4 in) at any point around the pe-rimeter, and the flanges should be in complete con-

tact with the glass around the perimeter of the

frame.

(7) If the pinchweld flanges require repair, remove

the windshield glass and straighten, align, or repair

the flange(s) as necessary.

(8) Position the windshield on the flanges and in-

spect the windshield fit again. If the fit is acceptable,

mark windshield final position on the glass and the

frame. The marks (or masking tape) will be used for

installation alignment reference.

(9) If the replacement windshield glass does not

have blackout primer:

²Attach a 25-mm (1-in) wide masking tape band

around the interior side of the glass 16 mm (5/8 in)

from the edge of the glass (Fig. 6).

²Attach the tape only to the interior side of

the glass.

²Thoroughly mix and apply blackout primer to the

16 mm (5/8 in) surface area around the interior side

of the glass (Fig. 6).

²Allow the primer to dry for at least 10-12 minutes.

(10) Cut the urethane adhesive applicator nozzle

(Fig. 7).

(11) Apply a 3-mm (1/8-in) diameter bead of ure-

thane to the surface area.

CAUTION: Be prepared to install the windshield

glass immediately after applying the adhesive. The

adhesive begins to cure within 10-15 minutes.

(12) Align windshield with reference marks (or the

tape strips) and position it on the frame pinchweld

flanges.

(13) Force the windshield glass inward just enough

to wet-out and set urethane. Use care to avoid exces-

sive squeeze-out of adhesive.

(14) Water test the windshield with a cold water

spray after installation. Do not direct high pressure

streams of water directly at the urethane. Use a

moderate spray only. If any leaks are detected, apply

urethane as necessary.

(15) Install the windshield reveal molding and (if

used) remove the masking tape from the inner sur-

face of the glass.

(16) Install all the other previously removed com-

ponents and clean the vehicle. If necessary, refer to

the applicable installation procedures.

(17) Open windows and liftgate to prevent pres-

sure build-up while the urethane is curing.

(18) Install the rearview mirror on the bracket and

tighten the mirror setscrew to 2 Nzm (15 in-lbs)

torque.

23 - 148 STATIONARY GLASSÐYJJ