Back JEEP CHEROKEE 1995 Service Repair Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 1995, Model line: CHEROKEE, Model: JEEP CHEROKEE 1995Pages: 2198, PDF Size: 82.83 MB

Page 32 of 2198

(5) Inspect the reservoir rubber diaphragm seal for

cracks, cuts and distortion.

(6) Inspect the brake fluid tubing fittings and the

master cylinder housing for indications of fluid leak-

age. Repair as necessary.

(7) Install the brake fluid reservoir cover.

ANTI-LOCK BRAKE SYSTEMÐXJ VEHICLES

The anti-lock brake system fluid reservoir for XJ

Vehicles is located in the engine compartment at the

left side of the dash panel.

(1) Turn the ignition switch ON and allow the

pump motor to operate until it automatically de-en-

ergizes.

(2) Clean the cover before removing it.

CAUTION: Over-filling could cause fluid overflow

and possible reservoir damage when the pump mo-

tor energizes.

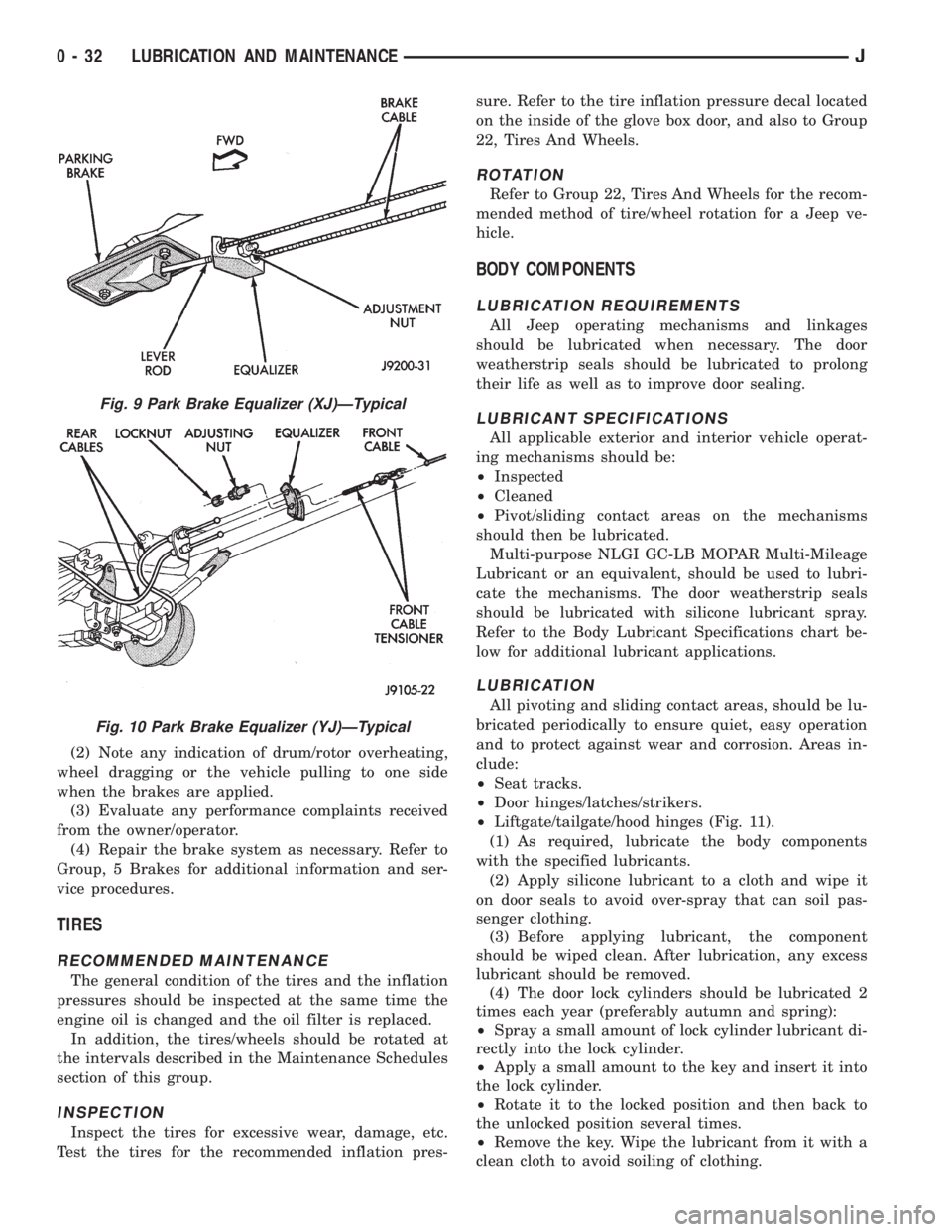

(3) The brake fluid level should be no lower than

the ADD indicator on the side of the reservoir (Fig.

8). If not, add brake fluid as necessary. Raise the

fluid level to the FULL indicator only. Do not over-fill

the reservoir.

(4) Turn the ignition switch OFF.

BRAKE SYSTEM INSPECTION

A brake system inspection should be included with

all brake service procedures, and also each time the

vehicle is lubricated.

(1) Inspect the brake pads and linings for excessive

wear, cracks, charred surfaces and broken rivets.

(2) Inspect brake pads and linings for contamina-

tion from brake fluid, and/or other fluids.

(3) Replace the brake pads linings if they are worn

to within 0.78 mm (1/32 in) of the rivet head.

(4) Operate the rear brake self-adjuster lever and

pivot. Test the operation of the self-adjuster screw for

ease of movement.

(5) Inspect the self-adjuster components for wear

or damage.

(6) Inspect the disc brake caliper dust boot for

damage and indications of brake fluid leakage. In-

spect the bushings and pins for corrosion, tears and a

binding condition.

(7) Pull the rear wheel cylinder dust boot back to

expose the wheel cylinder housing. Inspect for fluid

leaks. Inspect the pistons and cylinder bores.

(8) Inspect the brake differential warning valve

and housing for indications of leakage.

BRAKE FLUID HOSES/TUBING

The rubber brake fluid hoses should be inspected

for:

²Correct length

²Severe surface cracking

²Swelling

²Pulling

²Scuffing

²Excessively worn areas

If the hose has cracks or abrasions in the rub-

ber cover, the hose should be replaced.

(1) Inspect all the hoses for kinks, a distorted con-

dition and fluid leakage.

(2) Inspect the hose and tubing routing under the

vehicle. Verify that no hose/tubing is rubbing against

any exhaust or other underbody components.

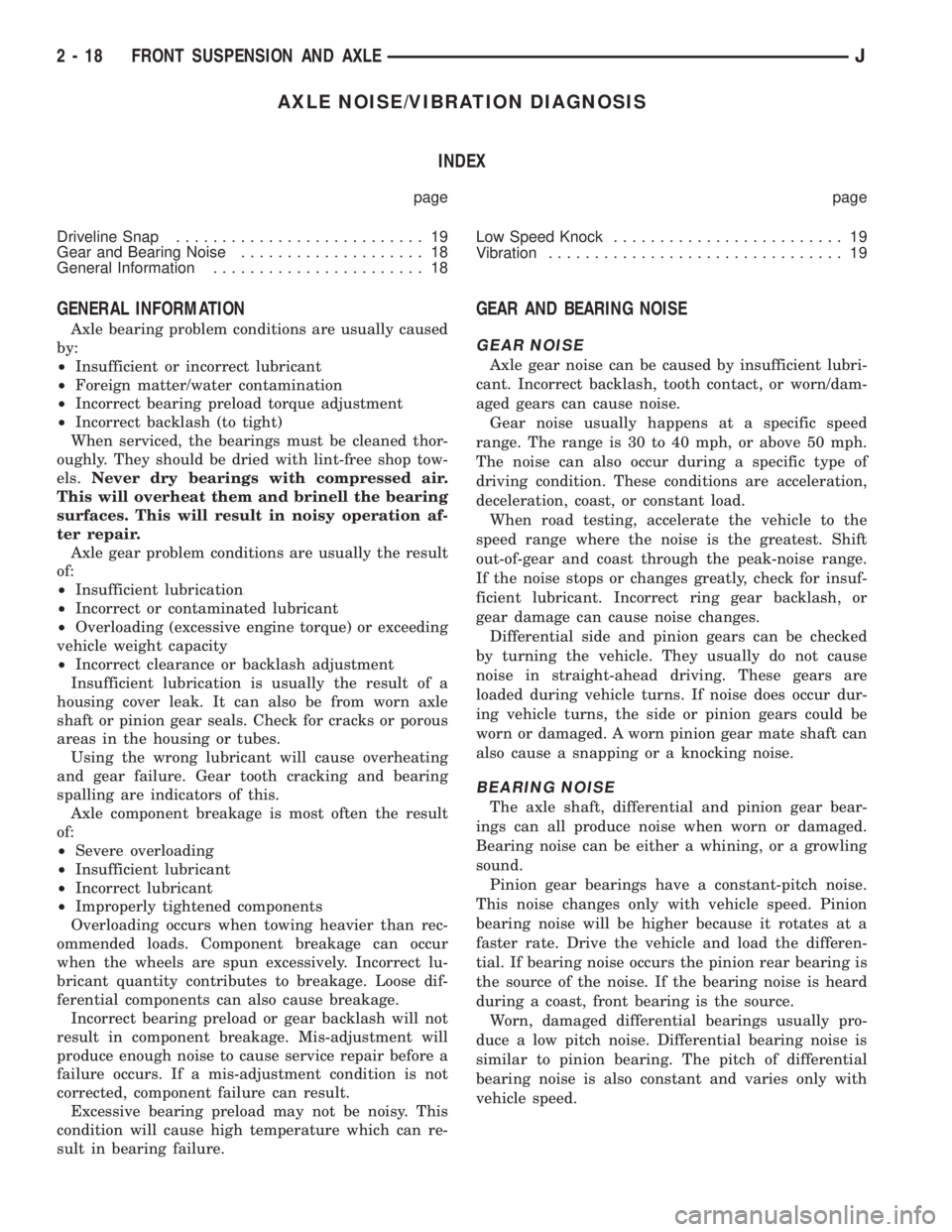

PARKING BRAKE

(1) Engage the parking brake pedal and then re-

lease it.

(2) Test it for smooth operation and vehicle-holding

capability.

(3) Inspect the parking brake cables.

(4) With the parking brake released, the rear

wheels should

rotate without restriction. Adjust the parking brake

cable tension, if necessary (Fig. 9 and 10).

(5) Repair any parking brake malfunctions.

BRAKE OPERATIONAL TEST

(1) Drive the vehicle and test for proper brake ac-

tion.

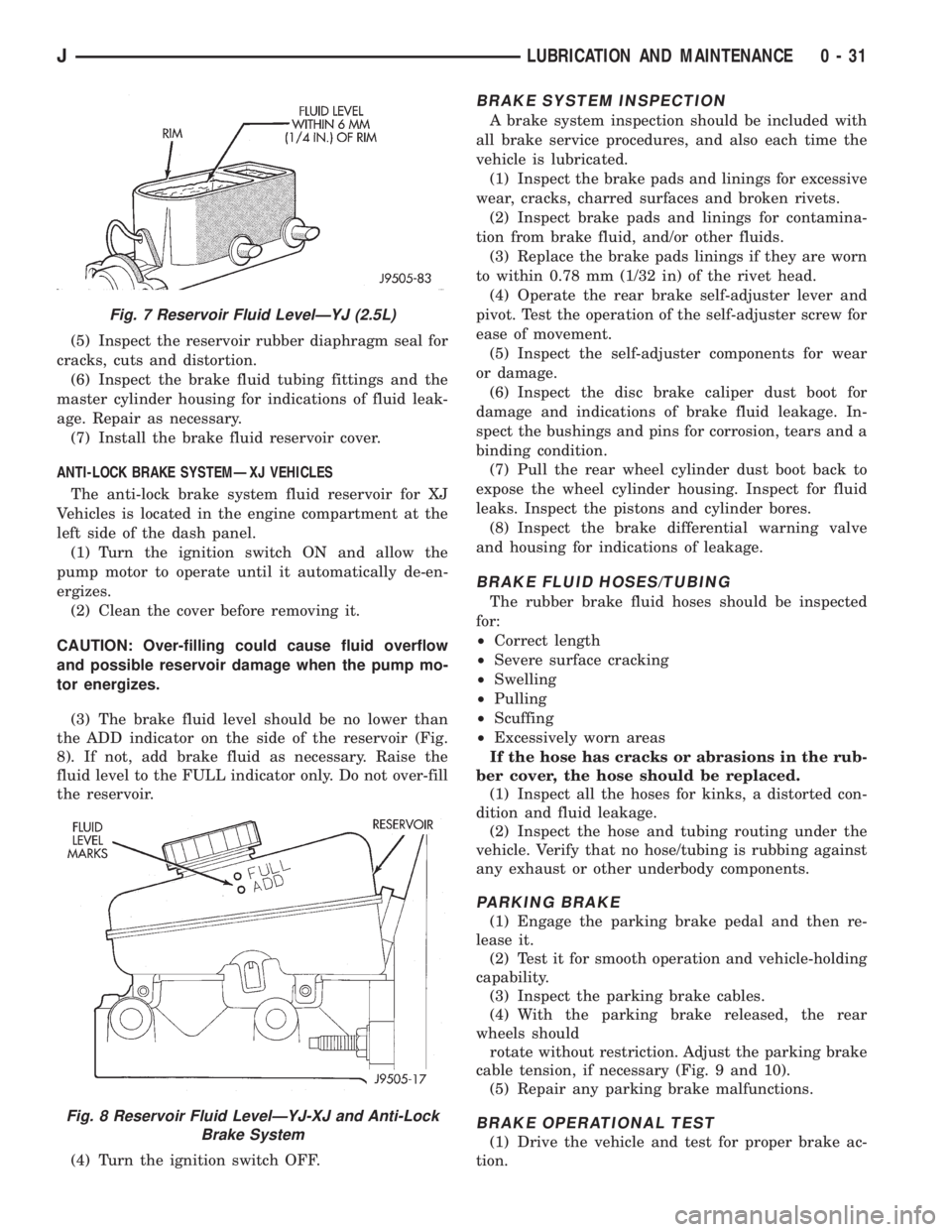

Fig. 7 Reservoir Fluid LevelÐYJ (2.5L)

Fig. 8 Reservoir Fluid LevelÐYJ-XJ and Anti-Lock

Brake System

JLUBRICATION AND MAINTENANCE 0 - 31

Page 33 of 2198

(2) Note any indication of drum/rotor overheating,

wheel dragging or the vehicle pulling to one side

when the brakes are applied.

(3) Evaluate any performance complaints received

from the owner/operator.

(4) Repair the brake system as necessary. Refer to

Group, 5 Brakes for additional information and ser-

vice procedures.

TIRES

RECOMMENDED MAINTENANCE

The general condition of the tires and the inflation

pressures should be inspected at the same time the

engine oil is changed and the oil filter is replaced.

In addition, the tires/wheels should be rotated at

the intervals described in the Maintenance Schedules

section of this group.

INSPECTION

Inspect the tires for excessive wear, damage, etc.

Test the tires for the recommended inflation pres-sure. Refer to the tire inflation pressure decal located

on the inside of the glove box door, and also to Group

22, Tires And Wheels.

ROTATION

Refer to Group 22, Tires And Wheels for the recom-

mended method of tire/wheel rotation for a Jeep ve-

hicle.

BODY COMPONENTS

LUBRICATION REQUIREMENTS

All Jeep operating mechanisms and linkages

should be lubricated when necessary. The door

weatherstrip seals should be lubricated to prolong

their life as well as to improve door sealing.

LUBRICANT SPECIFICATIONS

All applicable exterior and interior vehicle operat-

ing mechanisms should be:

²Inspected

²Cleaned

²Pivot/sliding contact areas on the mechanisms

should then be lubricated.

Multi-purpose NLGI GC-LB MOPAR Multi-Mileage

Lubricant or an equivalent, should be used to lubri-

cate the mechanisms. The door weatherstrip seals

should be lubricated with silicone lubricant spray.

Refer to the Body Lubricant Specifications chart be-

low for additional lubricant applications.

LUBRICATION

All pivoting and sliding contact areas, should be lu-

bricated periodically to ensure quiet, easy operation

and to protect against wear and corrosion. Areas in-

clude:

²Seat tracks.

²Door hinges/latches/strikers.

²Liftgate/tailgate/hood hinges (Fig. 11).

(1) As required, lubricate the body components

with the specified lubricants.

(2) Apply silicone lubricant to a cloth and wipe it

on door seals to avoid over-spray that can soil pas-

senger clothing.

(3) Before applying lubricant, the component

should be wiped clean. After lubrication, any excess

lubricant should be removed.

(4) The door lock cylinders should be lubricated 2

times each year (preferably autumn and spring):

²Spray a small amount of lock cylinder lubricant di-

rectly into the lock cylinder.

²Apply a small amount to the key and insert it into

the lock cylinder.

²Rotate it to the locked position and then back to

the unlocked position several times.

²Remove the key. Wipe the lubricant from it with a

clean cloth to avoid soiling of clothing.

Fig. 9 Park Brake Equalizer (XJ)ÐTypical

Fig. 10 Park Brake Equalizer (YJ)ÐTypical

0 - 32 LUBRICATION AND MAINTENANCEJ

Page 53 of 2198

AXLE NOISE/VIBRATION DIAGNOSIS

INDEX

page page

Driveline Snap........................... 19

Gear and Bearing Noise.................... 18

General Information....................... 18Low Speed Knock......................... 19

Vibration................................ 19

GENERAL INFORMATION

Axle bearing problem conditions are usually caused

by:

²Insufficient or incorrect lubricant

²Foreign matter/water contamination

²Incorrect bearing preload torque adjustment

²Incorrect backlash (to tight)

When serviced, the bearings must be cleaned thor-

oughly. They should be dried with lint-free shop tow-

els.Never dry bearings with compressed air.

This will overheat them and brinell the bearing

surfaces. This will result in noisy operation af-

ter repair.

Axle gear problem conditions are usually the result

of:

²Insufficient lubrication

²Incorrect or contaminated lubricant

²Overloading (excessive engine torque) or exceeding

vehicle weight capacity

²Incorrect clearance or backlash adjustment

Insufficient lubrication is usually the result of a

housing cover leak. It can also be from worn axle

shaft or pinion gear seals. Check for cracks or porous

areas in the housing or tubes.

Using the wrong lubricant will cause overheating

and gear failure. Gear tooth cracking and bearing

spalling are indicators of this.

Axle component breakage is most often the result

of:

²Severe overloading

²Insufficient lubricant

²Incorrect lubricant

²Improperly tightened components

Overloading occurs when towing heavier than rec-

ommended loads. Component breakage can occur

when the wheels are spun excessively. Incorrect lu-

bricant quantity contributes to breakage. Loose dif-

ferential components can also cause breakage.

Incorrect bearing preload or gear backlash will not

result in component breakage. Mis-adjustment will

produce enough noise to cause service repair before a

failure occurs. If a mis-adjustment condition is not

corrected, component failure can result.

Excessive bearing preload may not be noisy. This

condition will cause high temperature which can re-

sult in bearing failure.

GEAR AND BEARING NOISE

GEAR NOISE

Axle gear noise can be caused by insufficient lubri-

cant. Incorrect backlash, tooth contact, or worn/dam-

aged gears can cause noise.

Gear noise usually happens at a specific speed

range. The range is 30 to 40 mph, or above 50 mph.

The noise can also occur during a specific type of

driving condition. These conditions are acceleration,

deceleration, coast, or constant load.

When road testing, accelerate the vehicle to the

speed range where the noise is the greatest. Shift

out-of-gear and coast through the peak-noise range.

If the noise stops or changes greatly, check for insuf-

ficient lubricant. Incorrect ring gear backlash, or

gear damage can cause noise changes.

Differential side and pinion gears can be checked

by turning the vehicle. They usually do not cause

noise in straight-ahead driving. These gears are

loaded during vehicle turns. If noise does occur dur-

ing vehicle turns, the side or pinion gears could be

worn or damaged. A worn pinion gear mate shaft can

also cause a snapping or a knocking noise.

BEARING NOISE

The axle shaft, differential and pinion gear bear-

ings can all produce noise when worn or damaged.

Bearing noise can be either a whining, or a growling

sound.

Pinion gear bearings have a constant-pitch noise.

This noise changes only with vehicle speed. Pinion

bearing noise will be higher because it rotates at a

faster rate. Drive the vehicle and load the differen-

tial. If bearing noise occurs the pinion rear bearing is

the source of the noise. If the bearing noise is heard

during a coast, front bearing is the source.

Worn, damaged differential bearings usually pro-

duce a low pitch noise. Differential bearing noise is

similar to pinion bearing. The pitch of differential

bearing noise is also constant and varies only with

vehicle speed.

2 - 18 FRONT SUSPENSION AND AXLEJ

Page 54 of 2198

Axle shaft bearings produce noise and vibration

when worn or damaged. The noise generally changes

when the bearings are loaded. Road test the vehicle.

Turn the vehicle sharply to the left and to the right.

This will load the bearings and change the noise

level. Where axle bearing damage is slight, the noise

is usually not noticeable at speeds above 30 mph.

LOW SPEED KNOCK

Low speed knock is generally caused by a worn U-

joint or by worn side-gear thrust washers. A worn

pinion gear shaft bore will also cause low speed

knock.

VIBRATION

Vibration at the rear of the vehicle is usually

caused by a:

²Damaged drive shaft

²Missing drive shaft balance weight

²Worn, out-of-balance wheels

²Loose wheel lug nuts

²Worn U-joint

²Loose spring U-bolts

²Loose/broken springs

²Damaged axle shaft bearings

²Loose pinion gear nut

²Excessive pinion yoke run out²Bent axle shaft

Check for loose or damaged front-end components

or engine/transmission mounts. These components

can contribute to what appears to be a rear-end vi-

bration. Do not overlook engine accessories, brackets

and drive belts.

All driveline components should be examined be-

fore starting any repair.

Refer to Group 22ÐTires And Wheels for addi-

tional information involving vibration diagnosis.

DRIVELINE SNAP

A snap or clunk noise when the vehicle is shifted

into gear (or the clutch engaged), can be caused by:

²High engine idle speed

²Loose engine/transmission/transfer case mounts

²Worn U-joints

²Loose spring mounts

²Loose pinion gear nut and yoke

²Excessive ring gear backlash

²Excessive differential side gear-to-case clearance

The source of a snap or a clunk noise can be deter-

mined with the assistance of a helper. Raise the ve-

hicle on a hoist with the wheels free to rotate.

Instruct the helper to shift the transmission into

gear. Listen for the noise, a mechanics stethoscope is

helpful in isolating the source of a noise.

JFRONT SUSPENSION AND AXLE 2 - 19

Page 57 of 2198

MODEL 30 AXLE AND TUBE AXLE (2WD)

INDEX

page page

Axle Bushing Replacement.................. 34

Axle ShaftÐCardan U-Joint.................. 26

Backlash and Contact Pattern Analysis......... 45

Cleaning/Inspection........................ 37

Differential and Pinion Measurement........... 40

Differential Assembly....................... 38

Differential Disassembly.................... 35

Differential Installation...................... 44

Differential Removal....................... 34

Differential Shim Pack Measurement and

Adjustment............................ 43

Drive Axle Assembly ReplacementÐXJ Vehicles . . 23

Drive Axle Assembly ReplacementÐYJ Vehicles . . 24Final Assembly........................... 46

Hub Bearing and Axle Shaft................. 25

Information.............................. 22

Inner Axle Shaft Oil Seal Replacement......... 35

Lubricant Change......................... 23

Lubricant Specifications..................... 22

Pinion Gear Assembly/Installation............. 42

Pinion Gear Depth Information............... 39

Pinion Removal/Disassembly................. 36

Pinion Seal Replacement................... 25

Steering Knuckle and Ball Studs.............. 32

Vacuum Disconnect AxleÐYJ Vehicles......... 27

INFORMATION

The Model 30 front axles consists of a cast iron dif-

ferential housing with axle shaft tubes extending

from either side. The tubes are pressed into the dif-

ferential housing and welded.

The integral type housing, hypoid gear design has

the centerline of the pinion set above the centerline

of the ring gear.

The axle has a fitting for a vent hose used to re-

lieve internal pressure caused by lubricant vaporiza-

tion and internal expansion.

The axles are equipped with semi-floating axle

shafts, meaning that loads are supported by the hub

bearings. The axle shafts are retained by nuts at the

hub bearings. The hub bearings are bolted to the

steering knuckle at the outboard end of the axle tube

yoke. The hub bearings are serviced as an assembly.

The axles are equipped with ABS brake sensors.

The sensors are attached to the knuckle assemblies

and tone rings are pressed on the axle shaft.Use

care when removing axle shafts as NOT to dam-

age the tone wheel or the sensor.

The stamped steel cover provides a means for in-

spection and servicing the differential.

The Model 30 axle has the assembly part number

and gear ratio listed on a tag. The tag is attached to

the housing cover. Build date identification codes are

stamped on the axle shaft tube cover side.

The differential case is a one-piece design. The dif-

ferential pinion mate shaft is retained with a roll

pin. Differential bearing preload and ring gear back-

lash is adjusted by the use of shims (select thick-

ness). The shims are located between the differential

bearing cones and case. Pinion bearing preload is set

and maintained by the use of collapsible spacer.

COMMAND-TRACÐYJ VEHICLES

The Command-Trac system is a vacuum disconnect

axle. The system has a two-piece axle shaft coupled

together by a shift collar. For two-wheel drive opera-

tion, the vacuum motor and shift fork disengages the

axle shaft splines. For four-wheel drive operation, the

vacuum motor and shift fork engages the axle

splines.

SELEC-TRACÐXJ VEHICLES

The Selec-Trac system is a non-disconnect axle.

Shifting from two-wheel to four-wheel drive is done

at the transfer case.

For XJ vehicles equipped withSelec-Tracand

ABS brake system, refer to Group 5ÐBrakes for ad-

ditional service information.

LUBRICANT SPECIFICATIONS

Multi-purpose, hypoid gear lubricant should be

used for Model 30 axles. The lubricant should have

MIL-L-2105C and API GL 5 quality specifications.

MOPARtHypoid Gear Lubricant conforms to both of

these specifications.

²The factory fill for the Model 30 axle is SAE Ther-

mally Stable 80W-90 gear lubricant.Do not use

heavier weight lubricant, this will cause axle

engagement difficulties.

²The factory installed lubricant quantity for the

NON-DISCONNECT TYPE AXLE is 1.48 L (3.13

pts.).

²The factory installed lubricant quantity for the

VACUUM-DISCONNECT TYPE AXLE is 1.65 L (3.76

pts.).

Refer to Group 0, Lubrication and Maintenance for

additional information regarding temperature range,

viscosity and fluid level.

2 - 22 FRONT SUSPENSION AND AXLEJ

Page 73 of 2198

compressed air.Cup and bearing must be re-

placed as a matched sets only.

Clean axle shaft tubes and oil channels with clean

cloth.

Inspect for;

²Smooth appearance with no broken/dented sur-

faces on the bearing rollers or the roller contact sur-

faces.

²Bearing cups must not be distorted or cracked.

²Machined surfaces should be smooth and without

any raised edges.²Raised metal on shoulders of cup bores should be

removed with a hand stone.

²Wear or damage to pinion gear mate shaft, pinion

gears, side gears and thrust washers. Replace as a

matched set only.

²Worn or chipped teeth to ring and pinion gears.

²Damaged bolt threads to ring gear. Replaced as a

matched set only.

²Pinion yoke for cracks, worn splines, pitted areas,

and a rough/corroded seal contact surface. Repair or

replace the as necessary.

DIFFERENTIAL ASSEMBLY

ASSEMBLY

(1) Install the following components in the differ-

ential case (Fig. 37).

²Differential side gears and thrust washers

²Pinion gears and thrust washers

²Pinion gear mate shaft (align holes in shaft and

case)

(2) Install and seat the locking roll pin in the dif-

ferential case and mate shaft with a punch and ham-

mer (Fig. 37). Peen metal part of case over pin in two

places 180 degrees apart.

If replacement gears and thrust washers were

installed, it is not necessary to measure the

gear backlash. Correct fit is due to close ma-

chining tolerances during manufacture.

(3) Invert the differential case and start two ring

gear bolts. This will provide case-to-ring gear bolt

hole alignment.

(4) Install new ring gear bolts and alternately

tighten to 95-122 Nzm (70-90 ft. lbs.) torque (Fig. 38).

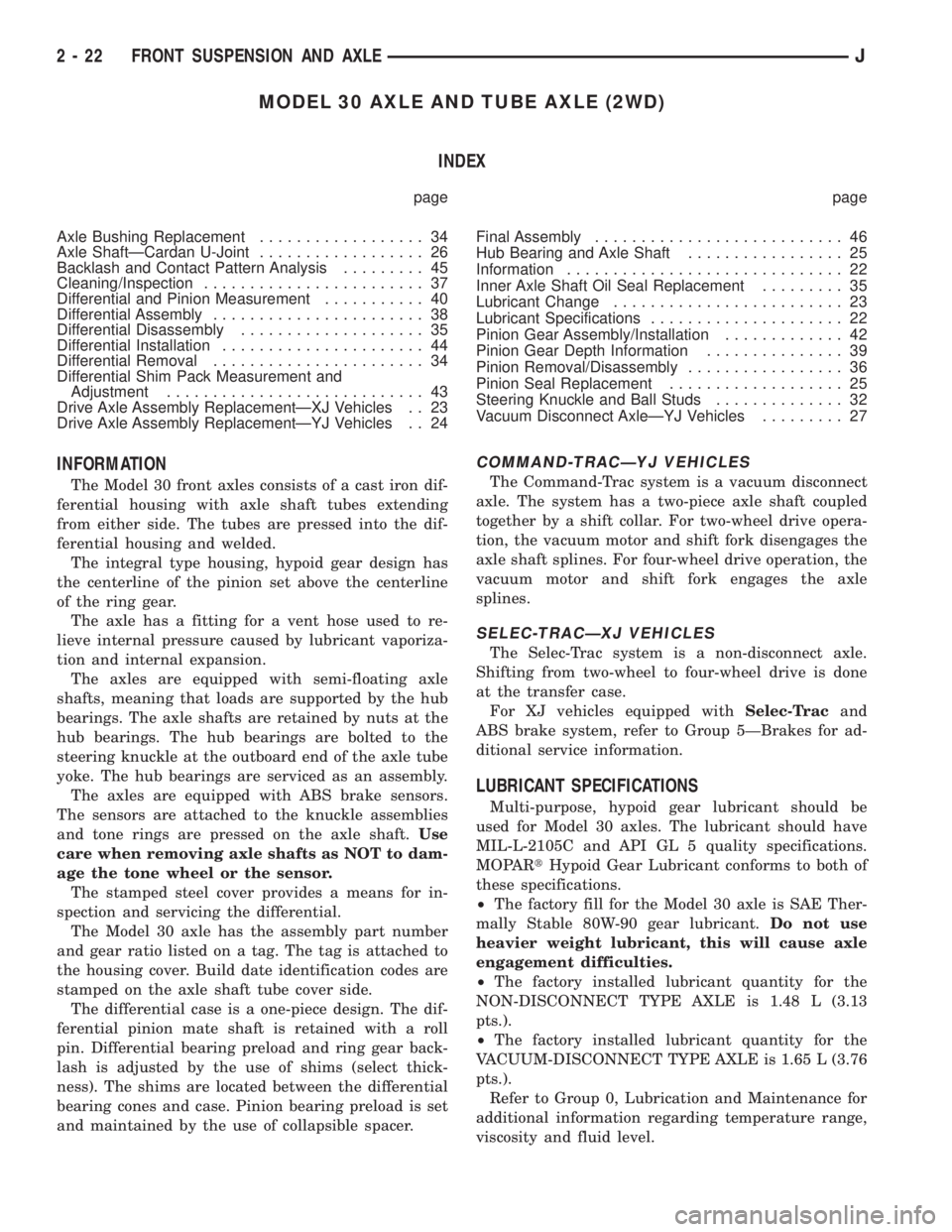

Fig. 35 Rear Bearing Cup Removal

Fig. 36 Inner Bearing Removal

Fig. 37 Mate Shaft Pin Installation

2 - 38 FRONT SUSPENSION AND AXLEJ

Page 74 of 2198

(5) Lubricate all differential components with hy-

poid gear lubricant.

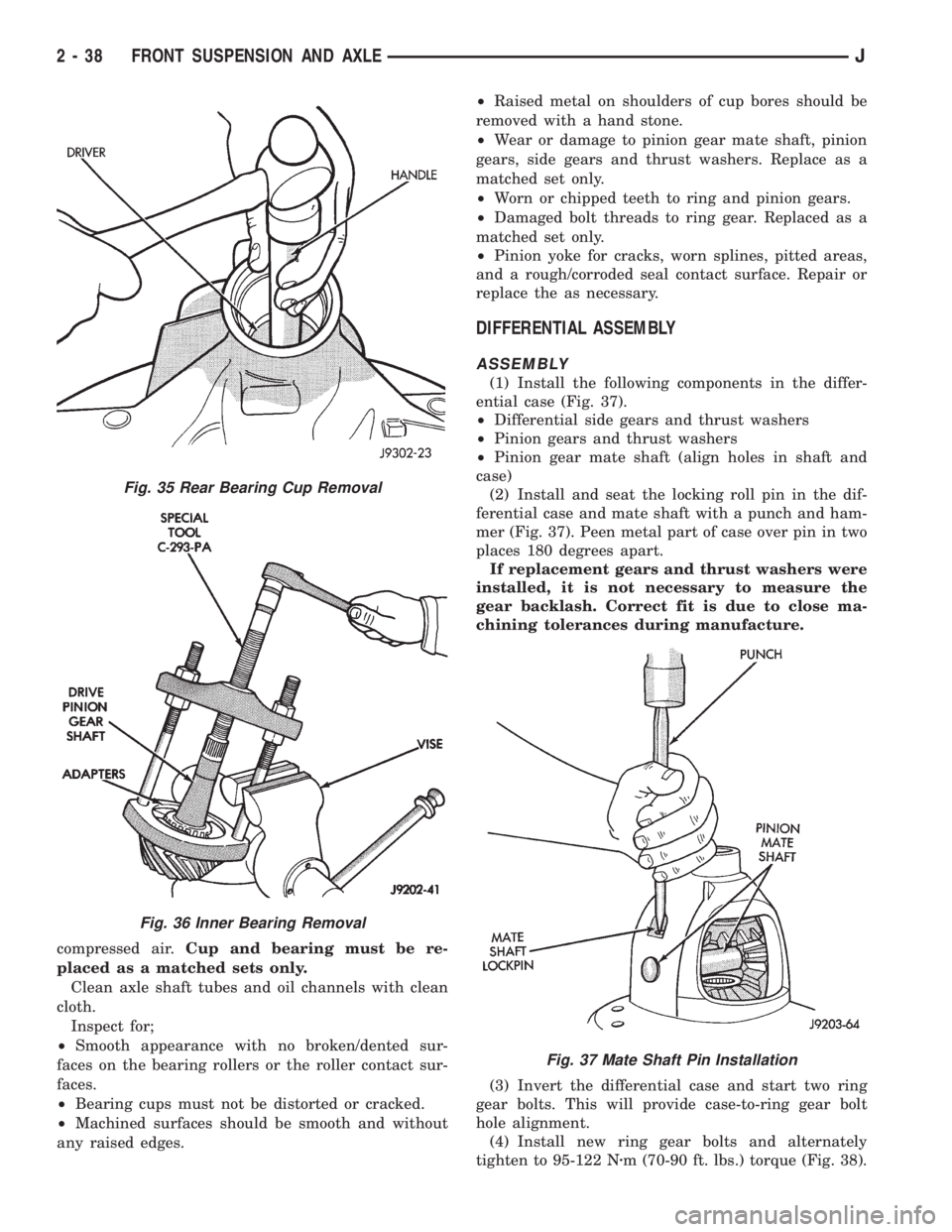

PINION GEAR DEPTH INFORMATION

Ring and pinion gears are supplied as matched sets

only. The identifying numbers for the ring and pinion

gear are etched into the face of each gear (Fig. 39). A

plus (+) number, minus (-) number or zero (0) is

etched into the face of the pinion gear. This number

is the amount (in thousandths of an inch) the depth

varies from the standard depth setting of a pinion

etched with a (0). The standard setting from the cen-

terline of the ring gear to the back face of the pinion

is 92.1 mm (3.625 inches) for Model 30 axles (Fig.

40). The standard depth provides the best teeth con-

tact pattern.THE BUTTON END ON THE PINION GEAR

HEAD IS NO LONGER A MACHINED-TO-SPECIFI-

CATIONS SURFACE. DO NOT USE THIS SUR-

FACE FOR PINION DEPTH SET-UP OR

CHECKING (Fig. 40).

Compensation for depth variance is achieved by a

selected thickness oil slinger (production) or shims

(service). The slinger is placed between the inner pin-

ion bearing cone and gear head (Fig. 41). The shim

pack is placed under the inner (rear) bearing cup for

service. To change the pinion adjustment, shims are

available in thicknesses of 0.003, 0.005, and 0.010

inch.The oil slinger or baffle must be measured

and the thickness included with the total shim

pack.

Fig. 38 Ring Gear Bolt Installation

Fig. 39 Pinion Gear ID Numbers

Fig. 40 Pinion Gear Head

Fig. 41 Shim Locations

JFRONT SUSPENSION AND AXLE 2 - 39

Page 75 of 2198

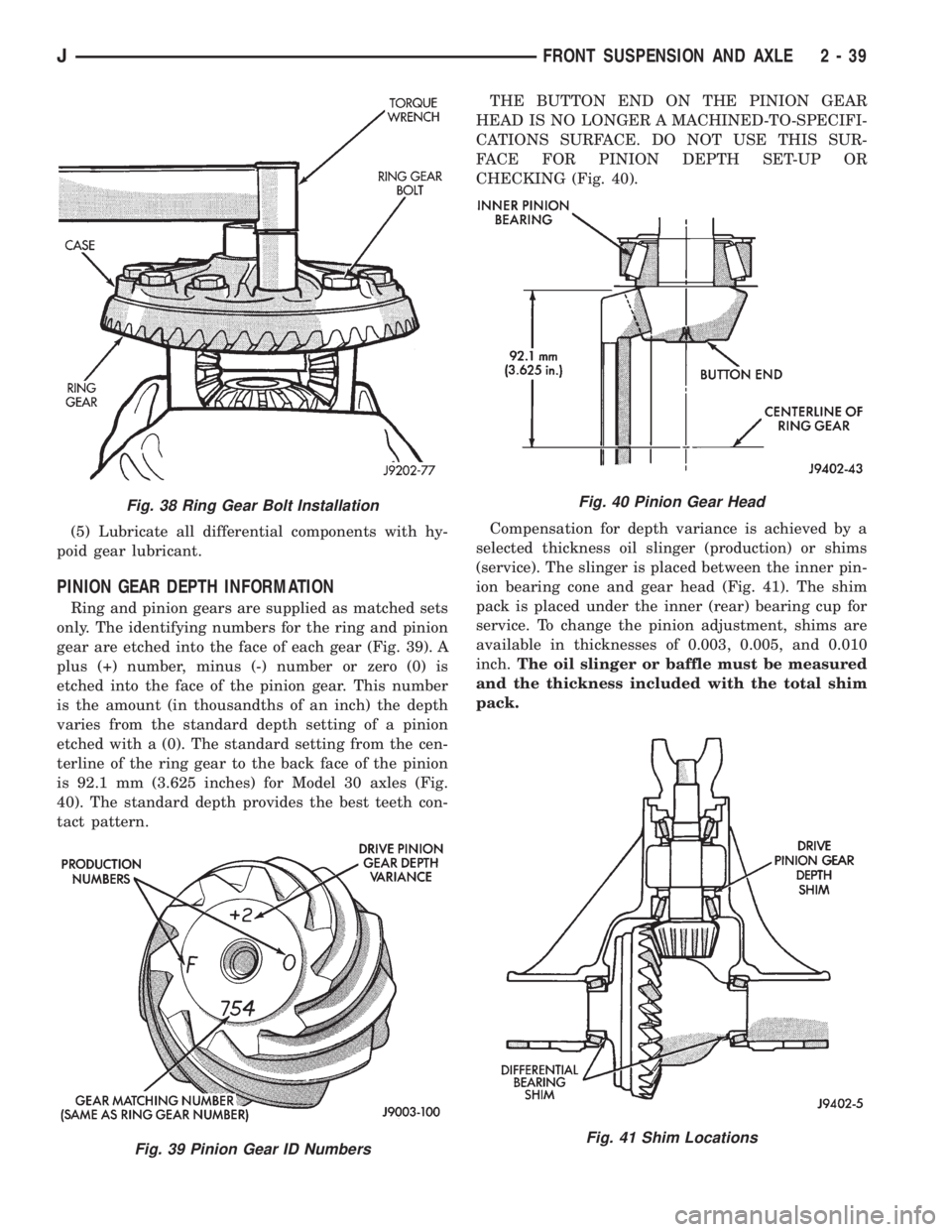

New gear set: note the depth variance etched

into both the original and the replacement pin-

ion gear. Add or subtract the thickness of the

original depth shims to compensate for the dif-

ference in the depth variances. Refer to the

Depth Variance charts.

Note where Old and New Pinion Marking columns

intersect. Intersecting figure represents plus or mi-

nus amount needed.

For example, if old pinion is plus (+) 1 and the new

pinion is minus (-) 3, intersecting figure is (+)0.004

inch (0.10mm). Add this amount to the original shim.

Or if the old pinion is (-) 3 and the new pinion is (-)

2, intersecting figure is (-)0.001 inch (0.025mm). Sub-

tract this amount from original shim.Refer to the

Pinion Gear Depth Variance Chart.

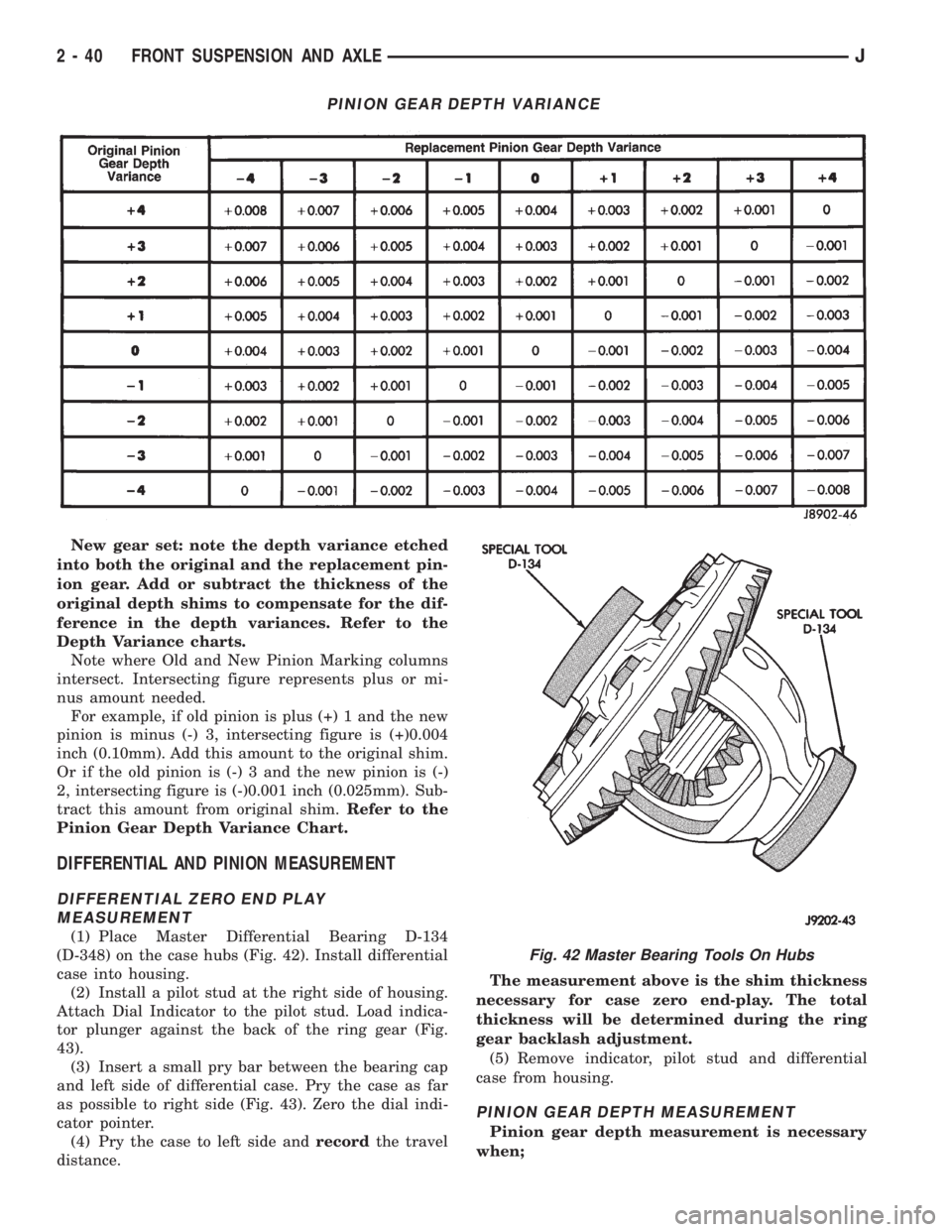

DIFFERENTIAL AND PINION MEASUREMENT

DIFFERENTIAL ZERO END PLAY

MEASUREMENT

(1) Place Master Differential Bearing D-134

(D-348) on the case hubs (Fig. 42). Install differential

case into housing.

(2) Install a pilot stud at the right side of housing.

Attach Dial Indicator to the pilot stud. Load indica-

tor plunger against the back of the ring gear (Fig.

43).

(3) Insert a small pry bar between the bearing cap

and left side of differential case. Pry the case as far

as possible to right side (Fig. 43). Zero the dial indi-

cator pointer.

(4) Pry the case to left side andrecordthe travel

distance.The measurement above is the shim thickness

necessary for case zero end-play. The total

thickness will be determined during the ring

gear backlash adjustment.

(5) Remove indicator, pilot stud and differential

case from housing.

PINION GEAR DEPTH MEASUREMENT

Pinion gear depth measurement is necessary

when;

PINION GEAR DEPTH VARIANCE

Fig. 42 Master Bearing Tools On Hubs

2 - 40 FRONT SUSPENSION AND AXLEJ

Page 78 of 2198

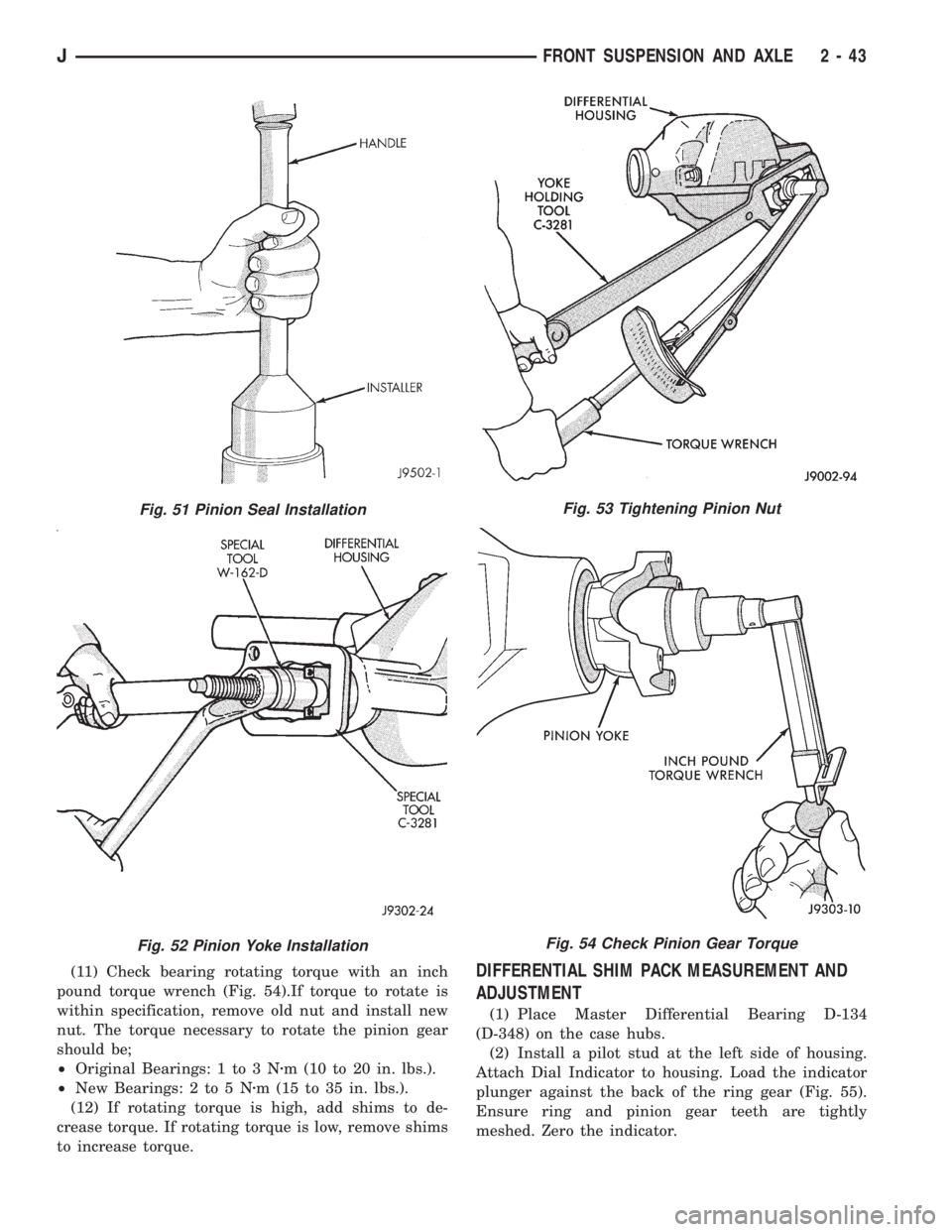

(11) Check bearing rotating torque with an inch

pound torque wrench (Fig. 54).If torque to rotate is

within specification, remove old nut and install new

nut. The torque necessary to rotate the pinion gear

should be;

²Original Bearings: 1 to 3 Nzm (10 to 20 in. lbs.).

²New Bearings: 2 to 5 Nzm (15 to 35 in. lbs.).

(12) If rotating torque is high, add shims to de-

crease torque. If rotating torque is low, remove shims

to increase torque.DIFFERENTIAL SHIM PACK MEASUREMENT AND

ADJUSTMENT

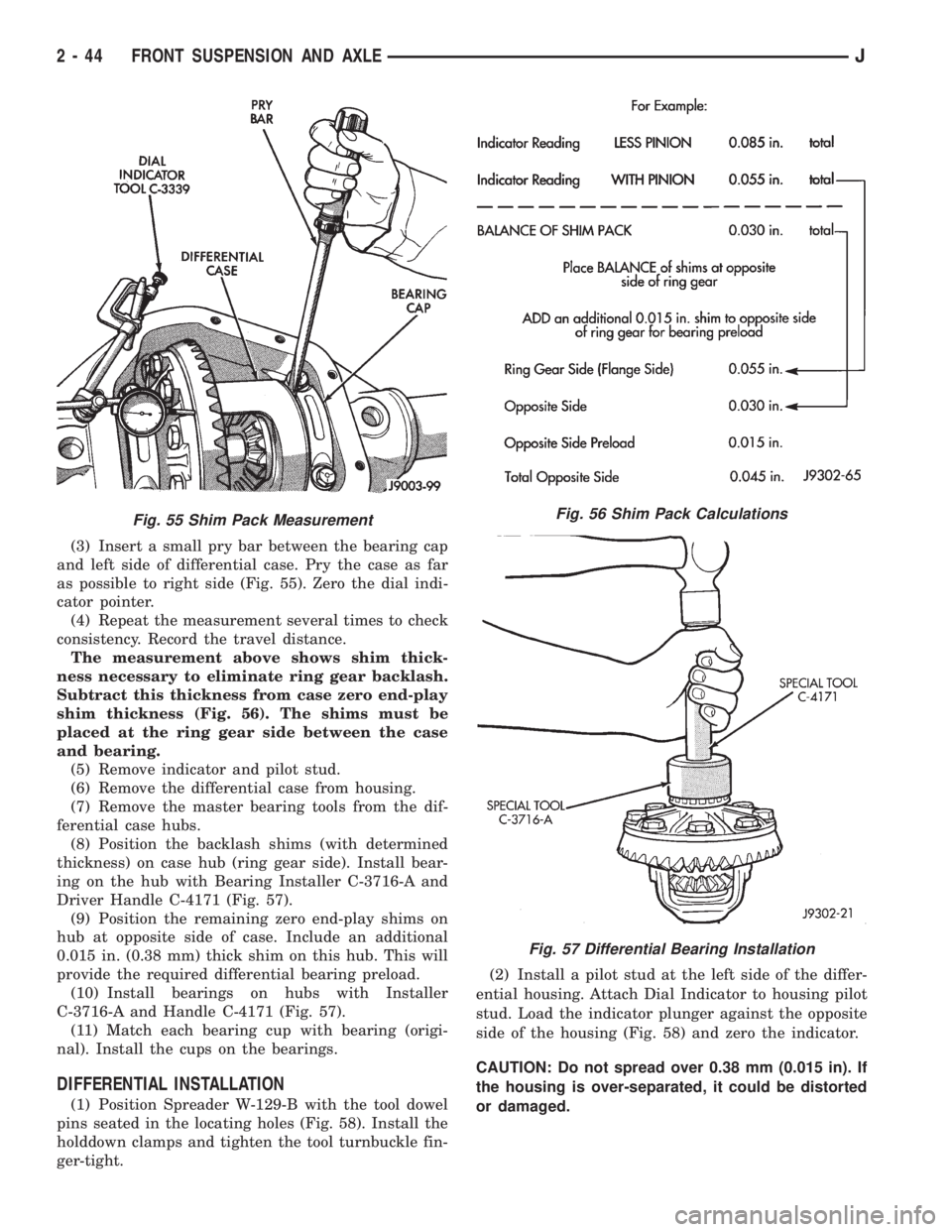

(1) Place Master Differential Bearing D-134

(D-348) on the case hubs.

(2) Install a pilot stud at the left side of housing.

Attach Dial Indicator to housing. Load the indicator

plunger against the back of the ring gear (Fig. 55).

Ensure ring and pinion gear teeth are tightly

meshed. Zero the indicator.

Fig. 51 Pinion Seal Installation

Fig. 52 Pinion Yoke Installation

Fig. 53 Tightening Pinion Nut

Fig. 54 Check Pinion Gear Torque

JFRONT SUSPENSION AND AXLE 2 - 43

Page 79 of 2198

(3) Insert a small pry bar between the bearing cap

and left side of differential case. Pry the case as far

as possible to right side (Fig. 55). Zero the dial indi-

cator pointer.

(4) Repeat the measurement several times to check

consistency. Record the travel distance.

The measurement above shows shim thick-

ness necessary to eliminate ring gear backlash.

Subtract this thickness from case zero end-play

shim thickness (Fig. 56). The shims must be

placed at the ring gear side between the case

and bearing.

(5) Remove indicator and pilot stud.

(6) Remove the differential case from housing.

(7) Remove the master bearing tools from the dif-

ferential case hubs.

(8) Position the backlash shims (with determined

thickness) on case hub (ring gear side). Install bear-

ing on the hub with Bearing Installer C-3716-A and

Driver Handle C-4171 (Fig. 57).

(9) Position the remaining zero end-play shims on

hub at opposite side of case. Include an additional

0.015 in. (0.38 mm) thick shim on this hub. This will

provide the required differential bearing preload.

(10) Install bearings on hubs with Installer

C-3716-A and Handle C-4171 (Fig. 57).

(11) Match each bearing cup with bearing (origi-

nal). Install the cups on the bearings.

DIFFERENTIAL INSTALLATION

(1) Position Spreader W-129-B with the tool dowel

pins seated in the locating holes (Fig. 58). Install the

holddown clamps and tighten the tool turnbuckle fin-

ger-tight.(2) Install a pilot stud at the left side of the differ-

ential housing. Attach Dial Indicator to housing pilot

stud. Load the indicator plunger against the opposite

side of the housing (Fig. 58) and zero the indicator.

CAUTION: Do not spread over 0.38 mm (0.015 in). If

the housing is over-separated, it could be distorted

or damaged.

Fig. 55 Shim Pack MeasurementFig. 56 Shim Pack Calculations

Fig. 57 Differential Bearing Installation

2 - 44 FRONT SUSPENSION AND AXLEJ