dimensions JEEP CHEROKEE 1995 Service Repair Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 1995, Model line: CHEROKEE, Model: JEEP CHEROKEE 1995Pages: 2198, PDF Size: 82.83 MB

Page 143 of 2198

pedal. The proper course of action is to bleed the sys-

tem, or replace thin drums and suspect quality brake

lines and hoses.

HARD PEDAL OR HIGH PEDAL EFFORT

A hard pedal or high pedal effort may be due to lin-

ing that is water soaked, contaminated, glazed, or

badly worn. The power booster or check valve could

also be faulty. Test the booster and valve as described

in this section.

BRAKE DRAG

Brake drag occurs when the lining is in constant

contact with the rotor or drum. Drag can occur at one

wheel, all wheels, fronts only, or rears only. It is a

product of incomplete brakeshoe release. Drag can be

minor or severe enough to overheat the linings, ro-

tors and drums. A drag condition also worsens as

temperature of the brake parts increases.

Brake drag also has a direct effect on fuel economy.

If undetected, minor brake drag can be misdiagnosed

as an engine or transmission/torque converter prob-

lem.

Minor drag will usually cause slight surface char-

ring of the lining. It can also generate hard spots in

rotors and drums from the overheat/cool down pro-

cess. In most cases, the rotors, drums, wheels and

tires are quite warm to the touch after the vehicle is

stopped.

Severe drag can char the brake lining all the way

through. It can also distort and score rotors and

drums to the point of replacement. The wheels, tires

and brake components will be extremely hot. In se-

vere cases, the lining may generate smoke as it chars

from overheating.

An additional cause of drag involves the use of in-

correct length caliper mounting bolts. Bolts that are

too long can cause a partial apply condition. The cor-

rect caliper bolts have a shank length of 67 mm

(2.637 in.), plus or minus 0.6 mm (0.0236 in.). Refer

to the Disc Brake service section for more detail on

caliper bolt dimensions and identification.

Some common causes of brake drag are:

²loose or damaged wheel bearing

²seized or sticking caliper or wheel cylinder piston

²caliper binding on bolts or slide surfaces

²wrong length caliper mounting bolts (too long)

²loose caliper mounting bracket

²distorted rotor, brake drum, or shoes

²brakeshoes binding on worn/damaged support

plates

²severely rusted/corroded components

²misassembled components.

If brake drag occurs at all wheels, the problem may

be related to a blocked master cylinder compensatorport or faulty power booster (binds-does not release).

The condition will worsen as brake temperature in-

creases.

The brakelight switch can also be a cause of drag.

An improperly mounted or adjusted brakelight

switch can prevent full brake pedal return. The re-

sult will be the same as if the master cylinder com-

pensator ports are blocked. The brakes would be

partially applied causing drag.

BRAKE FADE

Brake fade is a product of overheating caused by

brake drag. However, overheating and subsequent

fade can also be caused by riding the brake pedal,

making repeated high deceleration stops in a short

time span, or constant braking on steep roads. Refer

to the Brake Drag information in this section for

causes.

PEDAL PULSATION (NON-ABS BRAKES ONLY)

Pedal pulsation is caused by parts that are loose,

or beyond tolerance limits. This type of pulsation is

constant and will occur every time the brakes are ap-

plied.

Disc brake rotors with excessive lateral runout or

thickness variation, or out of round brake drums are

the primary causes of pulsation.

On vehicles with ABS brakes, remember that pedal

pulsation is normal during antilock mode brake

stops. If pulsation occurs during light to moderate

brake stops, a standard brake part is either loose, or

worn beyond tolerance.

BRAKE PULL

A front pull condition could be the result of:

²contaminated lining in one caliper

²seized caliper piston

²binding caliper

²wrong caliper mounting bolts (too long)

²loose caliper

²loose or corroded mounting bolts

²improper brakeshoes

²damaged rotor

²incorrect wheel bearing adjustment (at one wheel)

A worn, damaged wheel bearing or suspension com-

ponent are further causes of pull. A damaged front

tire (bruised, ply separation) can also cause pull.

Wrong caliper bolts (too long) will cause a partial ap-

ply condition and pull if only one caliper is involved.

A common and frequently misdiagnosed pull condi-

tion is where direction of pull changes after a few

stops. The cause is a combination of brake drag fol-

lowed by fade at the dragging brake unit.

As the dragging brake overheats, efficiency is so re-

duced that fade occurs. If the opposite brake unit is

still functioning normally, its braking effect is magni-

5 - 6 SERVICE BRAKE DIAGNOSISJ

Page 185 of 2198

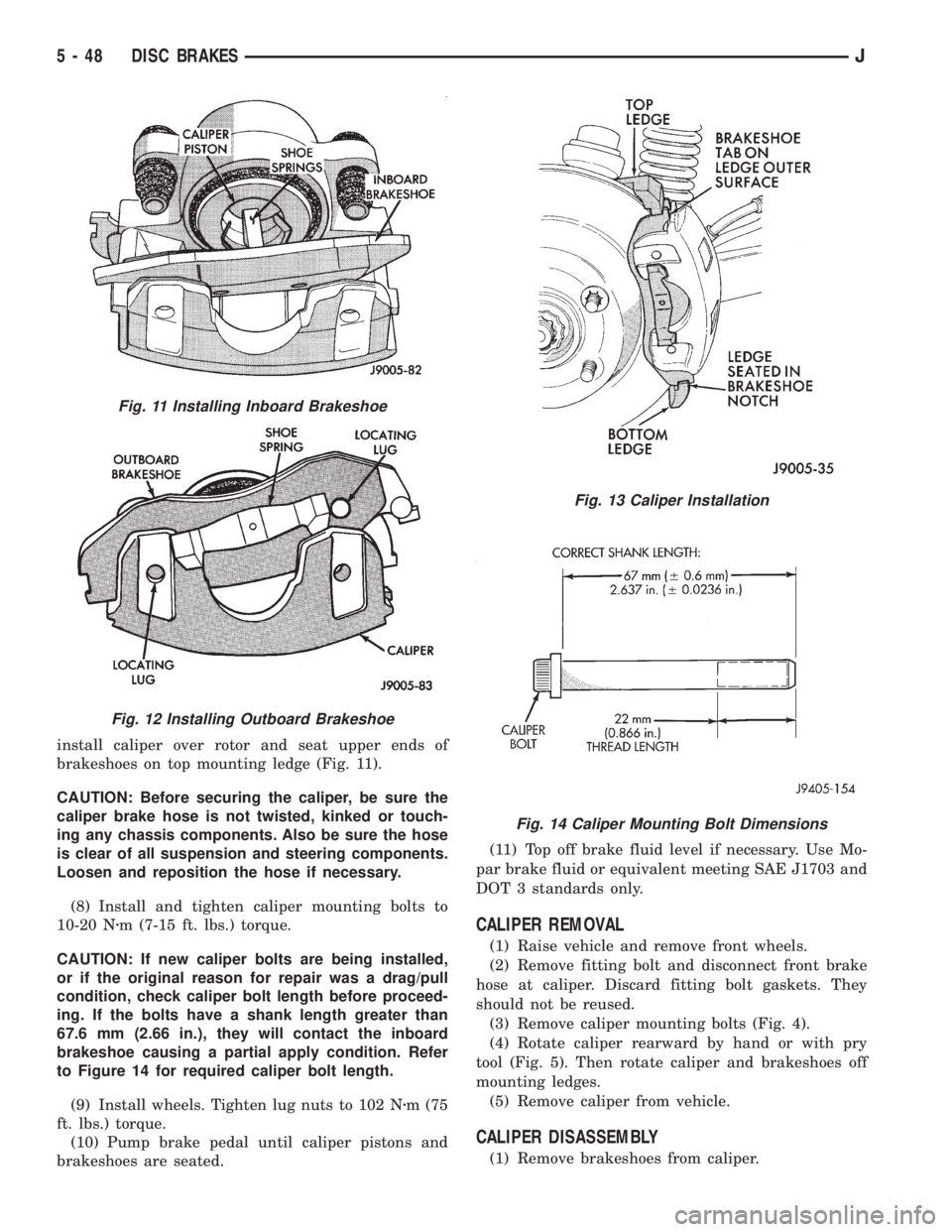

install caliper over rotor and seat upper ends of

brakeshoes on top mounting ledge (Fig. 11).

CAUTION: Before securing the caliper, be sure the

caliper brake hose is not twisted, kinked or touch-

ing any chassis components. Also be sure the hose

is clear of all suspension and steering components.

Loosen and reposition the hose if necessary.

(8) Install and tighten caliper mounting bolts to

10-20 Nzm (7-15 ft. lbs.) torque.

CAUTION: If new caliper bolts are being installed,

or if the original reason for repair was a drag/pull

condition, check caliper bolt length before proceed-

ing. If the bolts have a shank length greater than

67.6 mm (2.66 in.), they will contact the inboard

brakeshoe causing a partial apply condition. Refer

to Figure 14 for required caliper bolt length.

(9) Install wheels. Tighten lug nuts to 102 Nzm (75

ft. lbs.) torque.

(10) Pump brake pedal until caliper pistons and

brakeshoes are seated.(11) Top off brake fluid level if necessary. Use Mo-

par brake fluid or equivalent meeting SAE J1703 and

DOT 3 standards only.

CALIPER REMOVAL

(1) Raise vehicle and remove front wheels.

(2) Remove fitting bolt and disconnect front brake

hose at caliper. Discard fitting bolt gaskets. They

should not be reused.

(3) Remove caliper mounting bolts (Fig. 4).

(4) Rotate caliper rearward by hand or with pry

tool (Fig. 5). Then rotate caliper and brakeshoes off

mounting ledges.

(5) Remove caliper from vehicle.

CALIPER DISASSEMBLY

(1) Remove brakeshoes from caliper.

Fig. 11 Installing Inboard Brakeshoe

Fig. 12 Installing Outboard Brakeshoe

Fig. 13 Caliper Installation

Fig. 14 Caliper Mounting Bolt Dimensions

5 - 48 DISC BRAKESJ

Page 187 of 2198

CALIPER CLEANING AND INSPECTION

Clean the caliper and piston with Mopar brake

cleaner, clean brake fluid, or denatured alcohol only.

Do not use gasoline, kerosene, thinner, or similar sol-

vents. These products leave a residue that will dam-

age pistons and seals.

Wipe the caliper and piston dry with lint free tow-

els or use low pressure compressed air.

Inspect the piston and piston bore. Replace the cal-

iper if the bore is corroded, rusted, pitted, or scored.

Do not hone the caliper piston bore. Replace the cal-

iper if the bore exhibits any of the aforementioned

conditions.

Inspect the caliper piston. The piston is made from

a phenolic resin and should be smooth and clean. Re-

place the piston if cracked, chipped, or scored. Do not

attempt to restore a scored, or corroded piston sur-

face by sanding or polishing. The piston must be re-

placed if damaged.

CAUTION: Never interchange phenolic resin and

steel caliper pistons. The seals, seal grooves, cali-

per bores and piston tolerances are different for

resin and steel pistons. Do not intermix these com-

ponents.

Inspect the caliper mounting bolt bushings and

boots. Replace the boots if cut or torn. Clean and lu-

bricate the bushings with GE 661 or Dow 111 silicone

grease if necessary.

Inspect condition of the caliper mounting bolts. Re-

place the bolts if corroded, rusted, or worn. Do not

reuse the bolts if unsure of their condition.

Length of the caliper mounting bolts is also ex-

tremely important.

Use the replacement bolts specified in the parts

catalog at all times. Do not use substitute bolts. Bolts

that are too long will partially apply the inboard

brakeshoe causing drag and pull. Refer to the caliper

and brakeshoe installation procedures for service de-

tails and bolt dimensions.

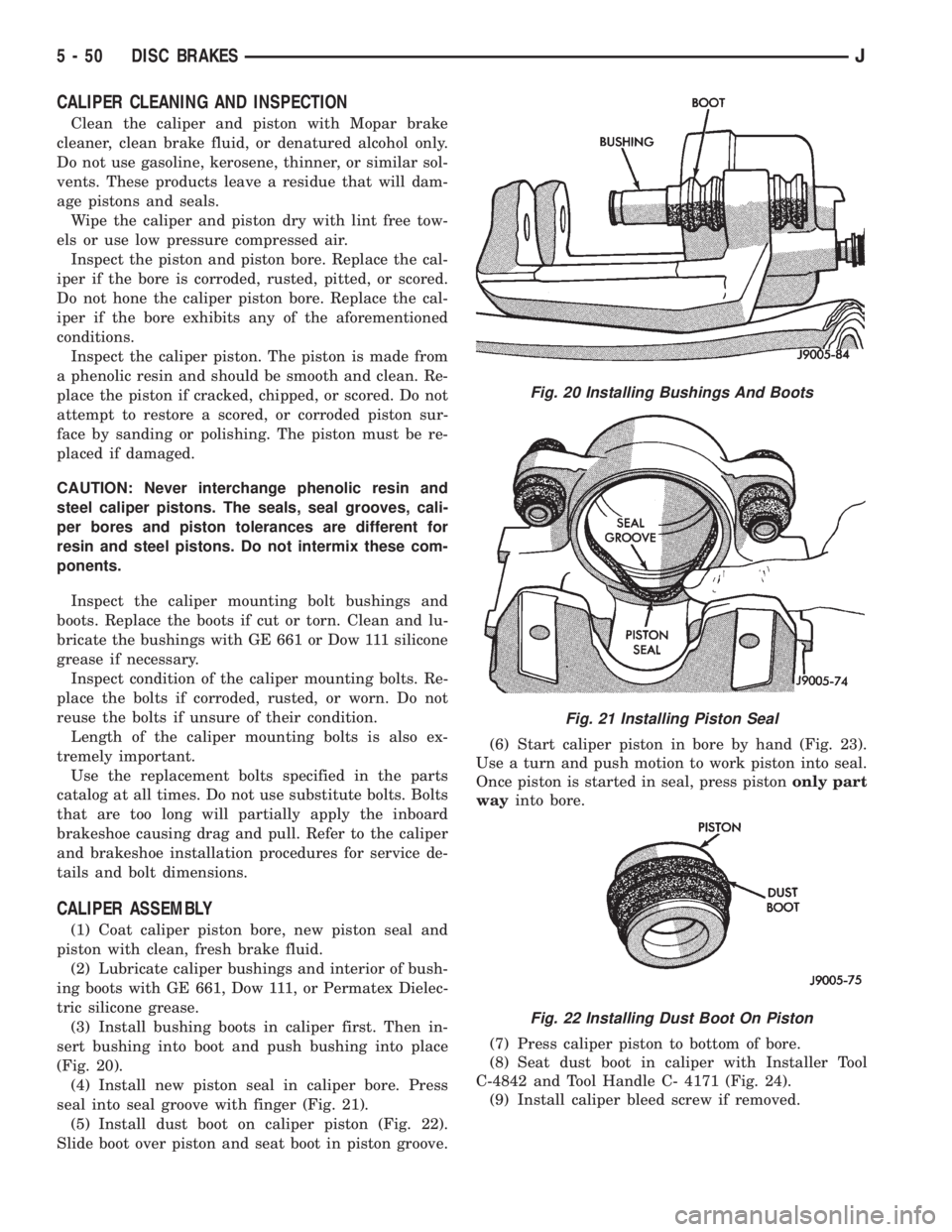

CALIPER ASSEMBLY

(1) Coat caliper piston bore, new piston seal and

piston with clean, fresh brake fluid.

(2) Lubricate caliper bushings and interior of bush-

ing boots with GE 661, Dow 111, or Permatex Dielec-

tric silicone grease.

(3) Install bushing boots in caliper first. Then in-

sert bushing into boot and push bushing into place

(Fig. 20).

(4) Install new piston seal in caliper bore. Press

seal into seal groove with finger (Fig. 21).

(5) Install dust boot on caliper piston (Fig. 22).

Slide boot over piston and seat boot in piston groove.(6) Start caliper piston in bore by hand (Fig. 23).

Use a turn and push motion to work piston into seal.

Once piston is started in seal, press pistononly part

wayinto bore.

(7) Press caliper piston to bottom of bore.

(8) Seat dust boot in caliper with Installer Tool

C-4842 and Tool Handle C- 4171 (Fig. 24).

(9) Install caliper bleed screw if removed.

Fig. 20 Installing Bushings And Boots

Fig. 21 Installing Piston Seal

Fig. 22 Installing Dust Boot On Piston

5 - 50 DISC BRAKESJ

Page 299 of 2198

CAUTION: Be certain that battery cables are con-

nected to the correct battery terminals. Reverse po-

larity can damage electrical components.

(12) Place oiled felt washer on battery positive ter-

minal post.

(13) Install and tighten battery positive cable ter-

minal clamp. Then install and tighten negative cableterminal clamp. Both cable clamp bolts require

torque of 8.5 Nzm (75 in. lbs.).

(14) Apply a thin coating of petroleum jelly or

chassis grease to cable terminals and battery posts.

STARTER AND STARTER RELAY

GENERAL INFORMATION

This section covers starter and starter relay service

procedures only. For diagnostic procedures, refer to

Group 8A - Battery/Starting/Charging Systems Diag-

nostics. Service procedures for other starting system

components can be found as follows:

²battery - see Battery, in this group

²ignition switch - refer to Group 8D - Ignition Sys-

tems

²park/neutral position switch (automatic transmis-

sion) - refer to Group 21 - Transmission and Transfer

Case

²wiring harness and connectors - refer to Group 8W

- Wiring Diagrams.

STARTER

The starter motor incorporates several features to

create a reliable, efficient, compact and lightweight

unit. A planetary gear system (intermediate trans-

mission) is used between the electric motor and pin-

ion gear. This feature makes it possible to reduce the

dimensions of the starter. At the same time, it allows

higher armature rotational speed and delivers in-

creased torque through the pinion gear to the fly-

wheel or drive plate ring gear.

The use of a permanent magnet field also reduces

starter size and weight. This field consists of six

high-strength permanent magnets. The magnets are

aligned according to their polarity and are perma-

nently fixed in the starter field frame.

The starter motors for all engines are activated by

a solenoid mounted to the overrunning clutch hous-

ing. However, the starter motor/solenoid are serviced

only as a complete assembly. If either component

fails, the entire assembly must be replaced.

This unit is highly sensitive to hammering, shocks

and external pressure.

CAUTION: The starter motor MUST NOT BE

CLAMPED in a vise by the starter field frame. Doing

so may damage the magnets. It may be clamped by

the mounting flange ONLY.CAUTION: Do not connect starter motor incorrectly

when tests are being performed. The permanent

magnets may be damaged and rendered unservice-

able.

STARTER RELAY

The starter relay is an International Standards Or-

ganization (ISO) type relay, and is located in the

Power Distribution Center (PDC). Refer to underside

of PDC cover for relay location.

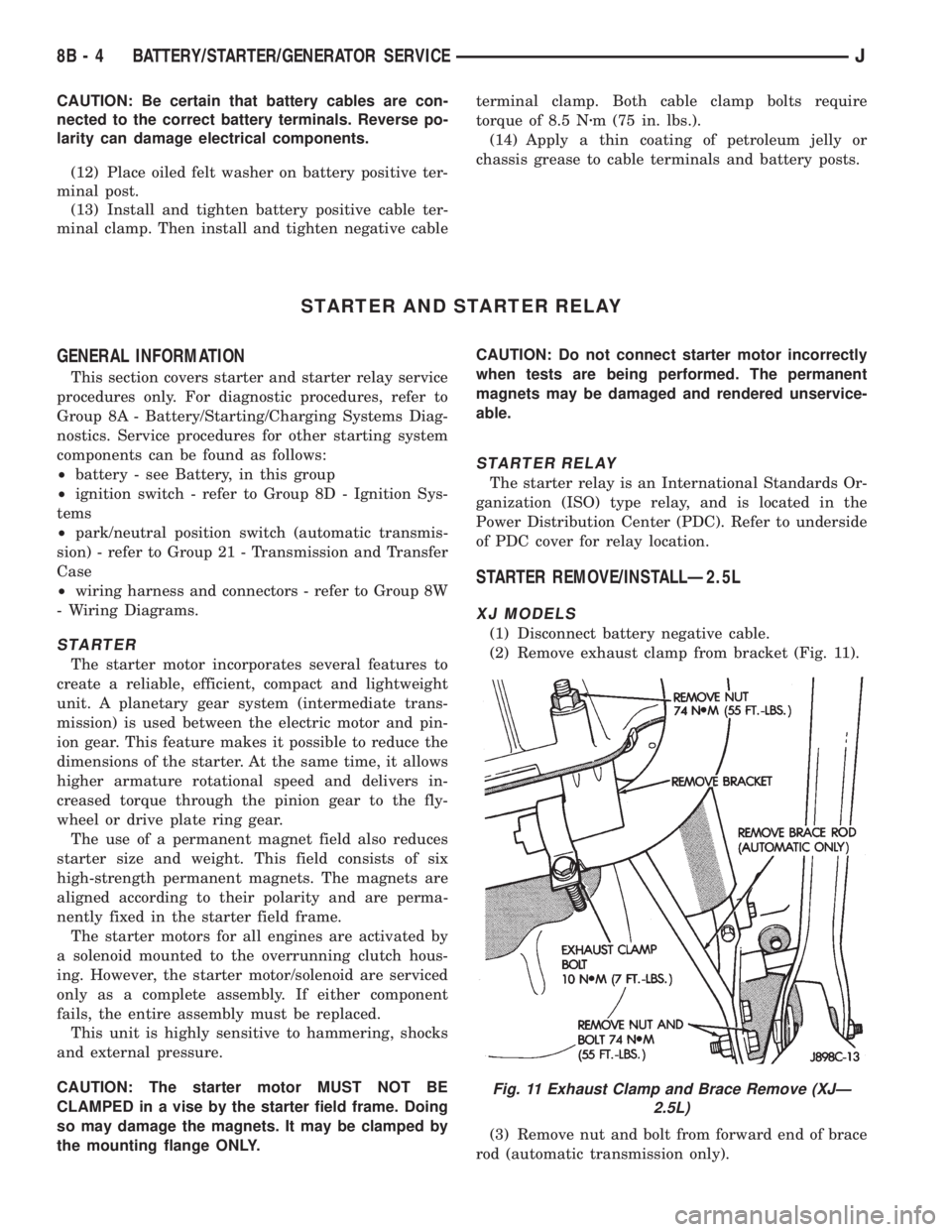

STARTER REMOVE/INSTALLÐ2.5L

XJ MODELS

(1) Disconnect battery negative cable.

(2) Remove exhaust clamp from bracket (Fig. 11).

(3) Remove nut and bolt from forward end of brace

rod (automatic transmission only).

Fig. 11 Exhaust Clamp and Brace Remove (XJÐ

2.5L)

8B - 4 BATTERY/STARTER/GENERATOR SERVICEJ

Page 1133 of 2198

SIDE CLEARANCE MEASUREMENT

Slide snug-fitting feeler gauge between the connect-

ing rod and crankshaft journal flange. Refer to En-

gine Specifications for the proper clearance. Replace

the connecting rod if the side clearance is not within

specification.

PISTON FITTING

BORE GAUGE METHOD

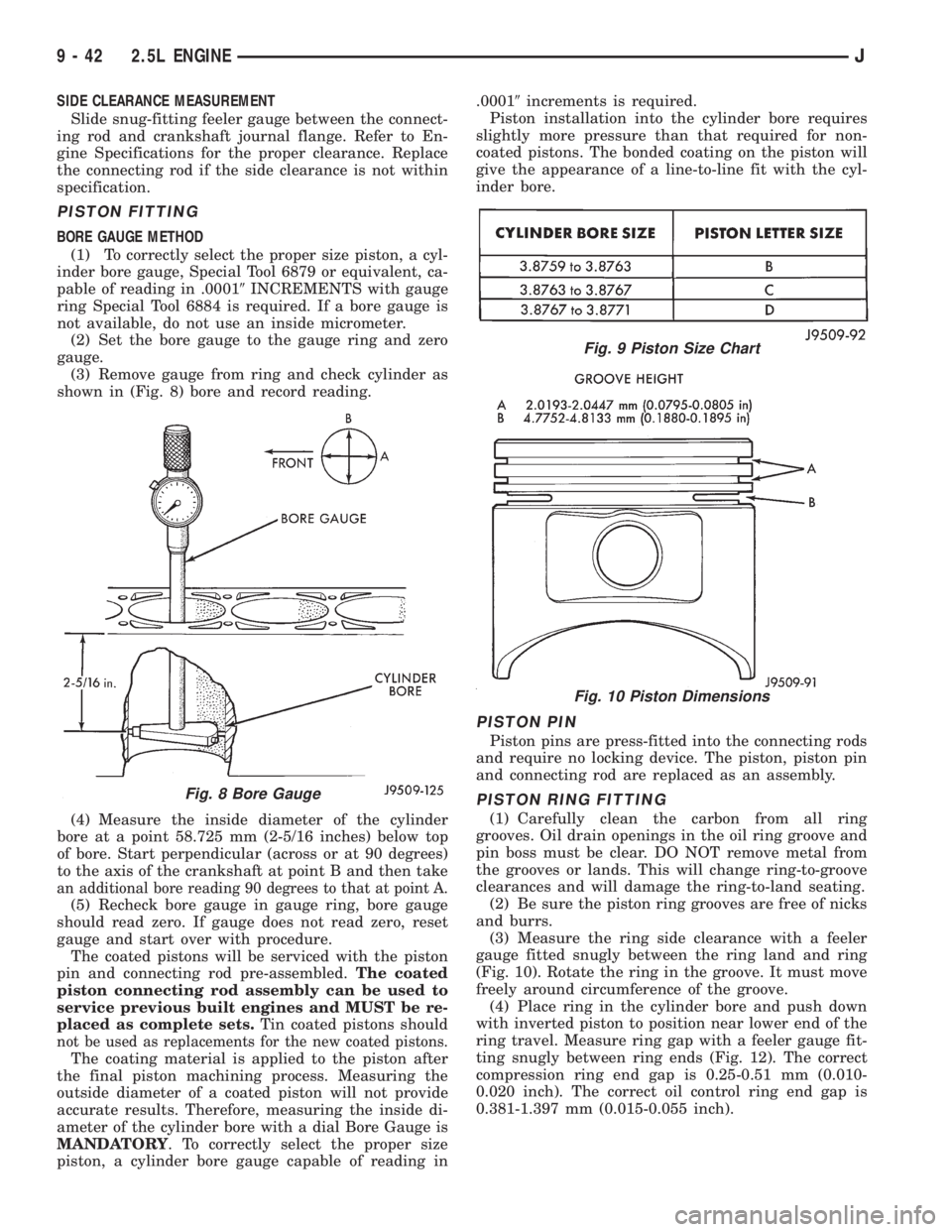

(1) To correctly select the proper size piston, a cyl-

inder bore gauge, Special Tool 6879 or equivalent, ca-

pable of reading in .00019INCREMENTS with gauge

ring Special Tool 6884 is required. If a bore gauge is

not available, do not use an inside micrometer.

(2) Set the bore gauge to the gauge ring and zero

gauge.

(3) Remove gauge from ring and check cylinder as

shown in (Fig. 8) bore and record reading.

(4) Measure the inside diameter of the cylinder

bore at a point 58.725 mm (2-5/16 inches) below top

of bore. Start perpendicular (across or at 90 degrees)

to the axis of the crankshaft at point B and then take

an additional bore reading 90 degrees to that at point A.

(5) Recheck bore gauge in gauge ring, bore gauge

should read zero. If gauge does not read zero, reset

gauge and start over with procedure.

The coated pistons will be serviced with the piston

pin and connecting rod pre-assembled.The coated

piston connecting rod assembly can be used to

service previous built engines and MUST be re-

placed as complete sets.Tin coated pistons should

not be used as replacements for the new coated pistons.

The coating material is applied to the piston after

the final piston machining process. Measuring the

outside diameter of a coated piston will not provide

accurate results. Therefore, measuring the inside di-

ameter of the cylinder bore with a dial Bore Gauge is

MANDATORY. To correctly select the proper size

piston, a cylinder bore gauge capable of reading in.00019increments is required.

Piston installation into the cylinder bore requires

slightly more pressure than that required for non-

coated pistons. The bonded coating on the piston will

give the appearance of a line-to-line fit with the cyl-

inder bore.

PISTON PIN

Piston pins are press-fitted into the connecting rods

and require no locking device. The piston, piston pin

and connecting rod are replaced as an assembly.

PISTON RING FITTING

(1) Carefully clean the carbon from all ring

grooves. Oil drain openings in the oil ring groove and

pin boss must be clear. DO NOT remove metal from

the grooves or lands. This will change ring-to-groove

clearances and will damage the ring-to-land seating.

(2) Be sure the piston ring grooves are free of nicks

and burrs.

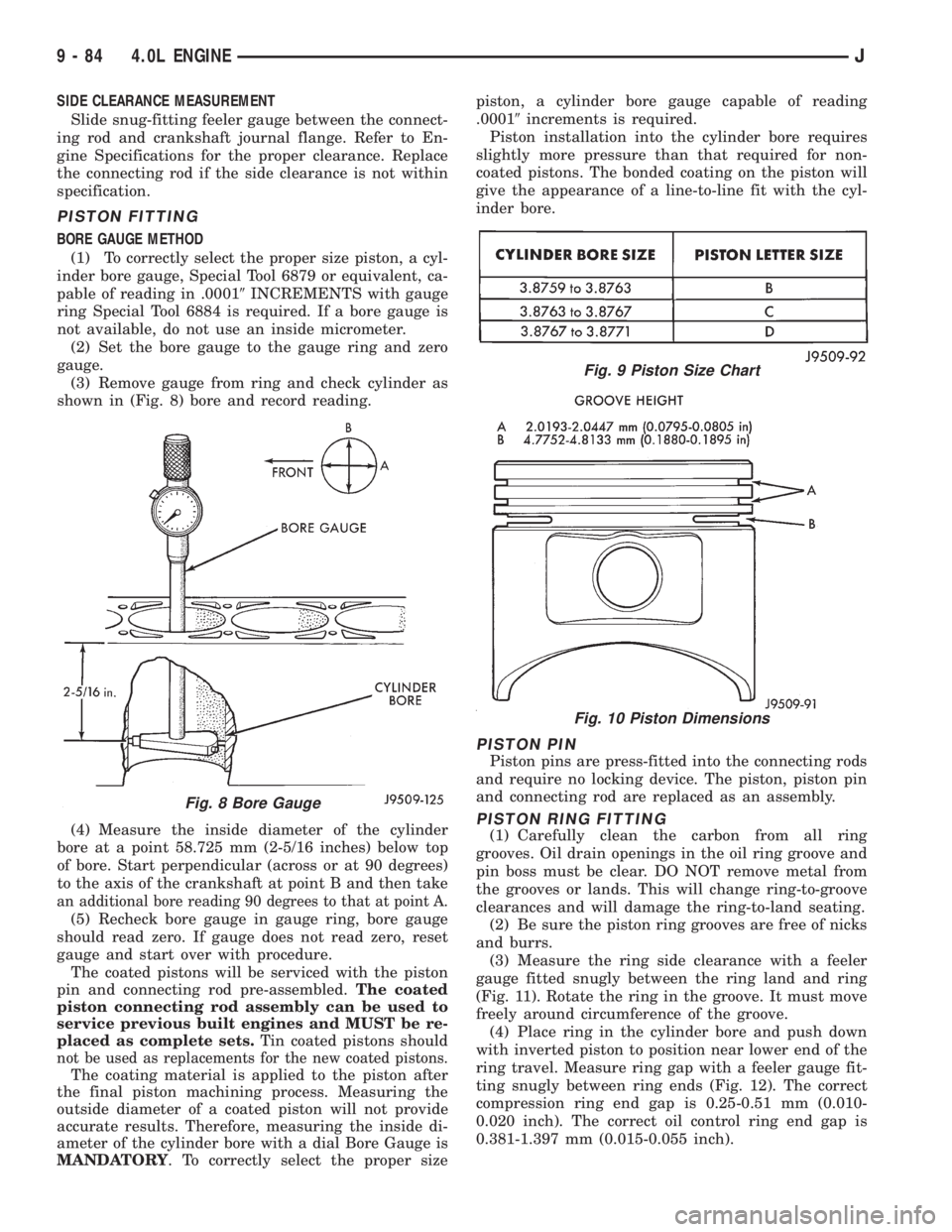

(3) Measure the ring side clearance with a feeler

gauge fitted snugly between the ring land and ring

(Fig. 10). Rotate the ring in the groove. It must move

freely around circumference of the groove.

(4) Place ring in the cylinder bore and push down

with inverted piston to position near lower end of the

ring travel. Measure ring gap with a feeler gauge fit-

ting snugly between ring ends (Fig. 12). The correct

compression ring end gap is 0.25-0.51 mm (0.010-

0.020 inch). The correct oil control ring end gap is

0.381-1.397 mm (0.015-0.055 inch).

Fig. 8 Bore Gauge

Fig. 9 Piston Size Chart

Fig. 10 Piston Dimensions

9 - 42 2.5L ENGINEJ

Page 1175 of 2198

SIDE CLEARANCE MEASUREMENT

Slide snug-fitting feeler gauge between the connect-

ing rod and crankshaft journal flange. Refer to En-

gine Specifications for the proper clearance. Replace

the connecting rod if the side clearance is not within

specification.

PISTON FITTING

BORE GAUGE METHOD

(1) To correctly select the proper size piston, a cyl-

inder bore gauge, Special Tool 6879 or equivalent, ca-

pable of reading in .00019INCREMENTS with gauge

ring Special Tool 6884 is required. If a bore gauge is

not available, do not use an inside micrometer.

(2) Set the bore gauge to the gauge ring and zero

gauge.

(3) Remove gauge from ring and check cylinder as

shown in (Fig. 8) bore and record reading.

(4) Measure the inside diameter of the cylinder

bore at a point 58.725 mm (2-5/16 inches) below top

of bore. Start perpendicular (across or at 90 degrees)

to the axis of the crankshaft at point B and then take

an additional bore reading 90 degrees to that at point A.

(5) Recheck bore gauge in gauge ring, bore gauge

should read zero. If gauge does not read zero, reset

gauge and start over with procedure.

The coated pistons will be serviced with the piston

pin and connecting rod pre-assembled.The coated

piston connecting rod assembly can be used to

service previous built engines and MUST be re-

placed as complete sets.Tin coated pistons should

not be used as replacements for the new coated pistons.

The coating material is applied to the piston after

the final piston machining process. Measuring the

outside diameter of a coated piston will not provide

accurate results. Therefore, measuring the inside di-

ameter of the cylinder bore with a dial Bore Gauge is

MANDATORY. To correctly select the proper sizepiston, a cylinder bore gauge capable of reading

.00019increments is required.

Piston installation into the cylinder bore requires

slightly more pressure than that required for non-

coated pistons. The bonded coating on the piston will

give the appearance of a line-to-line fit with the cyl-

inder bore.

PISTON PIN

Piston pins are press-fitted into the connecting rods

and require no locking device. The piston, piston pin

and connecting rod are replaced as an assembly.

PISTON RING FITTING

(1) Carefully clean the carbon from all ring

grooves. Oil drain openings in the oil ring groove and

pin boss must be clear. DO NOT remove metal from

the grooves or lands. This will change ring-to-groove

clearances and will damage the ring-to-land seating.

(2) Be sure the piston ring grooves are free of nicks

and burrs.

(3) Measure the ring side clearance with a feeler

gauge fitted snugly between the ring land and ring

(Fig. 11). Rotate the ring in the groove. It must move

freely around circumference of the groove.

(4) Place ring in the cylinder bore and push down

with inverted piston to position near lower end of the

ring travel. Measure ring gap with a feeler gauge fit-

ting snugly between ring ends (Fig. 12). The correct

compression ring end gap is 0.25-0.51 mm (0.010-

0.020 inch). The correct oil control ring end gap is

0.381-1.397 mm (0.015-0.055 inch).

Fig. 8 Bore Gauge

Fig. 9 Piston Size Chart

Fig. 10 Piston Dimensions

9 - 84 4.0L ENGINEJ

Page 1198 of 2198

FRAME AND BUMPERS

CONTENTS

page page

BUMPERS.............................. 5

BUMPERS............................. 16FRAME................................. 1

FRAME................................ 10

FRAME

INDEX

page page

Frame Dimensions......................... 1

Front Skid Plate........................... 1

Fuel Filler Hose Splash ShieldÐXJ Vehicles...... 4

Fuel Tank Skid Plate........................ 3Fuel Tank Support Strap..................... 4

General Information........................ 1

Transfer Case Skid Plate.................... 3

GENERAL INFORMATION

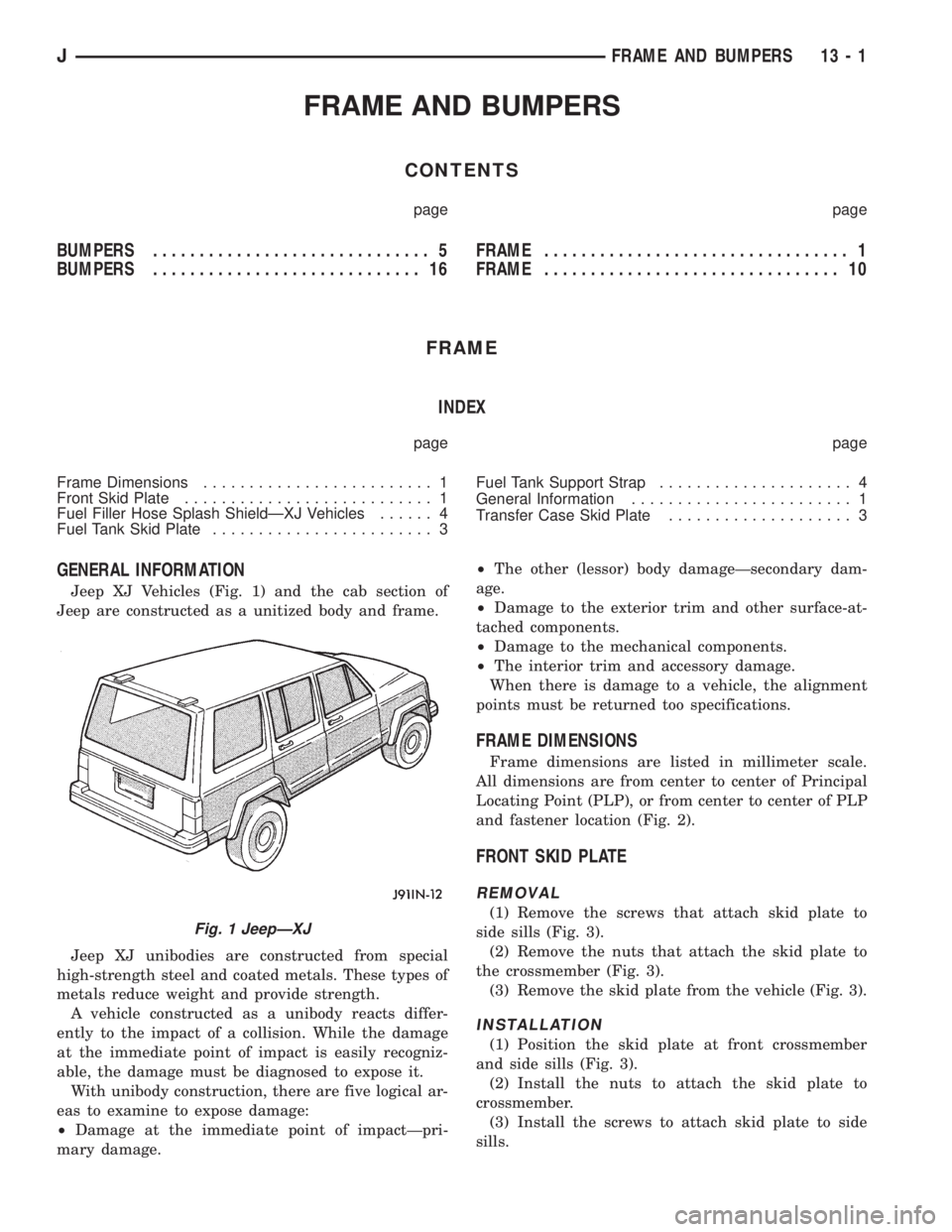

Jeep XJ Vehicles (Fig. 1) and the cab section of

Jeep are constructed as a unitized body and frame.

Jeep XJ unibodies are constructed from special

high-strength steel and coated metals. These types of

metals reduce weight and provide strength.

A vehicle constructed as a unibody reacts differ-

ently to the impact of a collision. While the damage

at the immediate point of impact is easily recogniz-

able, the damage must be diagnosed to expose it.

With unibody construction, there are five logical ar-

eas to examine to expose damage:

²Damage at the immediate point of impactÐpri-

mary damage.²The other (lessor) body damageÐsecondary dam-

age.

²Damage to the exterior trim and other surface-at-

tached components.

²Damage to the mechanical components.

²The interior trim and accessory damage.

When there is damage to a vehicle, the alignment

points must be returned too specifications.

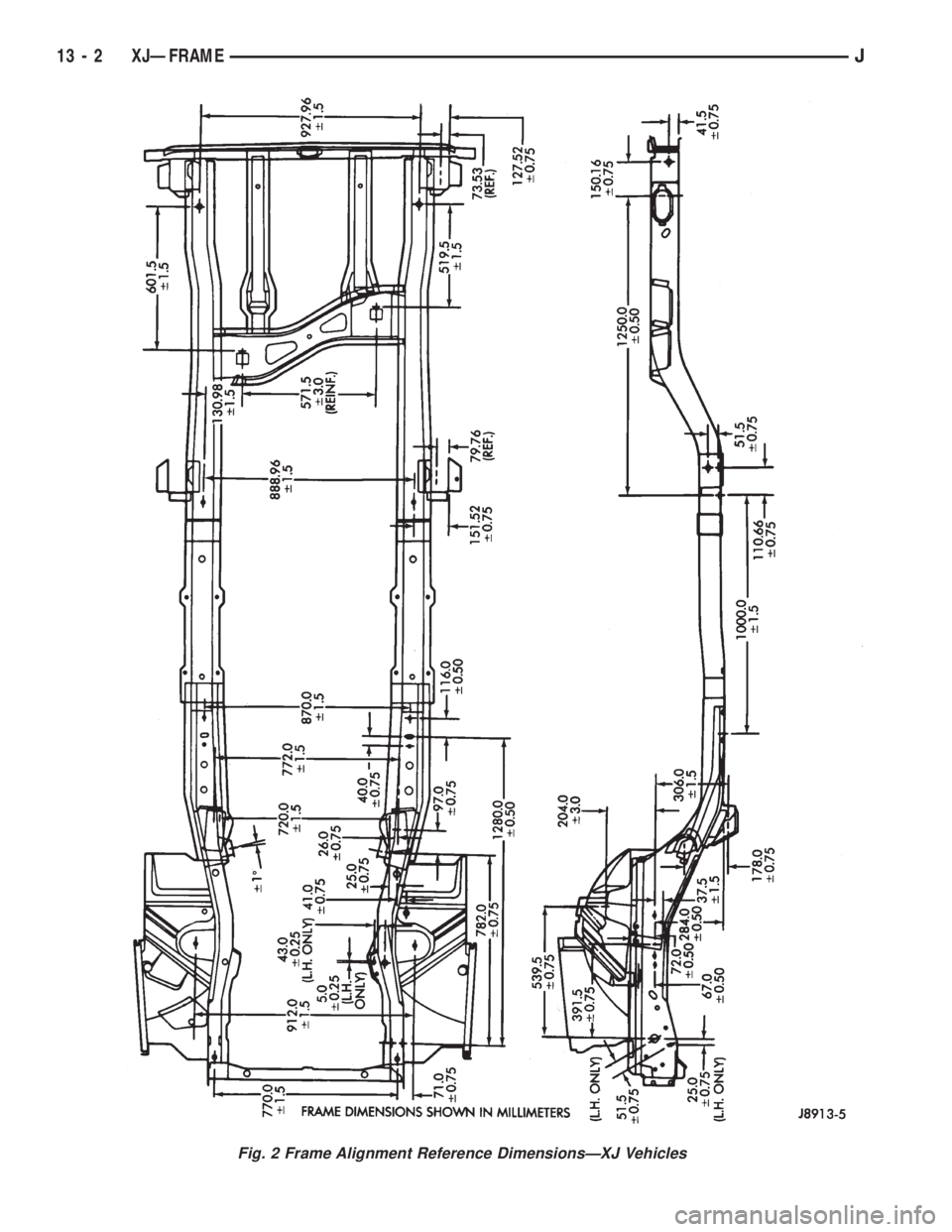

FRAME DIMENSIONS

Frame dimensions are listed in millimeter scale.

All dimensions are from center to center of Principal

Locating Point (PLP), or from center to center of PLP

and fastener location (Fig. 2).

FRONT SKID PLATE

REMOVAL

(1) Remove the screws that attach skid plate to

side sills (Fig. 3).

(2) Remove the nuts that attach the skid plate to

the crossmember (Fig. 3).

(3) Remove the skid plate from the vehicle (Fig. 3).

INSTALLATION

(1) Position the skid plate at front crossmember

and side sills (Fig. 3).

(2) Install the nuts to attach the skid plate to

crossmember.

(3) Install the screws to attach skid plate to side

sills.

Fig. 1 JeepÐXJ

JFRAME AND BUMPERS 13 - 1

Page 1199 of 2198

Fig. 2 Frame Alignment Reference DimensionsÐXJ Vehicles

13 - 2 XJÐFRAMEJ

Page 1207 of 2198

FRAME

INDEX

page page

Frame Dimensions........................ 13

Frame Repairs........................... 13

Frame Straightening....................... 13

Fuel Tank Skid Plate....................... 15

General Information....................... 10Generator Splash Shield.................... 13

Safety Precautions and Warnings............. 10

Tow Hooks.............................. 13

Transfer Case Skid Plate.................... 15

SAFETY PRECAUTIONS AND WARNINGS

WARNING: USE EYE PROTECTION WHEN GRIND-

ING OR WELDING METAL, SERIOUS EYE INJURY

CAN RESULT.

BEFORE PROCEEDING WITH FRAME REPAIR IN-

VOLVING GRINDING OR WELDING, VERIFY THAT

VEHICLE FUEL SYSTEM IS NOT LEAKING OR IN

CONTACT WITH REPAIR AREA, PERSONAL INJURY

CAN RESULT.

DO NOT ALLOW OPEN FLAME TO CONTACT

PLASTIC BODY PANELS. FIRE OR EXPLOSION CAN

RESULT.

WHEN WELDED FRAME COMPONENTS ARE RE-

PLACED, 100% PENETRATION WELD MUST BE

ACHIEVED DURING INSTALLATION. IF NOT, DAN-

GEROUS OPERATING CONDITIONS CAN RESULT.

STAND CLEAR OF CABLES OR CHAINS ON

PULLING EQUIPMENT DURING FRAME STRAIGHT-

ENING OPERATIONS, PERSONAL INJURY CAN RE-

SULT.

DO NOT VENTURE UNDER A HOISTED VEHICLE

THAT IS NOT SUPPORTED ON SAFETY STANDS,

PERSONAL INJURY CAN RESULT.

CAUTION: Do not reuse damaged fasteners, quality

of repair would be suspect.

Do not drill holes in top or bottom frame rail

flanges, frame rail failure can result.

Do Not use softer than Grade 3 bolts to replace

production fasteners, loosening or failure can re-

sult.When using heat to straighten frame components

do not exceed 566ÉC (1050ÉF), metal fatigue can re-

sult.

Welding the joints around riveted cross members

and frame side rails can weaken frame

GENERAL INFORMATION

The Jeep YJ (Fig. 1) frame is the structural center

of the vehicle. In addition to supporting the body and

payload, the frame provides a station for the engine.

The vehicle body is attached to the frame with hold-

downs (Fig. 2 and 3).

Fig. 1 JeepÐYJ

13 - 10 YJÐFRAMEJ

Page 1210 of 2198

The frame is constructed of high-strength channel

steel siderails and crossmembers. The crossmembers

join the siderails and retain them in alignment in re-

lation to each other. This provides resistance to

frame twists and strains.

FRAME STRAIGHTENING

When necessary, a conventional frame that is bent

or twisted can be straightened by application of heat.

The temperature must not exceed 566ÉC (1050ÉF).

The use of a specially designed heat crayon can de-

termine the desired temperature. Excessive heat will

decrease the strength of the metal and result in a

weakened frame.

Welding the joints around riveted cross members

and frame side rails is not recommended.

A straightening repair process should be limited to

frame members that are not severely damaged.

FRAME REPAIRS

DRILLING HOLES

Do not drill holes in frame side rail top and bottom

flanges, metal fatigue can result causing frame fail-

ure. Holes drilled in the side of the frame rail must

be at least 38 mm (1.5 in.) from the top and bottom

flanges.

Additional drill holes should be located away from

existing holes.

WELDING

Use MIG, TIG or arc welding equipment to repair

welded frame components.

Frame components that have been damaged should

be inspected for cracks before returning the vehicle

to use. If cracks are found in accessible frame com-

ponents perform the following procedures.

(1) Drill a hole at each end of the crack with a 3

mm (O.125 in.) diameter drill bit.

(2) Using a suitable die grinder with 3 inch cut off

wheel, V-groove the crack to allow 100% weld pene-

tration.

(3) Weld the crack.

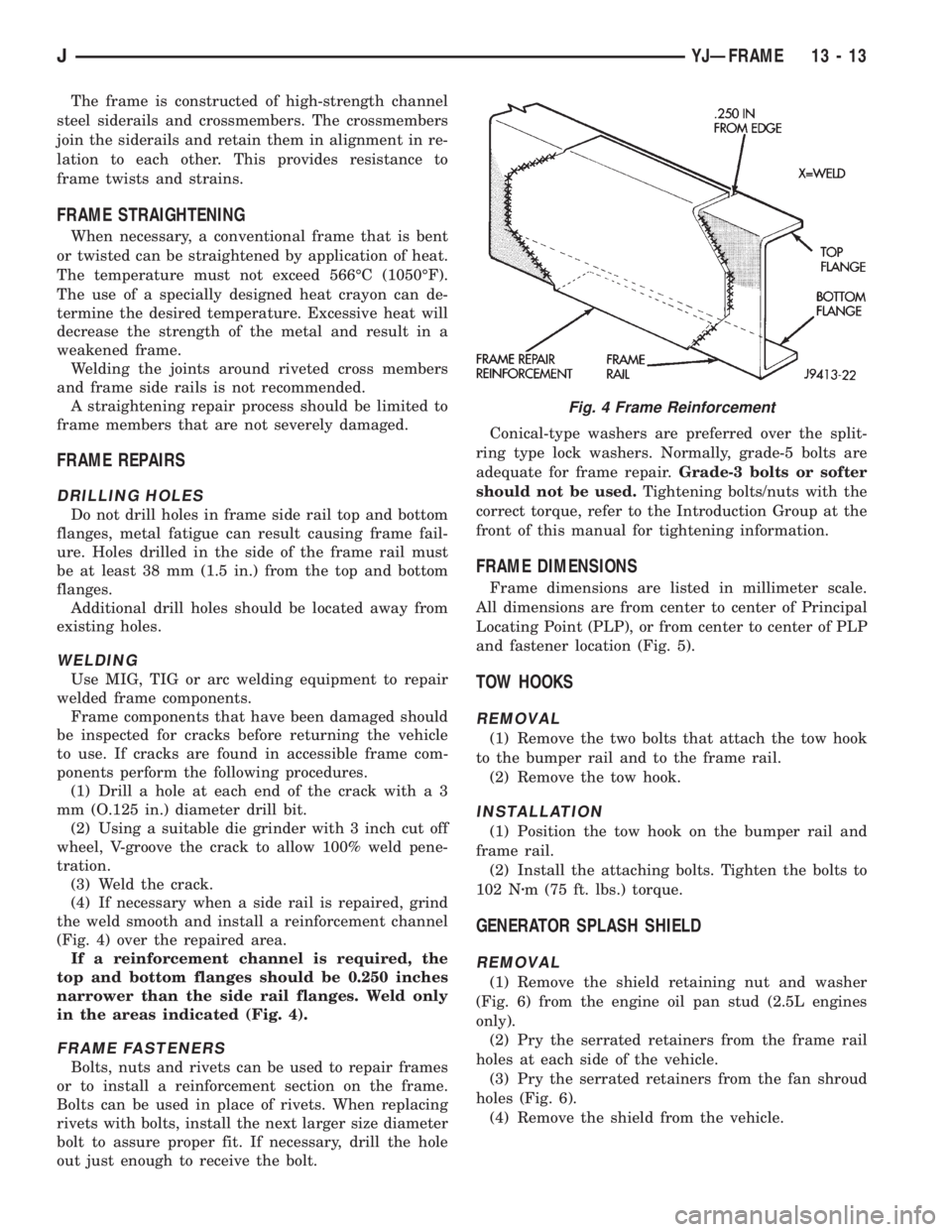

(4) If necessary when a side rail is repaired, grind

the weld smooth and install a reinforcement channel

(Fig. 4) over the repaired area.

If a reinforcement channel is required, the

top and bottom flanges should be 0.250 inches

narrower than the side rail flanges. Weld only

in the areas indicated (Fig. 4).

FRAME FASTENERS

Bolts, nuts and rivets can be used to repair frames

or to install a reinforcement section on the frame.

Bolts can be used in place of rivets. When replacing

rivets with bolts, install the next larger size diameter

bolt to assure proper fit. If necessary, drill the hole

out just enough to receive the bolt.Conical-type washers are preferred over the split-

ring type lock washers. Normally, grade-5 bolts are

adequate for frame repair.Grade-3 bolts or softer

should not be used.Tightening bolts/nuts with the

correct torque, refer to the Introduction Group at the

front of this manual for tightening information.

FRAME DIMENSIONS

Frame dimensions are listed in millimeter scale.

All dimensions are from center to center of Principal

Locating Point (PLP), or from center to center of PLP

and fastener location (Fig. 5).

TOW HOOKS

REMOVAL

(1) Remove the two bolts that attach the tow hook

to the bumper rail and to the frame rail.

(2) Remove the tow hook.

INSTALLATION

(1) Position the tow hook on the bumper rail and

frame rail.

(2) Install the attaching bolts. Tighten the bolts to

102 Nzm (75 ft. lbs.) torque.

GENERATOR SPLASH SHIELD

REMOVAL

(1) Remove the shield retaining nut and washer

(Fig. 6) from the engine oil pan stud (2.5L engines

only).

(2) Pry the serrated retainers from the frame rail

holes at each side of the vehicle.

(3) Pry the serrated retainers from the fan shroud

holes (Fig. 6).

(4) Remove the shield from the vehicle.

Fig. 4 Frame Reinforcement

JYJÐFRAME 13 - 13