j-2 JEEP CHEROKEE 1995 Service Repair Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 1995, Model line: CHEROKEE, Model: JEEP CHEROKEE 1995Pages: 2198, PDF Size: 82.83 MB

Page 4 of 2198

FLUID CAPACITIES

Fuel Tank

XJ .....................................................76.4 L (20.2 gal.)

YJ(Standard) ......................................56.8 L (15 gal.)

YJ(Optional) .......................................75.7 L (20 gal.)

Engine Oil

2.5L ......................................................3.8 L (4.0 qts.)

4.0L ......................................................5.7 L (6.0 qts.)

Cooling System

2.5L(XJ).............................................9.5 L* (10 qts.*)

2.5L(YJ) ........................................8.5 L** (9.0 qts.**)

4.0L(XJ) ........................................11.4 L* (12.0 qts.*)

4.0L(YJ) ......................................9.9 L** (10.5 qts.**)

* Includes (2.2 L) (2.3 qts) for coolant recovery res-

ervoir.

** Includes (0.9 L) (1.0 qt.) for coolant recovery res-

ervoir.

Automatic Transmission

Dry fill capacity.*

AW4 (XJ-4.0L) ...................................8.0 L (16.9 pts.)

30RH (YJ-2.5L) .................................8.2 L (17.5 pts.)

32RH (YJ-4.0L) .................................8.2 L (17.5 pts.)

*Depending on type and size of internal cooler,

length and inside diameter of cooler lines, or use ofan auxiliary cooler, these figures may vary. Refer to

Group 21, Transmission for proper fluid fill proce-

dure.

Manual Transmission

AX4/5 (4X2) .........................................3.3 L (3.5 qts.)

AX5 (4X4) ............................................3.2 L (3.3 qts.)

AX15 (4X2) ..........................................3.1 L (3.2 qts.)

AX15 (4X4) ......................................3.15 L (3.32 qts.)

Fill to bottom of fill hole.

Transfer Case

SELEC-TRAC 242(XJ) .......................1.4 L (3.0 pts.)

COMMAND-TRAC 231(XJ) ...............1.0 L (2.2 pts.)

COMMAND-TRAC 231(YJ-Man Trans) ..1.5 L (3.25

pts.)

COMMAND-TRAC 231(YJ-Auto Trans) ....1.0 L (2.2

pts.)

Front Axle

MODEL 30 (YJ) ..............................1.65 L (3.76 pts.)

MODEL 30 (XJ) ..............................1.48 L (3.13 pts.)

Rear Axle

MODEL 35 (XJ-YJ) ........................1.6 L (3.38 pts.*)

8-1/4 (XJ) .........................................2.08 L (4.4 pts.*)

* When equipped with TRAC-LOK, include 2

ounces of Friction Modifier Additive.

JLUBRICATION AND MAINTENANCE 0 - 3

Page 121 of 2198

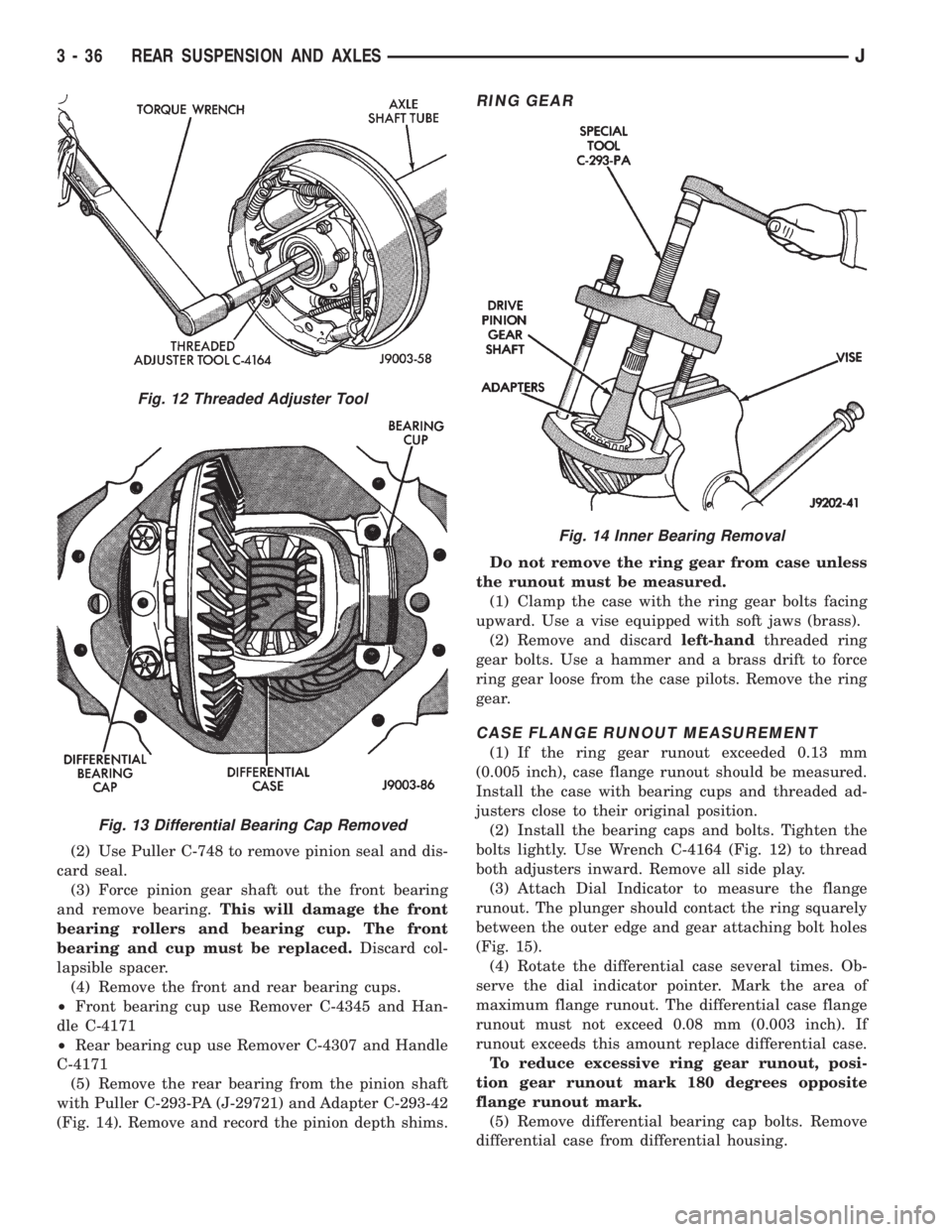

(2) Use Puller C-748 to remove pinion seal and dis-

card seal.

(3) Force pinion gear shaft out the front bearing

and remove bearing.This will damage the front

bearing rollers and bearing cup. The front

bearing and cup must be replaced.Discard col-

lapsible spacer.

(4) Remove the front and rear bearing cups.

²Front bearing cup use Remover C-4345 and Han-

dle C-4171

²Rear bearing cup use Remover C-4307 and Handle

C-4171

(5) Remove the rear bearing from the pinion shaft

with Puller C-293-PA (J-29721) and Adapter C-293-42

(Fig. 14). Remove and record the pinion depth shims.

RING GEAR

Do not remove the ring gear from case unless

the runout must be measured.

(1) Clamp the case with the ring gear bolts facing

upward. Use a vise equipped with soft jaws (brass).

(2) Remove and discardleft-handthreaded ring

gear bolts. Use a hammer and a brass drift to force

ring gear loose from the case pilots. Remove the ring

gear.

CASE FLANGE RUNOUT MEASUREMENT

(1) If the ring gear runout exceeded 0.13 mm

(0.005 inch), case flange runout should be measured.

Install the case with bearing cups and threaded ad-

justers close to their original position.

(2) Install the bearing caps and bolts. Tighten the

bolts lightly. Use Wrench C-4164 (Fig. 12) to thread

both adjusters inward. Remove all side play.

(3) Attach Dial Indicator to measure the flange

runout. The plunger should contact the ring squarely

between the outer edge and gear attaching bolt holes

(Fig. 15).

(4) Rotate the differential case several times. Ob-

serve the dial indicator pointer. Mark the area of

maximum flange runout. The differential case flange

runout must not exceed 0.08 mm (0.003 inch). If

runout exceeds this amount replace differential case.

To reduce excessive ring gear runout, posi-

tion gear runout mark 180 degrees opposite

flange runout mark.

(5) Remove differential bearing cap bolts. Remove

differential case from differential housing.

Fig. 12 Threaded Adjuster Tool

Fig. 13 Differential Bearing Cap Removed

Fig. 14 Inner Bearing Removal

3 - 36 REAR SUSPENSION AND AXLESJ

Page 131 of 2198

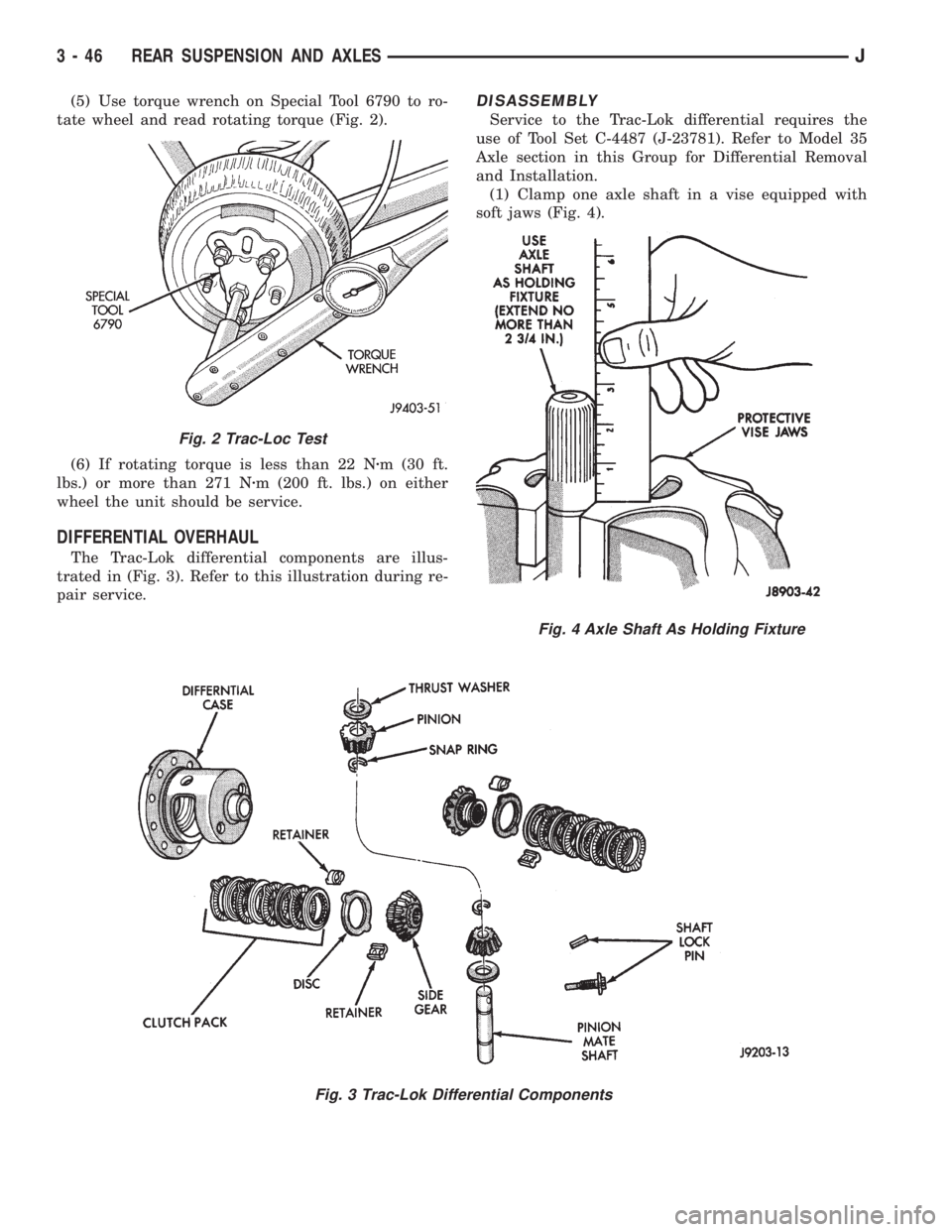

(5) Use torque wrench on Special Tool 6790 to ro-

tate wheel and read rotating torque (Fig. 2).

(6) If rotating torque is less than 22 Nzm (30 ft.

lbs.) or more than 271 Nzm (200 ft. lbs.) on either

wheel the unit should be service.

DIFFERENTIAL OVERHAUL

The Trac-Lok differential components are illus-

trated in (Fig. 3). Refer to this illustration during re-

pair service.

DISASSEMBLY

Service to the Trac-Lok differential requires the

use of Tool Set C-4487 (J-23781). Refer to Model 35

Axle section in this Group for Differential Removal

and Installation.

(1) Clamp one axle shaft in a vise equipped with

soft jaws (Fig. 4).

Fig. 3 Trac-Lok Differential Components

Fig. 2 Trac-Loc Test

Fig. 4 Axle Shaft As Holding Fixture

3 - 46 REAR SUSPENSION AND AXLESJ