open hood JEEP CHEROKEE 1995 Service Repair Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 1995, Model line: CHEROKEE, Model: JEEP CHEROKEE 1995Pages: 2198, PDF Size: 82.83 MB

Page 10 of 2198

JUMP STARTING, TOWING AND HOISTING

INDEX

page page

Four-Wheel-Drive Vehicle Towing............. 12

Ground Clearance and Ramp Angle............ 11

Hoisting Recommendations.................. 10

Jump Starting Procedure..................... 9Towing Recommendations................... 10

Towing When Keys Are Not Available.......... 13

Two-Wheel-Drive Vehicle TowingÐXJ.......... 11

JUMP STARTING PROCEDURE

WARNING: DO NOT ATTEMPT TO PUSH OR TOW A

VEHICLE TO START THE ENGINE. UNBURNED

FUEL COULD ENTER THE EXHAUST CATALYTIC

CONVERTER AND IGNITE AFTER THE ENGINE IS

STARTED. THIS COULD CAUSE THE CONVERTER

TO OVERHEAT AND RUPTURE.

WARNING: REVIEW ALL SAFETY PRECAUTIONS

AND WARNINGS IN GROUP 8A, BATTERY/START-

ING/CHARGING SYSTEMS DIAGNOSTICS.

DO NOT JUMP START A FROZEN BATTERY, PER-

SONAL INJURY CAN RESULT.

DO NOT JUMP START WHEN MAINTENANCE

FREE BATTERY INDICATOR DOT IS YELLOW OR

BRIGHT COLOR.

DO NOT JUMP START A VEHICLE WHEN THE

BATTERY FLUID IS BELOW THE TOP OF LEAD

PLATES.

DO NOT ALLOW JUMPER CABLE CLAMPS TO

TOUCH EACH OTHER WHEN CONNECTED TO A

BOOSTER SOURCE.

DO NOT USE OPEN FLAME NEAR BATTERY.

REMOVE METALLIC JEWELRY WORN ON HANDS

OR WRISTS TO AVOID INJURY BY ACCIDENTAL

ARCING OF BATTERY CURRENT.

WHEN USING A HIGH OUTPUT BOOSTING DE-

VICE, DO NOT ALLOW BATTERY VOLTAGE TO EX-

CEED 16 VOLTS. REFER TO INSTRUCTIONS

PROVIDED WITH DEVICE BEING USED.

CAUTION: When using another vehicle as a

booster, do not allow vehicles to touch. Electrical

systems can be damaged on either vehicle.

TO JUMP START A DISABLED VEHICLE:

(1) Raise hood on disabled vehicle and visually in-

spect engine compartment for:

²Battery cable clamp condition, clean if necessary.

²Frozen battery.

²Yellow or bright color test indicator, if equipped.

²Low battery fluid level.

²Generator drive belt condition and tension.²Fuel fumes or leakage, correct if necessary.

CAUTION: If the cause of starting problem on dis-

abled vehicle is severe, damage to booster vehicle

charging system can result.

(2) When using another vehicle as a booster

source, turn off all accessories, place gear selector in

park or neutral, set park brake and operate engine at

1200 rpm.

(3) On disabled vehicle, place gear selector in park

or neutral and set park brake. Turn off all accesso-

ries.

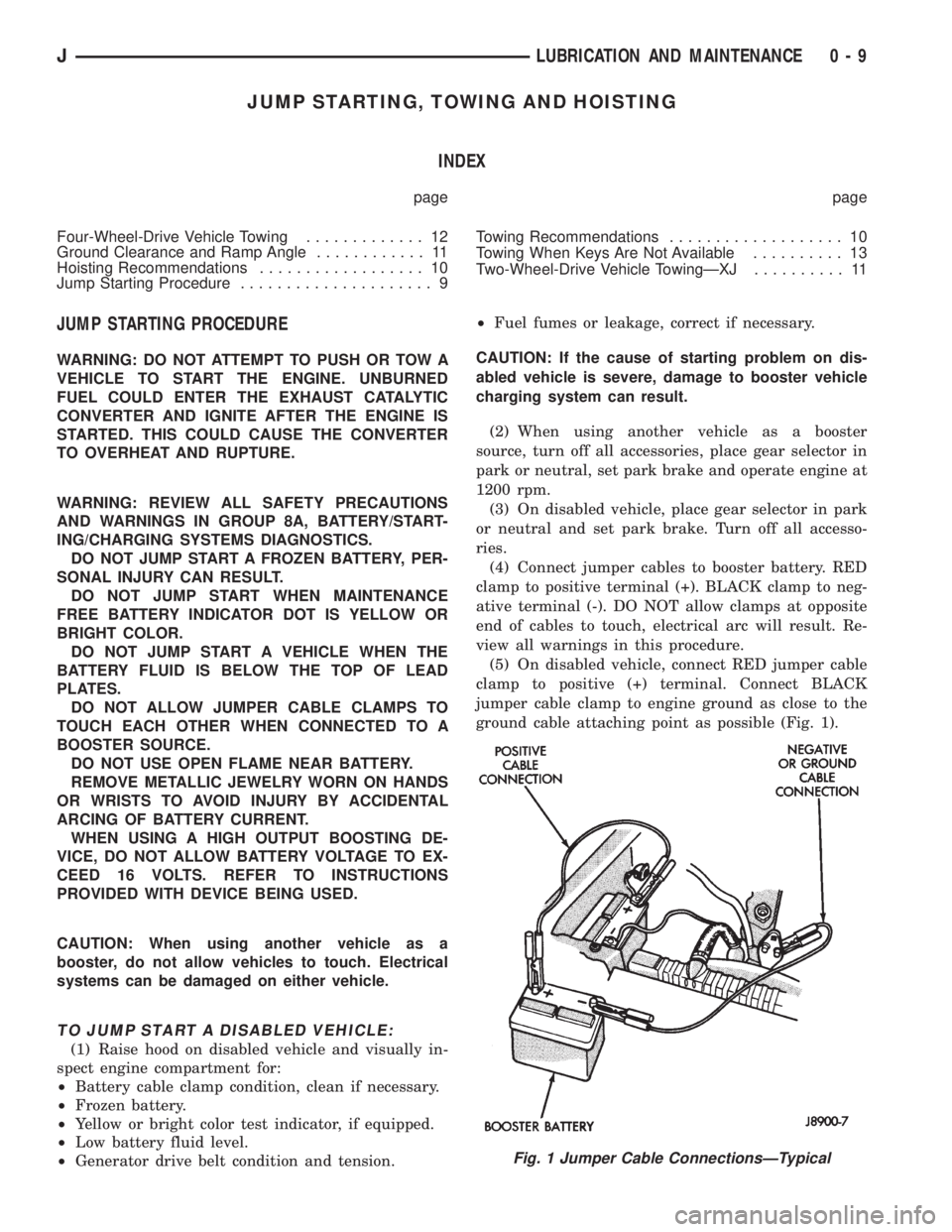

(4) Connect jumper cables to booster battery. RED

clamp to positive terminal (+). BLACK clamp to neg-

ative terminal (-). DO NOT allow clamps at opposite

end of cables to touch, electrical arc will result. Re-

view all warnings in this procedure.

(5) On disabled vehicle, connect RED jumper cable

clamp to positive (+) terminal. Connect BLACK

jumper cable clamp to engine ground as close to the

ground cable attaching point as possible (Fig. 1).

Fig. 1 Jumper Cable ConnectionsÐTypical

JLUBRICATION AND MAINTENANCE 0 - 9

Page 21 of 2198

line. You may encounter fuels containing 3 percent or

more methanol along with other alcohols called cosol-

vents.

Problems that are the result of using methanol/gas-

oline blends are not the responsibility of Chrysler

Corporation. They may not be covered by the vehicle

warranty.

MTBE/ETBE

Gasoline and MTBE (Methyl Tertiary Butyl Ether)

blends are a mixture of unleaded gasoline and up to

15 percent MTBE. Gasoline and ETBE (Ethyl Ter-

tiary Butyl Ether) are blends of gasoline and up to

17 percent ETBE. Gasoline blended with MTBE or

ETBE may be used.

CLEAN AIR GASOLINE

Many gasolines are now being blended that con-

tribute to cleaner air, especially in those areas of the

country where air pollution levels are high. These

new blends provide a cleaner burning fuel and some

are referred to asReformulated Gasoline.

In areas of the country where carbon monoxide lev-

els are high, gasolines are being treated with oxygen-

ated materials such as MTBE, ETBE and ethanol.

Chrysler Corporation supports these efforts toward

cleaner air and recommends the use of these gaso-

lines as they become available.

IGNITION CABLES, DISTRIBUTOR CAP AND

ROTOR

Inspect and test ignition cables, distributor cap and

rotor when the spark plugs are replaced. Oil and

grime should be cleaned from the ignition cables and

distributor cap to avoid possible spark plug fouling.

Mopar Foamy Engine Degreaser or equivalent is rec-

ommended for cleaning the engine compartment. For

proper service and diagnostic procedures refer to

Group 8D, Ignition System.

IGNITION TIMING

The ignition timing for 2.5L and 4.0L engines is

not adjustable. Refer to the specifications listed on

the engine Emission Control Information Label. Re-

fer to Group 25, Emission Control Systems for addi-

tional information.

SPARK PLUGS

Ignition spark plugs should be replaced at the

mileage interval described in the Lubrication and

Maintenance Schedules. Refer to the General Infor-

mation section of this group. For proper service pro-

cedures refer to Group 8D, Ignition Systems.

BATTERY

WARNING: WEAR SAFETY GLASSES, RUBBER

GLOVES AND PROTECTIVE CLOTHING WHEN HAN-DLING/SERVICING A BATTERY. THE BATTERY

ELECTROLYTE CONTAINS SULFURIC ACID AND

WILL CAUSE HARM IF IT CONTACTS SKIN, EYES

OR CLOTHING. IT WILL ALSO DAMAGE PAINTED

(AS WELL AS UN-PAINTED) SURFACES OF A VEHI-

CLE. IF SULFURIC ACID CONTACTS ANY OF

THESE, FLUSH IMMEDIATELY WITH LARGE

AMOUNTS OF WATER. IF SULFURIC ACID CON-

TACTS SKIN OR EYES, GET IMMEDIATE MEDICAL

ATTENTION. DO NOT SMOKE IN THE VICINITY OF A

BATTERY. KEEP OPEN FLAMES AND SPARKS

AWAY FROM BATTERY FILLER CAPS BECAUSE

EXPLOSIVE GAS IS ALWAYS PRESENT.

Inspect battery tray, hold down and terminal con-

nections when other under hood service is performed.

For proper diagnostic procedures refer to Group 8A,

Battery/Starting/Charging System Diagnostics. For

service and cleaning procedures refer to Group 8B,

Battery/Starter Service.

Care should be taken when disposing a bat-

tery after removal from a vehicle. Lead-acid

batteries are highly poisonous and, when indis-

criminately disposed, could create a problem

for the environment. Contact the applicable lo-

cal city or county government agency to deter-

mine where automobile (lead-acid) batteries

can be properly disposed in the local area.

RUBBER AND PLASTIC COMPONENT INSPECTION

CAUTION: Plastic hoses or wire harness covers will

melt or deform when exposed to heat from exhaust

system or engine manifolds.

Position plastic or rubber components away from

moving parts in engine compartment or under vehi-

cle, or damage will result.

Do not allow rubber engine mounts or other com-

ponents to become oil contaminated, repair cause

of oil contamination and clean area.

All rubber and plastic components should be in-

spected when engine compartment or under vehicle

service is performed. When evidence of deterioration

exists, replacement is required. To reduce deteriora-

tion of rubber components, Chrysler Corporation rec-

ommends Mopar Foamy Engine Degreaser or

equivalent be used to clean engine compartment of

oil and road grime.

EMISSION CONTROL SYSTEM

Inspect all emission control components and hoses

when other under hood service is performed. Refer to

emission system Vacuum Hose Label located on the

inside of the hood in the engine compartment and

Group 25, Emission Control Systems for proper ser-

vice procedures.

0 - 20 LUBRICATION AND MAINTENANCEJ

Page 23 of 2198

DRIVETRAIN

INDEX

page page

Automatic Transmission.................... 23

Clutch and Brake Pedal Bushings............. 22

Clutch Master Cylinder..................... 22

Drive Shafts............................. 26Front and Rear Axles...................... 24

Manual Transmission...................... 22

Rubber and Plastic Hoses/Tubing............. 26

Transfer Case (4WD Vehicles)................ 24

CLUTCH AND BRAKE PEDAL BUSHINGS

If the clutch and brake pedal mechanism squeaks,

the pivot bushings should be lubricated. Use Mopar

Multi-Purpose Lubricant, or an equivalent. Refer to

Group 5, Brakes for location of bushings.

CLUTCH MASTER CYLINDER

LEVEL INSPECTION

WARNING: DO NOT ALLOW PETROLEUM OR WA-

TER BASE LIQUIDS TO CONTAMINATE CLUTCH

FLUID, SEAL DAMAGE AND CLUTCH FAILURE CAN

RESULT.

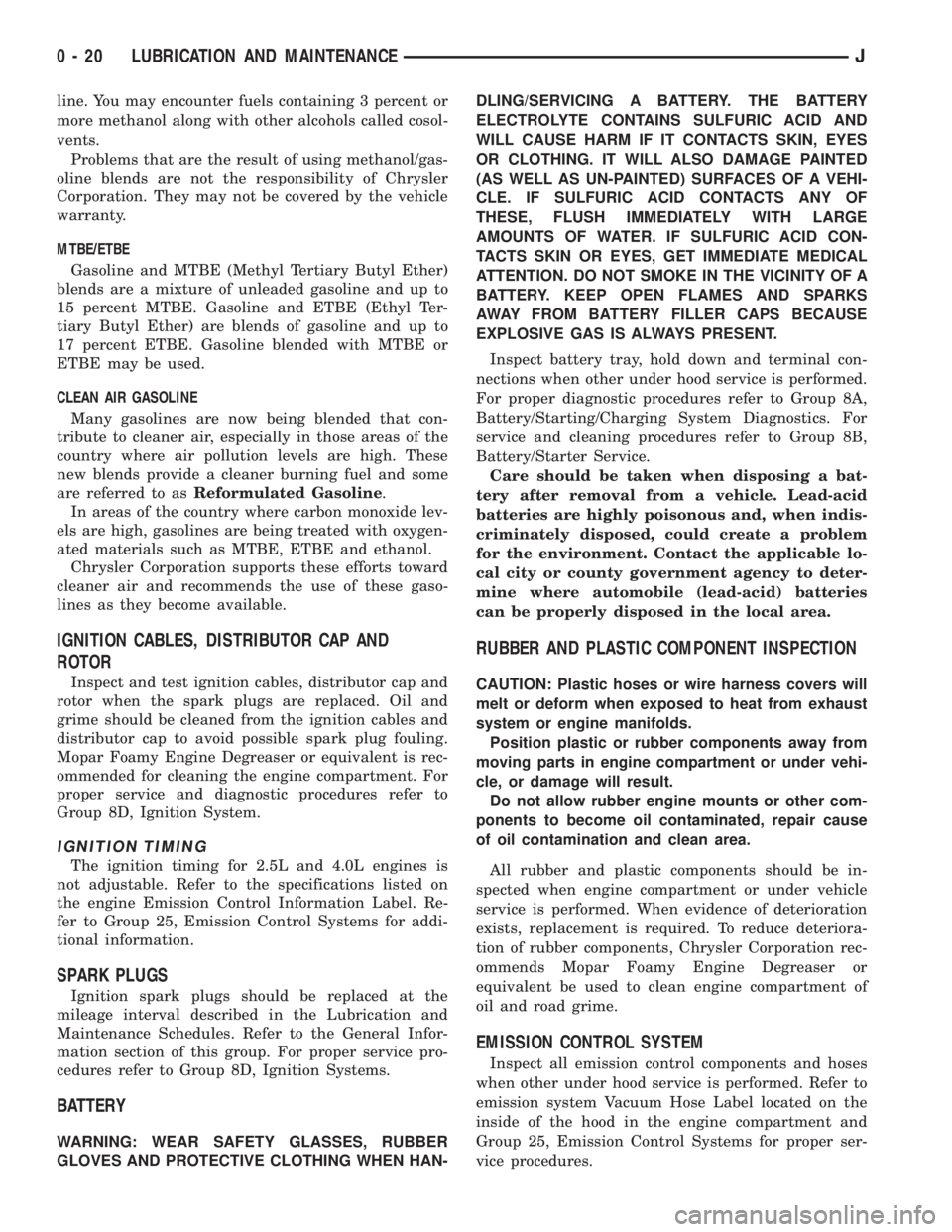

The clutch reservoir level should be inspected when

other underhood service is performed. (Fig. 1)

The fluid level is determined by its height in rela-

tion to the level indicator ring (Fig. 2) located inside

the reservoir. Add fluid until the height is level with

the indicator ring.

FLUID SPECIFICATION

Use Mopar, Brake And Hydraulic Clutch Fluid or

equivalent. Use only brake fluid conforming to DOT

3, Federal, Department of Transportation specifica-

tion. To avoid fluid contamination, use fluid from a

properly sealed container.CAUTION: Never use reclaimed brake fluid or fluid

from an unsealed container. In addition, do not use

fluid from a container that has been opened and al-

lowed to stand for an extended length of time.

Moisture in the air can be absorbed by the fluid,

which causes dilution with loss of effectiveness.

MANUAL TRANSMISSION

The manual transmission should be inspected for

oil leaks and proper oil level when other under vehi-

cle service is performed.

LUBRICANT SPECIFICATION

When it becomes necessary to add to or change the

lube oil in a Jeep manual transmission, use SAE

75W-90, API Quality Grade GL-5 gear lubricant.

LUBRICANT LEVEL

The fill-hole plug for all manual transmissions is

located on the right side of the case (Fig. 3). Deter-

mine the lubricant level according to the following

procedure.

(1) Remove the fill-hole plug (Fig. 3) from the

transmission. The lube oil should be level with the

bottom edge of the fill hole. The level can be slightly

below the bottom edge of the fill hole if the lube oil is

cold.

Fig. 1 Clutch Reservoir LocationÐTypical

Fig. 2 Hydraulic Clutch Fluid LevelÐTypical

0 - 22 LUBRICATION AND MAINTENANCEJ

Page 254 of 2198

(4) For access to radiator draincock, remove radia-

tor grille mounting screws and remove grill. Refer to

Group 23, Body for procedures.

(5) Attach one end of a 24 inch long X 1/4 inch ID

hose to the radiator draincock. Put the other end into

a clean container. Open draincock and drain radiator.

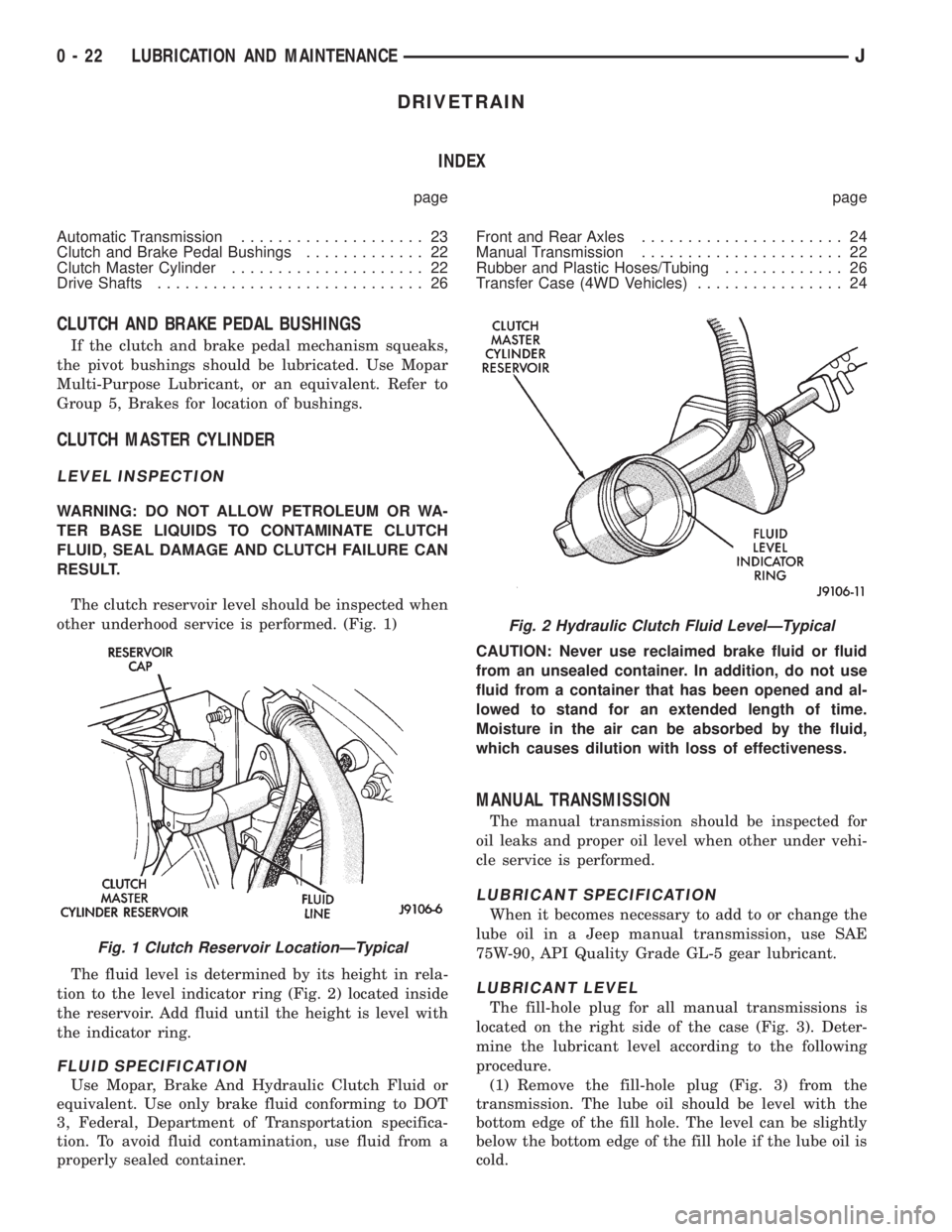

(6) If equipped, disconnect auxiliary electric cooling

fan electrical connector (Fig. 31).

(7) If equipped, remove two electric cooling fan

mounting bolts. Lift cooling fan straight up until

alignment tabs at the bottom are clear of slots in

bracket at bottom of radiator (Fig. 32).

(8) Remove the two mechanical (non-electrical) fan

shroud mounting bolts. Lift shroud straight up until

alignment tabs at the bottom are clear of slots in

bracket at bottom of radiator (Fig. 32). Place shroud

over mechanical fan.

(9) If equipped, disconnect and plug automatic

transmission fluid cooler lines. Refer to Group 21,

Transmissions for procedures. If equipped with re-

mote transmission cooler, remove line to cooler from

bracket at bottom of radiator.

(10) Disconnect radiator upper and lower hoses

clamps (Figs. 27 and 28). Disconnect radiator upper

and lower hoses.

(11) Mark the position of the hood latch striker on

the radiator crossmember and remove hood latch

striker.(12) Remove two radiator upper crossmember-to-

isolator nuts (Fig. 32).

Fig. 31 Auxiliary Electric Cooling Fan Wiring

ConnectorÐTypical

Fig. 32 Auxiliary Electric Cooling Fan and Fan ShroudÐTypical

JCOOLING SYSTEM SERVICE PROCEDURES 7 - 29

Page 281 of 2198

IGNITION-OFF DRAW

GENERAL INFORMATION

Ignition-Off Draw (IOD) refers to power being

drained from the battery with the ignition switch

turned OFF. A normal vehicle electrical system will

draw from 5 to 20 milliamps (0.005 - 0.020 amps).

This is with the ignition switch in the OFF position,

and all non-ignition controlled circuits in proper

working order. The 20 milliamps are needed to sup-

ply PCM memory, digital clock memory, and electron-

ically-tuned radio memory.

A vehicle that has not been operated for approxi-

mately 20 days, may discharge the battery to an in-

adequate level. When a vehicle will not be used for

20 days or more (stored), remove the IOD fuse in the

Power Distribution Center (PDC). This will reduce

battery discharging.

Excessive battery drain can be caused by:

²electrical items left on

²faulty or improperly adjusted switches

²internally shorted generator

²intermittent shorts in the wiring.

If the IOD is over 20 milliamps, the problem must

be found and corrected before replacing a battery. In

most cases, the battery can be charged and returned

to service.

DIAGNOSIS

Testing for high-amperage IOD must be per-

formed first to prevent damage to most milli-

amp meters.

(1) Verify that all electrical accessories are off.

Turn off all lamps, remove ignition key, and close all

doors. If the vehicle is equipped with illuminated en-

try or electronically-tuned radio, allow the systems to

automatically shut off (time out). This may take up

to 3 minutes.

(2) Determine that the underhood lamp is operat-

ing properly, then disconnect or remove bulb.

(3) Disconnect negative cable from battery.

(4) Connect a typical 12-volt test lamp (low-watt-

age bulb) between the negative cable clamp and the

battery negative terminal. Make sure that the doors

remain closed so that illuminated entry is not acti-

vated.The test lamp may light brightly for up to 3 min-

utes, or may not light at all, depending upon the ve-

hicle's electrical equipment. The term brightly, as

used throughout the following tests, implies the

brightness of the test lamp will be the same as if it

were connected across the battery.

The test lamp must be securely clamped to the neg-

ative cable clamp and battery negative terminal. If

the test lamp becomes disconnected during any part

of the IOD test, the electronic timer function will be

activated and all tests must be repeated.

(5) After 3 minutes the test lamp should turn off

or be dimly lit, depending upon the vehicle's electri-

cal equipment. If the test lamp remains brightly lit,

do not disconnect it. Remove each fuse or circuit

breaker (refer to Group 8W - Wiring Diagrams) until

test lamp is either off or dimly lit. This will isolate

each circuit and identify the source of the high-am-

perage draw.

If the test lamp is still brightly lit after disconnect-

ing each fuse and circuit breaker, disconnect the wir-

ing harness from the generator. If test lamp now

turns off or is dimly lit, see Charging System in this

group to diagnose faulty generator. Do not disconnect

the test lamp.

After high-amperage IOD has been corrected, low-

amperage IOD may be checked. It is now safe to in-

stall a milliamp meter to check for low- amperage

IOD.

(6) With test lamp still connected securely, clamp a

milliamp meter between battery negative terminal

and negative cable clamp.

Do not open any doors or turn on any electri-

cal accessories with the test lamp disconnected

or the milliamp meter may be damaged.

(7) Disconnect test lamp. Observe milliamp meter.

The current draw should not exceed 0.020 amp. If

draw exceeds 20 milliamps, isolate each circuit by re-

moving circuit breakers and fuses. The milliamp

meter reading will drop when the source of the draw

is disconnected. Repair this circuit as necessary,

whether a wiring short, incorrect switch adjustment

or a component failure is found.

8A - 10 BATTERY/STARTING/CHARGING SYSTEMS DIAGNOSTICSJ

Page 398 of 2198

HORNS

CONTENTS

page page

DIAGNOSIS............................. 2

GENERAL INFORMATION.................. 1SERVICE PROCEDURES................... 3

SPECIFICATIONS......................... 5

GENERAL INFORMATION

Following are general descriptions of the major

components in the XJ (Cherokee)/YJ (Wrangler) horn

systems. Refer to Group 8W - Wiring Diagrams for

complete circuit descriptions and diagrams.

HORN SWITCH

XJ

Two horn switches are installed in the steering

wheel, one on each side of the center-mounted driv-

er's airbag module. When either switch is depressed

it completes a circuit to ground for the coil side of the

horn relay. The steering wheel and steering column

must be properly grounded for the horn switches to

function. The horn switches are only serviced as a set

with their wiring. If either switch should fail, both

switches must be replaced.

YJ

A single switch is installed in the center of the

steering wheel, directly under the horn button. When

the horn button is depressed the switch completes a

circuit to ground for the coil side of the horn relay.

The steering wheel and steering column must be

properly grounded for the horn switch to function.

The horn switch is available for service.

HORN RELAY

On XJ models, the horn relay is a mini-relay in-

stalled in the relay center, which is mounted to the

lower instrument panel reinforcement inboard of thesteering column. On YJ models, the horn relay is a

ISO relay installed in the Power Distribution Center

(PDC) near the battery tray. Refer to underside of

PDC cover for relay identification.

One side of the horn relay electromagnetic coil re-

ceives battery voltage at all times. When a horn

switch is depressed, the other side of the relay coil is

grounded. The energized relay coil causes the nor-

mally open relay contacts to close, providing battery

voltage to the horn.

If a problem is encountered with a continuously

sounding horn, it can usually be quickly resolved by

removing the horn relay until further diagnosis is

completed.

HORNS

On YJ models, a standard single, low-note, dia-

phragm-type horn is mounted and grounded to the

left inner fender shield under the hood. Dual horns

are standard equipment on XJ models. The high-note

diaphragm-type horn is mounted and grounded to

the left radiator closure panel brace behind the front

bumper. The low-note diaphragm-type horn is con-

nected in parallel with the high-note horn and is

mounted and grounded to the right radiator closure

panel brace behind the front bumper.

On XJ models, a cadmium-plated screw is

used to attach the horns to the body. Do not

substitute other types of screws as they may be-

come corroded and cause a loss of ground.

JHORNS 8G - 1

Page 459 of 2198

BACK-UP/REAR TURN SIGNAL/TAIL LAMP BULB

REPLACEMENTÐXJ

REMOVAL

(1) Remove the tail lamp housing upper retaining

screws (Fig. 16). Slide the lamp housing upward off

the lower screw while tipping the top of the lamp

away from the body and separate it from the rear of

the vehicle.

(2) Rotate the bulb socket one-third turn and re-

move the bulb socket from the lamp housing (Fig.

17).

(3) Remove the bulb from the socket.

INSTALLATION

(1) Install a replacement bulb in the socket.

(2) Install the bulb and socket in the lamp hous-

ing.

(3) Position the lamp housing in the opening at the

rear of the vehicle.

(4) Install the lamp housing screws. Tighten the

screws securely.

LICENSE PLATE LAMPÐXJ

REMOVAL

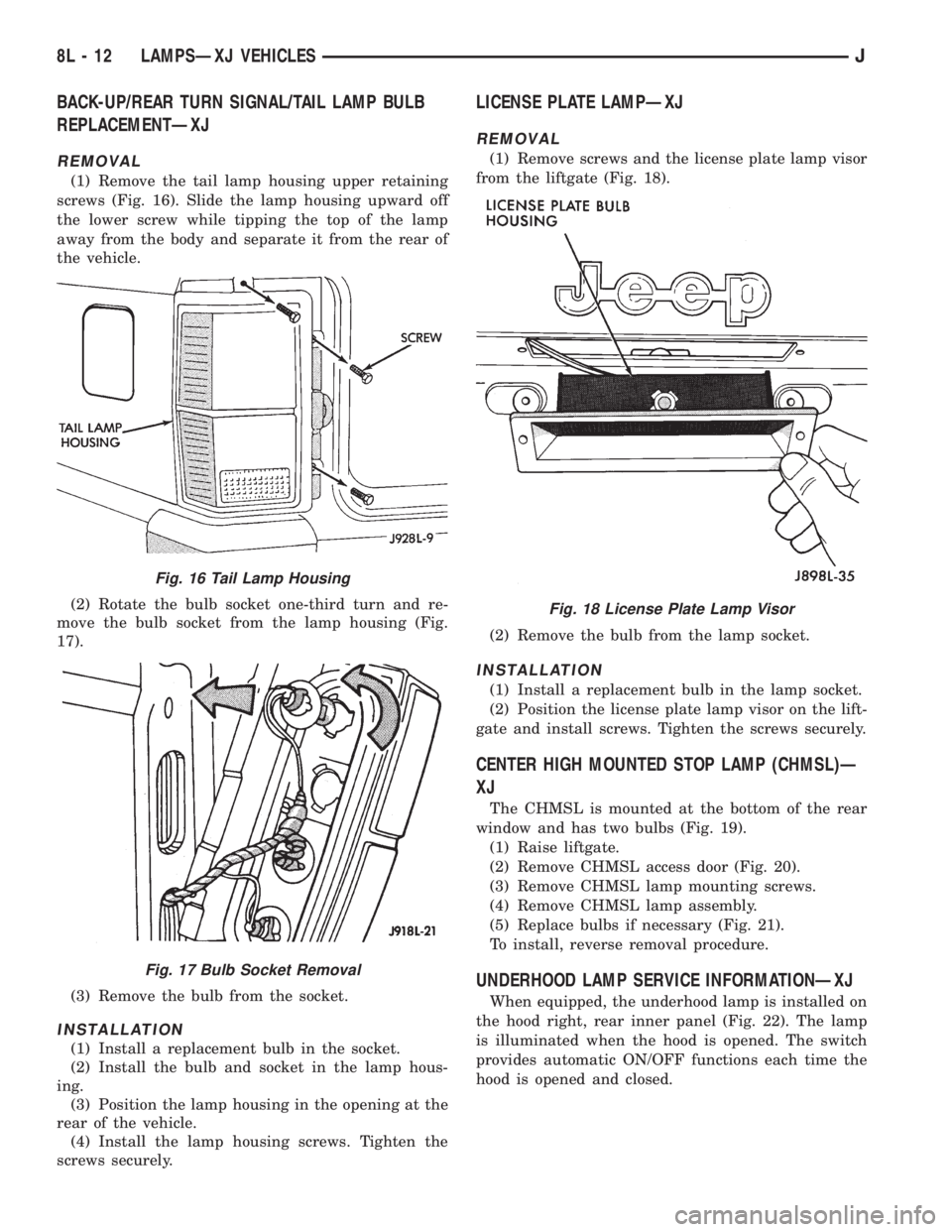

(1) Remove screws and the license plate lamp visor

from the liftgate (Fig. 18).

(2) Remove the bulb from the lamp socket.

INSTALLATION

(1) Install a replacement bulb in the lamp socket.

(2) Position the license plate lamp visor on the lift-

gate and install screws. Tighten the screws securely.

CENTER HIGH MOUNTED STOP LAMP (CHMSL)Ð

XJ

The CHMSL is mounted at the bottom of the rear

window and has two bulbs (Fig. 19).

(1) Raise liftgate.

(2) Remove CHMSL access door (Fig. 20).

(3) Remove CHMSL lamp mounting screws.

(4) Remove CHMSL lamp assembly.

(5) Replace bulbs if necessary (Fig. 21).

To install, reverse removal procedure.

UNDERHOOD LAMP SERVICE INFORMATIONÐXJ

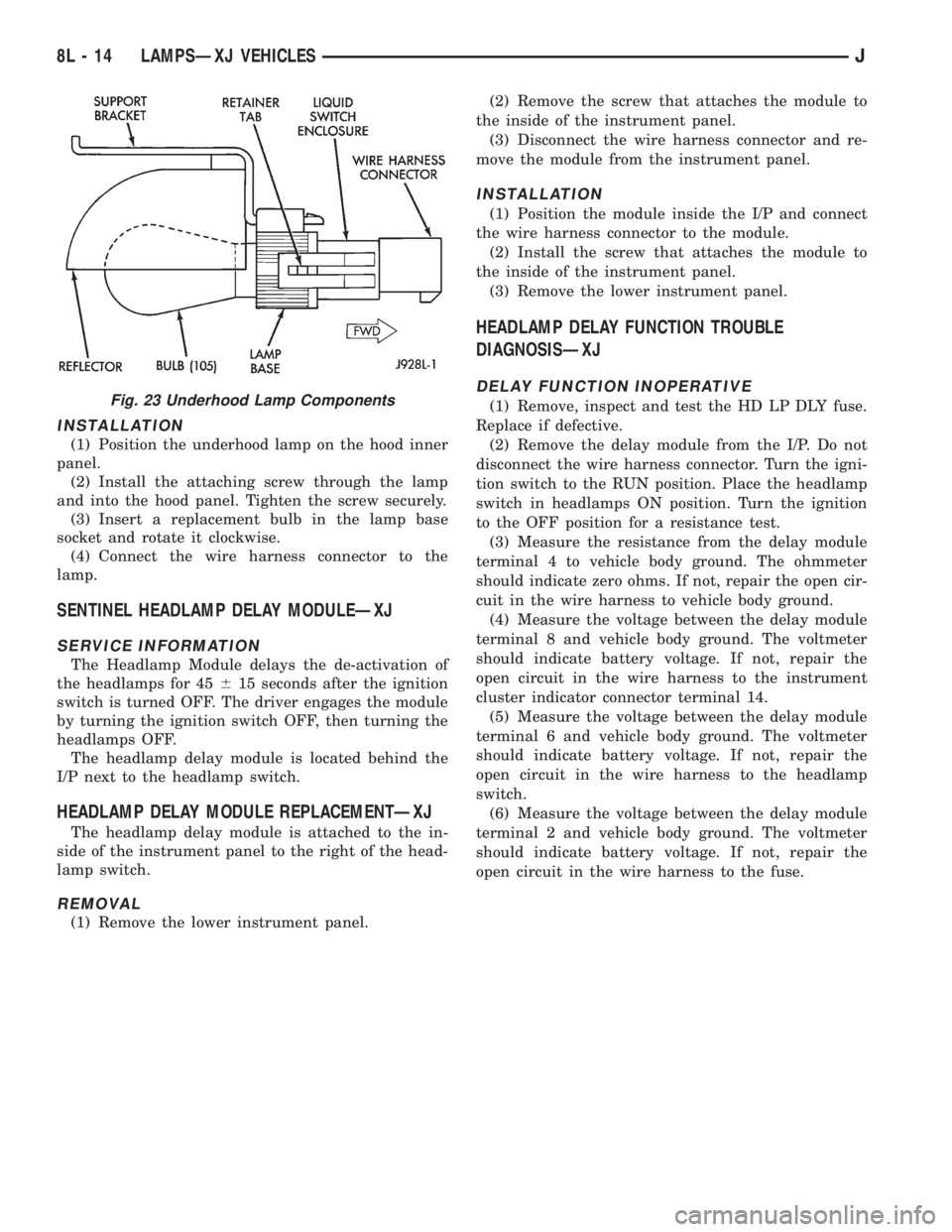

When equipped, the underhood lamp is installed on

the hood right, rear inner panel (Fig. 22). The lamp

is illuminated when the hood is opened. The switch

provides automatic ON/OFF functions each time the

hood is opened and closed.

Fig. 16 Tail Lamp Housing

Fig. 17 Bulb Socket Removal

Fig. 18 License Plate Lamp Visor

8L - 12 LAMPSÐXJ VEHICLESJ

Page 461 of 2198

INSTALLATION

(1) Position the underhood lamp on the hood inner

panel.

(2) Install the attaching screw through the lamp

and into the hood panel. Tighten the screw securely.

(3) Insert a replacement bulb in the lamp base

socket and rotate it clockwise.

(4) Connect the wire harness connector to the

lamp.

SENTINEL HEADLAMP DELAY MODULEÐXJ

SERVICE INFORMATION

The Headlamp Module delays the de-activation of

the headlamps for 45615 seconds after the ignition

switch is turned OFF. The driver engages the module

by turning the ignition switch OFF, then turning the

headlamps OFF.

The headlamp delay module is located behind the

I/P next to the headlamp switch.

HEADLAMP DELAY MODULE REPLACEMENTÐXJ

The headlamp delay module is attached to the in-

side of the instrument panel to the right of the head-

lamp switch.

REMOVAL

(1) Remove the lower instrument panel.(2) Remove the screw that attaches the module to

the inside of the instrument panel.

(3) Disconnect the wire harness connector and re-

move the module from the instrument panel.

INSTALLATION

(1) Position the module inside the I/P and connect

the wire harness connector to the module.

(2) Install the screw that attaches the module to

the inside of the instrument panel.

(3) Remove the lower instrument panel.

HEADLAMP DELAY FUNCTION TROUBLE

DIAGNOSISÐXJ

DELAY FUNCTION INOPERATIVE

(1) Remove, inspect and test the HD LP DLY fuse.

Replace if defective.

(2) Remove the delay module from the I/P. Do not

disconnect the wire harness connector. Turn the igni-

tion switch to the RUN position. Place the headlamp

switch in headlamps ON position. Turn the ignition

to the OFF position for a resistance test.

(3) Measure the resistance from the delay module

terminal 4 to vehicle body ground. The ohmmeter

should indicate zero ohms. If not, repair the open cir-

cuit in the wire harness to vehicle body ground.

(4) Measure the voltage between the delay module

terminal 8 and vehicle body ground. The voltmeter

should indicate battery voltage. If not, repair the

open circuit in the wire harness to the instrument

cluster indicator connector terminal 14.

(5) Measure the voltage between the delay module

terminal 6 and vehicle body ground. The voltmeter

should indicate battery voltage. If not, repair the

open circuit in the wire harness to the headlamp

switch.

(6) Measure the voltage between the delay module

terminal 2 and vehicle body ground. The voltmeter

should indicate battery voltage. If not, repair the

open circuit in the wire harness to the fuse.Fig. 23 Underhood Lamp Components

8L - 14 LAMPSÐXJ VEHICLESJ

Page 475 of 2198

(9) Raise and support the A/C evaporator housing

(Fig. 13).

(10) Install the evaporator housing-to-instrument

panel screws and evaporator support bracket screw.

BACK-UP/REAR TURN SIGNAL/TAIL LAMP BULB

REPLACEMENTÐYJ

REMOVAL

(1) Remove the lens retaining screws from the tail

lamp housing (Fig. 15).

(2) Separate the lens from the tail lamp housing.

(3) Remove the bulb from the lamp socket.

INSTALLATION

(1) Install a replacement bulb in the lamp socket.

(2) Position the lens on the lamp housing.

(3) Install the lens retaining screws. Tighten the

screws securely.

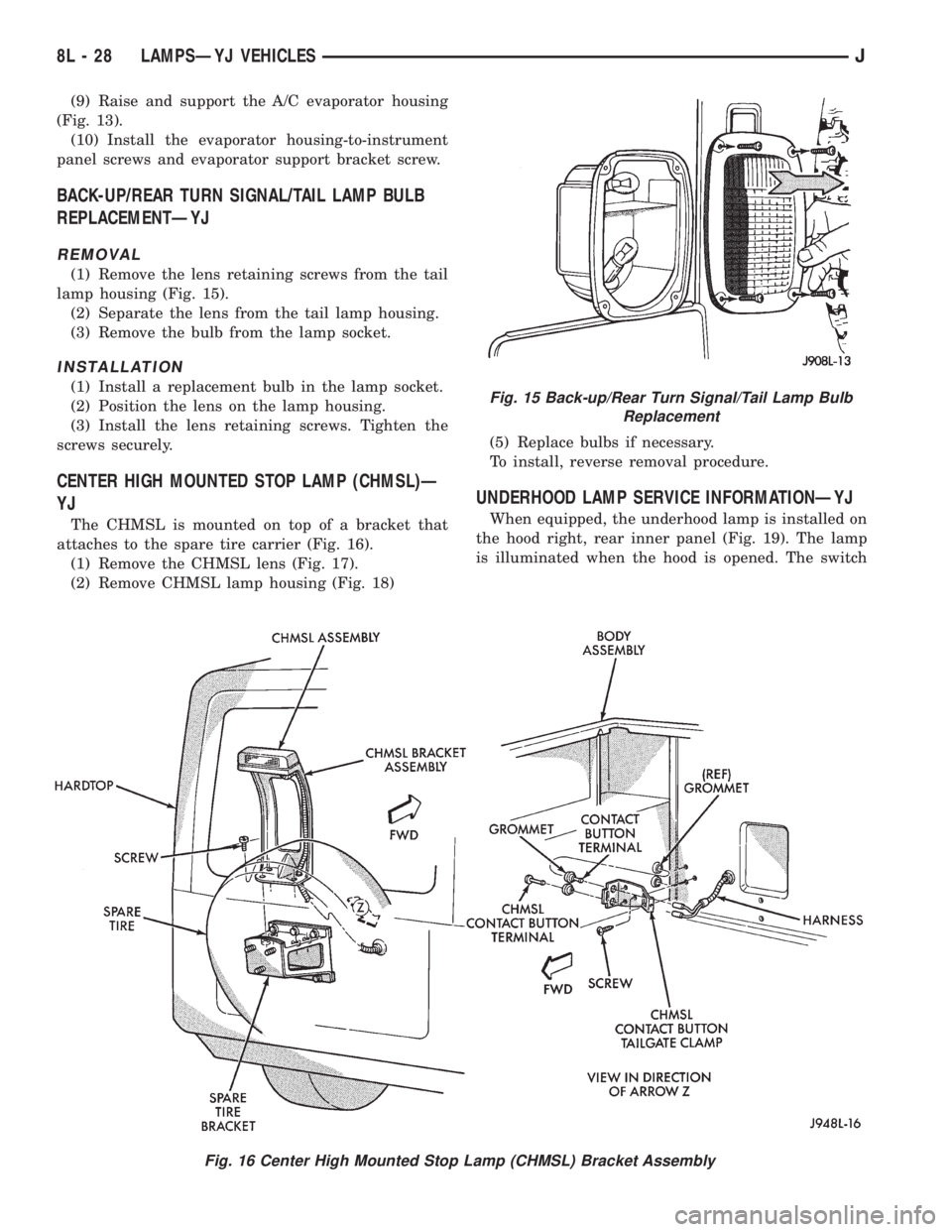

CENTER HIGH MOUNTED STOP LAMP (CHMSL)Ð

YJ

The CHMSL is mounted on top of a bracket that

attaches to the spare tire carrier (Fig. 16).

(1) Remove the CHMSL lens (Fig. 17).

(2) Remove CHMSL lamp housing (Fig. 18)(5) Replace bulbs if necessary.

To install, reverse removal procedure.

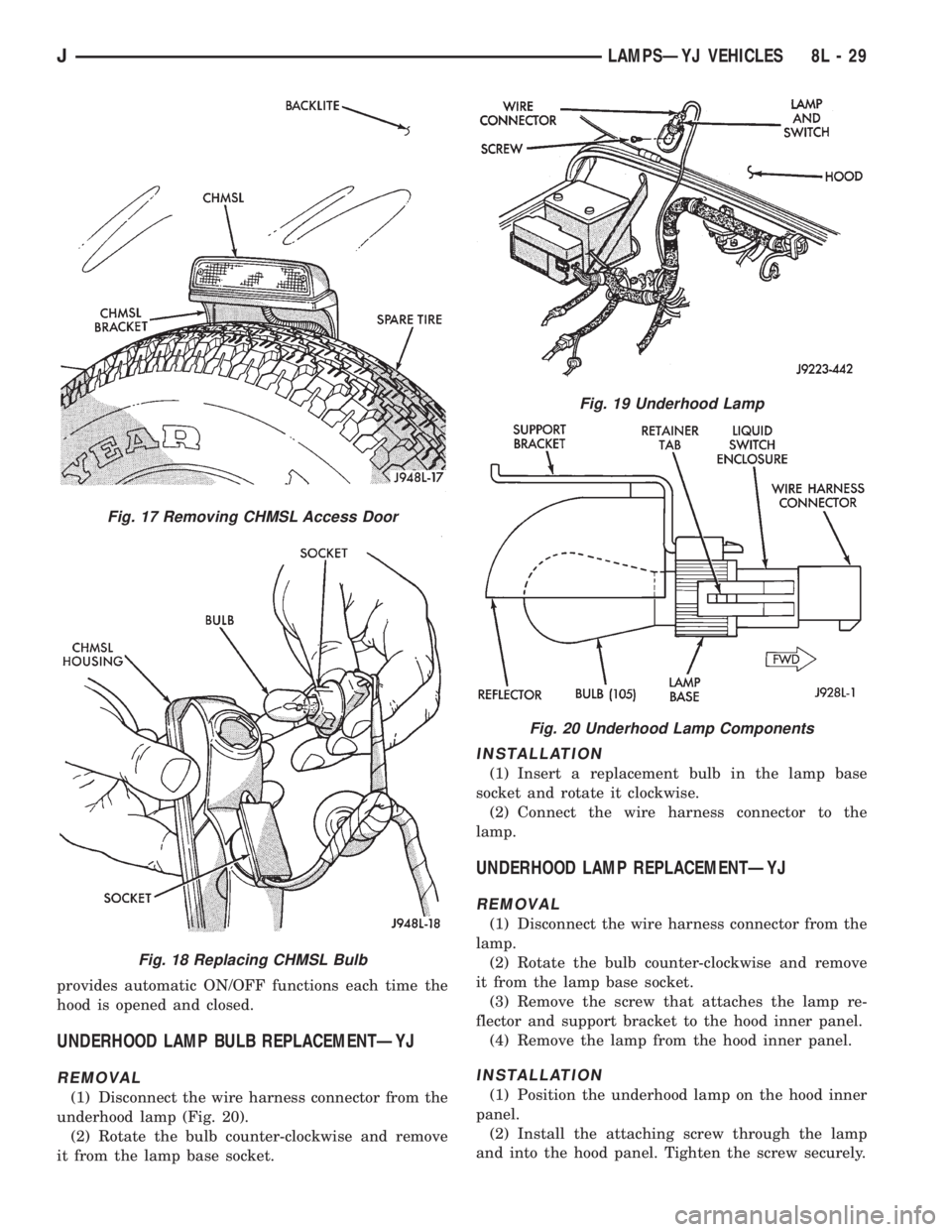

UNDERHOOD LAMP SERVICE INFORMATIONÐYJ

When equipped, the underhood lamp is installed on

the hood right, rear inner panel (Fig. 19). The lamp

is illuminated when the hood is opened. The switch

Fig. 15 Back-up/Rear Turn Signal/Tail Lamp Bulb

Replacement

Fig. 16 Center High Mounted Stop Lamp (CHMSL) Bracket Assembly

8L - 28 LAMPSÐYJ VEHICLESJ

Page 476 of 2198

provides automatic ON/OFF functions each time the

hood is opened and closed.

UNDERHOOD LAMP BULB REPLACEMENTÐYJ

REMOVAL

(1) Disconnect the wire harness connector from the

underhood lamp (Fig. 20).

(2) Rotate the bulb counter-clockwise and remove

it from the lamp base socket.

INSTALLATION

(1) Insert a replacement bulb in the lamp base

socket and rotate it clockwise.

(2) Connect the wire harness connector to the

lamp.

UNDERHOOD LAMP REPLACEMENTÐYJ

REMOVAL

(1) Disconnect the wire harness connector from the

lamp.

(2) Rotate the bulb counter-clockwise and remove

it from the lamp base socket.

(3) Remove the screw that attaches the lamp re-

flector and support bracket to the hood inner panel.

(4) Remove the lamp from the hood inner panel.

INSTALLATION

(1) Position the underhood lamp on the hood inner

panel.

(2) Install the attaching screw through the lamp

and into the hood panel. Tighten the screw securely.

Fig. 17 Removing CHMSL Access Door

Fig. 18 Replacing CHMSL Bulb

Fig. 19 Underhood Lamp

Fig. 20 Underhood Lamp Components

JLAMPSÐYJ VEHICLES 8L - 29