brake JEEP CHEROKEE 2017 KL / 5.G Owners Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2017, Model line: CHEROKEE, Model: JEEP CHEROKEE 2017 KL / 5.GPages: 615, PDF Size: 5.72 MB

Page 412 of 615

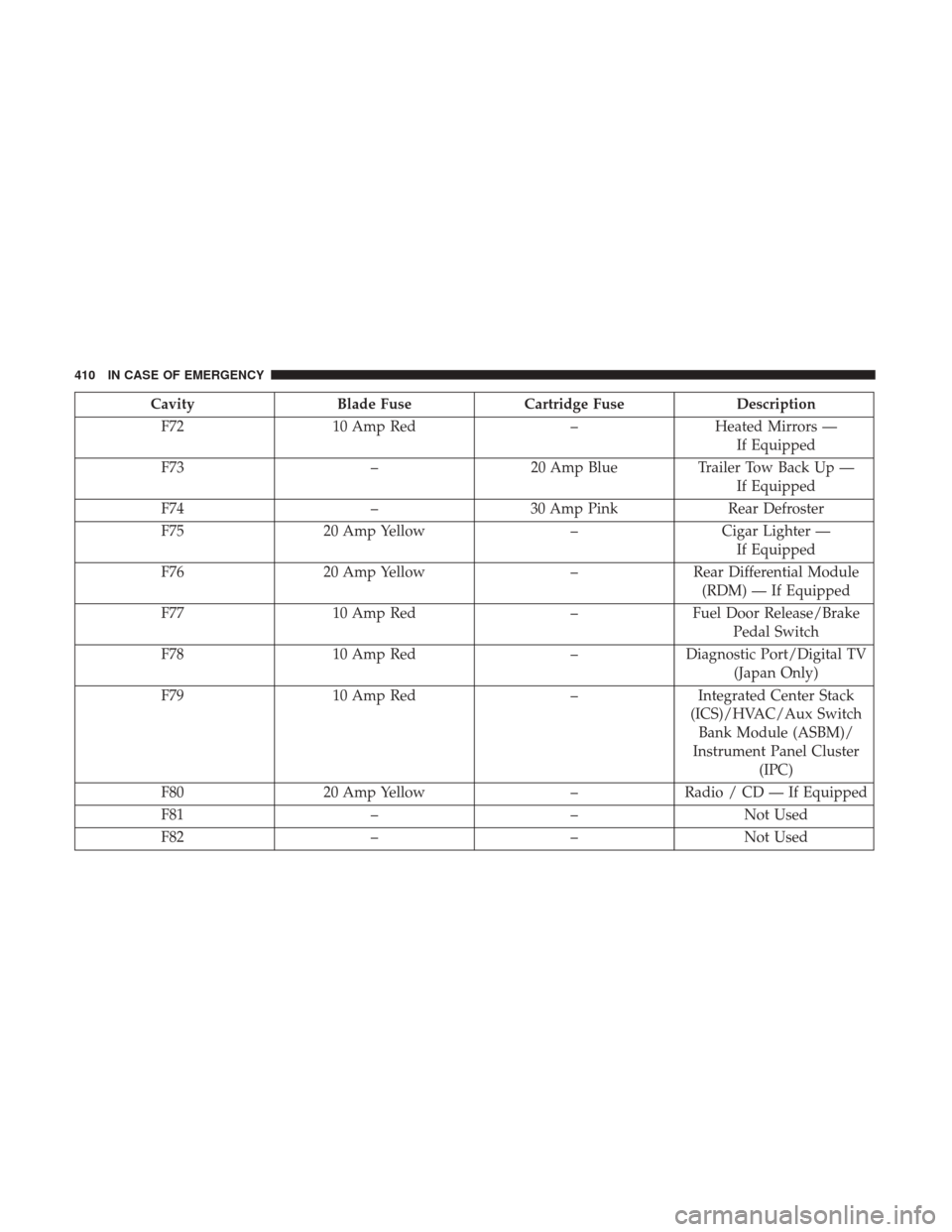

CavityBlade Fuse Cartridge Fuse Description

F72 10 Amp Red –Heated Mirrors —

If Equipped

F73 –20 Amp Blue Trailer Tow Back Up —

If Equipped

F74 –30 Amp Pink Rear Defroster

F75 20 Amp Yellow –Cigar Lighter —

If Equipped

F76 20 Amp Yellow –Rear Differential Module

(RDM) — If Equipped

F77 10 Amp Red –Fuel Door Release/Brake

Pedal Switch

F78 10 Amp Red –Diagnostic Port/Digital TV

(Japan Only)

F79 10 Amp Red –Integrated Center Stack

(ICS)/HVAC/Aux Switch Bank Module (ASBM)/

Instrument Panel Cluster (IPC)

F80 20 Amp Yellow –Radio / CD — If Equipped

F81 ––Not Used

F82 ––Not Used

410 IN CASE OF EMERGENCY

Page 413 of 615

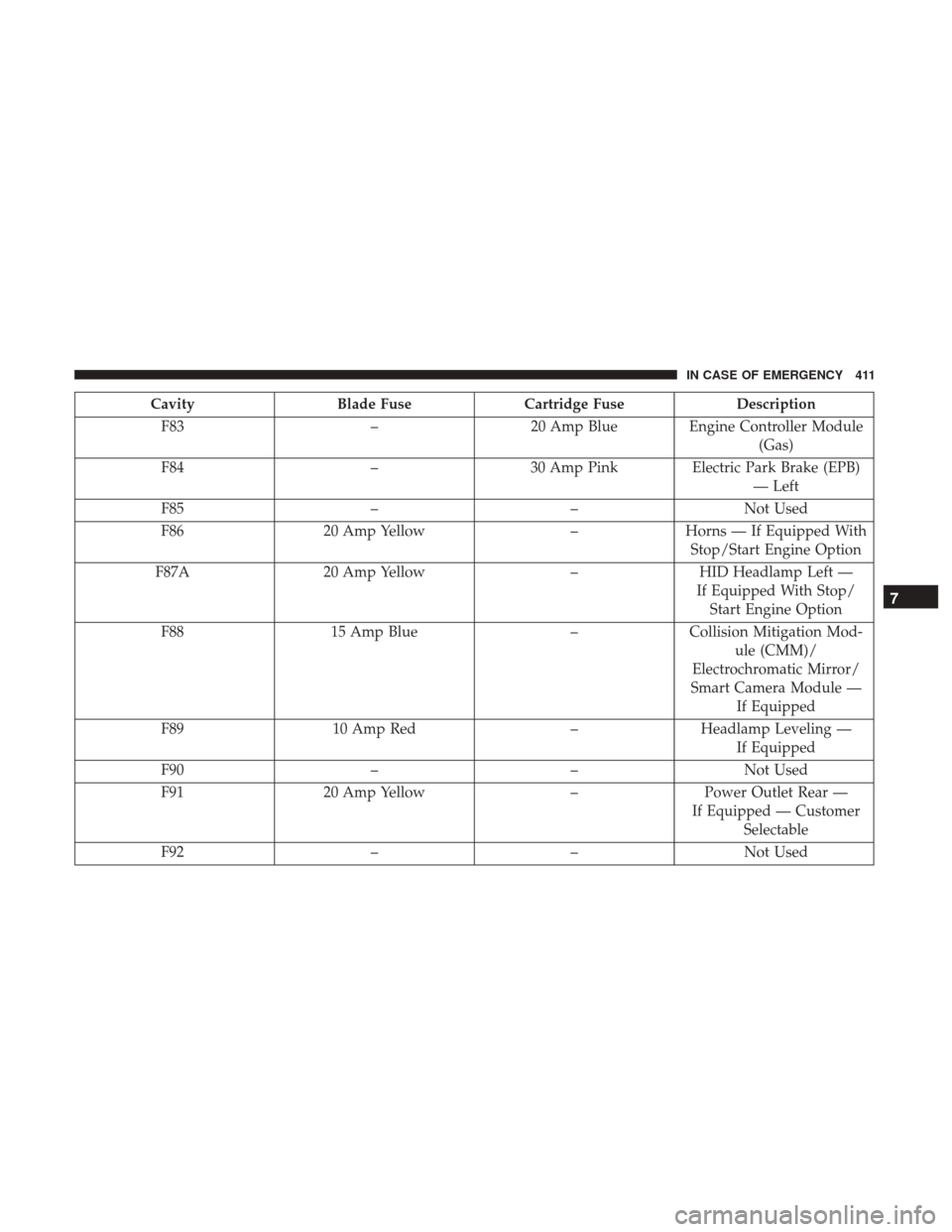

CavityBlade Fuse Cartridge Fuse Description

F83 –20 Amp Blue Engine Controller Module

(Gas)

F84 –30 Amp Pink Electric Park Brake (EPB)

— Left

F85 ––Not Used

F86 20 Amp Yellow –Horns — If Equipped With

Stop/Start Engine Option

F87A 20 Amp Yellow –HID Headlamp Left —

If Equipped With Stop/ Start Engine Option

F88 15 Amp Blue –Collision Mitigation Mod-

ule (CMM)/

Electrochromatic Mirror/

Smart Camera Module — If Equipped

F89 10 Amp Red –Headlamp Leveling —

If Equipped

F90 ––Not Used

F91 20 Amp Yellow –Power Outlet Rear —

If Equipped — Customer Selectable

F92 ––Not Used

7

IN CASE OF EMERGENCY 411

Page 414 of 615

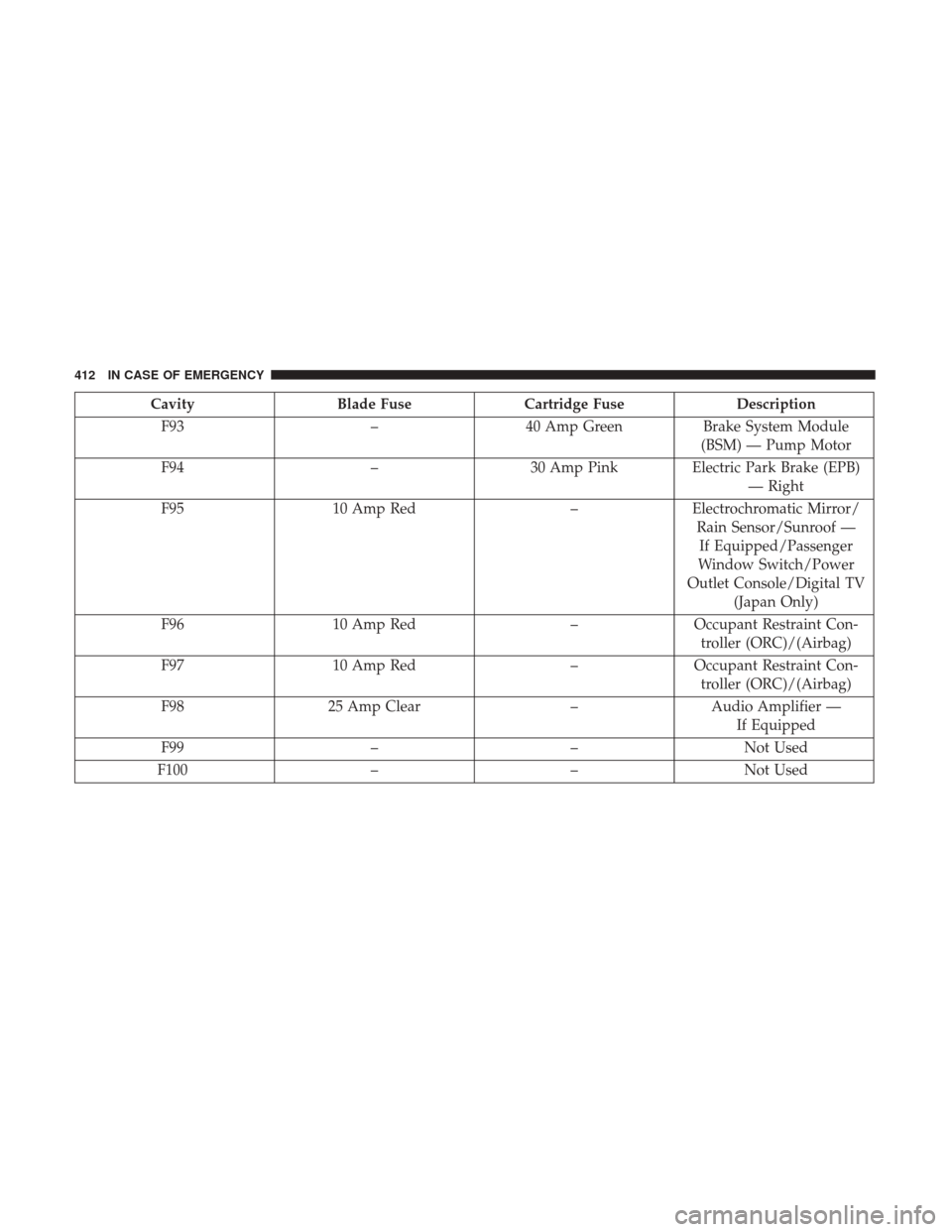

CavityBlade Fuse Cartridge Fuse Description

F93 –40 Amp Green Brake System Module

(BSM) — Pump Motor

F94 –30 Amp Pink Electric Park Brake (EPB)

— Right

F95 10 Amp Red –Electrochromatic Mirror/

Rain Sensor/Sunroof —If Equipped/Passenger

Window Switch/Power

Outlet Console/Digital TV (Japan Only)

F96 10 Amp Red –Occupant Restraint Con-

troller (ORC)/(Airbag)

F97 10 Amp Red –Occupant Restraint Con-

troller (ORC)/(Airbag)

F98 25 Amp Clear –Audio Amplifier —

If Equipped

F99 ––Not Used

F100 ––Not Used

412 IN CASE OF EMERGENCY

Page 418 of 615

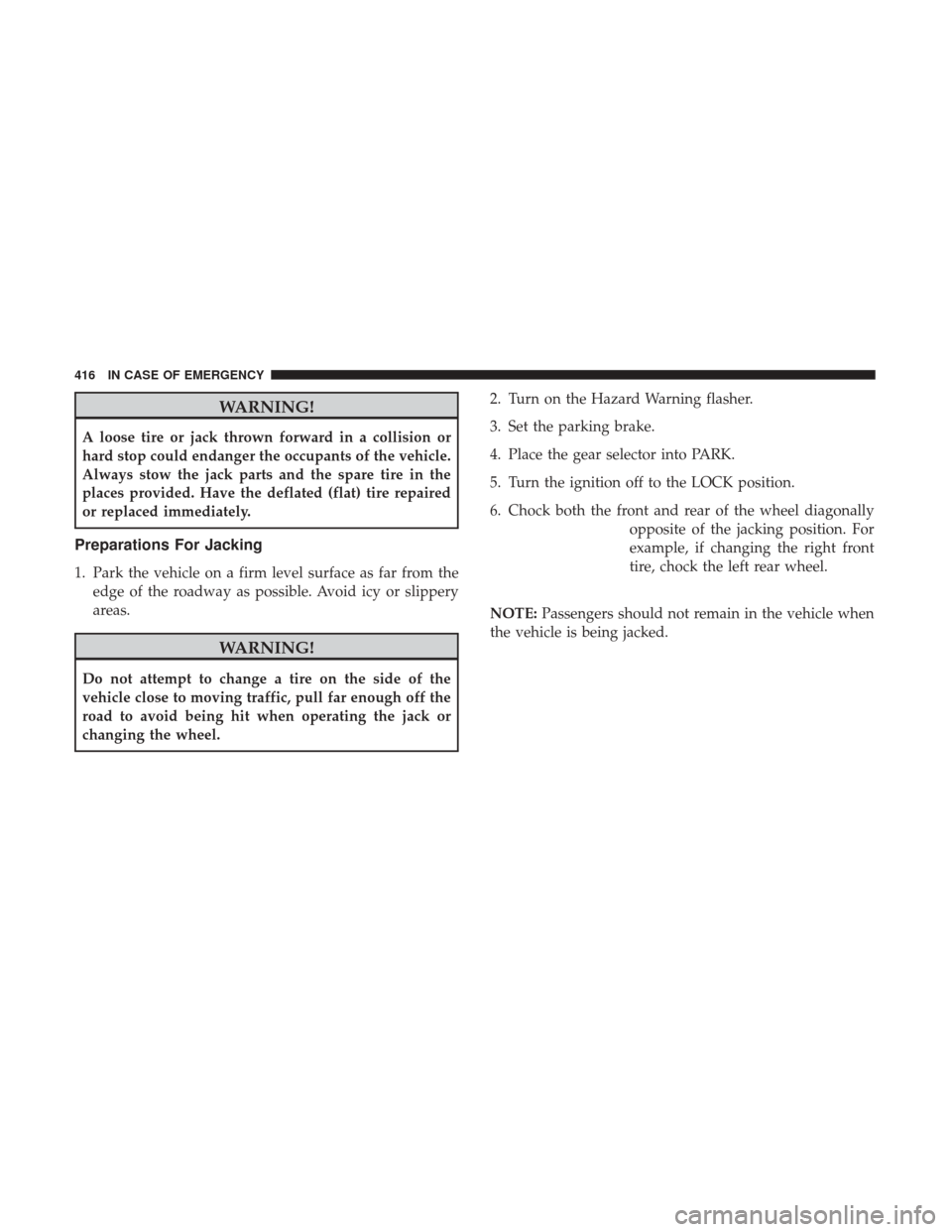

WARNING!

A loose tire or jack thrown forward in a collision or

hard stop could endanger the occupants of the vehicle.

Always stow the jack parts and the spare tire in the

places provided. Have the deflated (flat) tire repaired

or replaced immediately.

Preparations For Jacking

1. Park the vehicle on a firm level surface as far from theedge of the roadway as possible. Avoid icy or slippery

areas.

WARNING!

Do not attempt to change a tire on the side of the

vehicle close to moving traffic, pull far enough off the

road to avoid being hit when operating the jack or

changing the wheel. 2. Turn on the Hazard Warning flasher.

3. Set the parking brake.

4. Place the gear selector into PARK.

5. Turn the ignition off to the LOCK position.

6. Chock both the front and rear of the wheel diagonally

opposite of the jacking position. For

example, if changing the right front

tire, chock the left rear wheel.

NOTE: Passengers should not remain in the vehicle when

the vehicle is being jacked.

416 IN CASE OF EMERGENCY

Page 419 of 615

Jacking Instructions

WARNING!

Carefully follow these tire changing warnings to help

prevent personal injury or damage to your vehicle:

•

Always park on a firm, level surface as far from the

edge of the roadway as possible before raising the

vehicle.

• Turn on the Hazard Warning flasher.

•

Chock the wheel diagonally opposite the wheel to be

raised.

•Set the parking brake firmly and set the transmission

in PARK.

•Never start or run the engine with the vehicle on a

jack.

•Do not let anyone sit in the vehicle when it is on a jack.

•Do not get under the vehicle when it is on a jack. If you

need to get under a raised vehicle, take it to a service

center where it can be raised on a lift.

•Only use the jack in the positions indicated and for

lifting this vehicle during a tire change.

•If working on or near a roadway, be extremely careful

of motor traffic.

(Continued)

WARNING! (Continued)

•To assure that spare tires, flat or inflated, are securely

stowed, spares must be stowed with the valve stem

facing the ground.

Jack Warning Label

7

IN CASE OF EMERGENCY 417

Page 425 of 615

5. Lower the jack until it is free. Remove the wheel chocks.Reassemble the lug wrench to the jack assembly and

stow it in the spare tire area. Secure the assembly using

the means provided. Release the parking brake before

driving the vehicle.

6. After 25 miles (40 km) check the wheel bolt torque with a torque wrench to ensure that all wheel bolts are

properly seated against the wheel.

TIRE SERVICE KIT — IF EQUIPPED

Small punctures up to 1/4 inch (6 mm) in the tire tread can

be sealed with Tire Service Kit. Foreign objects (e.g., screws

or nails) should not be removed from the tire. Tire Service

Kit can be used in outside temperatures down to approxi-

mately -4°F (-20°C).

This kit will provide a temporary tire seal, allowing you to

drive your vehicle up to 100 miles (160 km) with a

maximum speed of 55 mph (90 km/h).

Tire Service Kit Storage

The Tire Service Kit is stowed under the load floor behind

the rear seat.

1. Open the liftgate.

2. Lift the access cover using the load floor handle.

Load Floor Handle

7

IN CASE OF EMERGENCY 423

Page 429 of 615

Sealing A Tire With Tire Service Kit

(A) Whenever You Stop To Use Tire Service Kit:

1. Pull over to a safe location and turn on the vehicle’sHazard Warning flashers.

2. Verify that the valve stem (on the wheel with the deflated tire) is in a position that is near to the ground.

This will allow the Tire Service Kit Hoses (6) and (7) to

reach the valve stem and keep the Tire Service Kit flat on

the ground. This will provide the best positioning of the

kit when injecting the sealant into the deflated tire and

running the air pump. Move the vehicle as necessary to

place the valve stem in this position before proceeding.

3. Place the transmission in PARK (auto transmission) or in Gear (manual transmission) and place the ignition in the

OFF position.

4. Set the parking brake.

(B) Setting Up To Use Tire Service Kit:

1. Push in the Mode Select Knob (5) and turn to the Sealant Mode position.

2. Uncoil the Sealant Hose (6) and then remove the cap from the fitting at the end of the hose.

3. Place the Tire Service Kit flat on the ground next to the deflated tire.

4. Remove the cap from the valve stem and then screw the fitting at the end of the Sealant Hose (6) onto the valve

stem.

5. Uncoil the Power Plug (8) and insert the plug into the vehicle’s 12 Volt power outlet.

NOTE: Do not remove foreign objects (e.g., screws or

nails) from the tire.

7

IN CASE OF EMERGENCY 427

Page 430 of 615

(C) Injecting Tire Service Kit Sealant Into The

Deflated Tire:

•Always start the engine before turning ON the Tire

Service Kit.

NOTE: Manual transmission vehicles must have the park-

ing brake engaged and the gear selector in NEUTRAL.

• After pushing the Power Button (4), the sealant (white

fluid) will flow from the Sealant Bottle (1) through the

Sealant Hose (6) and into the tire.

NOTE: Sealant may leak out through the puncture in the

tire. If the sealant (white fluid) does not flow within0–10

seconds through the Sealant Hose (6):

1. Push the Power Button (4) to turn Off the Tire Service

Kit. Disconnect the Sealant Hose (6) from the valve stem.

Make sure the valve stem is free of debris. Reconnect the

Sealant Hose (6) to the valve stem. Check that the Mode

Select Knob (5) is in the Sealant Mode position and not

Air Mode. Push the Power Button (4) to turn On the Tire

Service Kit.

2. Connect the Power Plug (8) to a different 12 Volt power outlet in your vehicle or another vehicle, if available.

Make sure the engine is running before turning ON the

Tire Service Kit.

3. The Sealant Bottle (1) may be empty due to previous use. Call for assistance.

NOTE: If the Mode Select Knob (5) is on Air Mode and the

pump is operating, air will dispense from the Air Pump

Hose (7) only, not the Sealant Hose (6).

428 IN CASE OF EMERGENCY

Page 435 of 615

1. Set the parking brake, shift the automatic transmissioninto PARK and turn the ignition to LOCK.

2. Turn off the heater, radio, and all unnecessary electrical accessories.

3. If using another vehicle to jump-start the battery, park the vehicle within the jumper cables reach, set the

parking brake and make sure the ignition is OFF.

WARNING!

Do not allow vehicles to touch each other as this could

establish a ground connection and personal injury

could result.

Jump Starting Procedure

WARNING!

Failure to follow this jump-starting procedure could

result in personal injury or property damage due to

battery explosion.

CAUTION!

Failure to follow these procedures could result in

damage to the charging system of the booster vehicle

or the discharged vehicle.

Connecting The Jumper Cables

1. Connect the positive (+)end of the jumper cable to the

positive (+)post of the discharged vehicle.

2. Connect the opposite end of the positive (+)jumper

cable to the positive (+)post of the booster battery.

3. Connect the negative (-)end of the jumper cable to the

negative (-)post of the booster battery.

4. Connect the opposite end of the negative (-)jumper

cable to a good engine ground (exposed metal part of

the discharged vehicle’s engine) away from the battery

and the fuel injection system.

7

IN CASE OF EMERGENCY 433

Page 439 of 615

GEAR SELECTOR OVERRIDE

If a malfunction occurs and the gear selector cannot be

moved out of the PARK position, you can use the following

procedure to temporarily move the gear selector:

1. Turn the engine OFF.

2. Apply the parking brake.

3. Using a screwdriver or similar tool, carefully separatethe shifter bezel and boot assembly from the center

console.

4. Press and maintain firm pressure on the brake pedal.

5. Insert a small screwdriver or similar tool down into the gear selector override access hole (at the right front

corner of the gear selector assembly), and push and hold

the override release lever down.

6. Move the gear selector to the NEUTRAL position.

7. The vehicle may then be started in NEUTRAL.

8. Reinstall the gear selector boot.

FREEING A STUCK VEHICLE

If your vehicle becomes stuck in mud, sand or snow, it can

often be moved using a rocking motion. Turn the steering

wheel right and left to clear the area around the front

wheels. Push and hold the lock button on the gear selector.

Then shift back and forth between DRIVE and REVERSE,

while gently pressing the accelerator.

NOTE: Shifts between DRIVE and REVERSE can only be

achieved at wheel speeds of 5 mph (8 km/h) or less.

Whenever the transmission remains in NEUTRAL for more

than two seconds, you must push the brake pedal to

engage DRIVE or REVERSE.

Use the least amount of accelerator pedal pressure that will

maintain the rocking motion without spinning the wheels

or racing the engine.

7

IN CASE OF EMERGENCY 437