JEEP CHEROKEE 2019 Owner handbook (in English)

Manufacturer: JEEP, Model Year: 2019, Model line: CHEROKEE, Model: JEEP CHEROKEE 2019Pages: 344, PDF Size: 6.35 MB

Page 211 of 344

WARNING!

handling the tire that was treated using

the Tire Service Kit.

5. Remove the Speed Limit sticker from the

instrument panel after the tire has been

repaired.

6. Replace the Sealant Bottle (1) and Seal-

ant Hose (6) assembly at an authorized

dealer as soon as possible. Refer to “(F)

Sealant Bottle And Hose Replacement”.

NOTE:

When having the tire serviced, advise the

authorized dealer or service center that the

tire has been sealed using the Tire Service

Kit.

(F) Sealant Bottle And Hose Replacement:

1. Uncoil the Sealant Hose (6) (clear in

color).

2. Locate the round Sealant Bottle release

button in the recessed area under the

sealant bottle.3. Push the Sealant Bottle release button.

The Sealant Bottle (1) will pop up. Re-

move the bottle and dispose of it

accordingly.

4. Clean any remaining sealant from the Tire

Service Kit housing.

5. Position the new Sealant Bottle (1) in the

housing so that the Sealant Hose (6)

aligns with the hose slot in the front of the

housing. Push the bottle into the housing.

An audible click will be heard indicating

the bottle is locked into place.

6. Verify that the cap is installed on the

fitting at the end of the Sealant Hose (6)

and return the hose to its storage area

(located on the bottom of the air pump).

7. Return the Tire Service Kit to its storage

location in the vehicle.

WARNING!

As required by current regulations, the

information on chemical substances for

the protection of human health and the

environment and on the safe use of the

WARNING!

sealing fluid are on the packaging label.

Compliance with the indications on the

label is an essential condition to ensure

the safety and effectiveness of the prod-

uct. Remember to carefully read the label

before use. The user of the product is

responsible for any damages caused by

improper use. The sealing fluid has an

expiration date. Replace the bottle if the

sealant has expired.

CAUTION!

Dispose of the bottle and the sealant liquid

properly. Have them disposed of in com-

pliance with national and local regula-

tions.

JUMP STARTING

If your vehicle has a discharged battery, it can

be jump started using a set of jumper cables

and a battery in another vehicle or by using a

209

Page 212 of 344

portable battery booster pack. Jump starting

can be dangerous if done improperly, so

please follow the procedures in this section

carefully.

NOTE:

When using a portable battery booster pack,

follow the manufacturer’s operating instruc-

tions and precautions.

WARNING!

Do not attempt jump starting if the battery

is frozen. It could rupture or explode and

cause personal injury.

CAUTION!

Do not use a portable battery booster pack

or any other booster source with a system

voltage greater than 12 Volts or damage to

the battery, starter motor, alternator or

electrical system may occur.

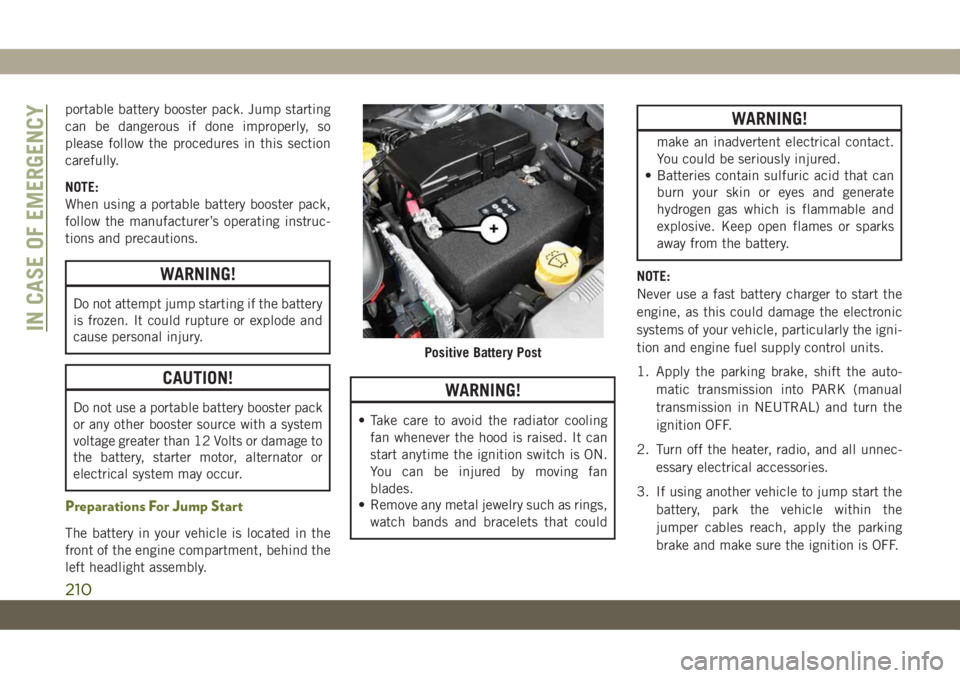

Preparations For Jump Start

The battery in your vehicle is located in the

front of the engine compartment, behind the

left headlight assembly.

WARNING!

• Take care to avoid the radiator cooling

fan whenever the hood is raised. It can

start anytime the ignition switch is ON.

You can be injured by moving fan

blades.

• Remove any metal jewelry such as rings,

watch bands and bracelets that could

WARNING!

make an inadvertent electrical contact.

You could be seriously injured.

• Batteries contain sulfuric acid that can

burn your skin or eyes and generate

hydrogen gas which is flammable and

explosive. Keep open flames or sparks

away from the battery.

NOTE:

Never use a fast battery charger to start the

engine, as this could damage the electronic

systems of your vehicle, particularly the igni-

tion and engine fuel supply control units.

1. Apply the parking brake, shift the auto-

matic transmission into PARK (manual

transmission in NEUTRAL) and turn the

ignition OFF.

2. Turn off the heater, radio, and all unnec-

essary electrical accessories.

3. If using another vehicle to jump start the

battery, park the vehicle within the

jumper cables reach, apply the parking

brake and make sure the ignition is OFF.

Positive Battery Post

IN CASE OF EMERGENCY

210

Page 213 of 344

WARNING!

Do not allow vehicles to touch each other

as this could establish a ground connec-

tion and personal injury could result.

Jump Starting Procedure

WARNING!

Failure to follow this jump starting proce-

dure could result in personal injury or

property damage due to battery explosion.

CAUTION!

Failure to follow these procedures could

result in damage to the charging system of

the booster vehicle or the discharged ve-

hicle.

Connecting The Jumper Cables

1. Connect the positive(+)end of the jumper

cable to the positive(+)post of the dis-

charged vehicle.2. Connect the opposite end of the positive

(+)jumper cable to the positive(+)post of

the booster battery.

3. Connect the negative(-)end of the jumper

cable to the negative(-)post of the

booster battery.

4. Connect the opposite end of the negative

(-)jumper cable to a good engine ground

(exposed metal part of the discharged

vehicle’s engine) away from the battery

and the fuel injection system.

WARNING!

Do not connect the jumper cable to the

negative (-) post of the discharged battery.

The resulting electrical spark could cause

the battery to explode and could result in

personal injury. Only use the specific

ground point, do not use any other exposed

metal parts.

5. Start the engine in the vehicle that has the

booster battery, let the engine idle for a

few minutes, and then start the engine in

the vehicle with the discharged battery.6. Once the engine is started, remove the

jumper cables in the reverse sequence:

Disconnecting The Jumper Cables

1. Disconnect the negative(-)end of the

jumper cable from the engine ground of

the vehicle with the discharged battery.

2. Disconnect the opposite end of the nega-

tive(-)jumper cable from the negative(-)

post of the booster battery.

3. Disconnect the positive(+)end of the

jumper cable from the positive(+)post of

the booster battery.

4. Disconnect the opposite end of the posi-

tive(+)jumper cable from the positive(+)

post of the vehicle with the discharged

battery.

If frequent jump starting is required to start

your vehicle, you should have the battery and

charging system inspected at an authorized

dealer.

211

Page 214 of 344

CAUTION!

Accessories plugged into the vehicle

power outlets draw power from the vehi-

cle’s battery, even when not in use (i.e.,

cellular devices, etc.). Eventually, if

plugged in long enough without engine

operation, the vehicle’s battery will dis-

charge sufficiently to degrade battery life

and/or prevent the engine from starting.

REFUELING IN EMERGENCY

Emergency Fuel Filler Door Release

If you are unable to open the fuel filler door,

use the fuel filler door emergency release.

1. Open the liftgate.

2. Remove access door located on right inte-

rior trim panel for release cable with the

tip of your key.

3. Grab the release cable tether and pull up

to release the fuel filler door.

IF YOUR ENGINE

OVERHEATS

In any of the following situations, you can

reduce the potential for overheating your en-

gine by taking the appropriate action.

• On the highways — slow down.

• In city traffic — while stopped, place the

transmission in NEUTRAL, but do not in-

crease engine idle speed.

CAUTION!

Driving with a hot cooling system could

damage your vehicle. If the temperature

gauge reads “H,” pull over and stop the

vehicle. Idle the vehicle with the air con-

ditioner turned off until the pointer drops

back into the normal range. If the pointer

remains on the “H” and you hear continu-

ous chimes, turn the engine off immedi-

ately and call for service.NOTE:

There are steps that you can take to slow

down an impending overheat condition:

• If your Air Conditioner (A/C) is on, turn it

off. The A/C system adds heat to the engine

cooling system and turning the A/C off can

help remove this heat.

• You can also turn the temperature control

to maximum heat, the mode control to floor

and the blower control to high. This allows

the heater core to act as a supplement to

the radiator and aids in removing heat from

the engine cooling system.WARNING!

You or others can be badly burned by hot

engine coolant (antifreeze) or steam from

your radiator. If you see or hear steam

coming from under the hood, do not open

the hood until the radiator has had time to

cool. Never try to open a cooling system

pressure cap when the radiator or coolant

bottle is hot.

IN CASE OF EMERGENCY

212

Page 215 of 344

GEAR SELECTOR OVERRIDE

If a malfunction occurs and the gear selector

cannot be moved out of the PARK position,

you can use the following procedure to tem-

porarily move the gear selector:

1. Turn the engine OFF.

2. Apply the parking brake.

3. Using a screwdriver or similar tool, care-

fully separate the shifter bezel and boot

assembly from the center console, and

raise it up to access the gear selector

mechanism.

4. Press and maintain firm pressure on the

brake pedal.

5. Insert a small screwdriver or similar tool

down into the gear selector override ac-

cess hole (at the left front corner of the

gear selector assembly), and push and

hold the override release lever down.

6. Move the gear selector to the NEUTRAL

position.

7. The vehicle may then be started in

NEUTRAL.

8. Reinstall the gear selector boot.

FREEING A STUCK VEHICLE

If your vehicle becomes stuck in mud, sand or

snow, it can often be moved using a rocking

motion. Turn the steering wheel right and left

to clear the area around the front wheels. For

vehicles with automatic transmission, push

and hold the lock button on the gear selector.

Then shift back and forth between DRIVE and

REVERSE (with automatic transmission) or

SECOND GEAR and REVERSE (with manual

transmission), while gently pressing the ac-

celerator.

NOTE:

For vehicles with automatic transmission:

Shifts between DRIVE and REVERSE can

only be achieved at wheel speeds of 5 mph

(8 km/h) or less. Whenever the transmission

remains in NEUTRAL for more than two sec-

onds, you must press the brake pedal to

engage DRIVE or REVERSE.

Use the least amount of accelerator pedal

pressure that will maintain the rocking mo-

tion without spinning the wheels or racing the

engine.

CAUTION!

• Racing the engine or spinning the

wheels may lead to transmission over-

heating and failure. Allow the engine to

idle with the transmission in NEUTRAL

for at least one minute after every five

rocking-motion cycles. This will mini-

mize overheating and reduce the risk of

clutch or transmission failure during

prolonged efforts to free a stuck vehicle.

• When “rocking” a stuck vehicle by shift-

ing between DRIVE/SECOND GEAR and

REVERSE, do not spin the wheels faster

than 15 mph (24 km/h), or drivetrain

damage may result.

• Revving the engine or spinning the

wheels too fast may lead to transmission

overheating and failure. It can also dam-

age the tires. Do not spin the wheels

above 30 mph (48 km/h) while in gear

(no transmission shifting occurring).

213

Page 216 of 344

NOTE:

Push the “ESC Off” switch (if necessary), to

place the Electronic Stability Control (ESC)

system in “Partial Off” mode, before rocking

the vehicle. Refer to “Electronic Brake Con-

trol System” in “Safety” for further informa-

tion. Once the vehicle has been freed, push

the "ESC Off" switch again to restore “ESC

On” mode.WARNING!

Fast spinning tires can be dangerous.

Forces generated by excessive wheel

speeds may cause damage, or even failure,

of the axle and tires. A tire could explode

and injure someone. Do not spin your

vehicle's wheels faster than 30 mph

(48 km/h) or for longer than 30 seconds

continuously without stopping when you

are stuck and do not let anyone near a

spinning wheel, no matter what the speed.

TOWING A DISABLED

VEHICLE

This section describes procedures for towing

a disabled vehicle using a commercial towing

service.

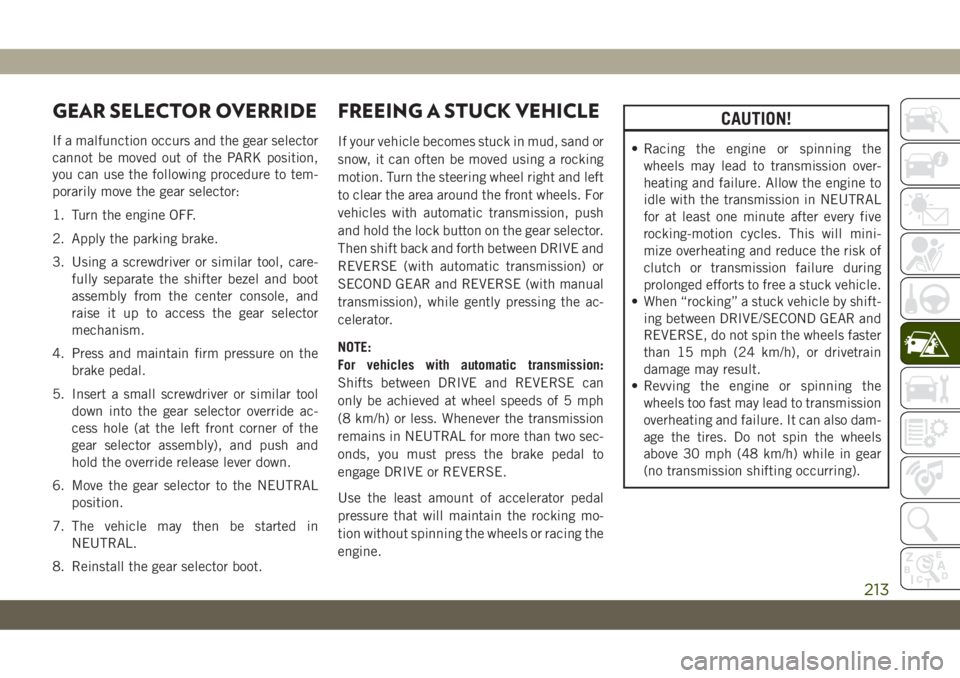

Towing Condition Wheels OFF The

GroundFWD MODELS 4X4 MODELS

Flat Tow NONENOT ALLOWED NOT ALLOWED

Wheel Lift Or Dolly TowRearNOT ALLOWED NOT ALLOWED

Front OKNOT ALLOWED

FlatbedALL BEST METHOD ONLY METHOD

Proper towing or lifting equipment is required

to prevent damage to your vehicle. Use only

tow bars and other equipment designed for

this purpose, following equipment manufac-

turer’s instructions. Use of safety chains is

mandatory. Attach a tow bar or other towingdevices to main structural members of the

vehicle, not to bumpers or associated brack-

ets. State and local laws regarding vehicles

under tow must be observed.

IN CASE OF EMERGENCY

214

Page 217 of 344

NOTE:

• You must ensure that the Auto Park Brake

feature is disabled before towing this ve-

hicle, to avoid inadvertent Electric Park

Brake engagement. The Auto Park Brake

feature is enabled or disabled via the cus-

tomer programmable features in the

Uconnect Settings.

• Vehicles with a discharged battery or total

electrical failure when the electric park

brake (EPB) is engaged, will need a wheel

dolly or jack to raise the rear wheels off the

ground when moving the vehicle onto a

flatbed.

If you must use the accessories (wipers, de-

frosters, etc.) while being towed, the ignition

must be in the ON/RUN mode, not the ACC

mode.

Note that the Safehold feature will engage

the Electric Park Brake whenever the driver's

door is opened (if the battery is connected,

ignition is ON, transmission is not in PARK,

and brake pedal is released). If you are towing

this vehicle with the ignition in the ON/RUNmode, you must manually disable the Elec-

tric Park Brake each time the driver's door is

opened, by pressing the brake pedal and then

releasing the EPB.

If the vehicle’s battery is discharged, refer to

“Gear Selector Override” in this section for

instructions on shifting the automatic trans-

mission out of PARK so that the vehicle can

be moved.

CAUTION!

• Do not use sling-type equipment when

towing. Vehicle damage may occur.

• When securing the vehicle to a flatbed

truck, do not attach to front or rear

suspension components. Damage to

your vehicle may result from improper

towing.

• Ensure that the Electric Park Brake is

released, and remains released, while

being towed.

Without The Key Fob

Special care must be taken when the vehicle

is towed with the ignition in the LOCK/OFF

mode. The only approved method of towing

without the key fob is with a flatbed truck.

Proper towing equipment is necessary to pre-

vent damage to the vehicle.

Front-Wheel Drive (FWD) Models

The manufacturer recommends towing your

vehicle with all four wheelsOFFthe ground

using a flatbed.

If flatbed equipment is not available, this

vehicle must be towed with the front wheels

OFF the ground (using a towing dolly, or

wheel lift equipment with the front wheels

raised).

Ensure that the Electric Park Brake is re-

leased, and remains released, while being

towed. The Electric Park Brake does not need

to be released, if all four wheels are off the

ground.

215

Page 218 of 344

CAUTION!

Towing this vehicle in violation of the

above requirements can cause severe en-

gine and/or transmission damage. Damage

from improper towing is not covered under

the New Vehicle Limited Warranty.

4x4 Models

The manufacturer requires towing with all

four wheelsOFFthe ground.

Acceptable methods are to tow the vehicle on

a flatbed, or with one end of vehicle raised

and the opposite end on a towing dolly.

CAUTION!

• Front or rear wheel lifts must not be used

(if the remaining wheels are on the

ground). Internal damage to the trans-

mission or power transfer unit will occur

if a front or rear wheel lift is used when

towing.

• Towing this vehicle in violation of the

above requirements can cause severe

transmission and/or power transfer unit

CAUTION!

damage. Damage from improper towing

is not covered under the New Vehicle

Limited Warranty.

Recovery Strap — If Equipped

Your vehicle may be included with a recovery

strap. Recovery straps do not act like tradi-

tional tow straps, chains, or winch cables.

WARNING!

Recovery straps should only be used in

emergencies to rescue stranded vehicles.

Only use Recovery straps on vehicles that

fit within the recommended GVW of your

recovery strap. Only attach recovery straps

to OE recommended anchor points or

emergency towing anchor points. Never

attach to tow ball or vehicle tie down point,

these are not designed for this purpose.

Never attach to vehicle steering, drive

train, or any other suspension compo-

nents. NEVER pull a strap over sharp

edges or abrasive surfaces that can dam-

age the recovery strap. NEVER use a dam-

WARNING!

aged strap, it has reduced strength. DO

NOT attempt to repair straps. ONLY per-

sons involved in the recovery should be in

either vehicle. No passengers. Anyone in-

side the vehicles can be struck by strap

recoil, causing serious injury. MOVE by-

standers at least 40 ft (12.2 m) from the

recovery area when using the recovery

strap.

Using Recovery Strap

1. Review all warnings and instructions first.

2. Position the recovery vehicle.

3. Connect the recovery strap.

4. Add a recovery damper or blanket.

5. Clear the danger zone.

6. Safely and slowly start pulling.

7. Disconnect the recovery strap after both

vehicles are secure and parked.

IN CASE OF EMERGENCY

216

Page 219 of 344

ENHANCED ACCIDENT

RESPONSE SYSTEM (EARS)

This vehicle is equipped with an Enhanced

Accident Response System.

Please refer to “Occupant Restraint Sys-

tems” in “Safety” for further information on

the Enhanced Accident Response System

(EARS) function.

EVENT DATA RECORDER

(EDR)

This vehicle is equipped with an Event Data

Recorder (EDR). The main purpose of an EDR

is to record data that will assist in under-

standing how a vehicle’s systems performed

under certain crash or near crash-like situa-

tions, such as an air bag deployment or hit-

ting a road obstacle.

Please refer to “Occupant Restraint Sys-

tems” in “Safety” for further information on

the Event Data Recorder (EDR).

217

Page 220 of 344

SCHEDULED SERVICING

Correct servicing is crucial for guaranteeing a

long life for the car under the best conditions.

For this reason, Jeep has planned a series of

checks and services at fixed distance inter-

vals and, where provided, at fixed time inter-

vals, as described in the Scheduled Servicing

plan. To keep the car’s efficiency in tip-top

condition, in the following Scheduled Service

plan pages a few additional checks are listed

that should be carried out more frequently

with respect to the normal coupon redemp-

tion schedule. Scheduled Servicing is offered

by all authorized dealerships according to

fixed time or mileage intervals. If, during

each operation, in addition to the ones

scheduled, the need arises for further re-

placements or repairs, these may be carried

out with the owner's explicit agreement only.

The technicians at your dealership know your

vehicle best, and have access to factory

trained information, genuine Mopar parts,

and specially designed electronic and me-

chanical tools that can help prevent future

costly repairs. If your car is used frequently

for towing, the interval between one sched-uled servicing operation and the next should

be reduced. More frequent maintenance may

be needed for vehicles in severe operating

conditions, such as dusty areas and very

short trip driving.

NOTE:

Scheduled Servicing interventions are set out

by the Manufacturer. Failure to have them

carried out may invalidate the warranty. It is

advised to inform an authorized dealership of

any small operating irregularities without

waiting for the next service.

Scheduled Servicing — Gasoline Engine

The oil change indicator system will remind

you that it is time to take your vehicle in for

engine oil replacement.

An “Oil Change Required” will be displayed

in the instrument cluster and a single chime

will sound, indicating that an oil change is

necessary.

The oil change indicator message will illumi-

nate approximately 7,000 miles

(11,200 km) after the most recent oil change

was performed. Have your vehicle serviced assoon as possible, within 500 miles (800 km)

(except for 2.0L gasoline engine with GPF –

Gasoline Particulate Filter).

NOTE:

• The oil change indicator message will not

monitor the time since the last oil change.

Change your vehicle’s oil if it has been

12 months since your last oil change even

if the oil change indicator message is NOT

illuminated.

• Change your engine oil more often if you

drive your vehicle off-road for an extended

period of time (refer to the “Heavy Duty

Use” section).

• Under no circumstances should oil change

intervals exceed 7,500 miles (12,000 km)

or 12 months, whichever comes first (ex-

cept for 2.0L gasoline engine with GPF –

Gasoline Particulate Filter).

Your authorized dealer will reset the oil

change indicator message after completing

the scheduled oil change.

SERVICING AND MAINTENANCE

218