ECO mode JEEP CHEROKEE 2023 Service Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2023, Model line: CHEROKEE, Model: JEEP CHEROKEE 2023Pages: 276, PDF Size: 12.55 MB

Page 185 of 276

SAFETY183

To Install A LATCH-Compatible Child

Restraint

If the selected seating position has a Switchable

Automatic Locking Retractor (ALR) seat belt, stow the seat

belt, following the instructions below. See

Úpage 183 to

check what type of seat belt each seating position has.

1. Loosen the adjusters on the lower straps and on the tether strap of the child seat so that you can more

easily attach the hooks or connectors to the vehicle

anchorages.

2. Place the child seat between the lower anchorages for that seating position. If the second row seat can

be reclined, you may recline the seat and/or raise the

head restraint (if adjustable) to get a better fit. If the

rear seat can be moved forward and rearward in the

vehicle, you may wish to move it to its rear-most

position to make room for the child seat. You may

also move the front seat forward to allow more room

for the child seat.

3. Attach the lower hooks or connectors of the child restraint to the lower anchorages in the selected

seating position.

4. If the child restraint has a tether strap, connect it to the top tether anchorage. See

Úpage 185 for

directions to attach a tether anchor.

5. Tighten all of the straps as you push the child restraint rearward and downward into the seat.

Remove slack in the straps according to the child

restraint manufacturer’s instructions. 6. Test that the child restraint is installed tightly by

pulling back and forth on the child seat at the belt

path. It should not move more than 1 inch (25.4 mm) in any direction.

How To Stow An Unused Switchable-ALR

(ALR) Seat Belt:

When using the LATCH attaching system to install a child

restraint, stow all ALR seat belts that are not being used

by other occupants or being used to secure child

restraints. An unused belt could injure a child if they play

with it and accidentally lock the seat belt retractor. Before

installing a child restraint using the LATCH system, buckle

the seat belt behind the child restraint and out of the

child’s reach. If the buckled seat belt interferes with the

child restraint installation, instead of buckling it behind

the child restraint, route the seat belt through the child

restraint belt path and then buckle it. Do not lock the seat

belt. Remind all children in the vehicle that the seat belts

are not toys and that they should not play with them.

Installing Child Restraints Using The

Vehicle Seat Belt

Child restraint systems are designed to be secured in

vehicle seats by lap belts or the lap belt portion of a lap/

shoulder belt.

The seat belts in the passenger seating positions are

equipped with a Switchable Automatic Locking Retractor

(ALR) that is designed to keep the lap portion of the seat

belt tight around the child restraint so that it is not

necessary to use a locking clip. The ALR retractor can be

“switched” into a locked mode by pulling all of the webbing

out of the retractor and then letting the webbing retract

back into the retractor. If it is locked, the ALR will make a

clicking noise while the webbing is pulled back into the

retractor. See the “Automatic Locking Mode” description

Úpage 165 for additional information on ALR.

Please see the table and the following sections for more

information.

WARNING!

Improper installation of a child restraint to the LATCH

anchorages can lead to failure of the restraint. The

child could be badly injured or killed. Follow the child

restraint manufacturer’s directions exactly when

installing an infant or child restraint.

Child restraint anchorages are designed to withstand

only those loads imposed by correctly-fitted child

restraints. Under no circumstances are they to be

used for adult seat belts, harnesses, or for attaching

other items or equipment to the vehicle.

WARNING!

Improper installation or failure to properly secure a

child restraint can lead to failure of the restraint. The

child could be badly injured or killed.

Follow the child restraint manufacturer’s directions

exactly when installing an infant or child restraint.

6

23_KL_OM_EN_USC_t.book Page 183

Page 187 of 276

SAFETY185

Installing A Child Restraint With A

Switchable Automatic Locking Retractor

(ALR):

Child restraint systems are designed to be secured in

vehicle seats by lap belts or the lap belt portion of a lap/

shoulder belt.

1. Place the child seat in the center of the seating

position. If the second row seat can be reclined, you

may recline the seat and/or raise the head restraint

(if adjustable) to get a better fit. If the rear seat can

be moved forward and rearward in the vehicle, you

may wish to move it to its rear-most position to make

room for the child seat. You may also move the front

seat forward to allow more room for the child seat.

2. Pull enough of the seat belt webbing from the retractor to pass it through the belt path of the child

restraint. Do not twist the belt webbing in the belt

path. 3. Slide the latch plate into the buckle until you hear a

“click.”

4. Pull on the webbing to make the lap portion tight against the child seat.

5. To lock the seat belt, pull down on the shoulder part of the belt until you have pulled all the seat belt

webbing out of the retractor. Then, allow the webbing

to retract back into the retractor. As the webbing

retracts, you will hear a clicking sound. This means

the seat belt is now in the Automatic Locking mode.

6. Try to pull the webbing out of the retractor. If it is locked, you should not be able to pull out any

webbing. If the retractor is not

locked, repeat step 5.

7. Finally, pull up on any excess webbing to tighten the lap portion around the child restraint while you push

the child restraint rearward and downward into the

vehicle seat.

8. If the child restraint has a top tether strap and the seating position has a top tether anchorage, connect

the tether strap to the anchorage and tighten the

tether strap. See

Úpage 185 for directions to attach

a tether anchor.

9. Test that the child restraint is installed tightly by pulling back and forth on the child seat at the belt

path. It should not move more than 1 inch (25.4 mm) in any direction.

Any seat belt system will loosen with time, so check the

belt occasionally, and pull it tight if necessary.

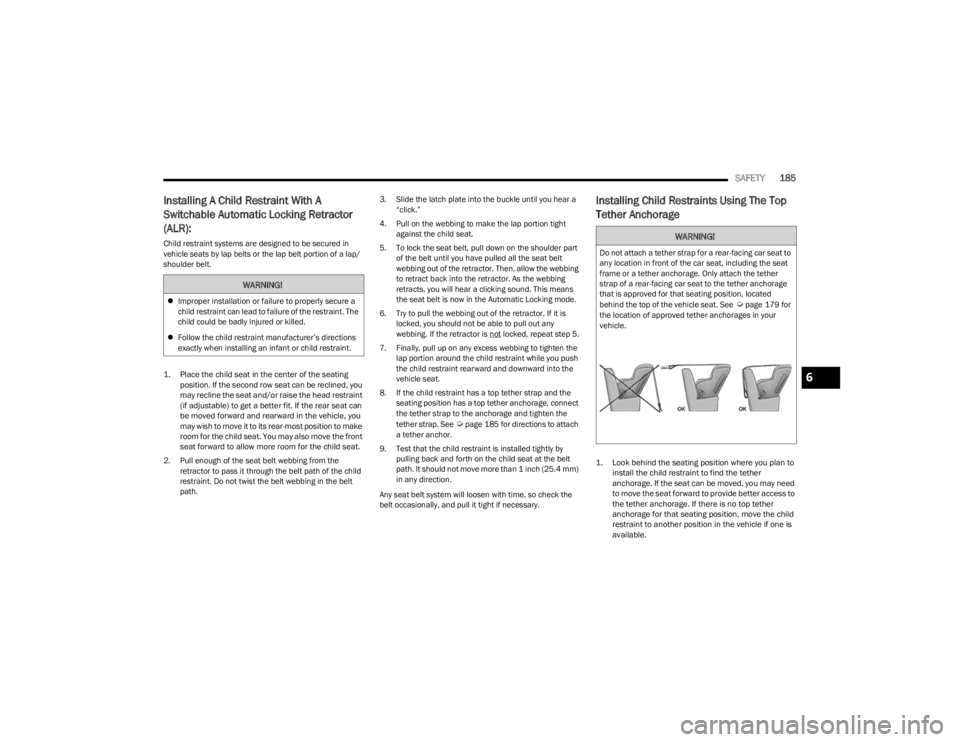

Installing Child Restraints Using The Top

Tether Anchorage

1. Look behind the seating position where you plan to install the child restraint to find the tether

anchorage. If the seat can be moved, you may need

to move the seat forward to provide better access to

the tether anchorage. If there is no top tether

anchorage for that seating position, move the child

restraint to another position in the vehicle if one is

available.

WARNING!

Improper installation or failure to properly secure a

child restraint can lead to failure of the restraint. The

child could be badly injured or killed.

Follow the child restraint manufacturer’s directions

exactly when installing an infant or child restraint.

WARNING!

Do not attach a tether strap for a rear-facing car seat to

any location in front of the car seat, including the seat

frame or a tether anchorage. Only attach the tether

strap of a rear-facing car seat to the tether anchorage

that is approved for that seating position, located

behind the top of the vehicle seat. See

Úpage 179 for

the location of approved tether anchorages in your

vehicle.

6

23_KL_OM_EN_USC_t.book Page 185

Page 189 of 276

SAFETY187

(Continued)

(Continued)

SAFETY CHECKS YOU SHOULD MAKE

I

NSIDE THE VEHICLE

Seat Belts

Inspect the seat belt system periodically, checking for

cuts, frays, and loose parts. Damaged parts must be

replaced immediately. Do not disassemble or modify the

system.

If your vehicle is involved in a collision, or if you have

questions regarding seat belt or retractor conditions, take

your vehicle to an authorized FCA dealer or authorized FCA

Certified Collision Care Program facility for inspection.

Air Bag Warning Light

The Air Bag Warning Light will turn on for four to

eight seconds as a bulb check when the

ignition switch is first placed in the ON/RUN

position. If the light is either not on during

starting, stays on, or turns on while driving, have the

system inspected at an authorized dealer as soon as

possible. After the bulb check, this light will illuminate with

a single chime when a fault with the Air Bag System has

been detected. It will stay on until the fault is removed. If

the light comes on intermittently or remains on while

driving, have an authorized dealer service the vehicle

immediately.

See

Úpage 159 for further information.

Defroster

Check operation by selecting the defrost mode and place

the blower control on high speed. You should be able to feel

the air directed against the windshield. See an authorized

dealer for service if your defroster is inoperable.

Floor Mat Safety Information

Always use floor mats designed to fit your vehicle. Only use

a floor mat that does not interfere with the operation of the

accelerator, brake or clutch pedals. Only use a floor mat

that is securely attached using the floor mat fasteners so

it cannot slip out of position and interfere with the

accelerator, brake or clutch pedals or impair safe

operation of your vehicle in other ways.

WARNING!

An improperly attached, damaged, folded, or stacked

floor mat, or damaged floor mat fasteners may cause

your floor mat to interfere with the accelerator, brake, or

clutch pedals and cause a loss of vehicle control. To

prevent SERIOUS INJURY or DEATH:

ALWAYS securely attach your floor mat

using the floor mat fasteners. DO NOT install

your floor mat upside down or turn your floor

mat over. Lightly pull to confirm mat is

secured using the floor mat fasteners on a regular basis.

ALWAYS REMOVE THE EXISTING FLOOR

MAT FROM THE VEHICLE before installing

any other floor mat. NEVER install or stack an

additional floor mat on top of an existing floor

mat.

ONLY install floor mats designed to fit your vehicle.

NEVER install a floor mat that cannot be properly

attached and secured to your vehicle. If a floor mat

needs to be replaced, only use a FCA approved floor

mat for the specific make, model, and year of your

vehicle.

ONLY use the driver’s side floor mat on the driver’s

side floor area. To check for interference, with the

vehicle properly parked with the engine off, fully

depress the accelerator, the brake, and the clutch

pedal (if present) to check for interference. If your

floor mat interferes with the operation of any pedal,

or is not secure to the floor, remove the floor mat

from the vehicle and place the floor mat in your

trunk.

ONLY use the passenger’s side floor mat on the

passenger’s side floor area.

ALWAYS make sure objects cannot fall or slide into

the driver’s side floor area when the vehicle is

moving. Objects can become trapped under acceler -

ator, brake, or clutch pedals and could cause a loss

of vehicle control.

NEVER place any objects under the floor mat (e.g.,

towels, keys, etc.). These objects could change the

position of the floor mat and may cause interference

with the accelerator, brake, or clutch pedals.

WARNING!

6

23_KL_OM_EN_USC_t.book Page 187

Page 190 of 276

188SAFETY

PERIODIC SAFETY CHECKS YOU SHOULD

M

AKE OUTSIDE THE VEHICLE

Tires

Examine tires for excessive tread wear and uneven wear

patterns. Check for stones, nails, glass, or other objects

lodged in the tread or sidewall. Inspect the tread for cuts

and cracks. Inspect sidewalls for cuts, cracks, and bulges.

Check the lug nut/bolt torque for tightness. Check the

tires (including spare) for proper cold inflation pressure.

Lights

Have someone observe the operation of brake lights and

exterior lights while you work the controls. Check turn signal

and high beam indicator lights on the instrument panel.

Door Latches

Check for proper closing, latching, and locking.

Fluid Leaks

Check the area under the vehicle after overnight parking

for fuel, coolant, oil, or other fluid leaks. Also, if gasoline

fumes are detected or if fuel or brake fluid leaks are

suspected, the cause should be located and corrected

immediately.

EXHAUST GAS

The best protection against carbon monoxide entry into

the vehicle body is a properly maintained engine exhaust

system. Whenever a change is noticed in the sound of the exhaust

system, when exhaust fumes can be detected inside the

vehicle, or when the underside or rear of the vehicle is

damaged, have an authorized dealer inspect the complete

exhaust system and adjacent body areas for broken,

damaged, deteriorated, or mispositioned parts. Open

seams or loose connections could permit exhaust fumes

to seep into the passenger compartment. In addition,

inspect the exhaust system each time the vehicle is raised

for lubrication or oil change. Replace as required.

CARBON MONOXIDE WARNINGS

If the vehicle carpet has been removed and

re-installed, always properly attach carpet to the floor

and check the floor mat fasteners are secure to the

vehicle carpet. Fully depress each pedal to check for

interference with the accelerator, brake, or clutch

pedals then re-install the floor mats.

It is recommended to only use mild soap and water

to clean your floor mats. After cleaning, always check

your floor mat has been properly installed and is

secured to your vehicle using the floor mat fasteners

by lightly pulling mat.

WARNING!

WARNING!

Exhaust gases can injure or kill. They contain carbon

monoxide (CO), which is colorless and odorless.

Breathing it can make you unconscious and can

eventually poison you. To avoid breathing (CO), follow

these safety tips:

Do not run the engine in a closed garage or in

confined areas any longer than needed to move your

vehicle in or out of the area.

If you are required to drive with the trunk/liftgate/

rear doors open, make sure that all windows are

closed and the climate control BLOWER switch is set

at high speed. DO NOT use the recirculation mode.

If it is necessary to sit in a parked vehicle with the

engine running, adjust your heating or cooling

controls to force outside air into the vehicle. Set the

blower at high speed.

WARNING!

Carbon monoxide (CO) in exhaust gases is deadly.

Follow the precautions below to prevent carbon

monoxide poisoning:

Do not inhale exhaust gases. They contain carbon

monoxide, a colorless and odorless gas, which can

kill. Never run the engine in a closed area, such as a

garage, and never sit in a parked vehicle with the

engine running for an extended period. If the vehicle

is stopped in an open area with the engine running

for more than a short period, adjust the ventilation

system to force fresh, outside air into the vehicle.

Guard against carbon monoxide with proper mainte -

nance. Have the exhaust system inspected every

time the vehicle is raised. Have any abnormal condi -

tions repaired promptly. Until repaired, drive with all

side windows fully open.

23_KL_OM_EN_USC_t.book Page 188

Page 199 of 276

IN CASE OF EMERGENCY197

(Continued)

Using The Mode Select Knob And Hoses

Your Tire Service Kit is equipped with the following

symbols to indicate the air or sealant mode.

Selecting Air Mode

Push in the Mode Select Knob and turn to this

position for air pump operation only. Use the

Black Air Pump Hose when selecting this mode.

Selecting Sealant Mode

Push in the Mode Select Knob and turn to this

position to inject the Tire Service Kit Sealant

and to inflate the tire. Use the Sealant Hose

(clear hose) when selecting this mode.

Using The Power Button

Push and release the Power Button once to

turn on the Tire Service Kit. Push and release

the Power Button again to turn Off the Tire

Service Kit.

Using The Deflation Button

Push the Deflation Button to reduce the air

pressure in the tire if it becomes overinflated.

TIRE SERVICE KIT USAGE PRECAUTIONS

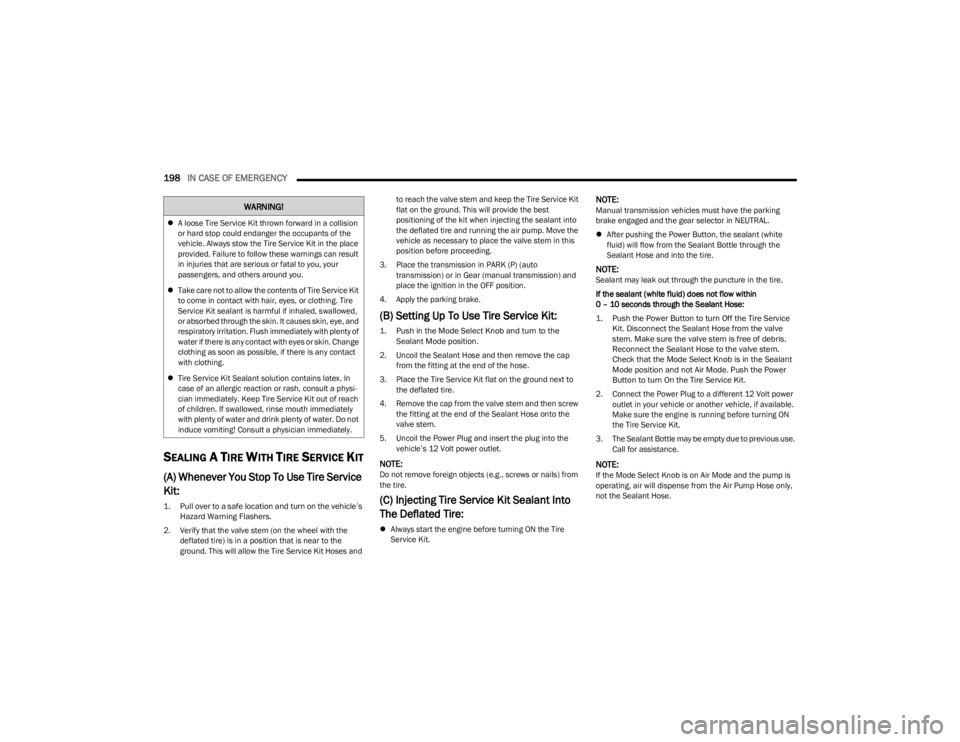

Replace the Tire Service Kit Sealant Bottle and Sealant

Hose prior to the expiration date (printed at the upper

left hand corner on the bottle label) to assure optimum

operation of the system

Úpage 200.

Tire Service Kit Sealant Expiration Date Location

The Sealant Bottle and Sealant Hose are a one tire

application use and need to be replaced after each

use. Always replace these components immediately at

your original equipment vehicle dealer.

When the Tire Service Kit sealant is in a liquid form,

clean water and a damp cloth will remove the material

from the vehicle or tire and wheel components. Once

the sealant dries, it can easily be peeled off and prop -

erly discarded.

For optimum performance, make sure the valve stem

on the wheel is free of debris before connecting the

Tire Service Kit.

You can use the Tire Service Kit air pump to inflate

bicycle tires. The kit also comes with two needles,

located in the Accessory Storage Compartment (on the

bottom of the air pump) for inflating sport balls, rafts,

or similar inflatable items. However, use only the Air

Pump Hose and make sure the Mode Select Knob is in

the Air Mode when inflating such items to avoid injecting sealant into them. The Tire Service Kit Sealant

is only intended to seal punctures less than 1/4 inch

(6 mm) diameter in the tread of your tire.

Do not lift or carry the Tire Service Kit by the hoses.

WARNING!

Do not attempt to seal a tire on the side of the vehicle

closest to traffic. Pull far enough off the road to avoid

the danger of being hit when using the Tire Service

Kit.

Do not use Tire Service Kit or drive the vehicle under

the following circumstances:

If the puncture in the tire tread is approximately

1/4 inch (6 mm) or larger.

If the tire has any sidewall damage.

If the tire has any damage from driving with

extremely low tire pressure.

If the tire has any damage from driving on a flat

tire.

If the wheel has any damage.

If you are unsure of the condition of the tire or

the wheel.

Keep Tire Service Kit away from open flames or heat

source.

7

23_KL_OM_EN_USC_t.book Page 197

Page 200 of 276

198IN CASE OF EMERGENCY

SEALING A TIRE WITH TIRE SERVICE KIT

(A) Whenever You Stop To Use Tire Service

Kit:

1. Pull over to a safe location and turn on the vehicle’s

Hazard Warning Flashers.

2. Verify that the valve stem (on the wheel with the deflated tire) is in a position that is near to the

ground. This will allow the Tire Service Kit Hoses and to reach the valve stem and keep the Tire Service Kit

flat on the ground. This will provide the best

positioning of the kit when injecting the sealant into

the deflated tire and running the air pump. Move the

vehicle as necessary to place the valve stem in this

position before proceeding.

3. Place the transmission in PARK (P) (auto transmission) or in Gear (manual transmission) and

place the ignition in the OFF position.

4. Apply the parking brake.

(B) Setting Up To Use Tire Service Kit:

1. Push in the Mode Select Knob and turn to the Sealant Mode position.

2. Uncoil the Sealant Hose and then remove the cap from the fitting at the end of the hose.

3. Place the Tire Service Kit flat on the ground next to the deflated tire.

4. Remove the cap from the valve stem and then screw the fitting at the end of the Sealant Hose onto the

valve stem.

5. Uncoil the Power Plug and insert the plug into the vehicle’s 12 Volt power outlet.

NOTE:Do not remove foreign objects (e.g., screws or nails) from

the tire.

(C) Injecting Tire Service Kit Sealant Into

The Deflated Tire:

Always start the engine before turning ON the Tire

Service Kit.

NOTE:Manual transmission vehicles must have the parking

brake engaged and the gear selector in NEUTRAL.

After pushing the Power Button, the sealant (white

fluid) will flow from the Sealant Bottle through the

Sealant Hose and into the tire.

NOTE:Sealant may leak out through the puncture in the tire.

If the sealant (white fluid) does not flow within

0 – 10 seconds through the Sealant Hose:

1. Push the Power Button to turn Off the Tire Service

Kit. Disconnect the Sealant Hose from the valve

stem. Make sure the valve stem is free of debris.

Reconnect the Sealant Hose to the valve stem.

Check that the Mode Select Knob is in the Sealant

Mode position and not Air Mode. Push the Power

Button to turn On the Tire Service Kit.

2. Connect the Power Plug to a different 12 Volt power outlet in your vehicle or another vehicle, if available.

Make sure the engine is running before turning ON

the Tire Service Kit.

3. The Sealant Bottle may be empty due to previous use. Call for assistance.

NOTE:If the Mode Select Knob is on Air Mode and the pump is

operating, air will dispense from the Air Pump Hose only,

not the Sealant Hose.

A loose Tire Service Kit thrown forward in a collision

or hard stop could endanger the occupants of the

vehicle. Always stow the Tire Service Kit in the place

provided. Failure to follow these warnings can result

in injuries that are serious or fatal to you, your

passengers, and others around you.

Take care not to allow the contents of Tire Service Kit

to come in contact with hair, eyes, or clothing. Tire

Service Kit sealant is harmful if inhaled, swallowed,

or absorbed through the skin. It causes skin, eye, and

respiratory irritation. Flush immediately with plenty of

water if there is any contact with eyes or skin. Change

clothing as soon as possible, if there is any contact

with clothing.

Tire Service Kit Sealant solution contains latex. In

case of an allergic reaction or rash, consult a physi -

cian immediately. Keep Tire Service Kit out of reach

of children. If swallowed, rinse mouth immediately

with plenty of water and drink plenty of water. Do not

induce vomiting! Consult a physician immediately.

WARNING!

23_KL_OM_EN_USC_t.book Page 198

Page 201 of 276

IN CASE OF EMERGENCY199

If the sealant (white fluid) does flow through the Sealant

Hose:

1. Continue to operate the pump until sealant is no

longer flowing through the hose (typically takes

30 - 70 seconds). As the sealant flows through the

Sealant Hose, the Pressure Gauge can read as high

as 70 psi (4.8 Bar). The Pressure Gauge will

decrease quickly from approximately 70 psi

(4.8 Bar) to the actual tire pressure when the

Sealant Bottle is empty.

2. The pump will start to inject air into the tire immediately after the Sealant Bottle is empty.

Continue to operate the pump and inflate the tire to

the pressure indicated on the tire pressure label on

the driver-side latch pillar (recommended pressure).

Check the tire pressure by looking at the Pressure

Gauge.

If the tire does not inflate to at least 26 psi (1.8 Bar)

pressure within 15 minutes:

NOTE:Never operate the compressor for longer than 20 minutes.

Risk of Overheating.

The tire is too badly damaged. Do not attempt to drive

the vehicle further. Call for assistance.

If the tire becomes overinflated, push the Deflation

Button to reduce the tire pressure to the recommended

inflation pressure before continuing. If the tire inflates to the recommended pressure or is at

least 26 psi (1.8 Bar) pressure within 15 minutes:

1. Push the Power Button to turn off the Tire Service

Kit.

2. Remove the Speed Limit sticker from the top of the Sealant Bottle and place the sticker on the

instrument panel.

3. Immediately disconnect the Sealant Hose from the valve stem, reinstall the cap on the fitting at the end

of the hose, and place the Tire Service Kit in the

vehicle storage location.

(D) Drive Vehicle:

Immediately after injecting sealant and inflating the tire,

drive the vehicle 5 miles (8 km) or 10 minutes to ensure

distribution of the Tire Service Kit Sealant within the tire.

Do not exceed 50 mph (80 km/h).

(E) After Driving:

Pull over to a safe location Úpage 198.

1. Push in the Mode Select Knob and turn to the Air Mode position.

2. Uncoil the power plug and insert the plug into the vehicle's 12 Volt power outlet.

3. Uncoil the Air Pump Hose (black in color) and screw the fitting at the end of hose onto the valve stem.

4. Check the pressure in the tire by reading the Pressure Gauge.

If tire pressure is less than 19 psi (1.3 Bar):

The tire is too badly damaged. Do not attempt to drive the

vehicle further. Call for assistance.

If the tire pressure is 19 psi (1.3 Bar) or higher:

1. Push the Power Button to turn on Tire Service Kit and inflate the tire to the pressure indicated on the

tire and loading information label on the driver-side

door opening.

CAUTION!

The metal end fitting from Power Plug may get hot

after use, so it should be handled carefully.

Failure to reinstall the cap on the fitting at the end of

the Sealant Hose can result in sealant contacting

your skin, clothing, and the vehicle’s interior. It can

also result in sealant contacting internal Tire Service

Kit components which may cause permanent

damage to the kit.

WARNING!

Tire Service Kit is not a permanent flat tire repair. Have

the tire inspected and repaired or replaced after using

Tire Service Kit. Do not exceed 50 mph (80 km/h) until

the tire is repaired or replaced. Failure to follow this

warning can result in injuries that are serious or fatal to

you, your passengers, and others around you.

7

23_KL_OM_EN_USC_t.book Page 199

Page 206 of 276

204IN CASE OF EMERGENCY

6. Move the gear selector to the NEUTRAL (N) position.

7. The vehicle may then be started in NEUTRAL (N).

8. Reinstall the gear selector boot.

FREEING A STUCK VEHICLE

If your vehicle becomes stuck in mud, sand or snow, it can

often be moved using a rocking motion. Turn the steering

wheel right and left to clear the area around the front

wheels. Push and hold the lock button on the gear

selector. Then shift back and forth between DRIVE (D) and

REVERSE (R), while gently pressing the accelerator.

NOTE:Shifts between DRIVE (D) and REVERSE (R) can only be

achieved at wheel speeds of 5 mph (8 km/h) or less.

Whenever the transmission remains in NEUTRAL (N) for

more than two seconds, you must press the brake pedal

to engage DRIVE (D) or REVERSE (R). Use the least amount of accelerator pedal pressure that

will maintain the rocking motion without spinning the

wheels or racing the engine.NOTE:Push the ESC OFF button (if necessary), to place the Elec

-

tronic Stability Control (ESC) system in “Partial Off” mode,

before rocking the vehicle

Úpage 145. Once the vehicle

has been freed, push the ESC OFF button again to restore

“ESC On” mode.

WARNING!

Fast spinning tires can be dangerous. Forces generated

by excessive wheel speeds may cause damage, or even

failure, of the axle and tires. A tire could explode and

injure someone. Do not spin your vehicle's wheels

faster than 30 mph (48 km/h) or for longer than 30

seconds continuously without stopping when you are

stuck and do not let anyone near a spinning wheel, no

matter what the speed.

CAUTION!

Racing the engine or spinning the wheels may lead to

transmission overheating and failure. Allow the

engine to idle with the transmission in NEUTRAL for

at least one minute after every five rocking-motion

cycles. This will minimize overheating and reduce the

risk of clutch or transmission failure during

prolonged efforts to free a stuck vehicle.

When “rocking” a stuck vehicle by shifting between

DRIVE and REVERSE, do not spin the wheels faster

than 15 mph (24 km/h), or drivetrain damage may

result.

Revving the engine or spinning the wheels too fast

may lead to transmission overheating and failure. It

can also damage the tires. Do not spin the wheels

above 30 mph (48 km/h) while in gear (no transmis -

sion shifting occurring).

23_KL_OM_EN_USC_t.book Page 204

Page 208 of 276

206IN CASE OF EMERGENCY

(Continued)

FRONT-WHEEL DRIVE (FWD) MODELS

The FCA US LLC recommends towing your vehicle with all

four wheels OFF of the ground using a flatbed.

If flatbed equipment is not available, this vehicle must be

towed with the front wheels OFF of the ground (using a

towing dolly, or wheel lift equipment with the front wheels

raised).

Ensure that the Electric Park Brake (EPB) is released, and

remains released, while being towed. The EPB does not

need to be released, if all four wheels are OFF the ground.

4X4 MODELS WITH 1–SPEED POWER

T

RANSFER UNIT

The FCA US LLC requires towing with all four wheels OFF

the ground.

Acceptable methods are to tow the vehicle on a flatbed, or

with one end of vehicle raised and the opposite end on a

towing dolly.

4X4 MODELS WITH 2–SPEED POWER

T

RANSFER UNIT

The FCA US LLC recommends towing with all four wheels

OFF the ground.

Acceptable methods are to tow the vehicle on a flatbed or

with one end of the vehicle raised and the opposite end on

a towing dolly.

If flatbed equipment is not available and the Power

Transfer Unit is operable, vehicles with a 2–speed Power

Transfer Unit may be towed (in the forward direction, with

ALL wheels on the ground), under the following conditions:

The Power Transfer Unit must be in NEUTRAL (N).

The transmission must be in PARK (P) .

Ensure that the EPB is released, and remains released,

while being towed

Úpage 120.

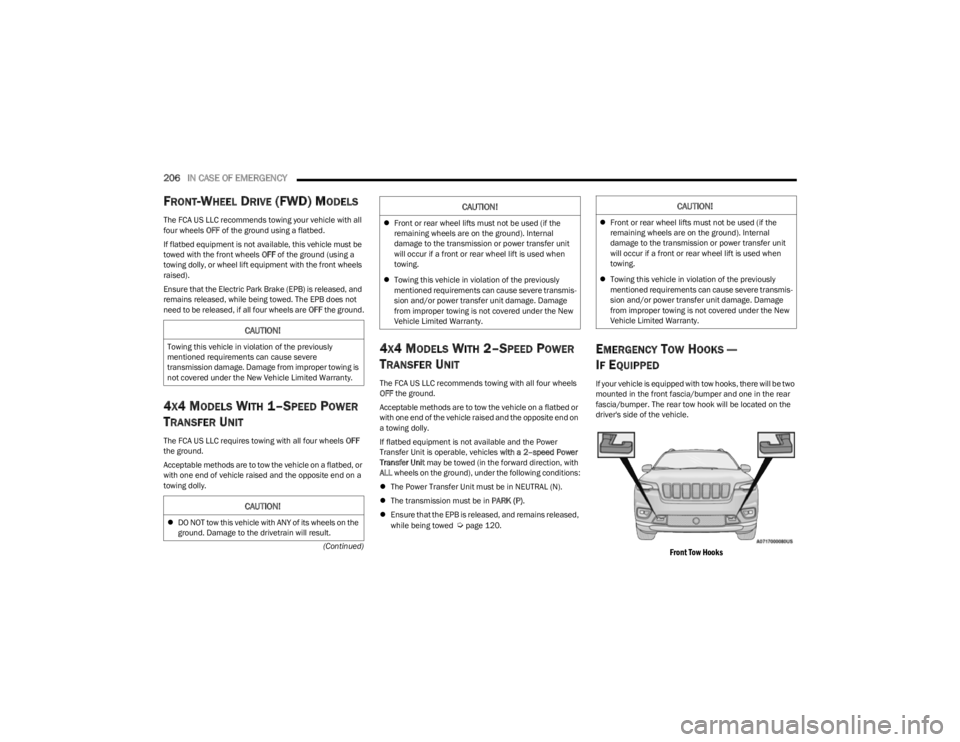

EMERGENCY TOW HOOKS —

I

F EQUIPPED

If your vehicle is equipped with tow hooks, there will be two

mounted in the front fascia/bumper and one in the rear

fascia/bumper. The rear tow hook will be located on the

driver's side of the vehicle.

Front Tow Hooks

CAUTION!

Towing this vehicle in violation of the previously

mentioned requirements can cause severe

transmission damage. Damage from improper towing is

not covered under the New Vehicle Limited Warranty.

CAUTION!

DO NOT tow this vehicle with ANY of its wheels on the

ground. Damage to the drivetrain will result.

Front or rear wheel lifts must not be used (if the

remaining wheels are on the ground). Internal

damage to the transmission or power transfer unit

will occur if a front or rear wheel lift is used when

towing.

Towing this vehicle in violation of the previously

mentioned requirements can cause severe transmis -

sion and/or power transfer unit damage. Damage

from improper towing is not covered under the New

Vehicle Limited Warranty.

CAUTION!CAUTION!

Front or rear wheel lifts must not be used (if the

remaining wheels are on the ground). Internal

damage to the transmission or power transfer unit

will occur if a front or rear wheel lift is used when

towing.

Towing this vehicle in violation of the previously

mentioned requirements can cause severe transmis -

sion and/or power transfer unit damage. Damage

from improper towing is not covered under the New

Vehicle Limited Warranty.

23_KL_OM_EN_USC_t.book Page 206

Page 219 of 276

SERVICING AND MAINTENANCE217

Engine Air Cleaner Filter Installation

NOTE:Inspect and clean the housing assembly if significant dirt

or debris is present before replacing the engine air cleaner

filter.

1. Install the engine air cleaner filter into the housing

assembly with the engine air cleaner filter

inspection surface facing downward.

2. Install the engine air cleaner filter cover onto the housing assembly locating tabs.

3. Install screws to secure the engine air cleaner filter cover to the housing assembly.

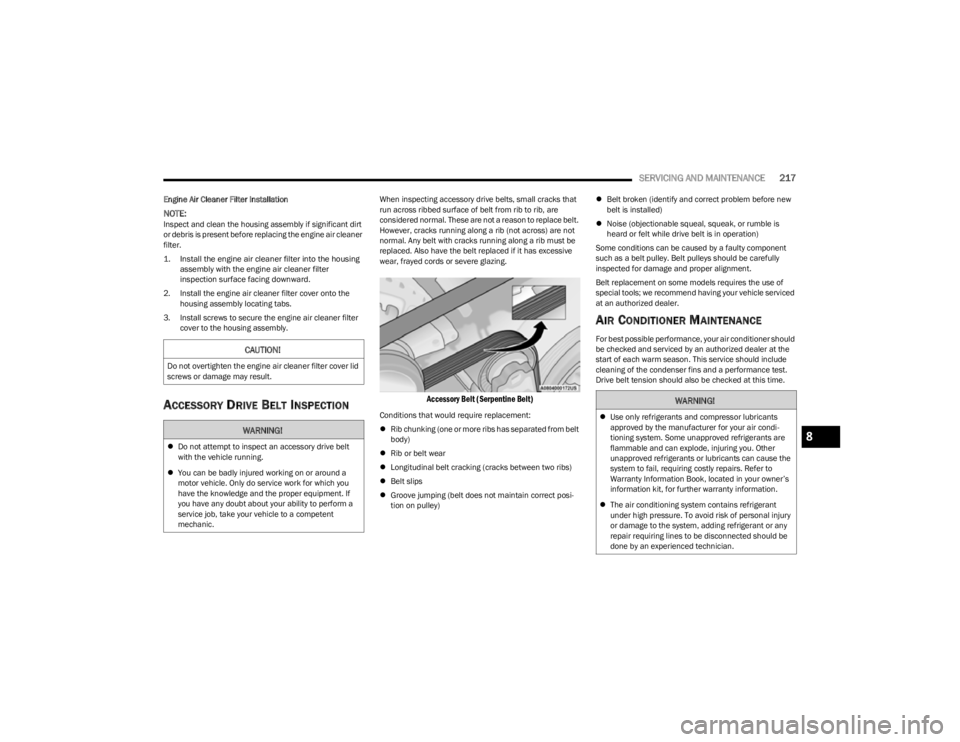

ACCESSORY DRIVE BELT INSPECTION

When inspecting accessory drive belts, small cracks that

run across ribbed surface of belt from rib to rib, are

considered normal. These are not a reason to replace belt.

However, cracks running along a rib (not across) are not

normal. Any belt with cracks running along a rib must be

replaced. Also have the belt replaced if it has excessive

wear, frayed cords or severe glazing.

Accessory Belt (Serpentine Belt)

Conditions that would require replacement:

Rib chunking (one or more ribs has separated from belt

body)

Rib or belt wear

Longitudinal belt cracking (cracks between two ribs)

Belt slips

Groove jumping (belt does not maintain correct posi -

tion on pulley)

Belt broken (identify and correct problem before new

belt is installed)

Noise (objectionable squeal, squeak, or rumble is

heard or felt while drive belt is in operation)

Some conditions can be caused by a faulty component

such as a belt pulley. Belt pulleys should be carefully

inspected for damage and proper alignment.

Belt replacement on some models requires the use of

special tools; we recommend having your vehicle serviced

at an authorized dealer.

AIR CONDITIONER MAINTENANCE

For best possible performance, your air conditioner should

be checked and serviced by an authorized dealer at the

start of each warm season. This service should include

cleaning of the condenser fins and a performance test.

Drive belt tension should also be checked at this time.CAUTION!

Do not overtighten the engine air cleaner filter cover lid

screws or damage may result.

WARNING!

Do not attempt to inspect an accessory drive belt

with the vehicle running.

You can be badly injured working on or around a

motor vehicle. Only do service work for which you

have the knowledge and the proper equipment. If

you have any doubt about your ability to perform a

service job, take your vehicle to a competent

mechanic.

WARNING!

Use only refrigerants and compressor lubricants

approved by the manufacturer for your air condi -

tioning system. Some unapproved refrigerants are

flammable and can explode, injuring you. Other

unapproved refrigerants or lubricants can cause the

system to fail, requiring costly repairs. Refer to

Warranty Information Book, located in your owner’s

information kit, for further warranty information.

The air conditioning system contains refrigerant

under high pressure. To avoid risk of personal injury

or damage to the system, adding refrigerant or any

repair requiring lines to be disconnected should be

done by an experienced technician.

8

23_KL_OM_EN_USC_t.book Page 217